Shaping and Characterization of Additively Manufactured Geopolymer Materials for Underwater Applications

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

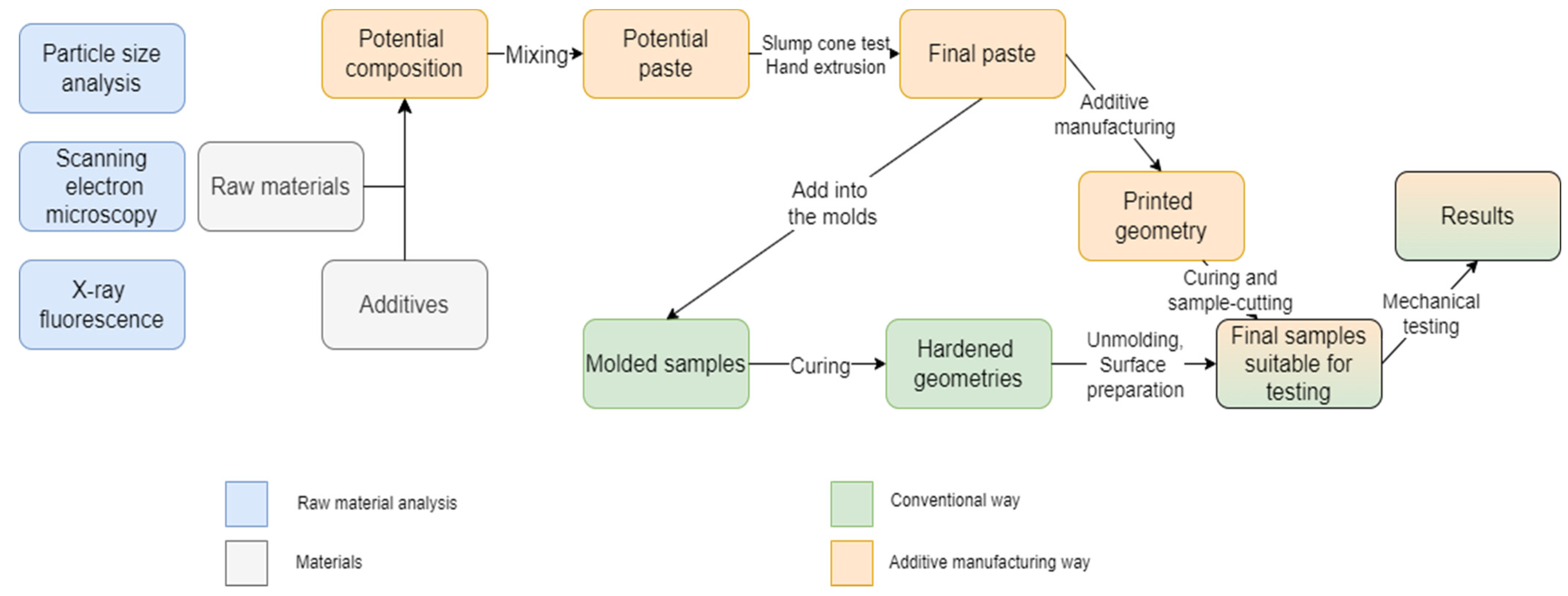

2.2. Sample Preparation

2.3. Experimental Program

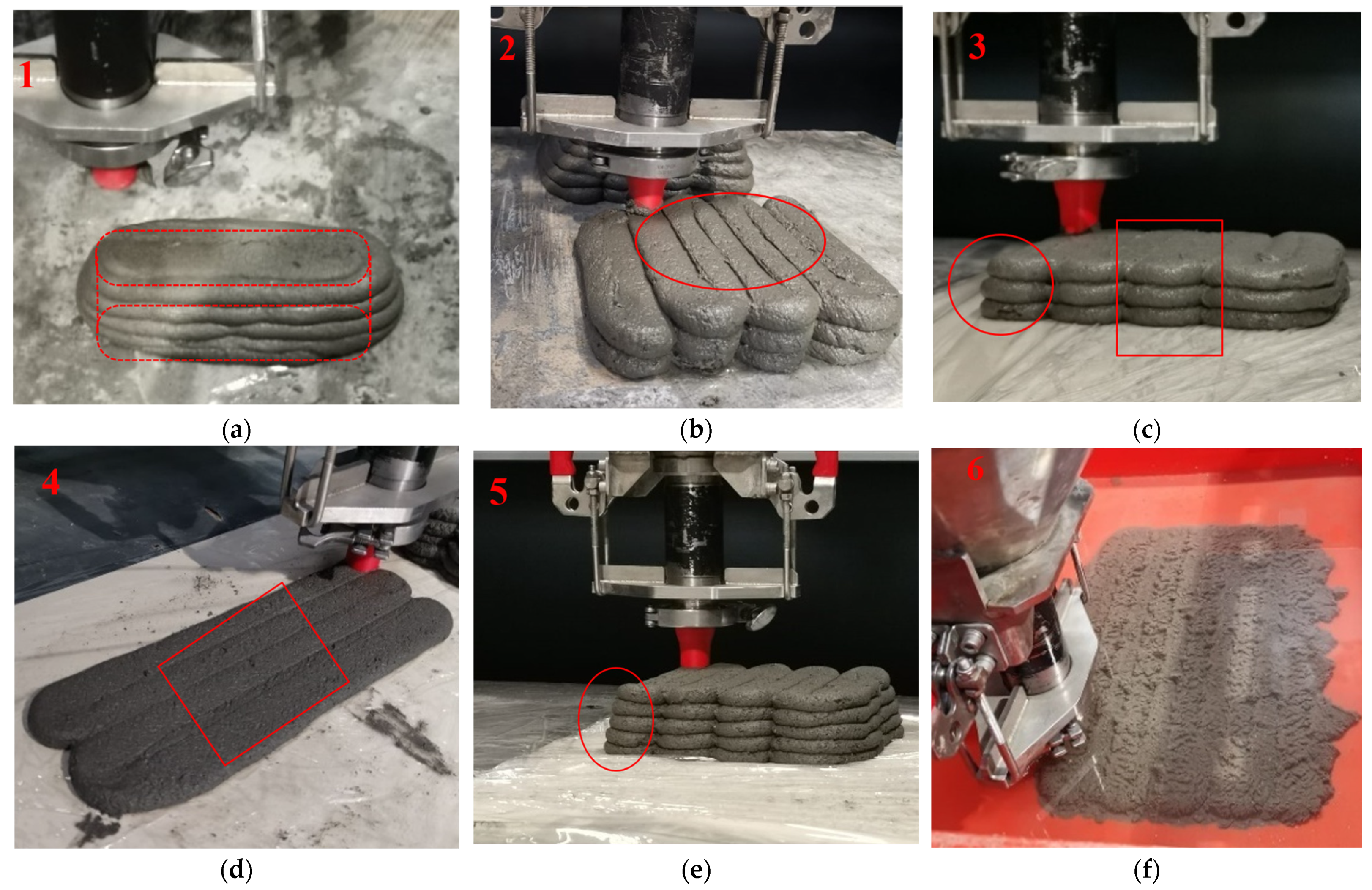

- Extrusion behavior—Extrusion should be as homogeneous as possible, without over- or under-extrusion and material loss.

- Material positioning—The material string should be deposited cleanly in conjunction with the printing speed and, if possible, should not create any voids in the component.

- Geometric accuracy—One layer should correspond to the cross-section created in the slicer. After all layers are applied, the component must not change its geometry significantly (no sagging) and should not deviate significantly from the target geometry.

