Comparison of Single-Arm and Dual-Arm Collaborative Robots in Precision Assembly

Abstract

1. Introduction

2. Materials and Methods

2.1. Characteristics of the Assembled Parts

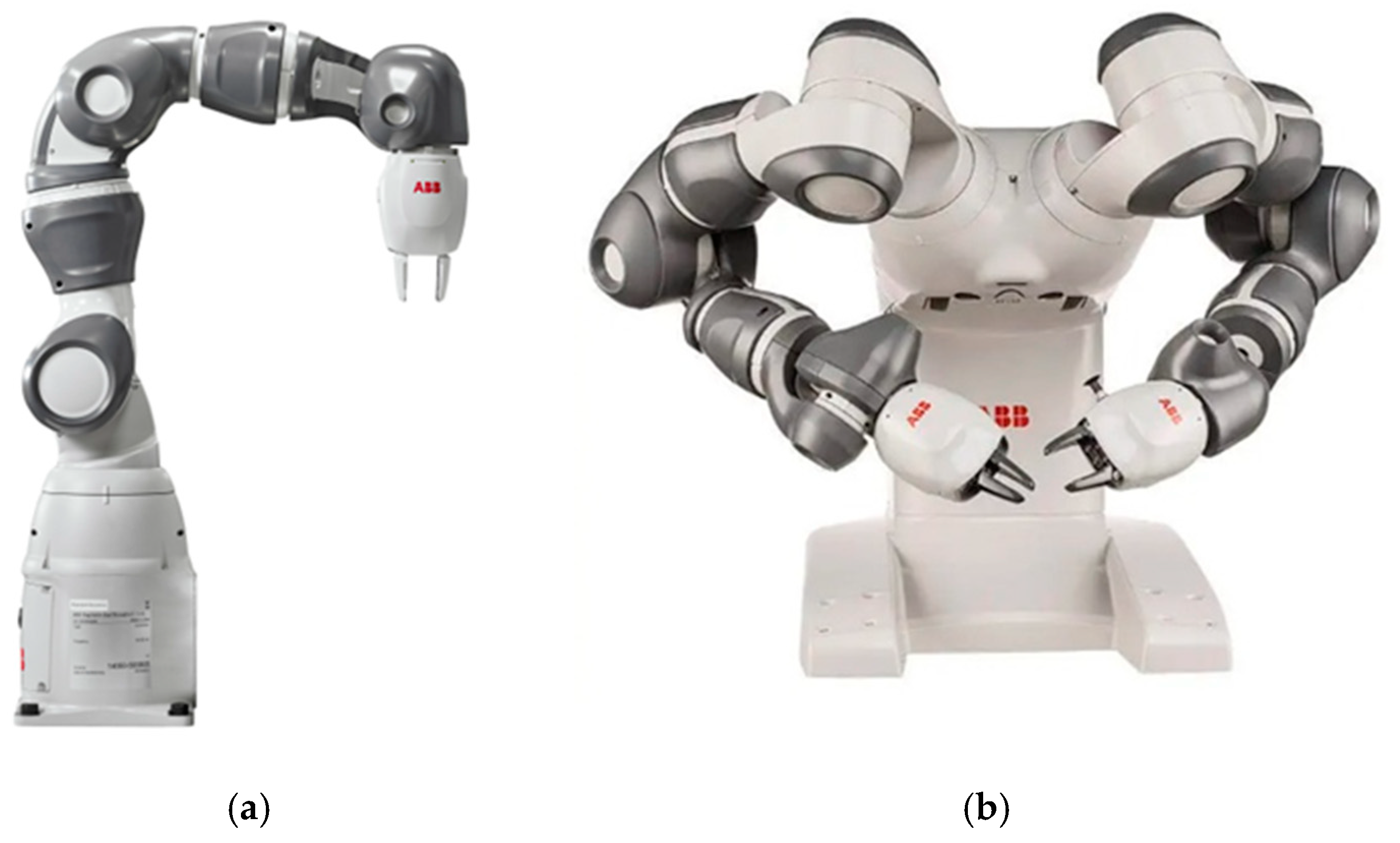

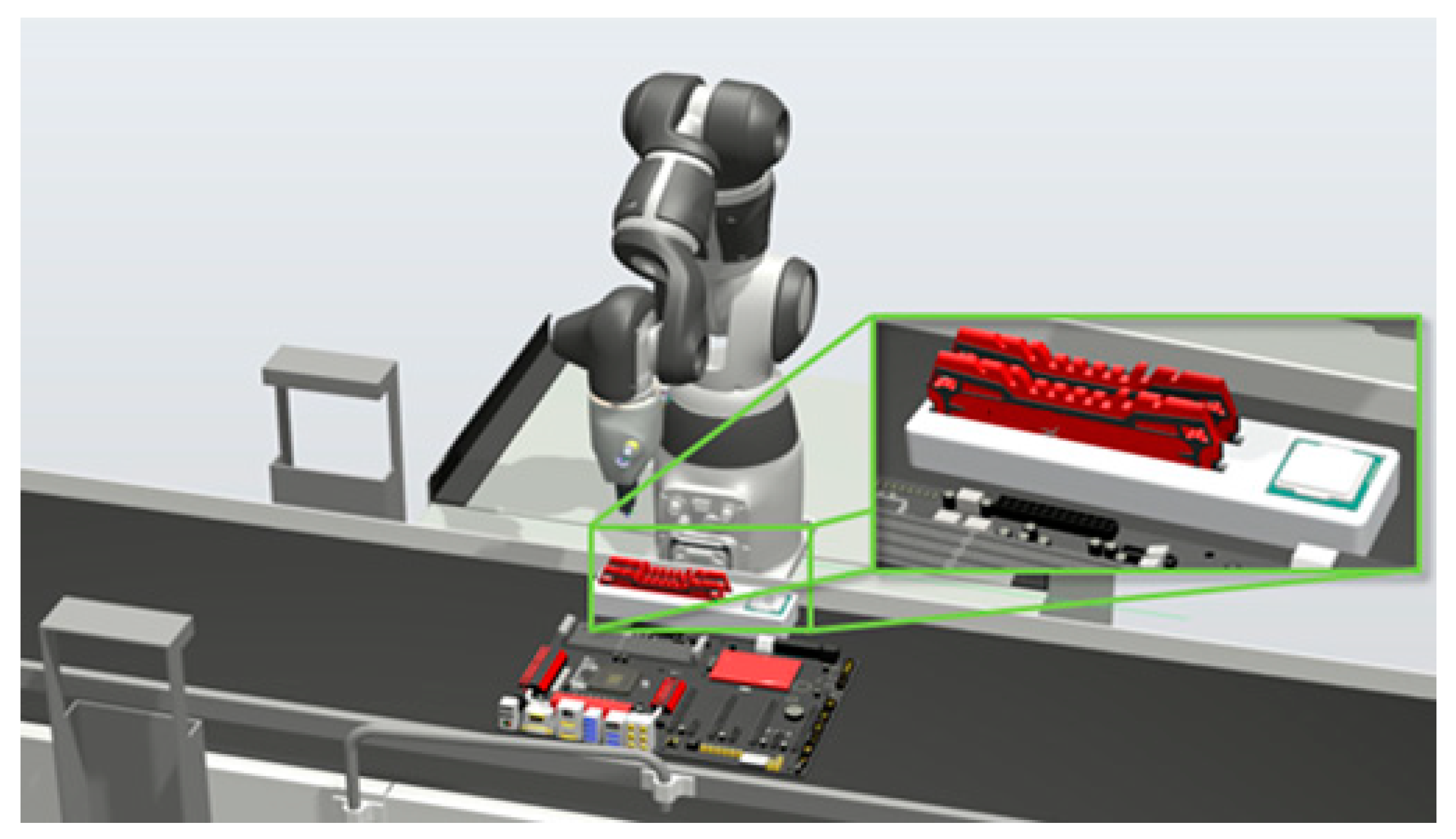

