Microstructure Characteristics and Mechanical Properties of High-Strength Invar Alloy by Wire Arc Additive Manufacturing

Abstract

:1. Introduction

2. Materials and Methods

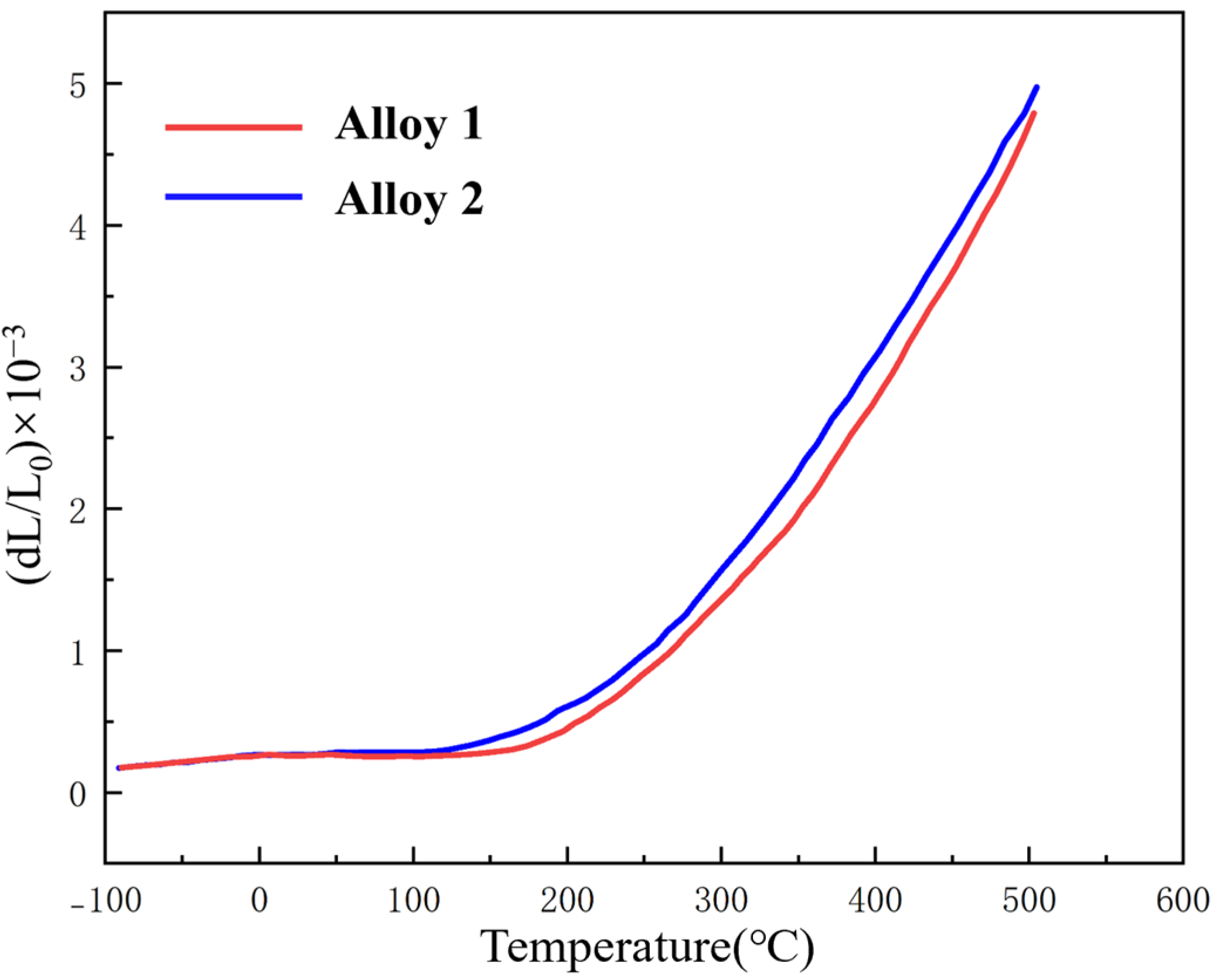

2.1. Materials

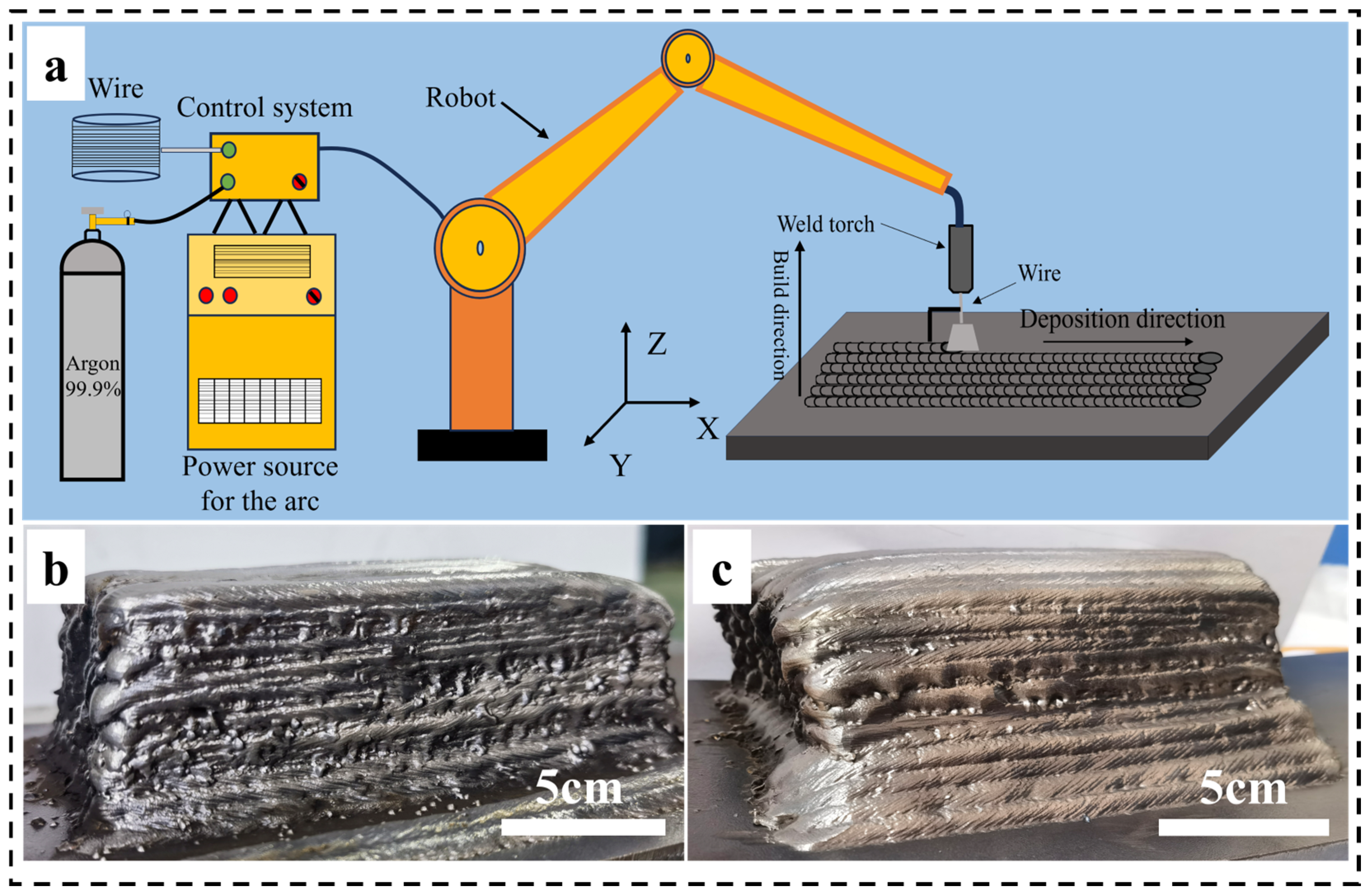

