Application of Long-Distance Drilling and Blasting Technology to Prevent Rock Bursts in High-Level Roofs

Abstract

1. Introduction

2. Engineering Background

2.1. Subsection

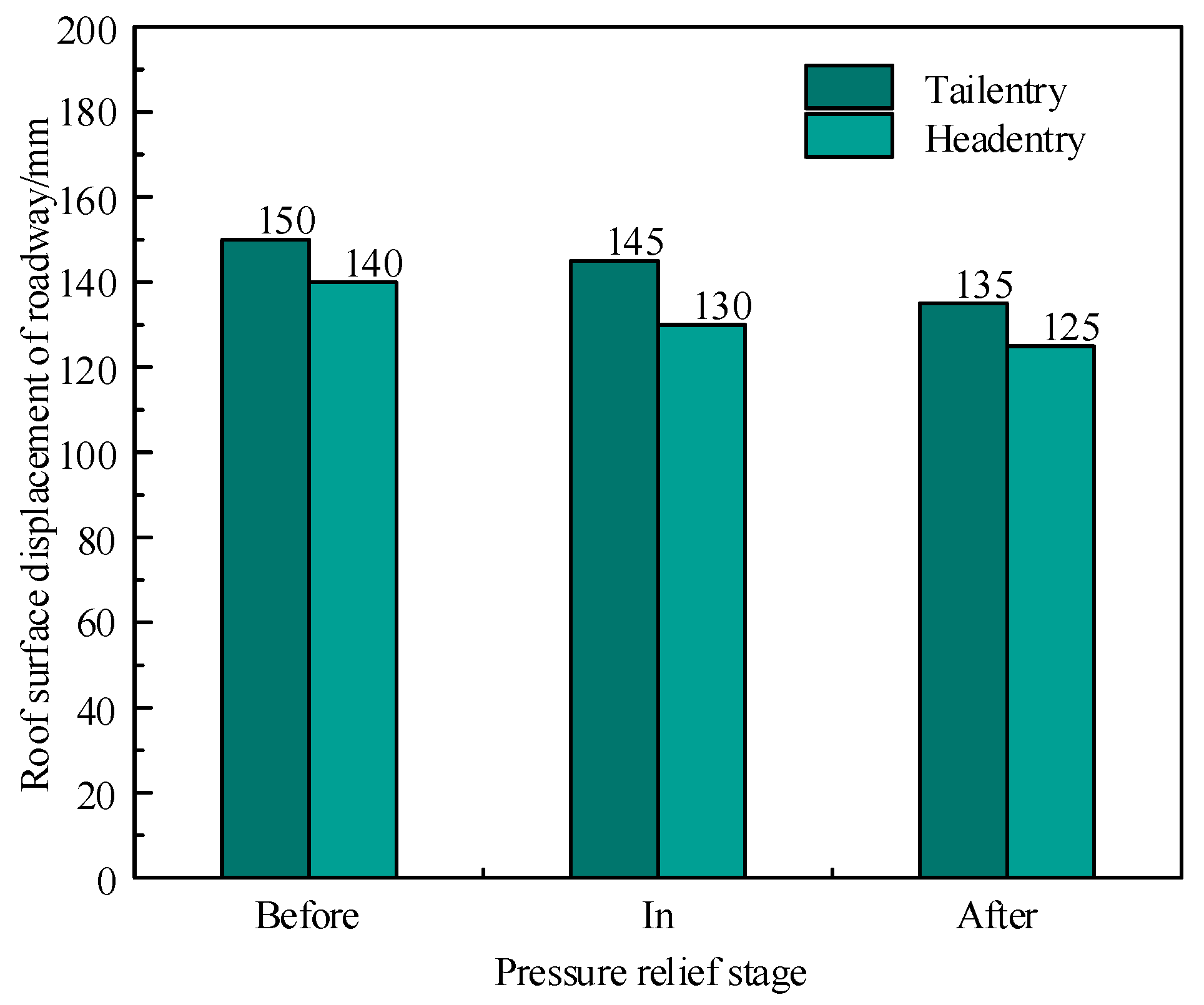

2.2. Deformation Characteristics of Entry

3. Mechanism of Load Reduction and Scour Reduction in Long-Distance Drilling Blasting