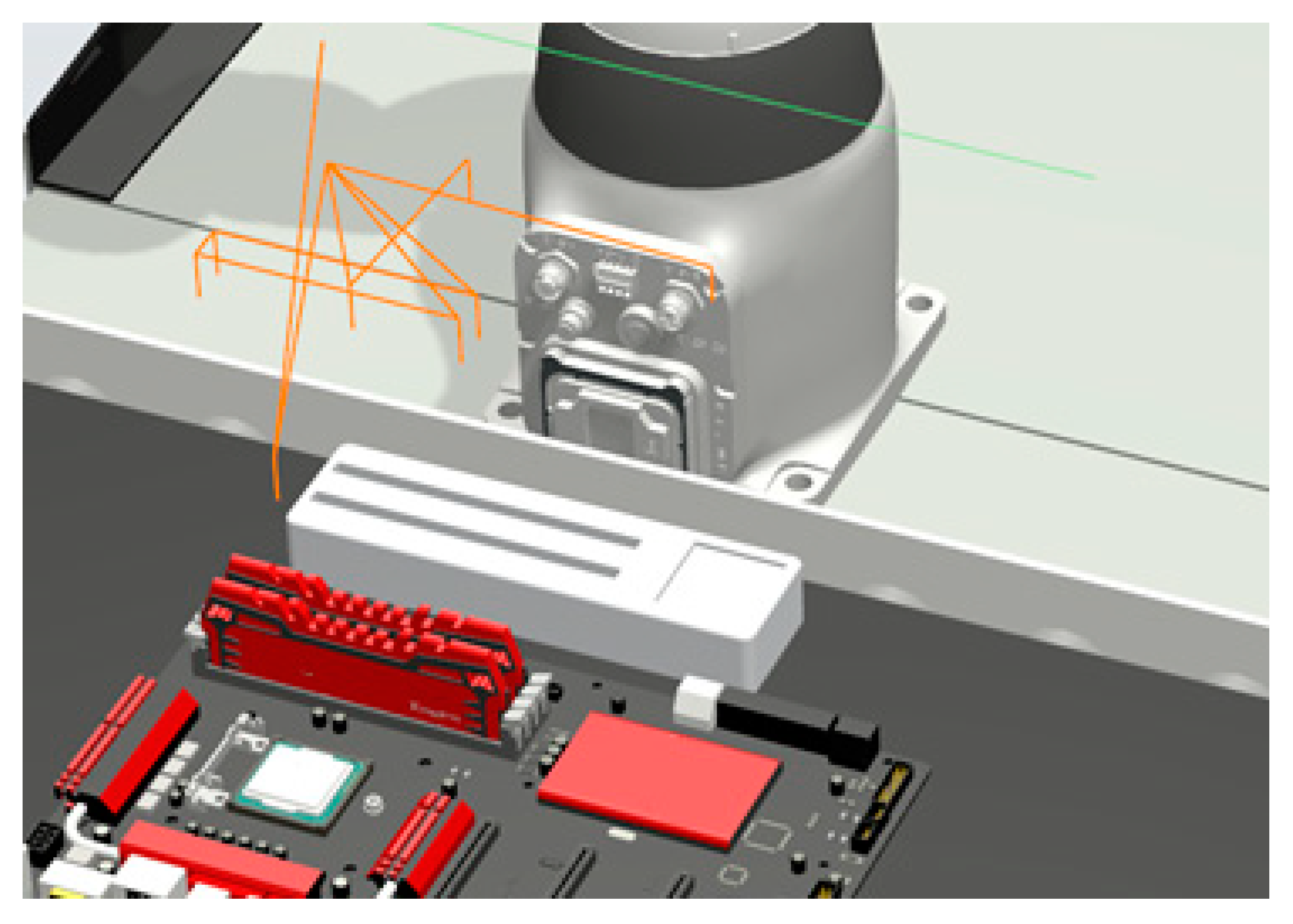

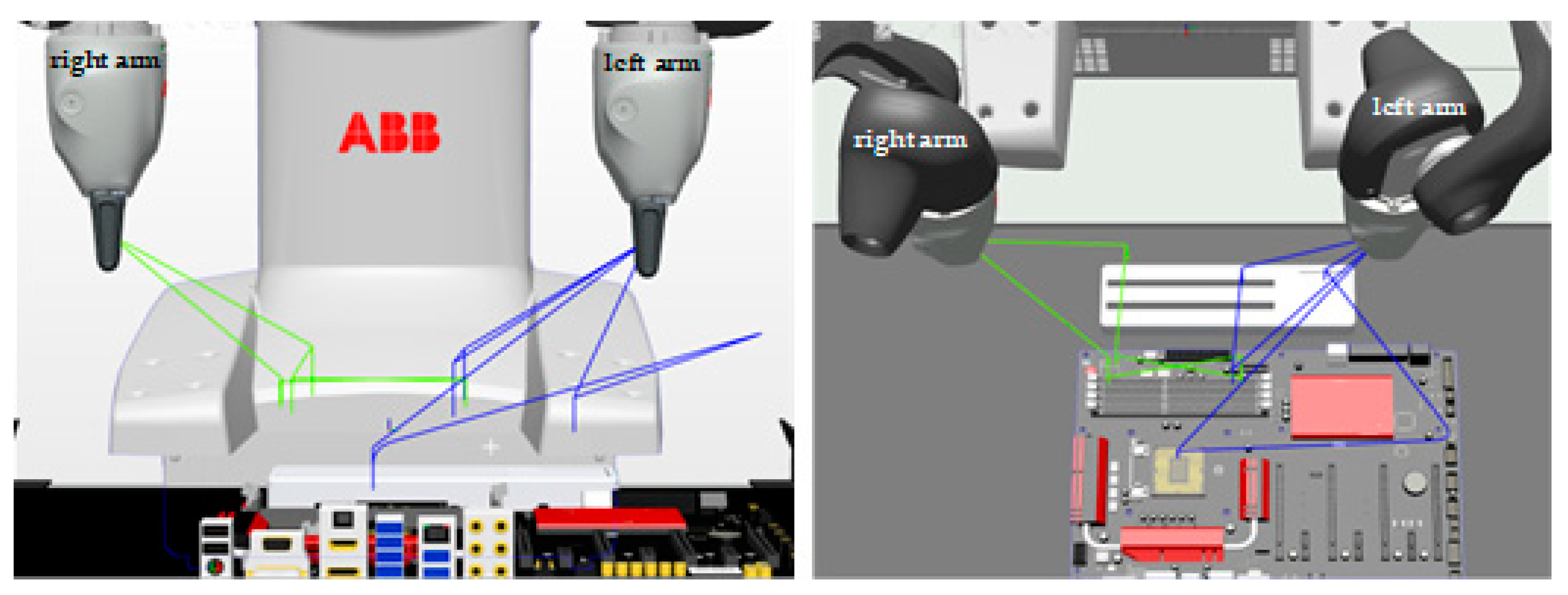

2.2. Robotic Cell

- construction and 3D visualization of a robotic station allowing one to observe how the station works and how the robot moves during the assembly process before implementation in the real environment,

