New Taipei City Smart Pavement Management Center and Road Maintenance Analysis

Abstract

1. Introduction

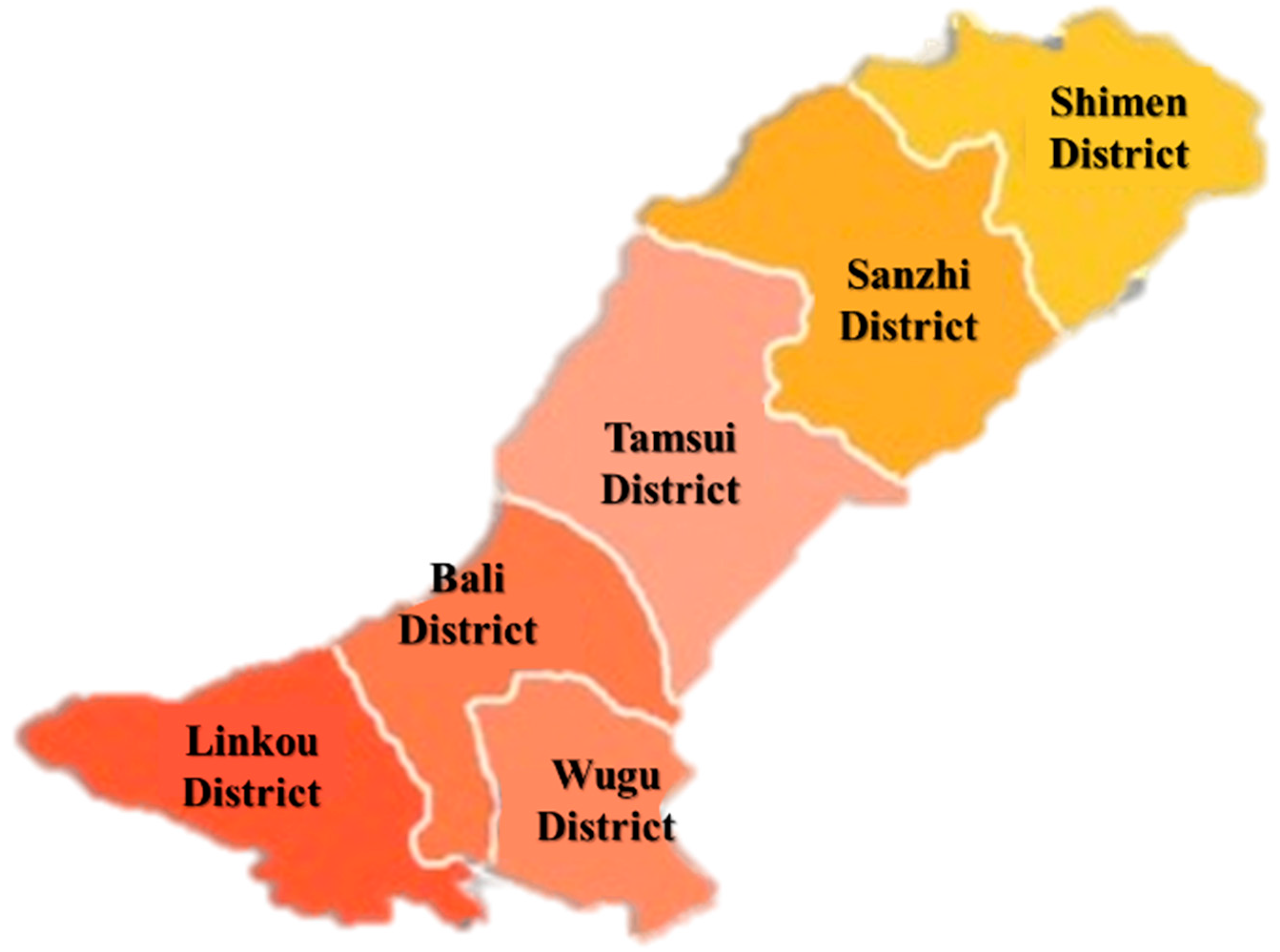

2. Intelligent Inspection Planning

2.1. Scope Planning

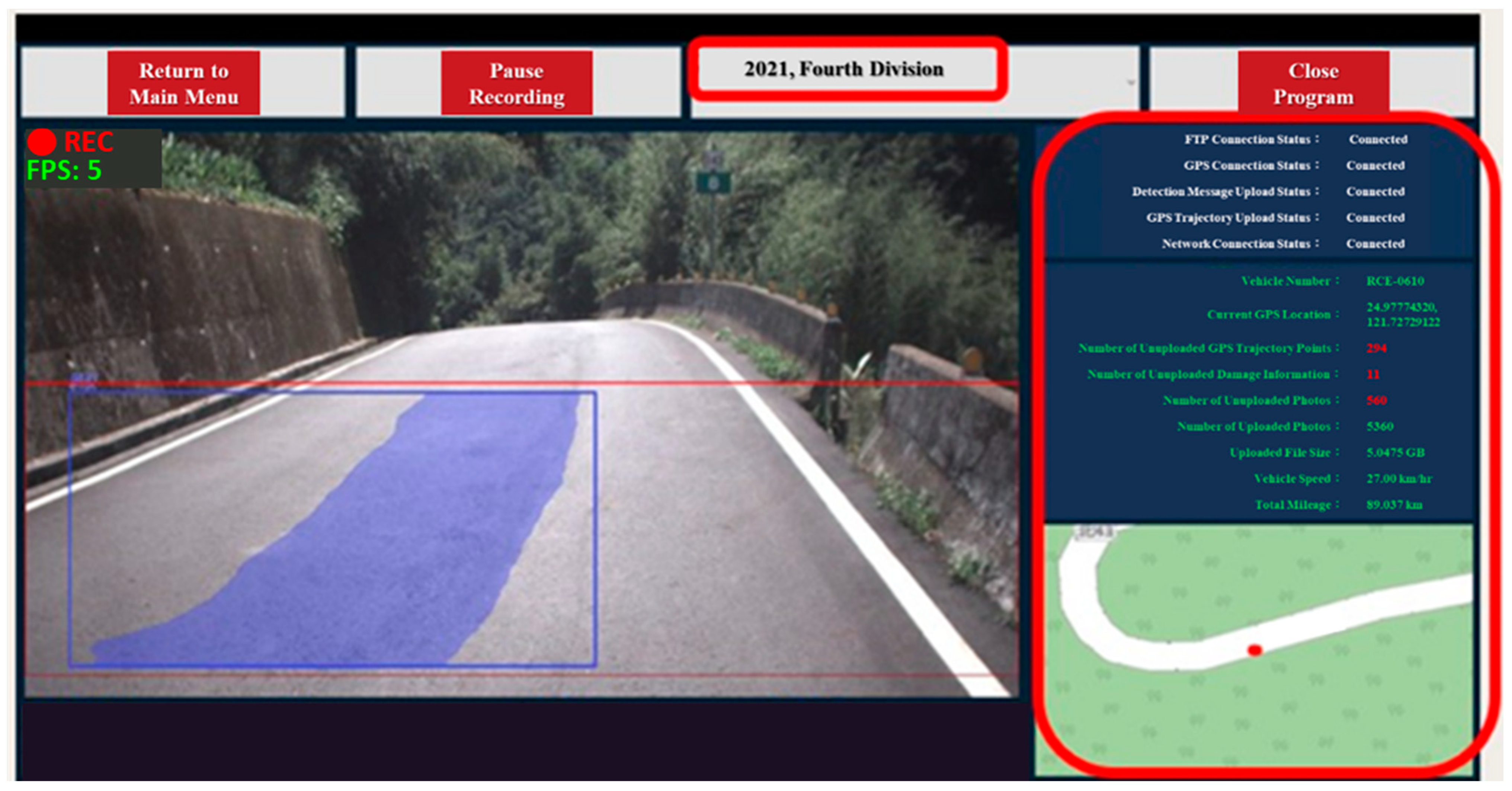

2.2. Hardware Equipment Requirements

2.3. Software Equipment and Training

- AI-Powered Inspection Vehicle

- 2.

