Shielding Efficacy of Tungsten Oxide-Reinforced Polyisoprene in Attenuating Technetium-99m Gamma Radiation: An Alternative Shielding Solution for Occupational Safety in Nuclear Medicine

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

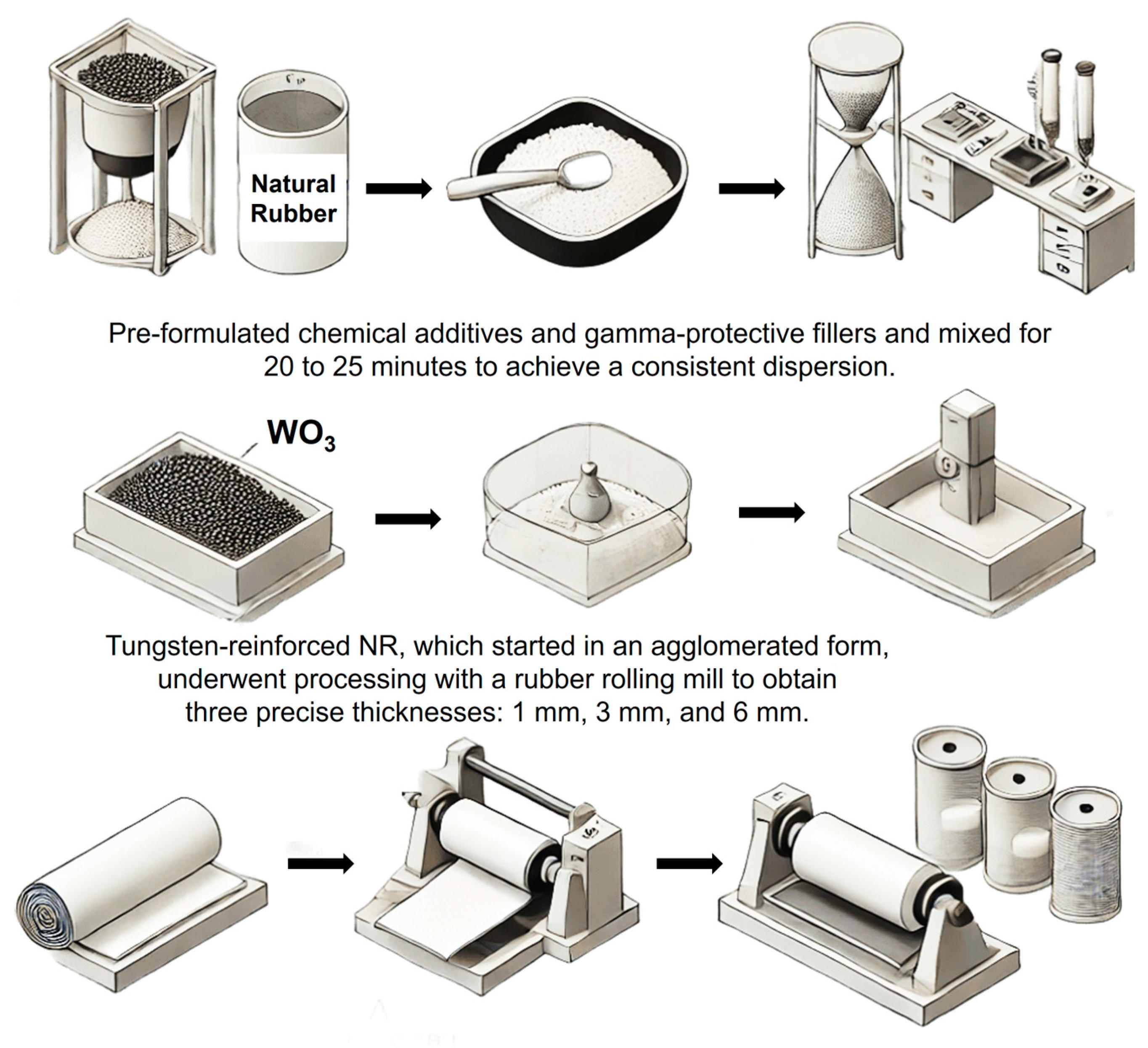

2.2. Preparation of Tungsten-Reinforced Polyisoprene

