Hybrid Organisation Structure: A Holistic and Adaptable Approach for Hybrid, Flow-Oriented Assembly Organisation

Abstract

Featured Application

Abstract

1. Introduction

1.1. Challenges in the Flexible Design of Assembly

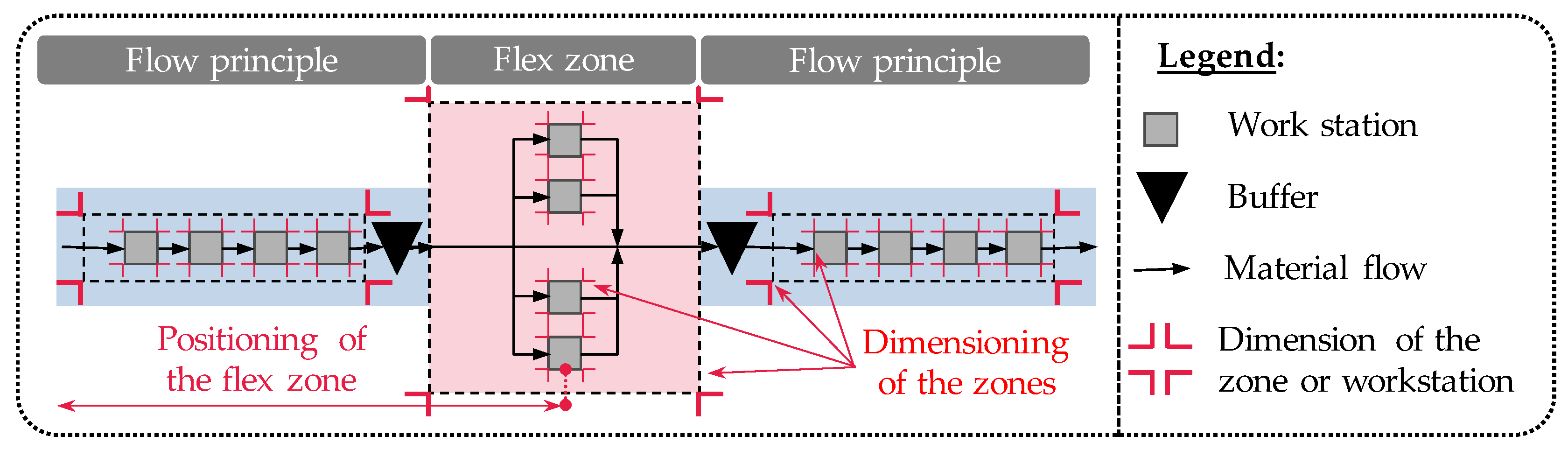

1.2. Hybrid Organisation Structures

2. Previous Research

2.1. Related Work

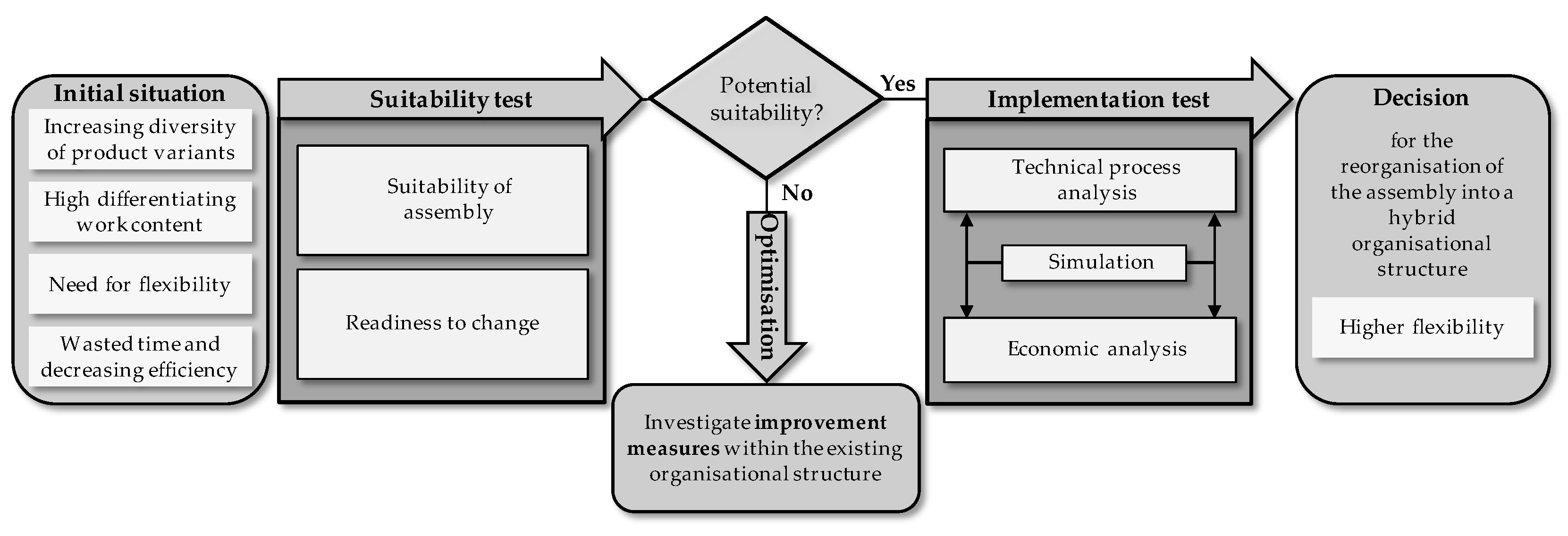

2.2. Selection of a Suitable Production Structure

2.3. Evaluation of the Flexibility Through the Production Programme’s Complexity

3. Concept

3.1. Influence Factor Analysis

- Product portfolio: How many different product variants should be considered in the hybrid organisation structure?

- Forecast production programme: In which quantities should the product variants be produced for a specific forecast period?

- Customer demand rate: What is the average period after a customer purchases a product?

- Assembly operations: Which assembly operations comprise the product portfolio’s product variants?

- Assembly precedence relationships: What precedence-related restrictions exist between the assembly operations of the products in the product portfolio?

- Duration of assembly operations: How long do the assembly operations take according to the flow and job shop principle?

