Methodology of Using CAx and Digital Twin Methods in the Development of a Multifunctional Portal Centre in Its Pre-Production Phase

Abstract

1. Introduction

1.1. Industry 4.0 and Industry 5.0

1.2. Focus on Machine Tools

- Fixed gantry machine (table-top design);

- Upper gantry;

- Bottom gantry.

1.3. CAx and Digital Twin Methods

- Digital twin of a product—This is a computer model of a product (for example, a real machine tool) on which its behaviour can be simulated. This means not only its stiffness but generally its functioning under certain conditions, specifically kinematic links between bodies, movements, communication (signals), or control system. Based on the data obtained from the virtual digital twin, it is possible to evaluate the behaviour and performance of the real machine.

- Digital twin of a process—It simulates complex processes such as a manufacturing plant, power grid, etc. It allows to analyse processes in real time.

- Digital twin of a system—It simulates entire systems, integrating several digital twins of products or processes together. For example, this includes simulations of transport networks, cities, etc.

- SIL—can consist of virtual SINUMERIK ONE controller Create MyVirtual Machine (CMVM) itself or it can consist of a combination of CMVM, machine PLC behaviour simulation (SIMIT), and functional 3D machine simulation (NX MCD).

- HIL—can consist of SIMIT and real SINUMERIK hardware (e.g., SINUMERIK ONE or SINUMERIK 840D) controller and functional 3D machine simulation (NX MCD).

