Additive Manufacturing and Chemical Engineering: Looking for Synergies from a Bibliometric Study

Abstract

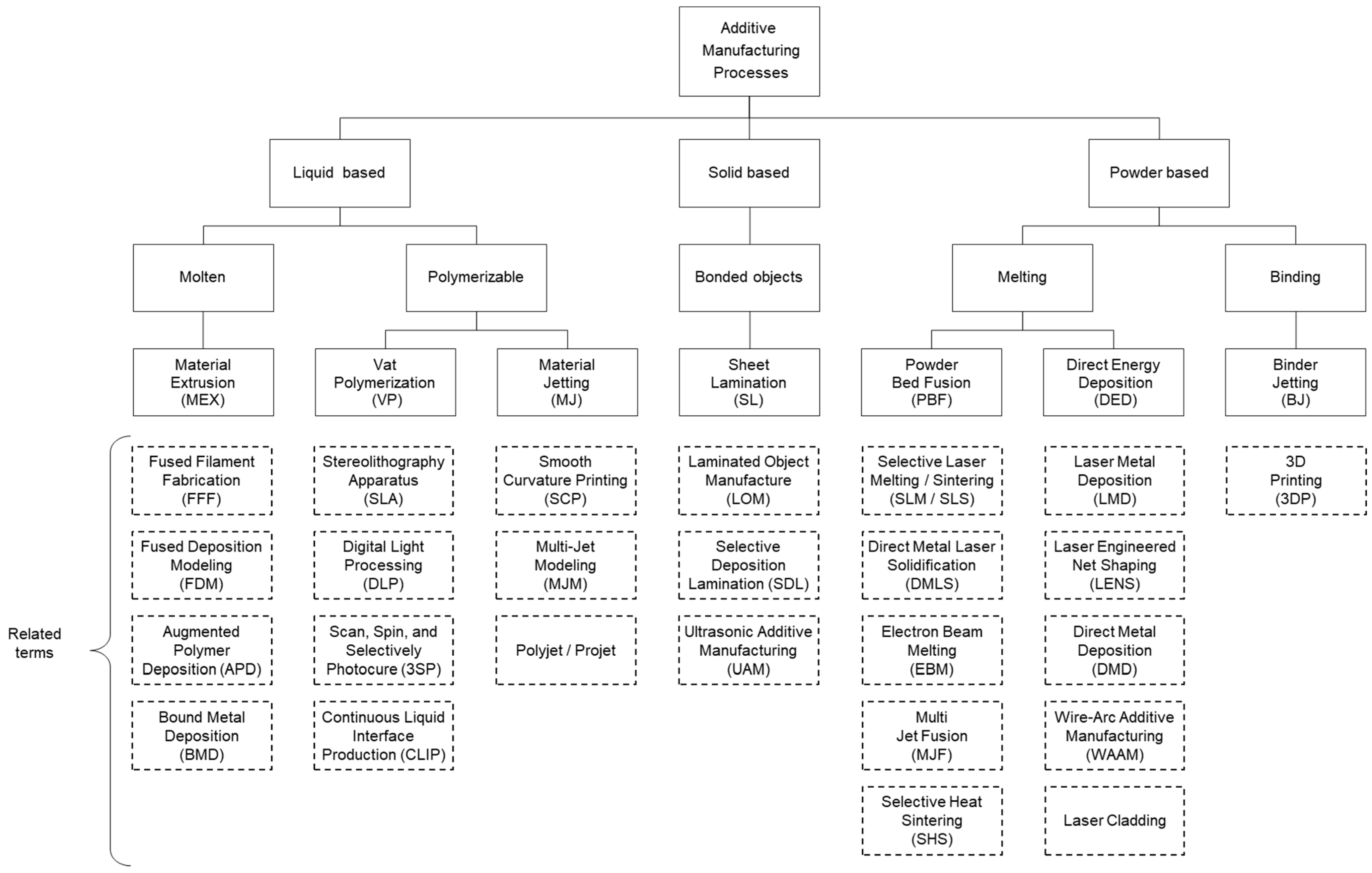

:1. Introduction

2. Data Sources and Methodology

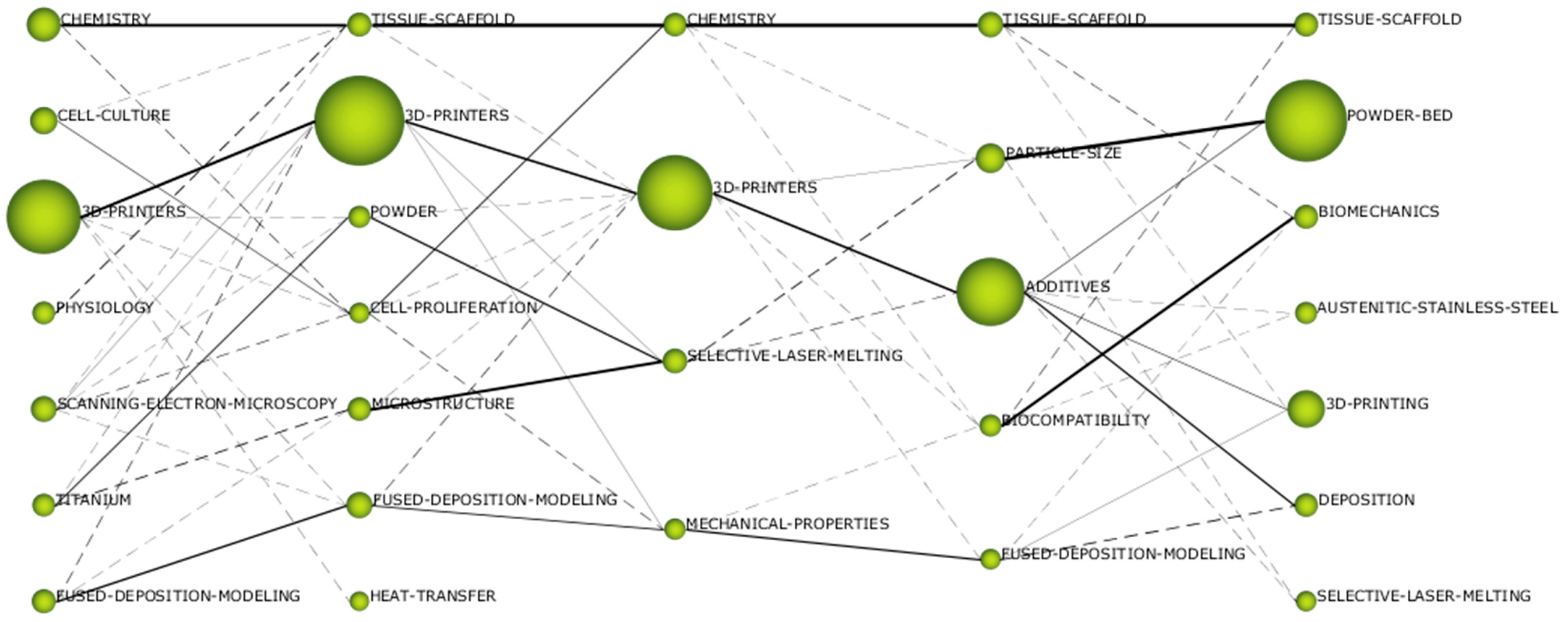

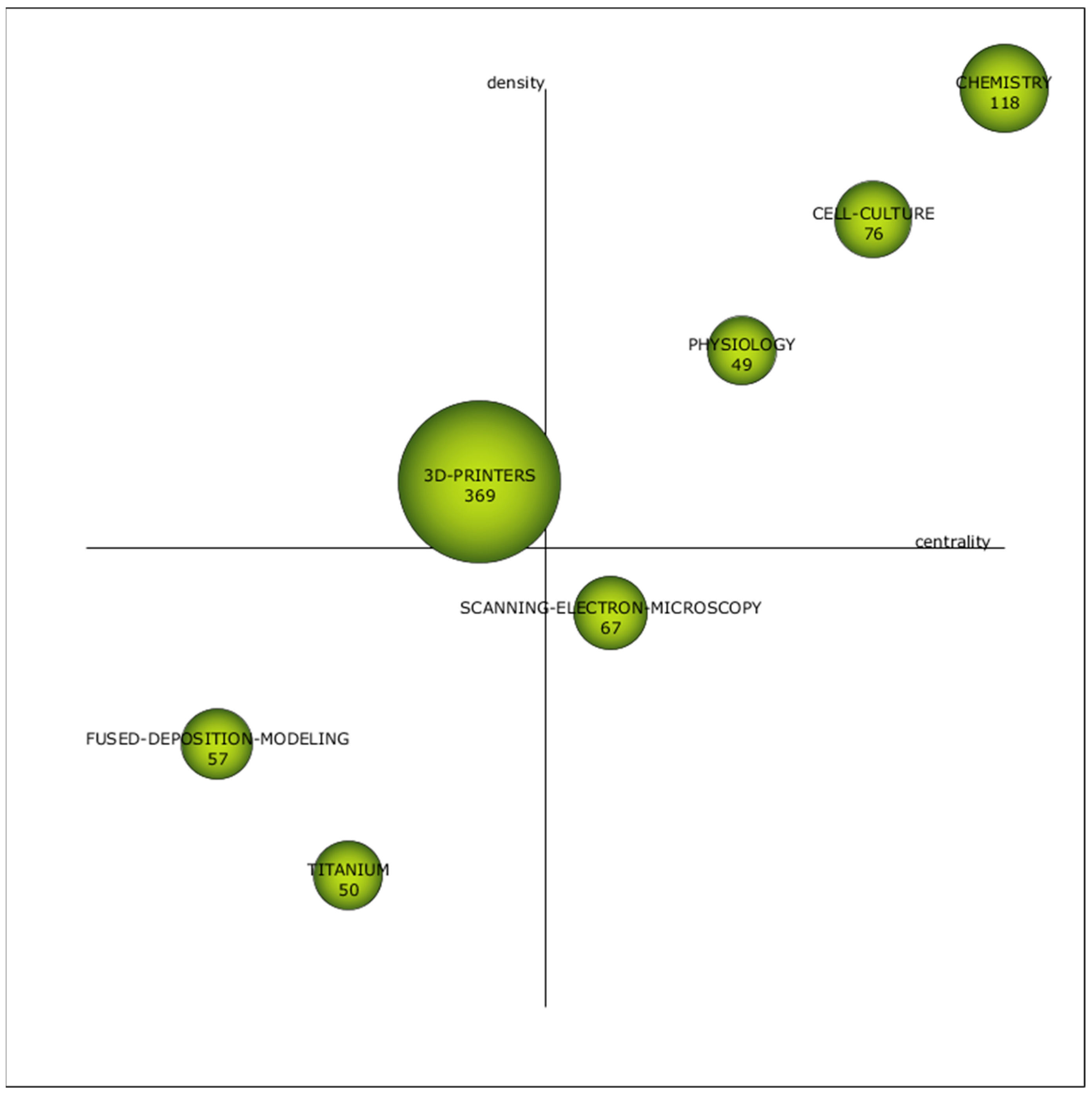

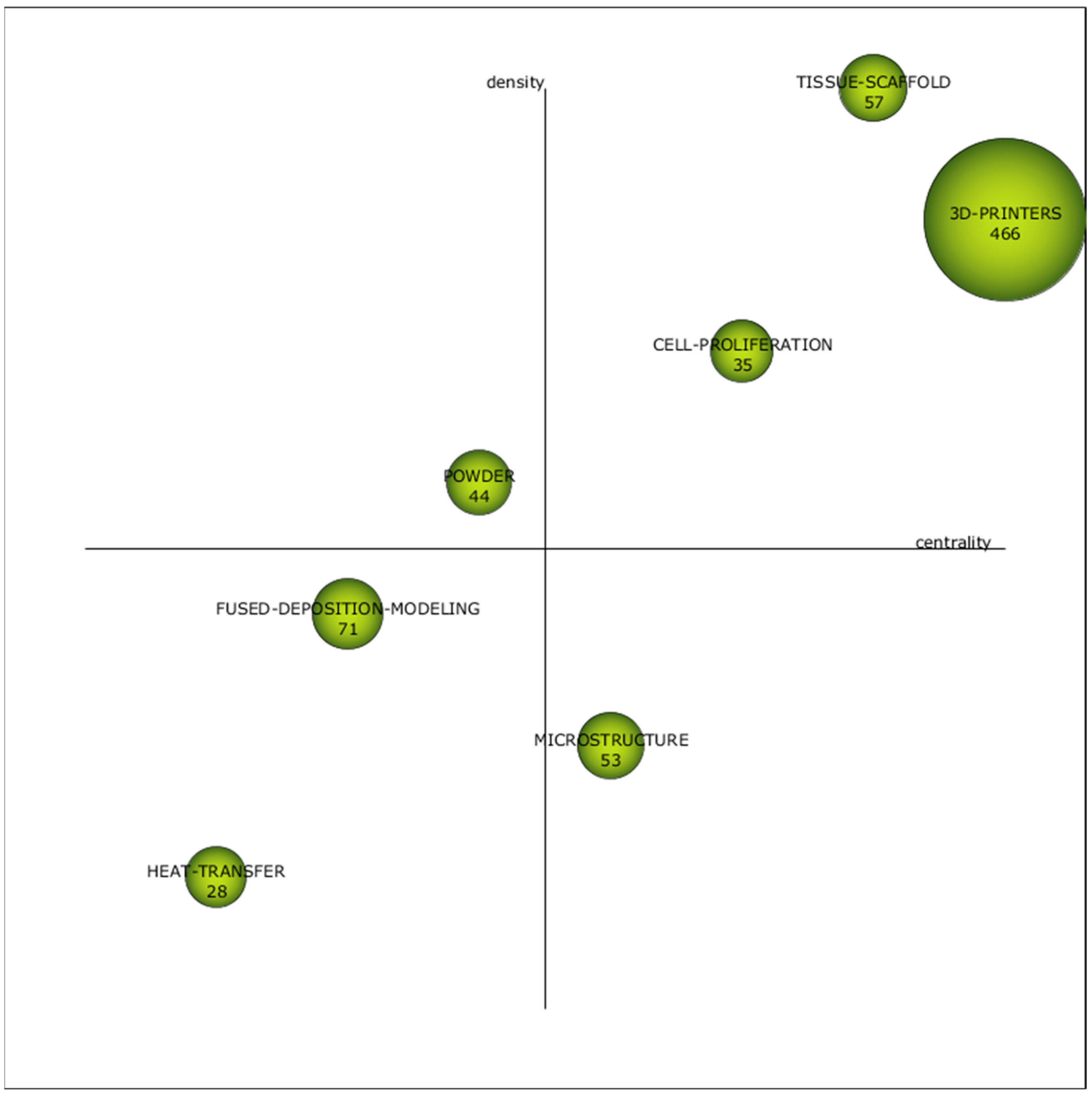

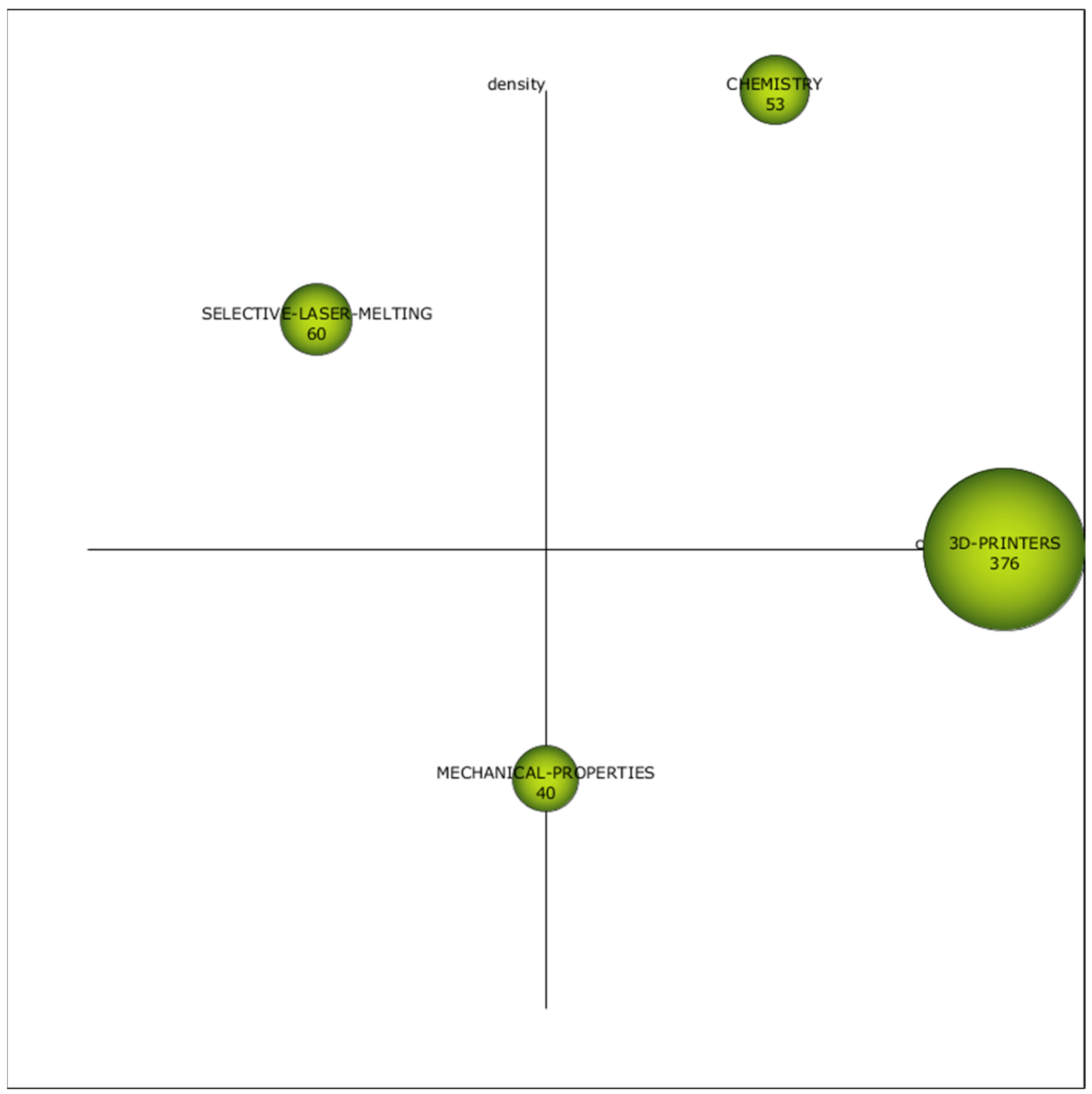

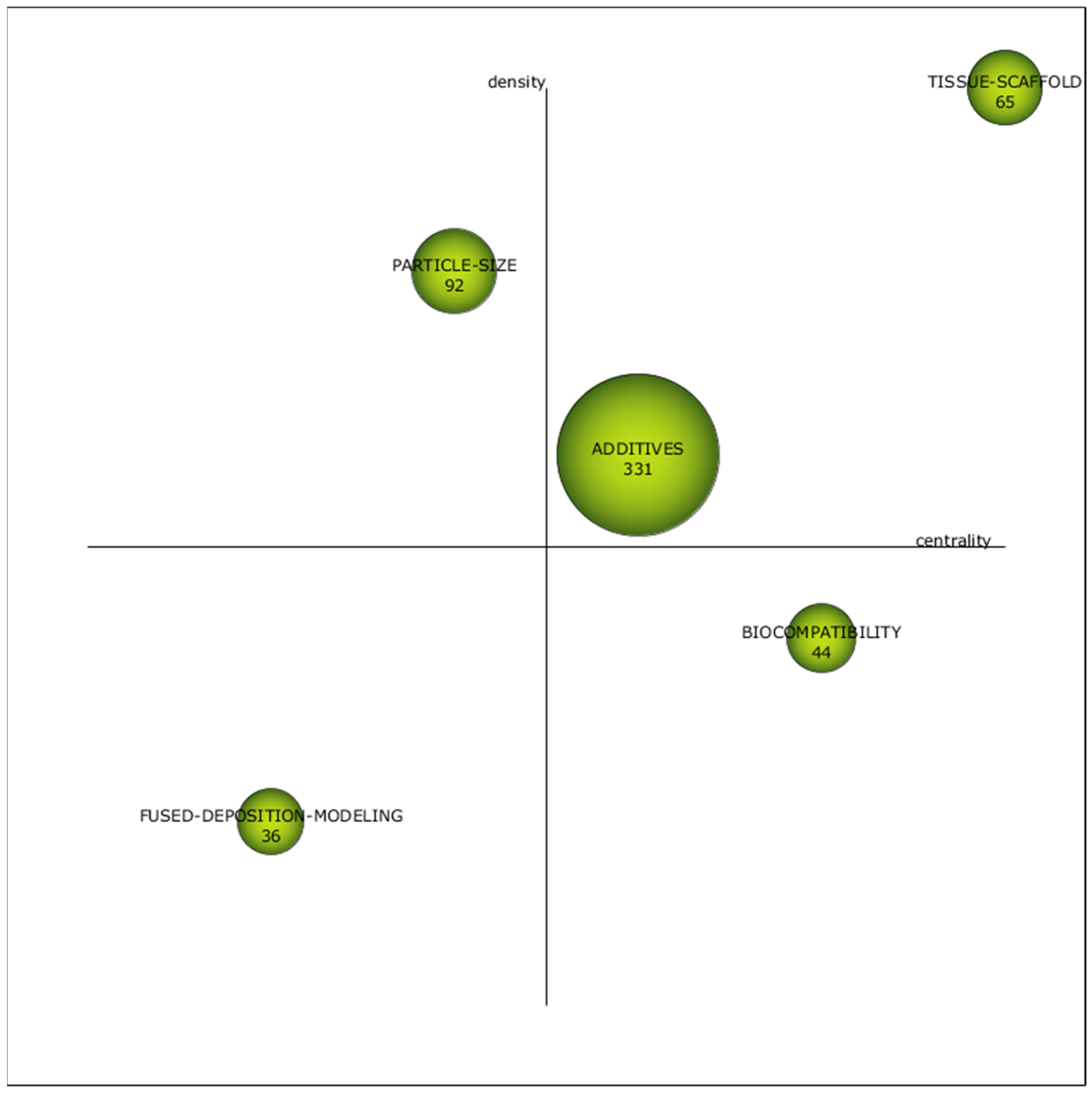

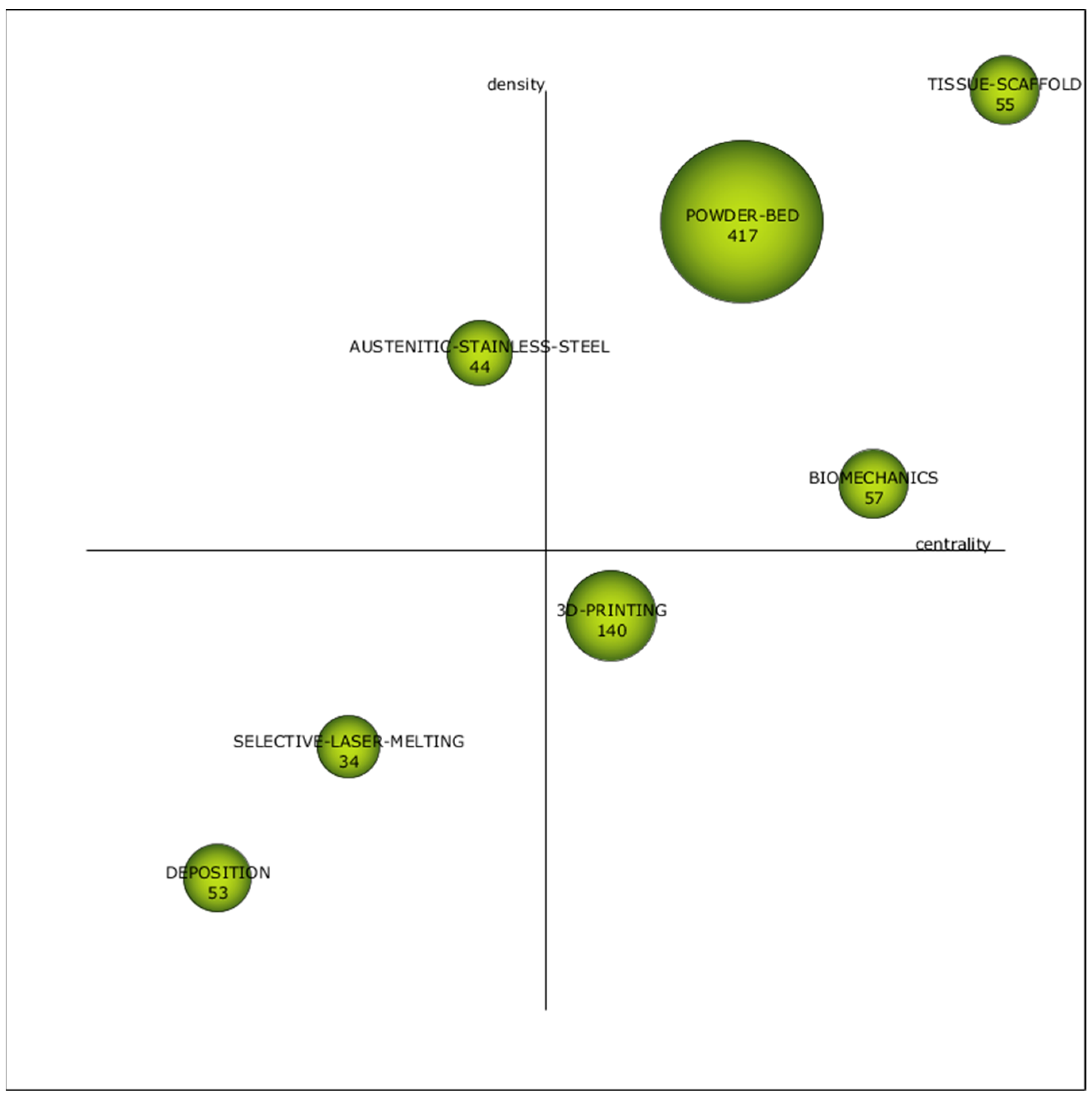

- Motor clusters: Situated in the upper right quadrant and pertain to well-developed and pivotal subjects within the scientific field, exhibiting robust centrality and high density.

- Highly developed and isolated clusters: Located in the upper left quadrant and correspond to topics that have marginal importance in the scientific field. These topics are characterized by being highly specialized and peripheral.

- Emerging or declining clusters: Located in the lower left quadrant and correspond to very undeveloped and marginal topics or to very recent topics having low density and centrality.

- Basic and transversal clusters: Located in the lower right quadrant and correspond to important topics that are not well developed.

