Featured Application

The findings of this study provide valuable insights for the optimization of cold-pressing processes in the production of high-oleic sunflower oil. By understanding the impact of hull and impurity content on pressing efficiency and pressing oil yield, manufacturers can improve oil extraction methods, enhance production efficiency, and maintain high product quality. The developed predictive models offer a practical tool for optimizing seed preparation and processing parameters, supporting sustainable and cost-effective industrial oil production. These results can be applied in the edible oil industry to refine mechanical pressing techniques, reduce waste, and improve the yield and stability of high-value oils.

Abstract

This study investigates the effects of hull and impurity content on the efficiency of cold-pressing high-oleic sunflower seeds using a screw press. High-oleic sunflower oil is valued for its oxidative stability and health benefits, and optimizing pressing conditions is crucial for maximizing yield and maintaining oil quality. The identification of high-oleic sunflower oil was performed by analyzing its fatty acid composition, iodine value, and refractive index. Eleven seed samples with varying hull and impurity contents were processed to assess their impact on cake composition, pressing efficiency, and pressing oil yield. Oil yield ranged from 39.24% to 76.52%, with higher hull content contributing to increased yield due to its role in facilitating oil drainage. Multiple linear regression models were developed to predict moisture and oil content in the cake, as well as pressing efficiency, based on hull and impurity content, demonstrating strong predictive accuracy. These parameters were selected as they represent economically significant indicators, given that moisture and oil content indirectly reflect the protein content in the cake, while sunflower cake is primarily used as animal feed. Additionally, pressing efficiency indicates oil yield during pressing, which is the most critical economic parameter of the cold-pressing process. Cluster analysis identified three sample groups with distinct characteristics, revealing interactions between seed composition and pressing performance. The results highlight the significance of seed preparation in optimizing cold-pressing efficiency and provide insights for improving oil extraction processes. These findings support the industrial application of high-oleic sunflower seed pressing and contribute to the development of sustainable, high-quality oil production methods.

1. Introduction

Edible vegetable oils are a source of lipids in human diets, providing energy, essential fatty acids, and fat-soluble vitamins [1,2]. With the growth of the global population, there is an increasing global demand for fat sources. Edible oils are used not only for direct consumption but also in food preparation, frying, baking, cooking, making salads, and as components in other industries [3,4,5]. Sunflower oil ranks among the five most common edible oils in the world, as well as sunflower seeds in the total production of oilseeds worldwide [6,7,8]. The fatty acid composition of sunflower oil significantly influences its oxidative status and, consequently, its potential applications. Standard sunflower oil is rich in polyunsaturated linoleic acid, with a content ranging from 45.4% to 74.0% [9]. To increase the oxidative stability and potential applications of sunflower oil, breeders have worked on altering the fatty acid composition in newly created hybrids [10]. Breeders have focused on increasing the content of saturated and monounsaturated fatty acids, such as palmitic, stearic, and especially oleic acid, leading to the development of various types of sunflower hybrids. Since oleic acid has gained increasing attention worldwide in recent years due to its beneficial health effects, particularly its association with a reduced risk of coronary diseases [11,12], the production of sunflower hybrids with high oleic acid content has increased, as well as the production of high-oleic sunflower oil. The oleic acid content in these oils ranges from 43.1% to 71.8% [9], making it more oxidatively stable and expanding its range of applications [13,14].

The method of oil extraction affects the content and composition of minor compounds that have functional properties and contribute to the oxidative stability of the oil. Cold-pressed oils are considered to have high nutritional value. Recently, the cold-pressing technology for oil extraction has become a desirable alternative to the widely used chemical oil extraction due to consumer demand for safe and natural edible products [15,16,17]. The advantages of cold-pressing technology at an industrial scale include lower energy consumption and lower investment costs. This oil extraction method does not use toxic solvents and does not generate wastewater, ensuring a safe working environment for employees. Mechanical oil extraction (cold-pressing) has a lower environmental impact compared to chemical extraction (using solvents) and shows greater flexibility as the processing of different seed types is quick and easy. Cold-pressed oils are preferred over refined oils because they contain more antioxidants and bioactive components such as sterols, carotenoids, and phenols. Furthermore, cold-pressed oils contain naturally occurring bioactive substances like phenolic compounds and tocopherols, which enhance the oxidative stability of the oil [18,19]. The main disadvantage of mechanical oil extraction through cold-pressing is its low efficiency and uneven quality [20]. Most cold-pressed oils contain high amounts of polyunsaturated fatty acids, which negatively affect oxidative stability. Cold-pressed oils also contain higher amounts of pro-oxidative compounds, resulting in shorter shelf-life compared to refined oils [21,22].

Mechanical oil extraction involves the use of hydraulic presses or screw presses powered by motors [23,24]. The advantages of screw presses over hydraulic presses are their slightly improved yields and the ability to continuously adjust the processing. The oil yield depends on the pre-treatment of the seeds (dehulling, drying, and enzymatic processing) and the parameters applied during the cold-pressing process. Cold-pressing machines have a simple working scheme, where the oilseed is fed into an inlet, and oil and cake are produced [25]. In principle, the seed is placed between chambers, where pressure is applied to reduce the available volume, thus extracting the oil from the seed [26,27]. Before pressing, the press head must be heated to a specific temperature to enable oil extraction. The temperature to which the press is heated depends on the press design and the raw material being processed and is often provided as a recommendation by the press manufacturer. The efficiency of the pressing primarily depends on the type of raw material, particularly the oil content in the feedstock, as well as on the preparation of the feedstock, its particle size distribution, hull content, and the presence of remaining impurities, etc. The design and power of the press, as well as pressing conditions (pressure, temperature, speed, process duration, moisture content of the feedstock, etc.), also affect the efficiency of the pressing process [28,29,30]. Key challenges include variability in seed composition, which directly affects oil yield and pressing efficiency. Specifically, high hull and impurity content can increase mechanical wear and reduce throughput, while low hull content may hinder effective oil drainage. Lužaić et al. [8] established a strong negative correlation (R2 = −0.8153) between the hull content in sunflower seeds and oil yield from cold pressing in 20 newly developed sunflower hybrids, with hull content ranging from 24.81 ± 0.48% to 46.74 ± 0.99%. Impurities can also introduce oxidative compounds, impacting the shelf-life of the final product [31].

As a by-product of cold-pressed oil production, press cake remains [8,32]. Sunflower press cake is primarily used as animal feed due to its poor functional properties, dark color, high fiber content, and low digestibility. However, by reducing the proportion of hulls and impurities in the raw seeds, sunflower proteins from press cake could potentially be utilized in human nutrition [33]. Considering that the preparation of sunflower seeds for pressing involves drying, dehulling, and removing impurities, the aim of this study is to examine the impact of hull and impurity content on the composition of the obtained cake (moisture and oil content) and the pressing oil yield of cold-pressed oil produced from high-oleic sunflower seeds using a screw press. For the purpose of identifying the high-oleic sunflower oil sample, the fatty acid composition, iodine value, and refractive index were analyzed. Additionally, multiple linear regression models were developed to predict the moisture and oil content in the cake and pressing oil yield as a function of hull and impurity content in the seed. Hierarchical cluster analysis was also applied to determine the similarity between samples in terms of capacity and yield during pressing.

2. Materials and Methods

2.1. Samples

This study utilized cake samples obtained by pressing the seeds of high-oleic sunflower. The sunflower seeds used in this study were of the hybrid NS-H-6326, developed through experimental cultivation at the Institute of Field and Vegetable Crops Novi Sad, National Institute of the Republic of Serbia, Novi Sad, Serbia. The hybrid NS-H-6326 was created using conventional selection methods. It was grown under standard cultivation conditions without irrigation, in a randomized complete block design with three replications. After harvesting, a representative amount of seed was stored at 20 °C for six months until the oil production (mechanical extraction/cold-pressing) process. The seeds were completely cleaned of impurities and dehulled. Subsequently, according to the experimental design, the hulls and impurities were reintroduced into each individual sample. A total of 1 kg was produced per sample, and immediately prior to pressing, each individual sample was homogenized. The impurities primarily consisted of organic non-fat impurities and dust.

2.1.1. Experimental Design

A total of 11 different seed and cake samples, shown in Table 1, were analyzed. These samples were derived from seeds with varying hull and impurity contents to assess the effects of these parameters on the quality of the produced oil. The experiment was divided into three major groups:

- Group 1—Repeated Sample (Sample 1): Sample 1 was produced with a 10% hull content and 5% impurities. This sample was repeated five times to ensure consistency and minimize variability.