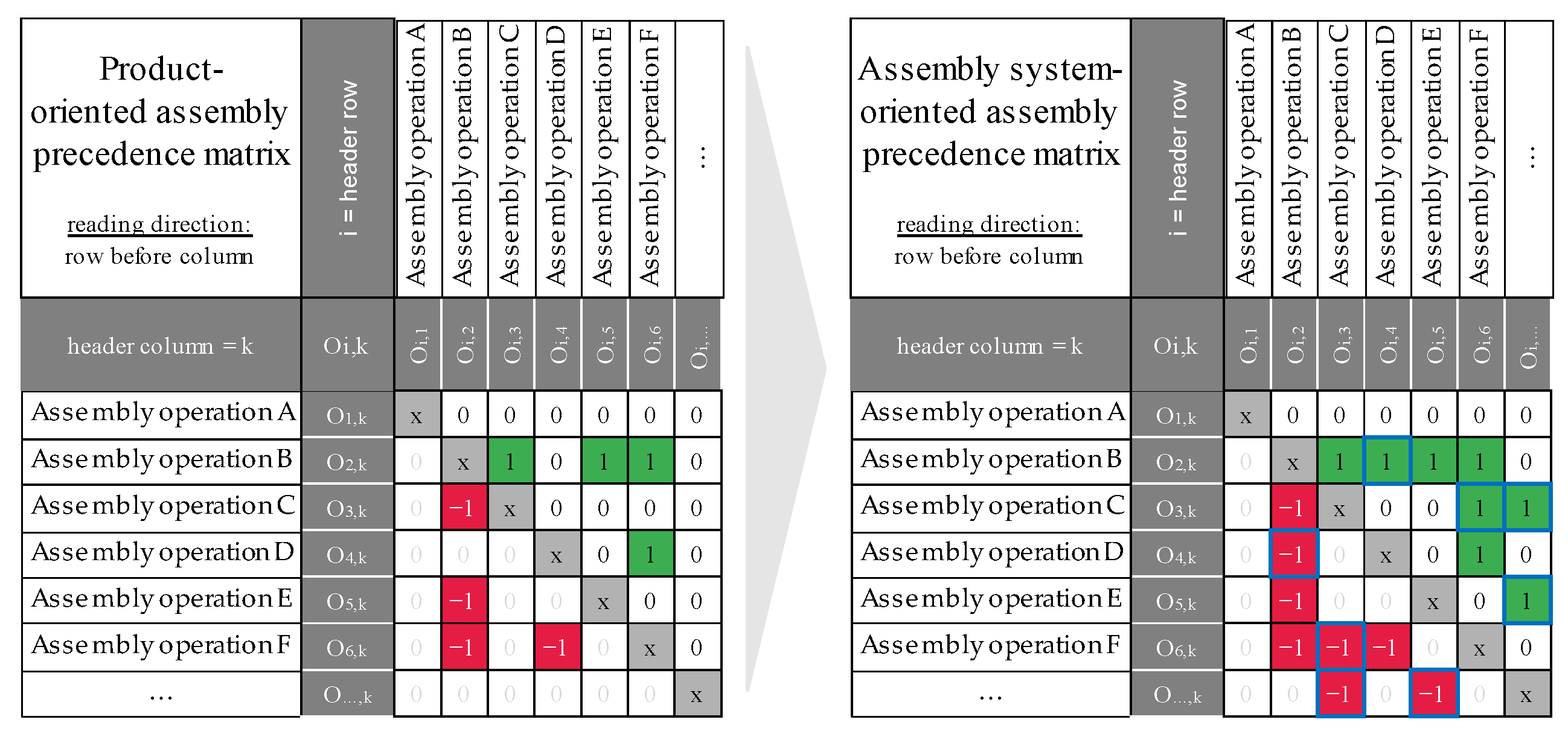

3.2. Description Model Assembly Precedence Matrix

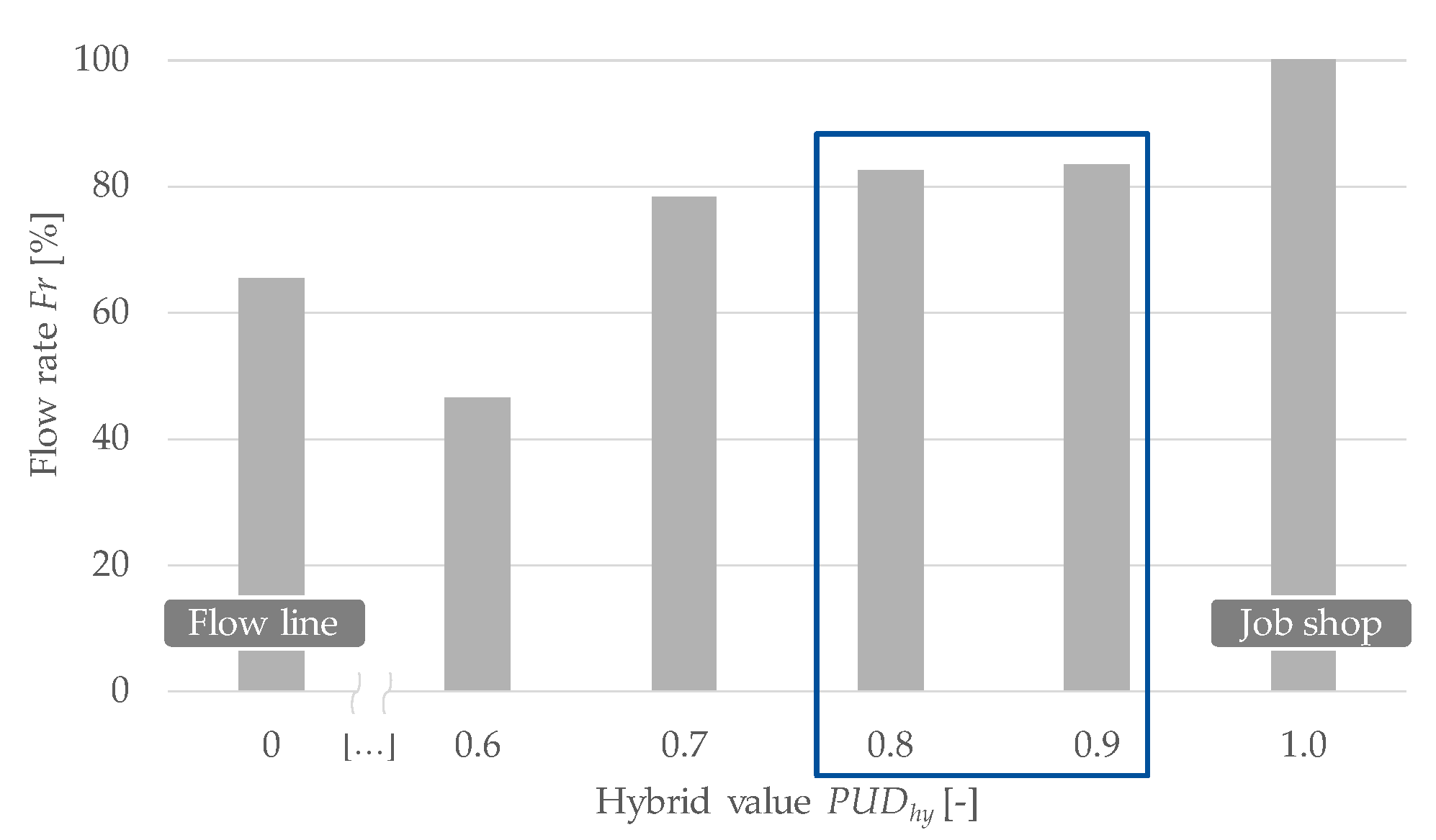

3.3. Impact Model Production Universality Degree

3.4. Decision Model for the Dimensioning of Hybrid Organisation Structures

4. Simulation Study and Results

4.1. Design and Execution of the Simulation Study

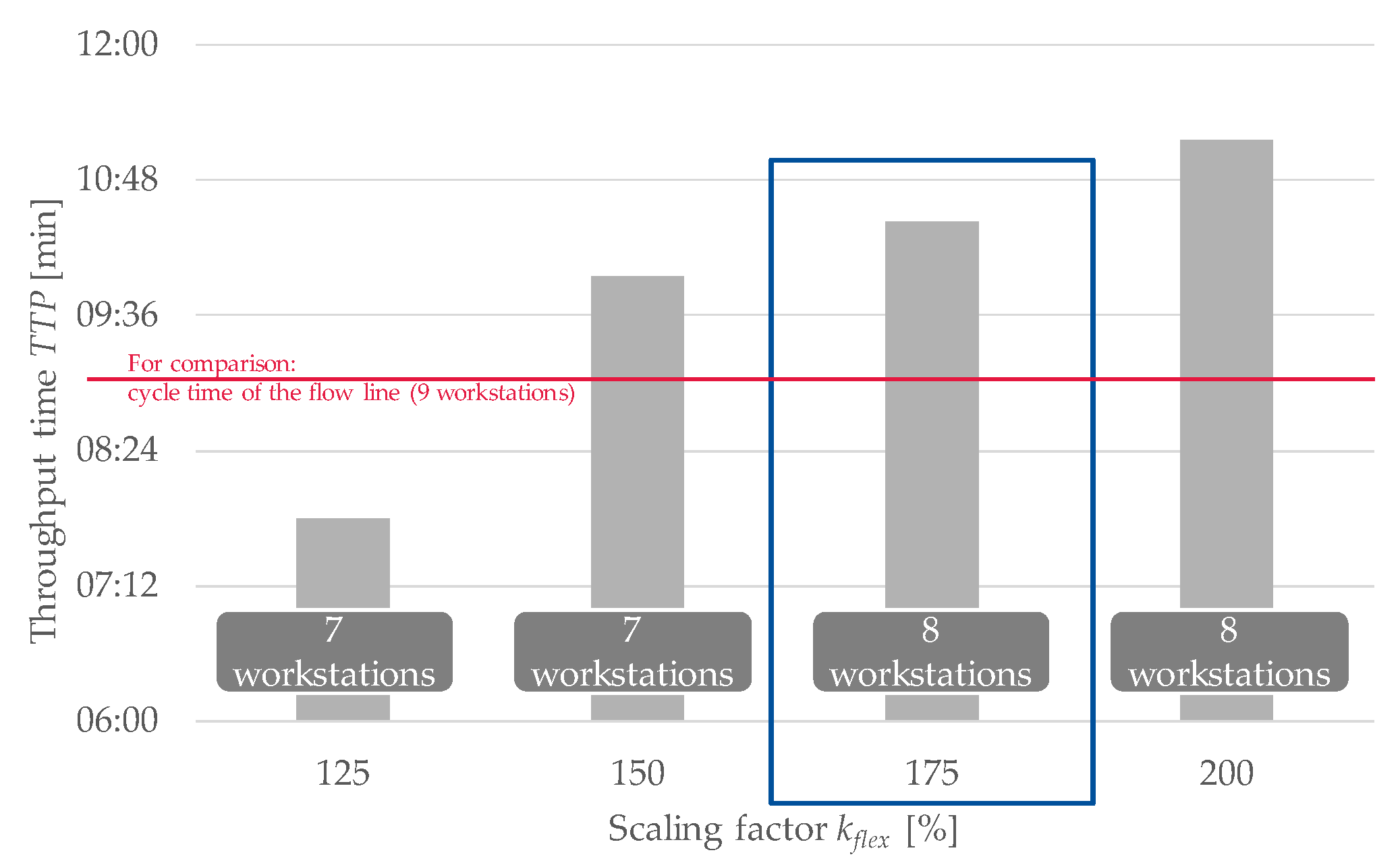

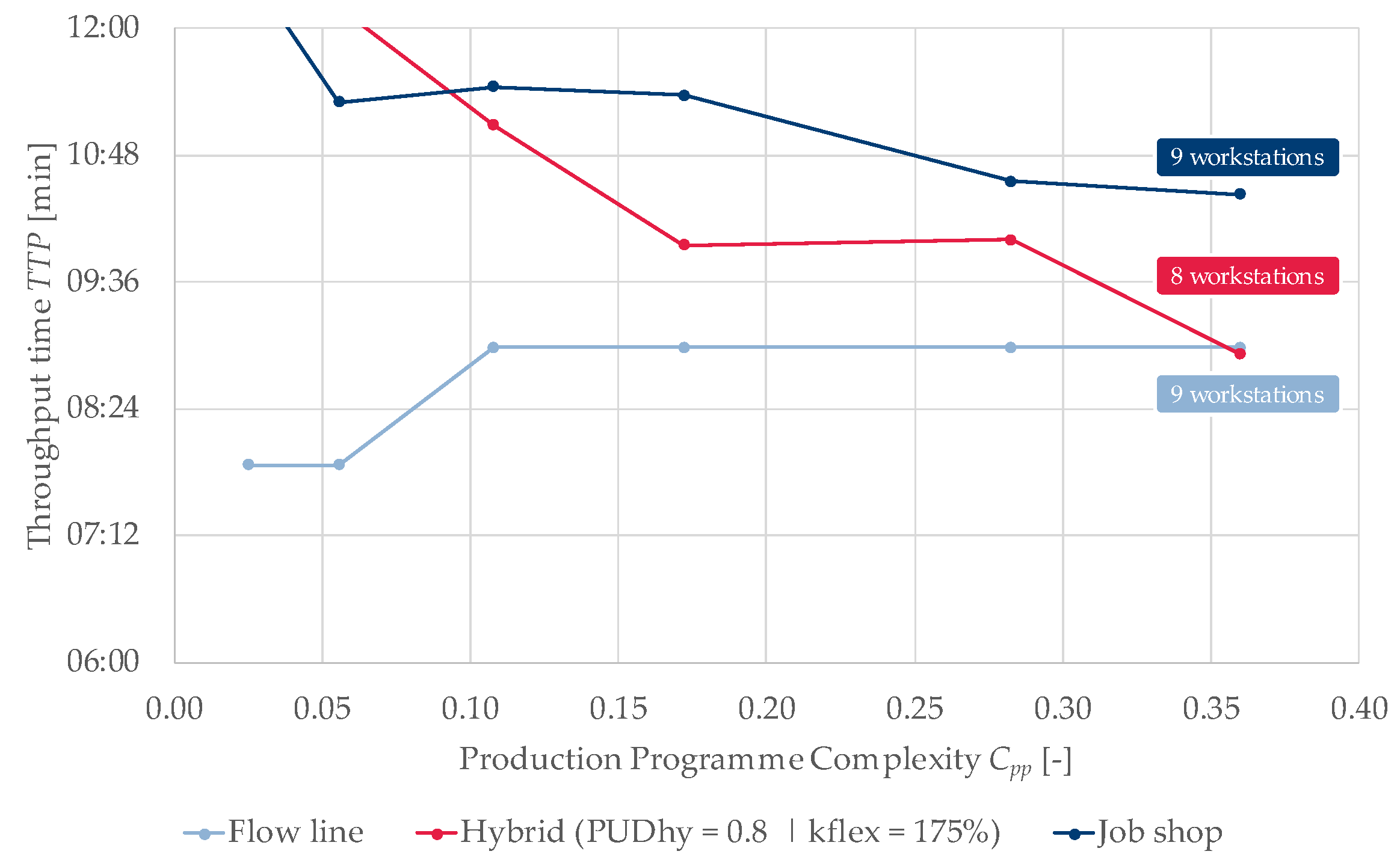

4.2. Results of the Simulation Study

5. Discussion

5.1. Scientific Findings

5.2. Limitations

6. Conclusions

6.1. Summary

6.2. Outlook

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WIP | Work-in-process |