1.4. Related Research

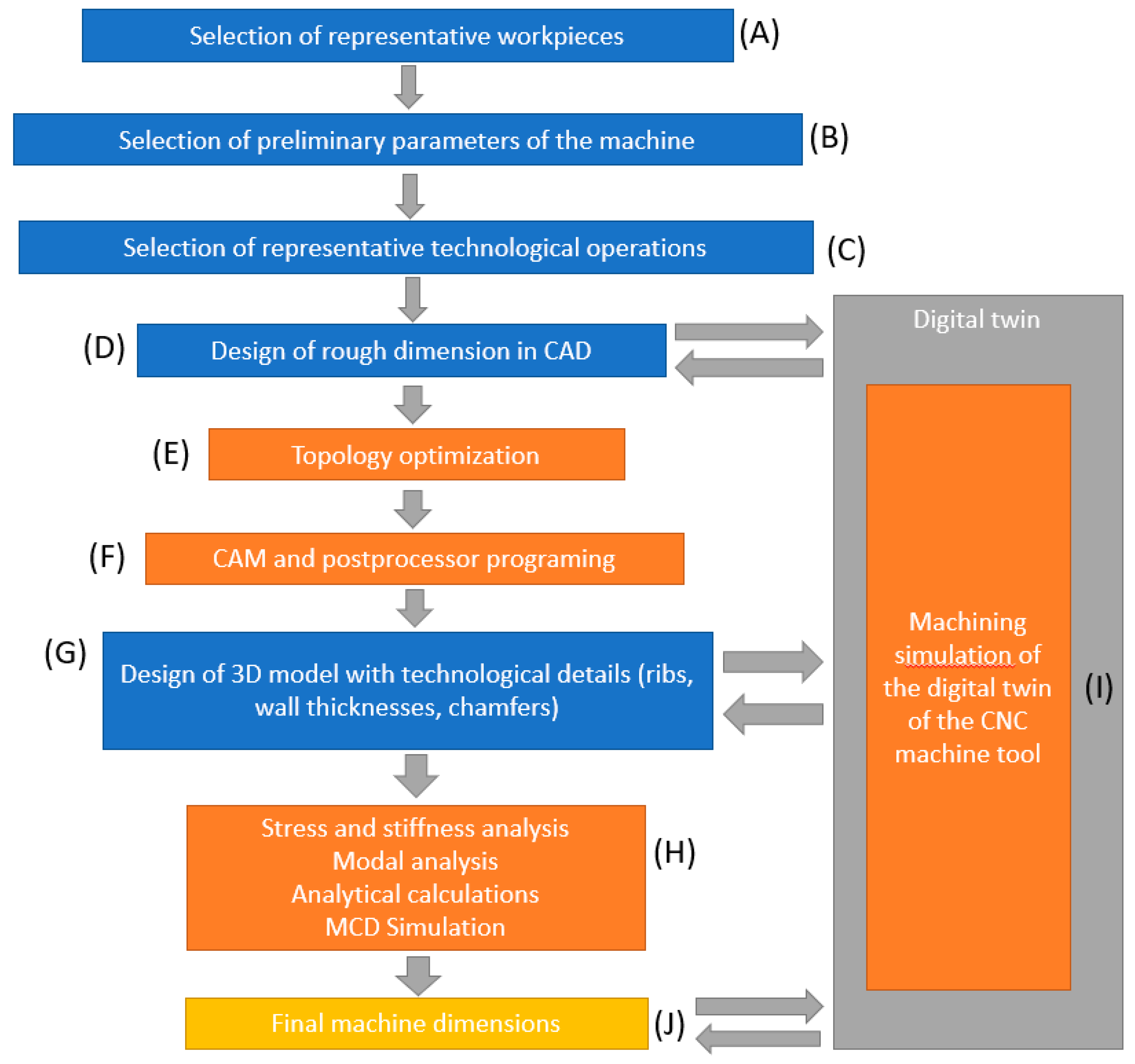

2. Methodology of Using CAx and Digital Twin Methods in the Development of a Multifunctional Portal Centre

3. Application of the Proposed Methodology

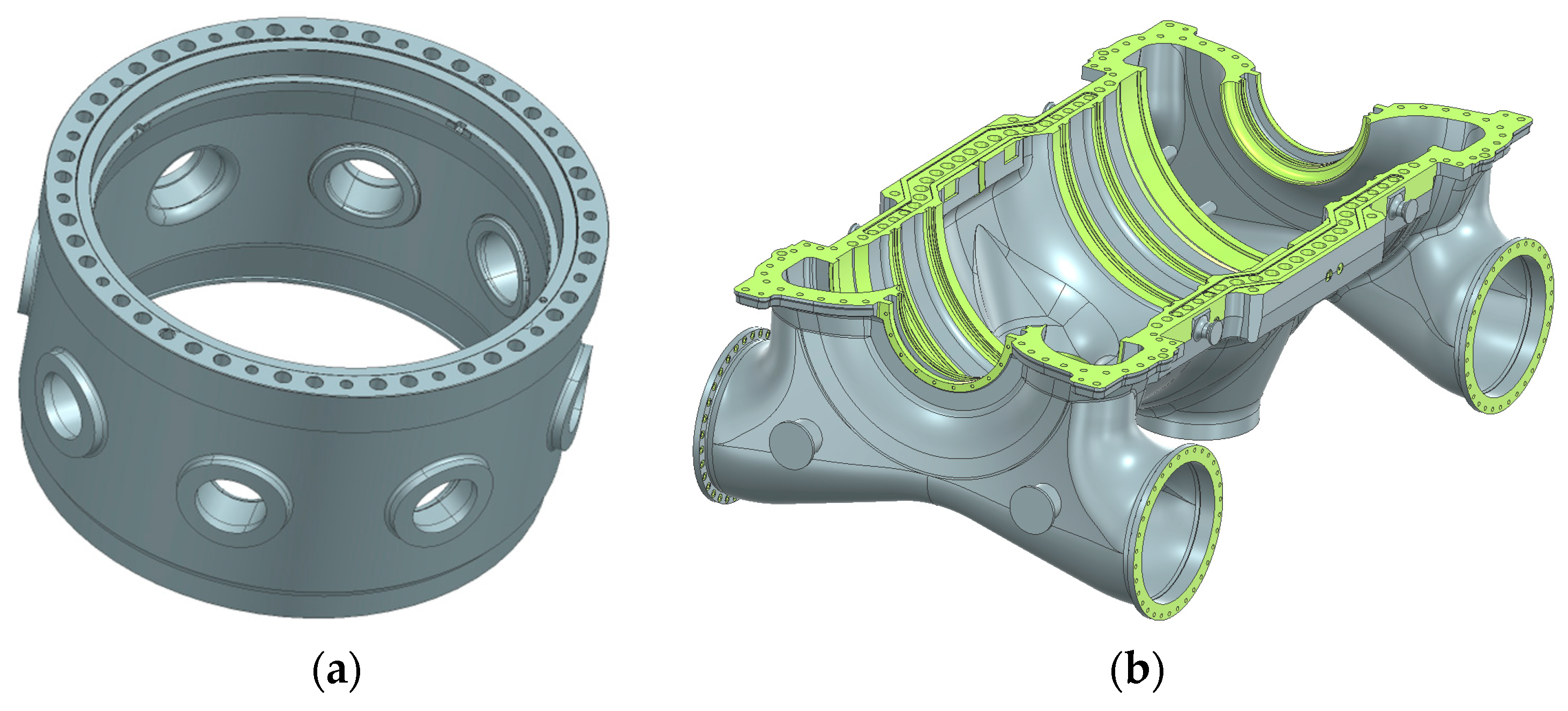

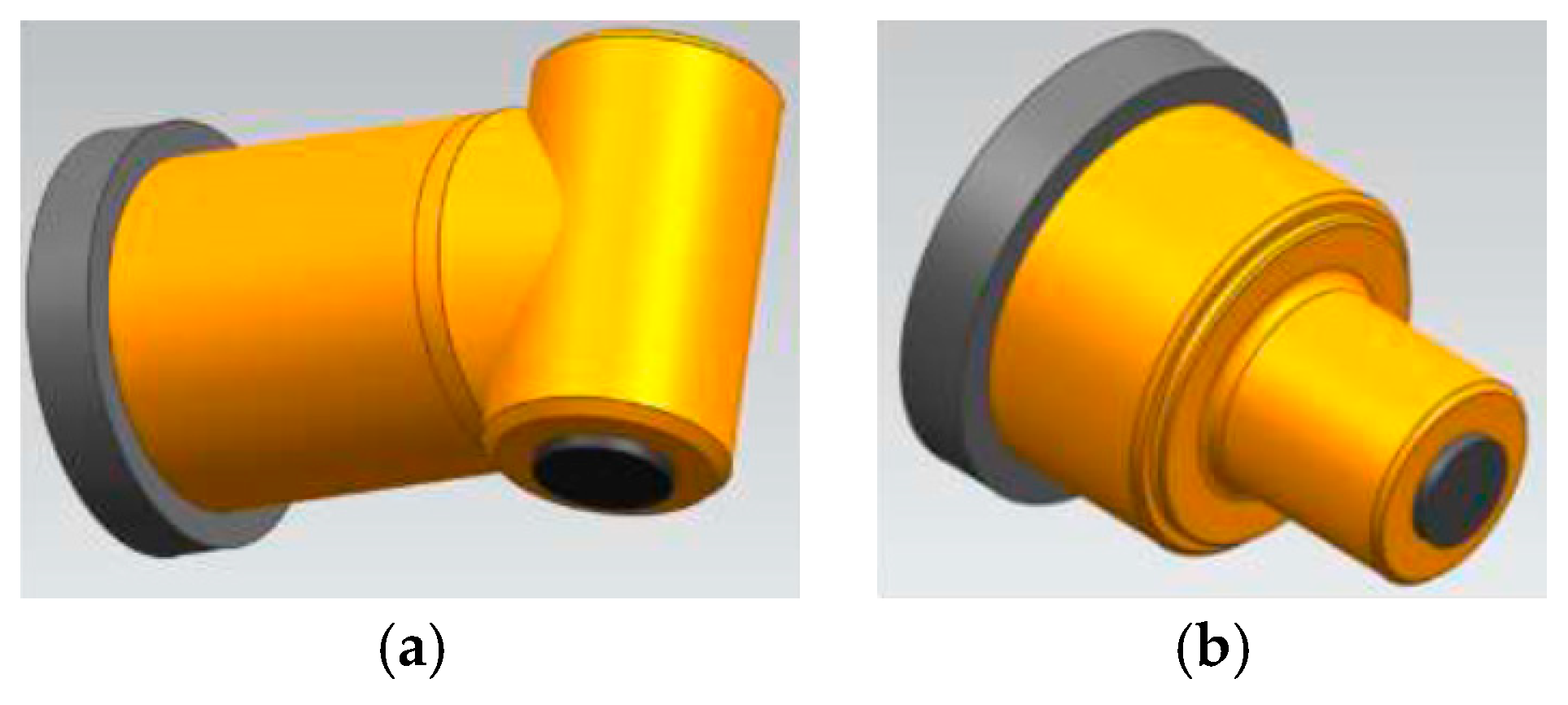