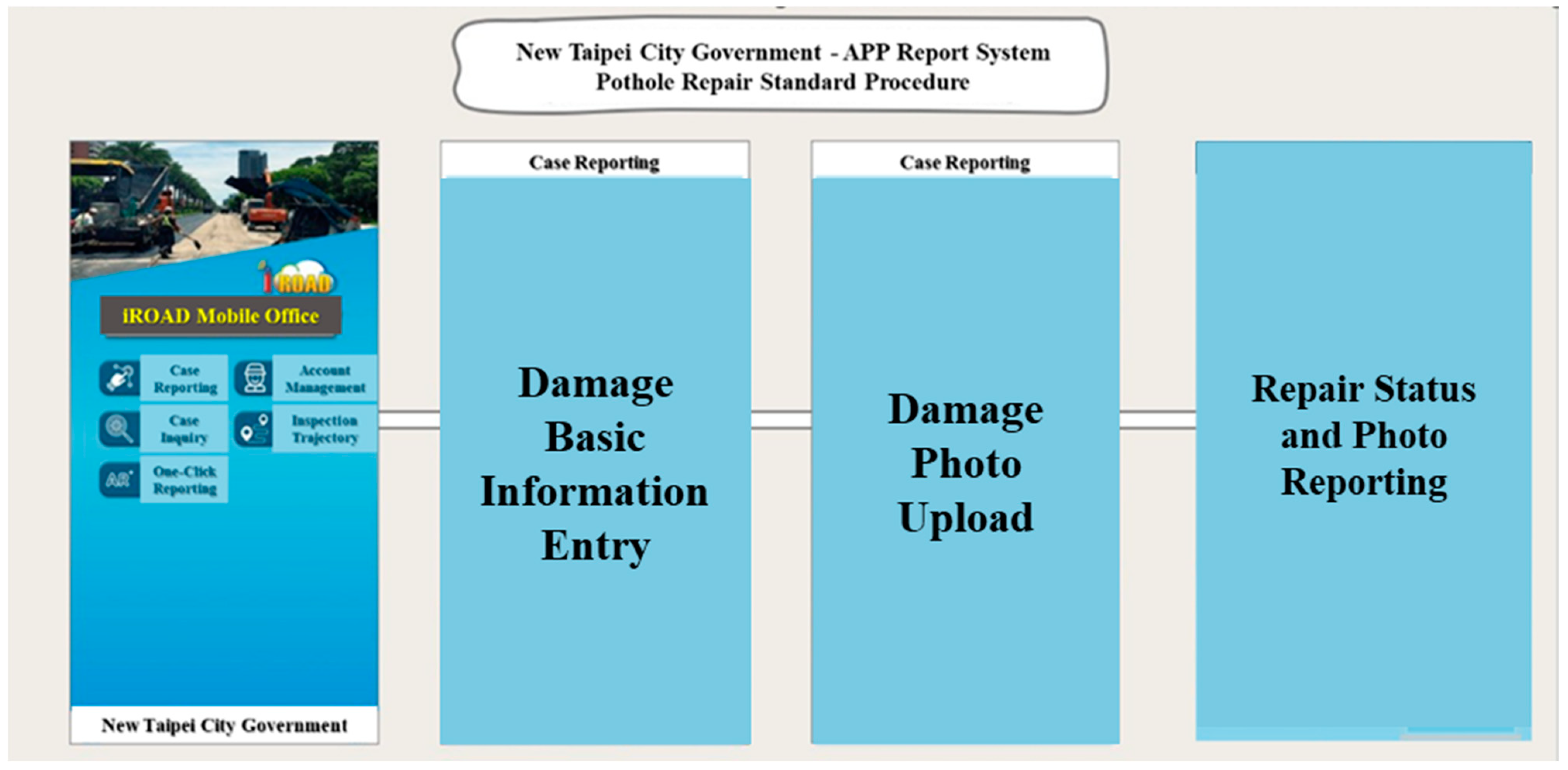

- APP Real-Time Reporting System Operation

2.4. Training for Inspection Personnel

2.5. System Data Setup

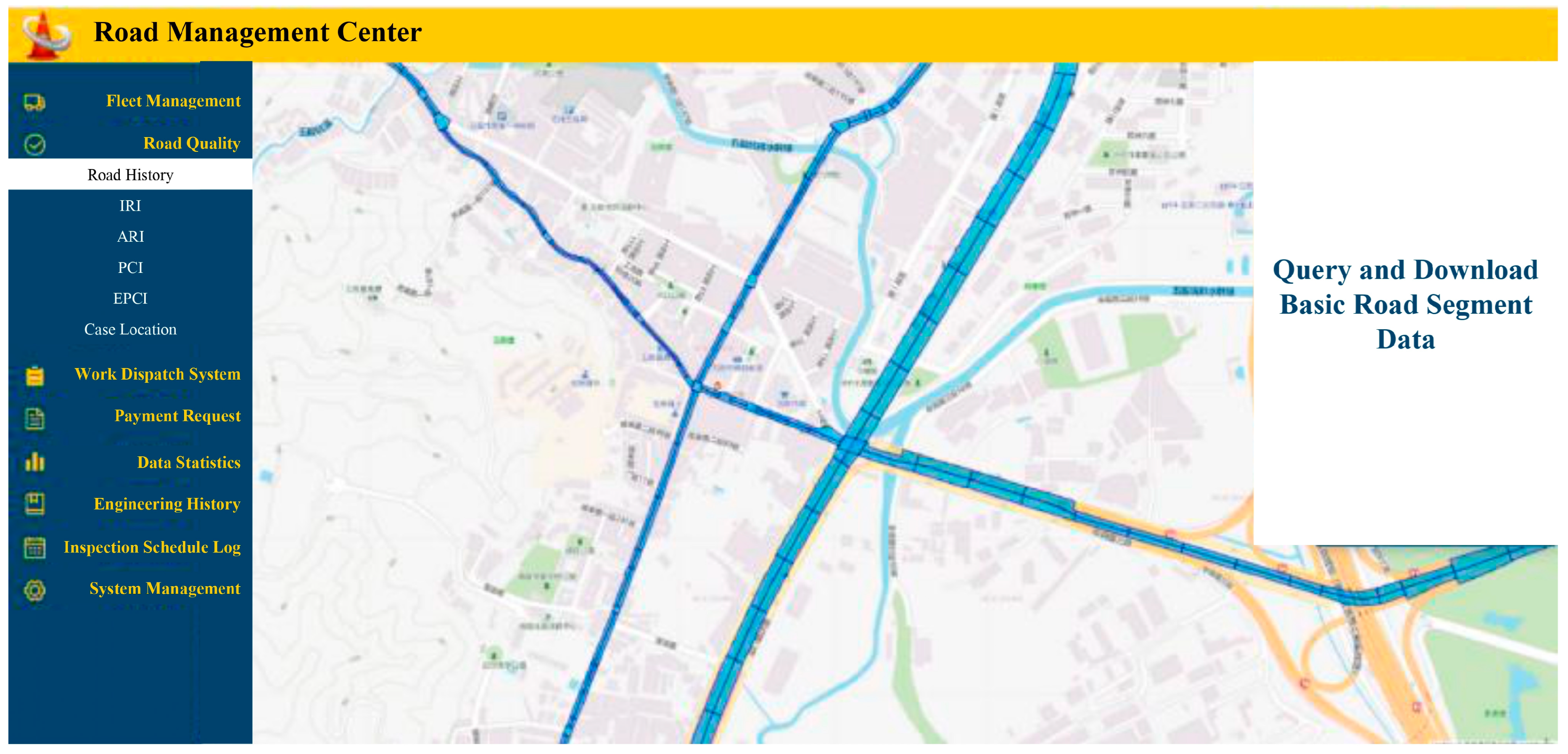

3. Road Management Center Information Platform

- Mobile App: This function provides a mobile application available at any time, allowing users to manually add cases, particularly for road damage information detected through image recognition. It enables quick access to the work order process. The app also supports photo documentation of the damage for maintenance purposes.

- Case Management System: The core of this system is real-time work order management for urgent cases. It classifies and ranks road sections that require priority improvement based on the four key pavement indicators, ensuring proper allocation of maintenance resources.