4. Analysis of Influencing Factors of Long-Distance Drilling Blasting

4.1. Numerical Model Establishment and Scheme Design

4.1.1. Numerical Modeling

4.1.2. Simulation Scheme Design

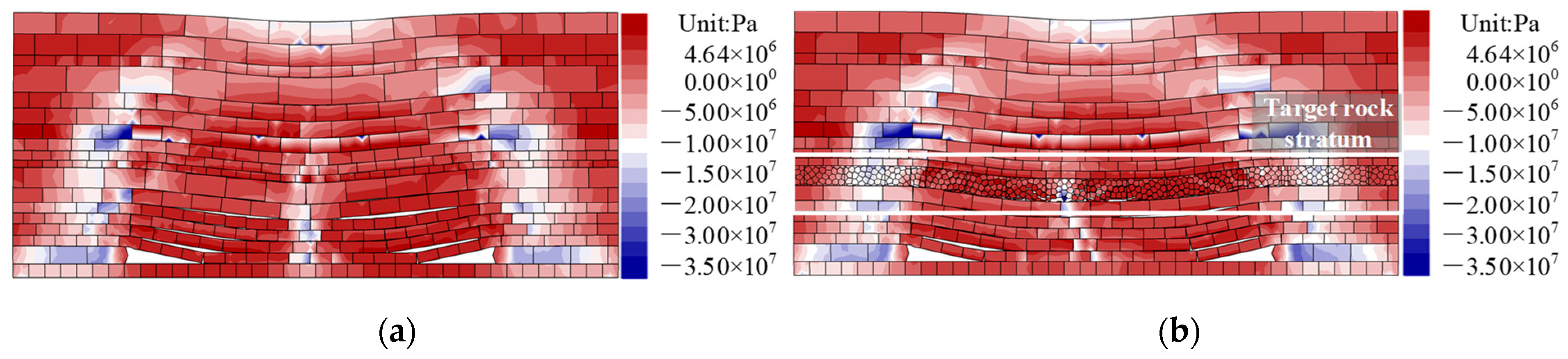

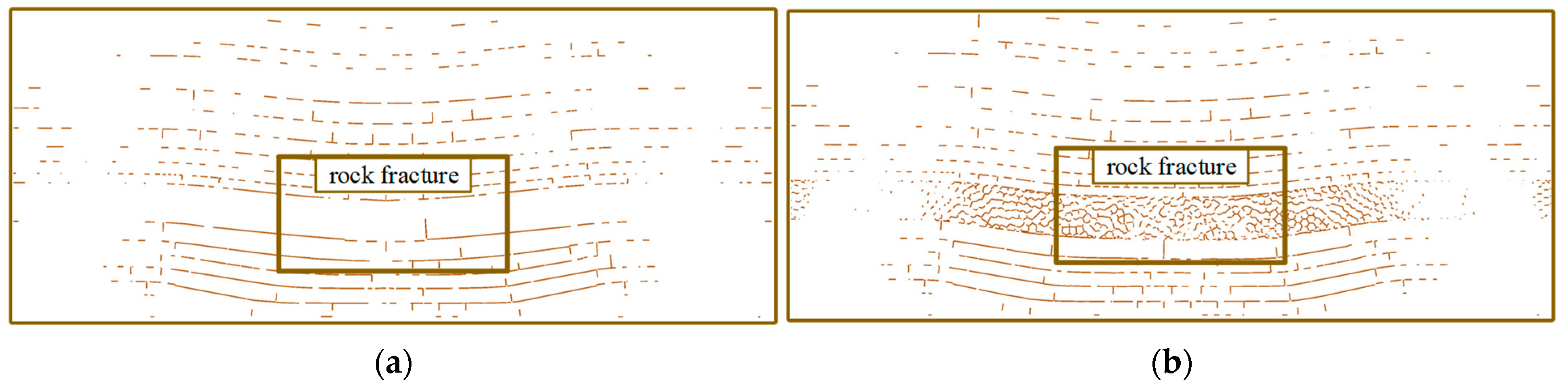

4.2. Overburden Rock Migration and Stress Variation Characteristics