3. Results and Discussion

3.1. Bibliometric Performance Analysis

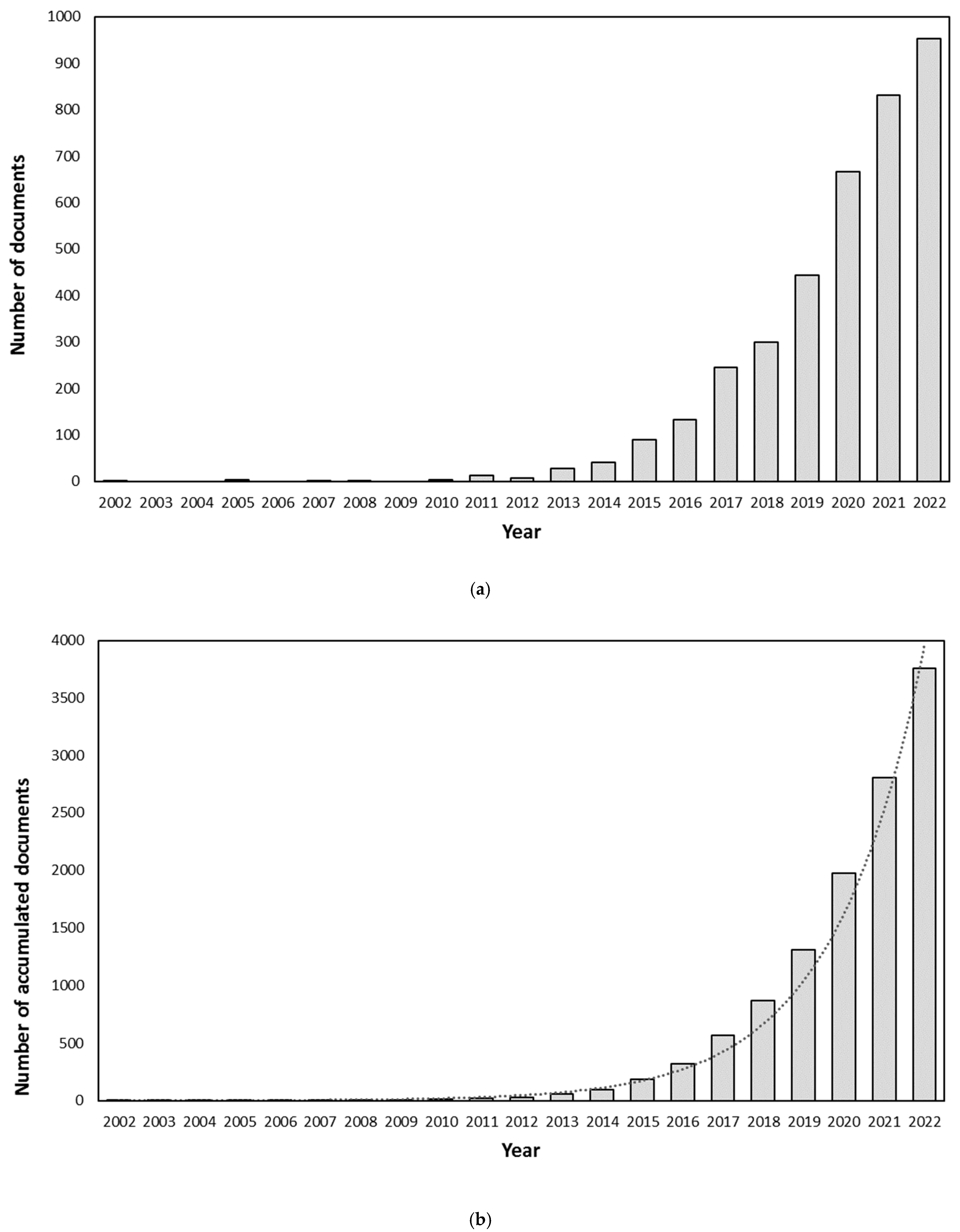

3.1.1. Publication Year, Language of Publications, and Document Type

3.1.2. Publication Distribution of Countries and Institutions

3.1.3. Distribution of Output in Subject Categories and Journals

3.1.4. Most Frequently Cited Documents

3.1.5. Distribution Analysis of Keywords

3.2. Bibliometric Network Analysis

4. Review of Research Focused on Additive Manufacturing and Chemical Engineering

4.1. Additive Manufacturing and Biofabrication

4.1.1. Bioprinting Technologies

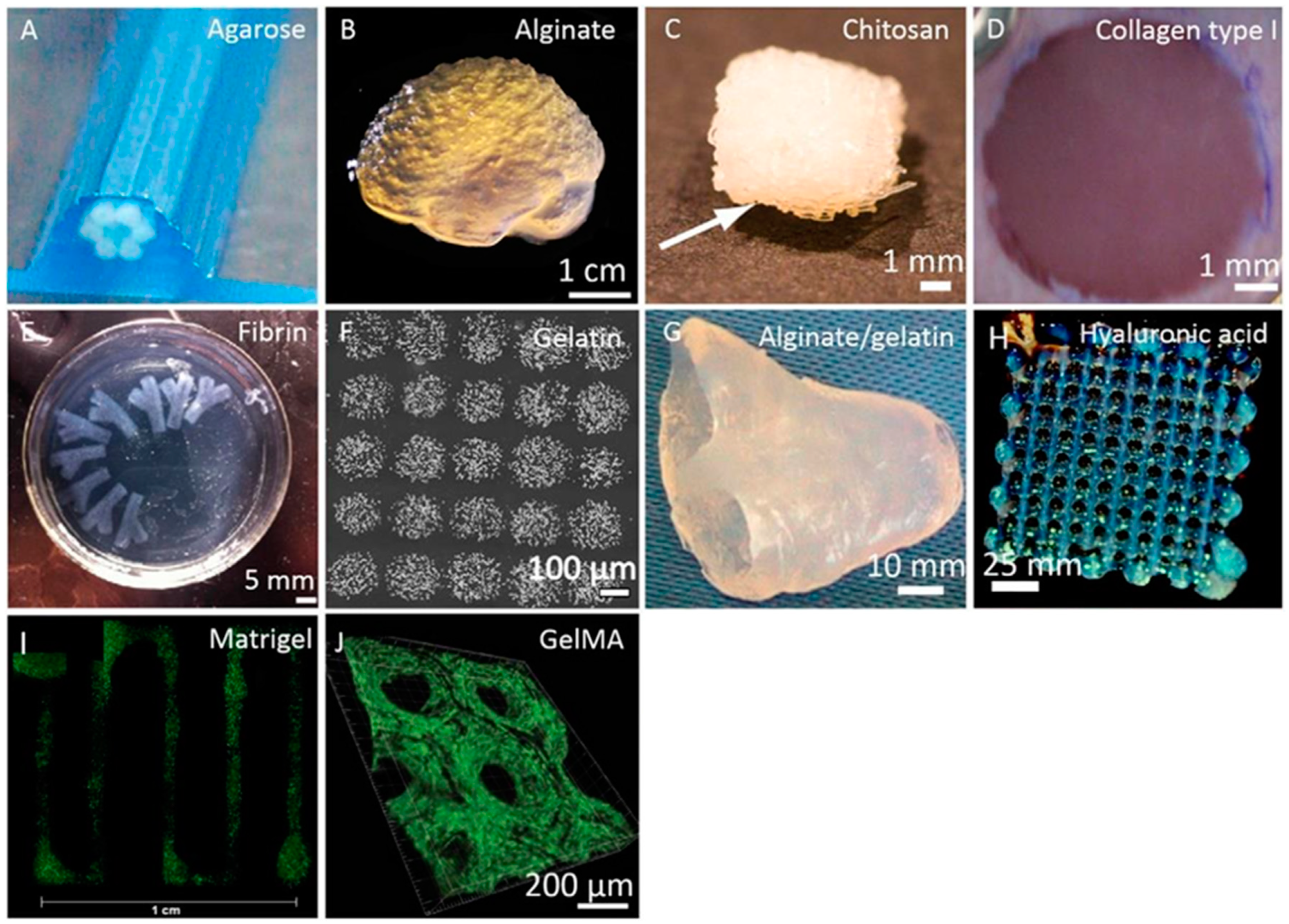

4.1.2. Bioprinting Materials

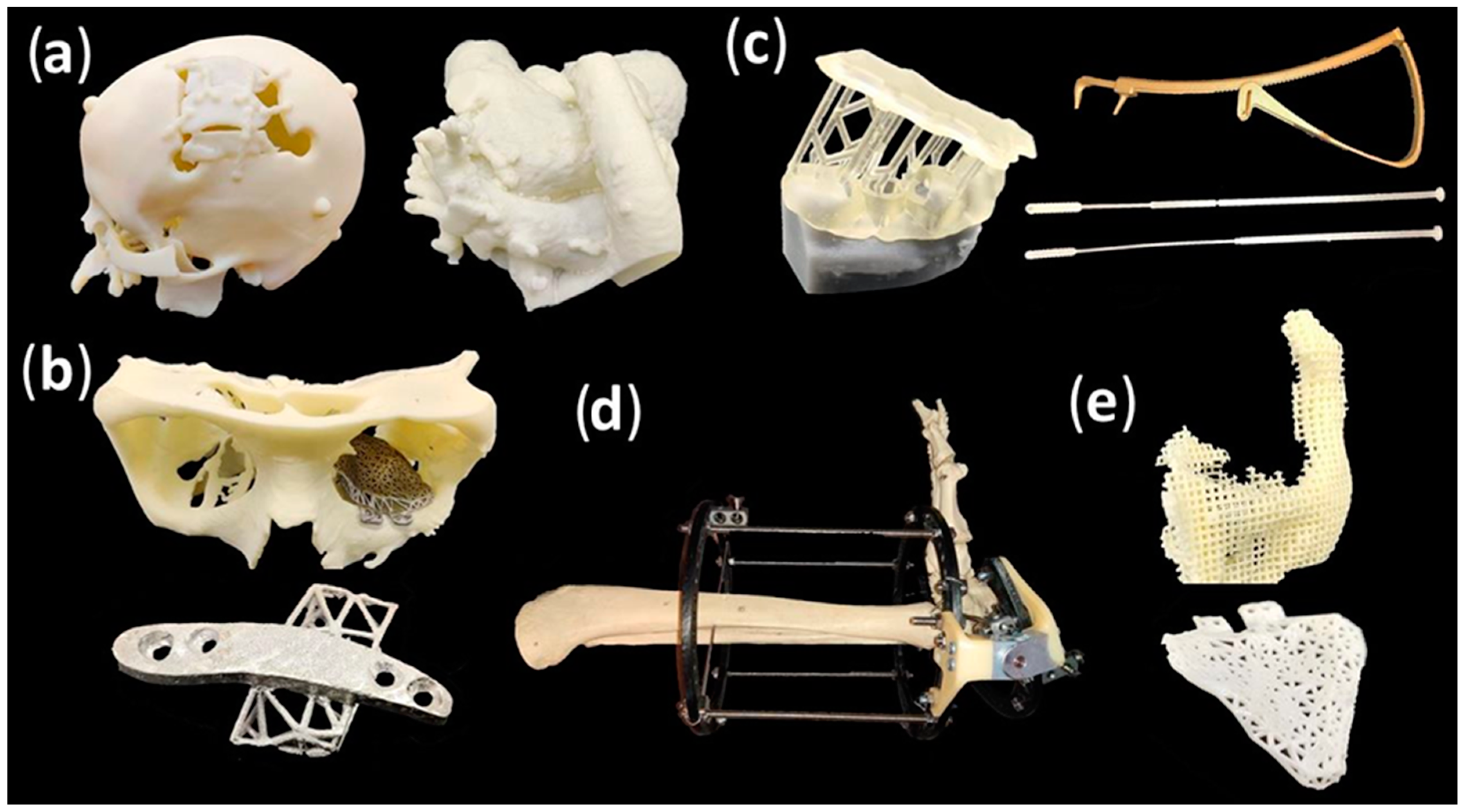

4.1.3. Bioprinting Applications

4.2. Additive Manufacturing and Chemical Engineering: Future Needs

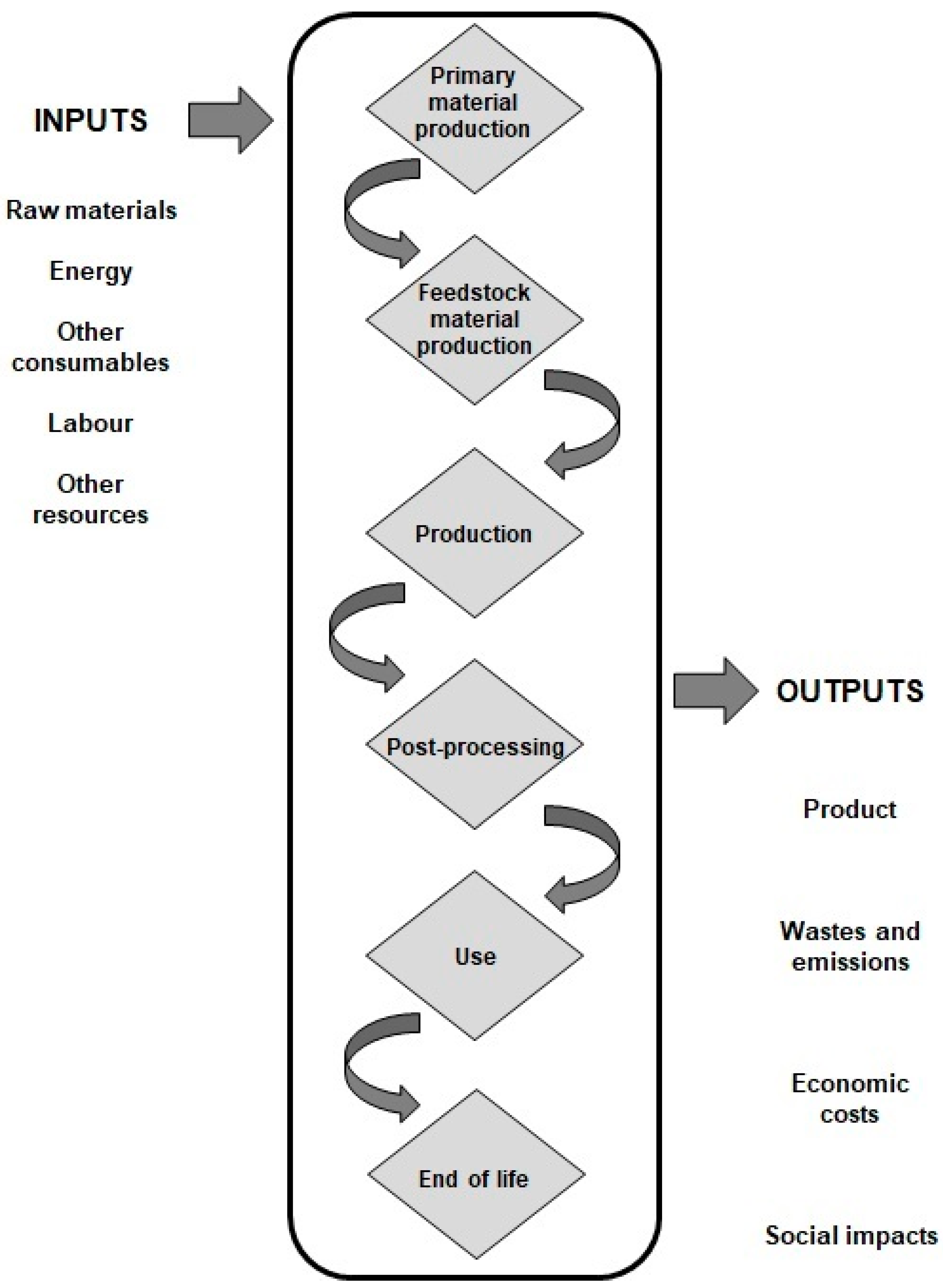

4.2.1. Additive Manufacturing and Life Cycle Assessment

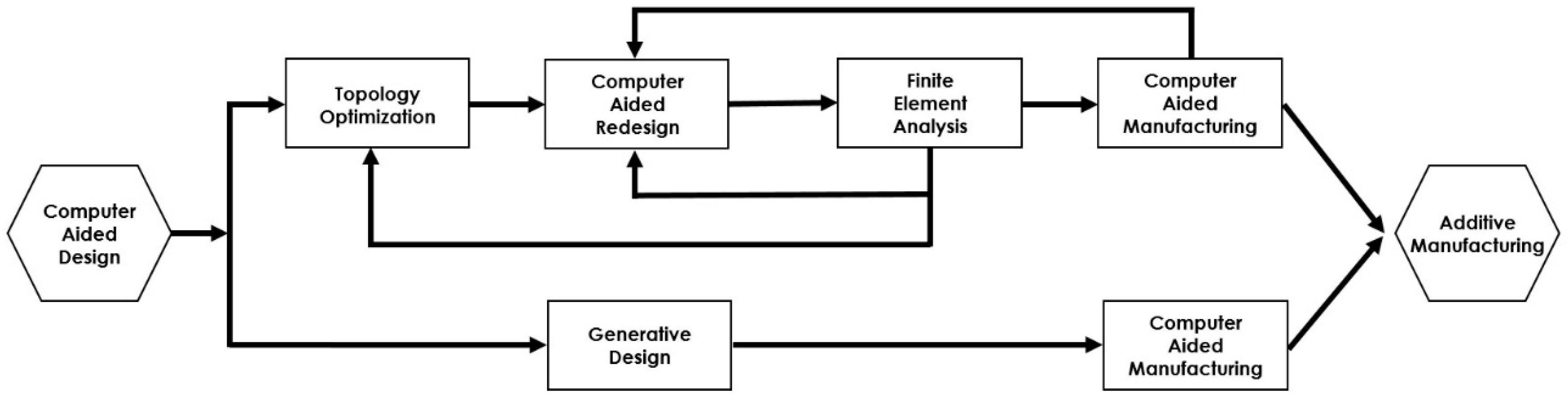

4.2.2. Optimization of Additive Manufacturing

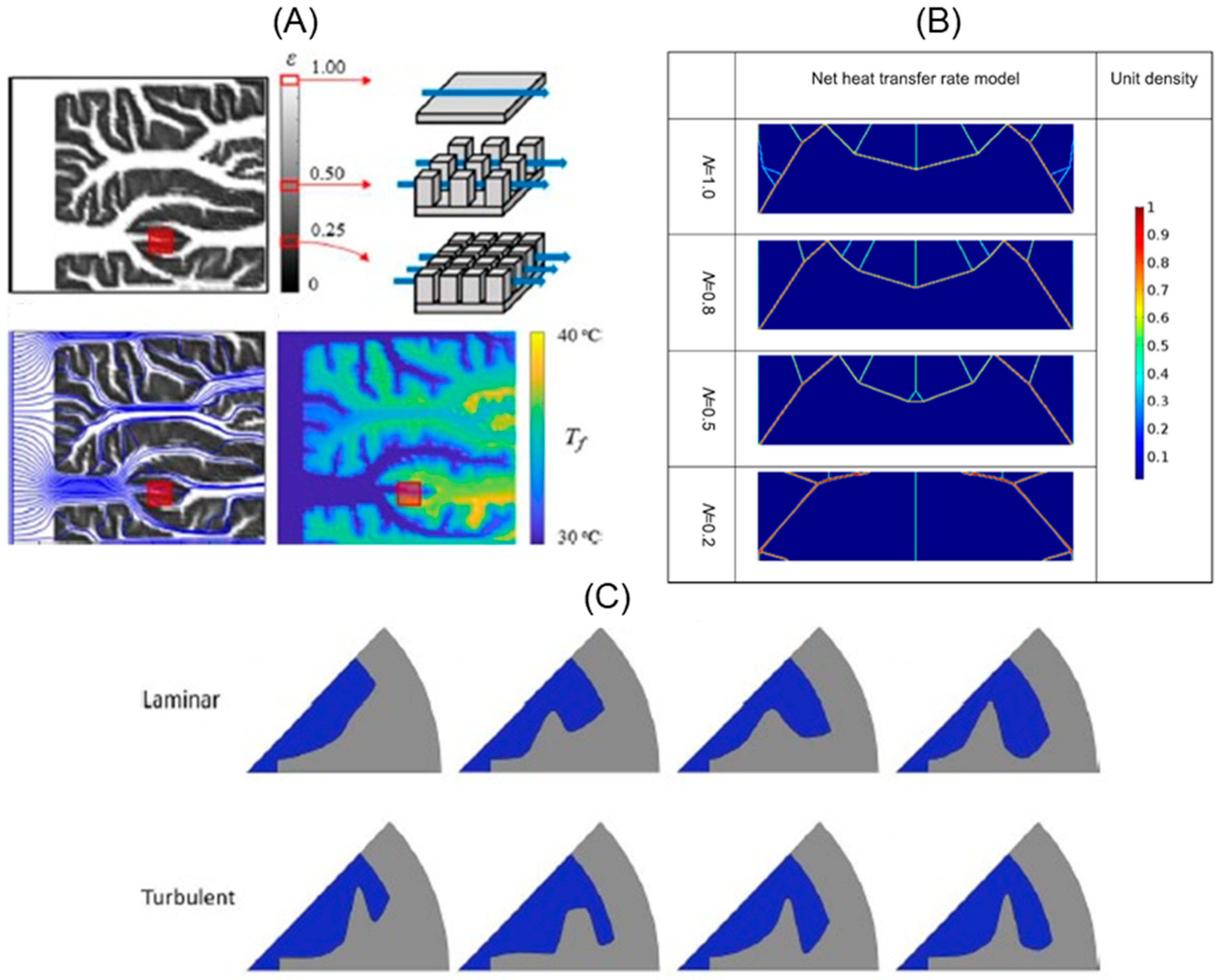

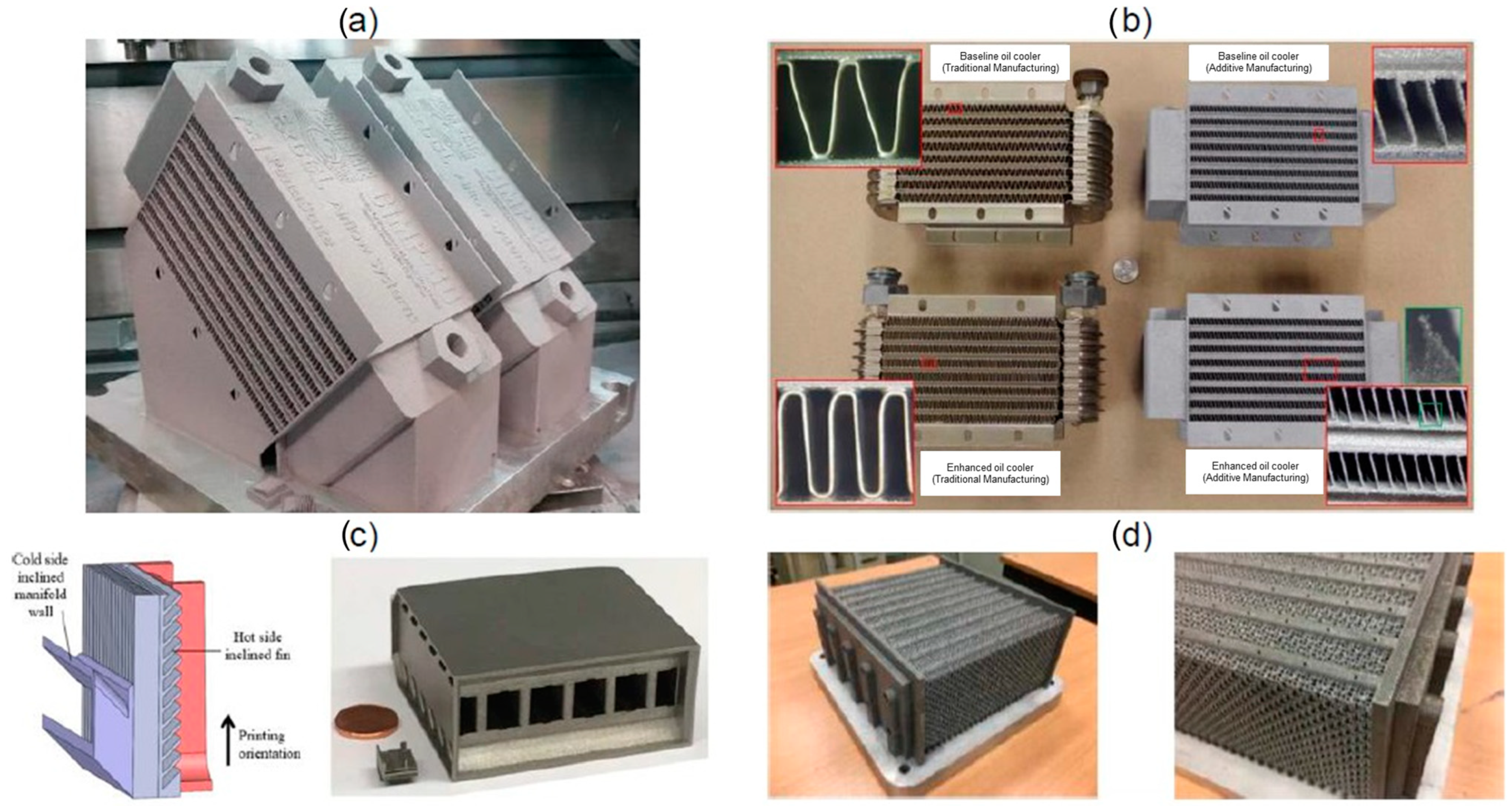

4.2.3. Additive Manufacturing and Heat Exchange

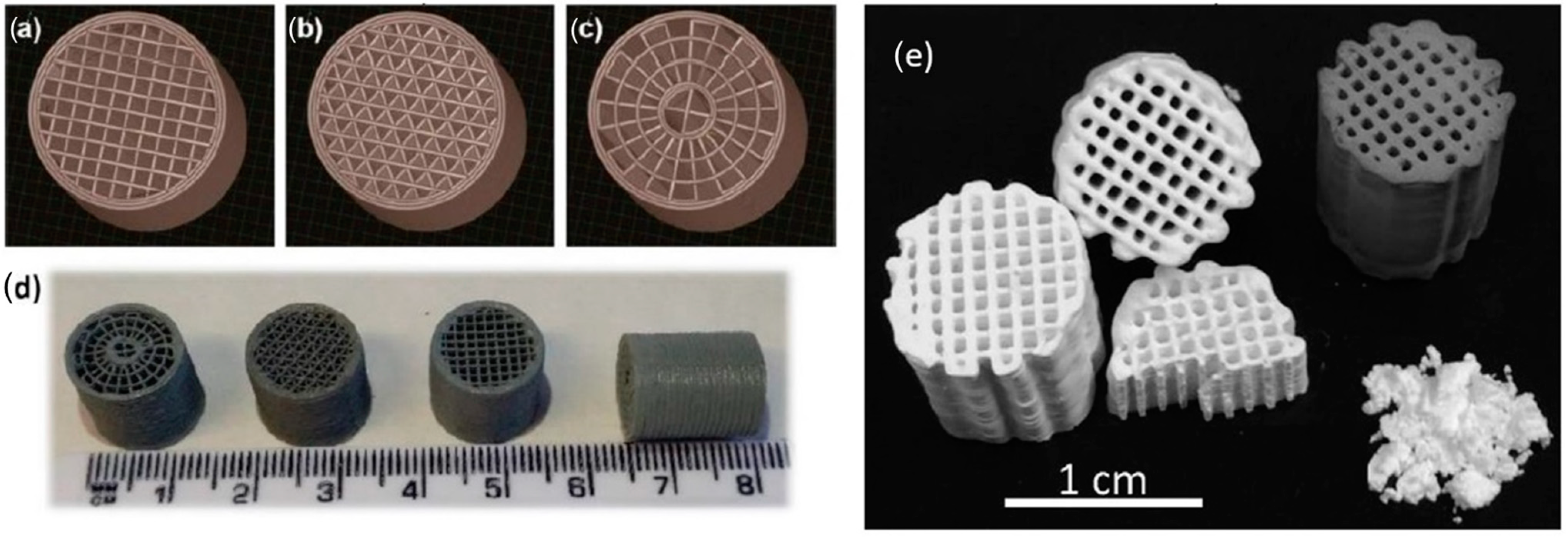

4.2.4. Catalysts and Sorbents Produced by Additive Manufacturing

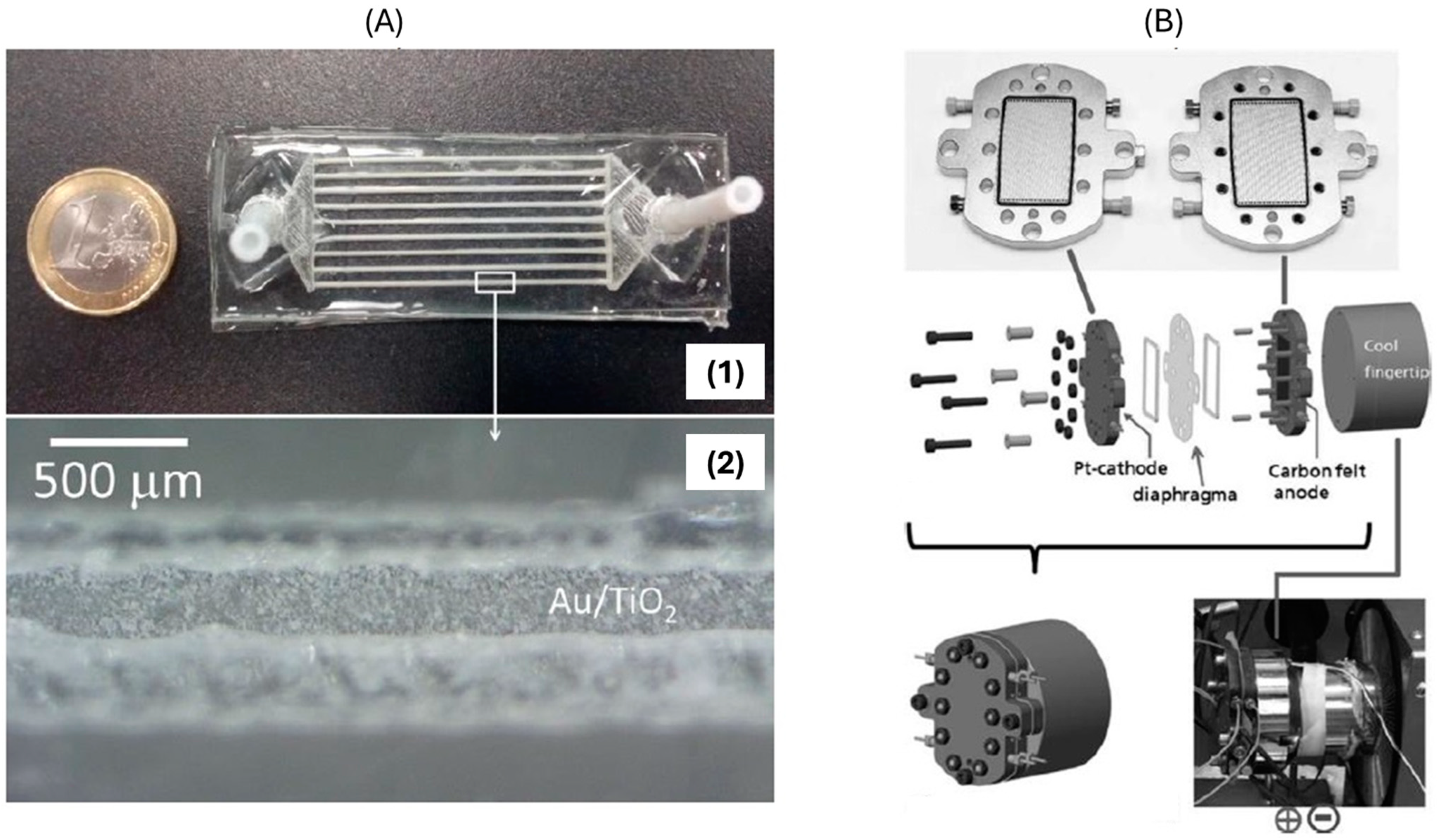

4.2.5. Additive Manufacturing for Microreactors and Miniaturized Devices

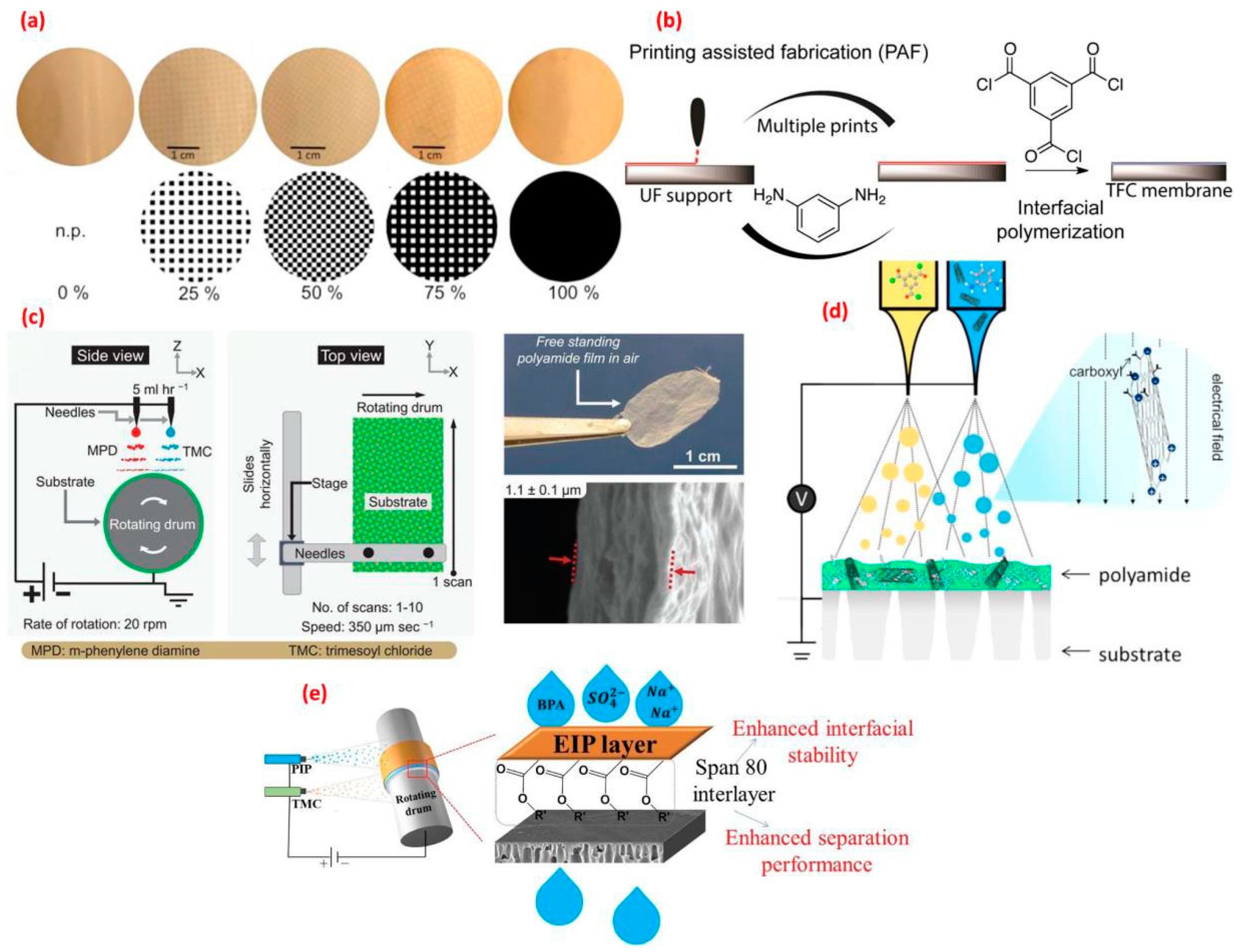

4.2.6. Additive Manufacturing and Separation Membranes