- Display System: This system is used to show inspection performance and the status of the four key pavement indicators. It provides real-time road condition updates, allowing management personnel to quickly understand the immediate maintenance needs, enhancing monitoring efficiency.

- Road Maintenance Information for the Road Engineering Office District: This function displays information about roads under the jurisdiction of the Road Engineering Office, including inspection records and maintenance progress, providing comprehensive data support for timely decision making.

- Road Maintenance Information for the Village Office District: Similarly, this function provides maintenance information queries for roads under the jurisdiction of the village offices, allowing local offices to easily track the condition and maintenance needs of roads in their area.

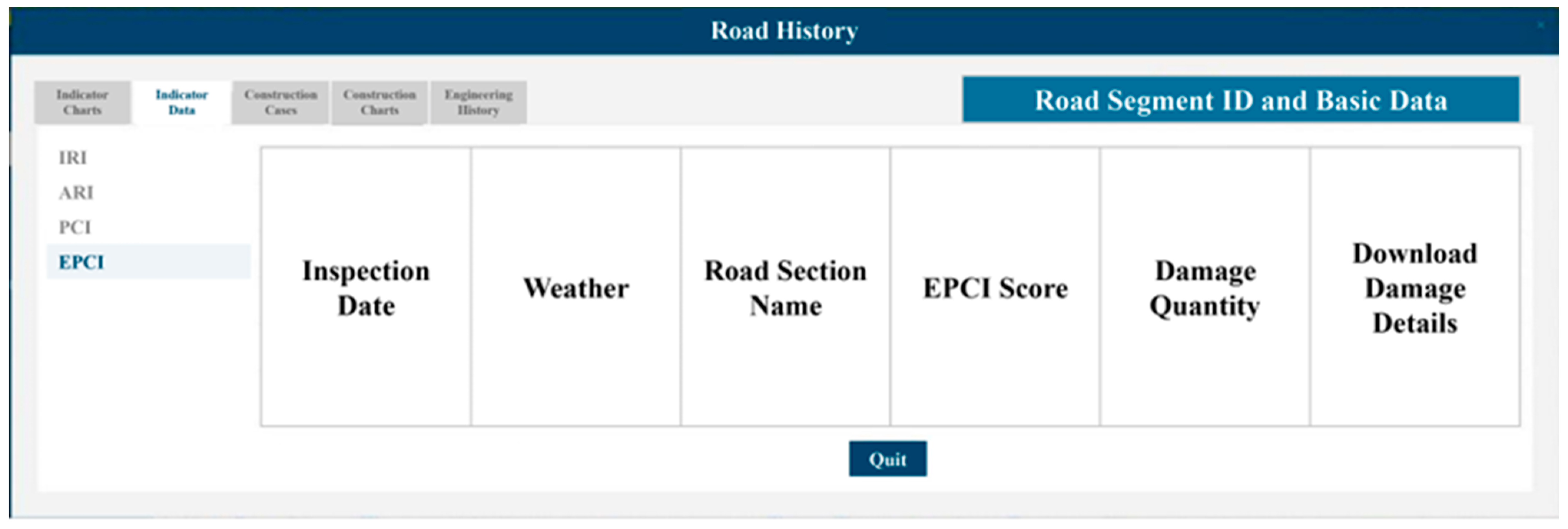

New Taipei City Road Project Case Management System

- Fleet Management Module: The primary function is to record the fleet’s operational status and dispatch details, facilitating subsequent tracking and scheduling.

