Detecting Defects in Materials Using Nondestructive Microwave Testing Techniques: A Comprehensive Review

Abstract

:1. Introduction

2. Standard Nondestructive Testing and Evaluation Techniques

2.1. Dye Penetrant Testing

2.2. Ultrasonic Testing

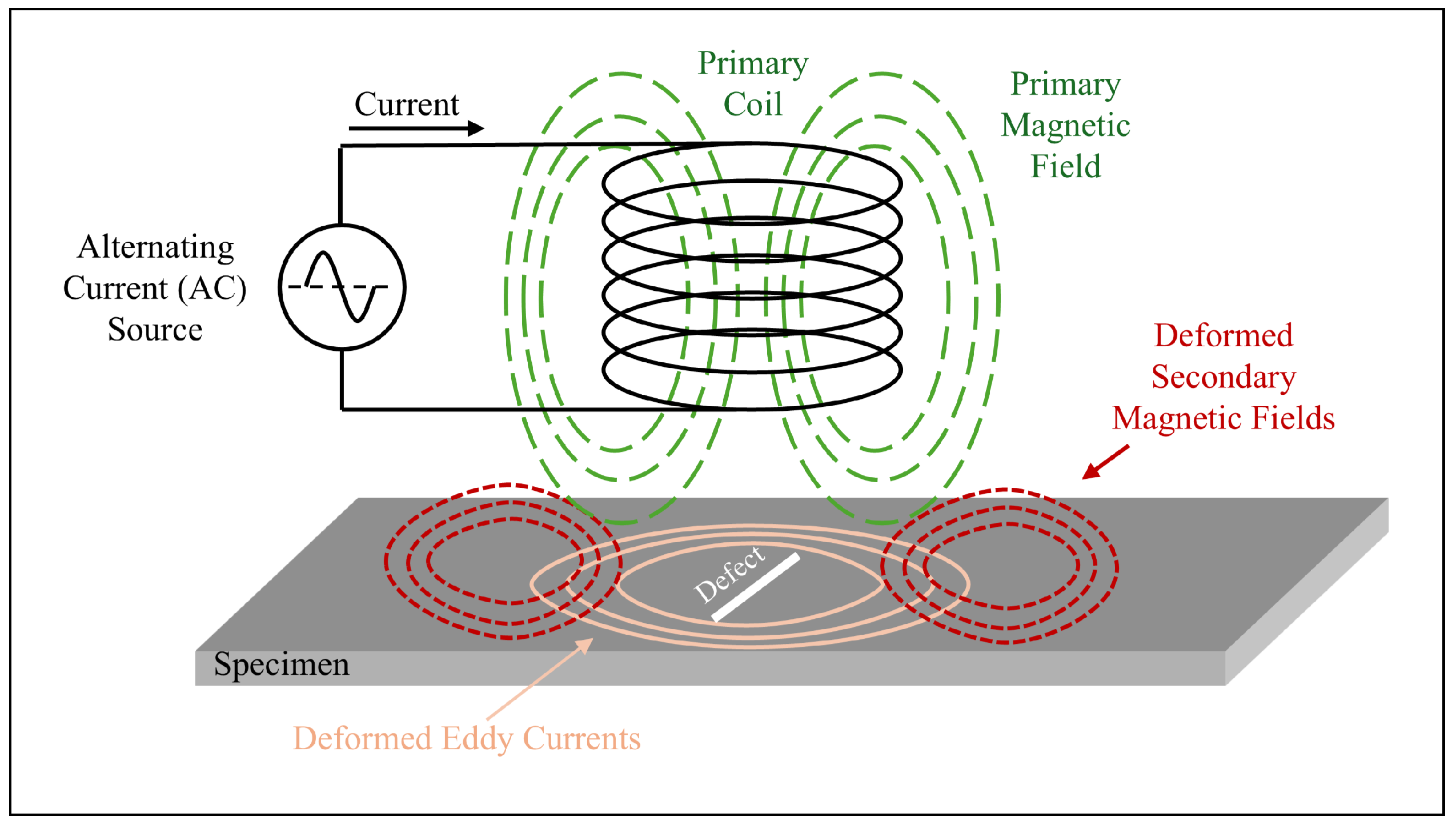

2.3. Eddy Current Testing

2.4. Magnetic Particle Testing

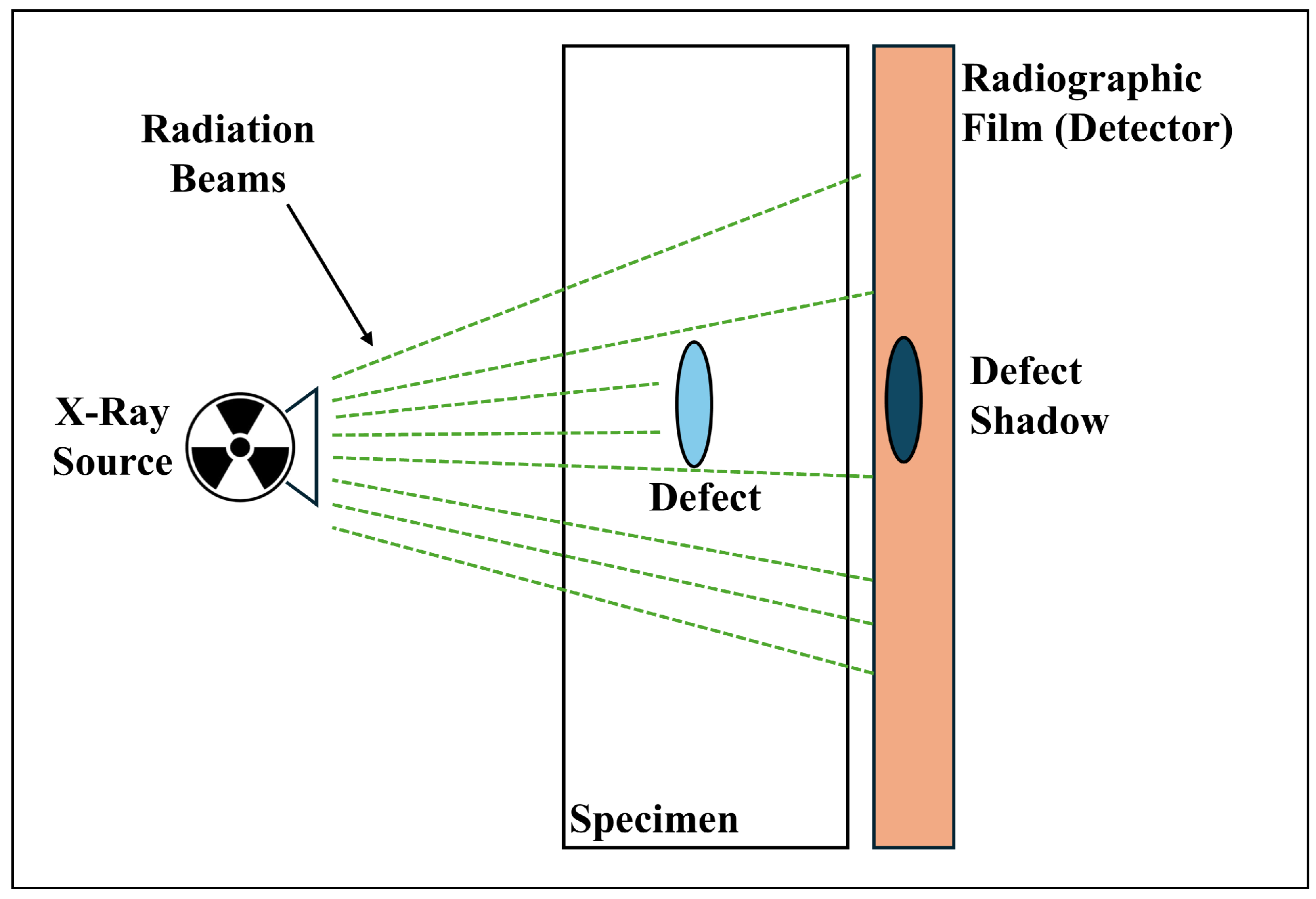

2.5. Radiography Testing

2.6. Conclusion and Comparison to MNDT

| NDT Technique | Working Principle | Advantages | Limitations | Applications |

|---|---|---|---|---|

| Visual inspection | Direct observation |

|

| |

| Dye penetrant testing | Dye reveals surface defects |

|

| |

| Ultrasonic testing | Sound waves detect flaws |

|

|

|

| Eddy current testing | Electric currents identify defects |

|

|

|

| Magnetic particle testing | Magnetic fields highlight flaws |

|

|

|

| Radiography testing | X-rays/gamma rays image defects |

|

|

| NDT Technique | Minimum Detectable Defect Size | Penetration Depth | Relative Cost |

|---|---|---|---|

| Dye penetrant testing | ≈0.02–0.1 mm | Surface only | Low |

| Ultrasonic testing | ≈0.1–1 mm | Up to several 100 mm (dependent on frequency) | Moderate–high |

| Eddy currents testing | ≈0.01–0.5 mm | ≈1–10 mm (dependent on material conductivity and frequency) | Moderate |

| Magnetic particle testing | ≈0.05–0.2 mm | ≈1–2 mm (surface and near-surface) | Low–moderate |

| Radiography testing | ≈0.1–1 mm | Several centimeters to decimeters (dependent on radiation energy) | High |

| Microwave testing | ≈0.5–2 mm | Several millimeters to centimeters (dependent on material’s electric properties and frequency) | Moderate |