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Debroy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Progress in Materials Science Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Hopkinson, E.N.; Dickens, P.M. An Industrial Revolution for the Digital Age; John Wiley: Hoboken, NJ, USA, 2006; ISBN 9780470016138. [Google Scholar]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive Manufacturing Methods and Modelling Approaches: A Critical Review. Int. J. Adv. Manuf. Technol. 2015, 83, 389–405. [Google Scholar] [CrossRef]

- Adam, G.A.O.; Zimmer, D. Design for Additive Manufacturing—Element Transitions and Aggregated Structures. CIRP J. Manuf. Sci. Technol. 2014, 7, 20–28. [Google Scholar] [CrossRef]

- Gebler, M.; Schoot Uiterkamp, A.J.M.; Visser, C. A Global Sustainability Perspective on 3D Printing Technologies. Energy Policy 2014, 74, 158–167. [Google Scholar] [CrossRef]

- Ribeiro, I.; Matos, F.; Jacinto, C.; Salman, H.; Cardeal, G.; Carvalho, H.; Godina, R.; Peças, P. Framework for Life Cycle Sustainability Assessment of Additive Manufacturing. Sustainability 2020, 12, 929. [Google Scholar] [CrossRef]

- Brandt, M.; Bhargava, S.K. An Introduction to the World of Additive Manufacturing. In Additive Manufacturing for Chemical Sciences and Engineering; Springer Nature: Melbourne, VIC, Australia, 2022; pp. 1–18. ISBN 978-981192292-3. [Google Scholar]

- ISO/ASTM 52900; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. ISO: Geneva, Switzerland, 2021.