2.2. Manufacturing Process

2.3. Material Characterization

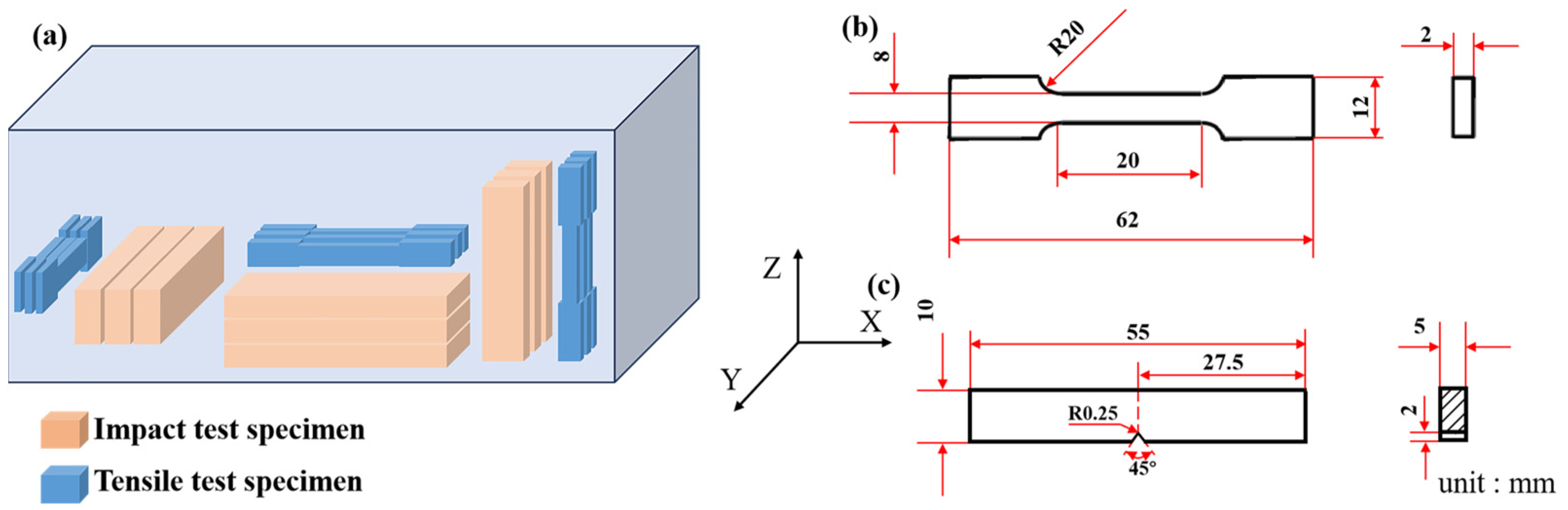

2.4. Mechanical Property Tests

3. Results and Discussion

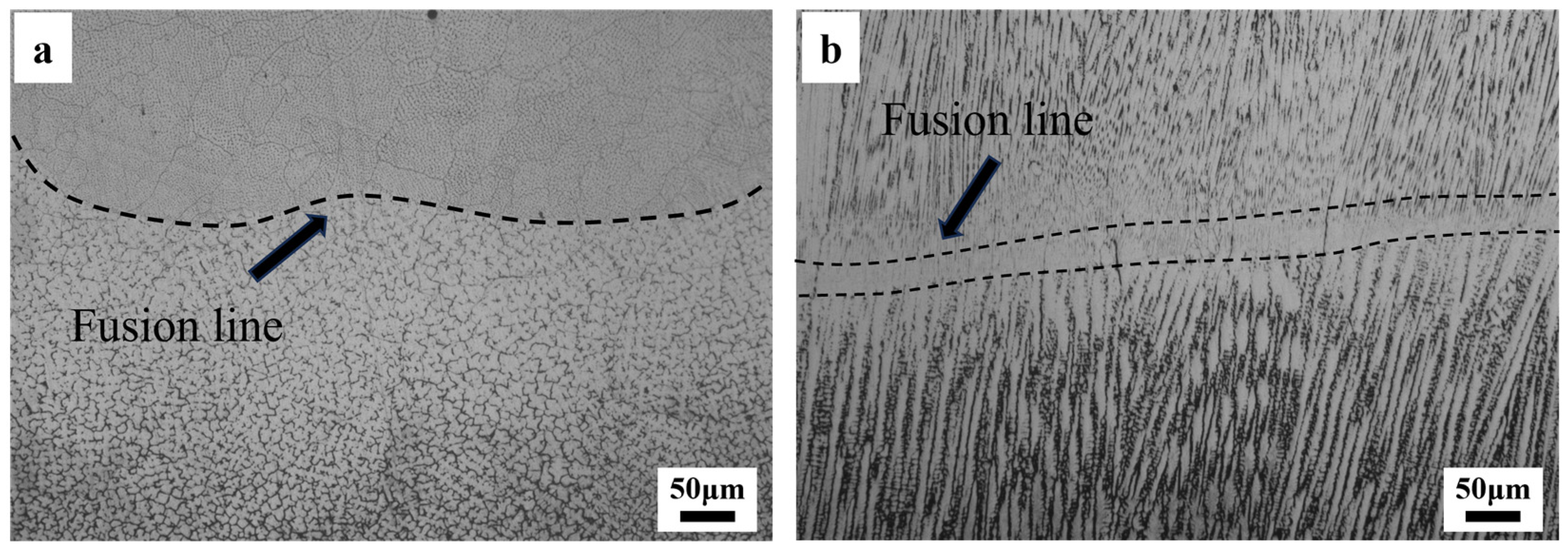

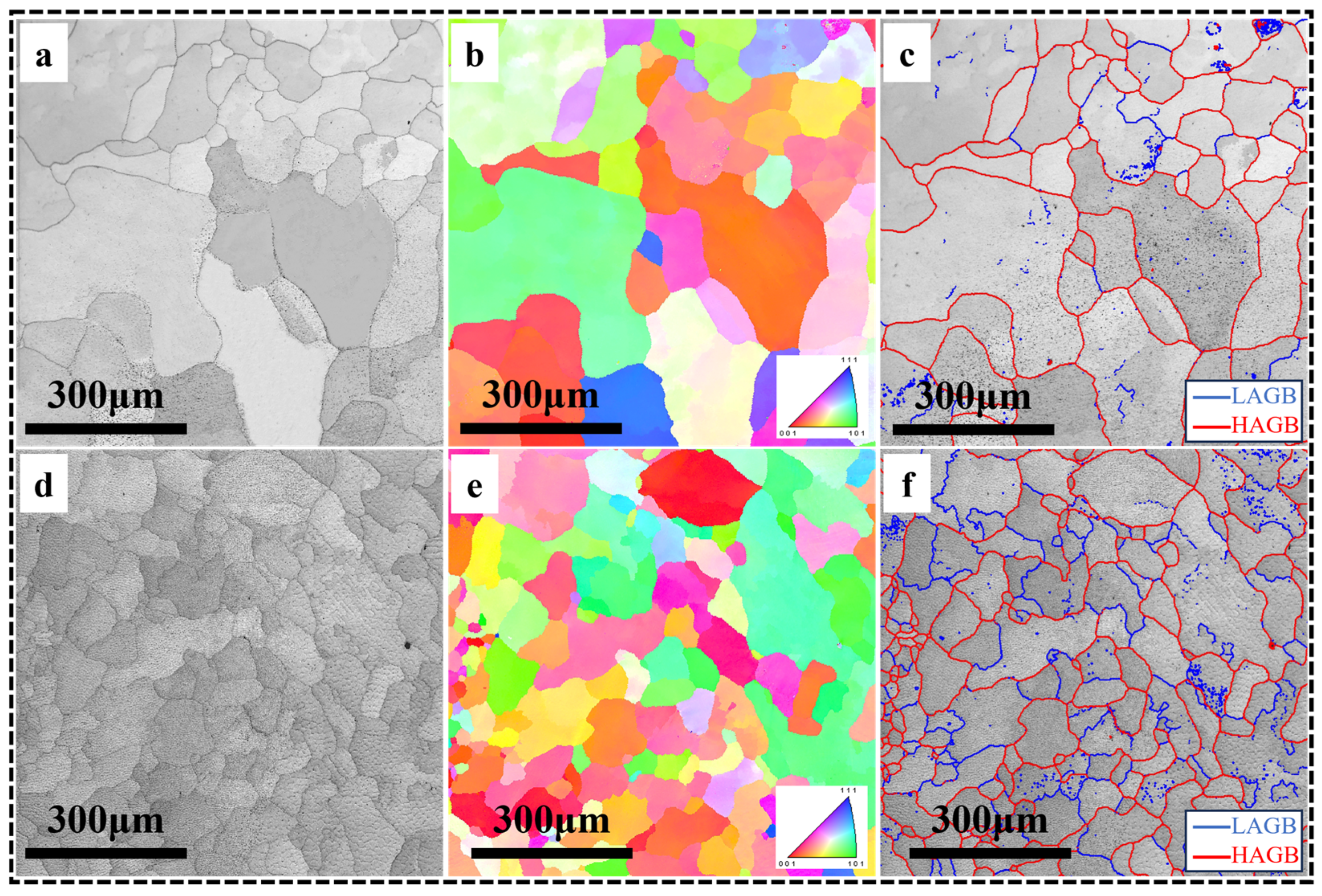