3. Microwave NDT Techniques

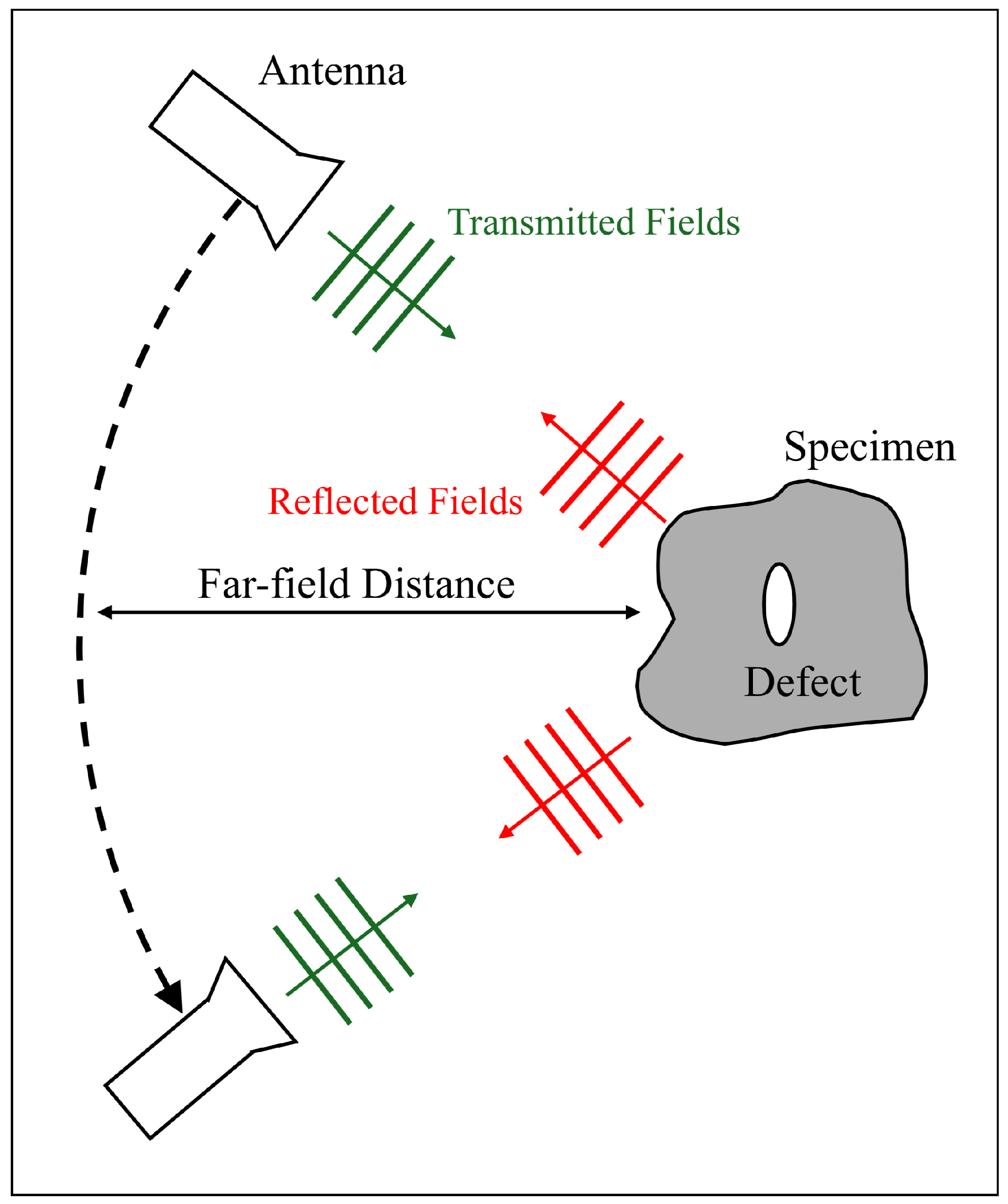

3.1. Far-Field Method

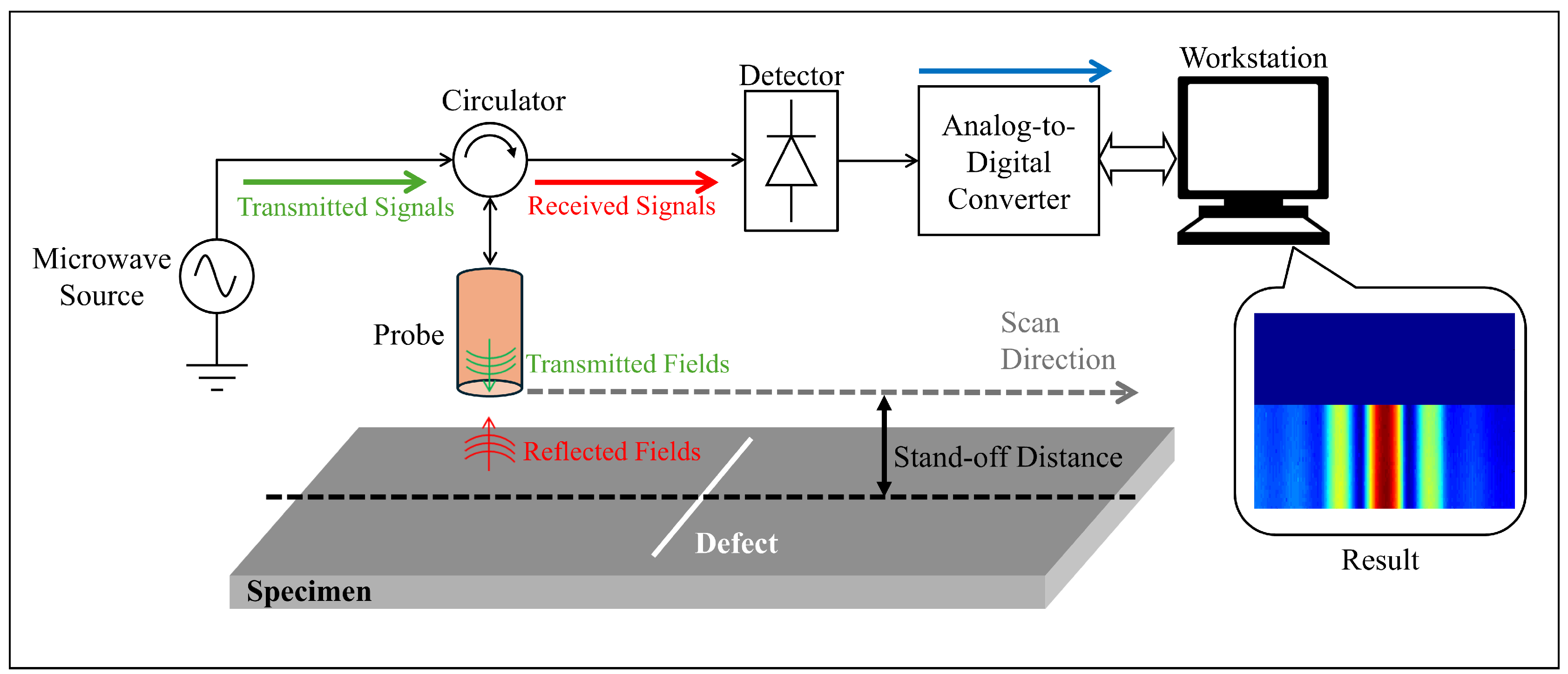

3.2. Near-Field Method

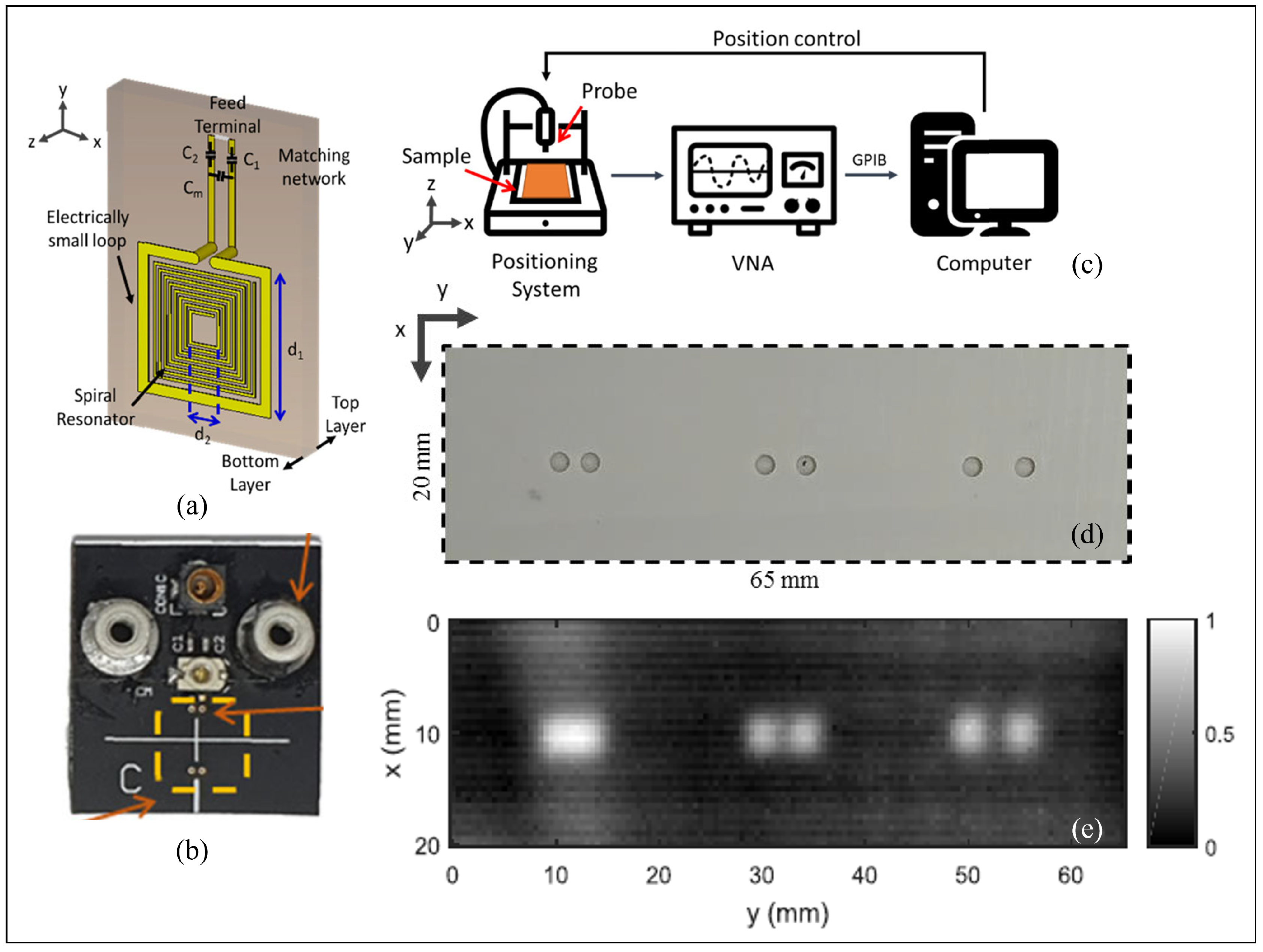

3.3. Resonator Method

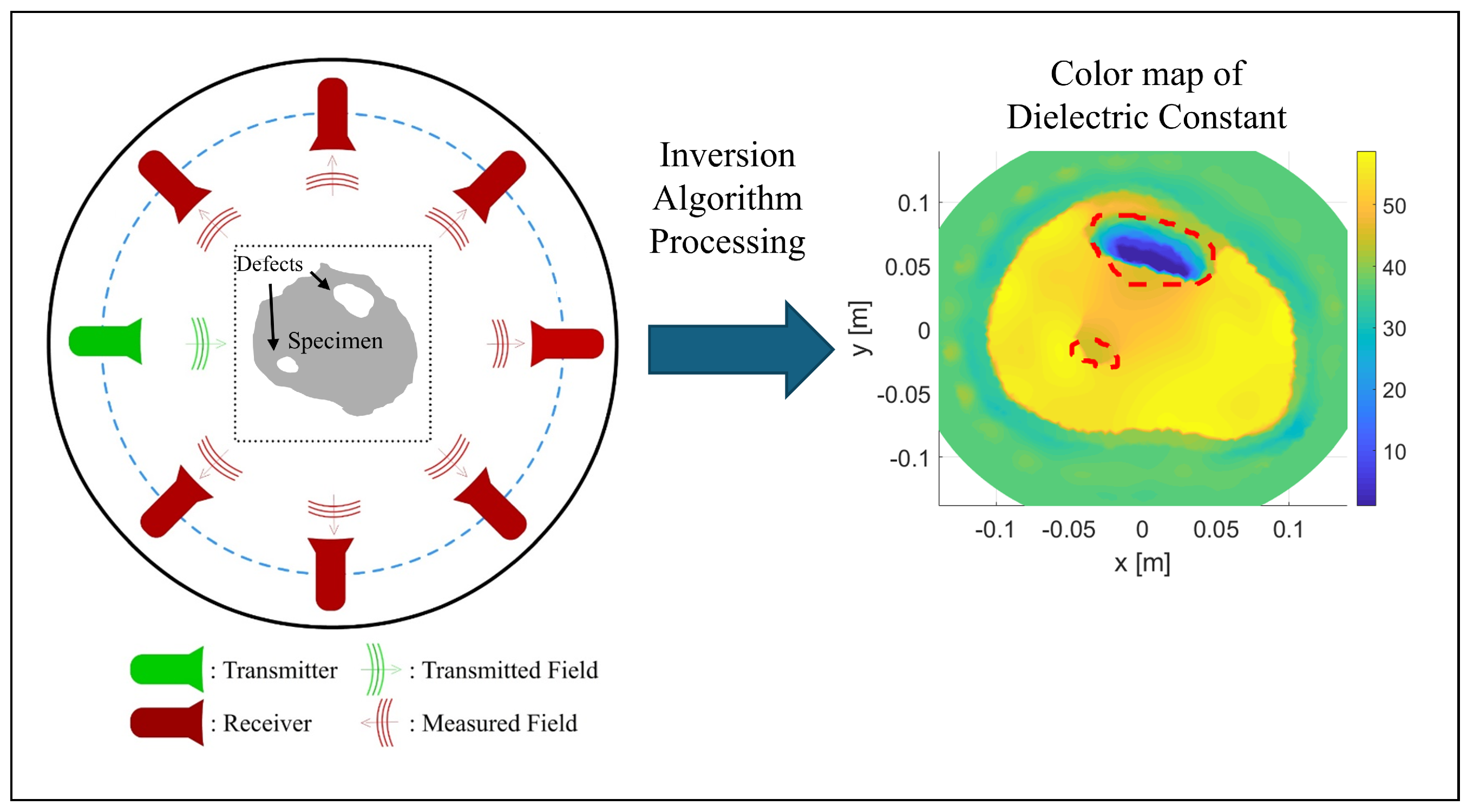

3.4. Microwave Imaging Method

3.5. Reflectometry Method

3.6. Conclusions

4. Emerging Microwave NDT Techniques

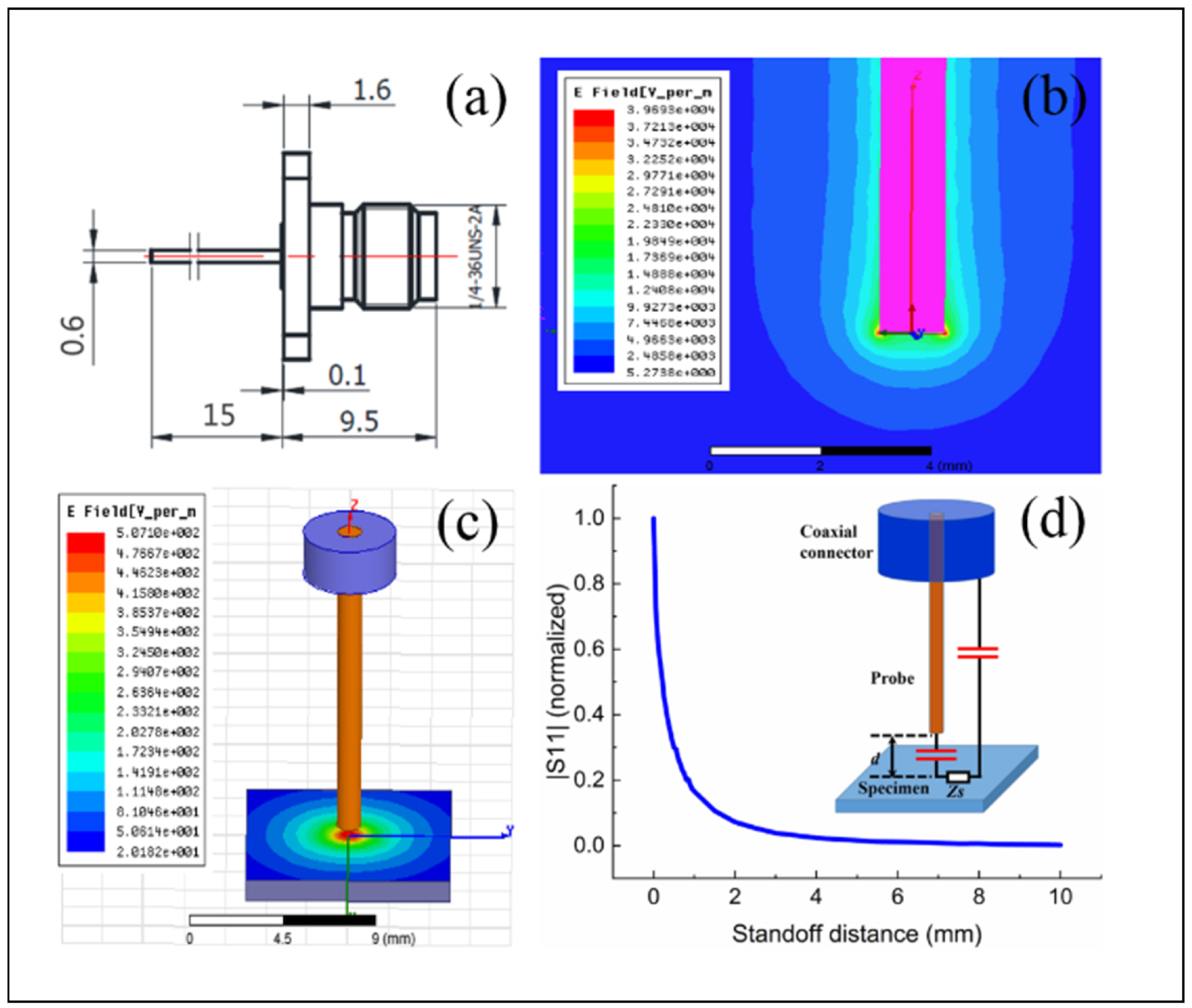

4.1. Microwave Microscopy

4.2. Active Microwave Thermography

4.3. Chipless Radio Frequency Identification

4.4. Conclusions

5. AI-Based Microwave NDT Algorithms

6. Discussion

7. Conclusions

- Detecting defects in materials is crucial for monitoring their structural health and ensuring their integrity. There are two main kinds of methods for detecting defects: destructive testing methods and nondestructive testing methods.

- While destructive testing methods guarantee definitive results, NDT approaches are still preferred, owing to their cost-effectiveness, safety, and reliability.

- NDT methods can be categorized into standard and MNDT techniques. Although standard NDT techniques are frequently employed in industry, MNDT offers exceptional advantages such as greater penetration depths in nonmetallic materials and safer inspection due to using low-power non-ionizing electromagnetic signals.

- MNDT techniques are highly effective in noninvasively detecting minute surface defects in materials as well as concealed imperfections in non-conductors, even at large distances from the specimen under test.

- Numerous microwave probes have been devised and refined for a wide range of inspection scenarios, each offering unique advantages and limitations.

- The resulting integration of MNDT techniques in different applications offers promising solutions for defect detection, making it vital for ensuring the structural integrity of components.

- Growing attention to MNDT techniques has spurred the scientific community to develop novel hardware for NDT techniques and new algorithms:

- −

- In hardware, microwave microscopy, active microwave thermography, and chipless radio frequency identification have emerged to enhance testing precision and sensitivity.