- offline programming of a collaborative robot means creating a program, as well as its editing, testing and optimization without the requirement of physically working with the robot,

- communication between the robot, external and peripheral devices and sensors makes it possible to conduct a full simulation of the entire production station and also enables subsequent implementation of ready-made programs to all devices, not only the robot,

- a library of functions in which many ready-made solutions can be used to quickly create simulations, including smart components for dynamic conversion of station inputs and outputs,

- simulation of the robot and objects of the entire station in order to test and optimize the robot’s movement trajectory, but also additional results of the robot’s work such as collisions, speeds, accelerations, energy consumption and many others,

- a realistic user interface for offline programming that significantly mirrors online programming, for example a virtual operator panel (FlexPendant).

2.3. Rapid Program Code

2.4. Methods of Comparative Evaluation of Collaborative Robots

3. Results and Discussion

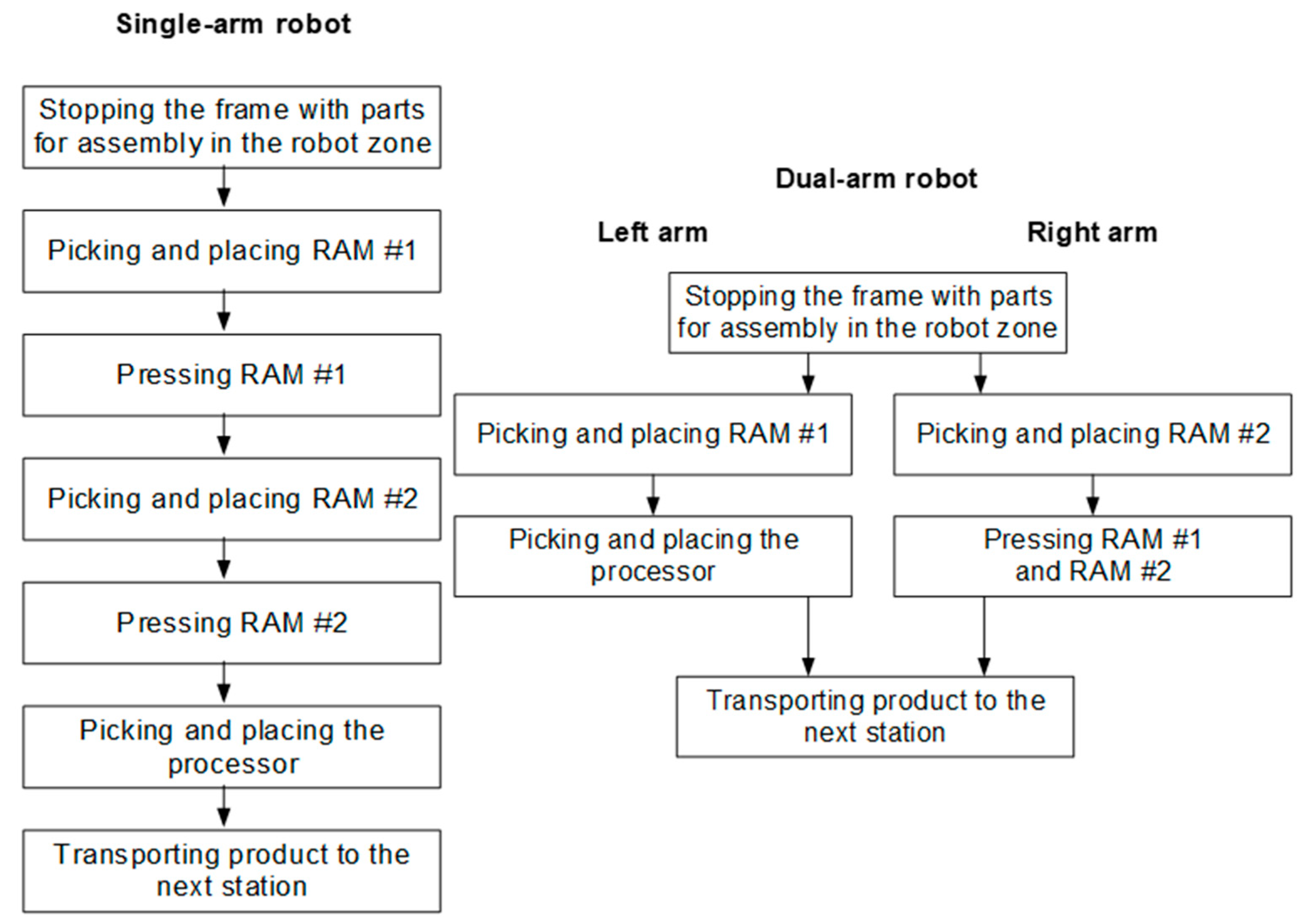

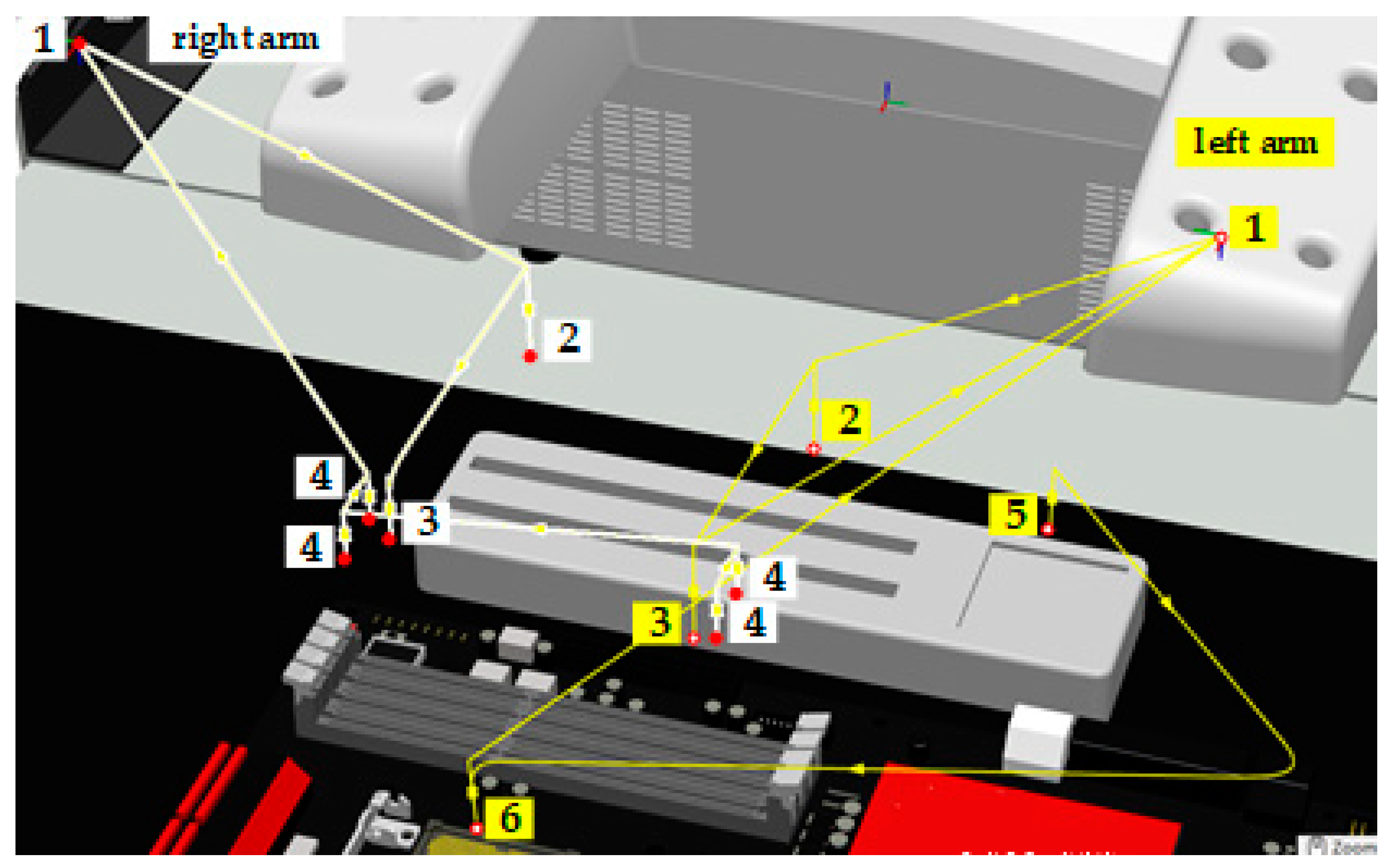