3.1. Selection of Representative Workpieces

3.2. Selection of Preliminary Parameters of the Machine

3.3. Selection of Representative Technological Operations

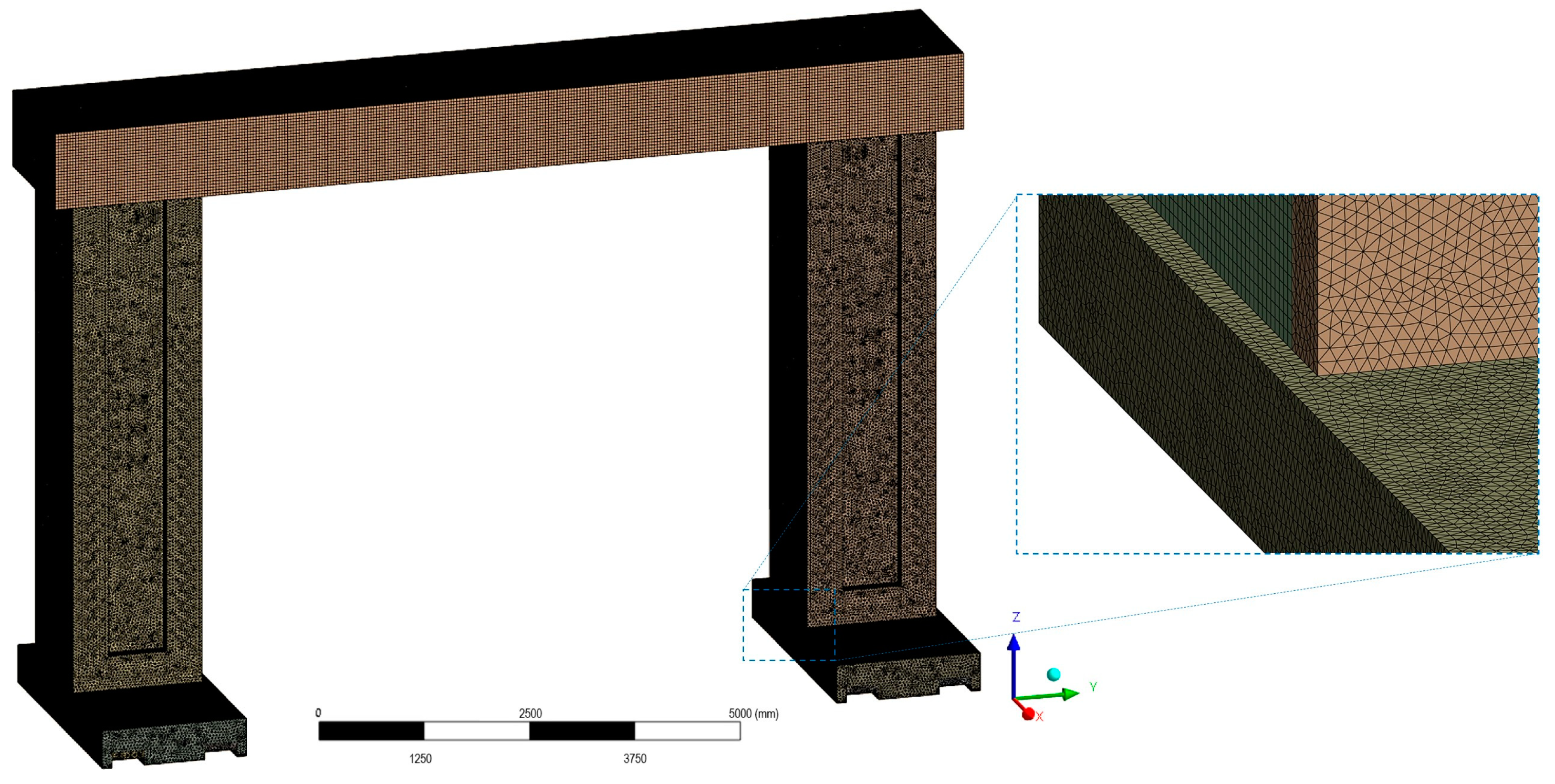

3.4. Design of Rough Dimensions in CAD

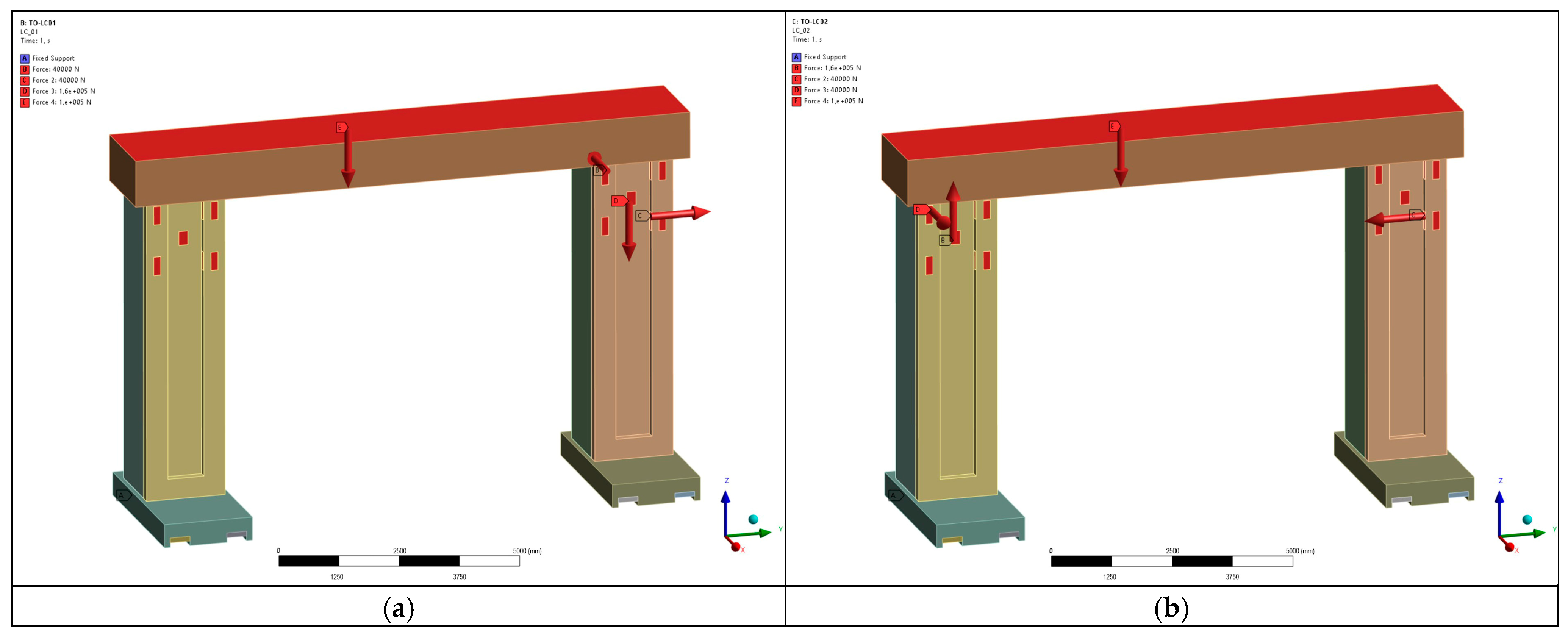

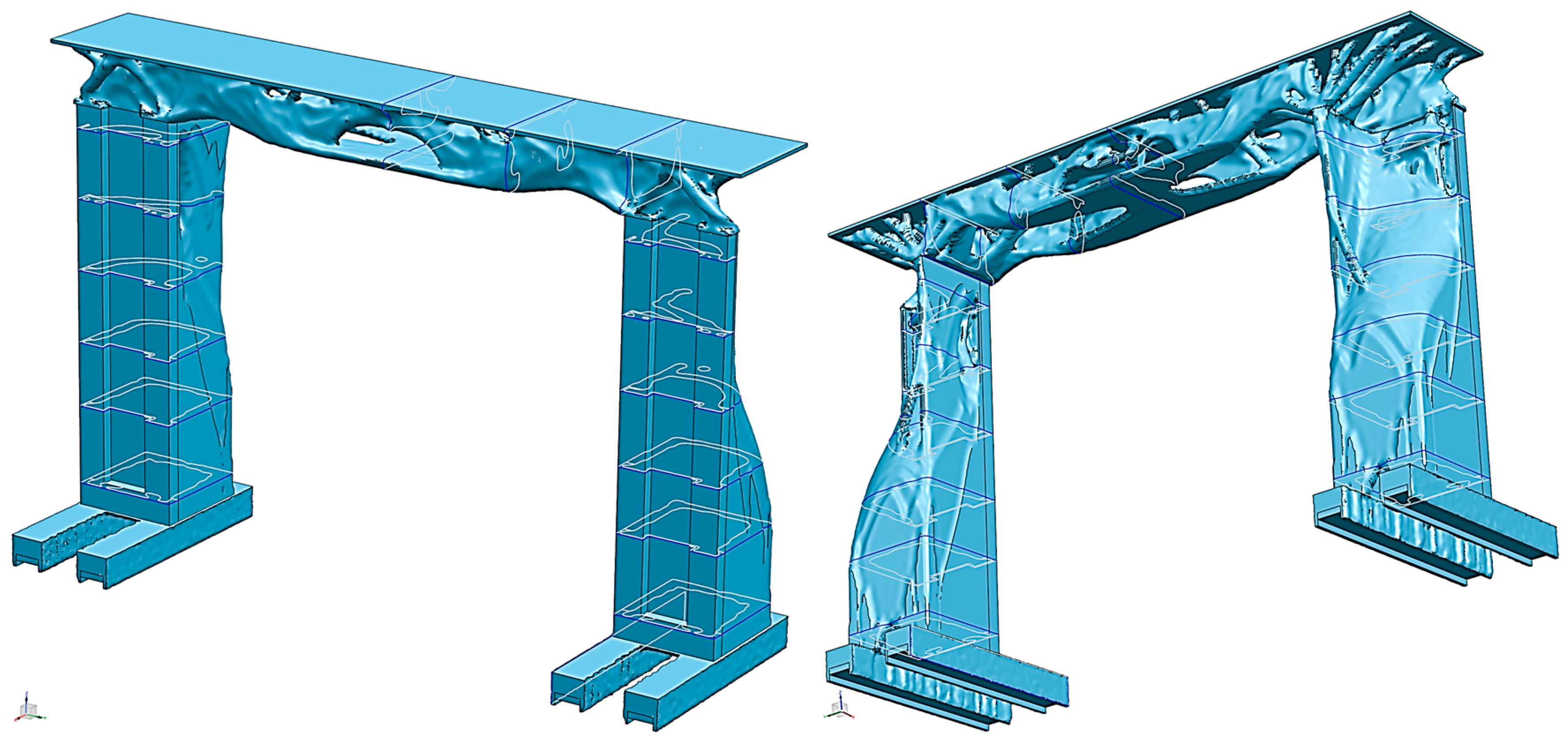