- −

- In algorithms, the incorporation of AI, and specifically ML, has been shown to improve the data analysis process, making MNDT methods more robust and reliable.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, B.; Zhong, S.; Lee, T.L.; Fancey, K.S.; Mi, J. Non-destructive testing and evaluation of composite materials/structures: A state-of-the-art review. Adv. Mech. Eng. 2020, 12, 1687814020913761. [Google Scholar] [CrossRef]

- Mix, P.E. Introduction to Nondestructive Testing: A Training Guide; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Burke, S.; Ditchburn, R. Review of Literature on Probability of Detection for Magnetic Particle Nondestructive Testing; Department of Defence, Australia: Fishermans Bend, VIC, Australia, 2013.

- Compass Technology Group, LLC. AMMP Spot Probe Family. Available online: https://compasstech.com/products/microwave-nde-equipment/ammp-spot-probes/ (accessed on 5 March 2025).

- Shah, J.; El-Hawwat, S.; Wang, H. Guided Wave ultrasonic testing for crack detection in polyethylene pipes: Laboratory experiments and numerical modeling. Sensors 2023, 23, 5131. [Google Scholar] [CrossRef]

- Rifai, D.; Abdalla, A.N.; Razali, R.; Ali, K.; Faraj, M.A. An Eddy current testing platform system for pipe defect inspection based on an optimized Eddy current technique probe design. Sensors 2017, 17, 579. [Google Scholar] [CrossRef] [PubMed]

- Gupta, M.; Khan, M.A.; Butola, R.; Singari, R.M. Advances in applications of Non-Destructive Testing (NDT): A review. Adv. Mater. Process. Technol. 2022, 8, 2286–2307. [Google Scholar] [CrossRef]

- Rehman, S.K.U.; Ibrahim, Z.; Memon, S.A.; Jameel, M. Nondestructive test methods for concrete bridges: A review. Constr. Build. Mater. 2016, 107, 58–86. [Google Scholar] [CrossRef]

- Khedmatgozar Dolati, S.S.; Caluk, N.; Mehrabi, A.; Khedmatgozar Dolati, S.S. Non-destructive testing applications for steel bridges. Appl. Sci. 2021, 11, 9757. [Google Scholar] [CrossRef]