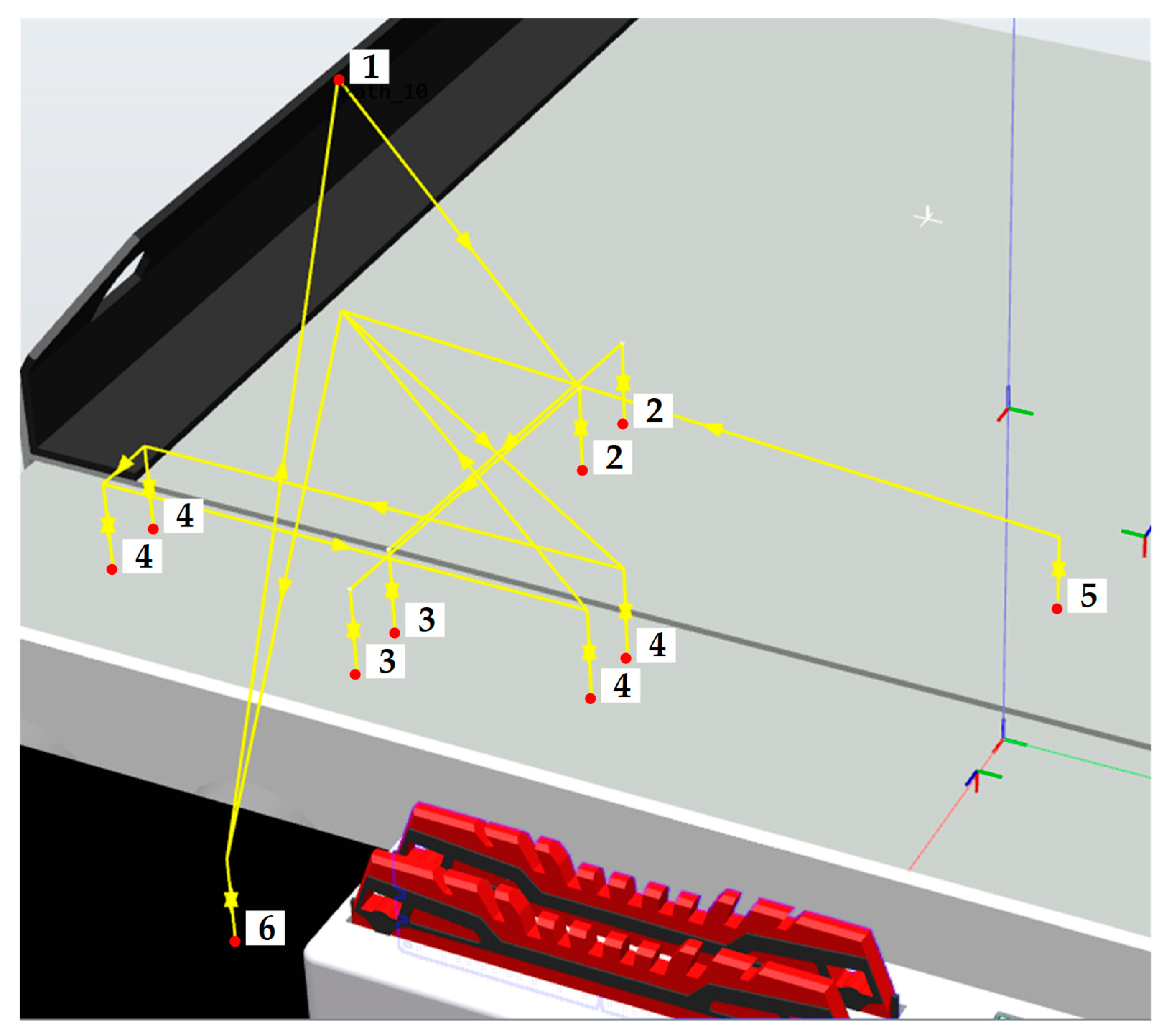

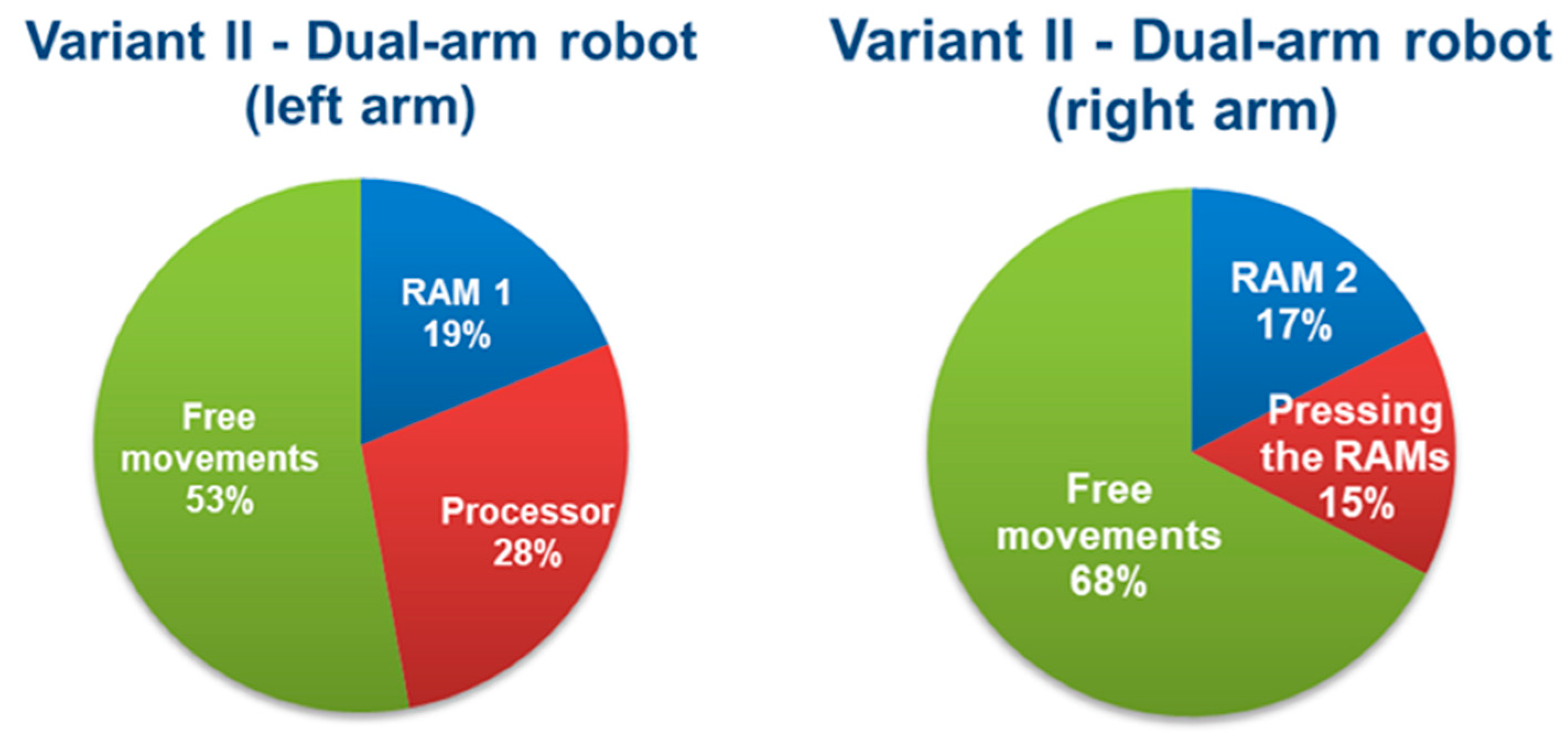

3.1. Time of the Assembly Process

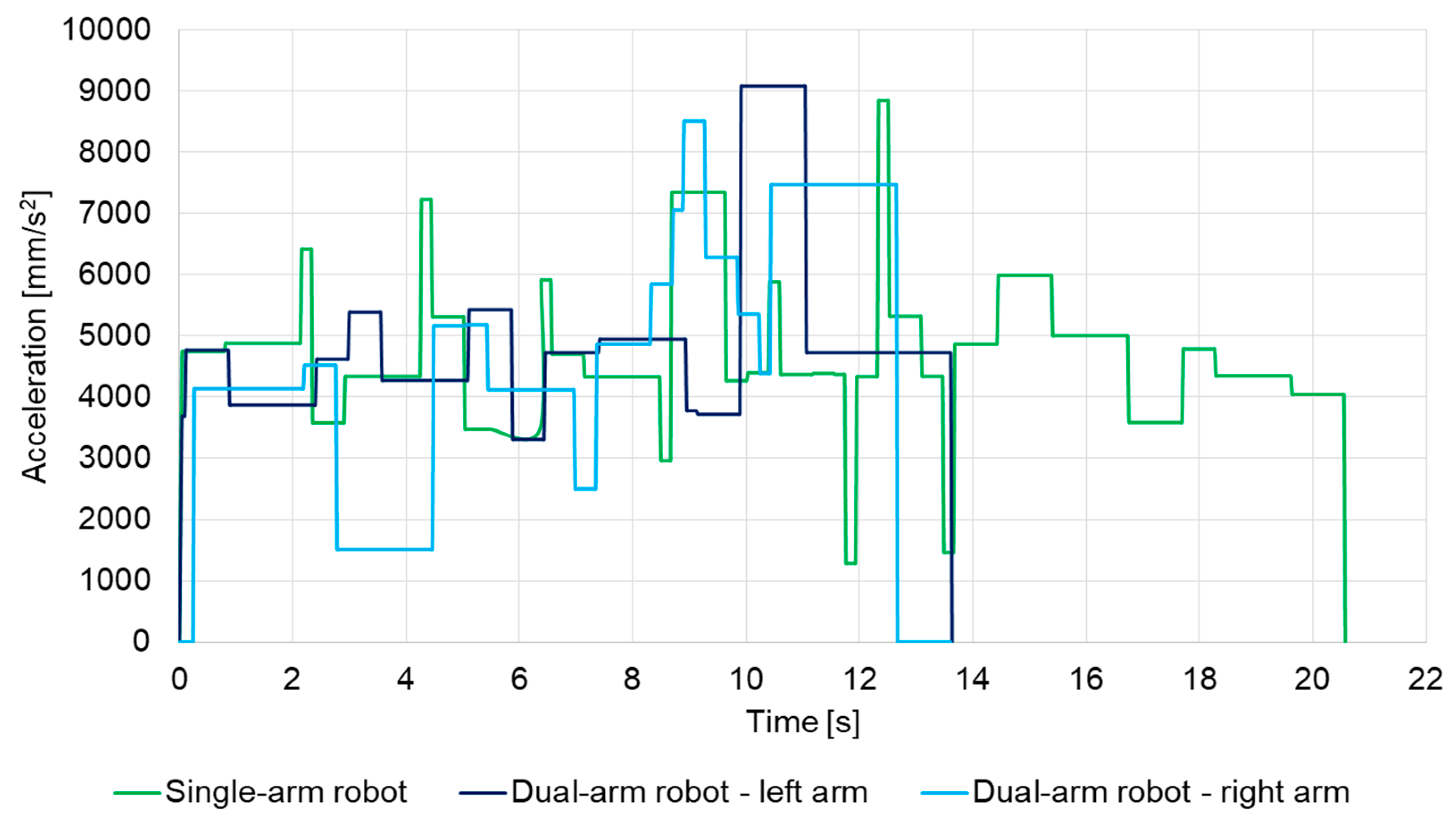

3.2. Speed and Acceleration

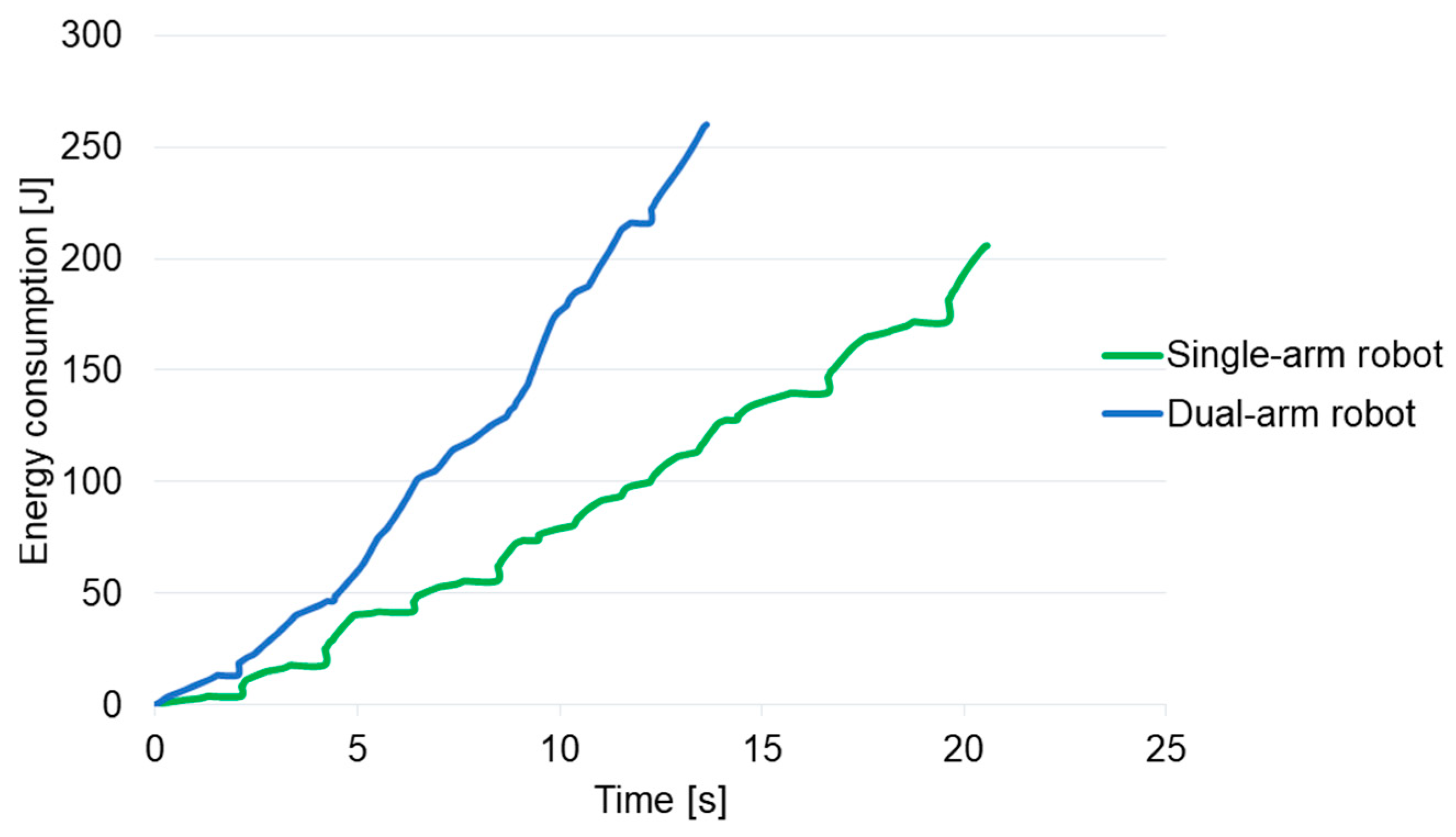

3.3. Energy Consumption

3.4. Costs

(No. of cycles per month ∗ Cost of producing 1 product) − (No. of shifts ∗ No. of hours per shift ∗ No. of working days per month ∗ cost per man hour) − (Energy consumed in a month ∗ cost per kWh)

- Kj—unit cost,

- K—total costs (purchase cost, energy, labor costs, etc.),

- P—production volume.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, G.; Banga, V.K. Robots and its types for industrial applications. Mater. Today Proc. 2022, 60, 1779–1786. [Google Scholar] [CrossRef]

- Li, J.; Barwood, M.; Rahimifard, S. Robotic disassembly for increased recovery of strategically important materials from electrical vehicles. Robot. Comput. Integr. Manuf. 2018, 50, 203–212. [Google Scholar] [CrossRef]

- Du, L.; Lin, W. Does the application of industrial robots overcome the Solow paradox? Evidence from China. Technol. Soc. 2022, 68, 101932. [Google Scholar] [CrossRef]