4.3. Quantitative Analysis of Pressure Relief Effect

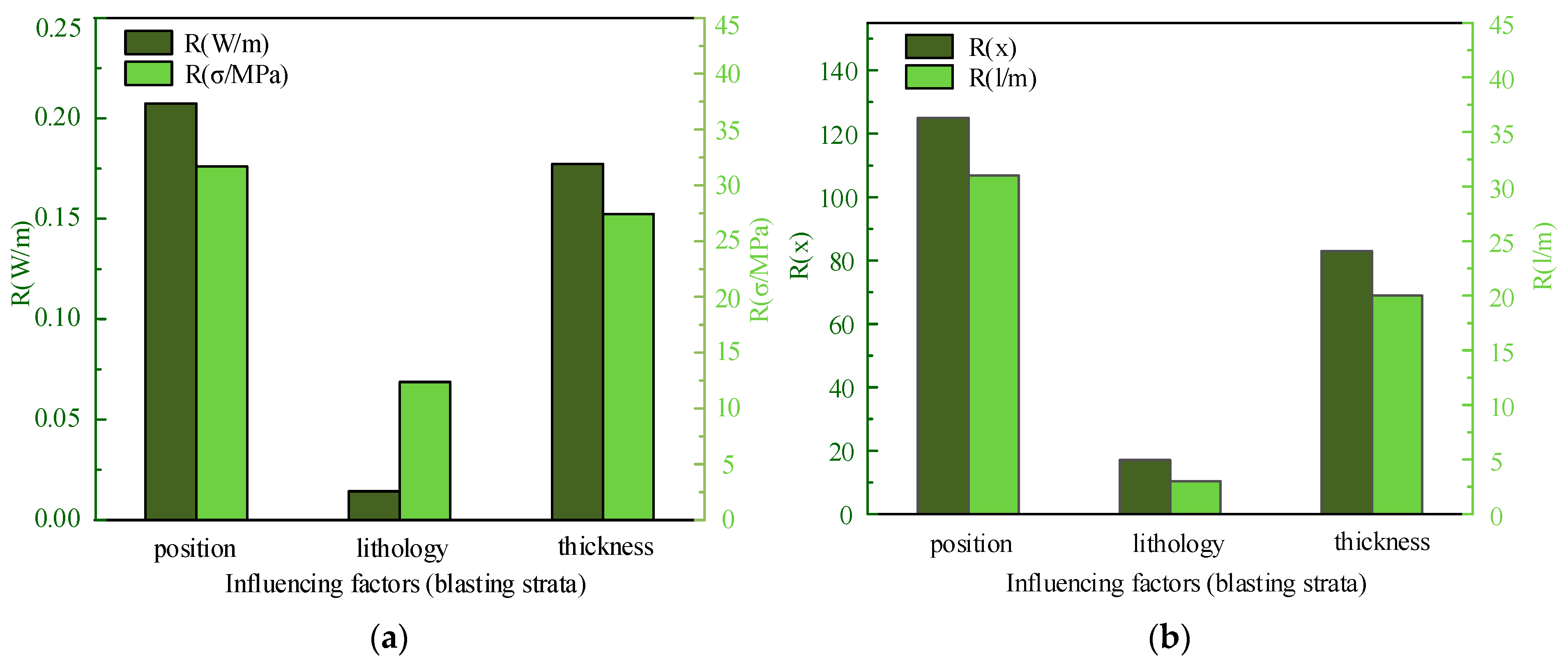

4.4. Sorting of Main Influencing Factors of Long-Distance Drilling Blasting

5. Blasting Scheme Design and Effect Evaluation

5.1. Selection of Pressure Relief Layer

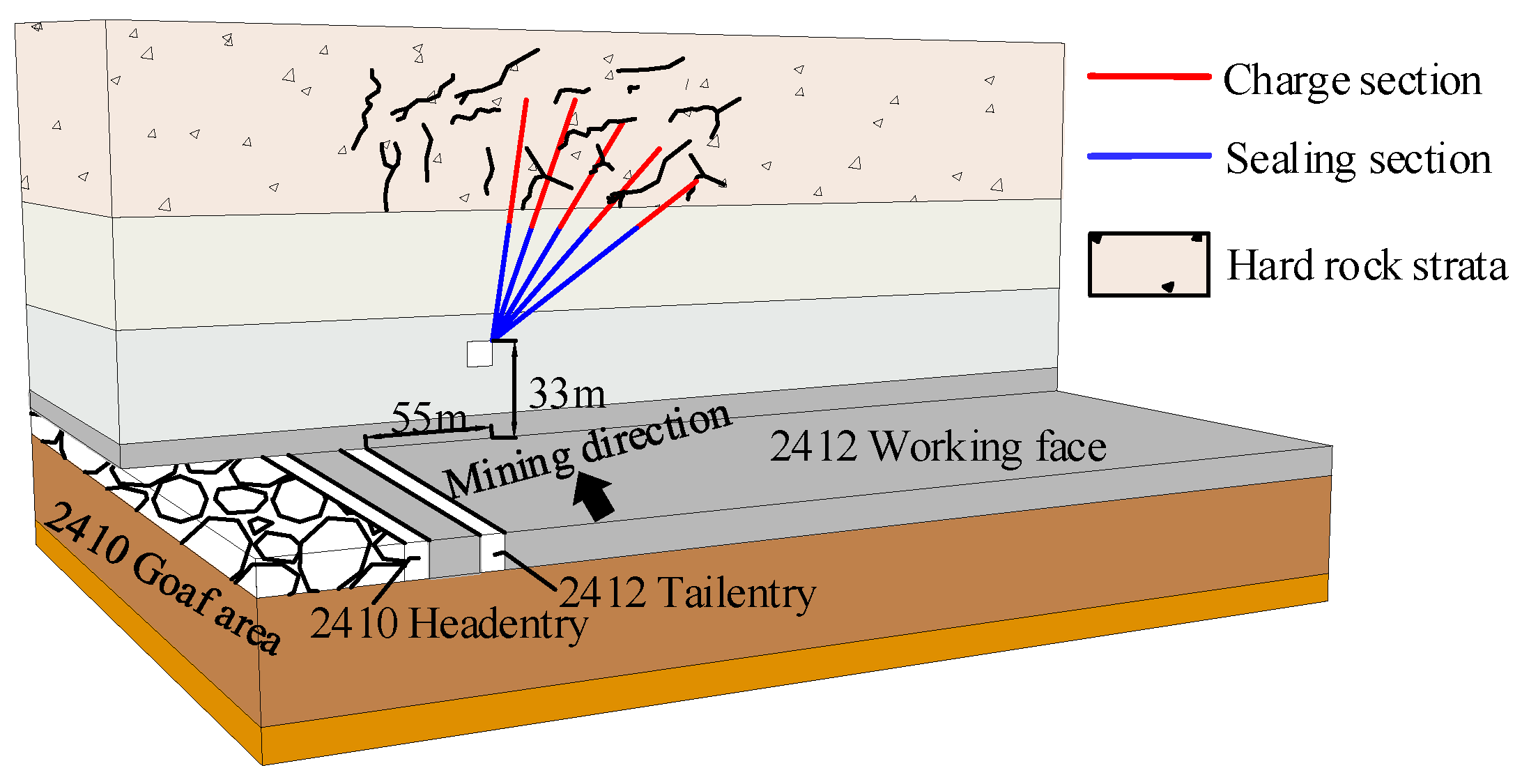