| AGV | Automated guided vehicle |

| APM | Assembly precedence matrix |

| OEE | Overall equipment effectiveness |

References

- Koren, Y. The Global Manufacturing Revolution: Product-Process-Business Integration and Reconfigurable Systems; Wiley: Hoboken, NJ, USA, 2010; ISBN 978-0-470-58377-7. [Google Scholar]

- Hu, S.J.; Ko, J.; Weyand, L.; ElMaraghy, H.A.; Lien, T.K.; Koren, Y.; Bley, H.; Chryssolouris, G.; Nasr, N.; Shpitalni, M. Assembly system design and operations for product variety. CIRP Ann. 2011, 60, 715–733. [Google Scholar] [CrossRef]

- Peng, Y.; Zhang, L.; Xia, B.; Han, Y. Research on balancing and sequencing problems of flexible mixed model assembly lines with alternative precedence relations. Int. J. Prod. Res. 2023, 61, 8451–8467. [Google Scholar] [CrossRef]

- Röhrdanz, F.; Mosemann, H.; Wahl, F.M. Constraint evaluation for assembly sequence planning. In Towards Flexible and Agile Assembly and Manufacturing; Lee, S., Ed.; Institute of Electrical and Electronics Engineers: New York, NY, USA, 1997; pp. 263–268. ISBN 0780338200. [Google Scholar]

- Wu, Y.; Zhao, X.; Xu, Y.; Chen, Y. A flexible planning methodology for product family assembly line based on improved NSGA_II. Assem. Autom. 2020, 40, 625–639. [Google Scholar] [CrossRef]