- Ottosen, L.M.; Kunther, W.; Ingeman-Nielsen, T.; Karatosun, S. Non-Destructive Testing for Documenting Properties of Structural Concrete for Reuse in New Buildings: A Review. Materials 2024, 17, 3814. [Google Scholar] [CrossRef]

- Silva, M.I.; Malitckii, E.; Santos, T.G.; Vilaça, P. Review of conventional and advanced non-destructive testing techniques for detection and characterization of small-scale defects. Prog. Mater. Sci. 2023, 138, 101155. [Google Scholar] [CrossRef]

- Hassani, S.; Dackermann, U. A systematic review of advanced sensor technologies for non-destructive testing and structural health monitoring. Sensors 2023, 23, 2204. [Google Scholar] [CrossRef]

- Mićić, M.; Brajović, L.; Lazarević, L.; Popović, Z. Inspection of RCF rail defects–Review of NDT methods. Mech. Syst. Signal Process. 2023, 182, 109568. [Google Scholar] [CrossRef]

- Maev, R.G.; Chertov, A.; Scott, R.; Stocco, D.; Ouellette, A.; Denisov, A.; Oberdorfer, Y. NDE in the Automotive Sector. In Handbook of Nondestructive Evaluation 4.0; Springer: Berlin/Heidelberg, Germany, 2024; pp. 1–38. [Google Scholar] [CrossRef]

- Olsen, A.A. Corrosion Monitoring and Non-destructive Testing. In Equipment Conditioning Monitoring and Techniques: Guidance for the Maritime Domain; Springer: Berlin/Heidelberg, Germany, 2024; pp. 99–116. [Google Scholar] [CrossRef]

- Dwivedi, S.K.; Vishwakarma, M.; Soni, A. Advances and researches on non destructive testing: A review. Mater. Today Proc. 2018, 5, 3690–3698. [Google Scholar] [CrossRef]

- Reddy, K.A. Non-destructive testing, evaluation of stainless steel materials. Mater. Today Proc. 2017, 4, 7302–7312. [Google Scholar] [CrossRef]

- Endramawan, T.; Sifa, A. Non destructive test dye penetrant and ultrasonic on welding SMAW Butt joint with acceptance criteria ASME standard. IOP Conf. Ser. Mater. Sci. Eng. 2018, 306, 012122. [Google Scholar] [CrossRef]

- ASME Committee. 2013 ASME Boiler and Pressure Vessel Code Section VIII Division I; American Society of Mechanical Engineers: New York, NY, USA, 2013; Available online: https://www.asme.org/wwwasmeorg/media/resourcefiles/aboutasme/who%20we%20are/bpvc%20resources/bpvc-cc-bpv-2013-supplement-4.pdf (accessed on 10 March 2025).