2.3. Structural and Morphological Characterization of Tungsten-Reinforced Polyisoprene

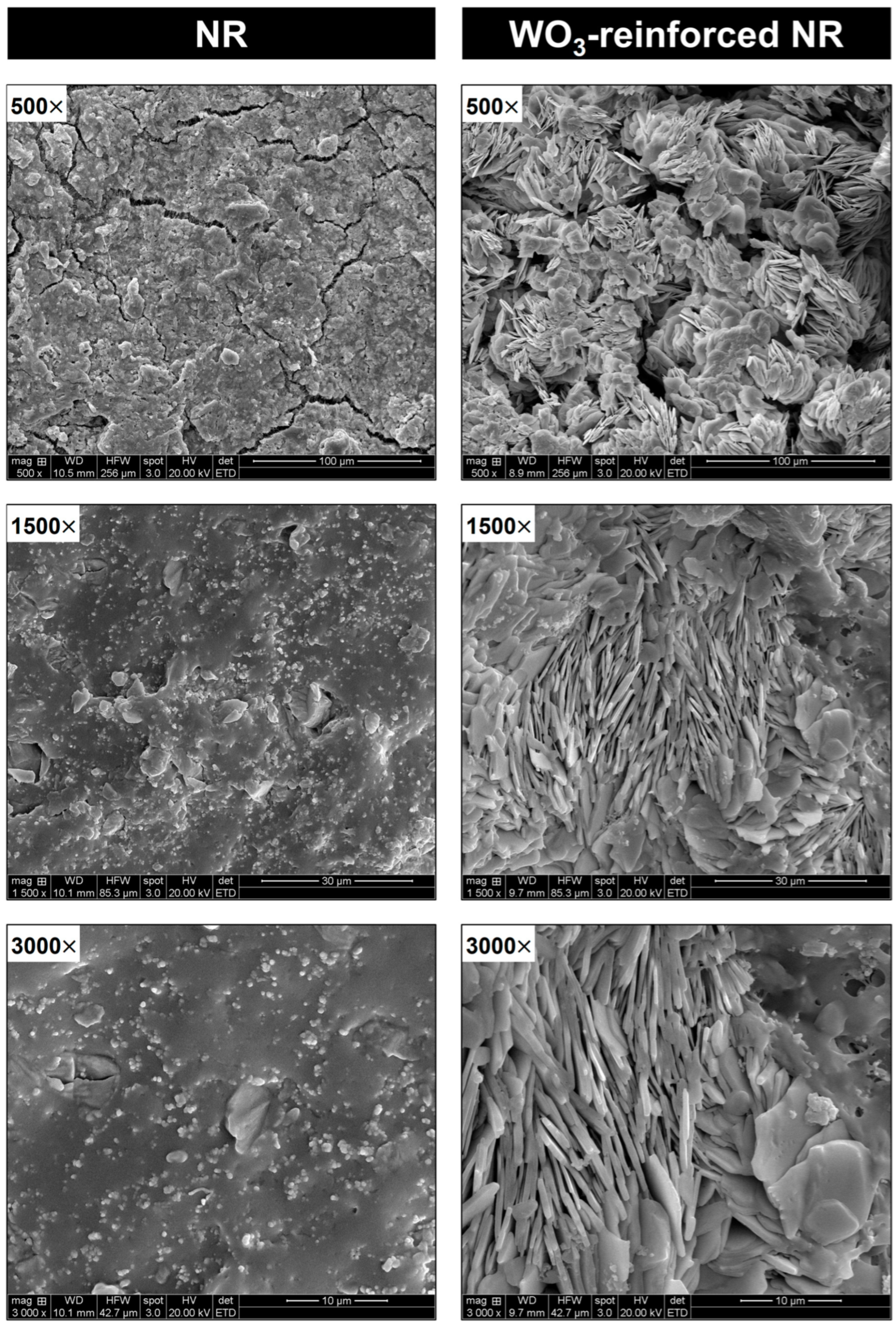

2.3.1. Material Characterization via Scanning Electron Microscopy (SEM) and Energy-Dispersive X-Ray Spectroscopy (EDX): Morphological and Compositional Analysis