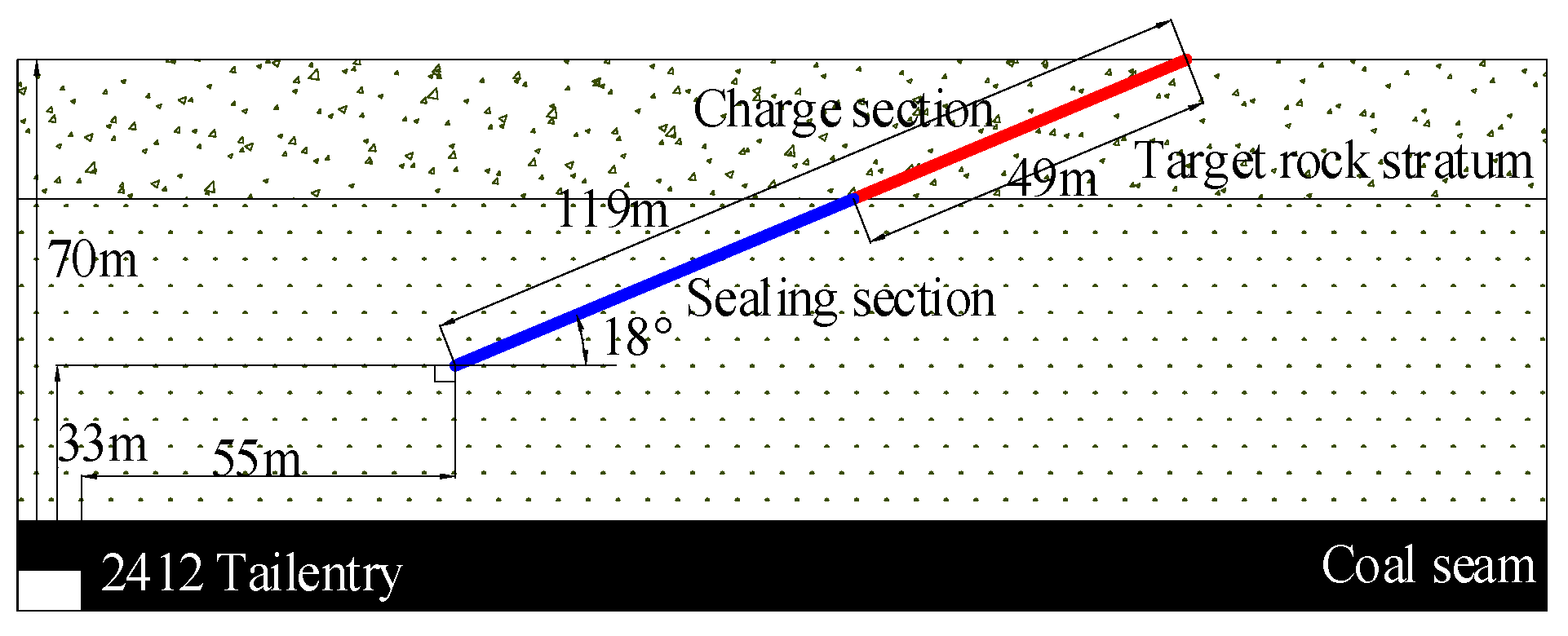

5.2. Long Distance Drilling Arrangement

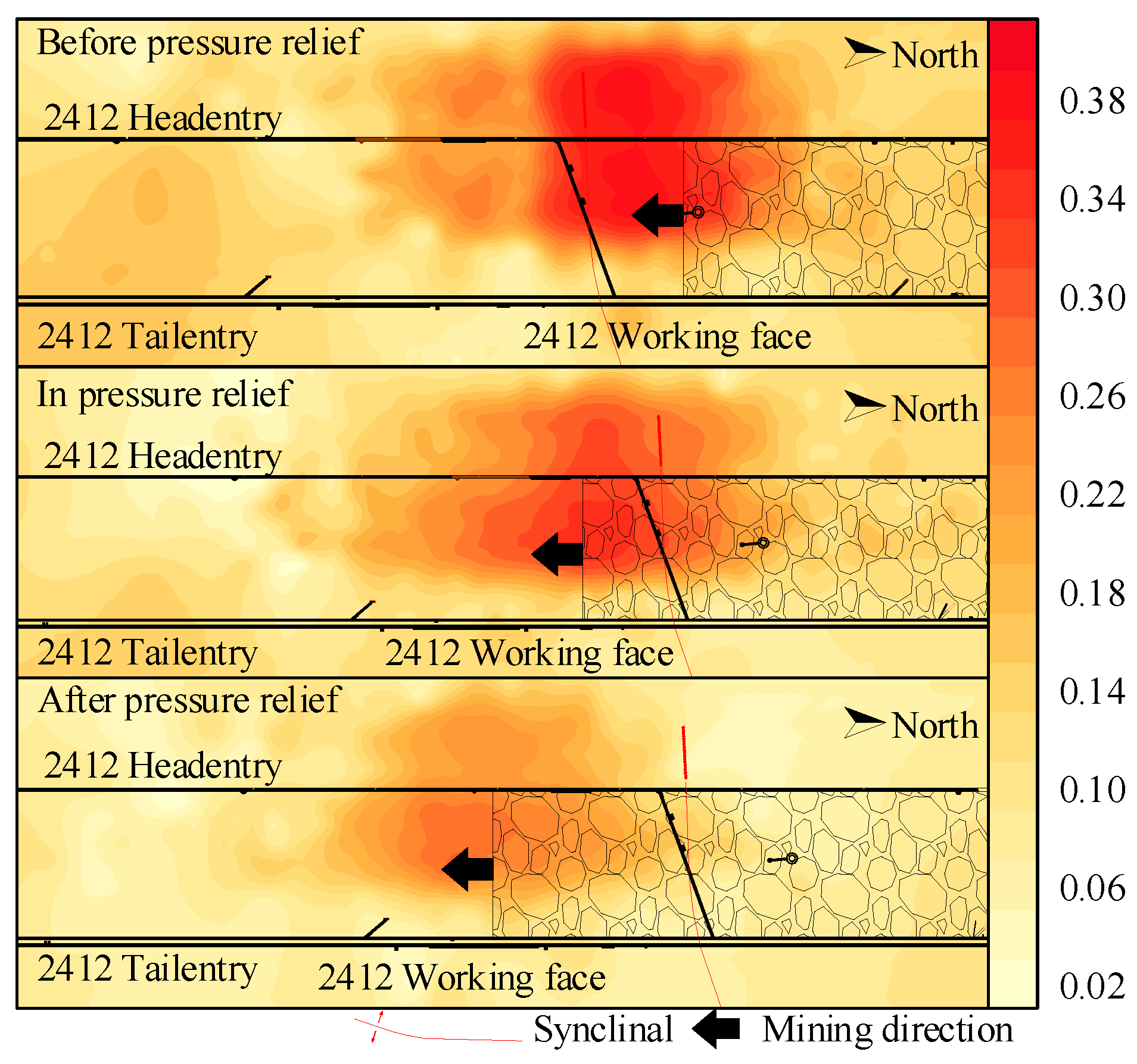

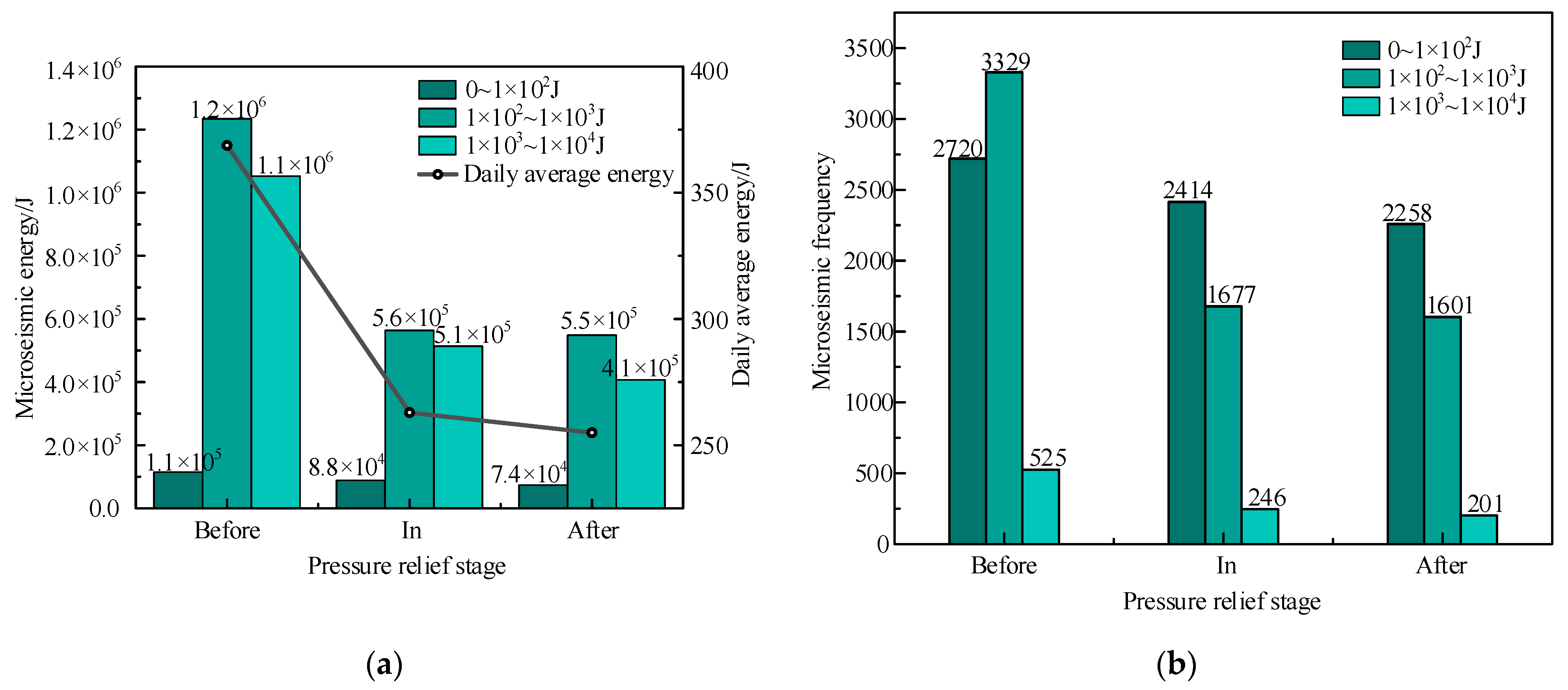

5.3. Evaluation of the Pressure Relief Effect of Long-Distance Drilling Blasting

6. Conclusions

- (1)

- Common blasting pressure relief has the limitations of a small pressure relief range and suitability only for low roof treatment. Long-distance drilling blasting pressure relief is arranged by arranging the high-level drilling field above the coal seam, and the long-distance drilling is arranged in a fan-shaped distribution, which effectively pre-splits the whole overburden rock;

- (2)