- Lim, W.S.; Dharmawan, A.G.; Soh, G.S. Development and performance evaluation of a hybrid-wire arc additive manufacturing system based on robot manipulators. Mater. Today Proc. 2022, 70, 587–592. [Google Scholar] [CrossRef]

- Dzedzickis, A.; Subačiūtė-žemaitienė, J.; Šutinys, E.; Samukaitė-Bubnienė, U.; Bučinskas, V. Advanced applications of industrial robotics: New trends and possibilities. Appl. Sci. 2022, 12, 135. [Google Scholar] [CrossRef]

- Muzan, I.W.; Faisal, T.; Al-Assadi, H.M.A.A.; Iwan, M. Implementation of industrial robot for painting applications. Procedia Eng. 2012, 41, 1329–1335. [Google Scholar] [CrossRef]

- IFR. World Robotics: Industrial Robots 2023; International Federation of Robotics: Frankfurt, Germany, 2023. [Google Scholar]

- Peta, K.; Wlodarczyk, J.; Maniak, M. Analysis of trajectory and motion parameters of an industrial robot cooperating with a numerically controlled machine tools. J. Manuf. Process. 2023, 101, 1332–1342. [Google Scholar] [CrossRef]

- Gui, W.; Zhou, F.; Tang, F. Research on Motion Simulation of Stacking Robot Workstation Based on RobotStudio. In Proceedings of the 2023 IEEE 3rd International Conference on Power, Electronics and Computer Applications (ICPECA), Shenyang, China, 29–31 January 2023; pp. 301–305. [Google Scholar] [CrossRef]