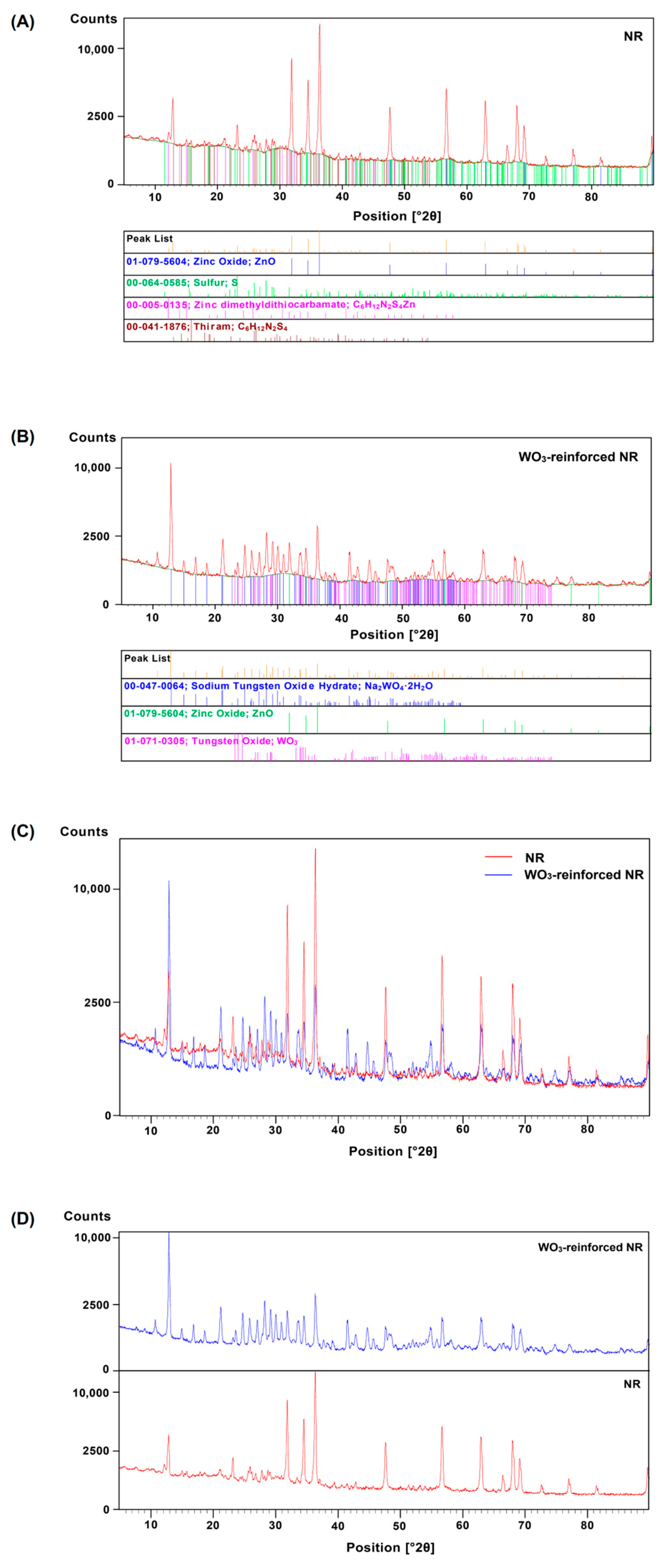

2.3.2. Structural Characterization of Tungsten-Reinforced Polyisoprene Using X-Ray Diffraction (XRD)

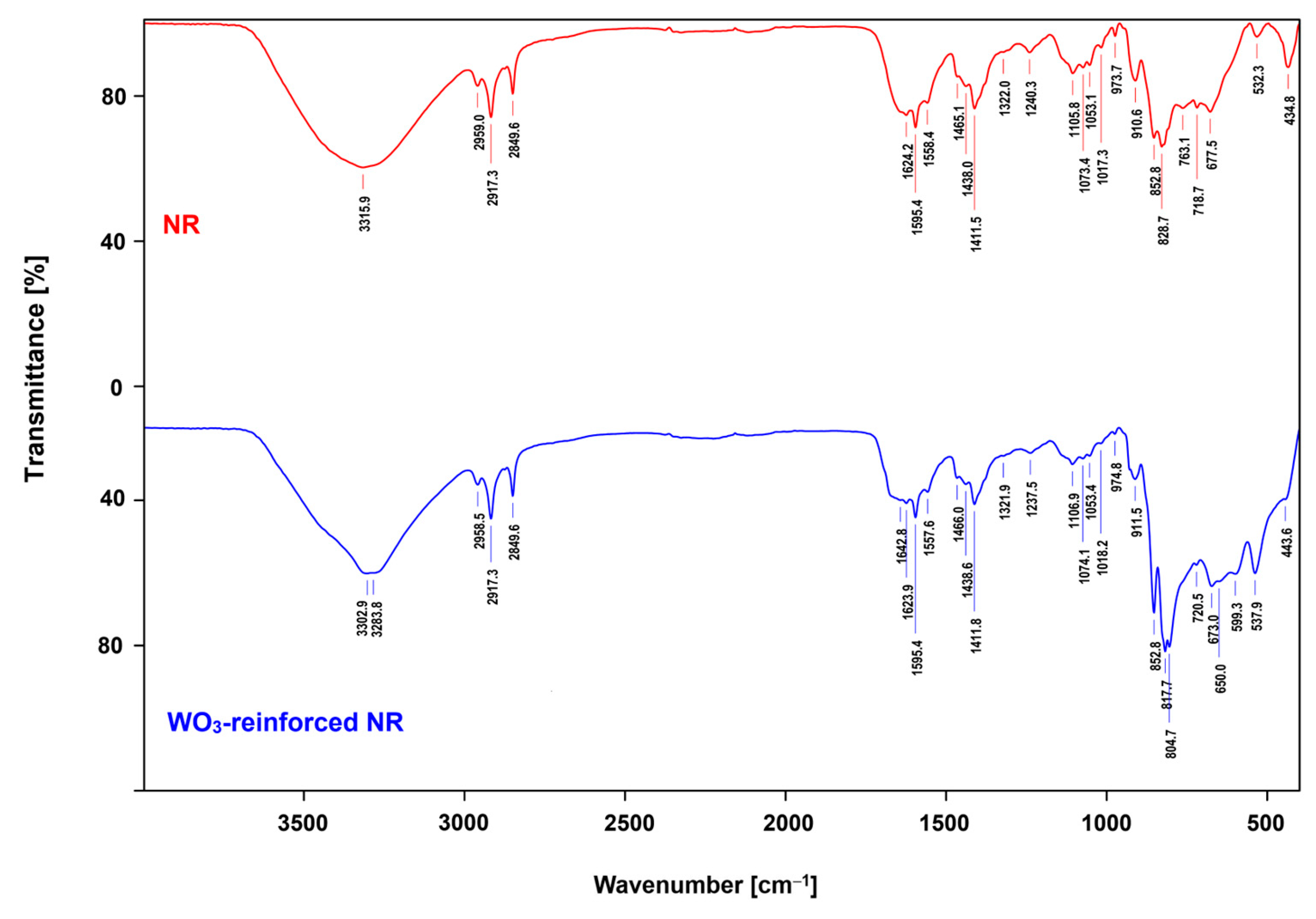

2.3.3. Characterization of Molecular Structures and Chemical Bonding in Tungsten-Reinforced Polyisoprene Using Fourier Transform Infrared Spectroscopy (FTIR)