- Group 2—Variable Hull and Impurity Contents: Samples 2 to 9 represented different combinations of hull content (ranging from 0% to 20% at 5% intervals) and impurities (ranging from 0% to 10% at 2.5% intervals), aimed at exploring the effects of changing seed properties on oil quality.

- Group 3—Boundary Samples (Samples 10 and 11): Sample 10 was produced using seeds with 0% hull content and 0% impurities, serving as a baseline with minimal interference from seed components. Sample 11 was produced with 20% hull content and 10% impurities, representing the maximum content of hulls and impurities to observe their most significant effects.

Control sample was the original sunflower hybrid NS-H-6326, with its natural (original) hull and impurity content.

Table 1.

Experimental design, specification and identification of samples.

Table 1.

Experimental design, specification and identification of samples.

| Hull content, h (%) | 20 | Sample 5 | Sample 11 ** | |||

| 15 | Sample 7 | Sample 4 | ||||

| 10 | Sample 9 | Sample 1 * | Sample 6 | |||

| 5 | Sample 2 | Sample 3 | ||||

| 0 | Sample 10 ** | Sample 8 | ||||

| 0 | 2.5 | 5 | 7.5 | 10 | ||

| Impurity content, i (%) | ||||||

* Sample 1 was repeated 5 times to ensure robustness of results. ** Samples 10 and 11 were designed to test the extreme cases of seed composition (minimal and maximal hull and impurity content).

2.1.2. Production of Cold-Pressed Oil and Cake

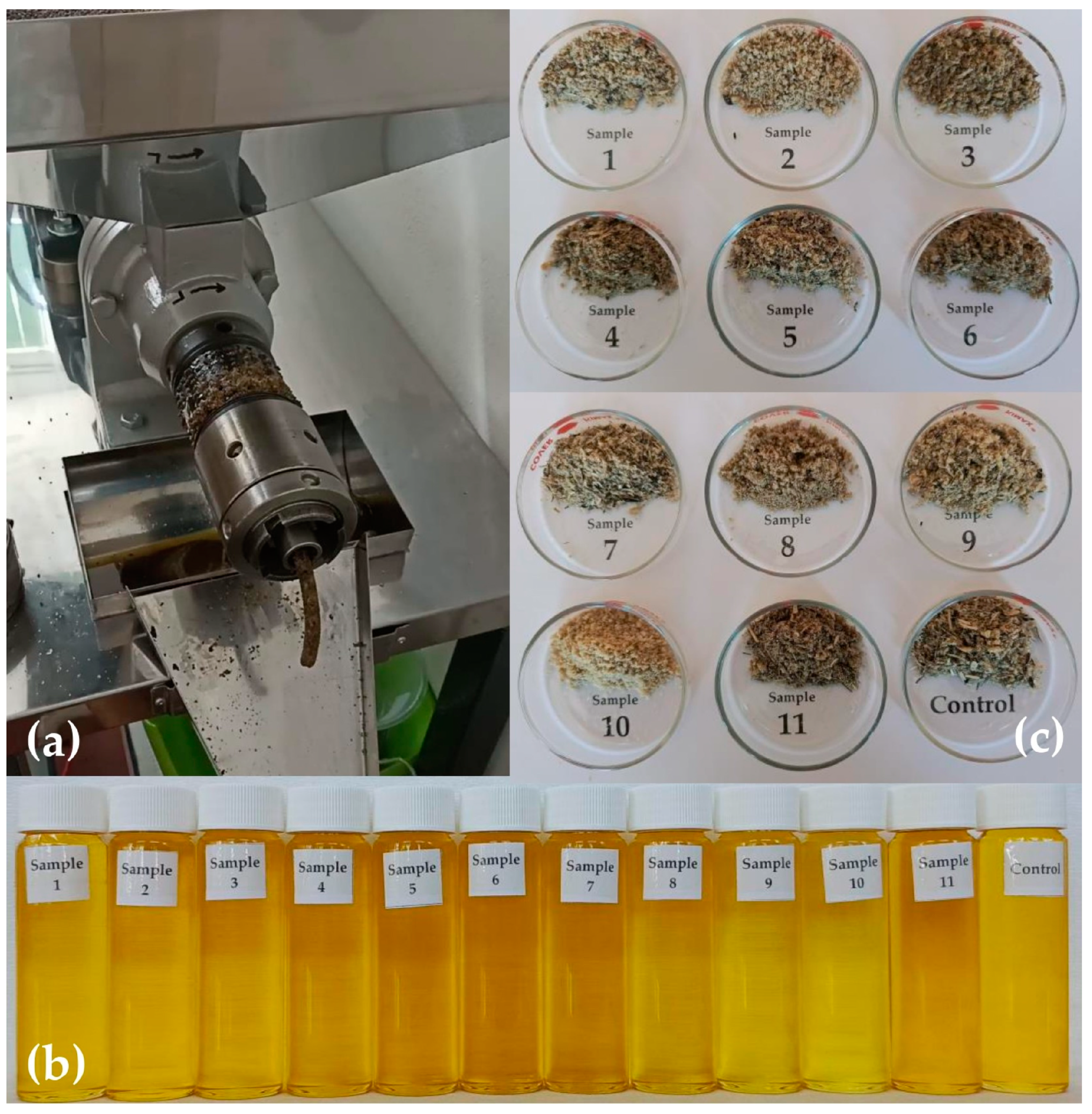

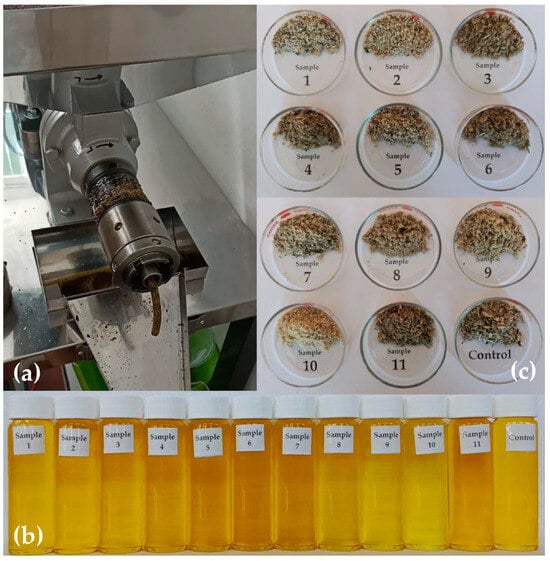

The cakes analyzed in this study were cold-pressed oils produced using a screw press with a maximum capacity of 30 kg/h, manufactured by Mikron SZR (Sole Proprietorship–Independent Craft Business), Temerin, Serbia (Figure 1). The average screw press speed was 40 rpm (0.67 Hz). The oil temperature at the press outlet was measured using a Pt-type K thermocouple probe and a digital thermometer 925 (Testo, Titisee-Neustadt, Germany) and ranged between 45 °C and 50 °C. Also, the cold-pressed oil obtained (Figure 1) was also collected, further processed, and used for additional investigations.

Figure 1.

Screw press used for cold-pressing (a), obtained cold-pressed oils (b) and press cakes (c) of high-oleic sunflower seed with different hull and impurities content.

2.2. Fatty Acid Composition

Identification was examined based on fatty acid composition, iodine value, and refractive index.

The fatty acid composition of the oil extracted from high-oleic sunflower seeds of the NS-H-6326 hybrid used in this study was determined. Gas chromatography-mass spectrometry (GC-MS) was used for the analysis, following the ISO 12966-4:2015 standard [34].

Fatty acid methyl esters, prepared in accordance with ISO 12966-2:2017 [35], were analyzed on a GC 7890B gas chromatograph equipped with a DB-23 capillary column (60 m × 0.25 mm i.d., film thickness 0.25 µm) and a MS 5977A mass-selective detector (Agilent Technologies, Palo Alto, CA, USA). Helium was used as the carrier gas at a flow rate of 1.0 mL/min.

The sample volume was 1 μL, with a split ratio of 1:50. The chromatographic procedure followed this temperature program:

- Injector temperature: 250 °C;

- Initial column temperature: 50 °C (held for 1 min);

- Increase to 200 °C at 25 °C/min;

- Further increase to 230 °C at 3 °C/min;

- Final hold at 230 °C for 7 min.

Mass spectra were recorded in SCAN mode over the m/z range of 50–400, with ionization energy of 70 eV. Fatty acids were identified based on mass spectra and retention times, while relative percentages (% w/w) were calculated using peak area normalization. Retention times were determined using a standard solution containing a 37-component mixture of fatty acid methyl esters (Supelco, Bellefonte, PA, USA).