3.1. Microstructure

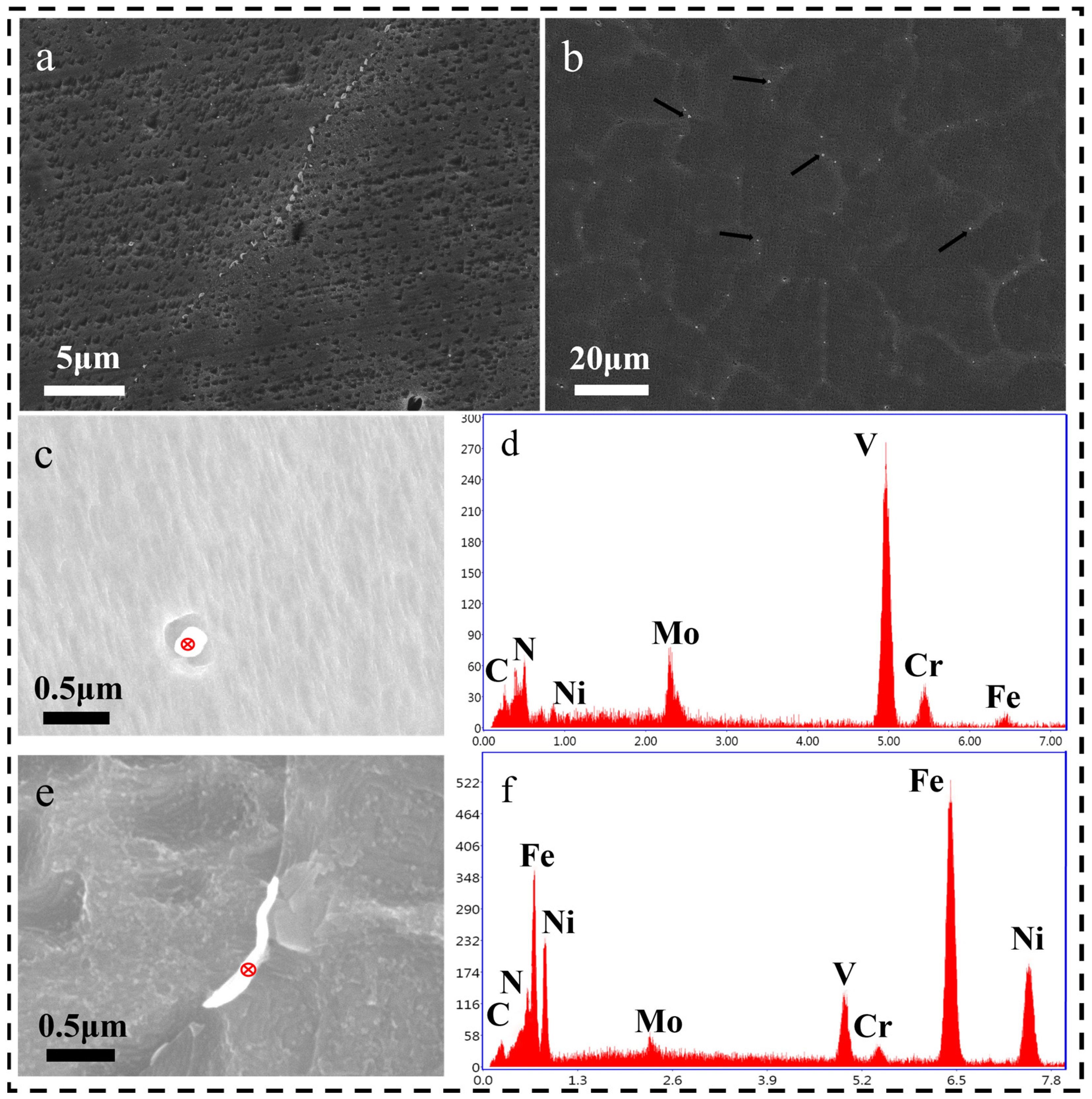

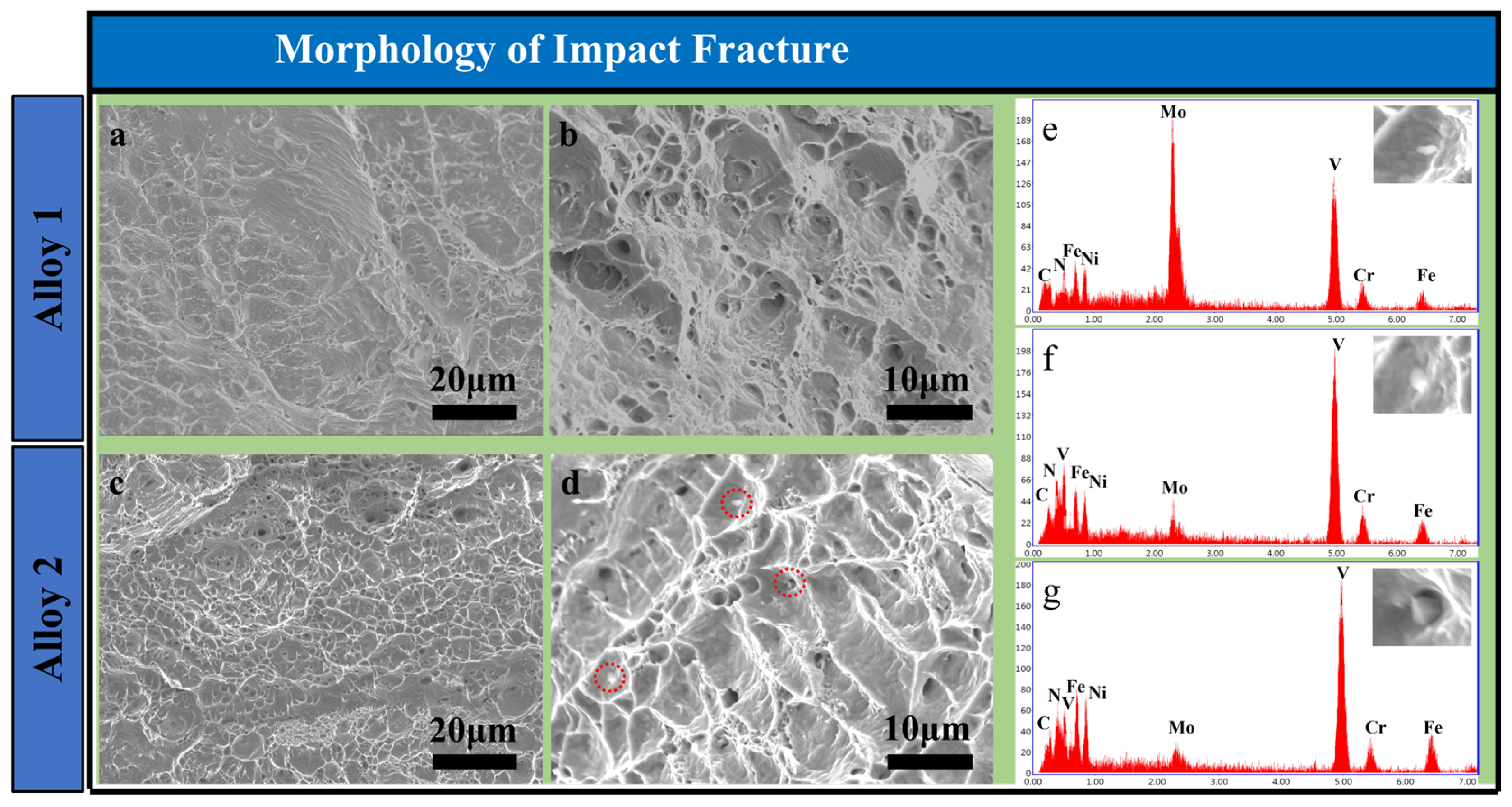

3.2. Morphology and Elemental Composition of Precipitated Phases

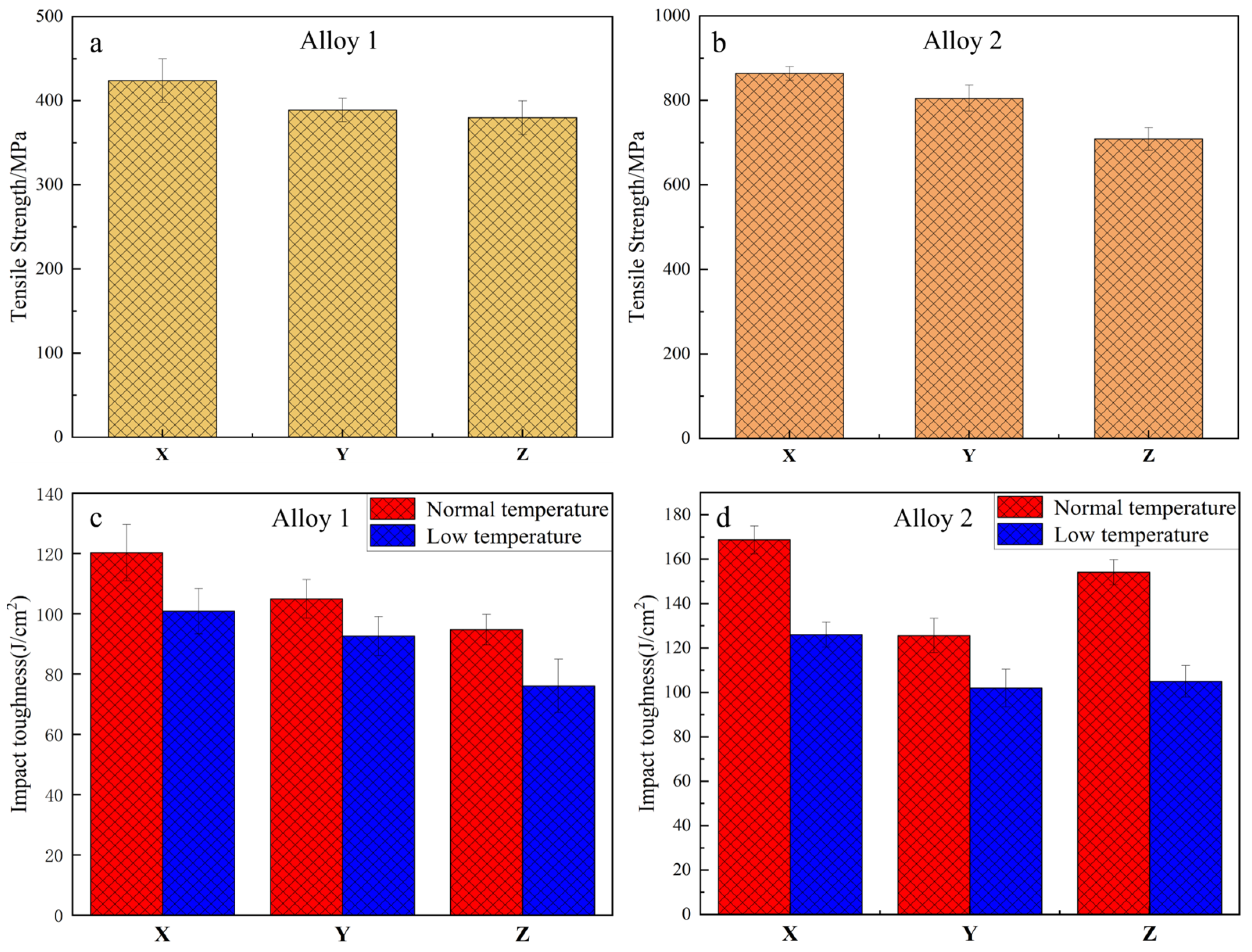

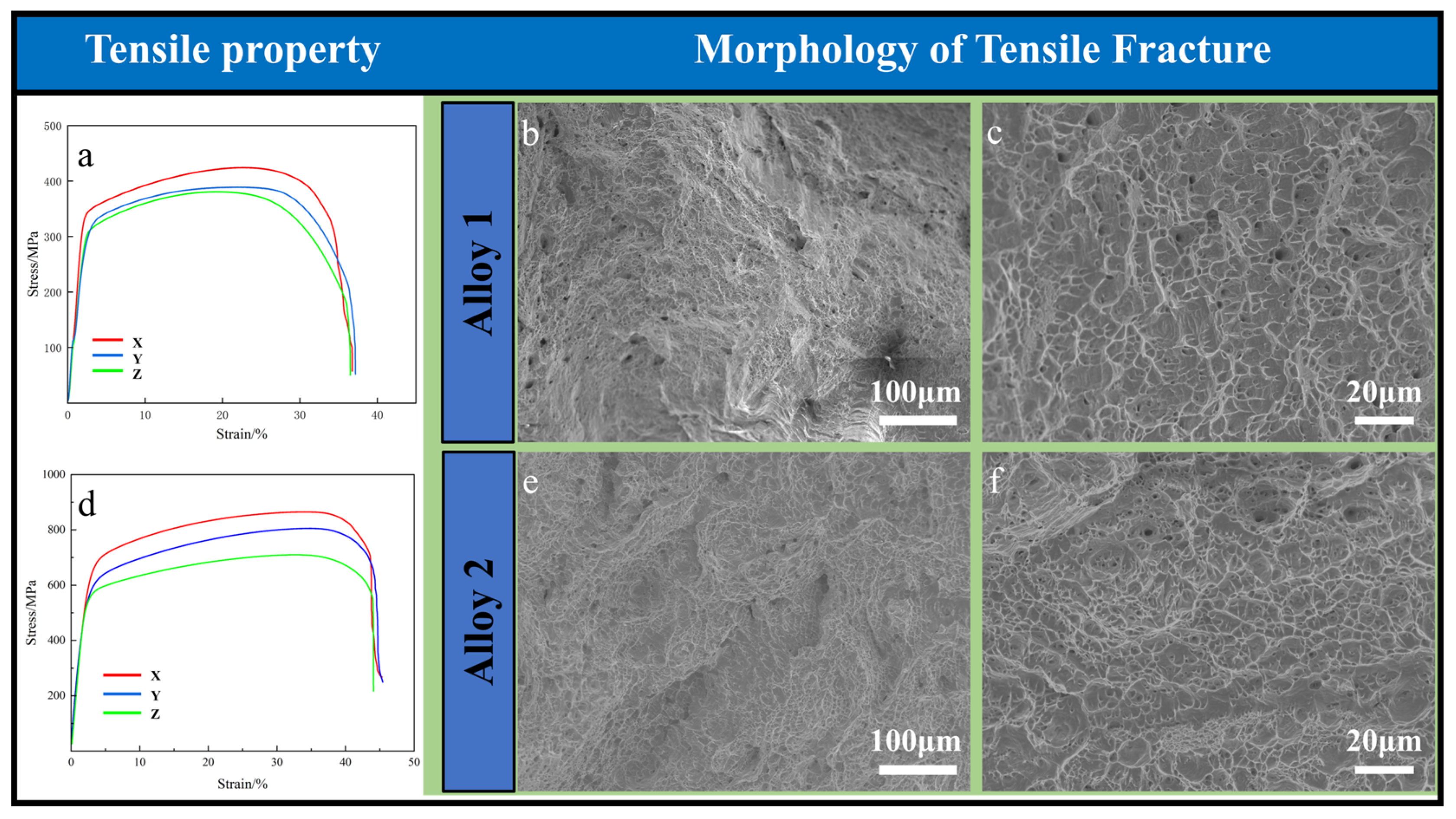