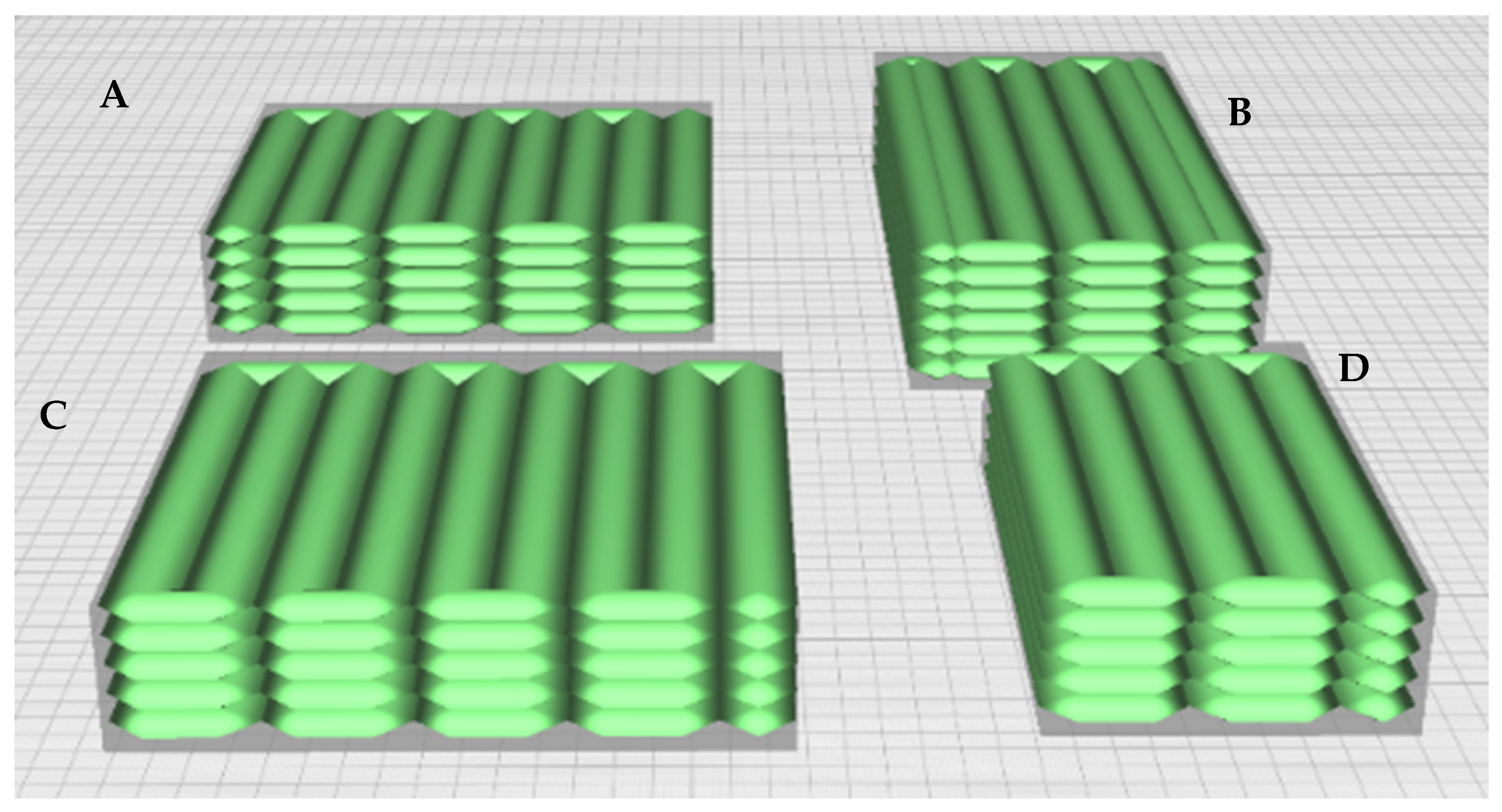

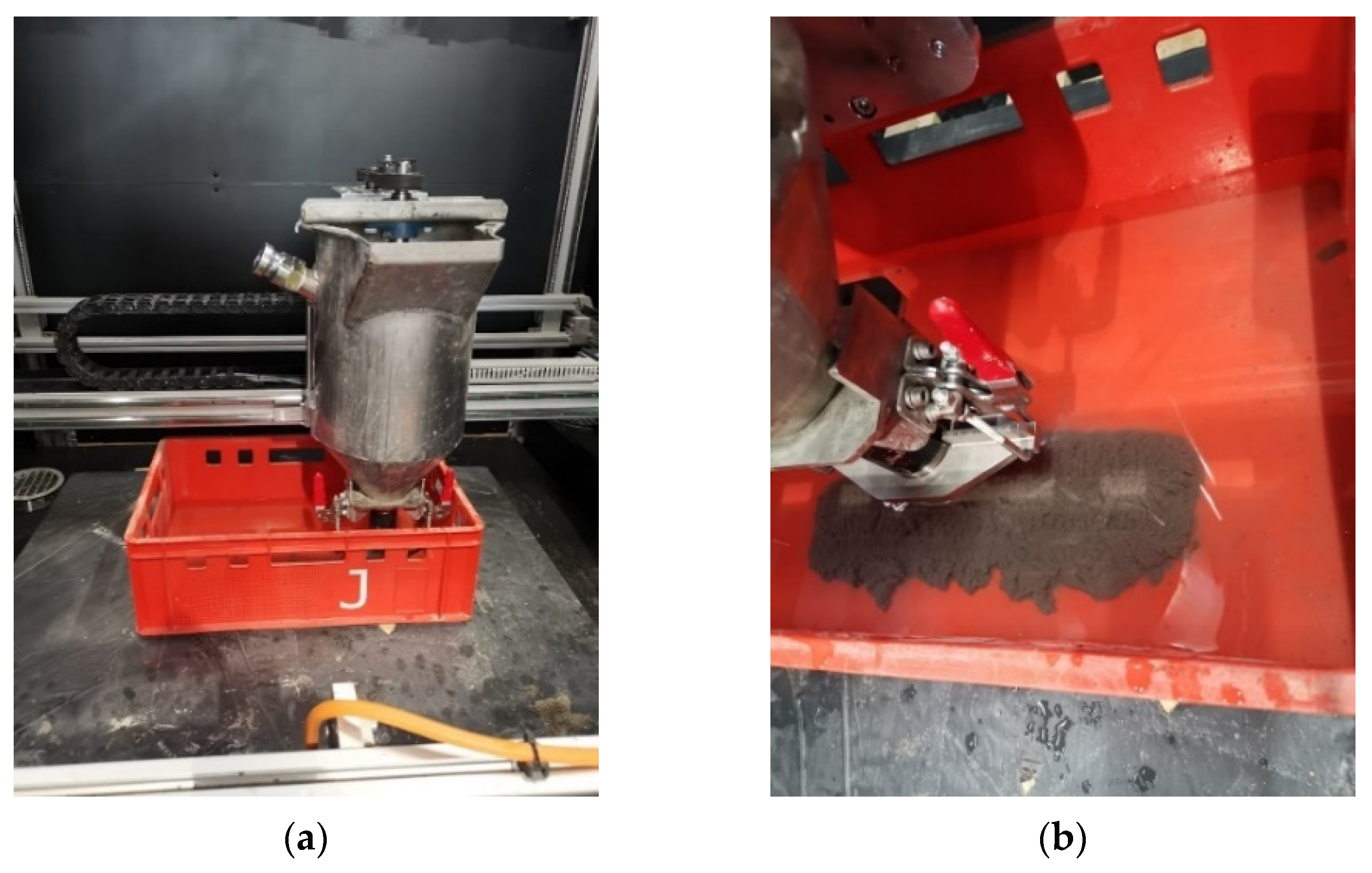

2.4. Additive Manufacturing

2.5. Casting

2.6. Methods

3. Results and Discussion

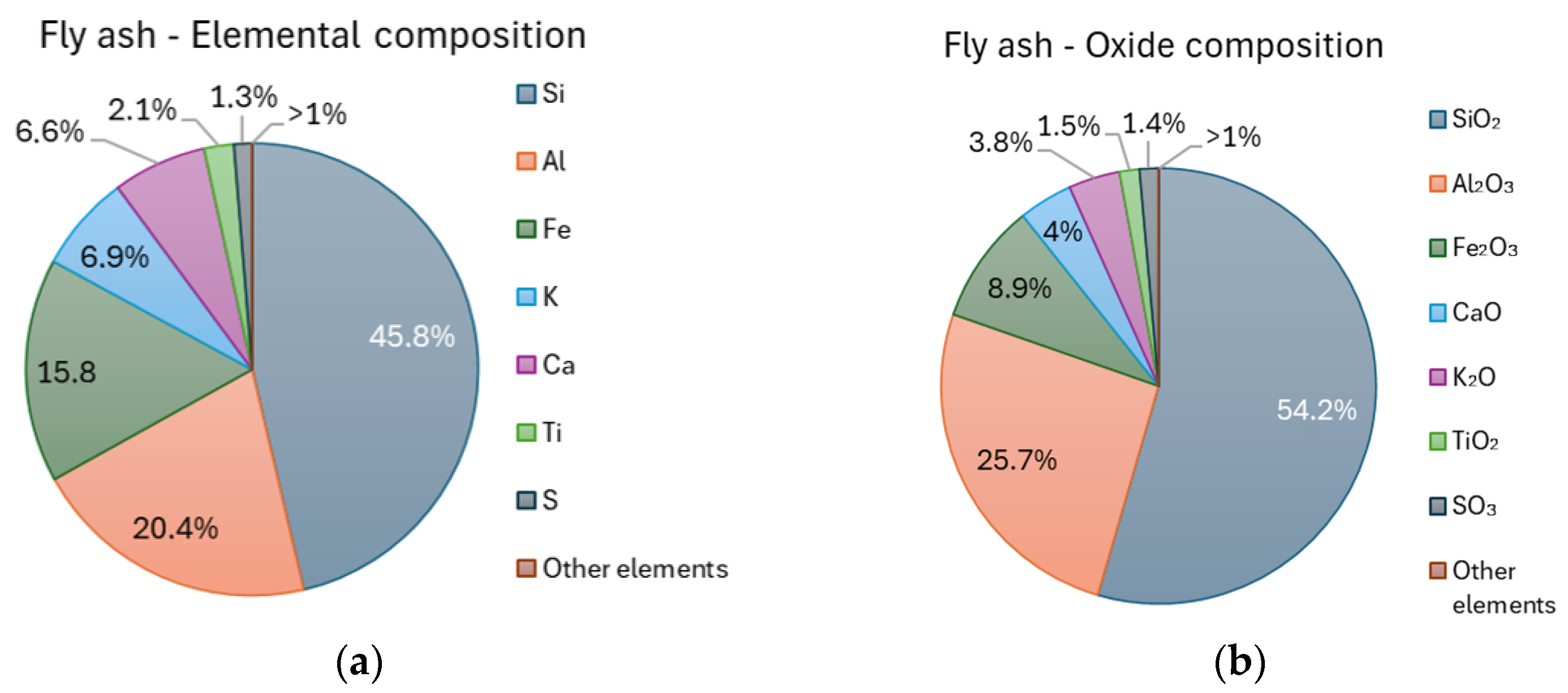

3.1. Raw Materials Investigation

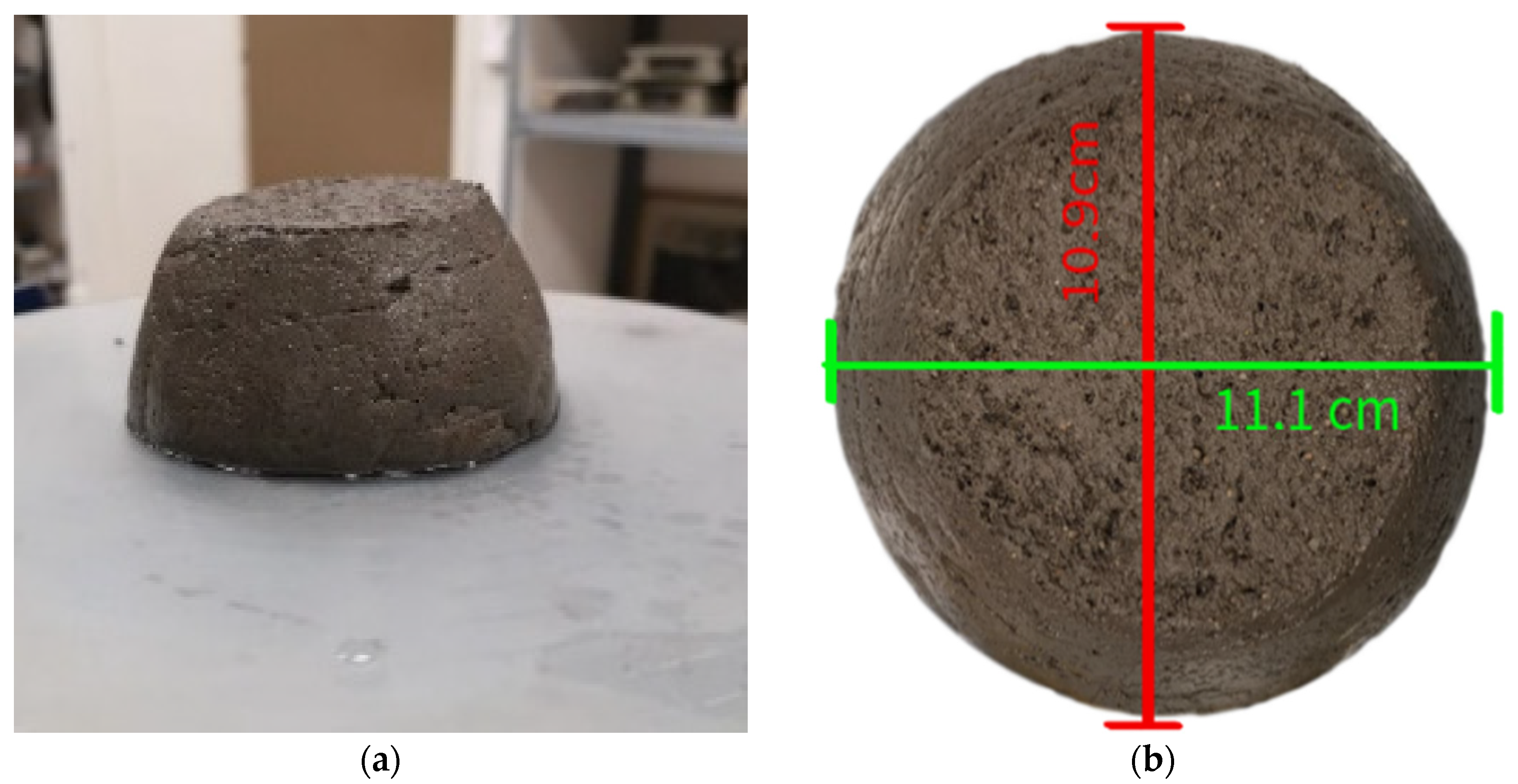

3.2. Fresh Paste Properties

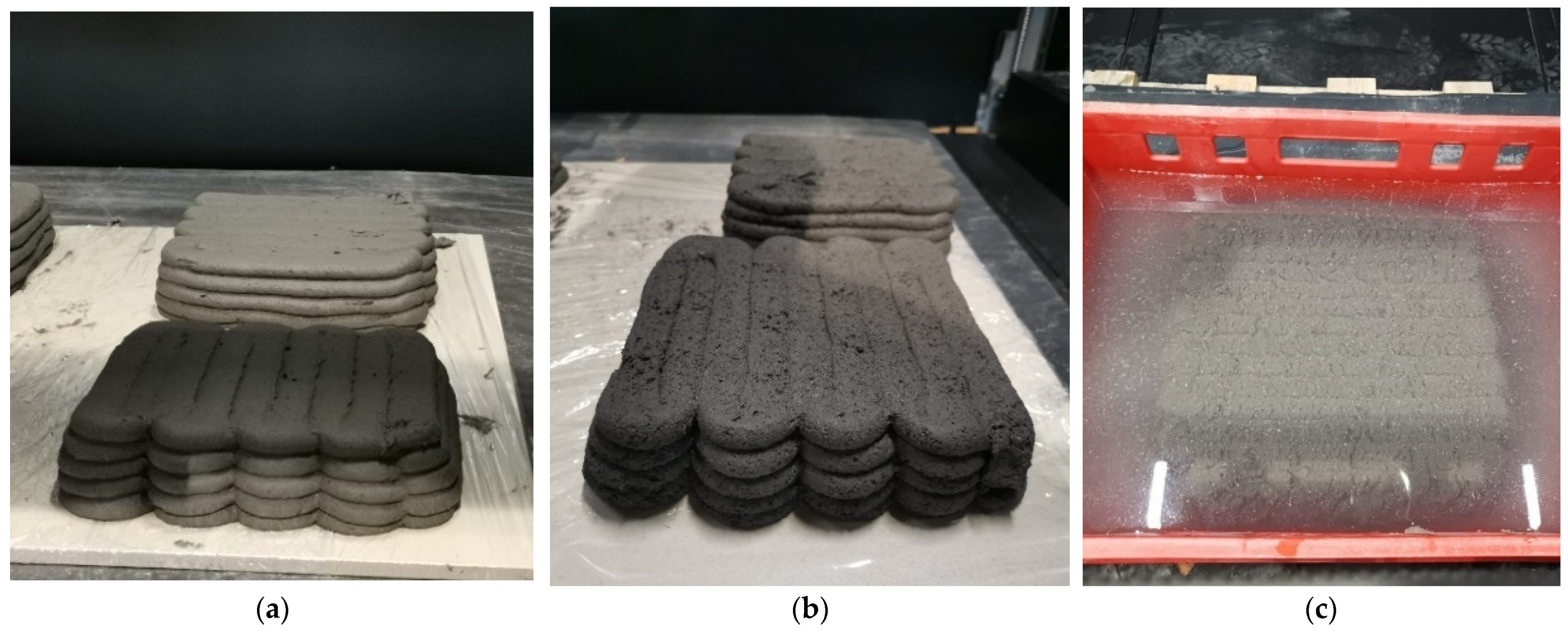

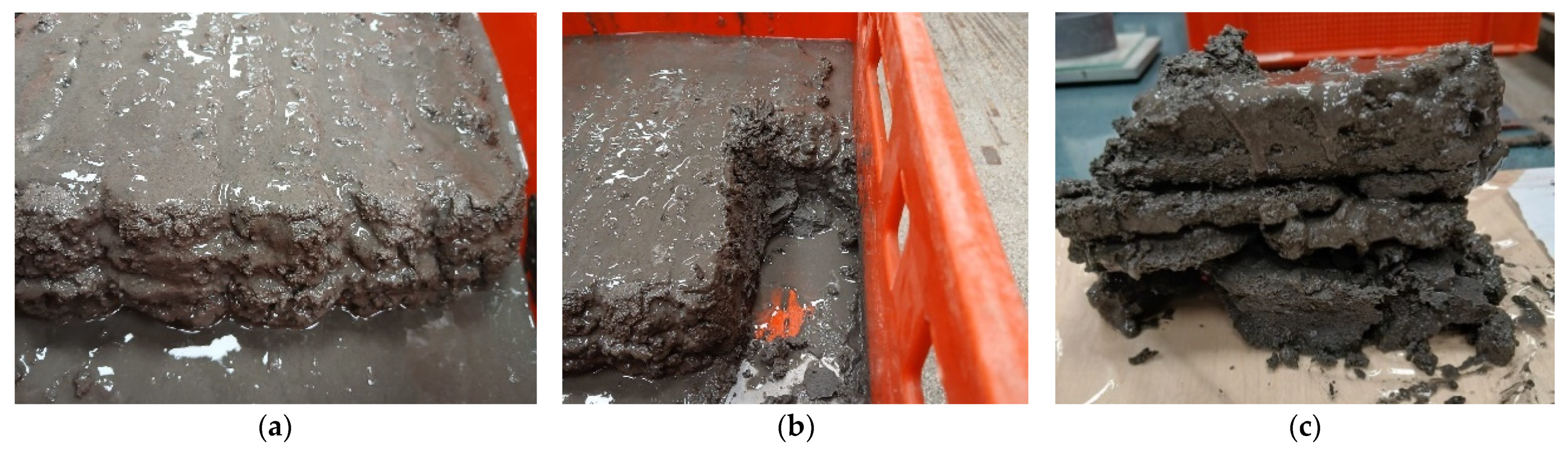

3.3. 3D Printing Process