3.5. Topology Optimisation

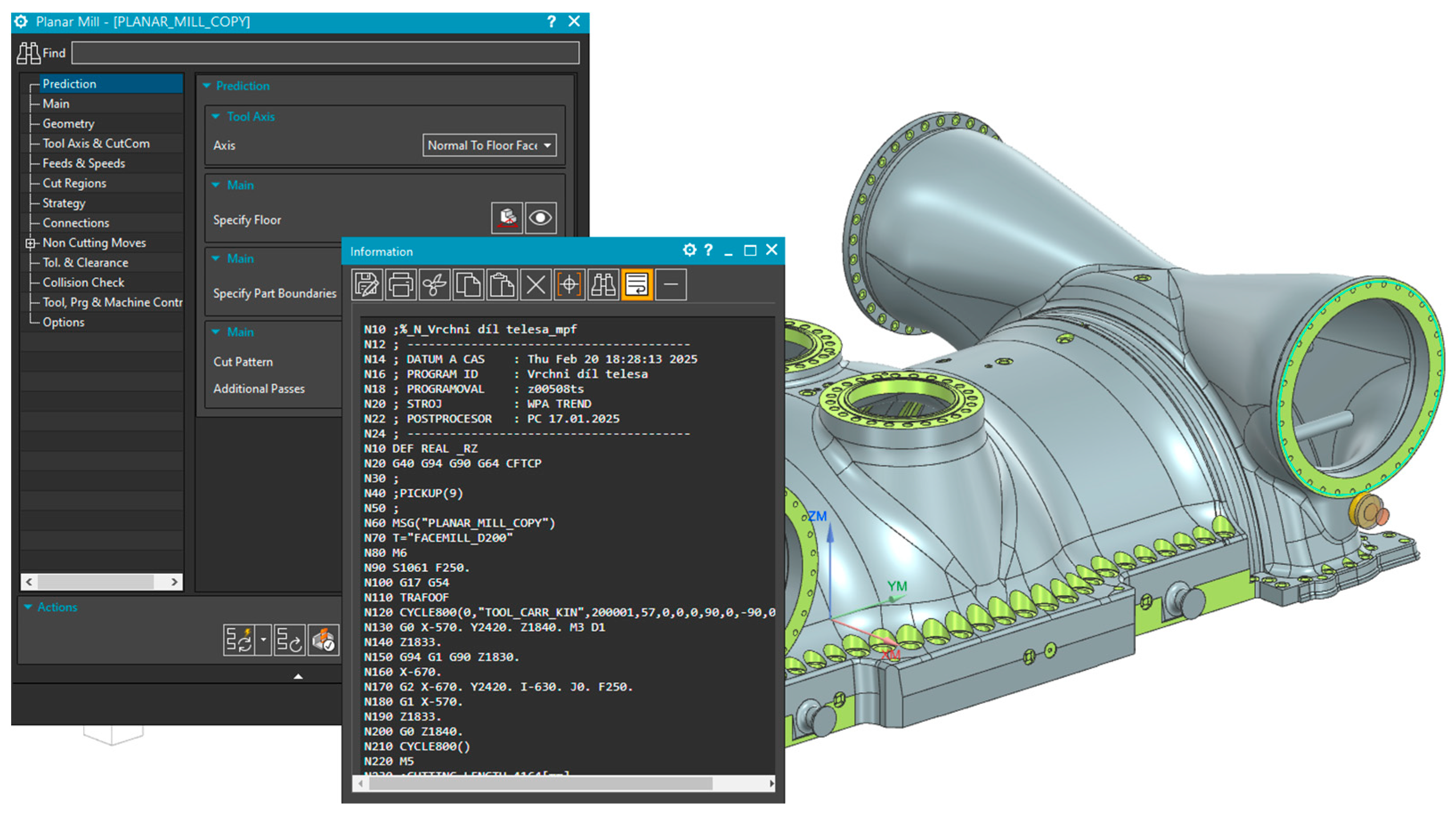

3.6. CAM and Postprocessor Programing

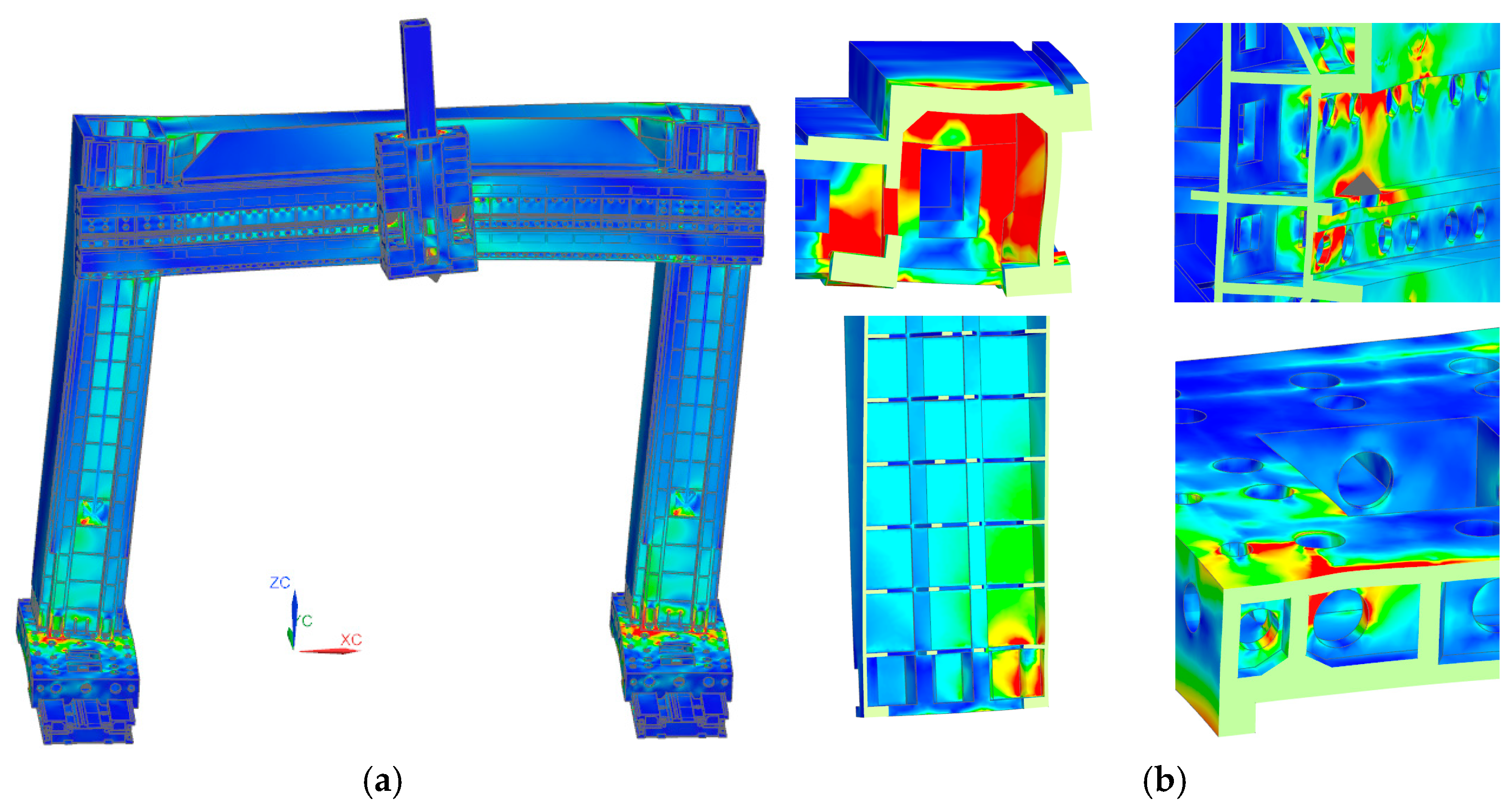

3.7. Stress and Stiffness Analysis

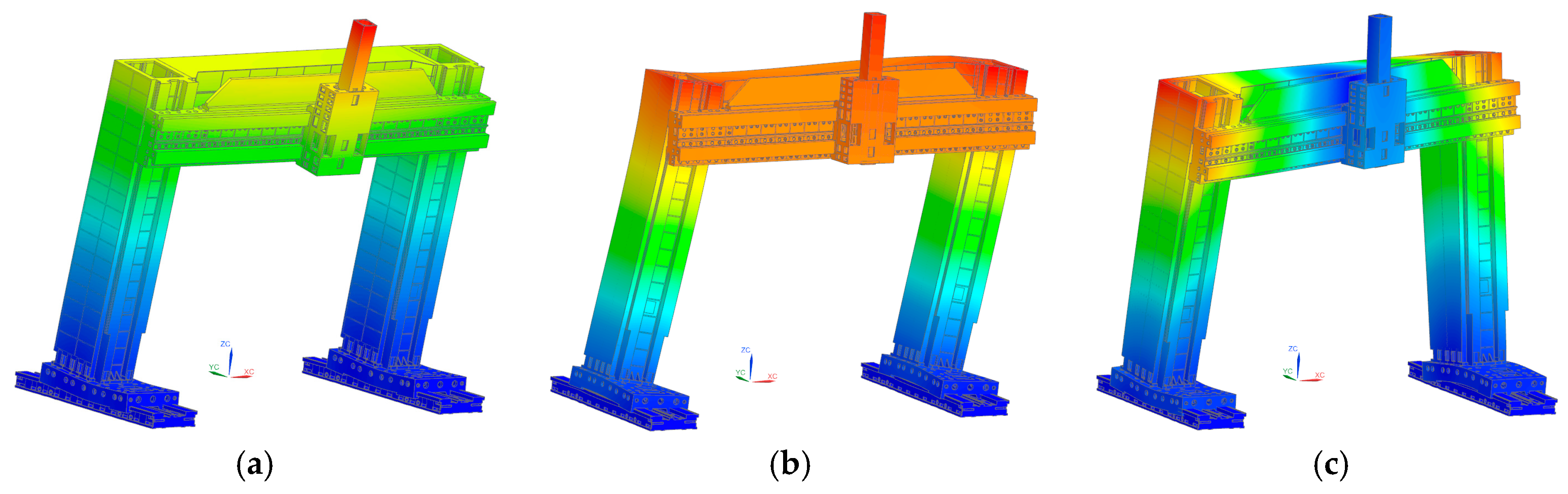

3.8. Modal Analysis

3.9. Analytical Calculations

- Guideways—Guideway of the bottom of the column on the bed, guideway of the cross-piece on the column, guideway of the spindle on the cross-piece, and guideway of the slide in the spindle.

- Feed mechanisms—Feed of the bottom of the column on the bed, feed of the cross-piece on the column, feed of the spindle on the cross-piece, and feed of the slide in the spindle.