2.3. Refractive Index

The refractive index was measured using an Abbe refractometer (Carl Zeiss, Jena, Germany), Ser. No. 734562 according to ISO 6320:2017 [36].

2.4. Iodine Value

The iodine value was determined volumetrically (iodometrically) according to ISO 3961:2024 [37].

2.5. Pressing Efficiency and Capacity

The pressing efficiency, or yield, of cold-pressed oil (Ep) was calculated based on the results obtained using Equation (1) [8,38]:

where:

Ep = [1 − [(Oc/(100 − Oc))/(Os/(100 − Os))]] × 100

- Ep is the efficiency (yield) of cold-pressed oil, expressed as a percentage (% w/w);

- Oc is the oil content in the cake, expressed as a percentage (%);

- Os is the oil content in the raw material (seeds), expressed as a percentage (% tel quel).

The oil content (Oc) in the cake and the seed (tel quel—with hulls and impurities) as raw material (Os) used for pressing was determined using the Soxhlet extraction method, following the ISO 659:2009 standard [39].

The pressing capacity, expressed as material flow rate (Qp), was also calculated as the ratio of S—the mass of the pressed material (kg), and t—the time required for pressing (h), using Equation (2):

Qp = S/t

Additionally, the capacity expressed in terms of the quantity of produced oil per unit of time (Q) was determined using Equation (3):

Q = (Qp × Ep)/100

The mass of the material (g) for pressing was measured using a technical scale (ET-1111, Tehtnica, Slovenia), and the pressing time (s) was measured with a stopwatch.

The moisture content in the cake (Mc) and the moisture content in the seed as raw material (Ms) were determined gravimetrically by drying them to a constant mass at a temperature of 103 ± 2 °C, in accordance with ISO 665:2020 [40].

2.6. Color Analysis

Prior to color measurement, the oil samples were conditioned at room temperature for 24 h. Instrumental color determination was performed according to the method described by Škaljac et al. [41]. The color was measured for each sample in three replicates. CIE Y-xy color coordinates were determined using a Minolta Chroma Meter CR-400 (Minolta Co., Ltd., Osaka, Japan) under D-65 illumination, with a standard angle of 2° and an 8 mm aperture on the measuring head. The instrument was prepared according to the manufacturer’s instructions and calibrated following the standard procedure. CIE Y-xy tristimulus system was used, and color characteristics were represented by Y (brightness, %), λ (dominant wavelength, nm), and P (color purity, %).

The color of the oil was also determined spectrophotometrically using a UV/VIS spectrophotometer, model T80+ (PG Instruments Limited, London, UK), by measuring the transparency (%T) of pure oil in glass cuvettes with a 10 mm optical path length at 455 nm, relative to an empty cuvette [42].

2.7. Statistics

The results are presented as the mean value ± standard deviation of three individual samples, except for Qp and Q, which were calculated for each individual pressing cycle (one pressing time t). The data were analyzed using one-way analysis of variance (ANOVA) with a Tukey HSD test to determine significant differences at a significance level of p < 0.05. Statistical analysis was performed using Microsoft Excel 2016, ver. 16.0 (Redmond, Washington, DC, USA), Statistica, ver. 14.0.0.15 (StatSoft, Tulsa, OK, USA), and NCSS 2024 (Kaysville, UT, USA), ver. 24.0.3.

2.7.1. Regression and Model Validation

Multiple linear regression (MLR) was used to predict the composition of the press cake (moisture and oil content) and pressing efficiency (pressing oil yield) as a function of hull and impurity content in the seed. When selecting variables for modeling, it is important to choose an optimal number of variables to prevent potential correlation among them [43]. Multicollinearity is expressed through the VIF value, which in the obtained models should not exceed 10 [44,45,46]. Model validation was performed by examining the following validation parameters: Pearson’s correlation coefficient (R), coefficient of determination (R2), adjusted coefficient of determination (R2adj), Fisher’s value (F), standard deviation (SD), probability (p), cross-validation coefficient of determination (R2cv), PRESS, PRESS/TSS (total sum of squares for prediction), and coefficient of variation (CV%) [47]. The models obtained are shown according to the following general Equation (4):

where Y is the independent variable; Xi are dependent variables; a and b are coefficients; and SE represents standard errors.

2.7.2. Clustered Heat Maps (Double Dendrograms)

The grouped heat maps display the clustering of samples based on seed characteristics (hull, impurities, oil, and moisture content), pressing conditions (efficiency (yield) of extracted oil, pressing time, pressing capacity, and oil produced per unit of time), and cake characteristics (oil and moisture content), as well as the clustering of the examined samples based on these parameters. The clustering method was chosen according to the recommendations of Ferguson and Mather [48]. They suggest using a method that provides the highest value of the coefficient of correlation of cophenetic coefficients, as well as the recommendations of Saracli et al. [49] on the selection of subgroup sizes, variable numbers, subgroup mean values, and variances. The coefficient of correlation is the correlation between the original distances and those resulting from the cluster configuration. Another measure of goodness-of-fit, called delta, is described in Ferguson and Mather [48]. These statistics measure the degree of distortion, rather than the degree of similarity (as in cophenetic correlation). Clustering was performed using the simple method of average values, Z-score scaling, and the differences between samples were expressed as the Euclidean distance. The match is considered reasonably good if the coefficient of correlation lies in the range of (0.7 to 0.8) on a scale from (0 to 1), good when it is in the range of (0.8 to 0.9), and very good for any value greater than 0.9 [50]. Additionally, values of delta 0.5 and delta 1 should be close to zero [48].

3. Results and Discussion

3.1. Fatty Acid Composition, Refractive Index, and Iodine Value

The fatty acid composition, refractive index, and iodine value of high-oleic sunflower oil obtained by cold-pressing of sunflower hybrid seeds (NS-H-6326) are presented in Table 2.

Table 2.

Fatty acid composition, refractive index and iodine value of high-oleic sunflower oil.

According to Codex Alimentarius [9], the oleic acid content in high-oleic sunflower oil should range between 75% w/w and 90.7% w/w, while the linoleic acid content should range between 2.1% w/w and 17% w/w. In the examined high-oleic sunflower oil, the oleic acid content was determined to be 83.32 ± 0.02% w/w, while the linoleic acid content was 7.46 ± 0.13% w/w. Among other unsaturated fatty acids, palmitoleic acid (C16:1) and alpha-linolenic acid (C18:3) were found in smaller amounts, contributing to a total content of 83.46 ± 0.06% w/w of monounsaturated and 7.81 ± 0.14% w/w of polyunsaturated fatty acids. Among the saturated fatty acids (total 8.71 ± 0.09% w/w), palmitic acid (C16:0) was detected with a content of 4.32 ± 0.07% w/w, stearic acid was detected at 4.04 ± 0.04% w/w, and traces of myristic and arachidic acids were found. Similar results have been reported by Lužaić et al. [51] and Liu et al. [52].

The iodine value and refractive index at 40 °C were also examined as key parameters for oil identification. Additionally, the iodine value indicates oil quality. The obtained value of 86 ± 1 g I2/100 g suggests a good oxidative potential of the analyzed sample. Both the iodine value and the refractive index of 1.462 ± 0.000 are consistent with previous studies [5,51] and the prescribed values outlined in the Codex Alimentarius [9].

3.2. Pressing Efficiency, Capacity, and Cold-Pressed Oil Yield

The preparation of the material for pressing, granulation composition, and hydrothermal treatment conditions, in addition to the press design and pressing conditions, significantly affect the oil yield during pressing [53,54,55]. The moisture and oil content in the seeds, which result from the seed’s characteristics and preparation, dictate the pressing conditions and further influence the yield of cold-pressed oil.

The moisture content in the initial material ranged from 4.98 ± 0.09% in Sample 10 to 6.49 ± 0.15% in Sample 11 (Table 3).

Table 3.

Sunflower seed characteristics and composition (hull, impurities, moisture, and oil content), cold-pressed cake composition (moisture and oil content), indicators of cold-pressed yield (pressing efficiency and pressing capacity), and color of cold pressed oil of the investigated samples.

The oil content in the initial seed samples varied from 41.38 ± 0.58% tel quel to 50.96 ± 0.07% tel quel in samples containing hull and impurities to 55.08 ± 0.90 g in clean kernels. Since the highest moisture content and the lowest oil content were observed in the sample with the highest hull (20%) and impurity (10%) content, while the lowest moisture content and highest oil content were found in the sample without hulls and impurities, these results confirm the significant influence of hull and impurity content on both the pressing process and oil yield [8,56,57].