- El Kouche, A.; Hassanein, H.S. Ultrasonic non-destructive testing (NDT) using wireless sensor networks. Procedia Comput. Sci. 2012, 10, 136–143. [Google Scholar] [CrossRef]

- Sharma, A.; Sinha, A. Ultrasonic testing for mechanical engineering domain: Present and future perspective. Int. J. Res. Ind. Eng. 2018, 7, 243–253. [Google Scholar] [CrossRef]

- Zhukov, D.; Konovalov, S.; Melnikov, A.; Chen, D. Metallography of non-metallic inclusions in pipe metal and impact assessment of defect structures on non-destructive testing outcomes. CIS Iron Steel Rev. 2021, 1, 58–63. [Google Scholar] [CrossRef]

- Helfen, T.; Venkat, R.S.; Rabe, U.; Hirsekorn, S.; Boller, C. Characterisation of CFRP through enhanced ultrasonic testing methods. Appl. Compos. Mater. 2012, 19, 913–919. [Google Scholar] [CrossRef]

- Mahmoud, A.M.; Ammar, H.H.; Mukdadi, O.M.; Ray, I.; Imani, F.S.; Chen, A.; Davalos, J.F. Non-destructive ultrasonic evaluation of CFRP–concrete specimens subjected to accelerated aging conditions. Ndt & E Int. 2010, 43, 635–641. [Google Scholar] [CrossRef]

- Bastianini, F.; Di Tommaso, A.; Pascale, G. Ultrasonic non-destructive assessment of bonding defects in composite structural strengthenings. Compos. Struct. 2001, 53, 463–467. [Google Scholar] [CrossRef]

- Berketis, K.; Tzetzis, D.; Hogg, P. Impact damage detection and degradation monitoring of wet GFRP composites using noncontact ultrasonics. Polym. Compos. 2009, 30, 1043–1049. [Google Scholar] [CrossRef]

- Waqar, M.; Memon, A.M.; Sabih, M.; Alhems, L.M. Composite pipelines: Analyzing defects and advancements in non-destructive testing techniques. Eng. Fail. Anal. 2024, 157, 107914. [Google Scholar] [CrossRef]

- OnestopNDT. A Comprehensive Overview on Ultrasonic Testing. 2022. Available online: https://www.onestopndt.com/ndt-articles/ultrasonic-testing (accessed on 5 March 2025).

- García-Martín, J.; Gómez-Gil, J.; Vázquez-Sánchez, E. Non-destructive techniques based on Eddy current testing. Sensors 2011, 11, 2525–2565. [Google Scholar] [CrossRef]

- Santos, D.; Machado, M.A.; Monteiro, J.; Sousa, J.P.; Proença, C.S.; Crivellaro, F.S.; Rosado, L.S.; Santos, T.G. Non-destructive inspection of high-temperature piping combining ultrasound and Eddy current testing. Sensors 2023, 23, 3348. [Google Scholar] [CrossRef] [PubMed]

- Ulapane, N.; Alempijevic, A.; Vidal Calleja, T.; Valls Miro, J. Pulsed Eddy current sensing for critical pipe condition assessment. Sensors 2017, 17, 2208. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Liu, X. Electromagnetic imaging methods for nondestructive evaluation applications. Sensors 2011, 11, 11774–11808. [Google Scholar] [CrossRef]

- Ito, F.; Nishimura, A. Fabrication and application of microcapsules including fluorescent magnetic particles for crack inspection of pipes. Trans. Mater. Res. Soc. Jpn. 2013, 38, 667–672. [Google Scholar] [CrossRef]

- Smith, M.; Sutherby, R. The detection of pipeline SCC flaws using the ACFM technique. Insight Non-Destr. Test. Cond. Monit. 2005, 47, 765–768. [Google Scholar] [CrossRef]

- Zolfaghari, A.; Zolfaghari, A.; Kolahan, F. Reliability and sensitivity of magnetic particle nondestructive testing in detecting the surface cracks of welded components. Nondestruct. Test. Eval. 2018, 33, 290–300. [Google Scholar] [CrossRef]

- Shafeek, H.; Gadelmawla, E.; Abdel-Shafy, A.; Elewa, I. Assessment of welding defects for gas pipeline radiographs using computer vision. NDT E Int. 2004, 37, 291–299. [Google Scholar] [CrossRef]

- Haith, M.I.; Huthwaite, P.; Lowe, M.J. Defect characterization from limited view pipeline radiography. NDT E Int. 2017, 86, 186–198. [Google Scholar] [CrossRef]

- Zoughi, R. Microwave Non-Destructive Testing and Evaluation Principles; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2000; Volume 4. [Google Scholar] [CrossRef]

- Ghasr, M.T.; Abou-Khousa, M.A.; Kharkovsky, S.; Zoughi, R.; Pommerenke, D. Portable real-time microwave camera at 24 GHz. IEEE Trans. Antennas Propag. 2011, 60, 1114–1125. [Google Scholar] [CrossRef]

- Verma, S.K.; Bhadauria, S.S.; Akhtar, S. Review of nondestructive testing methods for condition monitoring of concrete structures. J. Constr. Eng. 2013, 2013, 834572. [Google Scholar] [CrossRef]

- Hasar, U. Non-destructive testing of hardened cement specimens at microwave frequencies using a simple free-space method. NDT E Int. 2009, 42, 550–557. [Google Scholar] [CrossRef]

- Brinker, K.; Dvorsky, M.; Al Qaseer, M.T.; Zoughi, R. Review of advances in microwave and millimetre-wave NDT&E: Principles and applications. Philos. Trans. R. Soc. A 2020, 378, 20190585. [Google Scholar] [CrossRef]

- Ghodgaonkar, D.K.; Ali, N.A.; Giubbolini, L. Microwave nondestructive testing of composite materials using free-space microwave measurement techniques. In Proceedings of the 15th World Conference on Non-Destructive Testing, Roma, Italy, 15–21 October 2000; pp. 15–21. [Google Scholar]

- Deepak, J.; Raja, V.B.; Srikanth, D.; Surendran, H.; Nickolas, M. Non-destructive testing (NDT) techniques for low carbon steel welded joints: A review and experimental study. Mater. Today Proc. 2021, 44, 3732–3737. [Google Scholar] [CrossRef]

- Pushpakumara, B.J.; Silva, S.D.; Silva, G.S.D. Visual inspection and non-destructive tests-based rating method for concrete bridges. Int. J. Struct. Eng. 2017, 8, 74–91. [Google Scholar] [CrossRef]

- Vera, J.; Caballero, L.; Taboada, M. Reliability of dye penetrant inspection method to detect weld discontinuities. Russ. J. Nondestruct. Test. 2024, 60, 85–95. [Google Scholar] [CrossRef]

- Yang, L.; Chuai, R.; Cai, G.; Xue, D.; Li, J.; Liu, K.; Liu, C. Ultrasonic Non-Destructive Testing and Evaluation of Stainless-Steel Resistance Spot Welding Based on Spiral C-Scan Technique. Sensors 2024, 24, 4771. [Google Scholar] [CrossRef]

- Dai, L.; Feng, H.; Wang, T.; Xuan, W.; Liang, Z.; Yang, X. Pipe crack recognition based on Eddy current NDT and 2D impedance characteristics. Appl. Sci. 2019, 9, 689. [Google Scholar] [CrossRef]

- Bosse, S.; Lehmhus, D.; Kumar, S. Automated porosity characterization for aluminum die casting materials using X-ray radiography, synthetic X-ray data augmentation by simulation, and machine learning. Sensors 2024, 24, 2933. [Google Scholar] [CrossRef]

- Hena, B.; Ramos, G.; Ibarra-Castanedo, C.; Maldague, X. Automated Defect Detection through Flaw Grading in Non-Destructive Testing Digital X-ray Radiography. NDT 2024, 2, 378–391. [Google Scholar] [CrossRef]

- Abou-Khousa, M.A.; Rahman, M.S.U.; Donnell, K.M.; Al Qaseer, M.T. Detection of surface cracks in metals using microwave and millimeter-wave nondestructive testing techniques—A review. IEEE Trans. Instrum. Meas. 2023, 72, 1–18. [Google Scholar] [CrossRef]

- Zoughi, R.; Ganchev, S. Microwave nondestructive evaluation: State-of-the-art review. NASA STI/Recon Tech. Rep. N 1995, 95, 34346. [Google Scholar]

- Memon, M.U.; Lim, S. Review of electromagnetic-based crack sensors for metallic materials (recent research and future perspectives). Metals 2016, 6, 172. [Google Scholar] [CrossRef]

- Sobkiewicz, P.; Bieńkowski, P.; Błażejewski, W. Microwave defectoscopy–detection of composite delamination. J. Phys. Conf. Ser. 2021, 1782, 012034. [Google Scholar] [CrossRef]