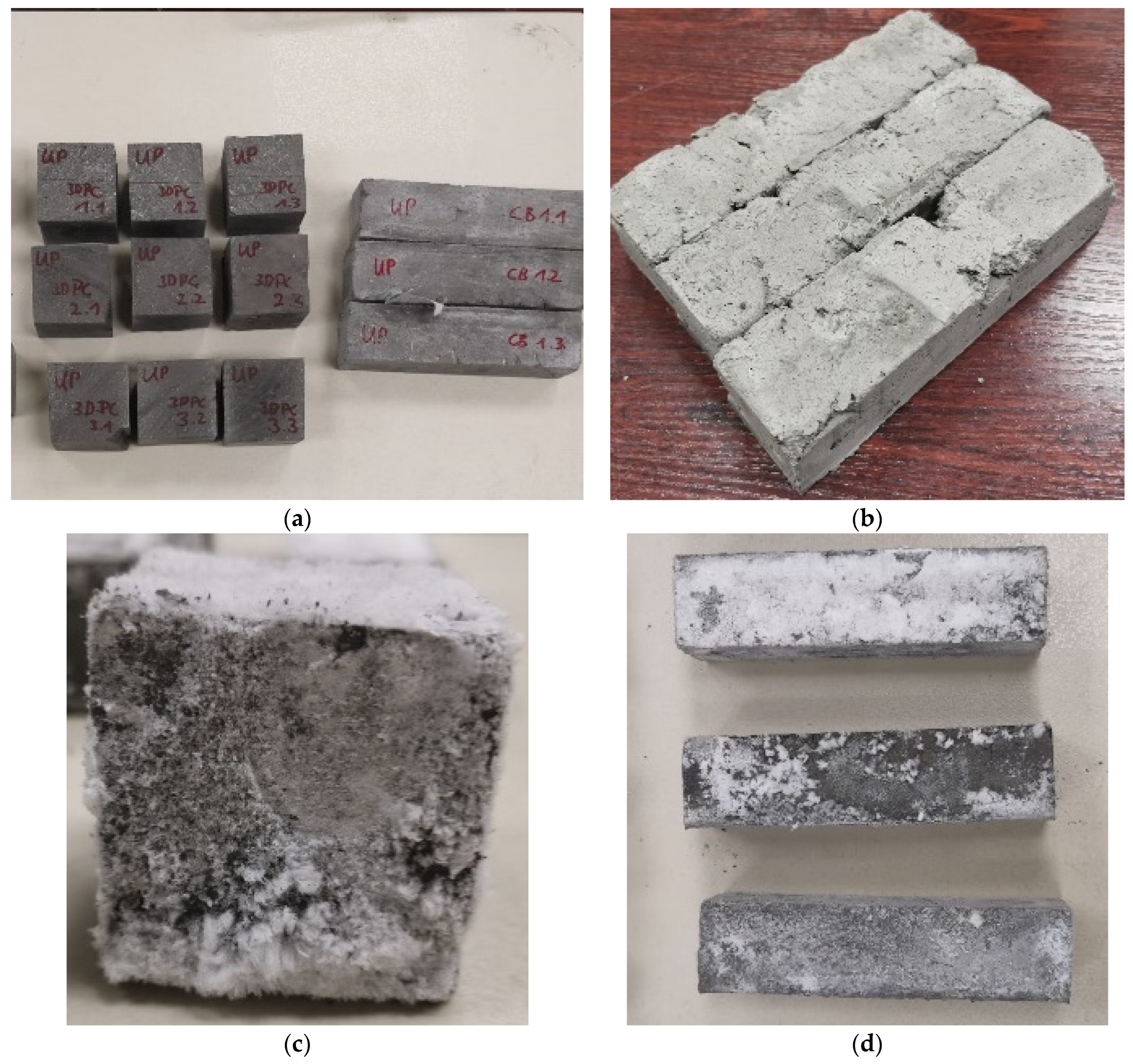

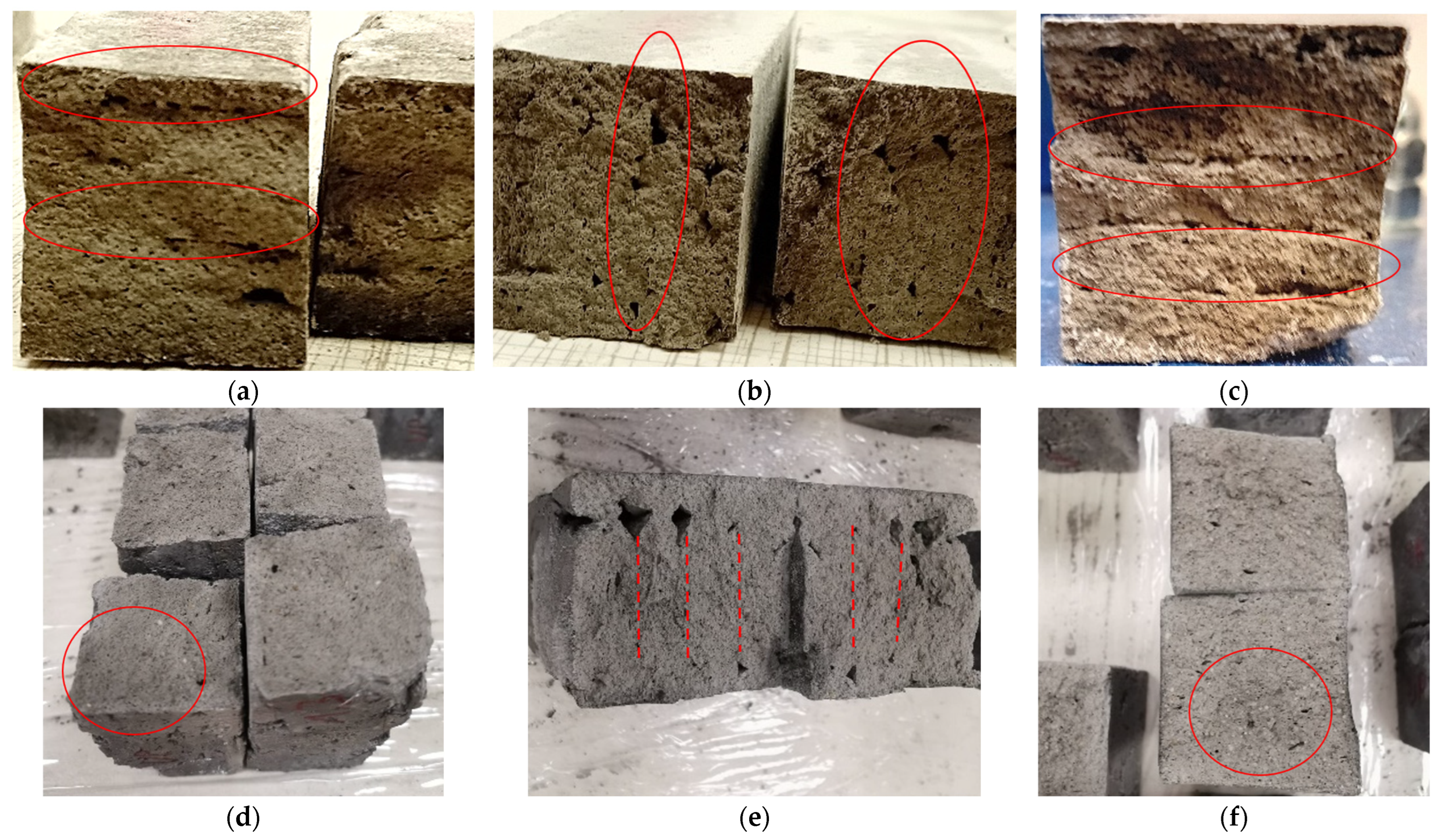

3.4. Comparison of the Properties of the Samples Made by Different Methods of Manufacturing

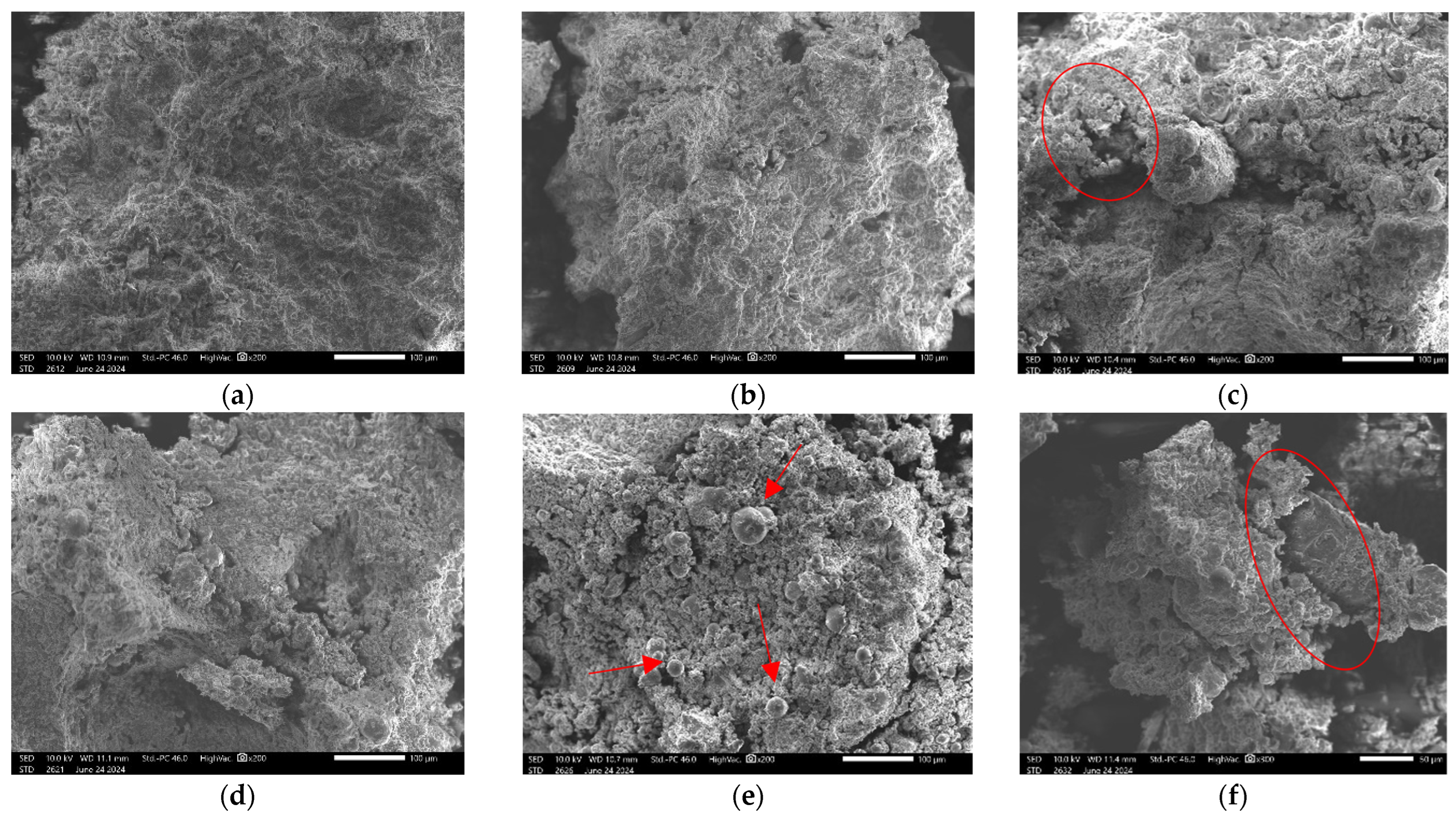

3.5. Structural Analysis

4. Conclusions

- Paste extrusion modeling can be used to generate solid bodies from fly ash-based geopolymer.

- By adding additives such as xanthan gum and superplasticizer, the rheological properties of the paste are modified to retain shape while being well extrudable.

- With the help of additive manufacturing, geopolymer samples with compressive strengths of up to 7.5 MPa and flexural strengths of up to 4.15 MPa after 28 and 35 days, respectively, have been produced. Compared to the average of the cast samples, the compressive strength of the printed samples was 5% (#21AB) and 9% (#20AB) lower. The flexural strength was, on average, 38% (#20AB) and 64% (#21AB) lower for printed samples.

- The sample series #21AB showed strong anisotropy between the tested orientations of the flexural strength samples. Values achieved for the “favorable” orientation (4.15 MPa) were almost 7.5 times as high as those for the other orientations (0.56 MPa). For a reliable prediction of strength, anisotropies that occur during the printing process must be avoided.