3.3. Mechanical Properties

4. Conclusions

- (1)

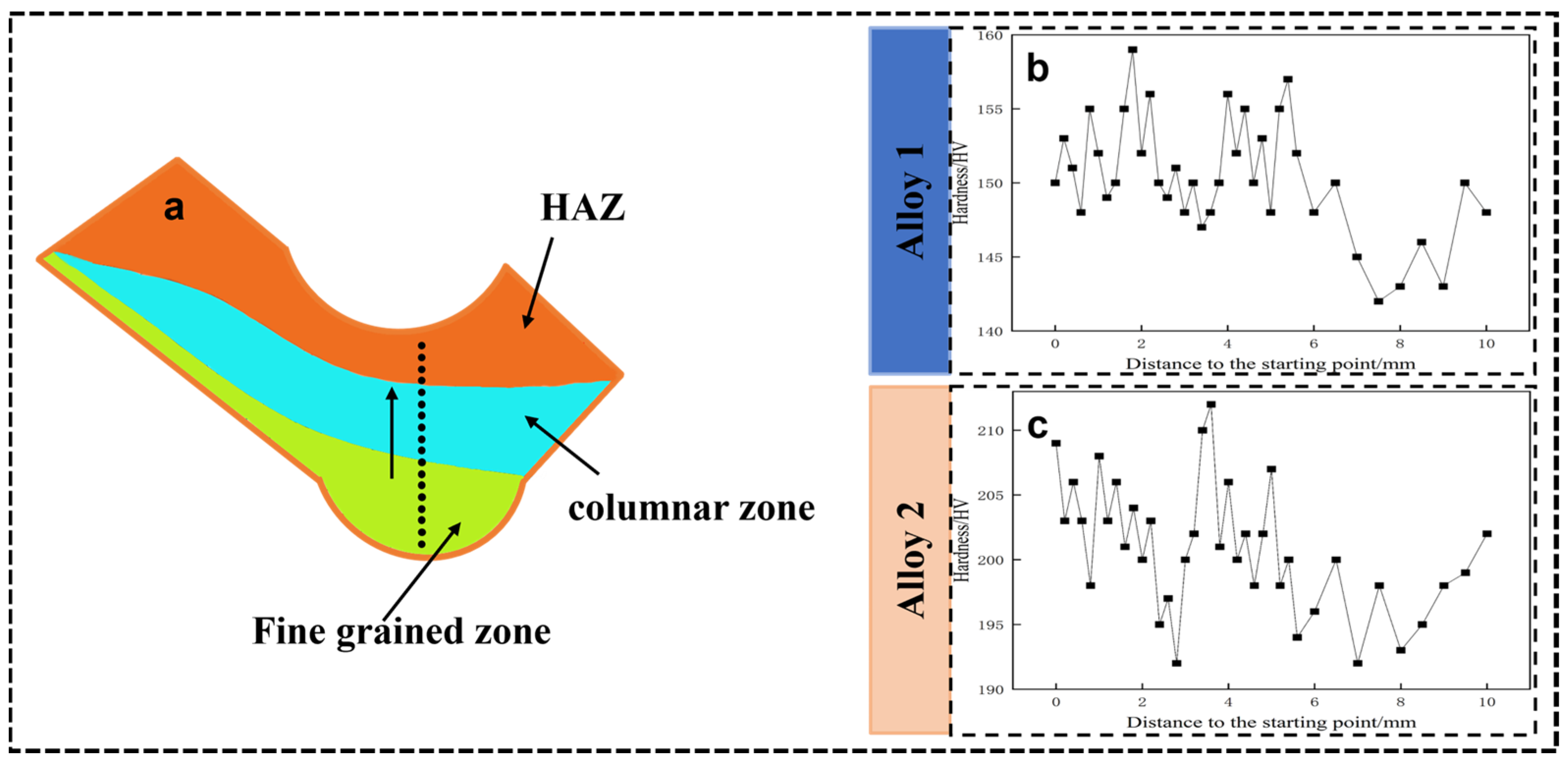

- In the WAAM-fabricated invar alloy, there are generally three regions in each deposition unit: the heat-affected zone at the top, the columnar grain region in the middle, and the fine-grain region at the bottom.

- (2)

- The precipitates in the WAAM-fabricated high-strength invar alloy specimen are composite phases consisting of VC, VN, Mo2C, Fe20Mo3C6, and Cr20Mo3C6 and are mainly distributed along grain boundaries and the cell wall of the cellular substructure. These precipitation phases can refine the grain and the cellular substructure within grains and can also effectively hinder the movement of dislocation, which contributes to the strength of the material.