- Hüttemann, G.; Buckhorst, A.F.; Schmitt, R.H. Modelling and Assessing Line-less Mobile Assembly Systems. Procedia CIRP 2019, 81, S724–S729. [Google Scholar] [CrossRef]

- Begue, C. The Performance and Flexibility of Mixed-Model Assembly Lines. Ph.D. Thesis, University of Wisconsin, Madison, WI, USA, 1995. [Google Scholar]

- Schumann, D.; Bleckmann, M.; Nyhuis, P. Hybrid Production Structures as a Solution for Flexibility and Transformability for Longer Life Cycles of Production Systems. In Product Lifecycle Management. Leveraging Digital Twins, Circular Economy, and Knowledge Management for Sustainable Innovation; Danjou, C., Harik, R., Nyffenegger, F., Rivest, L., Bouras, A., Eds.; IFIP Advances in Information and Communication Technology; Springer: Cham, Switzerland, 2024; Volume 702, pp. 289–299. [Google Scholar] [CrossRef]

- Wiendahl, H.-P.; Reichardt, J.; Nyhuis, P. Handbook Factory Planning and Design; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-662-46390-1. [Google Scholar]

- Nyhuis, P.; Bleckmann, M.; Demir, M.; Jahangirkhani, T.; Wenzel, A.; Schmidt, M. Risikoabhängige Auswahl der Veränderungsfähigkeitsarten. wt Werkstattstech. Online 2025, 115, 2–10. [Google Scholar] [CrossRef]

- Tseng, M.M.; Jiao, J.; Merchant, M.E. Design for Mass Customization. CIRP Ann. 1996, 45, 153–156. [Google Scholar] [CrossRef]