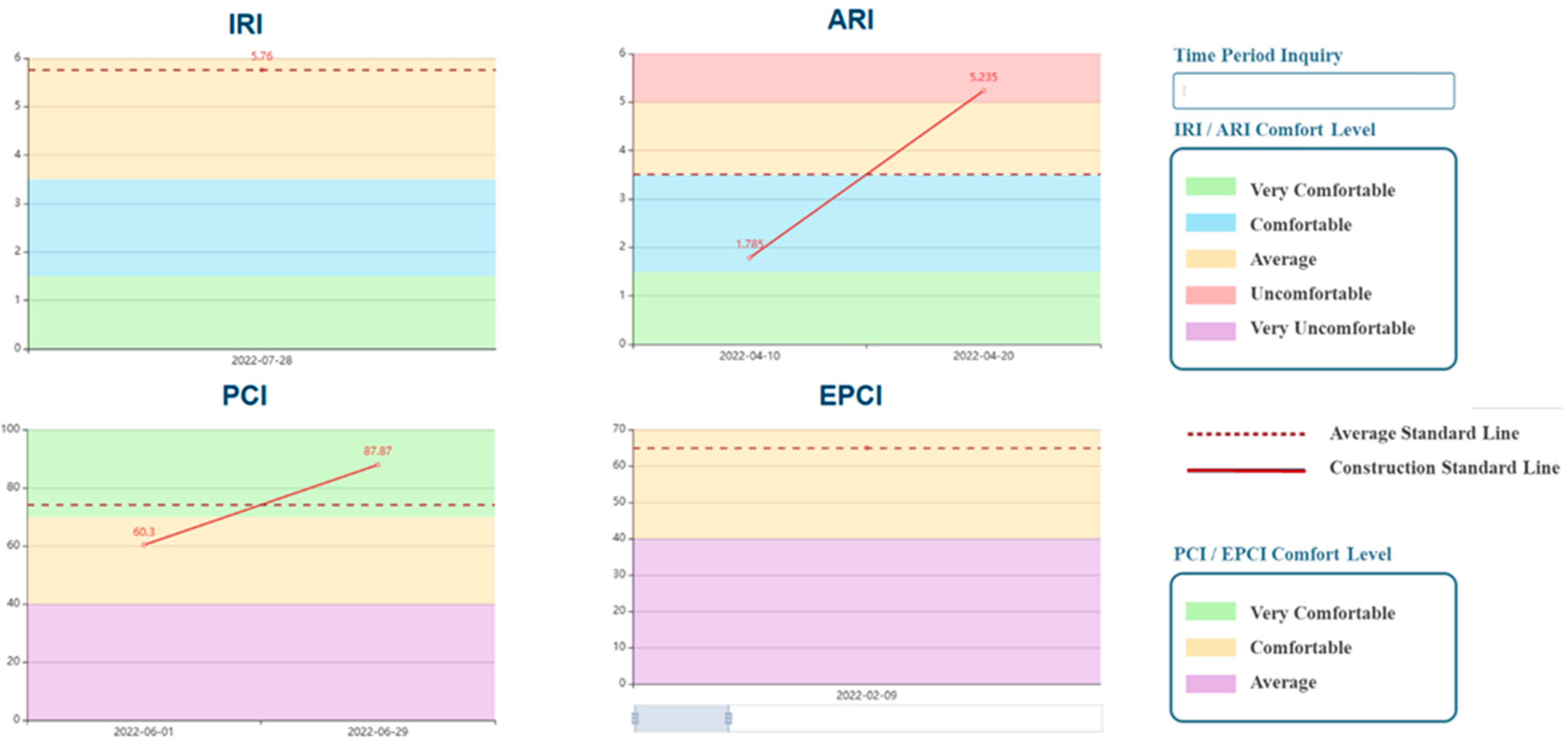

- Road Quality Module: This module includes several inspection items to ensure overall road quality, including the following:

- Four Pavement Indicators: the Simple Pavement Condition Index (EPCI), Simple Pavement Status Indicator (AARI), Pavement Roughness Index (IRI), and Pavement Condition Index (PCI);

- Case Location: Records the road inspection and maintenance locations;

- Road History: Collects and organizes case data at various stages of the road lifecycle.

- Work Order System Module: Responsible for managing cases that require dispatch. This module includes three types of cases:

- Case Inquiry: Classifies and consolidates road inspection and maintenance cases for supervisors to review detailed case information;

- New Case: If a road inspection update or repair request is received, a new case is added to the system for tracking and data uploading;

- Damage Case: When a road shows significant damage, it is recorded as a damage case, which is reviewed internally to determine whether maintenance is needed and which method should be used;

- Work Dispatch Case: If the damage case requires maintenance, it is categorized as a work dispatch case for unified management and dispatch;

- Internal Tracking Case: For damage cases that do not require dispatch, internal personnel will be responsible for tracking the case.