- Wang, X.; Liang, J.G.; Wu, J.K.; Gu, X.F.; Kim, N.Y. Microwave detection with various sensitive materials for humidity sensing. Sens. Actuators B Chem. 2022, 351, 130935. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, L.; Lei, H.; Pei, Y. Microwave near-field and far-field imaging of composite plate with hat stiffeners. Compos. Part B Eng. 2019, 161, 87–95. [Google Scholar] [CrossRef]

- Dvorsky, M.; Al Qaseer, M.T.; Zoughi, R. Crack sizing using dual-polarized microwave SAR imaging. In Proceedings of the 2020 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Dubrovnik, Croatia, 25–28 May 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Arunachalam, K.; Melapudi, V.; Udpa, L.; Udpa, S. Microwave NDT of cement-based materials using far-field reflection coefficients. NDT E Int. 2006, 39, 585–593. [Google Scholar] [CrossRef]

- Büyüköztürk, O.; Yu, T.Y. Far-field radar NDT technique for detecting GFRP debonding from concrete. Constr. Build. Mater. 2009, 23, 1678–1689. [Google Scholar] [CrossRef]

- Álvarez López, Y.; García Fernández, M.; Grau, R.; Las-Heras, F. A synthetic aperture radar (SAR)-based technique for microwave imaging and material characterization. Electronics 2018, 7, 373. [Google Scholar] [CrossRef]

- Abou-Khousa, M.A.; ur Rahman, M.S. Covered cracks detection using dual-polarization synthetic aperture radar imaging. IEEE Trans. Instrum. Meas. 2021, 70, 1–4. [Google Scholar] [CrossRef]

- Gacem, M.A.; Zakaria, A.S.; Ismail, M.H.; Tariq, U.; Yehia, S. Measurement of construction materials properties using Wi-Fi and convolutional neural networks. IEEE Access 2022, 10, 126100–126116. [Google Scholar] [CrossRef]

- Gacem, M.A.; Zakaria, A.; Ismail, M.H.; Yehia, S.; Tariq, U. Concrete classification using Wi-Fi channel state information and convolutional neural networks. Constr. Build. Mater. 2024, 439, 137280. [Google Scholar] [CrossRef]

- Daniels, D.J. Ground Penetrating Radar; IET: Herts, UK, 2004; Volume 1. [Google Scholar]

- Conyers, L.B. Ground-Penetrating Radar for Archaeology; Rowman & Littlefield: Lanham, MD, USA, 2023. [Google Scholar]

- GSSI. Ground Penetrating Radar (GPR) Equipment: GSSI Inc.: Georadar. Available online: https://www.geophysical.com/ (accessed on 5 March 2025).

- Screening Eagle. Subsurface Mapping Solutions for Resource Exploration. Available online: https://www.screeningeagle.com/en/industries/environmental/resource-exploration (accessed on 5 March 2025).

- Lee, J.S.; Pottier, E. Polarimetric Radar Imaging: From Basics to Applications; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar] [CrossRef]

- Amar, H.; Ghodbane, H.; Amir, M.; Guezoui, Z.; Zergoug, M.; Azzi, S. Detection of Defects Using Open-Ended Coaxial Probe. Int. J. Syst. Appl. Eng. Dev. 2017, 11, 297–300. [Google Scholar]

- Haryono, A.; Aljaberi, K.; Rahman, M.S.U.; Abou-Khousa, M.A. High resolution and polarization independent microwave near-field imaging using planar resonator probes. IEEE Access 2020, 8, 191421–191432. [Google Scholar] [CrossRef]

- Zoughi, R.; Kharkovsky, S. Microwave and millimetre wave sensors for crack detection. Fatigue Fract. Eng. Mater. Struct. 2008, 31, 695–713. [Google Scholar] [CrossRef]

- Case, J.T.; Kenderian, S. Microwave NDT: An inspection method. Mater. Eval. 2017, 75, 339–346. [Google Scholar]

- Qaddoumi, N.N.; Saleh, W.M.; Abou-Khousa, M. Innovative near-field microwave nondestructive testing of corroded metallic structures utilizing open-ended rectangular waveguide probes. IEEE Trans. Instrum. Meas. 2007, 56, 1961–1966. [Google Scholar] [CrossRef]

- Qaddoumi, N.N.; Abou-Khousa, M.; Saleh, W.M. Near-field microwave imaging utilizing tapered rectangular waveguides. IEEE Trans. Instrum. Meas. 2006, 55, 1752–1756. [Google Scholar] [CrossRef]

- Shafi, K.M.; ur Rahman, M.S.; Abou-Khousa, M.A.; Ramzi, M.R. Applied microwave imaging of composite structures using open-ended circular waveguide. In Proceedings of the 2017 IEEE International Conference on Imaging Systems and Techniques (IST), Beijing, China, 18–20 October 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Sediq, A.S.B.; Qaddoumi, N. Near-field microwave image formation of defective composites utilizing open-ended waveguides with arbitrary cross sections. Compos. Struct. 2005, 71, 343–348. [Google Scholar] [CrossRef]

- ur Rahman, M.S.; Yassin, A.; Abou-Khousa, M.A. Microwave imaging of thick composite structures using circular aperture probe. Meas. Sci. Technol. 2018, 29, 095403. [Google Scholar] [CrossRef]

- Ramzi, M.R.; Abou-Khousa, M.; Prayudi, I. Near-Field Microwave Imaging Using Open-Ended Circular Waveguide Probes. IEEE Sens. J. 2017, 17, 2359–2366. [Google Scholar] [CrossRef]

- Park, H.H.; Cho, Y.H.; Eom, H.J. Surface crack detection using flanged parallel-plate waveguide. Electronics Letters 2001, 37, 1526–1527. [Google Scholar] [CrossRef]

- Yadegari, A.M.; Moini, R.; Sadeghi, S.H.H.; Mazlumi, F. Output signal prediction of an open-ended rectangular waveguide probe when scanning cracks at a non-zero lift-off. NDT E Int. 2010, 43, 1–7. [Google Scholar] [CrossRef]

- Holtmann, P.H. Open-Ended Hollow Coaxial Cable Resonance Sensing via Permittivity Fluctuations for Applications to Exhaled Breath Health Monitoring. Master’s Thesis, Missouri University of Science and Technology, Rolla, MO, USA, 2022. [Google Scholar]

- Albishi, A.M.; Ramahi, O.M. Microwaves-Based High Sensitivity Sensors for Crack Detection in Metallic Materials. IEEE Trans. Microw. Theory Tech. 2017, 65, 1864–1872. [Google Scholar] [CrossRef]

- Albishi, A.M.; Boybay, M.S.; Ramahi, O.M. Complementary Split-Ring Resonator for Crack Detection in Metallic Surfaces. IEEE Microw. Wirel. Components Lett. 2012, 22, 330–332. [Google Scholar] [CrossRef]

- Mukherjee, S.; Shi, X.; Udpa, L.; Udpa, S.; Deng, Y.; Chahal, P. Design of a Split-Ring Resonator Sensor for Near-Field Microwave Imaging. IEEE Sens. J. 2018, 18, 7066–7076. [Google Scholar] [CrossRef]

- Yang, X.; Yin, Y.; Zhang, D.; Wu, S.; Huang, K.; Yuan, J.; Zhu, Z. Array Waveguide Probe Loaded with Split-Ring Resonators for Sizing the Cracks in Metal Surface. IEEE Microw. Wirel. Components Lett. 2018, 28, 171–173. [Google Scholar] [CrossRef]

- ur Rahman, M.S.; Mustapha, A.A.; Abou-Khousa, M.A. Detection of Cracks under Cover and Corrosion using UHF Probe. In Proceedings of the 2022 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Ottawa, ON, Canada, 16–19 May 2022; pp. 1–5. [Google Scholar] [CrossRef]

- ur Rahman, M.S.; Gaya, S.M.; Abou-Khousa, M.A. Non-destructive Testing and Evaluation of Surface-Breaking Cracks using Microwave Planar Resonator Probe. In Proceedings of the 2022 IEEE Microwaves, Antennas, and Propagation Conference (MAPCON), Bangalore, India, 12–16 December 2022; pp. 552–556. [Google Scholar] [CrossRef]

- Giri, P.; Kharkovsky, S. Dual-Laser Integrated Microwave Imaging System for Nondestructive Testing of Construction Materials and Structures. IEEE Trans. Instrum. Meas. 2018, 67, 1329–1337. [Google Scholar] [CrossRef]

- Navagato, M.D.; Narayanan, R.M. Microwave imaging of multilayered structures using ultrawideband noise signals. NDT E Int. 2019, 104, 19–33. [Google Scholar] [CrossRef]

- Caorsi, S.; Donelli, M.; Massa, A.; Pastorino, M.; Randazzo, A.; Rosani, A. A microwave imaging method for NDE/NDT based on the SMW technique for the electromagnetic field prediction. In Proceedings of the 21st IEEE Instrumentation and Measurement Technology Conference (IMTC), Como, Italy, 18–20 May 2004; Volume 1, pp. 184–189. [Google Scholar] [CrossRef]

- AlSawaftah, N.; El-Abed, S.; Dhou, S.; Zakaria, A. Microwave imaging for early breast cancer detection: Current state, challenges, and future directions. J. Imaging 2022, 8, 123. [Google Scholar] [CrossRef]

- Jiya, E.A.; Anwar, N.S.N.; Abdullah, M.Z. Detection of Cracks in Concrete Structure Using Microwave Imaging Technique. Int. J. Microw. Sci. Technol. 2016, 2016, 3195716. [Google Scholar] [CrossRef]

- Wang, Z.; Chang, T.; Cui, H.L. Review of active millimeter wave imaging techniques for personnel security screening. IEEE Access 2019, 7, 148336–148350. [Google Scholar] [CrossRef]

- Rohde & Schwarz. R&S QPS Security Scanners. Available online: https://www.rohde-schwarz.com/ae/home_48230.html (accessed on 5 March 2025).