- Lotter, B.; Wiendahl, H.-P. Changeable and Reconfigurable Assembly Systems. In Changeable and Reconfigurable Manufacturing Systems; ElMaraghy, H.A., Ed.; Springer: London, UK, 2009; pp. 127–142. ISBN 978-1-84882-066-1. [Google Scholar]

- Grigutsch, M.; Nywlt, J.; Schmidt, M.; Nyhuis, P. Highly Flexible Final Production Stages—Taking Advantages of Scale Effects by Reducing Internal Component Variants. Adv. Mater. Res. 2014, 907, 127–137. [Google Scholar] [CrossRef]

- Bley, H.; Zenner, C. Variant-oriented Assembly Planning. CIRP Ann. 2006, 55, 23–28. [Google Scholar] [CrossRef]

- Perwitz, J.; Sobottka, T.; Beicher, J.-N.; Gaal, A. Simulation-based evaluation of performance benefits from flexibility in assembly systems and matrix production. Procedia CIRP 2022, 107, 693–698. [Google Scholar] [CrossRef]

- Greschke, P.; Schönemann, M.; Thiede, S.; Herrmann, C. Matrix Structures for High Volumes and Flexibility in Production Systems. Procedia CIRP 2014, 17, 160–165. [Google Scholar] [CrossRef]

- Hofmann, C.; Brakemeier, N.; Krahe, C.; Stricker, N.; Lanza, G. The Impact of Routing and Operation Flexibility on the Performance of Matrix Production Compared to a Production Line. In Advances in Production Research, Proceedings of the 8th Congress of the German Academic Association for Production Technology (WGP), Aachen, Germany, 19–20 November 2018; Schmitt, R., Schuh, G., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 155–165. ISBN 978-3-030-03450-4. [Google Scholar]

- Kern, W.; Rusitschka, F.; Kopytynski, W.; Keckl, S.; Bauernhansl, T. Alternatives to assembly line production in the automotive industry. In Proceedings of the 23rd International Conference on Production Research, Manila, Philippines, 1–4 August 2015. [Google Scholar]

- Küber, C.; Westkämper, E.; Keller, B.; Jacobi, H.-F. Method for a Cross-architecture Assembly Line Planning in the Automotive Industry with Focus on Modularized, Order Flexible, Economical and Adaptable Assembly Processes. Procedia CIRP 2016, 57, 339–344. [Google Scholar] [CrossRef]

- Kampker, A.; Kawollek, S.; Marquardt, F.; Krummhaar, M. Potential of Hybrid Assembly Structures in Automotive Industry. SSRN Electron. J. 2020. [Google Scholar] [CrossRef]

- Göppert, A.; Schukat, E.; Burggräf, P.; Schmitt, R.H. Agile Hybrid Assembly Systems: Bridging the Gap Between Line and Matrix Configurations. In Advances in Automotive Production Technology—Theory and Application, Proceedings of the Stuttgart Conference on Automotive Production (SCAP2020), Stuttgart, Germany, 2–10 November 2020; Weißgraeber, P., Ed.; Springer: Berlin/Heidelberg, Germany, 2021; pp. 3–11. ISBN 978-3-662-62961-1. [Google Scholar]

- Kaiser, P.; Thevapalan, A.; Reining, C.; Roidl, M.; Kern-Isberner, G.; Hompel, M.t. Hybrid Production: Enabled By Controlling the Output Sequence of AMatrix Production Using Answer Set Programming. Procedia CIRP 2022, 107, 1305–1310. [Google Scholar] [CrossRef]

- Johnson, D.J. Converting assembly lines to assembly cells at Sheet Metal Products: Insights on performance improvements. Int. J. Prod. Res. 2005, 43, 1483–1509. [Google Scholar] [CrossRef]

- Modrák, V.; Semančo, P. Cell Design for Transforming the Job Shop Production Process to Lean. In Handbook of Research on Design and Management of Lean Production Systems; Semanco, P., Modrak, V., Eds.; IGI Global: Hershey, PA, USA, 2014; pp. 130–147. ISBN 9781466650398. [Google Scholar]