- Li, L.Y.; Long, Y.; Wang, T.Q.; Yue, J.F.; Meng, Q.Y. Operation space trajectory planning of welding robot based on rational B-splines curve. J. Tianjin Polytech. Univ. 2015, 34, 80–83+88. [Google Scholar] [CrossRef]

- Duan, H.F.; Han, W.; Chen, X.B.; Yang, A. Design of Grinding Robot Workstation for Automotive Water-Cooled Casing Castings. Zhuzao/Foundry 2023, 72, 607–611. [Google Scholar]

- Li, G.; Li, Y.; Han, H. The Simulation Design of Robot Automatic Sorting and Palletizing Workstation Based on RobotStudio. In Proceedings of the 2022 5th International Conference on Robotics, Control and Automation Engineering (RCAE), Changchun, China, 28–30 October 2022; pp. 205–208. [Google Scholar] [CrossRef]

- Gupta, R.S.P.K.A. Simulation of Robotized Mig Welding Using Robotstudio. Int. J. Sci. Res. 2014, 3, 523–528. [Google Scholar]

- Fang, D.; Zheng, Y.; Zhang, B.; Li, X.; Ju, P.; Li, H.; Zeng, C. Automatic robot trajectory for thermal-sprayed complex surfaces. Adv. Mater. Sci. Eng. 2018, 2018, 697056. [Google Scholar] [CrossRef]

- Peta, K.; Wiśniewski, M.; Pęczek, A.; Ciszak, O. Sustainable Robotic Process for Sealing Car Radiators. Sustainability 2024, 16, 865. [Google Scholar] [CrossRef]