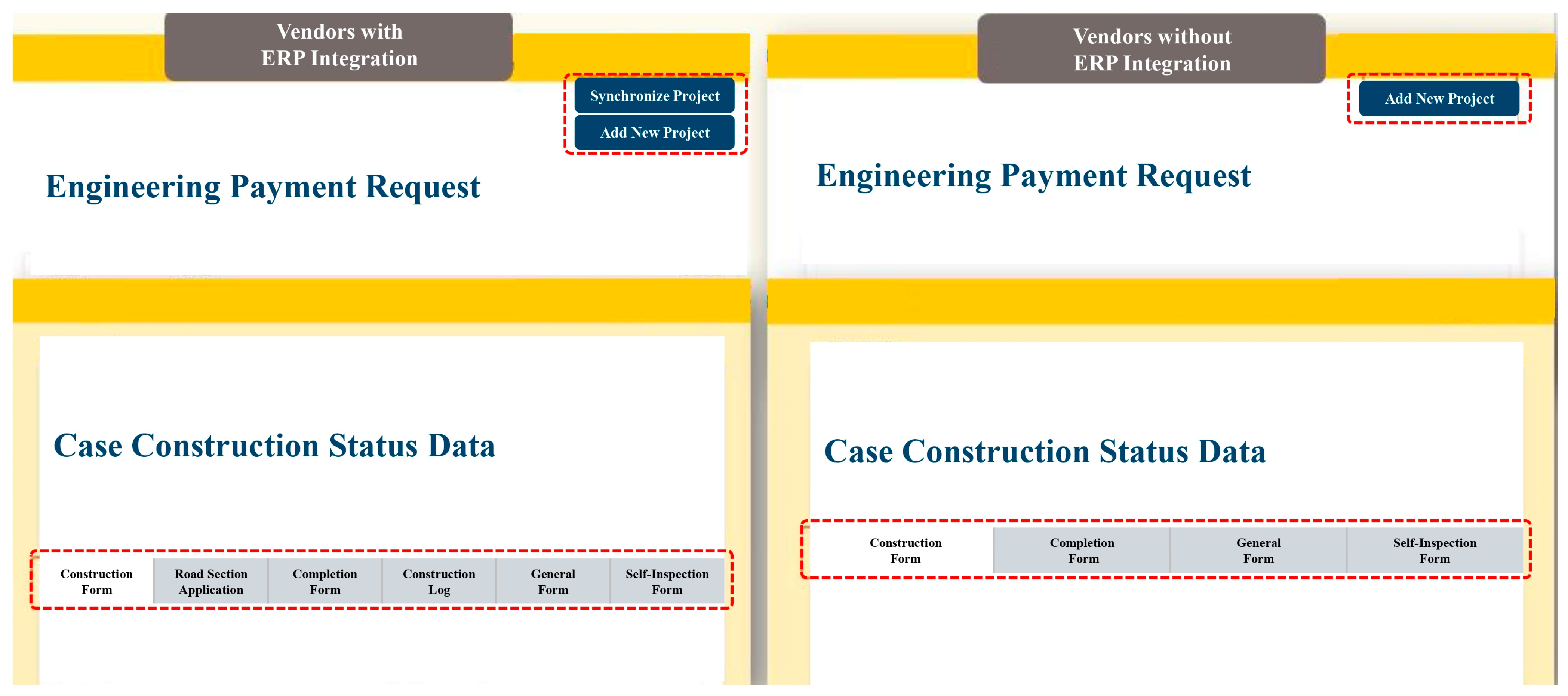

- Engineering Payment Request Module: Used to manage payment requests related to engineering projects, facilitating financial verification and management of project funds.

- Data Statistics Module: Includes case analysis and the recording and analysis of engineering data. These statistical data help management personnel to assess overall cases and provide references for road maintenance and decision-making.

- Project History Module: Responsible for recording detailed histories of each project, including the following:

- Official Document Control Table: Collects documents related to engineering projects for easier management;

- Project History Table: Displays the complete historical record of each project to ensure all data are traceable;

- Asphalt: Manages and tracks the asphalt used in various road projects;

- Ancillary Equipment: Records the ancillary equipment on the road, assisting in maintenance management.

- Inspection Schedule Log Module: Used to manage the inspection personnel’s schedules, including the following:

- Inspection Schedule: Manages the scheduling of inspection personnel to allocate labor effectively;

- Inspection Log: Records detailed inspection schedules to ensure that each time period has assigned personnel for inspections.

- System Administration Module: Provides account management functions, responsible for managing user accounts and permissions to ensure data security.

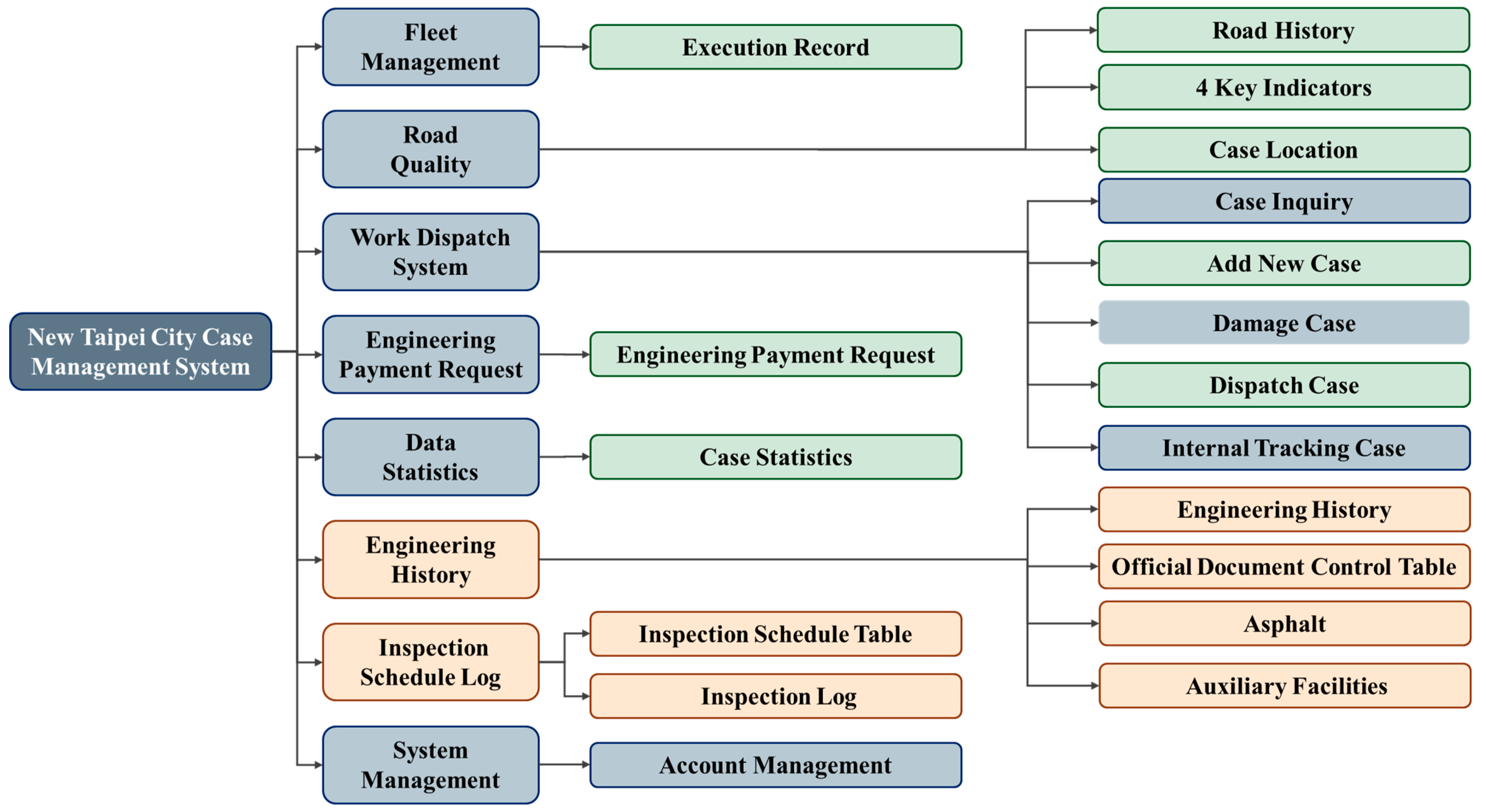

- Simple Pavement Roughness Index (AARI): AARI is primarily used to assess road smoothness, helping management personnel understand the degree of unevenness of the road surface. This indicator is measured using a simple pavement smoothness tool and provides quick data, allowing management units to identify areas in need of improvement, ensuring driving comfort and safety.