- Keckl, S.; Abou-Haydar, A.; Westkämper, E. Complexity-focused Planning and Operating of Mixed-model Assembly Lines in Automotive Manufacturing. Procedia CIRP 2016, 57, 333–338. [Google Scholar] [CrossRef]

- Florescu, A.; Barabas, S.A. Modeling and Simulation of a Flexible Manufacturing System—A Basic Component of Industry 4.0. Appl. Sci. 2020, 10, 8300. [Google Scholar] [CrossRef]

- Schumann, D.; van Kraan, F.d.; Nyhuis, P. Eignungsanalyse zur Einführung hybrider Organisationsformen in der Montage. Z. Wirtsch. Fabr. 2024, 119, 114–119. [Google Scholar] [CrossRef]

- Stickland, F. The Dynamics of Change: Insights into Organisational Transition from the Natural World; Routledge: London, UK, 1998; ISBN 9781134669806. [Google Scholar]

- Heinicke, M. Influence of Shifts in Production Programs on the Resilience of Production Systems. Procedia CIRP 2016, 41, 117–122. [Google Scholar] [CrossRef]

- Schumann, D.; Stöver, J.; Nyhuis, P. Effects of the Production Program’s Complexity on the Production Structure. In Proceedings of the CPSL 2024, Honolulu, HI, USA, 9–12 July 2024. [Google Scholar] [CrossRef]

- Lotter, B. Montage in der Industriellen Produktion: Ein Handbuch für Die Praxis; Springer: Berlin/Heidelberg, Germany, 2012; ISBN 978-3-642-29060-2. [Google Scholar]

- Zhang, Y.; Ni, J.; Lin, Z.; Lai, X. Automated sequencing and sub-assembly detection in automobile body assembly planning. J. Mater. Process. Technol. 2002, 129, 490–494. [Google Scholar] [CrossRef]

- Kilbridge, M.D.; Wester, L. A Review of Analytical Systems of Line Balancing. Oper. Res. 1962, 10, 626–638. [Google Scholar] [CrossRef]

- Bebersdorf, P.; Huchzermeier, A. Variabler Takt: Mit dem VarioTakt Varianz Beherrschen bei Grenzenloser Produktindividualisierung; Springer Gabler: Berlin/Heidelberg, Germany, 2021; ISBN 978-3-662-63930-6. [Google Scholar]

- Navaei, J.; ElMaraghy, H. Grouping part/product variants based on networked operations sequence. J. Manuf. Syst. 2016, 38, 63–76. [Google Scholar] [CrossRef]

- Takeda, H. The Synchronized Production System: Going Beyond Just-in-Time Through Kaizen, 1st ed.; Kogan Page: London, UK, 2006; ISBN 9780749447656. [Google Scholar]

- Pass, C.L.; Lowes, B.; Davies, L. Collins Dictionary of Economics, 2nd ed.; HarperCollins: Glasgow, UK, 1993; ISBN 0004703723. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bleckmann, M.; Schumann, D.; Mastroianni, L.; Schmidt, M.; Nyhuis, P. Hybrid Organisation Structure: A Holistic and Adaptable Approach for Hybrid, Flow-Oriented Assembly Organisation. Appl. Sci. 2025, 15, 3856. https://doi.org/10.3390/app15073856

Bleckmann M, Schumann D, Mastroianni L, Schmidt M, Nyhuis P. Hybrid Organisation Structure: A Holistic and Adaptable Approach for Hybrid, Flow-Oriented Assembly Organisation. Applied Sciences. 2025; 15(7):3856. https://doi.org/10.3390/app15073856

Chicago/Turabian StyleBleckmann, Marco, Dorit Schumann, Luca Mastroianni, Matthias Schmidt, and Peter Nyhuis. 2025. "Hybrid Organisation Structure: A Holistic and Adaptable Approach for Hybrid, Flow-Oriented Assembly Organisation" Applied Sciences 15, no. 7: 3856. https://doi.org/10.3390/app15073856

APA StyleBleckmann, M., Schumann, D., Mastroianni, L., Schmidt, M., & Nyhuis, P. (2025). Hybrid Organisation Structure: A Holistic and Adaptable Approach for Hybrid, Flow-Oriented Assembly Organisation. Applied Sciences, 15(7), 3856. https://doi.org/10.3390/app15073856