- Harsha Arigela, S.; Kumar Chintamreddy, V. Fused deposition modeling of an aircraft wing using industrial robot with non-linear tool path generation. Int. J. Eng. Trans. A Basics 2021, 34, 272–282. [Google Scholar] [CrossRef]

- Borboni, A.; Reddy, K.V.V.; Elamvazuthi, I.; AL-Quraishi, M.S.; Natarajan, E.; Azhar Ali, S.S. The Expanding Role of Artificial Intelligence in Collaborative Robots for Industrial Applications: A Systematic Review of Recent Works. Machines 2023, 11, 111. [Google Scholar] [CrossRef]

- Chemweno, P.; Torn, R.J. Innovative safety zoning for collaborative robots utilizing Kinect and LiDAR sensory approaches. Procedia CIRP 2022, 106, 209–214. [Google Scholar] [CrossRef]

- ABB. Product Specification—IRB 14000; ABB: Zürich, Switzerland, 2015. [Google Scholar]

- Li, W.S.; Yan, Q.; Chen, W.T.; Li, G.Y.; Cong, L. Global Research Trends in Robotic Applications in Spinal Medicine: A Systematic Bibliometric Analysis. World Neurosurg. 2021, 155, e778–e785. [Google Scholar] [CrossRef]

- Peta, K.; Love, G.; Brown, C.A. Comparing repeatability and reproducibility of topographic measurement types directly using linear regression analyses of measured heights. Precis. Eng. 2024, 88, 192–203. [Google Scholar] [CrossRef]

- Matheson, E.; Minto, R.; Zampieri, E.G.G.; Faccio, M.; Rosati, G. Human-robot collaboration in manufacturing applications: A review. Robotics 2019, 8, 100. [Google Scholar] [CrossRef]

- Bisen, A.S.; Payal, H. Collaborative robots for industrial tasks: A review. Mater. Today Proc. 2022, 52, 500–504. [Google Scholar] [CrossRef]

- Giberti, H.; Abbattista, T.; Carnevale, M.; Giagu, L.; Cristini, F. A Methodology for Flexible Implementation of Collaborative Robots in Smart Manufacturing Systems. Robotics 2022, 11, 9. [Google Scholar] [CrossRef]

- Andrusyshyn, V.; Andrusyshyn, I.; Židek, K.; Ivanov, V.; Piteľ, J.; Trojan, J. Creating a Digital Twin of the ABB YuMi Robot to Improve the Human-Robot Interaction Experience. In Proceedings of the 2024 25th International Carpathian Control Conference (ICCC), Krynica Zdrój, Poland, 22–24 May 2024. [Google Scholar] [CrossRef]

- Angleraud, A.; Mehman Sefat, A.; Netzev, M.; Pieters, R. Coordinating Shared Tasks in Human-Robot Collaboration by Commands. Front. Robot. AI 2021, 8, 734548. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Liu, H.; Chang, Q.; Wang, L.; Gao, R.X. Recurrent neural network for motion trajectory prediction in human-robot collaborative assembly. CIRP Ann. 2020, 69, 9–12. [Google Scholar] [CrossRef]

- Raviola, A.; Guida, R.; Bertolino, A.C.; De Martin, A.; Mauro, S.; Sorli, M. A Comprehensive Multibody Model of a Collaborative Robot to Support Model-Based Health Management. Robotics 2023, 12, 71. [Google Scholar] [CrossRef]

- Calvo, R.; Gil, P. Evaluation of Collaborative Robot Sustainable Integration in Manufacturing Assembly by Using Process Time Savings. Materials 2022, 15, 611. [Google Scholar] [CrossRef] [PubMed]

- Michalík, R.; Janota, A.; Gregor, M.; Hruboš, M. Human-robot motion control application with artificial intelligence for a cooperating YuMi robot. Electronics 2021, 10, 1976. [Google Scholar] [CrossRef]

- Eyam, A.T.; Mohammed, W.M.; Martinez Lastra, J.L. Emotion-driven analysis and control of human-robot interactions in collaborative applications. Sensors 2021, 21, 4626. [Google Scholar] [CrossRef]

- Pang, G.; Deng, J.; Wang, F.; Zhang, J.; Pang, Z.; Yang, G. Development of flexible robot skin for safe and natural human-robot collaboration. Micromachines 2018, 9, 576. [Google Scholar] [CrossRef]

- Cohen, Y.; Faccio, M.; Rozenes, S. Vocal Communication Between Cobots and Humans to Enhance Productivity and Safety: Review and Discussion. Appl. Sci. 2025, 15, 726. [Google Scholar] [CrossRef]

- Zafar, M.H.; Langås, E.F.; Sanfilippo, F. Exploring the synergies between collaborative robotics, digital twins, augmentation, and industry 5.0 for smart manufacturing: A state-of-the-art review. Robot. Comput. Integr. Manuf. 2024, 89, 102769. [Google Scholar] [CrossRef]

- Dhanda, M.; Rogers, B.A.; Hall, S.; Dekoninck, E.; Dhokia, V. Reviewing human-robot collaboration in manufacturing: Opportunities and challenges in the context of industry 5.0. Robot. Comput. Integr. Manuf. 2025, 93, 102937. [Google Scholar] [CrossRef]

- Lunt, A.M.; Fakhruldeen, H.; Pizzuto, G.; Longley, L.; White, A.; Rankin, N.; Clowes, R.; Alston, B.; Gigli, L.; Day, G.M.; et al. Modular, multi-robot integration of laboratories: An autonomous workflow for solid-state chemistry. Chem. Sci. 2023, 15, 2456–2463. [Google Scholar] [CrossRef] [PubMed]

- Mozafari, B.; O’Shea, N.; Fenelon, M.; Li, R.; Daly, D.F.M.; Villing, R. An automated platform for measuring infant formula powder rehydration quality using a collaborative robot integrated with computer vision. J. Food Eng. 2024, 383, 112229. [Google Scholar] [CrossRef]

- Li, C.; Gu, H. Improving the local absolute accuracy of robot with touch panel. In Proceedings of the 2017 IEEE International Conference on Robotics and Biomimetics (ROBIO), Macau, Macao, 5–8 December 2017; pp. 1838–1843. [Google Scholar] [CrossRef]

- Parigi Polverini, M.; Zanchettin, A.M.; Rocco, P. A constraint-based programming approach for robotic assembly skills implementation. Robot. Comput. Integr. Manuf. 2019, 59, 69–81. [Google Scholar] [CrossRef]

- Bejarano, R.; Ferrer, B.R.; Mohammed, W.M.; Martinez Lastra, J.L. Implementing a human-robot collaborative assembly workstation. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN), Helsinki, Finland, 22–25 July 2019; pp. 557–564. [Google Scholar] [CrossRef]

- Pantanetti, S.; Emiliani, F.; Costa, D.; Palmieri, G.; Bajrami, A. From Single to Dual-Arm Collaborative Robotic Assembly: A Case Study at I-Labs. In Proceedings of the 2024 20th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications (MESA), Genova, Italy, 2–4 September 2024. [Google Scholar] [CrossRef]

- Polonara, M.; Romagnoli, A.; Biancini, G.; Carbonari, L. Introduction of Collaborative Robotics in the Production of Automotive Parts: A Case Study. Machines 2024, 12, 196. [Google Scholar] [CrossRef]

- Mueller, S. Upgrading and Repairing PCs; Que Publishing: Seattle, WA, USA, 2015. [Google Scholar]

- Dual-arm YuMi®-IRB 14000. Available online: https://new.abb.com/products/robotics/robots/collaborative-robots/yumi/irb-14000-yumi (accessed on 15 October 2023).