- Simple Pavement Condition Index (EPCI): EPCI is used to assess the overall condition of the pavement, including the stability and durability of the road structure. This indicator is an important reference for road maintenance management, helping to identify structural damage or aging phenomena, thereby aiding in the development of more targeted repair plans.

- International Roughness Index (IRI): IRI is a key indicator used to assess road surface roughness and measures the smoothness of the road, which is directly related to driving comfort. Higher IRI values indicate rougher surfaces, which may lead to discomfort for passengers and potentially affect driving safety. Monitoring this indicator encourages road management units to conduct regular maintenance, reducing accident risks.

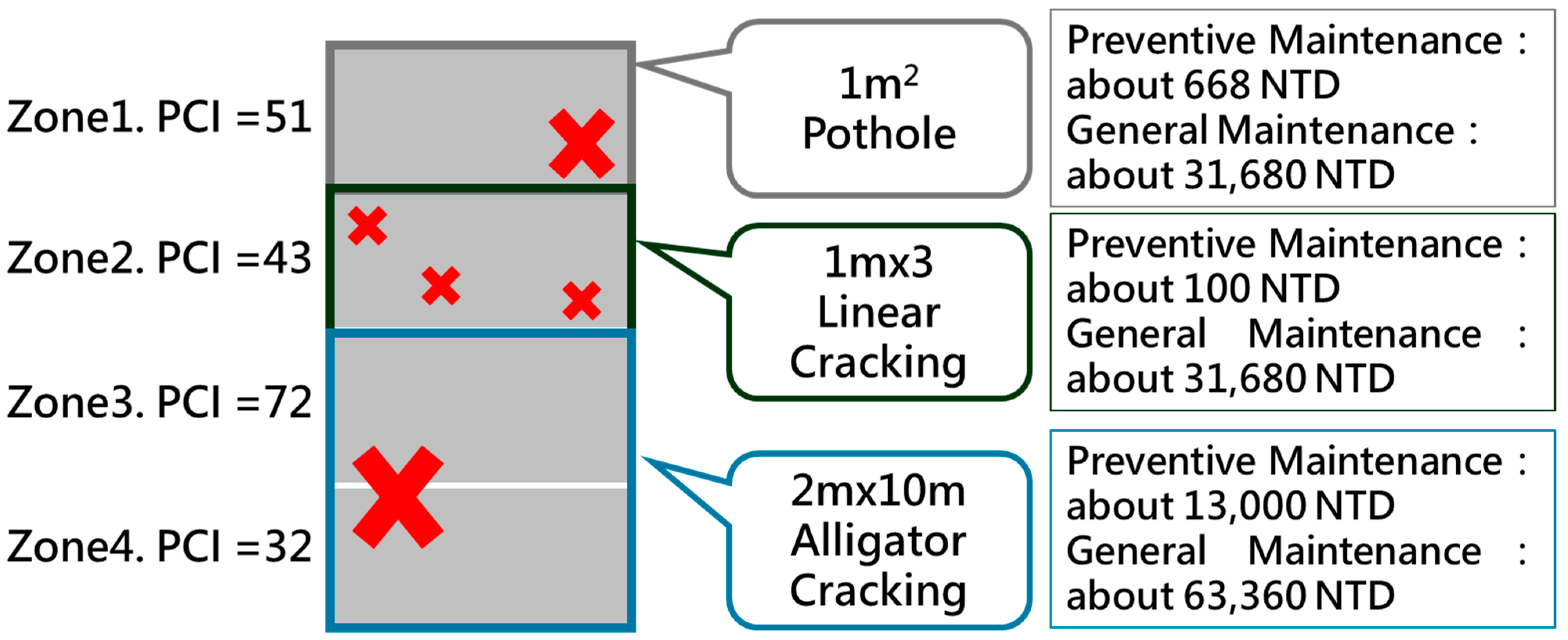

- Pavement Condition Index (PCI): PCI is a comprehensive index for evaluating road pavement conditions, covering a variety of road damage situations such as cracks, potholes, and surface deterioration. The data provided by PCI help to determine the road’s lifespan and immediate maintenance needs, assisting management personnel in prioritizing areas that require urgent attention, thus extending the road’s lifespan and reducing maintenance costs.