- Bourell, D.; Kruth, J.P.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.M.; Clare, A. Materials for Additive Manufacturing. CIRP Ann. Manuf. Technol. 2017, 66, 659–681. [Google Scholar] [CrossRef]

- Singh, S.; Mehla, S.; Bhargava, S.K.; Ramakrishna, S. History and Evolution of Additive Manufacturing. In Additive Manufacturing for Chemical Sciences and Engineering; Springer Nature: Melbourne, VIC, Australia, 2022; pp. 19–52. ISBN 978-981192292-3. [Google Scholar]

- Parra-Cabrera, C.; Achille, C.; Kuhn, S.; Ameloot, R. 3D printing in chemical engineering and catalytic technology: Structured catalysts, mixers and reactors. Chem. Soc. Rev. 2018, 47, 209–230. [Google Scholar] [CrossRef]

- Chang, F.; Zhang, X.; Zhan, G.; Duan, Y.; Zhang, S. Review of Methods for Sustainability Assessment of Chemical Engineering Processes. Ind. Eng. Chem. Res. 2021, 60, 52–66. [Google Scholar] [CrossRef]

- Zentel, K.M.; Fassbender, M.; Pauer, W.; Luinstra, G.A. 3D Printing as Chemical Reaction Engineering Booster. In Advances in Chemical Engineering; Moscatelli, D., Sponchioni, M., Eds.; Academic Press Inc.: Hamburg, Germany, 2020; Volume 56, pp. 97–137. ISBN 978-012820645-4. [Google Scholar]

- Chen, C. Science Mapping: A Systematic Review of the Literature. J. Data Inf. Sci. 2017, 2, 1–40. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to Conduct a Bibliometric Analysis: An Overview and Guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Elsevier. SCOPUS: Your Brilliance, Connected. Scopus Fact-Sheet; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Herrera-Viedma, E.; López-Robles, J.R.; Guallar, J.; Cobo, M.J. Global Trends in Coronavirus Research at the Time of COVID-19: A General Bibliometric Approach and Content Analysis Using SciMAT. Prof. Inf. 2020, 29, 11. [Google Scholar] [CrossRef]

- Cobo, M.J.; López-Herrera, A.G.; Herrera-Viedma, E.; Herrera, F. SciMAT: A New Science Mapping Analysis Software Tool. J. Am. Soc. Inf. Sci. Technol. 2012, 63, 1609–1630. [Google Scholar] [CrossRef]

- Zhou, H.; Li, D. Numerical Molding Simulation for Rapid-Prototyped Injection Molds. Polym. Plast. Technol. Eng. 2005, 44, 755–770. [Google Scholar] [CrossRef]

- Koester, J.J.; Langerman, M.A.; Korde, U.A.; Sears, J.W.; Buck, G.A. Preliminary Design of a Calorimeter for Experimental Determination of Effective Absorptivity of Metal Substrates during Laser Powder Deposition. In Proceedings of the ASME 2005 International Mechanical Engineering Congress and Exposition, Orlando, FL, USA, 5–11 November 2005; pp. 857–862. [Google Scholar] [CrossRef]

- Michaelis, B.M.; Dunn-Rankin, D.; Smith, R.F., Jr.; Bobrow, J.E. In-Flight Thermal Control of Molten Metal Droplet Streams. Int. J. Heat Mass Transf. 2007, 50, 4554–4558. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The Status, Challenges, and Future of Additive Manufacturing in Engineering. Comput.-Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Longhitano, G.A.; Nunes, G.B.; Candido, G.; da Silva, J.V.L. The Role of 3D Printing during COVID-19 Pandemic: A Review. Prog. Addit. Manuf. 2021, 6, 19–37. [Google Scholar] [CrossRef]

- Bielsa, E. Translating Academia. Implications for Knowledge Production in the Social Sciences and the Humanities. Soc. Sci. Inf. 2023, 62, 427–439. [Google Scholar] [CrossRef]

- Giwa, S.O.; Adegoke, K.A.; Taziwa, R.T.; Sharifpur, M. A Bibliometric Analysis of Studies on Diesel Engines Fuelled with Biodiesel and Its Blends: Trends, Hotspots, and Future Research. Biofuels 2023, 14, 1061–1075. [Google Scholar] [CrossRef]

- Abejón, R. Self-Healing Asphalt: A Systematic Bibliometric Analysis for Identification of Hot Research Topics during the 2003–2018 Period. Materials 2021, 14, 565. [Google Scholar] [CrossRef]

- Abejón, R.; Moya, L. Cross-Laminated Timber: Perspectives from a Bibliometric Analysis (2006–2018). Wood Mater. Sci. Eng. 2021, 17, 429–450. [Google Scholar] [CrossRef]

- Mudhivarthi, B.R.; Thakur, P. Integration of Artificial Intelligence in Robotic Vehicles: A Bibliometric Analysis. Paladyn 2022, 13, 110–120. [Google Scholar] [CrossRef]

- Kannazarova, Z.; Juliev, M.; Muratov, A.; Abuduwaili, J. Groundwater in the Commonwealth of Independent States: A Bibliometric Analysis of Scopus-Based Papers from 1972 to 2023, Emphasizing the Significance of Drainage. Groundw. Sustain. Dev. 2024, 25, 101083. [Google Scholar] [CrossRef]

- Abejón, R. A Bibliometric Analysis of Research on Selenium in Drinking Water during the 1990–2021 Period: Treatment Options for Selenium Removal. Int. J. Environ. Res. Public Health 2022, 19, 5834. [Google Scholar] [CrossRef] [PubMed]

- Huang, R.; Riddle, M.E.; Graziano, D.; Das, S.; Nimbalkar, S.; Cresko, J.; Masanet, E. Environmental and Economic Implications of Distributed Additive Manufacturing: The Case of Injection Mold Tooling. J. Ind. Ecol. 2017, 21, S130–S143. [Google Scholar] [CrossRef]

- Johns, J. Digital Technological Upgrading in Manufacturing Global Value Chains: The Impact of Additive Manufacturing. Glob. Netw. 2022, 22, 649–665. [Google Scholar] [CrossRef]

- Fang, Y.; Shao, Z. How Does Green Finance Affect Cleaner Industrial Production and End-of-Pipe Treatment Performance? Evidence from China. Environ. Sci. Pollut. Res. 2022, 30, 33485–33503. [Google Scholar] [CrossRef]

- Pei, Z.; Yu, T.; Yi, W.; Li, Y. Twenty-Year Retrospection on Green Manufacturing: A Bibliometric Perspective. IET Collab. Intell. Manuf. 2021, 3, 303–323. [Google Scholar] [CrossRef]

- Wang, L.; Lu, B. Development of Additive Manufacturing Technology and Industry in China. Strateg. Study Chin. Acad. Eng. 2022, 24, 202–211. [Google Scholar] [CrossRef]

- Cozzoni, E.; Passavanti, C.; Ponsiglione, C.; Primario, S.; Rippa, P. Interorganizational Collaboration in Innovation Networks: An Agent Based Model for Responsible Research and Innovation in Additive Manufacturing. Sustainability 2021, 13, 7460. [Google Scholar] [CrossRef]

- Patalas-Maliszewska, J.; Topczak, M. Assessment of Energy Consumption in the Context of Implementing Additive Manufacturing Technologies: Evidence from Polish Small and Medium Sized Production Companies. Energy Sustain. Dev. 2023, 73, 355–364. [Google Scholar] [CrossRef]

- Kaminsky, O.; Kravchenko, M.; Yereshko, J.; Boiarynova, K. The Model of Additive Manufacturing Business-Ecosystem in the Conditions of War in Europe. In Proceedings of the 2022 IEEE 3rd International Conference on System Analysis & Intelligent Computing (SAIC), Kyiv, Ukraine, 4–7 October 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Abbas, M.Z. Industrial Applications of 3D Printing to Scale-up Production of COVID-19-Related Medical Equipment. J. 3D Print. Med. 2021, 5, 97–110. [Google Scholar] [CrossRef]

- Ratchford, J.T.; Blanpied, W.A. Paths to the Future for Science and Technology in China, India and the United States. Technol. Soc. 2008, 30, 211–233. [Google Scholar] [CrossRef]

- Khosla, R.; Kamat, A.S.; Narayanamurti, V. Successful Clean Energy Technology Transitions in Emerging Economies: Learning from India, China, and Brazil. Prog. Energy 2020, 2, 043002. [Google Scholar] [CrossRef]

- Wong, D.S.K.; Zaw, H.M.; Tao, Z.J. Additive Manufacturing Teaching Factory: Driving Applied Learning to Industry Solutions. Virtual Phys. Prototyp. 2014, 9, 205–212. [Google Scholar] [CrossRef]

- Yaohua, R.; Muyu, L.; Weihu, C.; Xianyu, C. Efficiency, Technology and Productivity Change of Higher Educational Institutions Directly under the Ministry of Education of China in 2007–2012. Procedia Comput. Sci. 2018, 139, 598–604. [Google Scholar] [CrossRef]

- Xie, X.; Siau, K.; Chen, C. Does More Investment in Universities Improve Their Performances? A Study on the Performance of Chinese Universities Using Data Envelopment Analysis. J. Glob. Inf. Manag. 2023, 31, 320517. [Google Scholar] [CrossRef]

- Hu, S.; Wei, Y. Chinese Academy of Sciences ’ Recent Activities in Boosting Chinese Planetary Science Research. Earth Planet. Phys. 2019, 3, 459–466. [Google Scholar] [CrossRef]

- Monfared, V.; Ramakrishna, S.; Nasajpour-Esfahani, N.; Toghraie, D.; Hekmatifar, M.; Rahmati, S. Science and Technology of Additive Manufacturing Progress: Processes, Materials, and Applications. Met. Mater. Int. 2023, 29, 3442–3470. [Google Scholar] [CrossRef]

- Torres-Salinas, D.; Valderrama-Baca, P.; Arroyo-Machado, W. Is There a Need for a New Journal Metric? Correlations between JCR Impact Factor Metrics and the Journal Citation Indicator—JCI. J. Informetr. 2022, 16, 101315. [Google Scholar] [CrossRef]

- Murphy, S.V.; Atala, A. 3D Bioprinting of Tissues and Organs. Nat. Biotechnol. 2014, 32, 773–785. [Google Scholar] [CrossRef]

- Wang, X.; Xu, S.; Zhou, S.; Xu, W.; Leary, M.; Choong, P.; Qian, M.; Brandt, M.; Xie, Y.M. Topological Design and Additive Manufacturing of Porous Metals for Bone Scaffolds and Orthopaedic Implants: A Review. Biomaterials 2016, 83, 127–141. [Google Scholar] [CrossRef] [PubMed]

- Hölzl, K.; Lin, S.; Tytgat, L.; Van Vlierberghe, S.; Gu, L.; Ovsianikov, A. Bioink Properties before, during and after 3D Bioprinting. Biofabrication 2016, 8, 032002. [Google Scholar] [CrossRef]

- Mannoor, M.S.; Jiang, Z.; James, T.; Kong, Y.L.; Malatesta, K.A.; Soboyejo, W.O.; Verma, N.; Gracias, D.H.; McAlpine, M.C. 3D Printed Bionic Ears. Nano Lett. 2013, 13, 2634–2639. [Google Scholar] [CrossRef] [PubMed]

- Schuurman, W.; Levett, P.A.; Pot, M.W.; van Weeren, P.R.; Dhert, W.J.A.; Hutmacher, D.W.; Melchels, F.P.W.; Klein, T.J.; Malda, J. Gelatin-Methacrylamide Hydrogels as Potential Biomaterials for Fabrication of Tissue-Engineered Cartilage Constructs. Macromol. Biosci. 2013, 13, 551–561. [Google Scholar] [CrossRef]

- Tang, D.; Tare, R.S.; Yang, L.-Y.; Williams, D.F.; Ou, K.-L.; Oreffo, R.O.C. Biofabrication of Bone Tissue: Approaches, Challenges and Translation for Bone Regeneration. Biomaterials 2016, 83, 363–382. [Google Scholar] [CrossRef]

- Tan, X.P.; Tan, Y.J.; Chow, C.S.L.; Tor, S.B.; Yeong, W.Y. Metallic Powder-Bed Based 3D Printing of Cellular Scaffolds for Orthopaedic Implants: A State-of-the-Art Review on Manufacturing, Topological Design, Mechanical Properties and Biocompatibility. Mater. Sci. Eng. C 2017, 76, 1328–1343. [Google Scholar] [CrossRef]

- Kolken, H.M.A.; Zadpoor, A.A. Auxetic Mechanical Metamaterials. RSC Adv. 2017, 7, 5111–5129. [Google Scholar] [CrossRef]

- Kong, Y.L.; Tamargo, I.A.; Kim, H.; Johnson, B.N.; Gupta, M.K.; Koh, T.-W.; Chin, H.-A.; Steingart, D.A.; Rand, B.P.; McAlpine, M.C. 3D Printed Quantum Dot Light-Emitting Diodes. Nano Lett. 2014, 14, 7017–7023. [Google Scholar] [CrossRef]

- Friedrich, K. Polymer Composites for Tribological Applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- Lupi, F.; Pacini, A.; Lanzetta, M. Laser Powder Bed Additive Manufacturing: A Review on the Four Drivers for an Online Control. J. Manuf. Process. 2023, 103, 413–429. [Google Scholar] [CrossRef]

- Bandari, S.; Nyavanandi, D.; Dumpa, N.; Repka, M.A. Coupling Hot Melt Extrusion and Fused Deposition Modeling: Critical Properties for Successful Performance. Adv. Drug Deliv. Rev. 2021, 172, 52–63. [Google Scholar] [CrossRef] [PubMed]

- Musa, L.; Kumar, N.K.; Rahim, S.Z.A.; Rasidi, M.S.M.; Rennie, A.E.W.; Rahman, R.; Kanani, A.Y.; Azmi, A.A. A Review on the Potential of Polylactic Acid Based Thermoplastic Elastomer as Filament Material for Fused Deposition Modelling. J. Mater. Res. Technol. 2022, 20, 2841–2858. [Google Scholar] [CrossRef]

- Singla, A.K.; Banerjee, M.; Sharma, A.; Singh, J.; Bansal, A.; Gupta, M.K.; Khanna, N.; Shahi, A.S.; Goyal, D.K. Selective Laser Melting of Ti6Al4V Alloy: Process Parameters, Defects and Post-Treatments. J. Manuf. Process. 2021, 64, 161–187. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Pakkanen, J.; Aversa, A.; Ambrosio, E.P.; Lombardi, M.; Fino, P.; Manfredi, D. On the Selective Laser Melting (SLM) of the AlSi10Mg Alloy: Process, Microstructure, and Mechanical Properties. Materials 2017, 10, 76. [Google Scholar] [CrossRef]