- ABB YuMi IRB14000. Available online: https://unchainedrobotics.de/en/products/robot/abb-yumi-irb-14000 (accessed on 15 October 2023).

- ABB Single-arm YuMi IRB 14050. Available online: https://unchainedrobotics.de/en/products/robot/single-arm-yumi-irb-14050 (accessed on 15 October 2023).

- Available online: https://webshop.robotics.abb.com/us/catalog/product/view/id/63/2023 (accessed on 15 October 2023).

- Available online: https://webshop.robotics.abb.com/us/catalog/product/view/id/84/s/dual-arm-yumi-irb-14000-assembly/2023 (accessed on 15 October 2023).

| Function | Explanation |

|---|---|

| CONST robtarget Home | Assigning coordinates and names for the point |

| MoveL Home, v200, z0 | Linear movement command to a point called “Home” with a speed of 200 mm/s and zone z0 |

| WaitTime 1; | Command to wait the robot for a specified time |

| Reset/Set PickRam | Setting the signal that controls the movement of the mounting frame in position 0/1 |

| Task | RAM 1 | RAM 2 | Pressing the RAMs | Processor | Free Movements | Total |

|---|---|---|---|---|---|---|

| Time [s] | 2.1 | 2 | 3.6 | 4.2 | 8.7 | 20.6 |

| Task | RAM 1 | RAM 2 | Pressing the RAMs | Processor | Free Movement | Total |

|---|---|---|---|---|---|---|

| Left arm Time [s] | 2.6 | - | - | 3.9 | 7.1 | 13.6 |

| Right arm Time [s] | - | 2.4 | 2.1 | - | 9.1 | 13.6 |

| Single-Arm Robot | Dual-Arm Robot | ||||

|---|---|---|---|---|---|

| Left Arm | Right Arm | ||||

| Time [s] | Sequence | Time [s] | Sequence | Time [s] | Sequence |

| 0 | start | 0 | start | 0 | start |

| 0.72 | free movement | 0.768 | free movement | 2.784 | free movement |

| 1.08 | working movement | 1.344 | working movement | 3.36 | working movement |

| 2.112 | picking RAM1 | ||||

| 2.76 | free movement | 2.4 | picking RAM2 | 4.416 | picking RAM1 |

| 3.144 | working movement | 3.48 | free movement | 5.544 | free movement |

| 4.176 | inserting RAM1 | 4.056 | working movement | 5.832 | working movement |

| 4.92 | free movement | ||||

| 5.328 | working movement | 5.112 | inserting RAM2 | 6.864 | inserting RAM1 |

| 6.36 | picking RAM2 | 7.584 | free movement | 8.352 | free movement |

| 7.032 | free movement | 7.8 | working movement | 8.64 | working |

| 7.416 | working movement | 8.832 | picking processor | movement | |

| 8.448 | inserting RAM2 | 11.04 | free movement | 8.664 | pressing RAM 1 (corner 1) |

| 9.912 | free movement | 11.208 | working movement | 8.904 | free movement |

| 10.272 | working movement | 9.168 | working movement | ||

| 10.32 | pressing RAM 1 (corner 1) | 12.24 | inserting processor | ||

| 9.192 | pressing RAM 1 (corner 2) | ||||

| 11.064 | free movement | 13.632 | free movement | 9.84 | free movement |

| 11.448 | working movement | 10.128 | working movement | ||

| 11.496 | pressing RAM 1 (corner 2) | ||||

| 10.152 | pressing RAM 2 (corner 1) | ||||

| 11.784 | free movement | 10.392 | free movement | ||

| 12.168 | working movement | 10.656 | working movement | ||

| 12.216 | pressing RAM 2 (corner 1) | ||||

| 10.68 | pressing RAM 2 (corner 2) | ||||

| 12.936 | free movement | 13.632 | free movement | ||

| 13.344 | working movement | ||||

| 13.368 | pressing RAM 2 (corner 2) | ||||

| 15.24 | free movement | ||||

| 15.552 | working movement | ||||

| 16.608 | picking processor | ||||

| 18.192 | free movement | ||||

| 18.552 | working movement | ||||

| 19.584 | inserting processor | ||||

| 20.568 | free movement | ||||

| Time [s] | Energy Consumption [J] | |

|---|---|---|

| Variant I—single-arm robot | 20.6 | 205.8 |

| Variant II—dual-arm robot | 13.6 | 260 |

| Single-Arm Robot | Dual-Arm Robot | Unit | |

|---|---|---|---|

| Purchase cost | 37,369 [47] | 61,968 [48] | € |

| Cycle time | 25.60 | 18.60 | s |

| Energy consumed per cycle | 206 | 260 | J |

| Number of shifts | 3 | 3 | |

| Number of hours per shift | 8 | 8 | |

| Number of cycles per hour | 141 | 194 | pcs |

| Energy consumed per hour | 28,941 | 50,323 | J |

| Energy consumed per number of shifts | 694,575 | 1,207,742 | J |

| Number of working days/month | 22 | 22 | |

| Energy consumed in a month | 15,280,650 | 26,570,323 | J |

| Energy consumed in a month | 4.24 | 7.38 | kWh |

| Number of cycles per month | 74,250 | 10,2194 | pcs |

| Energy consumption in the year | 51 | 89 | kWh |

| Number of cycles per year | 891,000 | 1,226,323 | pcs |

| Cost per man hour | 10.78 | 21.55 | € |

| Cost of production pcs. | 0.32 | 0.32 | € |

| Cost per kWh | 0.27 | 0.27 | € |

| Monthly profit | 18,312 | 21,655 | € |

| Unit cost | 0.047 | 0.058 | €/pcs. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peta, K.; Wiśniewski, M.; Kotarski, M.; Ciszak, O. Comparison of Single-Arm and Dual-Arm Collaborative Robots in Precision Assembly. Appl. Sci. 2025, 15, 2976. https://doi.org/10.3390/app15062976

Peta K, Wiśniewski M, Kotarski M, Ciszak O. Comparison of Single-Arm and Dual-Arm Collaborative Robots in Precision Assembly. Applied Sciences. 2025; 15(6):2976. https://doi.org/10.3390/app15062976

Chicago/Turabian StylePeta, Katarzyna, Marcin Wiśniewski, Mikołaj Kotarski, and Olaf Ciszak. 2025. "Comparison of Single-Arm and Dual-Arm Collaborative Robots in Precision Assembly" Applied Sciences 15, no. 6: 2976. https://doi.org/10.3390/app15062976

APA StylePeta, K., Wiśniewski, M., Kotarski, M., & Ciszak, O. (2025). Comparison of Single-Arm and Dual-Arm Collaborative Robots in Precision Assembly. Applied Sciences, 15(6), 2976. https://doi.org/10.3390/app15062976