The pressing efficiency (yield of pressed oil) ranged from 39.24 ± 2.27% (w/w) in the sample without hulls and impurities (sample 10) to 65.12 ± 0.06–76.52 ± 0.67% (w/w) in samples with the following compositions: 5% hulls and 2.5% impurities (sample 2), 10% hulls without impurities (0%) (sample 9), 15% hulls and 2.5% impurities (sample 7), and 20% hulls and 5% impurities (sample 5). Pressing of the raw material with hull contents of 5%, 10%, 15%, and 20%, and impurity contents of 0%, 2.5%, and 5%, resulted in yields exceeding the average of 64.75 ± 15.00% (w/w). The highest oil yield, 76.52 ± 0.67% (w/w), was achieved by pressing material with 20% hull and 5% impurity content, as well as material with 15% hull and 2.5% impurity content, yielding 74.66 ± 0.36% (w/w). These results indicate that, in this case, the presence of hulls in the material contributes to improved oil yield, although the oil yield also depends on the oil content in the raw material. Lužaić et al. [8] investigated the yield of cold-pressed oil from the seeds of 20 newly developed sunflower hybrids and reported yields ranging from 20.10 ± 2.82% in seeds with 46.74 ± 0.99% hull content to 75.61 ± 1.99% in seeds with 30.10 ± 0.27% hull content. In their study, the oil yield was lower in samples with high hull content because they involved a confectionary hybrid with significantly lower oil content (23.84 ± 0.38%) compared to an oilseed hybrid where yields exceeded 75% (41.66 ± 3.16% oil). Pressing oil yield and optimization are also studied in other plant species. Crimaldi et al. [58] determined an oil yield of 73.38 ± 0.31% (w/w) for tobacco seeds at a pressing temperature of 70 °C and a screw speed of 32 rpm. On the other hand, Kabutey et al. [59] investigated the oil yield of sesame, pumpkin, flax, milk thistle, and hemp during cold-pressing and obtained values ranging from 13.37 ± 0.35% to 30.60 ± 1.69%, which is significantly lower compared to the lowest value obtained in the tested sample without hulls and impurities (sample 10).

The efficiency of continuous screw presses operating as pre-presses is approximately 50–60% relative to the oil content, while final presses can achieve an efficiency of 80–90% [42]. Karaj and Müller [38] investigated the oil yield (32.2–89.4% w/w) by pressing Jatropha curcas L. seeds under various screw press characteristics, including screw diameter, rotational speed, diameter of oil and cake outlet openings, and press head temperature. Pressing process parameters, particularly temperature, significantly influence the quality of the produced oil [30]. Gikuru and Lamech [60] studied the effects of temperature, compression pressure, and the duration of applied force on soybean oil yield and optimized the process by keeping some parameters constant while varying others. Their results demonstrated that increasing process parameters leads to higher oil yield, but exceeding an optimal temperature reduces yield. If the moisture content of the material is not adequate, pressing becomes difficult or even impossible [61]. Friction within the material and press is high, inevitably causing a temperature rise. However, during these investigations, no excessive temperature increase was observed, as the oil temperature at the press outlet was maintained at 45–50 °C. Reduced friction likely contributed to the improved oil yield. In this case, the hull in the pressing material acted as a „flow-enhancing material” [62]. Additionally, heating the material so that the oil temperature at the outlet was 45–50 °C provided a mild conditioning effect, facilitating oil extraction and improving yield. Šmit et al. [62], however, noted the necessity of partially removing the hulls to produce high-quality cold-pressed oil.

The results for pressing capacity are presented in Table 3. Pressing capacity (material flow rate and oil quantity produced) was calculated based on the retention time of a specific mass of material in the press and the determined pressing yield. The achieved pressing capacity, expressed as seed flow rate, is significantly lower than the maximum press capacity (30 kg/h). In the tested samples, it ranged from 5.35 kgseeds/h, calculated for sample 2 (sample with 5% hull and 2.5% impurities), to 13.04 kgseeds/h obtained in sample 7 (sample with 15% hull and 2.5% impurities). Additionally, the quantities of oil produced corresponded to these values. Thus, between 3.48 kg of oil (sample 2) and 9.74 kg of oil (sample 7) were produced per hour. Despite the high material flow rate of 11.43 kgseeds/h for sample 10 (sample without, 0% hull and without, 0% impurities), the oil quantity produced was significantly lower (4.48 kgoil/h), highlighting the importance of material composition in achieving optimal capacity.

3.3. Color of Cold-Pressed Oils

Color is one of the key factors influencing food acceptability. Moreover, it can be used to assess the composition and chemical changes in food products, serving as an important quality indicator [63]. Typically, color intensity is quantified using units proposed by the Commission Internationale de l’Éclairage (CIE). Colors are defined by their tristimulus values (X, Y, and Z), which can be used to calculate corresponding derived values. In this study, the color of the examined oil samples was significantly influenced by the hull and impurity content, as oil extraction during pressing incorporated some of these substances. The highest brightness (Y) values (4.01 ± 0.09% and 4.02 ± 0.16%) were observed in samples with the lowest hull and impurity content (sample 10: 0% hulls, 0% impurities; sample 9: 10% hulls, 0% impurities, respectively), as shown in Table 3. Significantly lower values were recorded for other samples, with the lowest brightness confirmed in the sample with the highest total hull and impurity content (sample 11). The dominant wavelength (λ) ranged within a narrow interval of 566 ± 1 nm to 571 ± 1 nm. The lowest color purity (P) was observed in the sample without hulls and impurities (sample 10), measuring 12.60 ± 1.97%, while the highest value (24.73 ± 0.20%) was found in sample 5 (20% hull, 5% impurities). The color parameters of the control sample fell within the examined range. Similar brightness (Y) values were reported for olive oils, ranging between 3.19 ± 0.06% and 4.14 ± 0.00%. However, the dominant wavelength (λ) of olive oil was significantly lower compared to sunflower oil, with values between 22.47 ± 0.00 nm and 24.13 ± 0.00 nm [64].

In most edible vegetable oils, carotenoids are the primary color-bearing compounds. These pigments exhibit maximum absorption at wavelengths between 440 and 460 nm, making transparency measurements within this range a standard practice. The highest transparency value among the examined samples was observed in the sample without hulls and impurities (sample 10), measuring 71.96 ± 0.14%. This value is close to the transparency level of refined oils, which should exceed 80% [42], indicating an exceptionally light-colored oil. As expected, the lowest transparency (32.00 ± 0.05%) was recorded in the sample with the highest hull and impurity content (sample 11). The transparency of the control sample was measured at 35.11 ± 0.26%.

3.4. Prediction of Cake Composition and Pressing Efficiency (Oil Yield) Using Multiple Linear Regression (MLR)

Using multiple linear regression (MLR), a mathematical method that accounts for multiple independent variables influencing one dependent variable. Models were developed to predict moisture (Mc) and content of oil (Oc) remaining in the cake and pressing efficiency—oil yield (Ep) based on the hull (h) and impurity (i) content in the seeds. Experimental data and calculated data (Table 3) were used to form MLR models for predicting selected dependent variables (Equations (5)–(7)).

Model 1 Mc = 0.087 (±0.010) × h(%) + 0.039 (±0.020) × i(%) + 5.382 (±0.127)

Model 2 Oc = −1.073 (±0.185) × h(%) − 0.581 (±0.370) × i(%) + 37.050 (±2.327)

Model 3 Ep = 1.361 (±0.338) × h(%) + 0.422 (±0.677) × i(%) + 49.779 (±4.257)

Validation parameters of the obtained MLR models are presented in Table 4.

Table 4.

Validation parameters of the obtained MLR models.

Based on the values of R and R2, the proposed MLR models describe strong to very strong correlations between variables, and the prediction of moisture and oil content in the cake, as well as pressing yield, can be achieved with acceptable prediction error. The high values of R2adj (0.9141 and 0.8324) and R2cv (0.8499 and 0.8629) in Models 1 and 2, as well as the PRESS/TSS ratios close to zero (0.1501 and 0.3071) indicate a high predictive capability of the models. In contrast, Model 3 shows slightly weaker statistical parameters (R2adj = 0.6679, R2cv = 0.3965, PRESS/TESS = 0.6035), suggesting a lower predictive capability for this model. For predicting pressing efficiency, further improvements can be made by increasing the number of variables or samples. The obtained VIF values (1.1905) suggest that multicollinearity among the variables is negligible. Relatively high F-values (54.20, 25.83, and 11.06) confirm a good fit of the data to the models. Similar results were reported by Lužaić et al. [8]. Using artificial neural networks, they modeled the extraction oil yield of 20 sunflower hybrids based on the initial seed characteristics, including hull content. They obtained a high-quality model with the following validation parameters: R2 = 0.975; root mean square error = 3.436; mean bias error = −0.266; mean percentage error = 6.827; sum of squared error = 234.673; average absolute relative deviation = 43.399.