- The addition of more water (20% total in #20AB versus 11% in #21AB) resulted in better layer bonding and less anisotropy in sample series #20AB. Excessively adding water leads to pore formation and insufficient development of the gel phase and should, therefore, be avoided.

- The 3D-printed samples showed strong anisotropy, including the samples 3D printed underwater.

- The extrusion of layers under water is possible with the tested paste, but the desired hardening did not occur after 7 weeks of immersion in water.

- One of the problems was the printer’s discontinuous process path. In the future, directly generated and optimized process paths should be used instead of sliced solids. Such g-codes can be created using the program Rhinoceros and the Grasshopper plug-in.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| 3D | Three Dimensional |

| CAD | Computer-Aided Design |

| SEM | Scanning Electron Microscopy |

| STL | Standard Tessellation Language |

| UW3DP | Underwater 3D printing |

| XRF | X-Ray Fluorescence |

Appendix A

References

- Krishna, R.S.; Rehman, A.U.; Mishra, J.; Saha, S.; Korniejenko, K.; Rehman, R.U.; Salamci, M.U.; Sglavo, V.M.; Shaikh, F.U.A.; Qureshi, T.S. Additive Manufacturing of Geopolymer Composites for Sustainable Construction: Critical Factors, Advancements, Challenges, and Future Directions. Prog. Addit. Manuf. 2025, 10, 1003–1061. [Google Scholar] [CrossRef]

- Mierzwiński, D.; Łach, M.; Gądek, S.; Lin, W.-T.; Tran, D.H.; Korniejenko, K. A Brief Overview of the Use of Additive Manufacturing of Con-Create Materials in Construction. Acta Innov. 2023, 48, 22–37. [Google Scholar] [CrossRef]

- Yoris-Nobile, A.I.; Slebi-Acevedo, C.J.; Lizasoain-Arteaga, E.; Indacoechea-Vega, I.; Blanco-Fernandez, E.; Castro-Fresno, D.; Alonso-Estebanez, A.; Alonso-Cañon, S.; Real-Gutierrez, C.; Boukhelf, F.; et al. Artificial Reefs Built by 3D Printing: Systematisation in the Design, Material Selection and Fabrication. Constr. Build. Mater. 2023, 362, 129766. [Google Scholar] [CrossRef]

- Yousaf, A.; Al Rashid, A.; Koç, M. 3D Printing of Alkali-Activated Geopolymers for Sustainable and Circular Economy Advancements. Circ. Econ. 2024, 3, 100101. [Google Scholar] [CrossRef]

- Szechyńska-Hebda, M.; Hebda, M.; Doğan-Sağlamtimur, N.; Lin, W.-T. Let’s Print an Ecology in 3D (and 4D). Materials 2024, 17, 2194. [Google Scholar] [CrossRef]

- Korniejenko, K.; Gądek, S.; Dynowski, P.; Tran, D.H.; Rudziewicz, M.; Pose, S.; Grab, T. Additive Manufacturing in Underwater Applications. Appl. Sci. 2024, 14, 1346. [Google Scholar] [CrossRef]

- Bassan De Moraes, M.J.; Nagata, E.Y.; Felício Peres Duran, A.J.; Rossignolo, J.A. Alkali Activated Materials Applied in 3D Printing Construction: A Review. Heliyon 2024, 10, e26696. [Google Scholar] [CrossRef]

- Ricciotti, L.; Apicella, A.; Perrotta, V.; Aversa, R. Geopolymer Materials for Extrusion-Based 3D-Printing: A Review. Polymers 2023, 15, 4688. [Google Scholar] [CrossRef]

- Ahmadifar, M.; Benfriha, K.; Shirinbayan, M.; Fitoussi, J.; Tcharkhtchi, A. Mechanical Behavior of Polymer-Based Composites Using Fused Filament Fabrication under Monotonic and Fatigue Loadings. Polym. Polym. Compos. 2022, 30, 09673911221082480. [Google Scholar] [CrossRef]

- Ahmadifar, M.; Benfriha, K.; Shirinbayan, M. Thermal, Tensile and Fatigue Behaviors of the PA6, Short Carbon Fiber-Reinforced PA6, and Continuous Glass Fiber-Reinforced PA6 Materials in Fused Filament Fabrication (FFF). Polymers 2023, 15, 507. [Google Scholar] [CrossRef]

- Shakeria, Z.; Benfriha, K.; Zirak, N.; Shirinbayan, M. Optimization of FFF Processing Parameters to Improve Geometrical Accuracy and Mechanical Behavior of Polyamide 6 Using Grey Relational Analysis (GRA). Preprint 2021. [Google Scholar]

- Shirinbayan, M.; Benfriha, K.; Tcharkhtchi, A. Geometric Accuracy and Mechanical Behavior of PA6 Composite Curved Tubes Fabricated by Fused Filament Fabrication (FFF). Adv. Eng. Mater. 2022, 24, 2101056. [Google Scholar] [CrossRef]

- Zirak, N.; Benfriha, K.; Shakeri, Z.; Shirinbayan, M.; Fitoussi, J.; Tcharkhtchi, A. Interlayer Bonding Improvement and Optimization of Printing Parameters of FFF Polyphenylene Sulfide Parts Using GRA Method. Prog. Addit. Manuf. 2024, 9, 505–516. [Google Scholar] [CrossRef]

- Luhar, S.; Luhar, I. Additive Manufacturing in the Geopolymer Construction Technology: A Review. Open Constr. Build. Technol. J. 2020, 14, 150–161. [Google Scholar] [CrossRef]

- Xia, M.; Sanjayan, J. Method of Formulating Geopolymer for 3D Printing for Construction Applications. Mater. Des. 2016, 110, 382–390. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A. Geopolymer Additive Manufacturing: A Review. Addit. Manuf. 2022, 55, 102782. [Google Scholar] [CrossRef]

- Baigarina, A.; Shehab, E.; Ali, M.H. Construction 3D Printing: A Critical Review and Future Research Directions. Prog. Addit. Manuf. 2023, 8, 1393–1421. [Google Scholar] [CrossRef]

- Amelia, H. How Does a Concrete 3D Printer Work? Available online: www.3dnatives.com/en/how-does-a-concrete-3d-printer-work-080120215 (accessed on 25 July 2024).

- Barve, P.; Bahrami, A.; Shah, S. A Comprehensive Review on Effects of Material Composition, Mix Design, and Mixing Regimes on Rheology of 3D-Printed Geopolymer Concrete. Open Constr. Build. Technol. J. 2024, 18, e18748368292859. [Google Scholar] [CrossRef]

- Gasmi, A.; Pélegris, C.; Davidovits, R.; Guessasma, M.; Tortajada, H.; Jean, F. Advanced Refinement of Geopolymer Composites for Enhanced 3D Printing via In-Depth Rheological Insights. Ceramics 2024, 7, 1316–1339. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, M. 3D Printing Geopolymers: A Review. Cem. Concr. Compos. 2022, 128, 104455. [Google Scholar] [CrossRef]

- Zhang, D.-W.; Wang, D.; Lin, X.-Q.; Zhang, T. The Study of the Structure Rebuilding and Yield Stress of 3D Printing Geopolymer Pastes. Constr. Build. Mater. 2018, 184, 575–580. [Google Scholar] [CrossRef]

- Sando, M.; Stephan, D. The Role of Mixing Sequence in Shaping the 3D-Printability of Geopolymers. Case Stud. Constr. Mater. 2025, 22, e04352. [Google Scholar] [CrossRef]

- Cong, P.; Cheng, Y. Advances in Geopolymer Materials: A Comprehensive Review. J. Traffic Transp. Eng. 2021, 8, 283–314. [Google Scholar] [CrossRef]

- Fang, G.; Ho, W.K.; Tu, W.; Zhang, M. Workability and Mechanical Properties of Alkali-Activated Fly Ash-Slag Concrete Cured at Ambient Temperature. Constr. Build. Mater. 2018, 172, 476–487. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and Hardened Properties of 3D Printable Cementitious Materials for Building and Construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Zhang, P.; Zheng, Y.; Wang, K.; Zhang, J. A Review on Properties of Fresh and Hardened Geopolymer Mortar. Compos. Part B Eng. 2018, 152, 79–95. [Google Scholar] [CrossRef]