- Screw connection

3.10. MCD Simulations

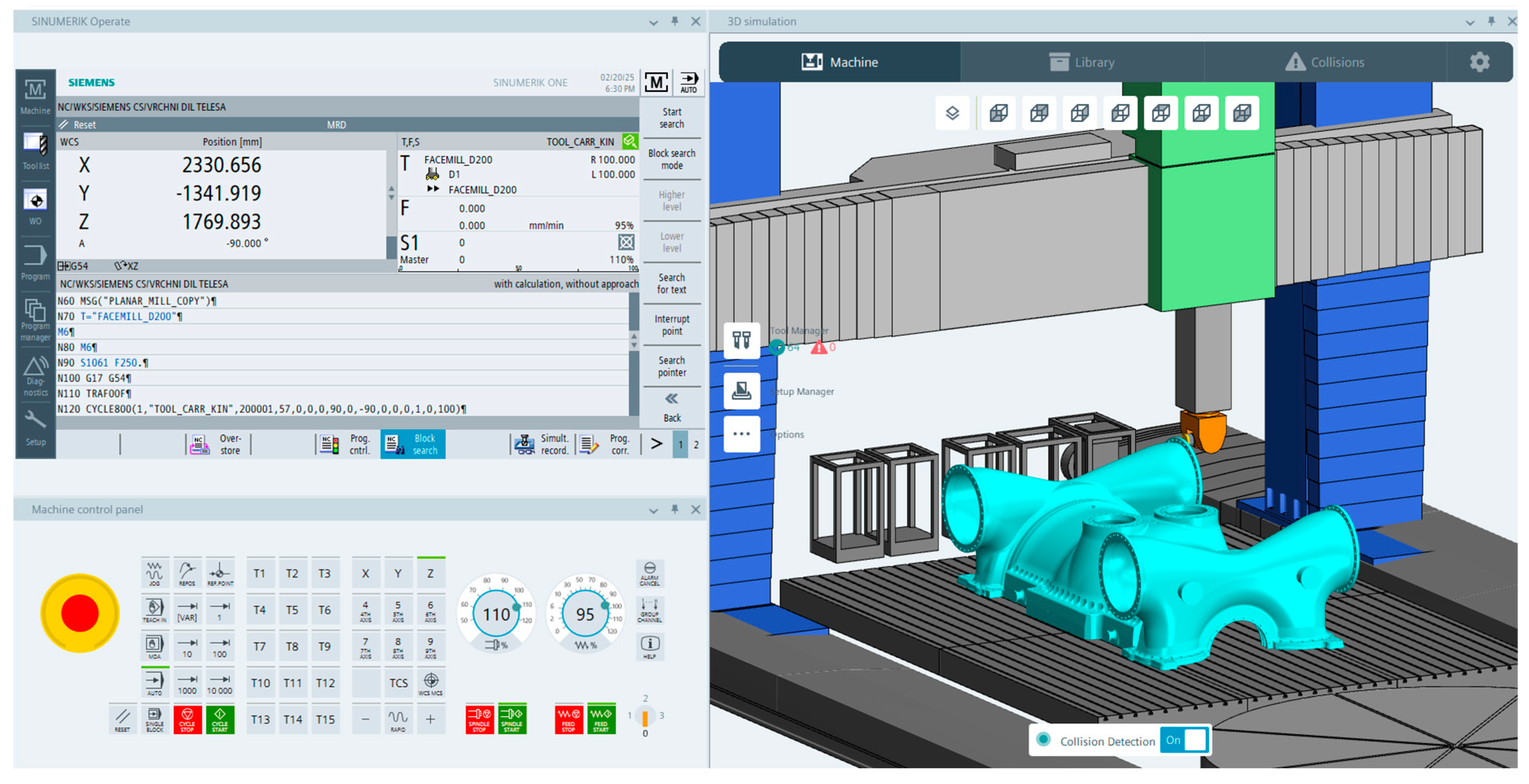

3.11. Machining Simulations of the Digital Twin of the CNC Machine Tool in Create MyVirtual Machine Software

- The kinematic model of the machine was developed in Create MyVirtual Machine 3D Builder 1.4.1.0 software.

- In CMVM software, the real control system was linked to the machine kinematics.

- The control system (SINUMERIK ONE) was configured for a given kinematic chain.

- Tool exchange and tool management were implemented.

- The machine kinematics were virtually compensated.

- A 3D model of the workpiece and tools was imported.

- The NC code generated by the postprocessor from the CAM tool was imported.

4. Results

- The rough dimensions were chosen;

- The main dimensions and especially the shape and internal dimensions of individual parts were optimised using the topology optimisation;

- The dimensions were optimised using the stress analysis;

- The dimensions were optimised using the stiffness analysis using the empirical stiffness value;

- The dimensions were optimised using the modal analysis;

- The dimensions were optimised using analytical calculations;

- MCD simulations were used to optimise the main dimensions in relation to the kinematics of the machine and the travel in each axis;

- The machining simulations (using the digital twin) verified the following dimensions in terms of the minimum values that were required for machining a given set of workpieces.

5. Discussion

6. Future Work

- Creation of MCD models in NX mechatronic concept designer (bodies, joints, actuators, signals);

- Setting up the SINUMERIK control system (installation of ADAS compile cycle, setting up simulation axes, disabling SAFETY INTEGRATED, etc.);

- Setting up LAN communication between PC and SIMIT UNIT;

- Setting up the HW configuration in SIMATIC Manager (adding ADAS);

- Creating a program in SIMATIC Manager;

- Creating a project in SIMIT software (mapping ProfiNET signals to Share Memory);

- Mapping signals between MCD and SIMIT software.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Paschek, D.; Luminosu, C.-T.; Ocakci, E. Industry 5.0 Challenges and Perspectives for Manufacturing Systems in the Society 5.0. In Sustainability and Innovation in Manufacturing Enterprises: Indicators, Models and Assessment for Industry 5.0; Draghici, A., Ivascu, L., Eds.; Springer: Singapore, 2022; pp. 17–63. ISBN 9789811673658. [Google Scholar]

- Kusiak, A. Smart Manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Dittrich, M.-A.; Denkena, B.; Boujnah, H.; Uhlich, F. Autonomous Machining—Recent Advances in Process Planning and Control. J. Mach. Eng. 2019, 19, 28–37. [Google Scholar] [CrossRef]

- Shirase, K.; Nakamoto, K. Simulation Technologies for the Development of an Autonomous and Intelligent Machine Tool. Int. J. Autom. Technol. 2013, 7, 6–15. [Google Scholar] [CrossRef]

- Ahmad, R.; Tichadou, S.; Hascoet, J.-Y. Generation of Safe and Intelligent Tool-Paths for Multi-Axis Machine-Tools in a Dynamic 2D Virtual Environment. Int. J. Comput. Integr. Manuf. 2016, 29, 982–995. [Google Scholar] [CrossRef]

- Ahmad, R.; Tichadou, S.; Hascoet, J.-Y. 3D Safe and Intelligent Trajectory Generation for Multi-Axis Machine Tools Using Machine Vision. Int. J. Comput. Integr. Manuf. 2013, 26, 365–385. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, X.; Wang, L. Smart Manufacturing Process and System Automation—A Critical Review of the Standards and Envisioned Scenarios. J. Manuf. Syst. 2020, 56, 312–325. [Google Scholar] [CrossRef]

- Chang, K.-H. E-Design: Computer-Aided Engineering Design; Academic Press: Cambridge, MA, USA, 2016; ISBN 978-0-12-809736-6. [Google Scholar]

- Gubbi, J.; Buyya, R.; Marusic, S.; Palaniswami, M. Internet of Things (IoT): A Vision, Architectural Elements, and Future Directions. Future Gener. Comput. Syst. 2013, 29, 1645–1660. [Google Scholar] [CrossRef]

- Buxmann, P.; Hess, T.; Ruggaber, R. Internet of Services. Bus. Inf. Syst. Eng. 2009, 1, 341–342. [Google Scholar] [CrossRef]

- Ráž, K.; Chval, Z.; Štěpánek, M.; Vyhnal, O. Mechanical Analysis of the Newly Developed 3D Printed Prosthetic Socket from PA12GB. MM Sci. J. 2022, 11, 6064–6068. [Google Scholar] [CrossRef]

- Gokalp, M.O.; Kayabay, K.; Akyol, M.A.; Eren, P.E.; Koçyiğit, A. Big Data for Industry 4.0: A Conceptual Framework. In Proceedings of the 2016 International Conference on Computational Science and Computational Intelligence (CSCI), Las Vegas, NV, USA, 15–17 December 2016; pp. 431–434. [Google Scholar]

- Gallala, A.; Kumar, A.A.; Hichri, B.; Plapper, P. Digital Twin for Human–Robot Interactions by Means of Industry 4.0 Enabling Technologies. Sensors 2022, 22, 4950. [Google Scholar] [CrossRef]

- Qian, L.; Luo, Z.; Du, Y.; Guo, L. Cloud Computing: An Overview. In Cloud Computing, Proceedings of the First International Conference, CloudCom 2009, Beijing, China, 1–4 December 2009; Jaatun, M.G., Zhao, G., Rong, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 626–631. [Google Scholar]

- Hunt, E.B. Artificial Intelligence; Academic Press: Cambridge, MA, USA, 2014; ISBN 978-1-4832-6317-5. [Google Scholar]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, Conception and Perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Coelho, P.; Bessa, C.; Landeck, J.; Silva, C. Industry 5.0: The Arising of a Concept. Procedia Comput. Sci. 2023, 217, 1137–1144. [Google Scholar] [CrossRef]

- Čechura, M.; Hlaváč, J.; Chval, Z.; Kubec, V. Přínosy řešení nových prototypů tvářecích strojů navržených CVTS na ZČU v Plzni se Šmeral Brno a.s. a TS Plzeň a.s. Benefits of solving new prototypes of forming machines designed by CVTS at UWB in Pilsen with Šmeral Brno a.s. and TS Plzeň a.s. Kovárenství 2019, 68, 79–83. [Google Scholar]

- Morgan, J.; Halton, M.; Qiao, Y.; Breslin, J.G. Industry 4.0 Smart Reconfigurable Manufacturing Machines. J. Manuf. Syst. 2021, 59, 481–506. [Google Scholar] [CrossRef]