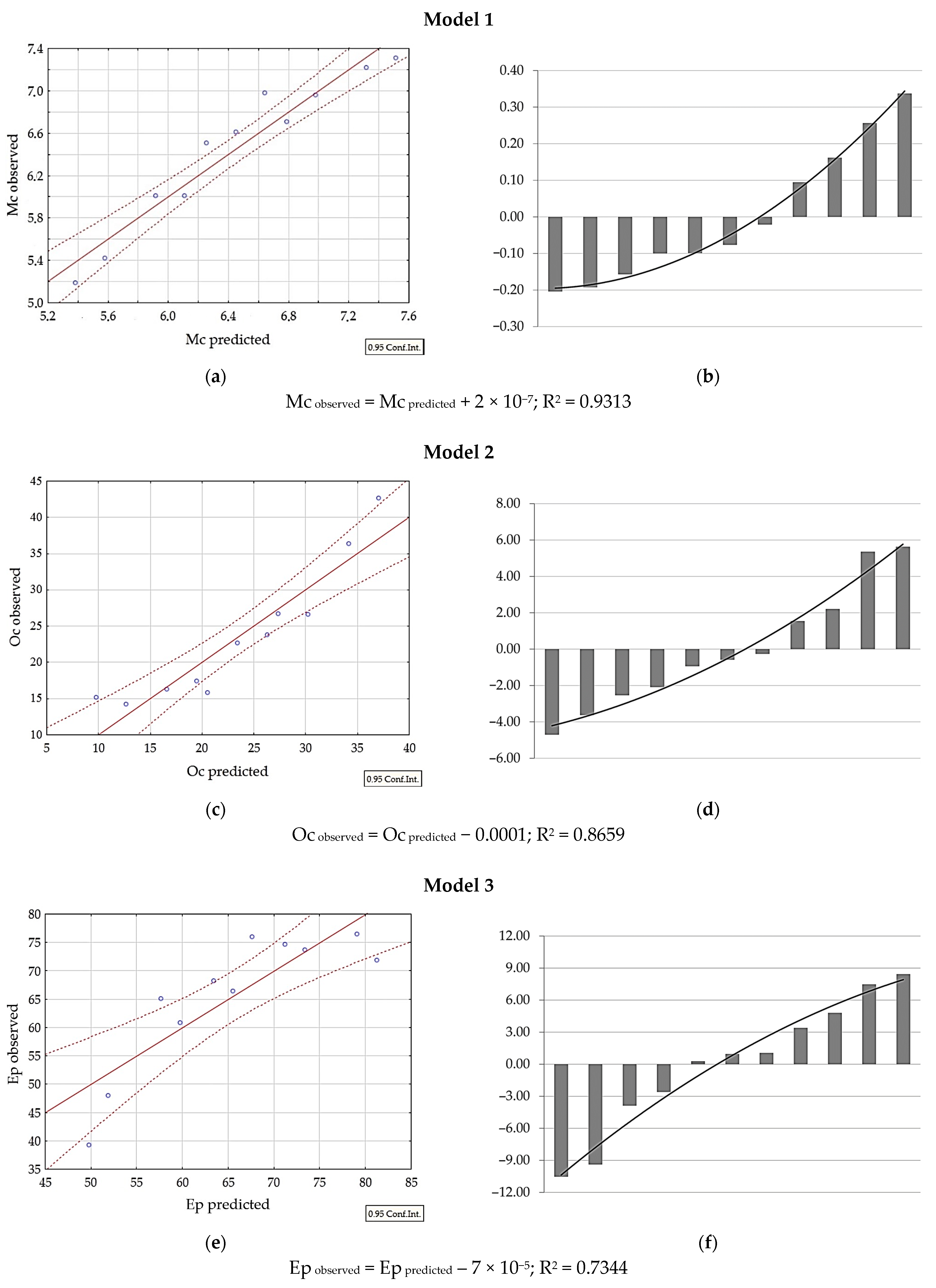

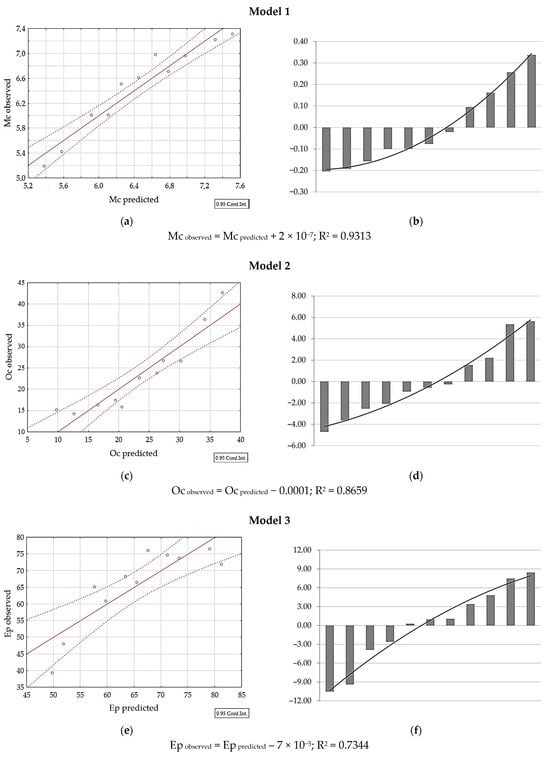

For the obtained models, the dependence between experimental and predicted values was determined and is shown in Figure 2.

Figure 2.

Validation of the obtained MLR models: Dependence between experimental and model-predicted values (a,c,e) and residual distribution around the y = 0 axis (b,d,f). In (a,c,e), the experimental and model-predicted values are represented by points, their dependence is shown with a solid line, while the dashed lines indicate the interval within which the values are expected to fall with 95% confidence.

Ideally, the dependence should coincide with the equation y = x with a determination coefficient of 1, while residuals (differences between experimental and predicted values) should evenly scatter around the y = 0 axis [65].

The dependencies between experimental and predicted values for the models are very close to theoretical values; the slopes are equal to one, while the intercepts are near zero. The residuals are evenly distributed around the y = 0 axis.

The findings of this study also have significant industrial implications for large-scale mechanical oil extraction processes but with adjustments of the models to the production conditions. The optimization of hull and impurity content in sunflower seeds can directly impact the efficiency of cold pressing, which is a critical factor for oil manufacturers seeking to maximize yield while minimizing waste. The hull and impurity content also affects the chemical quality and color of the oil [31], which is crucial for consumer acceptance. The higher nutritional quality and consumer preference for cold-pressed oils allow for premium market pricing, which economically justifies research aimed at optimizing the hull and impurity content in sunflower seeds.