- Pesode, P.; Barve, S. Bioprinting Additive Manufacturing of Magnesium Alloys and Its Biocompatibility. Bioprinting 2023, 36, e00318. [Google Scholar] [CrossRef]

- Backes, E.H.; Harb, S.V.; Beatrice, C.A.G.; Shimomura, K.M.B.; Passador, F.R.; Costa, L.C.; Pessan, L.A. Polycaprolactone Usage in Additive Manufacturing Strategies for Tissue Engineering Applications: A Review. J. Biomed Mater. Res. 2022, 110, 1479–1503. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Aversa, A.; Marchese, G.; Lombardi, M.; Biamino, S.; Ugues, D.; Manfredi, D. Additive Manufacturing of Titanium Alloys in the Biomedical Field: Processes, Properties and Applications. J. Appl. Biomater. Funct. Mater. 2018, 16, 57–67. [Google Scholar] [CrossRef]

- Zaeri, A.; Cao, K.; Zhang, F.; Zgeib, R.; Chang, R.C. A Review of the Structural and Physical Properties That Govern Cell Interactions with Structured Biomaterials Enabled by Additive Manufacturing. Bioprinting 2022, 26, e00201. [Google Scholar] [CrossRef]

- Zhou, Q.; Su, X.; Wu, J.; Zhang, X.; Su, R.; Ma, L.; Sun, Q.; He, R. Additive Manufacturing of Bioceramic Implants for Restoration Bone Engineering: Technologies, Advances, and Future Perspectives. ACS Biomater. Sci. Eng. 2023, 9, 1164–1189. [Google Scholar] [CrossRef]

- Groll, J.; Boland, T.; Blunk, T.; Burdick, J.A.; Cho, D.W.; Dalton, P.D.; Derby, B.; Forgacs, G.; Li, Q.; Mironov, V.A.; et al. Biofabrication: Reappraising the Definition of an Evolving Field. Biofabrication 2016, 8, 013001. [Google Scholar] [CrossRef]

- Ramadan, Q.; Zourob, M. 3D Bioprinting at the Frontier of Regenerative Medicine, Pharmaceutical, and Food Industries. Front. Med. Technol. 2021, 2, 607648. [Google Scholar] [CrossRef] [PubMed]

- Moura, D.; Pereira, R.F.; Gonçalves, I.C. Recent Advances on Bioprinting of Hydrogels Containing Carbon Materials. Mater. Today Chem. 2022, 23, 100617. [Google Scholar] [CrossRef]

- Malda, J.; Visser, J.; Melchels, F.P.; Jüngst, T.; Hennink, W.E.; Dhert, W.J.A.; Groll, J.; Hutmacher, D.W. 25th Anniversary Article: Engineering Hydrogels for Biofabrication. Adv. Mater. 2013, 25, 5011–5028. [Google Scholar] [CrossRef]

- Zhu, W.; Ma, X.; Gou, M.; Mei, D.; Zhang, K.; Chen, S. 3D Printing of Functional Biomaterials for Tissue Engineering. Curr. Opin. Biotechnol. 2016, 40, 103–112. [Google Scholar] [CrossRef] [PubMed]

- Gao, G.; Schilling, A.F.; Hubbell, K.; Yonezawa, T.; Truong, D.; Hong, Y.; Dai, G.; Cui, X. Improved Properties of Bone and Cartilage Tissue from 3D Inkjet-Bioprinted Human Mesenchymal Stem Cells by Simultaneous Deposition and Photocrosslinking in PEG-GelMA. Biotechnol. Lett. 2015, 37, 2349–2355. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.; Park, J.A.; Tuladhar, T.; Jung, S. Sonochemical Degradation of Gelatin Methacryloyl to Control Viscoelasticity for Inkjet Bioprinting. Macromol. Biosci. 2023, 23, e2200509. [Google Scholar] [CrossRef]

- Patrawalla, N.Y.; Liebendorfer, K.; Kishore, V. An Innovative 4D Printing Approach for Fabrication of Anisotropic Collagen Scaffolds. Biofabrication 2024, 17, 015002. [Google Scholar] [CrossRef]

- Ajji, Z.; Jafari, A.; Mousavi, A.; Ajji, A.; Heuzey, M.C.; Savoji, H. 3D Bioprinting of Thick Core–Shell Vascularized Scaffolds for Potential Tissue Engineering Applications. Eur. Polym. J. 2025, 222, 113564. [Google Scholar] [CrossRef]

- Hall, G.N.; Fan, Y.; Viellerobe, B.; Iazzolino, A.; Dimopoulos, A.; Poiron, C.; Clapies, A.; Luyten, F.P.; Guillemot, F.; Papantoniou, I. Laser-Assisted Bioprinting of Targeted Cartilaginous Spheroids for High Density Bottom-up Tissue Engineering. Biofabrication 2024, 16, 045029. [Google Scholar] [CrossRef]

- Groll, J.; Burdick, J.A.; Cho, D.W.; Derby, B.; Gelinsky, M.; Heilshorn, S.C.; Jüngst, T.; Malda, J.; Mironov, V.A.; Nakayama, K.; et al. A Definition of Bioinks and Their Distinction from Biomaterial Inks. Biofabrication 2019, 11, 013001. [Google Scholar] [CrossRef]

- Zhu, J.; Marchant, R.E. Design Properties of Hydrogel Tissue-Engineering Scaffolds. Expert Rev. Med. Devices 2011, 8, 607–626. [Google Scholar] [CrossRef] [PubMed]

- Hospodiuk, M.; Dey, M.; Sosnoski, D.; Ozbolat, I.T. The Bioink: A Comprehensive Review on Bioprintable Materials. Biotechnol. Adv. 2017, 35, 217–239. [Google Scholar] [CrossRef]

- Hunt, N.C.; Grover, L.M. Cell Encapsulation Using Biopolymer Gels for Regenerative Medicine. Biotechnol. Lett. 2010, 32, 733–742. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Kim, H.W. Emerging Properties of Hydrogels in Tissue Engineering. J. Tissue Eng. 2018, 9, 2041731418768285. [Google Scholar] [CrossRef] [PubMed]

- Decante, G.; Costa, J.B.; Silva-Correia, J.; Collins, M.N.; Reis, R.L.; Oliveira, J.M. Engineering Bioinks for 3D Bioprinting. Biofabrication 2021, 13, 032001. [Google Scholar] [CrossRef]

- Hassan, M.; Dave, K.; Chandrawati, R.; Dehghani, F.; Gomes, V.G. 3D Printing of Biopolymer Nanocomposites for Tissue Engineering: Nanomaterials, Processing and Structure-Function Relation. Eur. Polym. J. 2019, 121, 109340. [Google Scholar] [CrossRef]

- Li, J.; Wu, C.; Chu, P.K.; Gelinsky, M. 3D Printing of Hydrogels: Rational Design Strategies and Emerging Biomedical Applications. Mater. Sci. Eng. R Rep. 2020, 140, 100543. [Google Scholar] [CrossRef]

- Camacho, P.; Busari, H.; Seims, K.B.; Tolbert, J.W.; Chow, L.W. Materials as Bioinks and Bioink Design. In 3D Bioprinting in Medicine: Technologies, Bioinks, and Applications; Guvendiren, M., Ed.; Springer Nature: Berlin/Heidelberg, Germany, 2019; pp. 1–209. ISBN 9783030239060. [Google Scholar]

- Norouzi, F.; Bagheri, F.; Hashemi-Najafabadi, S. Alendronate Releasing Silk Fibroin 3D Bioprinted Scaffolds for Application in Bone Tissue Engineering: Effects of Alginate Concentration on Printability, Mechanical Properties and Stability. Results Eng. 2024, 22, 102186. [Google Scholar] [CrossRef]

- Iervolino, F.; Belgio, B.; Bonessa, A.; Potere, F.; Suriano, R.; Boschetti, F.; Mantero, S.; Levi, M. Versatile and Non-Cytotoxic GelMA-Xanthan Gum Biomaterial Ink for Extrusion-Based 3D Bioprinting. Bioprinting 2023, 31, e00269. [Google Scholar] [CrossRef]

- Kara Özenler, A.; Distler, T.; Tihminlioglu, F.; Boccaccini, A.R. Fish Scale Containing Alginate Dialdehyde-Gelatin Bioink for Bone Tissue Engineering. Biofabrication 2023, 15, 025012. [Google Scholar] [CrossRef]

- Ansari, A.I.; Sheikh, N.A.; Kumar, N.; Nath, J. Three-Dimensional Printed Silk Fibroin and Fenugreek Based Bio-Composites Scaffolds. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2024, 238, 2170–2188. [Google Scholar] [CrossRef]

- Merli, M.; Sardelli, L.; Baranzini, N.; Grimaldi, A.; Jacchetti, E.; Raimondi, M.T.; Briatico-Vangosa, F.; Petrini, P.; Tunesi, M. Pectin-Based Bioinks for 3D Models of Neural Tissue Produced by a PH-Controlled Kinetics. Front. Bioeng. Biotechnol. 2022, 10, 1032542. [Google Scholar] [CrossRef]

- Ning, L.; Sun, H.; Lelong, T.; Guilloteau, R.; Zhu, N.; Schreyer, D.J.; Chen, X. 3D Bioprinting of Scaffolds with Living Schwann Cells for Potential Nerve Tissue Engineering Applications. Biofabrication 2018, 10, 035014. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.H.; Jakus, A.E.; Jordan, S.W.; Dumanian, Z.; Parker, K.; Zhao, L.; Patel, P.K.; Shah, R.N. Three-Dimensionally Printed Hyperelastic Bone Scaffolds Accelerate Bone Regeneration in Critical-Size Calvarial Bone Defects. Plast. Reconstr. Surg. 2019, 143, 1397–1407. [Google Scholar] [CrossRef] [PubMed]

- Jeon, O.; Bin Lee, Y.; Jeong, H.; Lee, S.J.; Wells, D.; Alsberg, E. Individual Cell-Only Bioink and Photocurable Supporting Medium for 3D Printing and Generation of Engineered Tissues with Complex Geometries. Mater. Horizons 2019, 6, 1625–1631. [Google Scholar] [CrossRef]

- Noor, N.; Shapira, A.; Edri, R.; Gal, I.; Wertheim, L.; Dvir, T. 3D Printing of Personalized Thick and Perfusable Cardiac Patches and Hearts. Adv. Sci. 2019, 6, 1900344. [Google Scholar] [CrossRef]

- Baltazar, T.; Merola, J.; Catarino, C.; Xie, C.B.; Kirkiles-Smith, N.C.; Lee, V.; Hotta, S.; Dai, G.; Xu, X.; Ferreira, F.C.; et al. Three Dimensional Bioprinting of a Vascularized and Perfusable Skin Graft Using Human Keratinocytes, Fibroblasts, Pericytes, and Endothelial Cells. Tissue Eng. Part A 2020, 26, 227–238. [Google Scholar] [CrossRef]

- Teng, C.-L.; Chen, J.-Y.; Chang, T.-L.; Hsiao, S.-K.; Hsieh, Y.-K.; Villalobos Gorday, K.; Cheng, Y.-L.; Wang, J. Design of Photocurable, Biodegradable Scaffolds for Liver Lobule Regeneration via Digital Light Process-Additive Manufacturing. Biofabrication 2020, 12, 035024. [Google Scholar] [CrossRef]

- Sigen, A.; Lyu, J.; Johnson, M.; Creagh-Flynn, J.; Zhou, D.; Lara-Sáez, I.; Xu, Q.; Tai, H.; Wang, W. Instant Gelation System as Self-Healable and Printable 3D Cell Culture Bioink Based on Dynamic Covalent Chemistry. ACS Appl. Mater. Interfaces 2020, 12, 38918–38924. [Google Scholar] [CrossRef]

- Bhise, N.S.; Ribas, J.; Manoharan, V.; Zhang, Y.S.; Polini, A.; Massa, S.; Dokmeci, M.R.; Khademhosseini, A. Organ-on-a-Chip Platforms for Studying Drug Delivery Systems. J. Control. Release 2014, 190, 82–93. [Google Scholar] [CrossRef]

- Carvalho, V.; Gonçalves, I.; Lage, T.; Rodrigues, R.O.; Minas, G.; Teixeira, S.F.C.F.; Moita, A.S.; Hori, T.; Kaji, H.; Lima, R.A. 3D Printing Techniques and Their Applications to Organ-on-a-Chip Platforms: A Systematic Review. Sensors 2021, 21, 3304. [Google Scholar] [CrossRef]

- Lin, D.S.Y.; Guo, F.; Zhang, B. Modeling Organ-Specific Vasculature with Organ-on-a-Chip Devices. Nanotechnology 2019, 30, 024002. [Google Scholar] [CrossRef] [PubMed]

- Pourmostafa, A.; Bhusal, A.; Haridas Menon, N.; Li, Z.; Basuray, S.; Miri, A.K. Integrating Conductive Electrodes into Hydrogel-Based Microfluidic Chips for Real-Time Monitoring of Cell Response. Front. Bioeng. Biotechnol. 2024, 12, 1421592. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Xue, R.; Zhao, Y.; Ramsay, K.; Wang, E.Y.; Savoji, H.; Veres, T.; Cartmell, S.H.; Radisic, M. Automated Fabrication of a Scalable Heart-on-a-Chip Device by 3D Printing of Thermoplastic Elastomer Nanocomposite and Hot Embossing. Bioact. Mater. 2024, 33, 46–60. [Google Scholar] [CrossRef]

- Ni, J.; Ling, H.; Zhang, S.; Wang, Z.; Peng, Z.; Benyshek, C.; Zan, R.; Miri, A.K.; Li, Z.; Zhang, X.; et al. Three-Dimensional Printing of Metals for Biomedical Applications. Mater. Today Bio 2019, 3, 100024. [Google Scholar] [CrossRef]

- Salmi, M. Additive Manufacturing Processes in Medical Applications. Materials 2021, 14, 191. [Google Scholar] [CrossRef] [PubMed]

- Dissanayaka, N.; Maclachlan, L.R.; Alexander, H.; Redmond, M.; Carluccio, D.; Jules-Vandi, L.; Novak, J.I. Evaluation of 3D Printed Burr Hole Simulation Models Using 8 Different Materials. World Neurosurg. 2023, 176, e651–e663. [Google Scholar] [CrossRef]

- Dissanayaka, N.; Alexander, H.; Carluccio, D.; Redmond, M.; Vandi, L.-J.; Novak, J.I. How Safe Are 3D-Printed Skull Models for Neurosurgical Simulation? Measurement of Airborne Particles and VOCs While Burr Hole Drilling. Rapid Prototyp. J. 2024, 30, 1046–1054. [Google Scholar] [CrossRef]

- Dienel, K.; Abu-Shahba, A.; Kornilov, R.; Björkstrand, R.; van Bochove, B.; Snäll, J.; Wilkman, T.; Mesimäki, K.; Meller, A.; Lindén, J.; et al. Patient-Specific Bioimplants and Reconstruction Plates for Mandibular Defects: Production Workflow and In Vivo Large Animal Model Study. Macromol. Biosci. 2022, 22, 2100398. [Google Scholar] [CrossRef]

- Wulff, J.; Schweikl, H.; Rosentritt, M. Cytotoxicity of Printed Resin-Based Splint Materials. J. Dent. 2022, 120, 104097. [Google Scholar] [CrossRef]

- Godec, D.; Gonzalez-gutierrez, J.; Nordin, A.; Pei, E.; Ureña, J. A Guide to Additive Manufacturing; Springer Nature: Berlin/Heidelberg, Germany, 2022; ISBN 2730-9576. [Google Scholar]

- Govender, R.; Kissi, E.O.; Larsson, A.; Tho, I. Polymers in Pharmaceutical Additive Manufacturing: A Balancing Act between Printability and Product Performance. Adv. Drug Deliv. Rev. 2021, 177, 113923. [Google Scholar] [CrossRef]