- Ahmed, S.S. Microwave imaging in security—Two decades of innovation. IEEE J. Microwaves 2021, 1, 191–201. [Google Scholar] [CrossRef]

- EAS Envimet. ProVision PV2. Available online: https://www.envimet.com/en/product/provision-pv2/ (accessed on 5 March 2025).

- Appleby, R.; Anderton, R.N. Millimeter-wave and submillimeter-wave imaging for security and surveillance. Proc. IEEE 2007, 95, 1683–1690. [Google Scholar] [CrossRef]

- Carrigan, T.D.; Forrest, B.E.; Andem, H.N.; Gui, K.; Johnson, L.; Hibbert, J.E.; Lennox, B.; Sloan, R. Nondestructive Testing of Nonmetallic Pipelines Using Microwave Reflectometry on an In-Line Inspection Robot. IEEE Trans. Instrum. Meas. 2019, 68, 586–594. [Google Scholar] [CrossRef]

- Akbar, M.F.; Jawad, G.N.; Danoon, L.R.; Sloan, R. Delamination Detection in Glass-Fibre Reinforced Polymer (GFRP) Using Microwave Time Domain Reflectometry. In Proceedings of the 2018 15th European Radar Conference (EuRAD), Madrid, Spain, 26–28 September 2018; pp. 253–256. [Google Scholar] [CrossRef]

- Akbar, M.F.; Jawad, G.N.; Rashid, L.D.; Sloan, R. Nondestructive Evaluation of Coatings Delamination Using Microwave Time Domain Reflectometry Technique. IEEE Access 2020, 8, 114833–114841. [Google Scholar] [CrossRef]

- Xie, Y.; Yang, X.; Su, P.; He, Y.; Qiu, Y. A Microwave Time Domain Reflectometry Technique Combining the Wavelet Decomposition Analysis and Artificial Neural Network for Detection of Defects in Dielectric Structures. IEEE Trans. Instrum. Meas. 2022, 71, 1–11. [Google Scholar] [CrossRef]

- Amineh, R.K. Microwave nondestructive testing of nonmetallic pipes: An overview of the major developments. IEEE Instrum. Meas. Mag. 2024, 27, 54–66. [Google Scholar] [CrossRef]

- Donnell, K.M.; McClanahan, A.; Zoughi, R. On the crack characteristic signal from an open-ended coaxial probe. IEEE Trans. Instrum. Meas. 2014, 63, 1877–1879. [Google Scholar] [CrossRef]

- Iaccheri, E.; Varani, M.; Ragni, L. Cost-effective open-ended coaxial technique for liquid food characterization by using the reflection method for industrial applications. Sensors 2022, 22, 5277. [Google Scholar] [CrossRef] [PubMed]

- Balasubramanian, V.; Jain, M.C.; Golovin, K.; Zarifi, M.H. Real-time non-destructive erosion monitoring of coatings using passive microwave split ring resonator sensor. In Proceedings of the 2023 IEEE International Conference on Consumer Electronics (ICCE), Las Vegas, NV, USA, 6–8 January 2023; pp. 1–4. [Google Scholar] [CrossRef]

- Xie, Z.; Li, Y.; Sun, L.; Wu, W.; Cao, R.; Tao, X. A Simple High-Resolution Near-Field Probe for Microwave Non-Destructive Test and Imaging. Sensors 2020, 20, 2670. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.; Yang, X.; Chen, H.e.; Chen, Z.; Wang, R.; Li, Y.; Xie, S. Non-destructive quantitative evaluation of delamination depth and thickness in GFRP using microwave reflectometry. NDT E Int. 2024, 144, 103065. [Google Scholar] [CrossRef]

- Origlia, C.; Rodriguez-Duarte, D.O.; Tobon Vasquez, J.A.; Bolomey, J.C.; Vipiana, F. Review of microwave near-field sensing and imaging devices in medical applications. Sensors 2024, 24, 4515. [Google Scholar] [CrossRef]

- Yago Ruiz, Á.; Cavagnaro, M.; Crocco, L. An effective framework for deep-learning-enhanced quantitative microwave imaging and its potential for medical applications. Sensors 2023, 23, 643. [Google Scholar] [CrossRef] [PubMed]

- Sobkiewicz, P.; Bieńkowski, P.; Błażejewski, W. Microwave Non-Destructive Testing for Delamination Detection in Layered Composite Pipelines. Sensors 2021, 21, 4168. [Google Scholar] [CrossRef]

- Tabib-Azar, M.; Pathak, P.; Ponchak, G.; LeClair, S. Nondestructive Superresolution Imaging of Defects and Nonuniformities in Metals, Semiconductors, Dielectrics, Composites, and Plants Using Evanescent Microwaves. Rev. Sci. Instrum. 1999, 70, 2783–2792. [Google Scholar] [CrossRef]

- Wang, P.; Li, Z.; Pei, Y. In situ high temperature microwave microscope for nondestructive detection of surface and sub-surface defects. Opt. Express 2018, 26, 9595–9606. [Google Scholar] [CrossRef]

- Gu, S.; Haddadi, K.; Fellahi, A.E.; Lasri, T. Setting Parameters Influence on Accuracy and Stability of Near-Field Scanning Microwave Microscopy Platform. IEEE Trans. Instrum. Meas. 2016, 65, 890–897. [Google Scholar] [CrossRef]

- Yang, R.; Zhang, H.; Li, T.; He, Y. An investigation and review into microwave thermography for NDT and SHM. In Proceedings of the 2015 IEEE Far East NDT New Technology & Application Forum (FENDT), Zhuhai, China, 28–31 May 2015; pp. 133–137. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, R.; He, Y.; Foudazi, A.; Cheng, L.; Tian, G. A Review of Microwave Thermography Nondestructive Testing and Evaluation. Sensors 2017, 17, 1123. [Google Scholar] [CrossRef]

- Sun, J.G. Analysis of Pulsed Thermography Methods for Defect Depth Prediction. J. Heat Transf. 2005, 128, 329–338. [Google Scholar] [CrossRef]

- Vergani, L.; Colombo, C.; Libonati, F. A review of thermographic techniques for damage investigation in composites. Frat. E Integrità Strutt. 2014, 8, 1–12. [Google Scholar] [CrossRef]

- Waugh, R.C.; Dulieu-Barton, J.M.; Quinn, S. Modelling and evaluation of pulsed and pulse phase thermography through application of composite and metallic case studies. NDT E Int. 2014, 66, 52–66. [Google Scholar] [CrossRef]

- Roche, J.M.; Balageas, D. Common tools for quantitative pulse and step-heating thermography - Part II: Experimental investigation. Quant. Infrared Thermogr. J. 2015, 12, 1–20. [Google Scholar] [CrossRef]

- Maldague, X.P.V. Theory and Practice of Infrared Technology for Nondestructive Testing; John Wiley & Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Maldague, X.P.V.; Marinetti, S. Pulse Phase Thermography. J. Appl. Phys. 1996, 79, 2694–2698. [Google Scholar] [CrossRef]

- Foudazi, A.; Mirala, A.; Ghasr, M.T.; Donnell, K.M. Active Microwave Thermography for Nondestructive Evaluation of Surface Cracks in Metal Structures. IEEE Trans. Instrum. Meas. 2019, 68, 576–585. [Google Scholar] [CrossRef]

- Mirala, A.; Foudazi, A.; Al Qaseer, M.T.; Donnell, K.M. Active Microwave Thermography to Detect and Locate Water Ingress. IEEE Trans. Instrum. Meas. 2020, 69, 9774–9783. [Google Scholar] [CrossRef]