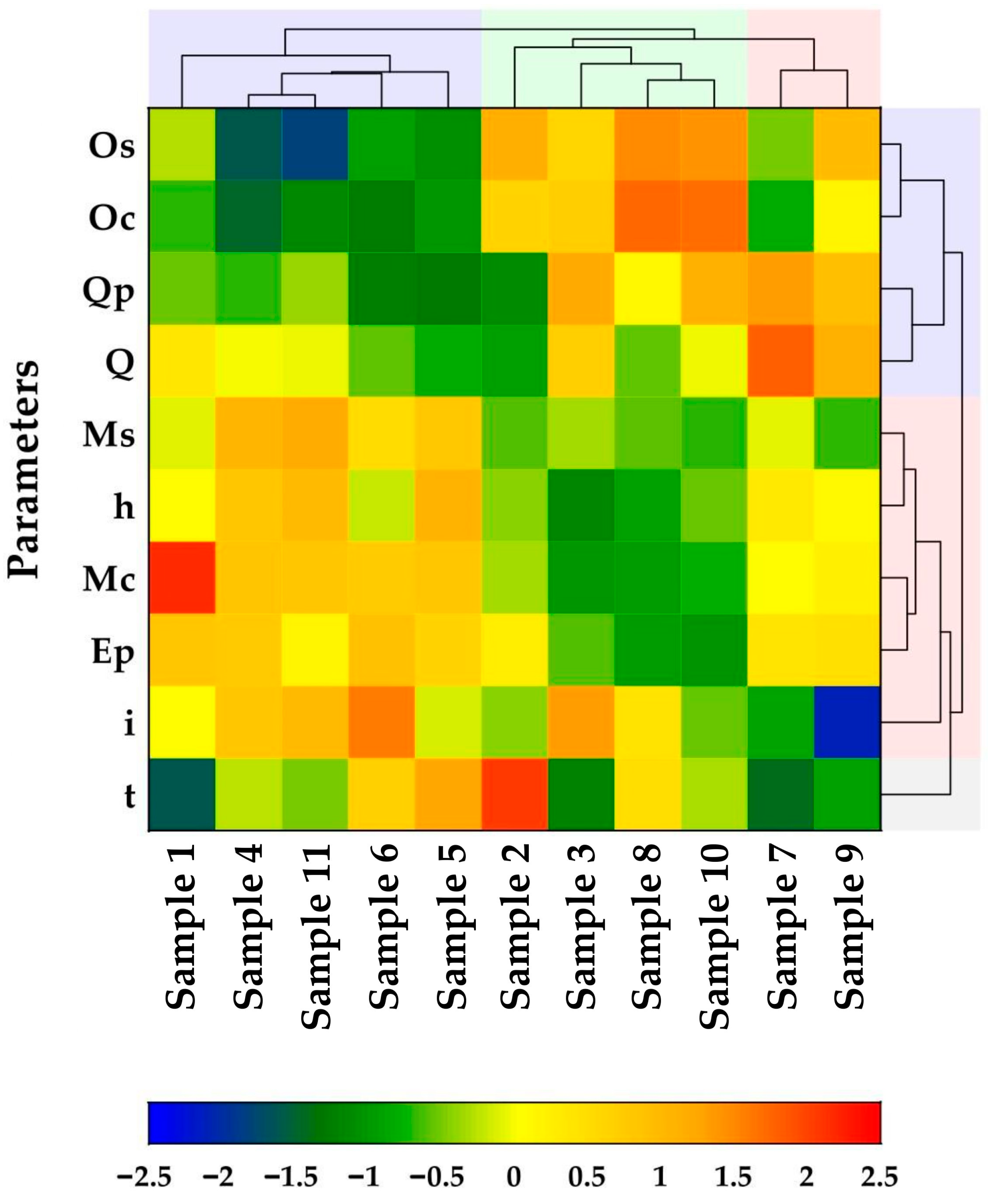

3.5. Clustered Heat Maps

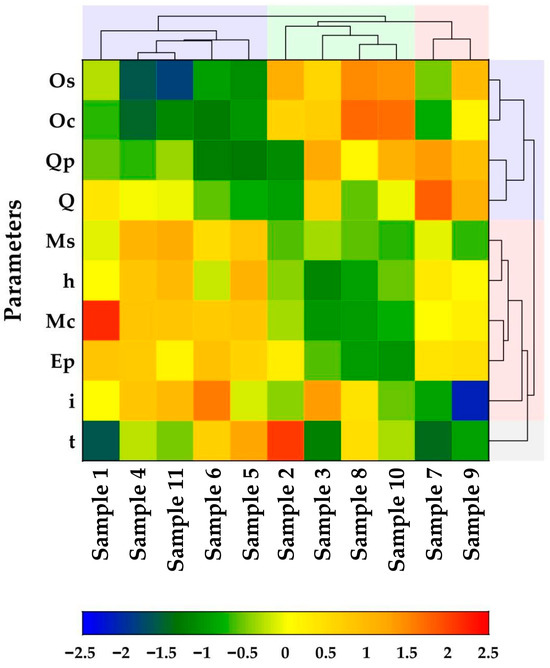

The cluster map shown in Figure 3 indicates the similarities among the samples based on seed characteristics, pressing conditions, and cake characteristics.

Figure 3.

Clustered heat map based on the seeds characteristics and composition (h—hull content, i—impurity content, Ms—moisture content, Os—oil content), cake composition (Mc—moisture content, Oc—oil content), and pressing characteristics (Ep—pressing efficiency, t—pressing time, Qp—material flow rate, Q—quantity of produced oil) of the tested samples.

Based on the aforementioned parameters, the examined samples were divided into three groups. The first group includes samples 1, 4, 5, 6, and 11. These samples were found to have a total hull and impurity content over 15%. The greatest similarity within the first cluster was observed between samples 4 and 11, which have the highest total hull and impurity content (22.5% and 20%, respectively), with a Euclidean distance value of only 0.27. The least similarity was found between samples 1 and 5. The total hull and impurity content in these samples differs the most (15% and 25%, respectively), and the Euclidean distance value was 1.21. The second group includes samples 2, 3, 8, and 10, which are very similar in the examined characteristics. Among the samples in this group, the greatest similarity (0.55 Euclidean distance) was observed between the samples with the lowest hull and impurity content, 0% (sample 10) and 5% (sample 8), while the greatest difference was found between samples 2 and 3 (1.55 Euclidean distance). The third group consists of samples 7 and 9, which have a low impurity content (2.5% and 0%, respectively) compared to their hull content (15% and 10%, respectively). These findings highlight a synergistic interaction between hull and impurity content, emphasizing their combined impact on pressing yield and capacity, as well as cake characteristics.

Similarity between parameters was also examined. The oil content in the seed and cake, pressing capacity, and oil produced per unit of time formed one cluster, while the hull content, impurities, moisture content in the seed and cake, as well as efficiency (yield) of extracted oil, clustered together in a second cluster. Pressing time did not belong to any cluster.

A statistical validation of the cluster analysis was also performed. High cophenetic correlation coefficients of 0.869 (in the cluster analysis of samples) and 0.871 (in the cluster analysis of parameters), as well as low values of delta 0.5 and delta 1.0 of 0.123 and 0.152, respectively (for parameters), and 0.107 and 0.141, respectively (for samples), indicate a good fit of the data.

4. Conclusions

This study demonstrated that hull and impurity content significantly influence the cold-pressing efficiency and oil yield of high-oleic sunflower seeds. The highest oil yield (76.52%) was obtained from seeds with 20% hulls and 5% impurities, while the lowest (39.24%) was from completely cleaned seeds, highlighting the positive role of hulls in enhancing oil drainage. Multiple linear regression models accurately predicted pressing efficiency, with R2 values of up to 0.93, confirming strong correlations between seed composition and oil yield. Cluster analysis grouped samples based on hull and impurity content, pressing efficiency, and cake characteristics, revealing three distinct patterns of processing performance. These findings provide valuable insights for optimizing cold-pressing conditions, improving oil recovery, and enhancing the sustainability of sunflower oil production. The practical implications of this research include recommendations for oil producers to strategically adjust seed preparation methods to maximize efficiency. By fine-tuning hull and impurity levels, manufacturers can optimize oil yield without compromising product quality. Additionally, the findings could inform the development of industry guidelines for sunflower seed processing in cold-pressing applications. Future research should explore large-scale validation of these findings in industrial settings, assessing the scalability of hull and impurity optimization under different processing conditions.

Author Contributions

Conceptualization, R.R.; methodology, T.L., S.K. and R.R.; software, T.L.; validation, T.L., G.N., S.J., S.K. and R.R.; formal analysis, T.L., S.K. and R.R.; investigation, R.R.; resources, T.L., G.N., S.J., S.K. and R.R.; data curation, T.L. and R.R.; writing—original draft preparation, T.L. and G.N.; writing—review and editing, S.J., S.K. and R.R.; visualization, T.L. and R.R.; supervision, R.R.; project administration, R.R.; funding acquisition, G.N. and R.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

This research was supported by the Ministry of Science, Technological Development, and Innovation of the Republic of Serbia, under contract numbers 451-03-136/2025-03/200134 and 451-03-137/2025-03/200134. Also, this work was created as a collaboration supported by COST (European Cooperation in Science and Technology) under COST Action 20133: Cross Border Transfer and Development of Sustainable Resource Recovery Strategies Towards Zero Waste (FULLRECO4US), https://fullreco4us.eu/ (accessed on 15 February 2025).