- Xu, X. Machine Tool 4.0 for the New Era of Manufacturing. Int. J. Adv. Manuf. Technol. 2017, 92, 1893–1900. [Google Scholar] [CrossRef]

- Lee, E.A. CPS Foundations. In Proceedings of the 47th Design Automation Conference, Anaheim, CA, USA, 13–18 July 2010; Association for Computing Machinery: New York, NY, USA, 2010; pp. 737–742. [Google Scholar]

- Derler, P.; Lee, E.; Sangiovanni-Vincentelli, A. Modeling Cyber-Physical Systems. Proc. IEEE 2012, 100, 13–28. [Google Scholar] [CrossRef]

- Altintas, Y.; Brecher, C.; Weck, M.; Witt, S. Virtual Machine Tool. CIRP Ann. 2005, 54, 115–138. [Google Scholar] [CrossRef]

- Lee, K. Principles of CAD/CAM/CAE Systems; Addison-Wesley Longman Publishing Co., Inc.: Boston, MA, USA, 1999; ISBN 978-0-201-38036-1. [Google Scholar]

- Werner Dankwort, C.; Weidlich, R.; Guenther, B.; Blaurock, J.E. Engineers’ CAx Education—It’s Not Only CAD. Comput.-Aided Des. 2004, 36, 1439–1450. [Google Scholar] [CrossRef]

- Janda, P.; Polák, R. Virtual Prototyping and Optimization of Heavy Machine Tools. In Proceedings of the 26th DAAAM International Symposium on Intelligent Manufacturing and Automation, Zadar, Croatia, 18–25 October 2015; pp. 0967–0973, ISBN 978-3-902734-07-5. [Google Scholar]

- Hajicek, Z.; Marek, V. Simulation of Virtual Machine Tool During the Machine Design. In DAAAM Proceedings, Proceedings of the 28th DAAAM International Symposium on Intelligent Manufacturing and Automation, Zadar, Croatia, 8–11 November 2017; Katalinic, B., Ed.; DAAAM International: Vienna, Austria, 2017; Volume 1, pp. 0555–0560. ISBN 978-3-902734-11-2. [Google Scholar]

- Lasova, V.; Bernardin, P.; Švagr, M.; Kubicek, J. Alternative Solution of A Milling Head Housing Using the Computer Aided Systems. MM Sci. J. 2021, 2021, 4304–4309. [Google Scholar] [CrossRef]

- Sedláček, F.; Lasova, V.; Bernardin, P.; Janda, P.; Švagr, M. Optimization of Main Parts of a Heavy Duty CNC Machine Centre Using a Topological Optimization. In Proceedings of the 30th DAAAM International Symposium on Intelligent Manufacturing and Automation, Zadar, Croatia, 23–26 October 2019; pp. 0525–0532, ISBN 978-3-902734-22-8. [Google Scholar]

- Lo, C.K.; Chen, C.H.; Zhong, R.Y. A Review of Digital Twin in Product Design and Development. Adv. Eng. Inform. 2021, 48, 101297. [Google Scholar] [CrossRef]

- Meng, Z.; Guoxi, L. Digital Twinning Method Based on Multi-Model Integration and Interoperation. In Proceedings of the 2024 3rd International Conference on Innovations and Development of Information Technologies and Robotics (IDITR), Hong Kong, 23–25 May 2024; pp. 183–188. [Google Scholar]

- Gusev, M.P.; Nikolaev, S.M.; Uzhinsky, I.K.; Padalitsa, D.I.; Mozhenkov, E.R. Application of Optimization in the Early Stages of Product Development, Using a Small UAV Case Study. In Product Lifecycle Management to Support Industry 4.0, Proceedings of the 15th IFIP WG 5.1 International Conference, PLM 2018, Turin, Italy, 2–4 July 2018; Chiabert, P., Bouras, A., Noël, F., Ríos, J., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 294–303. [Google Scholar]

- Kenett, R.S.; Bortman, J. The Digital Twin in Industry 4.0: A Wide-Angle Perspective. Qual. Reliab. Eng. Int. 2022, 38, 1357–1366. [Google Scholar] [CrossRef]

- Onaji, I.; Tiwari, D.; Soulatiantork, P.; Song, B.; Tiwari, A. Digital Twin in Manufacturing: Conceptual Framework and Case Studies. Int. J. Comput. Integr. Manuf. 2022, 35, 831–858. [Google Scholar] [CrossRef]

- Sim, B.; Lee, W. Digital Twin Based Machining Condition Optimization for CNC Machining Center. Int. J. Precis. Eng. Manuf.-Smart Tech. 2023, 1, 115–123. [Google Scholar] [CrossRef]

- Zhang, K.; Ding, Z. Virtual Simulation Design and Debugging of Lift-and-Transverse Stereo Garage Based on the Digital Twin. Appl. Sci. 2024, 14, 3896. [Google Scholar] [CrossRef]

- Schacht, J.; Wölk, A.; Pingel, S.; Herbst, U.; Naujoks, D. Simulation System for the Wendelstein 7-X Safety Control System. IEEE Trans. Nucl. Sci. 2019, 66, 1262–1266. [Google Scholar] [CrossRef]

- Oppelt, M.; Wolf, G.; Urbas, L. Towards an Integrated Use of Simulation within the Life-Cycle of a Process Plant. In Proceedings of the 2015 IEEE 20th Conference on Emerging Technologies & Factory Automation (ETFA), Luxembourg, 8–11 September 2015; pp. 1–8. [Google Scholar]

- Kopček, M.; Križanová, G.; Ružarovský, R. A Brief Survey of Creating a Digital Twin Architecture for Virtual Commissioning on the Machine Level. Res. Pap. Fac. Mater. Sci. Technol. Slovak Univ. Technol. 2022, 30, 71–80. [Google Scholar] [CrossRef]

- Bargiela, A.; Ali, S.A.; Crowley, D.; Kerckhoffs, E.J.H. Proceedings of the 24th European Conference on Modelling and Simulation, Kuala Lumpur, Malaysia, 1–4 June 2010; ECMS Press: Hong Kong, China, 2010; ISBN 978-0-9564944-0-5. [Google Scholar]

- Janda, P. Mechatronic Concept of Heavy Machine Tools; DAAAM: Vienna, Austria, 2018; ISBN 978-3-902734-20-4. [Google Scholar]

- Janda, P.; Hájíček, Z.; Bernardin, P. Implementation of The Digital Twin Methodology. In Proceedings of the 30th DAAAM International Symposium on Intelligent Manufacturing and Automation, Zadar, Croatia, 23–26 October 2019; pp. 0533–0538, ISBN 978-3-902734-22-8. [Google Scholar]

- Rao, S.S. The Finite Element Method in Engineering; Butterworth-Heinemann: Oxford, UK, 2017; ISBN 978-0-12-814364-3. [Google Scholar]

- Querin, O.M.; Young, V.; Steven, G.P.; Xie, Y.M. Computational Efficiency and Validation of Bi-Directional Evolutionary Structural Optimisation. Comput. Methods Appl. Mech. Eng. 2000, 189, 559–573. [Google Scholar] [CrossRef]

- Querin, O.M.; Steven, G.P.; Xie, Y.M. Evolutionary Structural Optimisation Using an Additive Algorithm. Finite Elem. Anal. Des. 2000, 34, 291–308. [Google Scholar] [CrossRef]