- Nikolov, A.; Karamanov, A. Thermal Properties of Geopolymer Based on Fayalite Waste from Copper Production and Metakaolin. Materials 2022, 15, 2666. [Google Scholar] [CrossRef]

- Panda, B.; Unluer, C.; Tan, M.J. Extrusion and Rheology Characterization of Geopolymer Nanocomposites Used in 3D Printing. Compos. Part B Eng. 2019, 176, 107290. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Effect of Alkali Reactions on the Rheology of One-Part 3D Printable Geopolymer Concrete. Cem. Concr. Compos. 2021, 116, 103899. [Google Scholar] [CrossRef]

- Sun, C.; Xiang, J.; Xu, M.; He, Y.; Tong, Z.; Cui, X. 3D Extrusion Free Forming of Geopolymer Composites: Materials Modification and Processing Optimization. J. Clean. Prod. 2020, 258, 120986. [Google Scholar] [CrossRef]

- Chougan, M.; Hamidreza Ghaffar, S.; Jahanzat, M.; Albar, A.; Mujaddedi, N.; Swash, R. The Influence of Nano-Additives in Strengthening Mechanical Performance of 3D Printed Multi-Binder Geopolymer Composites. Constr. Build. Mater. 2020, 250, 118928. [Google Scholar] [CrossRef]

- Shilton, R.; Wang, S.; Banthia, N. Use of Polysaccharides as a Rheology Modifying Admixture for Alkali Activated Materials for 3D Printing. Constr. Build. Mater. 2025, 458, 139661. [Google Scholar] [CrossRef]

- Gasmi, A. Additive Manufacturing of Ceramic Type Geopolymer for Complex and Tiny Objects. Available online: www.geopolymer.org/conference/gpcamp-2023 (accessed on 25 July 2024).

- Panda, B.; Unluer, C.; Tan, M.J. Investigation of the Rheology and Strength of Geopolymer Mixtures for Extrusion-Based 3D Printing. Cem. Concr. Compos. 2018, 94, 307–314. [Google Scholar] [CrossRef]

- Raza, M.H.; Zhong, R.Y. A Sustainable Roadmap for Additive Manufacturing Using Geopolymers in Construction Industry. Resour. Conserv. Recycl. 2022, 186, 106592. [Google Scholar] [CrossRef]

- Kriven, W.M.; Leonelli, C.; Provis, J.L.; Boccaccini, A.R.; Attwell, C.; Ducman, V.S.; Ferone, C.; Rossignol, S.; Luukkonen, T.; Van Deventer, J.S.J.; et al. Why Geopolymers and Alkali-activated Materials Are Key Components of a Sustainable World: A Perspective Contribution. J. Am. Ceram. Soc. 2024, 107, 5159–5177. [Google Scholar] [CrossRef]

- Valente, M.; Sibai, A.; Sambucci, M. Extrusion-Based Additive Manufacturing of Concrete Products: Revolutionizing and Remodeling the Construction Industry. J. Compos. Sci. 2019, 3, 88. [Google Scholar] [CrossRef]

- Ahmaruzzaman, M. A Review on the Utilization of Fly Ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Zhuang, X.Y.; Chen, L.; Komarneni, S.; Zhou, C.H.; Tong, D.S.; Yang, H.M.; Yu, W.H.; Wang, H. Fly Ash-Based Geopolymer: Clean Production, Properties and Applications. J. Clean. Prod. 2016, 125, 253–267. [Google Scholar] [CrossRef]

- Ponomar, V.; Luukkonen, T.; Yliniemi, J. Revisiting Alkali-Activated and Sodium Silicate-Based Materials in the Early Works of Glukhovsky. Constr. Build. Mater. 2023, 398, 132474. [Google Scholar] [CrossRef]

- DIN EN 12350-5; Prüfung von Frischbeton—Teil 5: Ausbreitmaß; Deutsche Fassung EN 12350-5:2019-09. Beuth Verlag GmbH, ICS 91.100.30: Berlin, Germany, 2019.

- DIN EN 12390-3; Prüfung von Festbeton—Teil 3: Druckfestigkeit von Probekörpern; Deutsche Fassung EN 12390-3:2019. Beuth Verlag GmbH, ICS 91.100.30: Berlin, Germany, 2019.

- DIN EN 12390-5; Prüfung von Festbeton—Teil 5: Biegezugfestigkeit von Probekörpern; Deutsche Fassung EN 12390-5:2019-10. Beuth Verlag GmbH, ICS 91.100.30: Berlin, Germany, 2019.

- Assi, L.N.; Eddie Deaver, E.; Ziehl, P. Effect of Source and Particle Size Distribution on the Mechanical and Microstructural Properties of Fly Ash-Based Geopolymer Concrete. Constr. Build. Mater. 2018, 167, 372–380. [Google Scholar] [CrossRef]

- Korniejenko, K.; Łach, M.; Mikuła, J. The Influence of Short Coir, Glass and Carbon Fibers on the Properties of Composites with Geopolymer Matrix. Materials 2021, 14, 4599. [Google Scholar] [CrossRef]

- Korniejenko, K.; Kejzlar, P.; Louda, P. The Influence of the Material Structure on the Mechanical Properties of Geopolymer Composites Reinforced with Short Fibers Obtained with Additive Technologies. Int. J. Mol. Sci. 2022, 23, 2023. [Google Scholar] [CrossRef] [PubMed]

- Panda, B.; Tan, M.J. Experimental Study on Mix Proportion and Fresh Properties of Fly Ash Based Geopolymer for 3D Concrete Printing. Ceram. Int. 2018, 44, 10258–10265. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Hui, L.J.; Tay, Y.W.D.; Tan, M.J. Additive Manufacturing of Geopolymer for Sustainable Built Environment. J. Clean. Prod. 2017, 167, 281–288. [Google Scholar] [CrossRef]

- Nematollahi, B.; Bong, S.H.; Xia, M.; Sanjayan, J. Digital Fabrication of ‘Just-Add-Water’ Geopolymers: Effects of Curing Condition and Print-Time Interval. In Second RILEM International Conference on Concrete and Digital Fabrication; Bos, F.P., Lucas, S.S., Wolfs, R.J.M., Salet, T.A.M., Eds.; RILEM Bookseries; Springer International Publishing: Cham, Switzerland, 2020; Volume 28, pp. 93–102. ISBN 978-3-030-49915-0. [Google Scholar]

- Vitola, L.; Pundiene, I.; Pranckeviciene, J.; Bajare, D. The Impact of the Amount of Water Used in Activation Solution and the Initial Temperature of Paste on the Rheological Behaviour and Structural Evolution of Metakaolin-Based Geopolymer Pastes. Sustainability 2020, 12, 8216. [Google Scholar] [CrossRef]

- Wan, Q.; Zhang, Y.; Zhang, R. The Effect of Pore Behavior and Gel Structure on the Mechanical Property at Different Initial Water Content. Constr. Build. Mater. 2021, 309, 125146. [Google Scholar] [CrossRef]

- Al-Noaimat, Y.A.; Ghaffar, S.H.; Chougan, M.; Al-Kheetan, M.J. A Review of 3D Printing Low-Carbon Concrete with One-Part Geopolymer: Engineering, Environmental and Economic Feasibility. Case Stud. Constr. Mater. 2023, 18, e01818. [Google Scholar] [CrossRef]

- Longhi, M.A.; Zhang, Z.; Walkley, B.; Rodríguez, E.D.; Kirchheim, A.P. Strategies for Control and Mitigation of Efflorescence in Metakaolin-Based Geopolymers. Cem. Concr. Res. 2021, 144, 106431. [Google Scholar] [CrossRef]