- Mirala, A.; Ghasr, M.T.; Donnell, K.M. Nondestructive assessment of microwave absorbing structures via active microwave thermography. In Proceedings of the 2018 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Houston, TX, USA, 14–17 May 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Marindra, A.M.J. Chipless RFID Sensor Systems for Structural Health Monitoring. Ph.D. Thesis, Newcastle University, Newcastle upon Tyne, UK, 2020. [Google Scholar]

- Marindra, A.M.J.; Tian, G.Y. Chipless RFID sensor tag for metal crack detection and characterization. IEEE Trans. Microw. Theory Tech. 2018, 66, 2452–2462. [Google Scholar] [CrossRef]

- Tedjini, S.; Karmakar, N.; Perret, E.; Vena, A.; Koswatta, R.; E-Azim, R. Hold the Chips: Chipless Technology, an Alternative Technique for RFID. IEEE Microw. Mag. 2013, 14, 56–65. [Google Scholar] [CrossRef]

- Preradovic, S.; Karmakar, N.C. Chipless RFID: Bar Code of the Future. IEEE Microw. Mag. 2010, 11, 87–97. [Google Scholar] [CrossRef]

- Karmakar, N.C. Tag, You’re It: Radar Cross Section of Chipless RFID Tags. IEEE Microw. Mag. 2016, 17, 64–74. [Google Scholar] [CrossRef]

- Brinker, K.; Zoughi, R. Embedded chipless RFID measurement methodology for microwave materials characterization. In Proceedings of the 2018 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Houston, TX, USA, 14–17 May 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Brinker, K. Chipless RFID Tag Design, Measurement, and Sensing for Nondestructive Evaluation (NDE) Applications. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2022. [Google Scholar]

- Zakaria, A. The Finite-Element Contrast Source Inversion Method for Microwave Imaging Applications; University of Manitoba: Winnipeg, MB, Canada, 2012. [Google Scholar]

- Takahashi, S.; Kidera, S. Efficient Inverse Scattering Algorithm by Incorporating RPM Method for Microwave Non-destructive Imaging. In Proceedings of the 2018 26th European Signal Processing Conference (EUSIPCO), Rome, Italy, 3–7 September 2018; pp. 1222–1226. [Google Scholar] [CrossRef]

- Arkadan, A.; Sareen, T.; Subramaniam, S. Genetic algorithms for nondestructive testing in crack identification. IEEE Trans. Magn. 1994, 30, 4320–4322. [Google Scholar] [CrossRef]

- Caorsi, S.; Massa, A.; Pastorino, M. A crack identification microwave procedure based on a genetic algorithm for nondestructive testing. IEEE Trans. Antennas Propag. 2001, 49, 1812–1820. [Google Scholar] [CrossRef]

- Mojabi, P.; LoVetri, J. Overview and classification of some regularization techniques for the Gauss–Newton inversion method applied to inverse scattering problems. IEEE Trans. Antennas Propag. 2009, 57, 2658–2665. [Google Scholar] [CrossRef]

- Chew, W.C.; Wang, Y.M. Reconstruction of two-dimensional permittivity distribution using the distorted Born iterative method. IEEE Trans. Med. Imaging 1990, 9, 218–225. [Google Scholar] [CrossRef]

- Van Den Berg, P.M.; Kleinman, R.E. A contrast source inversion method. Inverse Probl. 1997, 13, 1607. [Google Scholar] [CrossRef]

- Rubæk, T.; Meaney, P.M.; Meincke, P.; Paulsen, K.D. Nonlinear microwave imaging for breast-cancer screening using Gauss–Newton’s method and the CGLS inversion algorithm. IEEE Trans. Antennas Propag. 2007, 55, 2320–2331. [Google Scholar] [CrossRef]

- Donelli, M.; Massa, A. Computational approach based on a particle swarm optimizer for microwave imaging of two-dimensional dielectric scatterers. IEEE Trans. Microw. Theory Tech. 2005, 53, 1761–1776. [Google Scholar] [CrossRef]

- Ali, A.; Hu, B.; Ramahi, O. Intelligent Detection of Cracks in Metallic Surfaces Using a Waveguide Sensor Loaded with Metamaterial Elements. Sensors 2015, 15, 11402–11416. [Google Scholar] [CrossRef]

- Shrifan, N.H.M.M.; Jawad, G.N.; Isa, N.A.M.; Akbar, M.F. Microwave Nondestructive Testing for Defect Detection in Composites Based on K-Means Clustering Algorithm. IEEE Access 2021, 9, 4820–4828. [Google Scholar] [CrossRef]

- Maricar, M.F.; Zakaria, A.; Qaddoumi, N. Attention-Unet for Electromagnetic Inverse Scattering Problems in Microwave Imaging. IEEE Trans. Microw. Theory Tech. 2024. [Google Scholar] [CrossRef]

- Ronneberger, O.; Fischer, P.; Brox, T. U-Net: Convolutional Networks for Biomedical Image Segmentation. arXiv 2015, arXiv:1505.04597. [Google Scholar]

- Deng, L. The MNIST Database of Handwritten Digit Images for Machine Learning Research. IEEE Signal Process. Mag. 2012, 29, 141–142. [Google Scholar] [CrossRef]

- Doshvarpassand, S.; Wu, C.; Wang, X. An overview of corrosion defect characterization using active infrared thermography. Infrared Phys. Technol. 2019, 96, 366–389. [Google Scholar] [CrossRef]

- Vallerand, S.; Maldague, X. Defect characterization in pulsed thermography: A statistical method compared with Kohonen and Perceptron neural networks. NDT E Int. 2000, 33, 307–315. [Google Scholar] [CrossRef]

- Yee, T.S.; Shrifan, N.H.M.M.; Al-Gburi, A.J.A.; Isa, N.A.M.; Akbar, M.F. Prospect of Using Machine Learning-Based Microwave Nondestructive Testing Technique for Corrosion Under Insulation: A Review. IEEE Access 2022, 10, 88191–88210. [Google Scholar] [CrossRef]

- Shrifan, N.; Akbar, M.F.; Isa, N. Prospect of Using Artificial Intelligence for Microwave Nondestructive Testing Technique: A Review. IEEE Access 2019, 7, 110628–110650. [Google Scholar] [CrossRef]

| Far-Field | Near-Field | Resonant Method | Microwave Imaging | Reflectometry | |

|---|---|---|---|---|---|

| Working principle | Based on the propagation of electromagnetic waves in the far-field region. | Relies on the electromagnetic interaction between the probe and the specimen at distances in the near-field region. | Utilizes the change in the resonance characteristics (frequency, quality factor, amplitude) of a resonant structure when interacting with the specimen under test. | Involves illuminating the object with microwave signals and then using the scattered or reflected signals to reconstruct images, revealing internal structures or defects. | Based on measuring the reflection of microwave signals from a structure. Variations in the reflected signal indicate changes in impedance, revealing defects or features. |

| Probe type |

|

| |||

|

|

|

| ||

|

|

| |||

| Advantages |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

| |

| Limitations |

|

| Can be complex and expensive |

| |

|

|

|

|

| |

|

|

| Sensitivity to noise and interference |

| |

| Applications |

|

| |||

|

|

| Microwave Microscopy | Active Microwave Thermography | Chipless RFID | |

|---|---|---|---|

| Working Principle | Employs microwave interaction with the sample at a microscopic level to generate high-resolution images or data | Heats the specimen with microwave signals and uses thermal cameras to identify temperature variations due to defects | Uses encoded electromagnetic fields reflected by chipless objects to transmit data |

| Probe type | |||

| Advantages |

|

|

|

| Limitations |

|

|

|

| Applications |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghattas, A.; Al-Sharawi, R.; Zakaria, A.; Qaddoumi, N. Detecting Defects in Materials Using Nondestructive Microwave Testing Techniques: A Comprehensive Review. Appl. Sci. 2025, 15, 3274. https://doi.org/10.3390/app15063274

Ghattas A, Al-Sharawi R, Zakaria A, Qaddoumi N. Detecting Defects in Materials Using Nondestructive Microwave Testing Techniques: A Comprehensive Review. Applied Sciences. 2025; 15(6):3274. https://doi.org/10.3390/app15063274

Chicago/Turabian StyleGhattas, Ahmad, Ramzi Al-Sharawi, Amer Zakaria, and Nasser Qaddoumi. 2025. "Detecting Defects in Materials Using Nondestructive Microwave Testing Techniques: A Comprehensive Review" Applied Sciences 15, no. 6: 3274. https://doi.org/10.3390/app15063274

APA StyleGhattas, A., Al-Sharawi, R., Zakaria, A., & Qaddoumi, N. (2025). Detecting Defects in Materials Using Nondestructive Microwave Testing Techniques: A Comprehensive Review. Applied Sciences, 15(6), 3274. https://doi.org/10.3390/app15063274