- (3)

- The average tensile strength of the WAAM-fabricated high-strength invar alloy specimen is 793 MPa, an increase of about 99%, and the impact toughness at low temperature (−196 °C) is 111 J/cm2, an increase of about 23%. However, the thermal interaction of adjacent deposition units will cause the mechanical properties of the invar alloy specimen to exhibit anisotropy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WAAM | Wire Arc Additive Manufacturing |

| GMAW | Gas Metal Arc Welding |

| PAW | Plasma Arc Welding |

References

- Guillaume, C. Invar and its applications. Nature 1904, 71, 134–139. [Google Scholar] [CrossRef]

- Kim, B.; Lee, D. The design of an optical sensor arrangement for the detection of oil contamination in an adhesively bonded structure of a liquefied natural gas (LNG) ship. Meas. Sci. Technol. 2009, 20, 6. [Google Scholar] [CrossRef]

- Li, S.; Yue, X.; Li, Q.; Peng, H.; Dong, B.; Liu, T.; Yang, H.; Fan, J.; Shu, S.; Qiu, F.; et al. Development and applications of aluminum alloys for aerospace industry. J. Mater. Res. Technol. 2023, 27, 944–983. [Google Scholar] [CrossRef]

- Davis, R. The story of Invar [Basic Metrology]. IEEE Instru. Meas. Mag. 2017, 20, 27–29. [Google Scholar] [CrossRef]

- Barka, L.; Balat-Pichelin, M.; Sans, J.-L.; Bêche, E. Oxidation and emissivity of Invar 36 alloy in air plasma at high temperatures. J. Alloy Compd. 2019, 772, 1003–1006. [Google Scholar] [CrossRef]

- He, G.; Peng, X.; Zhou, H.; Huang, G.; Xie, Y.; He, Y.; Liu, H.; Huang, K. Superior Mechanical Properties of Invar36 Alloy Lattices Structures Manufactured by Laser Powder Bed Fusion. Materials 2023, 16, 4433. [Google Scholar] [CrossRef]

- Eissel, A.; Engelking, L.; Gustus, R.; Treutler, K.; Wesling, V.; Schroepfer, D.; Kannengiesser, T. Alloy modification for additive manufactured Ni alloy components—Part I: Effect on microstructure and hardness of Invar alloy. Weld. World. 2023, 67, 1049–1057. [Google Scholar] [CrossRef]

- Kim, S.H.; Choi, S.G.; Choi, W.K.; Yang, B.Y.; Lee, E.S. Pulse electrochemical machining on Invar alloy: Optical microscopic/SEM and non-contact 3D measurement study of surface analyses. Appl. Surf. Sci. 2014, 314, 822–831. [Google Scholar] [CrossRef]

- Kim, S.-H.; Choi, S.-G.; Choi, W.-K.; Lee, E.-S. Surface characteristics of Invar alloy according to micro-pulse electrochemical machining. Mater. Tehnol. 2017, 51, 745–749. [Google Scholar] [CrossRef]

- Liu, J.; Xu, M.; Zhang, R.; Zhang, X.; Xi, W. Progress of Porous/Lattice Structures Applied in Thermal Management Technology of Aerospace Applications. Aerospace 2022, 9, 827. [Google Scholar] [CrossRef]

- Gil Del Val, A.; Cearsolo, X.; Suarez, A.; Veiga, F.; Altuna, I.; Ortiz, M. Machinability characterization in end milling of Invar 36 fabricated by wire arc additive manufacturing. J. Mater. Res. Technol. 2023, 23, 300–315. [Google Scholar] [CrossRef]

- Kumar, N.; Bhavsar, H.; Mahesh, P.; Srivastava, A.K.; Bora, B.J.; Saxena, A.; Dixit, A.R. Wire Arc Additive Manufacturing—A revolutionary method in additive manufacturing. Mater. Chem. Phys. 2022, 285, 126144. [Google Scholar] [CrossRef]

- Zhao, Y.; Wu, A.P.; Ren, J.L.; Sato, Y.S.; Kokawa, H.; Miyake, M.; Yan, D.Y. Temperature and force response characteristics of friction stir welding on Invar 36 alloy. Sci. Technol. Weld. Joi. 2013, 18, 232–238. [Google Scholar] [CrossRef]

- Jiang, Z.; Chen, X.; Li, H.; Lei, Z.; Chen, Y.; Wu, S.; Wang, Y. Grain refinement and laser energy distribution during laser oscillating welding of Invar alloy. Mater. Des. 2020, 186, 108195. [Google Scholar] [CrossRef]

- Veiga, F.; Suarez, A.; Aldalur, E.; Artaza, T. Wire arc additive manufacturing of invar parts: Bead geometry and melt pool monitoring. Measurement 2022, 189, 110452. [Google Scholar] [CrossRef]

- Veiga, F.; Suárez, A.; Artaza, T.; Aldalur, E. Effect of the Heat Input on Wire-Arc Additive Manufacturing of Invar 36 Alloy: Microstructure and Mechanical Properties. Weld. World. 2022, 66, 1081–1091. [Google Scholar] [CrossRef]

- Sood, A.; Schimmel, J.; Ferreira, V.M.; Bosman, M.; Goulas, C.; Popovich, V.; Hermans, M.J. Directed energy deposition of Invar 36 alloy using cold wire pulsed gas tungsten arc welding: Effect of heat input on the microstructure and functional behaviour. J. Mater. Res. Technol. 2023, 25, 6183–6197. [Google Scholar] [CrossRef]

- Aldalur, E.; Suárez, A.; Veiga, F. Thermal expansion behaviour of Invar 36 alloy parts fabricated by wire-arc additive manufacturing. J. Mater. Res. Technol. 2022, 19, 3634–3645. [Google Scholar] [CrossRef]

- Jiao, G.; Fang, X.; Chen, X.; Xi, N.; Zhang, M.; Liu, Y.; Wu, H.; Huang, K. The origin of low thermal expansion coefficient and enhanced tensile properties of Invar alloy fabricated by directed energy deposition. J. Mater. Process. Technol. 2023, 317, 117994. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, M.; Zhang, T.; Xie, J.; Wei, K.; Wang, S.; Yin, L.; He, P. Grain refinement and mechanical properties improvement of Inconel 625 alloy fabricated by ultrasonic-assisted wire and arc additive manufacturing. J. Alloy Compd. 2022, 910, 164957. [Google Scholar] [CrossRef]

- Sui, Q.; He, J.; Zhang, X.; Sun, Z.; Zhang, Y.; Wu, Y.; Zhu, Z.; Zhang, Q.; Peng, H. Strengthening of the Fe-Ni Invar Alloy Through Chromium. Materials 2019, 12, 1297. [Google Scholar] [CrossRef] [PubMed]