- Simão, L.; Fernandes, E.; Hotza, D.; Ribeiro, M.J.; Montedo, O.R.K.; Raupp-Pereira, F. Controlling Efflorescence in Geopolymers: A New Approach. Case Stud. Constr. Mater. 2021, 15, e00740. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Law, R.; Gibb, A.G.F.; Thorpe, T. Hardened Properties of High-Performance Printing Concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef]

| No | Additive | Function | Source |

|---|---|---|---|

| 1 | Attapulgite clay | Thixotropic thickener; improves yield stress due to particle characteristics | [29] |

| 2 | Magnesium alumino silicate | Thixotropy enhancer | [30] |

| 3 | Sodium carboxymethyl starch | Modifies viscosity and has a retarding effect, increases water retention and setting time of the geopolymer paste | [31] |

| 4 | Sucrose | Retarder that extends the setting time | [29] |

| 5 | Nano graphene | Influences workability, flowability, and shape stability | [32] |

| 6 | Xanthan gum | Improves material adhesion, as well as extrusion and nozzle behavior | [33,34] |

| 7 | Silica Fume | Controls yield stress and viscosity; its small spherical particles enable smooth extrusion | [35] |

| No | Additive | Description |

|---|---|---|

| 1 | Plasticizer | Commercially available admix from the company Jurga (Zbrudzewo, Polska) is used. |

| 2 | Burned clay | Burned clay is added to bind excess water in the mix. |

| 3 | Gorkal 70 | High-alumina cement (Górka Cement Sp. z o.o., Trzebinia, Poland) is mainly used for refractory applications and is characterized by its high Al2O3 content and short bonding time. |

| 4 | Methylcellulose | Methylcellulose (Instytut Technologii Chemicznej, Warsaw, Poland) is a commonly used thickening and gelling agent that is soluble in water. |

| 5 | Xanthan gum | Xanthan gum (Synthetika Sp. z o.o., Łódź, Poland) is used to improve printability and rheology. |

| 6 | Sealing additive (Waterproof) | Supports setting underwater; a sealing additive from the company Jurga (Jurga Sp. k., Zbrudzewo, Poland) is utilized. It is present in liquid form. |

| Constituent | NaOH | H2O | Waterglass |

|---|---|---|---|

| Mass [g] | 628 | 2000 | 4900 |

| Vol. [%] | 8.34 | 26.57 | 65.09 |

| No | Designation | Fly Ash [g] | Sand [g] | Plasticizer [g] | Burned Clay [g] | Gorkal 70 [g] | Metylocellulose [g] | Xantan Gum [g] | Sealing Additive (Waterproof) [g] | Solution [g] | Additional Water [g] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | #2AB | 400 | 400 | --- | --- | --- | --- | --- | --- | 196 | --- |

| 2 | #3AB | 350 | 350 | 0.28 | --- | --- | --- | --- | --- | 171.5 | --- |

| 3 | #4AB | 350 | 350 | 0.56 | --- | --- | --- | --- | 8.73 | 171.5 | --- |

| 4 | #5AB | 350 | 350 | 0.28 | --- | --- | --- | --- | 8.6 | 160.6 | --- |

| 5 | #6AB | 250 | 250 | 0.20 | --- | 100 | --- | --- | 6.17 | 155 | --- |

| 6 | #7AB | 100 | 100 | 0.20 | --- | --- | 30 | --- | 2.46 | 65 | --- |

| 7 | #8AB | 250 | 250 | --- | --- | 60 | 15 | --- | 7.2 | 150 | --- |

| 8 | #9AB | 3000 | 3000 | 2.50 | --- | 600 | 120 | --- | 83.4 | 1922 | --- |

| 9 | #10AB | 250 | 250 | 0.218 | 15 | 15 | 15 | --- | 6.81 | 140 | --- |

| 10 | #11AB | 4000 | 5250 | 5.5 | 115 | 340 | 115 | --- | 108.4 | 2231 | --- |

| 11 | #12AB | 350 | 350 | 0.28 | --- | 30 | --- | 21 | 8.75 | 390 | --- |

| 12 | #13AB | 2000 | 2000 | 2.00 | --- | 200 | --- | 150 | --- | 2750 | --- |

| 13 | #14AB | 300 | 300 | 0.24 | --- | 30 | --- | 9 | --- | 250 | --- |

| 14 | #15AB | 3000 | 3000 | 3.00 | --- | 300 | --- | 150 | --- | 3500 | --- |

| 15 | #16AB | 4000 | 4000 | 4.00 | --- | 160 | --- | 320 | --- | 4200 | 1000 |

| 16 | #17AB | 4000 | 5000 | 4.50 | --- | --- | --- | 180 | --- | 3000 | 1500 |

| 17 | #20AB | 3000 | 3750 | 3.38 | --- | --- | --- | 135 | --- | 2230 | 1000 |

| 18 | #21AB | 4000 | 4000 | 4.00 | --- | --- | --- | 130 | 100 | 3650 | --- |

| Volume | Width [mm] | Length [mm] | Height [mm] |

|---|---|---|---|

| A | 180 | 180 | 50 |

| B | 120 | 280 | 70 |

| C | 200 | 180 | 50 |

| D | 100 | 200 | 50 |

| No | Parameter | Value |

|---|---|---|

| 1 | Layer Height | 10 mm |

| 2 | Line Width | 20 mm |

| 3 | Infill Line Width | 20 mm |

| 4 | Wall line Count | 0 |

| 5 | Top/Bottom Thickness | 10 mm |

| 6 | Top/Bottom Layers | 0 |

| 7 | Infill Density | 100% |

| 8 | Infill Pattern | Zig Zag [90,90] |

| 9 | Infill Layer Thickness | 10 mm |

| 10 | Print Speed | 60 mm/s |

| 11 | Build Plate Adhesion | none |

| Raw Material 1 | D10 [µm] | D50 [µm] | D90 [µm] | Mean Size [µm] | Span |

|---|---|---|---|---|---|

| Sand | 196.794 | 382.365 | 489.673 | 422.662 | 0.766 |

| Fly ash | 2.867 | 18.820 | 57.531 | 26.692 | 2.907 |

| No | Additive | Effect and Content | Suitability to 3D Printing |

|---|---|---|---|

| 1 | Plasticizer | After addition, a significantly more resistance-free flow behavior is observed in the paste. Proportions from 0.04 to 0.1% are tested. The best results are achieved with an addition of 0.05%. | Yes |

| 2 | Burned clay | An attempt is made to add 1.24 to 3% of burnt clay, but no improvement in the properties can be observed at any proportion. | No |

| 3 | Gorkal 70 | Between 2 and 20% of Gorkal70 is added. This leads to a significant increase in viscosity and good test results. However, for over 7% added, the effect continued to increase over time, resulting in insufficient workability and the extrusion stopped. Best values seemed to be around 3 to 4%, though significantly more liquid is needed to achieve the desired consistency | Yes, in small quantities or with fast processing time |

| 4 | Methylcellulose | Adding 1.25 to 14% methylcellulose decreases the extrusion properties but considerably accelerates hardening. Although an addition of 3% achieved good results, the additive is unsuitable due to its large particle size. | Partial |

| 5 | Xanthan gum | The addition of 1.5 to 3% results in a strong cohesion in the material and a viscous behavior. By adding solution, the paste becomes extrudable and still retains its shape after extrusion. Significantly more liquid is needed to achieve the desired consistency. Values around 2% provide the best results. | Yes |

| 6 | Sealing additive (waterproof) | The sealing additive is added in the amount recommended by the manufacturer (1.23%) and improves the hardening of the paste under water. Although samples to which the additive is added harden more quickly, the strength is not sufficient for mechanical tests after 28 days | Partial (UW3DP) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Becher, A.F.; Zeidler, H.; Gądek, S.; Korniejenko, K. Shaping and Characterization of Additively Manufactured Geopolymer Materials for Underwater Applications. Appl. Sci. 2025, 15, 3449. https://doi.org/10.3390/app15073449

Becher AF, Zeidler H, Gądek S, Korniejenko K. Shaping and Characterization of Additively Manufactured Geopolymer Materials for Underwater Applications. Applied Sciences. 2025; 15(7):3449. https://doi.org/10.3390/app15073449

Chicago/Turabian StyleBecher, Anton Frederik, Henning Zeidler, Szymon Gądek, and Kinga Korniejenko. 2025. "Shaping and Characterization of Additively Manufactured Geopolymer Materials for Underwater Applications" Applied Sciences 15, no. 7: 3449. https://doi.org/10.3390/app15073449

APA StyleBecher, A. F., Zeidler, H., Gądek, S., & Korniejenko, K. (2025). Shaping and Characterization of Additively Manufactured Geopolymer Materials for Underwater Applications. Applied Sciences, 15(7), 3449. https://doi.org/10.3390/app15073449