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| h | hull content (%) |

| i | impurity content (%) |

| Ms | moisture content in the seed (%) |

| Mc | moisture content in the cake (%) |

| Os | oil content in the seed (% tel quel) |

| Oc | oil content in the cake (%) |

| Ep | pressing efficiency (% w/w) |

| S | seed mass/mass of the pressed material (kg) |

| t | pressing time (h) |

| Qp | material flow rate (kgseeds/h) |

| Q | quantity of produced oil (kgoil/h) |

| Y | brightness (%) |

| λ | dominant wavelength (nm) |

| P | color purity (%) |

| T | transparency (%) |

| MLR | multiple linear regression |

| R | Pearson’s correlation coefficient |

| R2 | determination coefficient |

| R2adj | adjusted coefficient of determination |

| F | Fisher’s value |

| SD | standard deviation |

| p | probability |

| R2cv | cross-validation coefficient of determination |

| TSS | total squares sum |

| PRESS | predicted residual squares sum |

| CV | coefficient of variation |

| VIF | variance inflation factor |

References

- Yang, Y.; Zhang, L.; Li, P.; Yu, L.; Mao, J.; Wang, X.; Zhang, Q. A review of chemical composition and nutritional properties of minor vegetable oils in China. Trends Food Sci. Technol. 2018, 74, 26–32. [Google Scholar] [CrossRef]

- Dorni, C.; Sharma, P.; Saikia, G.; Longvah, T. Fatty acid profile of edible oils and fats consumed in India. Food Chem. 2018, 238, 9–15. [Google Scholar] [CrossRef]

- O’Brien, R.D. Fats and Oils: Formulating and Processing for Applications, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2009; pp. 1–147. [Google Scholar]

- Majchrzak, T.; Wojnowski, W.; Dymerski, T.; Gębicki, J.; Namieśnik, J. Electronic noses in classification and quality control of edible oils: A review. Food Chem. 2018, 246, 192–201. [Google Scholar] [CrossRef]

- Konuskan, D.B.; Arslan, M.; Oksuz, A. Physicochemical properties of cold pressed sunflower, peanut, rapeseed, mustard and olive oils grown in the Eastern Mediterranean region. Saudi J. Biol. Sci. 2019, 26, 340–344. [Google Scholar] [CrossRef] [PubMed]

- USDA. Oilseeds: World Markets and Trade. World Agricultural Outlook Board; United States Department of Agriculture: Washington, DC, USA, 2025. Available online: https://apps.fas.usda.gov/psdonline/circulars/oilseeds.pdf (accessed on 3 February 2025).

- FAO. Food Outlook, Biannual Report on Global Food Markets; Food and Agriculture Organization of United Nations: Rome, Italy, 2024; Available online: https://openknowledge.fao.org/server/api/core/bitstreams/f8c73abe-d26d-4d47-9272-c9b464cc0fc1/content (accessed on 3 February 2025).

- Lužaić, T.; Romanić, R.; Grahovac, N.; Jocić, S.; Cvejić, S.; Hladni, N.; Pezo, L. Prediction of mechanical extraction oil yield of new sunflower hybrids: Artificial neural network model. J. Sci. Food Agric. 2021, 101, 5827–5833. [Google Scholar] [CrossRef]

- Codex Alimentarius. Standard for Named Vegetable Oils Codex Stan 210-1999; Codex Alimentarius: Rome, Italy, 1999. [Google Scholar]

- Salas, J.; Bootello, M.; Garcés, R. Food Uses of Sunflower Oils. In Sunflower Chemistry, Production, Processing, and Utilization; Martínez-Force, E., Turgut Dunford, N., Salas, J.J., Eds.; AOCS Press: Urbana, IL, USA, 2015; pp. 441–464. [Google Scholar]

- Sales-Campos, H.; Reis de Souza, P.; Crema Peghini, B.; Santana da Silva, J.; Ribeiro Cardoso, C. An overview of the modulatory effects of oleic acid in health and disease. Mini Rev. Med. Chem. 2013, 13, 201–210. [Google Scholar]

- FDA. Completes Review of Qualified Health Claim Petition for Oleic Acid and the Risk of Coronary Heart Disease; Food and Drug Administration: Silver Spring, MD, USA, 2018. Available online: https://www.fda.gov/food/hfp-constituent-updates/fda-completes-review-qualified-health-claim-petition-oleic-acid-and-risk-coronary-heart-disease (accessed on 3 February 2025).

- Yu, K.S.; Cho, H.; Hwang, K.T. Physicochemical properties and oxidative stability of frying oils during repeated frying of potato chips. Food Sci. Biotechnol. 2017, 27, 651–659. [Google Scholar] [CrossRef]

- Romano, R.; Filosa, G.; Pizzolongo, F.; Durazzo, A.; Lucarini, M.; Severino, P.; Souto, E.B.; Santini, A. Oxidative stability of high oleic sunflower oil during deep-frying process of purple potato Purple Majesty. Heliyon 2021, 7, e06294. [Google Scholar] [CrossRef] [PubMed]

- Ramadan, M.F. Healthy blends of high linoleic sunflower oil with selected cold pressed oils: Functionality, stability and antioxidative characteristics. Ind. Crops Prod. 2013, 43, 65–72. [Google Scholar] [CrossRef]

- Kiralan, M.; Çalik, G.; Kiralan, S.; Ramadan, M.F. Monitoring stability and volatile oxidation compounds of cold-pressed flax seed, grape seed and black cumin seed oils upon photo-oxidation. J. Food Meas. Charact. 2018, 12, 616–621. [Google Scholar] [CrossRef]

- El Makawy, A.I.; Ibrahim, F.M.; Mabrouk, D.M.; Ahmed, K.A.; Fawzy Ramadan, M. Effect of antiepileptic drug (Topiramate) and cold pressed ginger oil on testicular genes expression, sexual hormones and histopathological alterations in mice. Biomed. Pharmacother. 2019, 110, 409–419. [Google Scholar] [CrossRef] [PubMed]

- Bhatnagar, A.S.; Gopala Krishna, A.G. Lipid classes and subclasses of cold-pressed and solvent-extracted oils from commercial Indian Niger (Guizotia abyssinica (L.f.) Cass.) seed. J. Am. Oil Chem. Soc. 2014, 91, 1205–1216. [Google Scholar] [CrossRef]

- Prescha, A.; Grajzer, M.; Dedyk, M.; Grajeta, H. The antioxidant activity and oxidative stability of cold-pressed oils. J. Am. Oil Chem. Soc. 2014, 91, 1291–1301. [Google Scholar] [CrossRef]

- Ramadan, M.F. Introduction to cold pressed oils: Green technology, bioactive compounds, functionality, and applications. In Cold Pressed Oils: Green Technology, Bioactive Compounds, Functionality, and Applications; Ramadan, M.F., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 1–5. [Google Scholar]

- Brühl, L. Determination of trans fatty acids in cold pressed oils and in dried seeds. Fett/Lipid 1996, 98, 380–383. [Google Scholar] [CrossRef]

- Rotkiewicz, D.; Konopka, I.; Zylik, S. State of works on the rapeseed oil processing optimization. I. Oil obtaining. Rośliny Oleiste/Oilseed Crops 1999, 20, 151–168. [Google Scholar]

- Bhuiya, M.M.K.; Rasul, M.G.; Khan, M.M.K.; Ashwath, N.; Azad, A.K.; Mofijur, M. Optimisation of Oil Extraction Process from Australian Native Beauty Leaf Seed (Calophyllum inophyllum). Energy Procedia 2015, 75, 56–61. [Google Scholar] [CrossRef]

- Guédé, S.S.; Soro, Y.R.; Kouamé, A.F.; Brou, K. Optimization of Screw Press Extraction of Citrillus Lanatus Seed Oil and Physiochemical Characterization. Eur. Food Res. Technol. 2017, 5, 35–46. [Google Scholar]

- Çakaloğlu, B.; Özyurt, V.H.; Ötleş, S. Cold press in oil extraction. A review. Ukr. Food J. 2018, 7, 640–654. [Google Scholar] [CrossRef]

- Elhassan, S.H.A.R. Mechanical Expression of Oil from Sesame (Sesamum indicum L.). Ph.D. Thesis, University of Khartoum: Khartoum, Sudan, 2009. [Google Scholar]

- Nde, D.B.; Foncha, A.C. Optimization methods for the extraction of vegetable oils: A review. Processes 2020, 8, 209. [Google Scholar] [CrossRef]

- Fils, J.M. The production of oils. In Edible Oil Processing; Hamm, W., Hamilton, R.J., Eds.; Sheffield Academic Press: Sheffield, UK, 2000; pp. 47–48. [Google Scholar]

- Zheng, Y.; Wiesenborn, P.; Tostenson, K.; Kangas, N. Screw pressing of whole and dehulled flaxseed for organic oil. J. Am. Oil Chem. Soc. 2003, 80, 1039–1045. [Google Scholar] [CrossRef]

- Matthäus, B.; Brühl, L. Cold-pressed edible rapeseed oil production in Germany. INFORM 2004, 15, 266–268. [Google Scholar]

- Dimić, E.; Premović, T.; Takači, A. Effects of the contents of impurities and seed hulls on the quality of cold-pressed sunflower oil. Czech J. Food Sci. 2012, 30, 343–350. [Google Scholar] [CrossRef]

- Popović, S.; Hromiš, N.; Šuput, D.; Bulut, S.; Romanić, R.; Lazić, V. Valorization of by-products from the production of pressed edible oils to produce biopolymer films. In Cold Pressed Oils: Green Technology, Bioactive Compounds, Functionality, and Applications; Ramadan, M.F., Ed.; Academic Press: London, UK, 2020; pp. 15–30. [Google Scholar]

- Pedroche, J. Utilization of Sunflower Proteins. In Sunflower Chemistry, Production, Processing, and Utilization; Martínez-Force, E., Turgut Dunford, N., Salas, J.J., Eds.; AOCS Press: Urbana, IL, USA, 2015; pp. 395–439. [Google Scholar]

- ISO 12966-4:2015; Animal and Vegetable Fats and Oils—Gas Chromatography of Fatty Acid Methyl Esters—Part 4: Determination by Capillary Gas Chromatography. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO 12966-2:2017; Animal and Vegetable Fats and Oils—Gas Chromatography of Fatty Acid Methyl Esters—Part 2: Preparation of Methyl Esters of Fatty Acids. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 6320:2017; Animal and Vegetable Fats and Oils—Determination of Refractive Index. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 3961:2024; Animal and Vegetable Fats and Oils—Determination of Iodine Value. International Organization for Standardization: Geneva, Switzerland, 2024.