- Samaro, A.; Shaqour, B.; Goudarzi, N.M.; Ghijs, M.; Cardon, L.; Boone, M.N.; Verleije, B.; Beyers, K.; Vanhoorne, V.; Cos, P.; et al. Can Filaments, Pellets and Powder Be Used as Feedstock to Produce Highly Drug-Loaded Ethylene-Vinyl Acetate 3D Printed Tablets Using Extrusion-Based Additive Manufacturing? Int. J. Pharm. 2021, 607, 120922. [Google Scholar] [CrossRef]

- Sundarkumar, V.; Nagy, Z.K.; Reklaitis, G.V. Small-Scale Continuous Drug Product Manufacturing Using Dropwise Additive Manufacturing and Three Phase Settling for Integration with Upstream Drug Substance Production. J. Pharm. Sci. 2022, 111, 2330–2340. [Google Scholar] [CrossRef] [PubMed]

- Grinschek, F.; Ladewig, B.; Navarrete Munoz, A.; Klahn, C.; Dittmeyer, R. Getting Chemical and Biochemical Engineers Excited about Additive Manufacturing. Chem. Ing. Tech. 2022, 94, 931–938. [Google Scholar] [CrossRef]

- Dautzenburg, F.M.; Mukherjee, M. Process Intensification Using Multifunctional Reactors. Chem. Eng. Sci. 2001, 56, 251–267. [Google Scholar] [CrossRef]

- Van Gerven, T.; Stankiewicz, A. Structure, Energy, Synergy, Time—The Fundamentals of Process Intensification. Ind. Eng. Chem. Res. 2009, 48, 2465–2474. [Google Scholar] [CrossRef]

- Kokare, S.; Oliveira, J.P.; Godina, R. Life Cycle Assessment of Additive Manufacturing Processes: A Review. J. Manuf. Syst. 2023, 68, 536–559. [Google Scholar] [CrossRef]

- Psihoyos, H.O.; Mouzakitis, Y.; Adamides, E.D.; Lampeas, G.N. Assessing 3D Printing Processes as Enablers of Circular Economy. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022; Volume 1123. [Google Scholar] [CrossRef]

- Romani, A.; Levi, M. Large-Format Material Extrusion Additive Manufacturing for Circular Economy Practices: A Focus on Product Applications with Materials from Recycled Plastics and Biomass Waste. Sustainability 2024, 16, 7966. [Google Scholar] [CrossRef]

- Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic Recycling in Additive Manufacturing: A Systematic Literature Review and Opportunities for the Circular Economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Zhao, J.; Yang, Y.; Kobir, M.H.; Faludi, J.; Zhao, F. Driving Additive Manufacturing towards Circular Economy: State-of-the-Art and Future Research Directions. J. Manuf. Process. 2024, 124, 621–637. [Google Scholar] [CrossRef]

- Al Rashid, A.; Koç, M. Additive Manufacturing for Sustainability and Circular Economy: Needs, Challenges, and Opportunities for 3D Printing of Recycled Polymeric Waste. Mater. Today Sustain. 2023, 24, 100529. [Google Scholar] [CrossRef]

- Akbari, M. Data-Driven Review of Additive Manufacturing on Supply Chains: Regionalization, Key Research Themes and Future Directions. Comput. Ind. Eng. 2023, 184, 109600. [Google Scholar] [CrossRef]

- Morrow, W.R.; Qi, H.; Kim, I.; Mazumder, J.; Skerlos, S.J. Environmental Aspects of Laser-Based and Conventional Tool and Die Manufacturing. J. Clean. Prod. 2007, 15, 932–943. [Google Scholar] [CrossRef]

- Dao, D.; Howlett, R.J.; Setchi, R.; Vlacic, L. Sustainable Design and Manufacturing 2018: Proceedings of the 5th International Conference on Sustainable Design and Manufacturing (KES-SDM-18); Springer: Berlin/Heidelberg, Germany, 2018; ISBN 9783030042899. [Google Scholar]

- Ramirez Rebollo, D.R.; Alam, S.I.; Mendez, P.F. Zero Programming Robotics in Additive Manufacturing Repairs. J. Adv. Join. Process. 2023, 7, 100145. [Google Scholar] [CrossRef]

- Dircksen, M.; Feldmann, C. Holistic Evaluation of the Impacts of Additive Manufacturing on Sustainability, Distribution Costs, and Time in Global Supply Chains. Transp. Res. Procedia 2020, 48, 2140–2165. [Google Scholar] [CrossRef]

- Kellens, K.; Mertens, R.; Paraskevas, D.; Dewulf, W.; Duflou, J.R. Environmental Impact of Additive Manufacturing Processes: Does AM Contribute to a More Sustainable Way of Part Manufacturing? Procedia CIRP 2017, 61, 582–587. [Google Scholar] [CrossRef]

- Psarommatis, F.; Sousa, J.; Mendonça, J.P.; Kiritsis, D. Zero-Defect Manufacturing the Approach for Higher Manufacturing Sustainability in the Era of Industry 4.0: A Position Paper. Int. J. Prod. Res. 2022, 60, 73–91. [Google Scholar] [CrossRef]

- Garcia, F.L.; da Moris, V.A.S.; Nunes, A.O.; Silva, D.A.L. Environmental Performance of Additive Manufacturing Process—An Overview. Rapid Prototyp. J. 2018, 24, 1166–1177. [Google Scholar] [CrossRef]

- Saade, M.R.M.; Yahia, A.; Amor, B. How Has LCA Been Applied to 3D Printing? A Systematic Literature Review and Recommendations for Future Studies. J. Clean. Prod. 2020, 244, 118803. [Google Scholar] [CrossRef]

- Martorelli, M.; Gloria, A. Strategies and Generative Design Towards the Development of Innovative Products. In Handbook of Additive Manufacturing; Pei, E., Bernard, A., Gu, D., Klahn, C., Monzón, M., Petersen, M., Sun, T., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 269–286. ISBN 978-3-031-20752-5. [Google Scholar]

- Sotomayor, N.A.S.; Caiazzo, F.; Alfieri, V. Enhancing Design for Additive Manufacturing Workflow: Optimization, Design and Simulation Tools. Appl. Sci. 2021, 11, 6628. [Google Scholar] [CrossRef]

- Moreno-Nieto, D.; Moreno-Sánchez, D. Design for Additive Manufacturing: Tool Review and a Case Study. Appl. Sci. 2021, 11, 1571. [Google Scholar] [CrossRef]

- Barbieri, L.; Muzzupappa, M. Performance-Driven Engineering Design Approaches Based on Generative Design and Topology Optimization Tools: A Comparative Study. Appl. Sci. 2022, 12, 2106. [Google Scholar] [CrossRef]

- Sigmund, O.; Maute, K. Topology Optimization Approaches: A Comparative Review. Struct. Multidiscip. Optim. 2013, 48, 1031–1055. [Google Scholar] [CrossRef]

- Sun, H.; Ma, L. Generative Design by Using Exploration Approaches of Reinforcement Learning in Density-Based Structural Topology Optimization. Designs 2020, 4, 10. [Google Scholar] [CrossRef]

- McKnight, M. Generative Design: What It Is? How Is It Being Used? Why It’s a Game Changer? KnE Eng. 2017, 2, 176–186. [Google Scholar] [CrossRef]

- Antil, H.; Kouri, D.P.; Ridzal, D.; Robinson, D.B.; Salloum, M. Uniform Flow in Axisymmetric Devices through Permeability Optimization. Optim. Eng. 2024, 25, 669–697. [Google Scholar] [CrossRef]

- Xie, G.; Dong, Y.; Zhou, J.; Sheng, Z. Topology Optimization Design of Hydraulic Valve Blocks for Additive Manufacturing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 1899–1912. [Google Scholar] [CrossRef]

- Ghosh, S.; Kapat, J.S. Topology Optimization of Serpentine Channels for Minimization of Pressure Loss and Maximization of Heat Transfer Performance As Applied for Additive Manufacturing. In Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019. [Google Scholar]

- Lange, A.; Fieg, G. Designing Novel Structured Packings by Topology Optimization and Additive Manufacturing. In Computer Aided Chemical Engineering; Elsevier B.V.: Hamburg, Germany, 2022; Volume 49, pp. 1291–1296. ISBN 15707946. [Google Scholar]

- Sagbas, B.; Durakbasa, M.N. Industrial Computed Tomography for Nondestructive Inspection of Additive Manufactured Parts. In Proceedings of the International Symposium for Production Research 2019, Vienna, Austria, 28–30 August 2019; Durakbasa, N., Gençyılmaz, M., Eds.; Lecture Notes in Mechanical Engineering. Springer: Cham, Switzerland, 2019; pp. 481–490. [Google Scholar]

- Ozguc, S.; Pan, L.; Weibel, J.A. Topology Optimization of Microchannel Heat Sinks Using a Homogenization Approach. Int. J. Heat Mass Transf. 2021, 169, 120896. [Google Scholar] [CrossRef]

- Yang, Q.; Gao, B.; Xu, Z.; Xie, W.; Meng, S. Topology Optimisations for Integrated Thermal Protection Systems Considering Thermo-Mechanical Constraints. Appl. Therm. Eng. 2019, 150, 995–1001. [Google Scholar] [CrossRef]

- Moon, H.; Boyina, K.; Miljkovic, N.; King, W.P. Heat Transfer Enhancement of Single-Phase Internal Flows Using Shape Optimization and Additively Manufactured Flow Structures. Int. J. Heat Mass Transf. 2021, 177, 121510. [Google Scholar] [CrossRef]

- Kaur, I.; Singh, P. State-of-the-Art in Heat Exchanger Additive Manufacturing. Int. J. Heat Mass Transf. 2021, 178, 121600. [Google Scholar] [CrossRef]

- McDonough, J.R. A Perspective on the Current and Future Roles of Additive Manufacturing in Process Engineering, with an Emphasis on Heat Transfer. Therm. Sci. Eng. Prog. 2020, 19, 100594. [Google Scholar] [CrossRef]

- Saltzman, D.; Bichnevicius, M.; Lynch, S.; Simpson, T.W.; Reutzel, E.W.; Dickman, C.; Martukanitz, R. Experimental Comparison of a Traditionally Built versus Additively Manufactured Aircraft Heat Exchanger. In Proceedings of the 55th AIAA Aerospace Sciences Meeting, Grapevine, TX, USA, 9–13 January 2017; pp. 1–11. [Google Scholar] [CrossRef]

- Zhang, X.; Tiwari, R.; Shooshtari, A.H.; Ohadi, M.M. An Additively Manufactured Metallic Manifold-Microchannel Heat Exchanger for High Temperature Applications. Appl. Therm. Eng. 2018, 143, 899–908. [Google Scholar] [CrossRef]

- Ho, J.Y.; Leong, K.C.; Wong, T.N. Additively-Manufactured Metallic Porous Lattice Heat Exchangers for Air-Side Heat Transfer Enhancement. Int. J. Heat Mass Transf. 2020, 150, 119262. [Google Scholar] [CrossRef]

- Soliman, A.; Alamoodi, N.; Karanikolos, G.N.; Doumanidis, C.C.; Polychronopoulou, K. A Review on New 3-D Printed Materials’ Geometries for Catalysis and Adsorption: Paradigms from Reforming Reactions and CO2 Capture. Nanomaterials 2020, 10, 2198. [Google Scholar] [CrossRef]

- Thakkar, H.; Eastman, S.; Hajari, A.; Rownaghi, A.A.; Knox, J.C.; Rezaei, F. 3D-Printed Zeolite Monoliths for CO2 Removal from Enclosed Environments. ACS Appl. Mater. Interfaces 2016, 8, 27753–27761. [Google Scholar] [CrossRef]

- Li, X.; Li, W.; Rezaei, F.; Rownaghi, A. Catalytic Cracking of N-Hexane for Producing Light Olefins on 3D-Printed Monoliths of MFI and FAU Zeolites. Chem. Eng. J. 2018, 333, 545–553. [Google Scholar] [CrossRef]

- Pereira, A.; Ferreira, A.F.P.; Rodrigues, A.E.; Ribeiro, A.M.; Regufe, M.J. Additive Manufacturing for Adsorption-Related Applications—A Review. J. Adv. Manuf. Process. 2022, 4, e10108. [Google Scholar] [CrossRef]

- Vega, G.; Quintanilla, A.; Menendez, N.; Belmonte, M.; Casas, J.A. 3D Honeycomb Monoliths with Interconnected Channels for the Sustainable Production of Dihydroxybenzenes: Towards the Intensification of Selective Oxidation Processes. Chem. Eng. Process.-Process Intensif. 2021, 165, 108437. [Google Scholar] [CrossRef]

- Couck, S.; Cousin-Saint-Remi, J.; Van der Perre, S.; Baron, G.V.; Minas, C.; Ruch, P.; Denayer, J.F.M. 3D-Printed SAPO-34 Monoliths for Gas Separation. Microporous Mesoporous Mater. 2018, 255, 185–191. [Google Scholar] [CrossRef]

- Zafanelli, L.F.A.S.; Henrique, A.; Steldinger, H.; Diaz de Tuesta, J.L.; Gläsel, J.; Rodrigues, A.E.; Gomes, H.T.; Etzold, B.J.M.; Silva, J.A.C. 3D-Printed Activated Carbon for Post-Combustion CO2 Capture. Microporous Mesoporous Mater. 2022, 335, 111818. [Google Scholar] [CrossRef]

- Suryawanshi, P.L.; Gumfekar, S.P.; Bhanvase, B.A.; Sonawane, S.H.; Pimplapure, M.S. A Review on Microreactors: Reactor Fabrication, Design, and Cutting-Edge Applications. Chem. Eng. Sci. 2018, 189, 431–448. [Google Scholar] [CrossRef]

- Yao, X.; Zhang, Y.; Du, L.; Liu, J.; Yao, J. Review of the Applications of Microreactors. Renew. Sustain. Energy Rev. 2015, 47, 519–539. [Google Scholar] [CrossRef]

- Fagundes, A.P.; Lira, J.O.D.B.; Padoin, N.; Soares, C.; Riella, H.G. Additive Manufacturing of Functional Devices for Environmental Applications: A Review. J. Environ. Chem. Eng. 2022, 10, 108049. [Google Scholar] [CrossRef]

- Castedo, A.; Mendoza, E.; Angurell, I.; Llorca, J. Silicone Microreactors for the Photocatalytic Generation of Hydrogen. Catal. Today 2016, 273, 106–111. [Google Scholar] [CrossRef]

- Ziogas, A.; Hofmann, C.; Baranyai, S.; Löb, P.; Kolb, G. Novel Flexible Electrochemical Microreactor and Its Validation by Three Model Electrosyntheses. Chem. Ing. Tech. 2020, 92, 513–524. [Google Scholar] [CrossRef]

- Zheng, T.; Zhou, W.; Geng, D.; Li, Y.; Liu, Y.; Zhang, C. Methanol Steam Reforming Microreactor with Novel 3D-Printed Porous Stainless Steel Support as Catalyst Support. Int. J. Hydrogen Energy 2020, 45, 14006–14016. [Google Scholar] [CrossRef]

- Qian, X.; Ostwal, M.; Asatekin, A.; Geise, G.M.; Smith, Z.P.; Phillip, W.A.; Lively, R.P.; McCutcheon, J.R. A Critical Review and Commentary on Recent Progress of Additive Manufacturing and Its Impact on Membrane Technology. J. Membr. Sci. 2022, 645, 120041. [Google Scholar] [CrossRef]

- Ostwal, M.; Wazer, E.; Pemberton, M.; McCutcheon, J.R. Scaling Electrospray Based Additive Manufacturing of Polyamide Membranes. J. Membr. Sci. Lett. 2022, 2, 100035. [Google Scholar] [CrossRef]