- Based on existing research, the influence of three factors, i.e., blasting the pre-splitting layer, blasting rock thickness, and blasting rock lithology, on the pressure relief effect of long-distance drilling blasting in practical applications, e.g., a working face, is analyzed, and an orthogonal test was designed. Based on the actual drilling information of the working face, a UDEC numerical model was established to analyze the overburden subsidence, stress change, and rock fracture. Taking Scheme 1 as an example, it was found that after long-distance drilling and blasting, the average value of overburden subsidence increased by 21.2%, the maximum value increased by 15.2%, the average stress value decreased by 22.8%, and the maximum stress value decreased by 34%. The orthogonal test results showed that the weight ratio of the blasting effect was as follows: blasting layer position → blasting rock thickness → blasting rock lithology;

- (3)

- Combined with our analysis of the factor weight ratio, the selection of a blasting horizon should be given priority in the design of a long-distance drilling blasting implementation scheme. Combined with actual drilling information, the roof above the 2412 working face was set as the blasting horizon at about 52–67 m. According to our analysis of measured micro seismic data, long-distance drilling blasting can effectively reduce the frequency of micro seismic energy and events, reduce the spatial activity of the working face, avoid the influence of a high roof on the mining period of a working face from the source, release energy over time, avoid the accumulation of large energy events, and reduce the risk of rock burst.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, J.; Huang, S.; Wang, H.; Wang, H.; Zhou, N.; Deng, X. Research progress of multi-disaster coordinated prevention and control technology for coal seams with an extra-thick water-bearing sandstone roof. J. Min. Saf. Eng. 2025, 42, 1–15. [Google Scholar]

- Wang, G.; Pan, Y.; Zhao, S.; Pang, Y.; He, Y.; Wei, W. How to realize safe-efficient-intelligent mining of rock burst coal seam. Coal Sci. Technol. 2024, 52, 1–14. [Google Scholar]

- Zhong, T.; Song, Y.; Liu, J. Pattern, hange and new situation of coal mine rock burst prevention and control in China. Chin. J. Rock Mech. Eng. 2023, 42, 2081–2095. [Google Scholar]

- Pan, J.; Xia, Y.; Wang, S.; Ma, W.; Zhang, C.; Wang, B. Technical difficulties and emerging development directions of deep rock burst prevention in China. J. China Coal Soc. 2024, 49, 1291–1302. [Google Scholar]

- Wu, J.; Pan, J.; Feng, M.; Lu, C.; Gao, J.; Yan, Y.; Ma, H. Study on the response characteristics of overlying rock mining with different levels of fracturing in different areas of the roof. J. China Coal Soc. 2024, 49, 4351–4364. [Google Scholar]

- Zhu, S.; Zhang, X.; Jiang, F.; Ma, J.; Zhang, X.; Xia, K.; Wang, C.; Li, S.; Liu, J.; Zhu, Q.; et al. Mechanism and application of energy release modification of coal pillar in high stress entry in deep well. J. China Coal Soc. 2024, 49, 3711–3727. [Google Scholar]

- Zhu, S.; Liu, J.; Jiang, F.; Shang, X.; Sun, X.; Zhang, X.; Song, D.; Zhang, M.; Wang, A.; Xie, H.; et al. Classification, prediction, prevention and control of roof movement type mine earthquake and induced disasters in China’s coal mines. J. China Coal Soc. 2022, 47, 807–816. [Google Scholar]

- Sun, W.; Wang, Z.; Li, Q.; Wang, W.; Cao, P.; Xu, H. Multiple synergistic control technology of rock burst disasters in deep hard roof working faces. Chin. J. Rock Mech. Eng. 2024, 43, 1736–1750. [Google Scholar]

- Mu, Z.; Dou, L.; Zhang, G.; Zhang, S.; Li, Z.; Zhang, J. Study of prevention methods of rock burst disaster caused by hard rock roof. J. China Univ. Min. Technol. 2006, 35, 737–741. [Google Scholar]

- Hall, A.; Simser, B.; Cai, M.; Lindsay, J. Preconditioning blasting for rockburst control in a deep shaft sink. Int. J. Rock Mech. Min. Sci. 2024, 181, 105841. [Google Scholar] [CrossRef]

- Tang, B. Rockburst Control Using Destress Blasting. Ph.D. Thesis, McGill University, Montréal, QC, Canada, 2000. [Google Scholar]

- Vennes, I.; Mitri, H.; Chinnasane, D.R.; Yao, M. Large-scale destress blasting for seismicity control in hard rock mines: A case study. Int. J. Min. Sci. Technol. 2020, 30, 141–149. [Google Scholar] [CrossRef]

- Zhang, J.; Dong, X.; Bai, J.; Jia, L. The mechanism and prevention of rock burst induced by the instability of the composite hard-roof coal structure and roof fractures. Eng. Fract. Mech. 2024, 310, 110512. [Google Scholar] [CrossRef]

- Lv, H.; Cheng, Z.; Xie, F.; Pan, J.; Liu, F. Study on hydraulic fracturing prevention and control of rock burst in roof of deep extra-thick coal seam entry group. Sci. Rep. 2024, 14, 29537. [Google Scholar] [CrossRef] [PubMed]

- Dai, X.; Gao, R.; Gao, W.; Bai, D.; Huang, X. Exploring the Distribution Characteristics of High Static Load in the Island Working Face of Extra-Thick Coal Seams with Hard Roof: Addressing the Challenge of Rock burst Risk. Appl. Sci. 2024, 14, 1961. [Google Scholar] [CrossRef]