- Karaj, S.; Müller, J. Optimizing mechanical oil extraction of Jatropha curcas L. seeds with respect to press capacity, oil recovery and energy efficiency. Ind. Crop. Prod. 2011, 34, 1010–1016. [Google Scholar] [CrossRef]

- ISO 659:2009; Oilseeds—Determination of Oil Content (Reference Method). International Organization for Standardization: Geneva, Switzerland, 2009.

- ISO 665:2020; Oilseeds—Determination of Moisture and Volatile Matter Content. International Organization for Standardization: Geneva, Switzerland.

- Škaljac, S.; Jokanović, M.; Tomović, V.; Ivić, M.; Tasić, T.; Ikonić, P.; Šojić, B.; Džinić, N.; Petrović, L. Influence of smoking in traditional and industrial conditions on colour and content of polycyclic aromatic hydrocarbons in dry fermented sausage “Petrovská klobása”. LWT 2018, 87, 158–162. [Google Scholar] [CrossRef]

- Dimić, E.; Turkulov, J. Kontrola Kvaliteta u Tehnologiji Jestivih Ulja; University of Novi Sad, Faculty of Technology Novi Sad: Novi Sad, Serbia, 2000. [Google Scholar]

- Minovski, N.; Jezierska-Mazzarello, A.; Vračko, M.; Solmajer, T. Investigation of 6-fluoroquinolones activity against Mycobacterium tuberculosis using theoretical molecular descriptors: A case study. Open Chem. 2011, 9, 855–866. [Google Scholar] [CrossRef]

- Marquardt, D.W.; Snee, R.D. Ridge regression in practice. Am. Stat. 1975, 29, 3–19. [Google Scholar] [CrossRef]

- O’Brien, R.M. A caution regarding rules of thumb for variance inflation factors. Qual. Quant. 2007, 41, 673–690. [Google Scholar] [CrossRef]

- Young, T.M.; Shaffer, L.B.; Guess, F.M.; Bensmail, H.; Léon, R.V. A Comparison of multiple linear regression and quantile regression for modeling the internal bond of medium density fiberboard. For. Prod. J. 2008, 58, 39–48. [Google Scholar]

- Jevrić, L.R.; Karadžić, M.; Podunavac-Kuzmanović, S.O.; Tepić Horecki, A.N.; Kovačević, S.Z.; Vidović, S.S.; Šumić, Z.M.; Ilin, Ž.M. New guidelines for prediction of antioxidant activity of Lactuca sativa L. varieties based on phytochemicals content and multivariate chemometrics. J. Food Process. Preserv. 2018, 42, e13355. [Google Scholar] [CrossRef]

- Ferguson, R.I.; Mather, P.M. Computational Methods of Multivariate Analysis in Physical Geography. J. Biogeogr. 1977, 4, 201–202. [Google Scholar] [CrossRef]

- Saraçli, S.; Doǧan, N.; Doǧan, I. Comparison of hierarchical cluster analysis methods by cophenetic correlation. J. Inequal. Appl. 2013, 2013, 203. [Google Scholar] [CrossRef]

- Rohlf, J.F. NTSYSpc, Numerical Taxonomy and Multivariate Analysis System Version 2.0 User Guide; Natural History: London, UK, 1998. [Google Scholar]

- Lužaić, T.Z.; Grahovac, N.L.; Hladni, N.T.; Romanić, R.S. Evaluation of oxidative stability of new cold-pressed sunflower oils during accelerate thermal stability tests. Food Sci. Tech.—Brazil 2022, 42, e67320. [Google Scholar] [CrossRef]

- Liu, J.; Meng, P.; Yang, G.; Yang, R.; Chen, J.; Sun, C.; Liu, W. Effects of interesterification with solid base catalyst on physicochemical properties of lard and high-oleic sunflower oil blends. LWT—Food Sci. Technol. 2024, 211, 116915. [Google Scholar] [CrossRef]

- Dunford, N. Oil and oilseed processing I. Food Technol. Fact Sheet 2008, 158, 1–4. [Google Scholar]

- Laisney, J. Obtention des corps gras. In Manuel des Corps Gras; Lavoisier, T., Ed.; Technique et Documentation—Lavoisier: Paris, France, 1992; pp. 695–768. [Google Scholar]

- Savoire, R.; Lanoisellé, J.L.; Vorobiev, E. Mechanical Continuous Oil Expression from Oilseeds: A Review. Food Bioprocess Technol. 2012, 6, 1–16. [Google Scholar] [CrossRef]

- De Figueiredo, A.K.; Rodríguez, L.M.; Riccobene, I.C.; Nolasco, S.M. Analysis of the Performance of a Dehulling System for Confectionary Sunflower Seeds. Food Nutr. Sci. 2014, 5, 541–548. [Google Scholar] [CrossRef][Green Version]

- Romanić, R.S.; Lužaić, T.Z. Dehulling effectiveness of high-oleic and linoleic sunflower oilseeds using air-jet impact dehuller: A comparative study. Food Sci. Tech.—Brazil 2022, 42, e58620. [Google Scholar] [CrossRef]

- Crimaldi, M.; Faugno, S.; Sannino, M.; Ardito, L. Optimization of hemp seeds (Canapa sativa L.) oil mechanical extraction. Chem. Eng. Trans. 2017, 58, 373–378. [Google Scholar]

- Kabutey, A.; Herák, D.; Mizera, Č. Assessment of Quality and Efficiency of Cold-Pressed Oil from Selected Oilseeds. Foods 2023, 12, 363. [Google Scholar] [CrossRef]

- Gikuru, M.; Lamech, M.A. Study of Yield Characteristics During Mechanical Oil Extraction of Preheated and Ground Soybeans. J. Appl. Sci. Res. 2007, 3, 1146–1151. [Google Scholar]

- Wiesenborn, D.; Doddapaneni, R.; Tostenson, K.; Kangas, N. Cooking indices to predict screw-press perfomance for crambe seed. J. Am. Oil Chem. Soc. 2001, 78, 467–471. [Google Scholar] [CrossRef]

- Šmit, K.; Dimić, E.; Romanić, R.; Bjelobaba-Bošnjak, K.; Mojsin, K. Uticaj ljuske na kvalitet hladno ceđenog ulja suncokreta. In Zbornik Radova 46; Savetovanje Industrije Ulja, Proizvodnja i Prerada Uljarica: Petrovac na Moru, Montenegro, 2005. [Google Scholar]

- Sikorska, E.; Caponio, F.; Bilancia, M.T.; Summo, C.; Pasqualone, A.; Khmelinskii, I.V.; Sikorski, M. Changes in colour of extra-virgin olive oil during storage. Pol. J. Food Nutr. Sci. 2007, 57, 495–498. [Google Scholar]

- Esalami, S.M. Karakterizacija Kvaliteta, Nutritivne Vrednosti i Stabilnosti Devičanskih Maslinovih Ulja Proizvedenih u Različitim Regionima Libije/Characterization of the Quality, Nutritive Value and Stability of Virgin Olive Oils Produced Indifferent Regions of Libya. PhD Thesis, University of Novi Sad, Faculty of Technology, Novi Sad, Serbia, 2018. [Google Scholar]

- Bollinger, G.; Belsley, D.A.; Kuh, E.; Welsch, R.E. Regression Diagnostics: Identifying Influential Data and Sources of Collinearity. J. Mark. Res. 1981, 18, 392–393. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).