- Xie, Y.M.; Huang, X. Recent Developments in Evolutionary Structural Optimization (ESO) for Continuum Structures. IOP Conf. Ser. Mater. Sci. Eng. 2010, 10, 012196. [Google Scholar] [CrossRef]

- Beckers, M.; Fleury, C. Topology Optimization Involving Discrete Variables; Polish Academy of Sciences, Institute of Fundamental Technological Research: Warsaw, Poland, 1997. [Google Scholar]

- Allaire, G. The Homogenization Method for Topology and Shape Optimization. In Topology Optimization in Structural Mechanics; Rozvany, G.I.N., Ed.; Springer: Vienna, Austria, 1997; pp. 101–133. ISBN 978-3-7091-2566-3. [Google Scholar]

- Stolpe, M.; Svanberg, K. An Alternative Interpolation Scheme for Minimum Compliance Topology Optimization. Struct. Multidisc. Optim. 2001, 22, 116–124. [Google Scholar] [CrossRef]

- Bendsøe, M.P. Optimal Shape Design as a Material Distribution Problem. Struct. Optim. 1989, 1, 193–202. [Google Scholar] [CrossRef]

- Zhou, M.; Rozvany, G.I.N. The COC Algorithm, Part II: Topological, Geometrical and Generalized Shape Optimization. Comput. Methods Appl. Mech. Eng. 1991, 89, 309–336. [Google Scholar] [CrossRef]

- Sakata, K.; Fujimoto, H. Master-Slave Synchronous Position Control for Precision Stages Based on Multirate Control and Dead-Time Compensation. In Proceedings of the 2009 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Singapore, 14–17 July 2009; pp. 263–268. [Google Scholar]

- Okubo, N.; Yoshida, Y.; Hoshi, T. Application of Modal Analysis to Machine Tool Structures. CIRP Ann. 1982, 31, 243–246. [Google Scholar] [CrossRef]

- Zeman, V.; Hlaváč, Z. Kmitání Mechanických Soustav, 2nd ed.; Západočeská Univerzita: Plzeň, Czech Republic, 2004; ISBN 807043337X. [Google Scholar]

- Huang, D.T.-Y.; Lee, J.-J. On Obtaining Machine Tool Stiffness by CAE Techniques. Int. J. Mach. Tools Manuf. 2001, 41, 1149–1163. [Google Scholar] [CrossRef]

- Lianqing, Y.; Liping, W. Stiffness Analysis of Machine Tools Using Finite Element Method. In Proceedings of the 2009 Third International Symposium on Intelligent Information Technology Application, Nanchang, China, 21–22 November 2009; Volume 3, pp. 553–556. [Google Scholar]

| Parameter | Unit | High Speed Solution | High Torque Solution |

|---|---|---|---|

| Power | [kW] | 119 | |

| Spindle speed | [rpm] | 4000 | 3000 |

| Torque | [Nm] | 3000 | 8500 |

| Clearance under spindle | [mm] | 7000 | 7000 |

| Clearance between column | [mm] | 9000 | 9000 |

| X (Gantry)—axis | [mm] | n × 2000 | |

| Y (Headstock)—axis | [mm] | 10,000 | |

| Z (Ram)—axis | [mm] | 2000 | |

| W (Cross-piece)—axis | [mm] | 5000 | |

| Feed rates | [mm/min] | 0.5–15,000 | |

| Ram extension | [mm] | 2000 | |

| Tool | Workpiece/Tool Diameter | Power | Cutting Torque | Cutting Force |

|---|---|---|---|---|

| Cutting unit C10-PSRNL-58110-25 | 190 mm | 34.9 kW | 7690 Nm | 40 kN |

| Square shoulder milling cutter A490-254R63-14M | 254 mm | 96.3 kW | 6270 Nm | 24.6 kN |

| Square shoulder milling cutter R390-160Q40-18L | 160 mm | 48 kW | 1360 Nm | 8.5 kN |

| Face milling cutter 345-100Q32-13H | 100 mm | 30.3 kW | 431 Nm | 4.3 kN |

| Square shoulder milling cutter 490-050C5-08M | 50 mm | 16.6 kW | 110 Nm | 2.2 kN |

| Solid carbide end mill 1K223-2000-050-NH H10F | 20 mm | 31.8 kW | 14.9 Nm | 0.75 kN |

| Solid carbide end mill 1K212-0200-XA 1730 | 2 mm | 0.09 kW | 0.0381 Nm | 0.02 kN |

| Face disc milling cutter R331.32-315Q60RM23.50 | 315 mm | 23.2 kW | 1438 Nm | 8 kN |

| Parameter | Stiffness of Fixators (Normal/Tangential) | Displacement | |||

|---|---|---|---|---|---|

| X | Y | Z | XYZ | ||

| Displacement in the tool position | 6000/500 kN/mm | 0.319 mm | 0.374 mm | 0.184 mm | 0.525 mm |

| Stiffness in the tool position | 125.4 kN/mm | 107 kN/mm | 217.4 kN/mm | ||

| Natural Frequency | Value | Units | Natural Frequency | Value | Units | Natural Frequency | Value | Units | Natural Frequency | Value | Units |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. | 4.3 | Hz | 6. | 22.4 | Hz | 11. | 35.6 | Hz | 16. | 38.8 | Hz |

| 2. | 4.5 | Hz | 7. | 27.6 | Hz | 12. | 36.7 | Hz | 17. | 39.5 | Hz |

| 3. | 8.5 | Hz | 8. | 28.7 | Hz | 13. | 37.1 | Hz | 18. | 40.4 | Hz |

| 4. | 16.4 | Hz | 9. | 31.3 | Hz | 14. | 37.5 | Hz | 19. | 48.8 | Hz |

| 5. | 19.8 | Hz | 10. | 31.7 | Hz | 15. | 38.0 | Hz | 20. | 49.7 | Hz |

| X (Headstock)—axis | 10,000 mm |

| Y (Gantry)—axis | 21,000 mm |

| Z (Ram)—axis | 2500 mm |

| W (Cross-piece)—axis | 3500 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bernardin, P.; Hajicek, Z.; Janda, P.; Kozak, J.; Sedlacek, F.; Lasova, V.; Kubicek, J. Methodology of Using CAx and Digital Twin Methods in the Development of a Multifunctional Portal Centre in Its Pre-Production Phase. Appl. Sci. 2025, 15, 3312. https://doi.org/10.3390/app15063312

Bernardin P, Hajicek Z, Janda P, Kozak J, Sedlacek F, Lasova V, Kubicek J. Methodology of Using CAx and Digital Twin Methods in the Development of a Multifunctional Portal Centre in Its Pre-Production Phase. Applied Sciences. 2025; 15(6):3312. https://doi.org/10.3390/app15063312

Chicago/Turabian StyleBernardin, Petr, Zdenek Hajicek, Petr Janda, Josef Kozak, Frantisek Sedlacek, Vaclava Lasova, and Jiri Kubicek. 2025. "Methodology of Using CAx and Digital Twin Methods in the Development of a Multifunctional Portal Centre in Its Pre-Production Phase" Applied Sciences 15, no. 6: 3312. https://doi.org/10.3390/app15063312

APA StyleBernardin, P., Hajicek, Z., Janda, P., Kozak, J., Sedlacek, F., Lasova, V., & Kubicek, J. (2025). Methodology of Using CAx and Digital Twin Methods in the Development of a Multifunctional Portal Centre in Its Pre-Production Phase. Applied Sciences, 15(6), 3312. https://doi.org/10.3390/app15063312