- Yang, S.; Bian, J.; Liu, A.; Li, X.; Li, F.; Ma, X.; Gong, S. Comparative Study on the Prevention and Control Effects of Rock burst Between Hydraulic Fracturing Sections and Blank Sections. Sensors 2024, 24, 7281. [Google Scholar] [CrossRef]

- Cheng, L.; Zhang, Z.; Jiang, P.; Yang, J. Research and application of stress field response mechanism based on roof hydraulic fracturing pressure relief. J. Min. Saf. Eng. 2023, 40, 722–729. [Google Scholar]

- Zhao, S.; Ouyang, Z.; Liu, J.; Zhang, G.; Wang, Y.; Li, X. Theory and application of prevention of rock burst by advanced deep hole roof blasting. Chin. J. Rock Mech. Eng. 2013, 32 (Suppl. S2), 3768–3775. [Google Scholar]

- Lv, R.; Li, J.; Zhu, L.; Wang, C.; Quan, X.; Ni, X.; Wang, B.; Zhang, S. Study on the technology of acid pressure relief and coal burst reduction in surface wells with extremely thick conglomerate roof. Coal Sci. Technol. 2025. Available online: http://kns.cnki.net/kcms/detail/11.2402.TD.20241021.1103.001.html (accessed on 1 June 2024).

- Zheng, K.; Yuan, L.; Zhang, P.; Wang, L. Rock bursts induced by thick-hard roof with compound key strata: Mechanisms and technical modes for prevention. Coal Geol. Explor. 2024, 52, 14–24. [Google Scholar]

- Fu, B.; Gao, M.; Tu, M.; Zhang, P. Composite effect of key stratum and its influence on strata behaviors. J. Min. Saf. Eng. 2016, 33, 220–225. [Google Scholar]

- Lai, X.; Zhu, H.; Guo, Z.; Gu, H.; Li, X.; Zhao, Q.; Shan, P. Breaking dynamic load mechanism and application of high key strata in gully area of shallow coal seam. J. Min. Saf. Eng. 2024, 41, 879–888. [Google Scholar]

- Jiao, W.; Ma, W.; Shang, N.; Si, L.; Ma, J.; Wang, Y. Directional deep hole hydraulic fracturing pressure relief and erosion prevention technology in hard roof of extra-thick coal seam. Coal Technol. 2024, 43, 213–216. [Google Scholar]

- Wang, S.; Zhi, B.; Du, T.; Yang, G.; Lu, C.; Xia, Y. Ground fracturing pre-control technology for potential mine seismic risk of thick and hard roof. Coal Sci. Technol. 2023, 51, 1–11. [Google Scholar]

- Fan, J.; Dou, L.; He, H.; Du, T.; Zhang, S.; Gui, B.; Sun, X. Directional hydraulic fracturing to control hard-roof rock burst in coal mines. Int. J. Min. Sci. Technol. 2012, 22, 177–181. [Google Scholar] [CrossRef]

- Zhuang, J.; Mu, Z.; Cai, W.; He, H.; Hosking, L.J.; Xi, G.; Jiao, B. Multistage hydraulic fracturing of a horizontal well for hard roof related coal burst control: Insights from numerical modelling to field application. Int. J. Min. Sci. Technol. 2024, 34, 1095–1114. [Google Scholar] [CrossRef]

- Yu, B.; Peng, M.; Tai, Y.; Guo, S. Assessment and control of the mine tremor disaster induced by the energy accumulation and dispersion of thick-hard roofs. Int. J. Min. Sci. Technol. 2024, 34, 925–941. [Google Scholar] [CrossRef]

- Pan, J.; Lu, C.; Ma, X.; Xia, Y.; Xie, F.; Xu, G.; Dou, G.; Lv, D.; Sun, X.; Ma, W. System and application of regional fracking of coal seam roof on and under the ground to prevent rock burst. Coal Sci. Technol. 2023, 51, 106–115. [Google Scholar]

- Pan, J.; Kang, H.; Yan, Y.; Ma, X.; Ma, W.; Lu, C.; Lv, D.; Xu, G.; Feng, M.; Xia, Y.; et al. The method, mechanism and application of preventing rock burst by artificial liberation layer of roof. J. China Coal Soc. 2023, 48, 636–648. [Google Scholar]

- Hao, X.; Sun, X.; Tang, Z.; Fu, P.; Luo, J.; Shen, L.; Tang, K. Technology system and application of “Artificial Pre-Fracture Layer” by high level whole layer blasting for pressure releasing to source prevention and control of Rock burst. J. China Coal Soc. 2024, 49, 1318–1331. [Google Scholar]

- Zhao, Z.; Yan, R.; Cong, J. Advanced deep hole pre-splitting blasting of hard roof type and effect evaluation analysis. Coal Sci. Technol. 2023, 51, 68–76. [Google Scholar]

- Ma, W.; Ma, X.; Lv, D.; Wang, B.; Zhu, G. Blasting pressure relief technology for preventing rock burst in deep heading roaday. Ind. Mine Autom. 2022, 48, 119–124. [Google Scholar]

- Zhao, S. Mechanism and application of force-structure cooperative prevention and control on rock burst with deep hole roof pre-blasting. J. China Coal Soc. 2021, 46, 3419–3432. [Google Scholar]

- Brady, B.H.G.; Brown, E.T. Rock Mechanics: For Underground Mining; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2006; Available online: https://www.researchgate.net/publication/49184303_Rock_Mechanics_For_Underground_Mining (accessed on 1 June 2024).