4. Pavement System Modular Work Order and Budget Analysis

4.1. Pavement Management Center Work Order Process

4.2. Project Dispatch and Billing Stage

4.3. Maintenance Methods and Cost Analysis for Dispatch

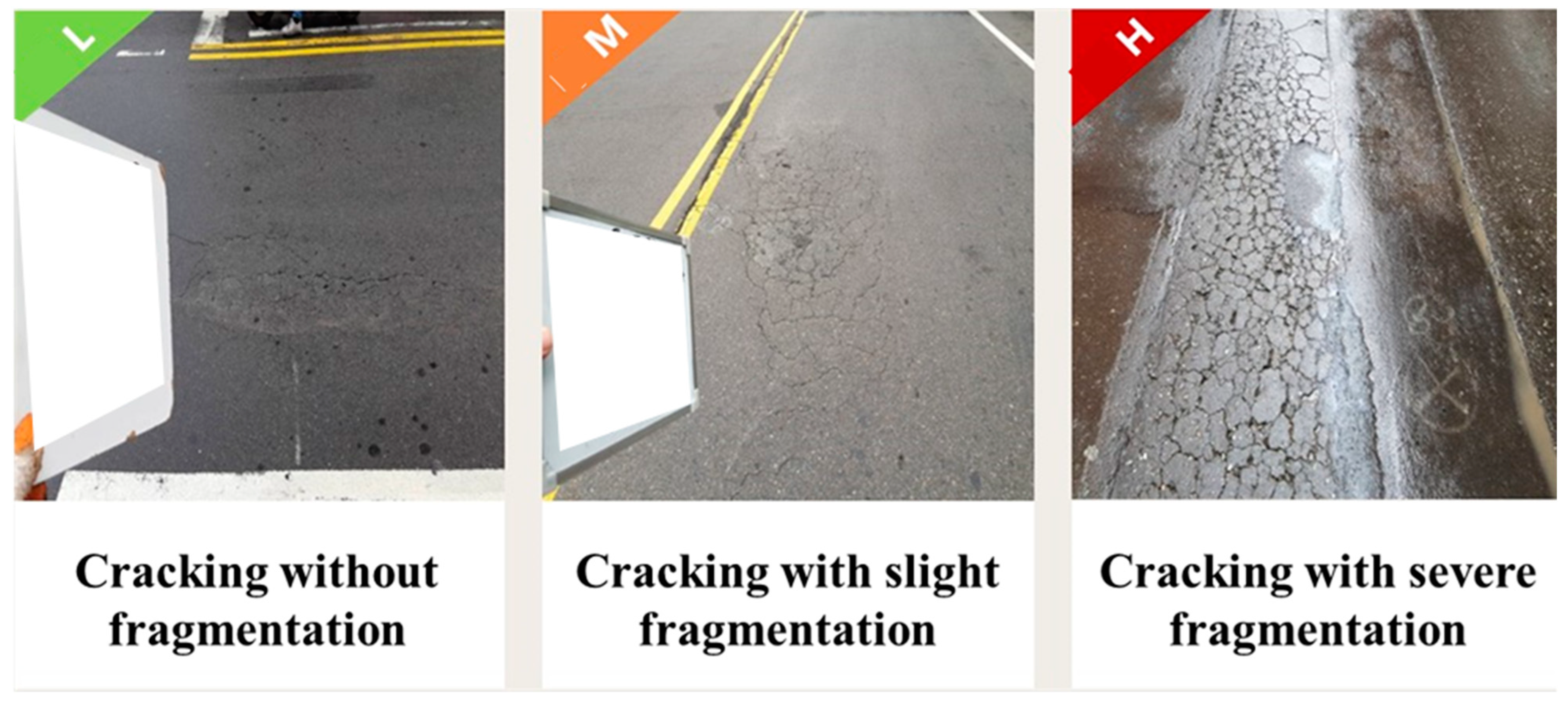

- Low damage includes potholes smaller than 10 cm, linear cracks less than 1 cm wide, and manhole height differences between 0.5 and 1 cm. These have a minimal impact on driving.

- Medium damage includes potholes between 10 and 20 cm, alligator cracks with minor fragmentation, cracks wider than 1 cm but no longer than 7.5 cm, and manhole height differences between 1 and 2.5 cm. These cause some discomfort for drivers.

- High damage includes potholes larger than 30 cm, alligator cracks with significant fragmentation, cracks wider than 1 cm and longer than 7.5 cm, cracks with severely damaged edges, and manhole height differences greater than 2.5 cm. These conditions result in extreme discomfort for drivers.

| Damage Type/Severity | Low | Medium | High |

|---|---|---|---|

| Pothole | Pothole < 10 cm | 10 cm < Pothole < 20 cm | Pothole > 30 cm |

| Alligator Cracking | Cracking without fragmentation | Cracking with slight fragmentation | Cracking with severe fragmentation |

| Linear Cracking | Crack width < 1 cm | Crack width > 1 cm, length < 7.5 cm | Crack width > 1 cm, length > 7.5 cm |

| Block Cracking | Fine crack width, no damage | Crack width is more obvious (0.3–0.5 cm), with some intersecting cracks showing damage | Noticeable cracks (over 0.5 cm), severe edge damage |

| Heaving and Settling | Slight driving discomfort | Moderate driving discomfort | Severe driving discomfort |

| Patch and Pipeline Excavation Repair | Patch in good condition | Patch with cracks or slight discomfort for drivers | Patch with cracks or significant height differences, very uncomfortable |

| Manhole Cover Alignment | Manhole height difference 0.5–1 cm | Manhole height difference 1–2.5 cm | Manhole height difference > 2.5 cm |

- Pothole:

- Low: No treatment or partial depth repair;

- Medium: Partial or full depth repair;

- High: Full depth repair.

- Alligator Cracking:

- Low: Surface sealing or overlay;

- Medium: Partial depth repair, overlay, or reconstruction;

- High: Partial or full depth repair, overlay, and reconstruction.

- Linear Cracking:

- Low: Crack filling for cracks wider than 1/8 inch;

- Medium and High: Crack filling or partial depth repair.

- Block Cracking:

- Low: Crack filling or surface sealing;

- Medium: Surface rejuvenation with overlay or hot milling with overlay;

- High: Crack filling, surface rejuvenation, overlay, and hot milling.

- Heaving and Settling:

- Low: No treatment;

- Medium and High: Cold milling, shallow or partial depth repair with overlay;

- Patch and Pipeline Excavation Repair:

- Medium and High: Replacement of patching.

- Manhole Cover Alignment:

- Low: No treatment;

- Medium: Manhole replacement;

- High: Manhole replacement and leveling the road surface.

| Damage Type/Severity | Low | Medium | High |

|---|---|---|---|

| Pothole | No treatment; partial or full depth repair | Partial or full depth repair | Full depth repair |

| Alligator Cracking | No treatment; surface sealing; overlay | Partial or full depth repair; overlay; reconstruction | Partial or full depth repair; overlay; reconstruction |

| Linear Cracking | No treatment; seal cracks > 1/8 inch wide | Crack filling | Crack filling; partial depth repair |

| Block Cracking | Seal cracks > 1/8 inch wide; surface sealing | Crack filling; surface rejuvenation; hot milling with overlay | Crack filling; surface rejuvenation; hot milling with overlay |

| Heaving and Settling | No treatment | Cold milling; shallow, partial, or full depth repair | Cold milling; shallow, partial, or full depth repair; overlay |

| Patch and Pipeline Excavation Repair | No treatment | No treatment; replace patch | Replace patch |

| Manhole Cover Alignment | No treatment | No treatment; replace manhole and level with road surface | Replace manhole and level with road surface |

4.4. Maintenance Dispatch Cost Analysis

5. Conclusions and Recommendations

5.1. Conclusions

- The New Taipei City Government’s Maintenance Engineering Division has established standards and repair solutions for the seven main types of road damage in the city, providing appropriate maintenance measures based on the severity of damage, such as potholes, alligator cracks, and depressions.

- This study presents several real-world repair cases and statistical analysis of repair areas, unit prices, and costs. These data will be integrated into the Road Management Center’s information platform for optimizing the work order module.

- To enhance the quality of roadworks, contractors independently monitor road performance and implement pavement performance indicator management. This approach uses an intelligent platform to ensure road maintenance service quality, offering the most effective solutions while maximizing the utilization of limited funds.