- Vinogradov, A.; Hashimoto, S.; Kopylov, V. Enhanced strength and fatigue life of ultra-fine grain Fe–36Ni Invar alloy. Mater. Sci. Eng. A 2003, 355, 277–285. [Google Scholar] [CrossRef]

- Dilip, J.; Ram, G.J.; Starr, T.L.; Stucker, B. Selective laser melting of HY100 steel: Process parameters, microstructure and mechanical properties. Addit. Manuf. 2017, 13, 49–60. [Google Scholar] [CrossRef]

- Huang, G.; He, G.; Liu, Y.; Huang, K. Anisotropy of microstructure, mechanical properties and thermal expansion in Invar 36 alloy fabricated via laser powder bed fusion. Addit. Manuf. 2024, 82, 104025. [Google Scholar] [CrossRef]

- Gardner, L.; Kyvelou, P.; Herbert, G.; Buchanan, C. Testing and initial verification of the world’s first metal 3D printed bridge. J. Constr. Steel Res. 2020, 172, 106233. [Google Scholar] [CrossRef]

- Fan, H.; Shi, G.; Peng, T.; Wang, Q.; Wang, L.; Wang, Q.; Zhang, F. N-induced microstructure refinement and toughness improvement in the coarse grain heat-affected zone of a low carbon Mo–V–Ti–B steel subjected to a high heat input welding thermal cycle. Mater. Sci. Eng. A 2021, 824, 141799. [Google Scholar] [CrossRef]

- Liu, K.; Chen, C.; He, J.; Liu, B.; Ma, B.; Xue, H.; Yang, B.; Wang, S.; Liu, H. Microstructure, corrosion behavior and rust resistance of Ti and Ce added invar alloys. Mater. Res. Express. 2021, 8, 096518. [Google Scholar] [CrossRef]

- Nakama, K.; Sugita, K.; Shirai, Y. Effect of MC Type Carbides on Age Hardness and Thermal Expansion of Fe–36 wt%Ni–0.2 wt%C Alloy. Metallogr. Microstruct. Anal. 2013, 2, 383–387. [Google Scholar] [CrossRef]

- Nakama, K.; Furuya, S.; Sugita, K.; Inoue, K.; Shirai, Y. Lattice Defects of Cold-drawn and Aged Fe-36wt%Ni Alloys and Effects of Additions of C and V on Hardness and Thermal Expansion. Tetsu-to-Hagane 2013, 99, 380–389. [Google Scholar] [CrossRef]

- Liu, H.; Sun, Z.; Wang, G.; Sun, X.; Li, J.; Xue, F.; Peng, H.; Zhang, Y. Effect of aging on microstructures and properties of Mo-alloyed Fe–36Ni invar alloy. Mater. Sci. Eng. A 2016, 654, 107–112. [Google Scholar] [CrossRef]

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; et al. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 2018, 17, 63–71. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Y.; Liu, L.; Wikman, S.; Cui, D.; Shen, Z. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. J. Nucl. Mater. 2016, 470, 170–178. [Google Scholar] [CrossRef]

- Fang, Q.; Zhao, L.; Liu, B.; Chen, C.; Peng, Y.; Tian, Z.; Yin, F. Microstructure and Mechanical Properties of 800-MPa-Class High-Strength Low-Alloy Steel Part Fabricated by Wire Arc Additive Manufacturing. J. Mater. Eng. Perform. 2022, 31, 7461–7471. [Google Scholar] [CrossRef]

| Elements | C | Ni | V | Mo | Cr | Mn | N | Fe |

|---|---|---|---|---|---|---|---|---|

| Alloy 1 | 0.06 | 36.06 | / | / | / | 0.023 | / | Bal. |

| Alloy 2 | 0.15 | 36.5 | 1.0 | 1.5 | 0.8 | 0.013 | 0.012 | Bal. |

| Elements | C | N | V | Mo | Cr | Fe | Ni |

|---|---|---|---|---|---|---|---|

| Weight% | 9.82 | 14.19 | 56.75 | 8.89 | 2.27 | 5.11 | 2.97 |

| Atomic% | 26.92 | 31.58 | 33.25 | 2.62 | 1.31 | 2.74 | 1.58 |

| Error% | 13.65 | 13.55 | 11.29 | 15.37 | 37.64 | 26.95 | 58.97 |

| Elements | C | N | Mo | V | Cr | Fe | Ni |

|---|---|---|---|---|---|---|---|

| Weight% | 7.85 | 3.96 | 1.08 | 3.28 | 0.89 | 53.39 | 29.55 |

| Atomic% | 26.26 | 11.36 | 0.45 | 2.59 | 0.69 | 38.42 | 20.23 |

| Error% | 15.07 | 21.63 | 44.10 | 13.28 | 36.99 | 3.04 | 4.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Zhao, C.; Sun, Z.; He, J.; Guo, W.; Xue, H.; Liu, B.; Zhang, C.; Zhang, H. Microstructure Characteristics and Mechanical Properties of High-Strength Invar Alloy by Wire Arc Additive Manufacturing. Appl. Sci. 2025, 15, 3351. https://doi.org/10.3390/app15063351

Chen C, Zhao C, Sun Z, He J, Guo W, Xue H, Liu B, Zhang C, Zhang H. Microstructure Characteristics and Mechanical Properties of High-Strength Invar Alloy by Wire Arc Additive Manufacturing. Applied Sciences. 2025; 15(6):3351. https://doi.org/10.3390/app15063351

Chicago/Turabian StyleChen, Cuixin, Chenyu Zhao, Zhonghua Sun, Jun He, Weibing Guo, Haitao Xue, Baoxi Liu, Caidong Zhang, and Hongxin Zhang. 2025. "Microstructure Characteristics and Mechanical Properties of High-Strength Invar Alloy by Wire Arc Additive Manufacturing" Applied Sciences 15, no. 6: 3351. https://doi.org/10.3390/app15063351

APA StyleChen, C., Zhao, C., Sun, Z., He, J., Guo, W., Xue, H., Liu, B., Zhang, C., & Zhang, H. (2025). Microstructure Characteristics and Mechanical Properties of High-Strength Invar Alloy by Wire Arc Additive Manufacturing. Applied Sciences, 15(6), 3351. https://doi.org/10.3390/app15063351