- Badalov, S.; Oren, Y.; Arnusch, C.J. Ink-Jet Printing Assisted Fabrication of Patterned Thin Film Composite Membranes. J. Membr. Sci. 2015, 493, 508–514. [Google Scholar] [CrossRef]

- Badalov, S.; Arnusch, C.J. Ink-Jet Printing Assisted Fabrication of Thin Film Composite Membranes. J. Membr. Sci. 2016, 515, 79–85. [Google Scholar] [CrossRef]

- Chowdhury, M.R.; Steffes, J.; Huey, B.D.; Mccutcheon, J.R. 3D Printed Polyamide Membranes for Desalination. Science 2018, 361, 682–686. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.H.; Guo, H.; Yang, Z.; Yao, Z.K.; Qing, W.H.; Chen, Y.L.; Xu, Z.L.; Tang, C.Y. Carbon Nanotubes Enhance Permeability of Ultrathin Polyamide Rejection Layers. J. Membr. Sci. 2019, 570–571, 139–145. [Google Scholar] [CrossRef]

- Yang, S.; Wang, J.; Fang, L.; Lin, H.; Liu, F.; Tang, C.Y. Electrosprayed Polyamide Nanofiltration Membrane with Intercalated Structure for Controllable Structure Manipulation and Enhanced Separation Performance. J. Membr. Sci. 2020, 602, 117971. [Google Scholar] [CrossRef]

- Mohd Yusoff, N.H.; Irene Teo, L.-R.; Phang, S.J.; Wong, V.-L.; Cheah, K.H.; Lim, S.-S. Recent Advances in Polymer-Based 3D Printing for Wastewater Treatment Application: An Overview. Chem. Eng. J. 2022, 429, 132311. [Google Scholar] [CrossRef]

| Additive Manufacture Processes | Feed Material |

|---|---|

| Material Extrusion (MEX) | Thermoplastic filaments and pellets, paste-like materials, and liquids in syringes |

| Vat Polymerization (VP) | Liquid photo-curable resins |

| Material Jetting (MJ) | Polymers and wax-like materials (fillers are optional) |

| Sheet Lamination (SL) | Paper, polymer, and metal sheets |

| Powder Bed Fusion (PBF) | Polymer, metal, ceramic, and sand powders |

| Direct Energy Deposition (DED) | Metal wires and powders and ceramic powders |

| Binder Jetting (BJ) | Polymer, metal, ceramic, glass, and sand powders |

| Parameter | Value |

|---|---|

| Unit of analysis | Words (author’s words, source’s words, and added words) |

| Frequency reduction | 12 |

| Kind of matrix | Co-occurrence |

| Edge value reduction | 4 |

| Normalization measure | Equivalence index |

| Clustering algorithm | Simple centers |

| Maximum network size | 11 |

| Minimum network size | 7 |

| Evolution map measure | Jaccard’s index |

| Language | Publications | Contribution (%) |

|---|---|---|

| English | 3691 | 98.14 |

| Chinese | 38 | 1.01 |

| German | 12 | 0.32 |

| Japanese | 8 | 0.21 |

| Polish | 5 | 0.13 |

| Bosnian | 2 | 0.05 |

| Korean | 2 | 0.05 |

| Turkish | 2 | 0.05 |

| Croatian | 1 | 0.03 |

| Russian | 1 | 0.03 |

| Language | Publications | Contribution (%) |

|---|---|---|

| Article | 2471 | 65.70 |

| Conference Paper | 663 | 17.63 |

| Review | 385 | 10.24 |

| Book Chapter | 134 | 3.56 |

| Conference Review | 41 | 1.09 |

| Editorial | 29 | 0.77 |

| Note | 15 | 0.40 |

| Book | 9 | 0.24 |

| Erratum | 9 | 0.24 |

| Short Survey | 4 | 0.11 |

| Letter | 1 | 0.03 |

| Country | Publications | Contribution (%) |

|---|---|---|

| United States | 887 | 23.58 |

| China | 569 | 15.13 |

| Germany | 374 | 9.94 |

| Italy | 298 | 7.92 |

| India | 283 | 7.52 |

| United Kingdom | 278 | 7.39 |

| Australia | 144 | 3.83 |

| Spain | 117 | 3.11 |

| Singapore | 109 | 2.90 |

| France | 108 | 2.87 |

| Canada | 89 | 2.37 |

| South Korea | 86 | 2.29 |

| Japan | 83 | 2.21 |

| Netherlands | 81 | 2.15 |

| Poland | 80 | 2.13 |

| Russian Federation | 78 | 2.07 |

| Malaysia | 70 | 1.86 |

| Austria | 67 | 1.78 |

| Switzerland | 67 | 1.78 |

| Belgium | 60 | 1.60 |

| Portugal | 57 | 1.52 |

| Turkey | 53 | 1.41 |

| Brazil | 52 | 1.38 |

| Institution | Country | Publications | Contribution (%) |

|---|---|---|---|

| Nanyang Technological University | Singapore | 60 | 1.60 |

| Ministry of Education China | China | 59 | 1.57 |

| CNRS Centre National de la Recherche Scientifique | France | 51 | 1.36 |

| School of Mechanical and Aerospace Engineering | Singapore | 49 | 1.30 |

| Chinese Academy of Sciences | China | 48 | 1.28 |

| Friedrich-Alexander-Universität Erlangen-Nürnberg | Germany | 47 | 1.25 |

| Politecnico di Torino | Italy | 42 | 1.12 |

| Huazhong University of Science and Technology | China | 35 | 0.93 |

| Virginia Polytechnic Institute and State University | United States | 33 | 0.88 |

| Singapore Centre for 3D Printing | Singapore | 33 | 0.88 |

| Università degli Studi di Padova | Italy | 32 | 0.85 |

| University of Maryland, College Park | United States | 31 | 0.82 |

| Purdue University | United States | 30 | 0.80 |

| Rheinisch-Westfälische Technische Hochschule Aachen | Germany | 29 | 0.77 |

| Beijing Institute of Technology | China | 28 | 0.74 |

| National University of Singapore | Singapore | 28 | 0.74 |

| Monash University | Australia | 27 | 0.72 |

| Georgia Institute of Technology | United States | 27 | 0.72 |

| Tsinghua University | China | 27 | 0.72 |

| Delft University of Technology | The Netherlands | 26 | 0.69 |

| Xi’an Jiaotong University | China | 26 | 0.69 |

| Universiteit Twente | The Netherlands | 26 | 0.69 |

| Politecnico di Milano | Italy | 26 | 0.69 |

| Oak Ridge National Laboratory | United States | 26 | 0.69 |

| ETH Zürich | Switzerland | 26 | 0.69 |

| A. James Clark School of Engineering | United States | 26 | 0.69 |

| Subject | Publications | Contribution (%) |

|---|---|---|

| Chemical Engineering | 3761 | 100.00 |

| Engineering | 2119 | 56.34 |

| Materials Science | 1839 | 48.90 |

| Chemistry | 938 | 24.94 |

| Physics and Astronomy | 861 | 22.89 |

| Computer Science | 592 | 15.74 |

| Biochemistry, Genetics, and Molecular Biology | 544 | 14.46 |

| Energy | 240 | 6.38 |

| Environmental Science | 198 | 5.26 |

| Medicine | 145 | 3.86 |

| Source | 2023 SJR | 2023 IF | 2023 JCI | Publications | Contribution (%) |

|---|---|---|---|---|---|

| Lecture Notes in Mechanical Engineering | 0.167 | - | - | 447 | 11.89 |

| Applied Sciences | 0.508 | 2.5 | 0.56 | 402 | 10.69 |

| Ceramics International | 0.938 | 5.1 | 1.27 | 178 | 4.73 |

| Powder Technology | 0.970 | 4.5 | 0.78 | 130 | 3.46 |

| International Journal of Heat and Mass Transfer | 1.224 | 5.0 | 1.23 | 114 | 3.03 |

| Annual Technical Conference ANTEC Conference Proceedings | 0.107 | - | - | 89 | 2.37 |

| Crystals | 0.449 | 2.4 | 0.74 | 70 | 1.86 |

| Biofabrication | 1.769 | 8.2 | 1.70 | 69 | 1.83 |

| Corrosion Science | 1.897 | 7.4 | 1.66 | 58 | 1.54 |

| Frontiers in Bioengineering and Biotechnology | 0.893 | 4.3 | 0.83 | 57 | 1.52 |

| Macromolecular Materials and Engineering | 0.811 | 4.2 | 0.71 | 52 | 1.38 |

| ACS Applied Polymer Materials | 0.982 | 4.4 | 0.90 | 47 | 1.25 |

| Nanomaterials | 0.798 | 4.4 | 0.74 | 44 | 1.17 |

| Processes | 0.525 | 2.8 | 0.44 | 40 | 1.06 |

| Ranking | Article | Times Cited |

|---|---|---|

| 1 | Title: 3D bioprinting of tissues and organs Author(s): Murphy S.V.; Atala A. Journal: Nature Biotechnology (2023 Impact Factor = 33.1) Year: 2014 | 4516 |

| 2 | Title: Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: A review Author(s): Wang X.; Xu S.; Zhou S.; Xu W.; Leary M.; Choong P.; Qian M.; Brandt M.; Xie Y.M. Journal: Biomaterials (2023 Impact Factor = 12.8) Year: 2016 | 1344 |

| 3 | Title: Bioink properties before, during and after 3D bioprinting Author(s): Hölzl K.; Lin S.; Tytgat L.; Van Vlierberghe S.; Gu L.; Ovsianikov A. Journal: Biofabrication (2023 Impact Factor = 8.2) Year:2016 | 688 |

| 4 | Title: 3D printed bionic ears Author(s): Mannoor M.S.; Jiang Z.; James T.; Kong Y.L.; Malatesta K.A.; Soboyejo W.O.; Verma N.; Gracias D.H.; McAlpine M.C. Journal: Nano Letters (2023 Impact Factor = 9.6) Year: 2013 | 664 |

| 5 | Title: Gelatin-methacrylamide hydrogels as potential biomaterials for fabrication of tissue-engineered cartilage constructs Author(s): Schuurman W.; Levett P.A.; Pot M.W.; van Weeren P.R.; Dhert W.J.A.; Hutmacher D.W.; Melchels F.P.W.; Klein T.J.; Malda J. Journal: Macromolecular Bioscience (2023 Impact Factor = 4.4) Year: 2013 | 585 |

| 6 | Title: Biofabrication of bone tissue: Approaches, challenges and translation for bone regeneration Author(s): Tang D.; Tare R.S.; Yang L.-Y.; Williams D.F.; Ou K.-L.; Oreffo R.O.C. Journal: Biomaterials (2023 Impact Factor = 12.8) Year: 2016 | 442 |

| 7 | Title: Auxetic mechanical metamaterials Author(s): Kolken H.M.A.; Zadpoor A.A. Journal: RSC Advances (2023 Impact Factor = 3.9) Year: 2017 | 428 |

| 8 | Title: Metallic powder-bed based 3D printing of cellular scaffolds for orthopaedic implants: A state-of-the-art review on manufacturing, topological design, mechanical properties Author(s): Tan X.P.; Tan Y.J.; Chow C.S.L.; Tor S.B.; Yeong W.Y. Journal: Materials Science and Engineering C (2023 Impact Factor = 8.1) Year: 2017 | 361 |

| 9 | Title: 3D printed quantum dot light-emitting diodes Author(s): Kong Y.L.; Tamargo I.A.; Kim H.; Johnson B.N.; Gupta M.K.; Koh T.-W.; Chin H.-A.; Steingart D.A.; Rand B.P.; McAlpine M.C. Journal: Nano Letters (2023 Impact Factor = 9.6) Year: 2014 | 349 |

| 10 | Title: Polymer composites for tribological applications Author(s): Friedrich K. Journal: Advanced Industrial and Engineering Polymer Research (2023 Impact Factor = 9.9) Year: 2018 | 337 |

| Cluster | Number of Documents | h-index | Cites | Centrality | Density |

|---|---|---|---|---|---|

| Subperiod 1 (2002–2017) | |||||

| Chemistry | 118 | 54 | 11,910 | 386.42 | 103.97 |

| Cell Culture | 76 | 47 | 7657 | 266.77 | 45.20 |

| 3D Printers | 369 | 83 | 27,622 | 148.69 | 38.17 |

| Bone Prosthesis | 52 | 36 | 5430 | 183.87 | 47.02 |

| Scanning Electron Microscopy | 55 | 35 | 5646 | 143.35 | 13.46 |

| Fused Deposition Modeling | 57 | 13 | 798 | 38.42 | 22.15 |

| Melting | 37 | 28 | 3323 | 26.58 | 12.30 |

| Subperiod 2 (2018–2019) | |||||

| Tissue Engineering | 56 | 33 | 2866 | 122.11 | 81.57 |

| 3D Printers | 466 | 62 | 14,441 | 124.65 | 31.47 |

| Powder | 44 | 24 | 2208 | 60.33 | 18.93 |

| Bone | 33 | 21 | 1723 | 98.50 | 16.78 |

| Microstructure | 53 | 27 | 2145 | 61.96 | 13.28 |

| Fused Deposition Modeling | 78 | 20 | 1341 | 33.36 | 14.78 |

| Heat Transfer | 28 | 16 | 831 | 13.29 | 6.84 |

| Subperiod 3 (2020) | |||||

| Chemistry | 53 | 24 | 1827 | 84.35 | 64.35 |

| 3D Printers | 377 | 45 | 8575 | 83.04 | 21.75 |

| Selective Laser Melting | 60 | 20 | 1291 | 25.26 | 32.22 |

| Mechanical Properties | 40 | 15 | 957 | 35.57 | 3.18 |

| Subperiod 4 (2021) | |||||

| Tissue Scaffold | 65 | 20 | 1265 | 95.23 | 59.05 |

| Particle Size | 92 | 20 | 1368 | 61.73 | 26.67 |

| Additives | 331 | 30 | 4265 | 79.65 | 14.13 |

| Biocompatibility | 44 | 16 | 649 | 86.16 | 12.95 |

| Fused Deposition Modeling | 36 | 12 | 383 | 10.04 | 4.07 |

| Subperiod 5 (2022) | |||||

| Tissue Scaffold | 55 | 10 | 380 | 86.87 | 61.56 |

| Powder Bed | 417 | 17 | 1806 | 88.20 | 51.91 |

| Biomechanics | 55 | 10 | 358 | 78.09 | 14.33 |

| Austenitic Stainless Steel | 44 | 8 | 188 | 40.80 | 33.66 |

| 3D Printing | 140 | 13 | 743 | 61.43 | 8.05 |

| Deposition | 53 | 7 | 169 | 25.42 | 5.91 |

| Selective Laser Melting | 34 | 6 | 115 | 27.51 | 7.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Estévez, R.; Quijada-Maldonado, E.; Romero, J.; Abejón, R. Additive Manufacturing and Chemical Engineering: Looking for Synergies from a Bibliometric Study. Appl. Sci. 2025, 15, 2962. https://doi.org/10.3390/app15062962

Estévez R, Quijada-Maldonado E, Romero J, Abejón R. Additive Manufacturing and Chemical Engineering: Looking for Synergies from a Bibliometric Study. Applied Sciences. 2025; 15(6):2962. https://doi.org/10.3390/app15062962

Chicago/Turabian StyleEstévez, Rodrigo, Esteban Quijada-Maldonado, Julio Romero, and Ricardo Abejón. 2025. "Additive Manufacturing and Chemical Engineering: Looking for Synergies from a Bibliometric Study" Applied Sciences 15, no. 6: 2962. https://doi.org/10.3390/app15062962

APA StyleEstévez, R., Quijada-Maldonado, E., Romero, J., & Abejón, R. (2025). Additive Manufacturing and Chemical Engineering: Looking for Synergies from a Bibliometric Study. Applied Sciences, 15(6), 2962. https://doi.org/10.3390/app15062962