- By integrating intelligent recognition systems, contractors can independently manage quality control, develop a clear separation mechanism for inspection and repair, and maintain road safety to prevent potholes. The inspection records are stored in the road inspection center platform, categorizing frequently repaired and secondary repair sections to guide decisions on whether milling is necessary.

- The continued improvement of data integration and module development will apply maintenance data to the work order module, enabling better cost prediction for repairs, improving the efficiency of the work order system, and enhancing the accuracy of resource allocation.

5.2. Recommendations

- To apply the system developed in this study to other cities, we recommend first collecting data on various types of pavement distress and corresponding maintenance methods specific to the target city. A dedicated database should be established, and, once completed, optimization of construction methods can be analyzed based on effectiveness or cost considerations.

- The main challenge currently faced by this system is the time-consuming process of organizing road inspection data, resulting in an insufficient amount of comprehensive data. To enhance system performance, we recommend improving road inspection efforts and streamlining the integration of inspection results into the system, thereby maximizing its ability to analyze and determine optimal construction methods.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.R. Establishing a Pavement Maintenance Management System for Asphalt Pavements in Taiwan—A Case Study of the Zhongli Work Section of the Highway Bureau. Master’s Thesis, Department of Civil Engineering, National Central University, Tao-Yuan, Taiwan, China, 2001. [Google Scholar]

- Lin, K.H. A Study on the Establishment of a Pavement Management Framework for Urban Roads: A Case Study of Taipei City. Master’s Thesis, Department of Civil Engineering, National Central University, Tao-Yuan, Taiwan, China, 2015. [Google Scholar]

- Chen, J.D.; Yang, Z.Z.; Chen, H.X.; You, X.Q. Feasibility Study on the Introduction of Artificial Intelligence into Road Inspection Work in New Taipei City. Pavement Eng. 2021, 57–70. [Google Scholar]

- Yang, Z.Z. A Study on the Establishment of a Pavement Maintenance Information Management Center. Master’s Thesis, Department of Civil Engineering, National Central University, Tao-Yuan, Taiwan, China, 2009. [Google Scholar]

- Zhou, J.B.; Chen, A.Q. A Study on the Improvement of Pavement Smoothness Management for Urban Roads; Research Commissioned by the Ministry of the Interior; Ministry of the Interior: Beijing, China, 2018.

- Chinese Pavement Engineering Association. Training Course Materials for Certification of Road Construction Supervision and On-Site Management Personnel in Taipei City; Chinese Pavement Engineering Association: Taipei, Taiwan, China, 2023. [Google Scholar]

| No. | Item |

|---|---|

| 1 | Road Repair Vehicle with Warning Signals |

| 2 | Satellite Imaging System (Including GPS Tracking) |

| 3 | Vehicle Warning System (Warning Lights, Warning Sirens, Flashing Message Signs, Public Address System) |

| 4 | Repair Materials (Cold Mix Asphalt Concrete, High-Performance Asphalt Concrete, Cold Bitumen) |

| 5 | Power Supply Equipment (Generator) |

| 6 | Surface Removal Equipment (Surface Remover, Handheld Cutting Machine) |

| 7 | Compactor |

| 8 | Repair Tools (Round Shovels, Rakes, etc.) |

| 9 | Traffic Maintenance Equipment (Traffic Cones, Traffic Barriers, Flashing Warning Lights) |

| No. | Item |

|---|---|

| 1 | Inspection Vehicle |

| 2 | High-Precision GPS |

| 3 | Recognition Host (Processing Unit) |

| 4 | Power Supply Unit |

| 5 | Touchscreen Interface |

| 6 | CCD Camera |

| 7 | Vehicle-Mounted System |

| 8 | Memory Storage |

| 9 | Display Screen |

| 10 | GPS Tracking System |

| 11 | OBD Connector Cable |

| 12 | Basic Pavement Leveling Tool |

| Repair Method | Cost (NTD) | |

|---|---|---|

| Preventive Maintenance | Pothole Repair | 178/place (30 cm × 30 cm) 307/place (60 cm × 60 cm) |

| Hot Recycled Material Repair | 668/m2 | |

| Crack Filler | 33/m | |

| Repair Material | - | |

| General Maintenance | Square Milling | 650/m2 |

| Cold Mix Subgrade Improvement | 1378/m2 | |

| Subgrade Improvement (Dry Mix Cement) | 983/m2 | |

| Full Milling | 440/m2 | |

| Damage Type | Repair Method | Repair Area (m2) | Unit Price (NTD) | Total Cost (NTD) | Damage Photo |

|---|---|---|---|---|---|

| Single Block: Multiple Cracks, Depressions, and Alligator Cracks | Full Milling | 18,655.8 | 440 | 8,208,552 |  |

| Single Block: Block Cracks, Partial Alligator Cracks | Square Milling | 1397 | 650 | 908,050 |  |

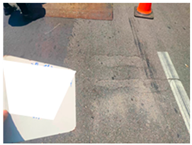

| Single Block: Depressions, Ruts, Partial Alligator Cracks | Cold Mix Subgrade Improvement | 8.14 | 1378 | 11,217 |  |

| Single Block: Local Cracks, Longitudinal Cracks | Hot Recycled Material Repair | 3.42 | 668 | 2285 |  |

| Single Block: Longitudinal Cracks | Crack Filler | 26 (m) | 33 | 866 |  |

| Single Block: Potholes | Pothole Repair | 1 place (0.7 m × 0.9 m) | 307 | 307 |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, P.-Y.; Lin, J.-D.; Ho, M.-C.; Zou, C.-C. New Taipei City Smart Pavement Management Center and Road Maintenance Analysis. Appl. Sci. 2025, 15, 3617. https://doi.org/10.3390/app15073617

Song P-Y, Lin J-D, Ho M-C, Zou C-C. New Taipei City Smart Pavement Management Center and Road Maintenance Analysis. Applied Sciences. 2025; 15(7):3617. https://doi.org/10.3390/app15073617

Chicago/Turabian StyleSong, Pin-You, Jyh-Dong Lin, Min-Che Ho, and Chia-Chi Zou. 2025. "New Taipei City Smart Pavement Management Center and Road Maintenance Analysis" Applied Sciences 15, no. 7: 3617. https://doi.org/10.3390/app15073617

APA StyleSong, P.-Y., Lin, J.-D., Ho, M.-C., & Zou, C.-C. (2025). New Taipei City Smart Pavement Management Center and Road Maintenance Analysis. Applied Sciences, 15(7), 3617. https://doi.org/10.3390/app15073617