- Müller, L. Fundamentals of Rock Mechanics; International Centre for Mechanical Sciences: Berlin/Heidelberg, Germany, 1969. [Google Scholar]

- Yang, Z.; Lv, Q.; Shen, J.; Zheng, J.; Liu, J. Quantitative evaluation of rock mass basic quality index considering influence of joint surface. Chin. J. Rock Mech. Eng. 2023, 42 (Suppl. S1), 3219–3225. [Google Scholar]

- Pan, J.; Ma, W.; Liu, S.; Gao, J. A prevention technology of rock burst based on directional presplitting of water jet prefabricated slot in hard roof. Chin. J. Rock Mech. Eng. 2021, 40, 1591–1602. [Google Scholar]

- Jiao, Z.; Zhao, Y.; Jiang, Y.; Wang, H.; Lu, Z.; Wang, X. Fault damage induced by mining and its sensitivity analysis of influencing factors. J. China Coal Soc. 2017, 42 (Suppl. S1), 36–42. [Google Scholar]

- Ma, Y.; Zhu, S.; Pan, J.; Gao, Y.; Zhang, X.; Jiang, F.; Liu, J.; Wang, B.; Chen, Y. Identification and on-site application of the main hazard-causing stratum of overlying strata in coal mines. J. China Coal Soc. 2024, 49, 2589–2603. [Google Scholar]

- Xu, J.; Qian, M. Method for discriminating the location of key strata in overlying strata. J. China Univ. Min. Technol. 2000, 29, 463–467. [Google Scholar]

- Qian, M.; Miao, X.; Xu, J. Research on key layer theory in rock strata control. J. China Coal Soc. 1996, 2–7. Available online: https://kns.cnki.net/kcms2/article/abstract?v=YvzTZTPVeK4EYWTjHiLb4Vm_5HwIXug5EsN66x2JAhI9Sc5Zgazw7hFa7qah3umM1t5Vd4H_idOPMvWzAMzPEWrA4n60A5it9lFdeAt5NvD1tbUmBn9OWYZ92-jBvnHXPKXSx2utUOS_5g79pRYnSo72-LjIxImwJCNdTZbjNYk=&uniplatform=NZKPT&language=CHS (accessed on 1 June 2024).

| Lithologic Characters | Density/kg·m−3 | Cohesion/MPa | Internal Friction Angle/° |

|---|---|---|---|

| Conglomerate | 2670 | 5.00 | 35 |

| Kern stone | 2556 | 5.00 | 34 |

| Medium grained sandstone | 2560 | 12.10 | 36 |

| Fine sandstone | 2550 | 3.20 | 42 |

| Siltstone | 2540 | 3.75 | 38 |

| Mudstone | 2600 | 1.20 | 32 |

| Sandy mudstone | 2509 | 2.16 | 36 |

| Coal | 1460 | 1.00 | 28 |

| Jp/(Strip·m−3) | >35 | 35~20 | 20~10 | 10~3 | <3 |

|---|---|---|---|---|---|

| Kv | <0.15 | 0.15~0.35 | 0.35~0.55 | 0.55~0.75 | >0.75 |

| Level | Factors | ||

|---|---|---|---|

| Distance from Coal Seam/m | Lithology of Blasting Layer | Blasting Layer Thickness/m | |

| 1 | 50 | Siltstone | 20 |

| 2 | 80 | Kern stone | 30 |

| Test Scheme | Distance from Coal Seam/m | Lithology of Blasting Layer | Blasting Layer Thickness/m | Overburden Rock Subsidence W/m | Stress σ/Pa | Fracture Number | Fracture Length/m |

|---|---|---|---|---|---|---|---|

| 1 | 50 | Siltstone | 20 | 3.02 | 2.62 × 107 | 1827 | 162 |

| 2 | 50 | Kern stone | 30 | 2.86 | 2.23 × 107 | 1727 | 145 |

| 3 | 80 | Siltstone | 30 | 3.05 | 2.67 × 107 | 1869 | 173 |

| 4 | 80 | Kern stone | 20 | 3.25 | 2.82 × 107 | 1935 | 196 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, Q.; Cao, A.; Zhao, W.; Yang, Y.; Xue, C.; Hao, Q. Application of Long-Distance Drilling and Blasting Technology to Prevent Rock Bursts in High-Level Roofs. Appl. Sci. 2025, 15, 1821. https://doi.org/10.3390/app15041821

Gu Q, Cao A, Zhao W, Yang Y, Xue C, Hao Q. Application of Long-Distance Drilling and Blasting Technology to Prevent Rock Bursts in High-Level Roofs. Applied Sciences. 2025; 15(4):1821. https://doi.org/10.3390/app15041821

Chicago/Turabian StyleGu, Qianyue, Anye Cao, Weiwei Zhao, Yao Yang, Chengchun Xue, and Qi Hao. 2025. "Application of Long-Distance Drilling and Blasting Technology to Prevent Rock Bursts in High-Level Roofs" Applied Sciences 15, no. 4: 1821. https://doi.org/10.3390/app15041821

APA StyleGu, Q., Cao, A., Zhao, W., Yang, Y., Xue, C., & Hao, Q. (2025). Application of Long-Distance Drilling and Blasting Technology to Prevent Rock Bursts in High-Level Roofs. Applied Sciences, 15(4), 1821. https://doi.org/10.3390/app15041821