2.3.4. Structural Deformation in Tungsten-Reinforced Polyisoprene: An ANSYS-Based Bending Analysis

2.4. Radiation-Shielding Performance of Tungsten-Reinforced Polyisoprene: Simulation and Experimental Assessment

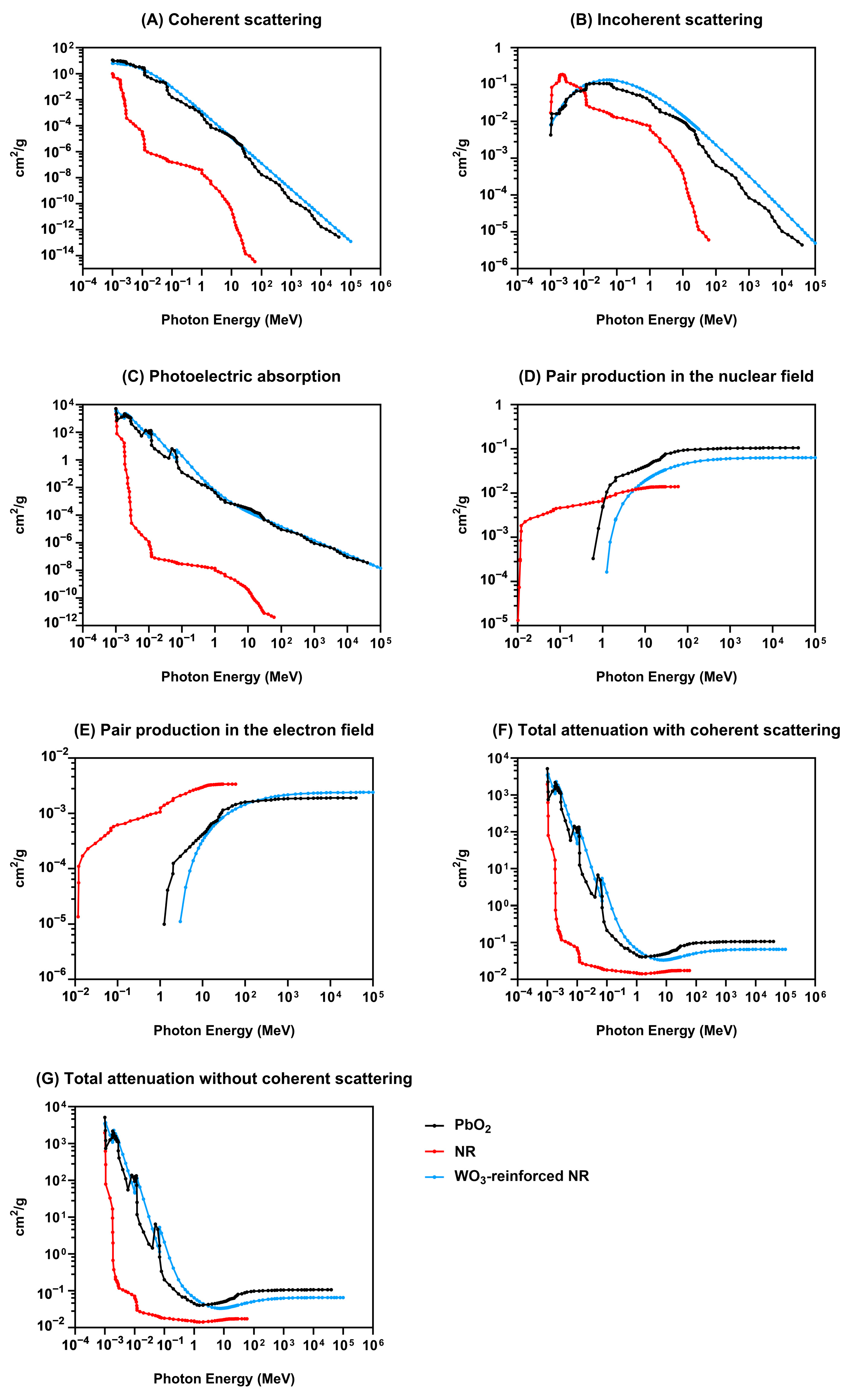

2.4.1. Utilizing XCOM Simulations for the Design and Evaluation of Radiation-Shielding Materials

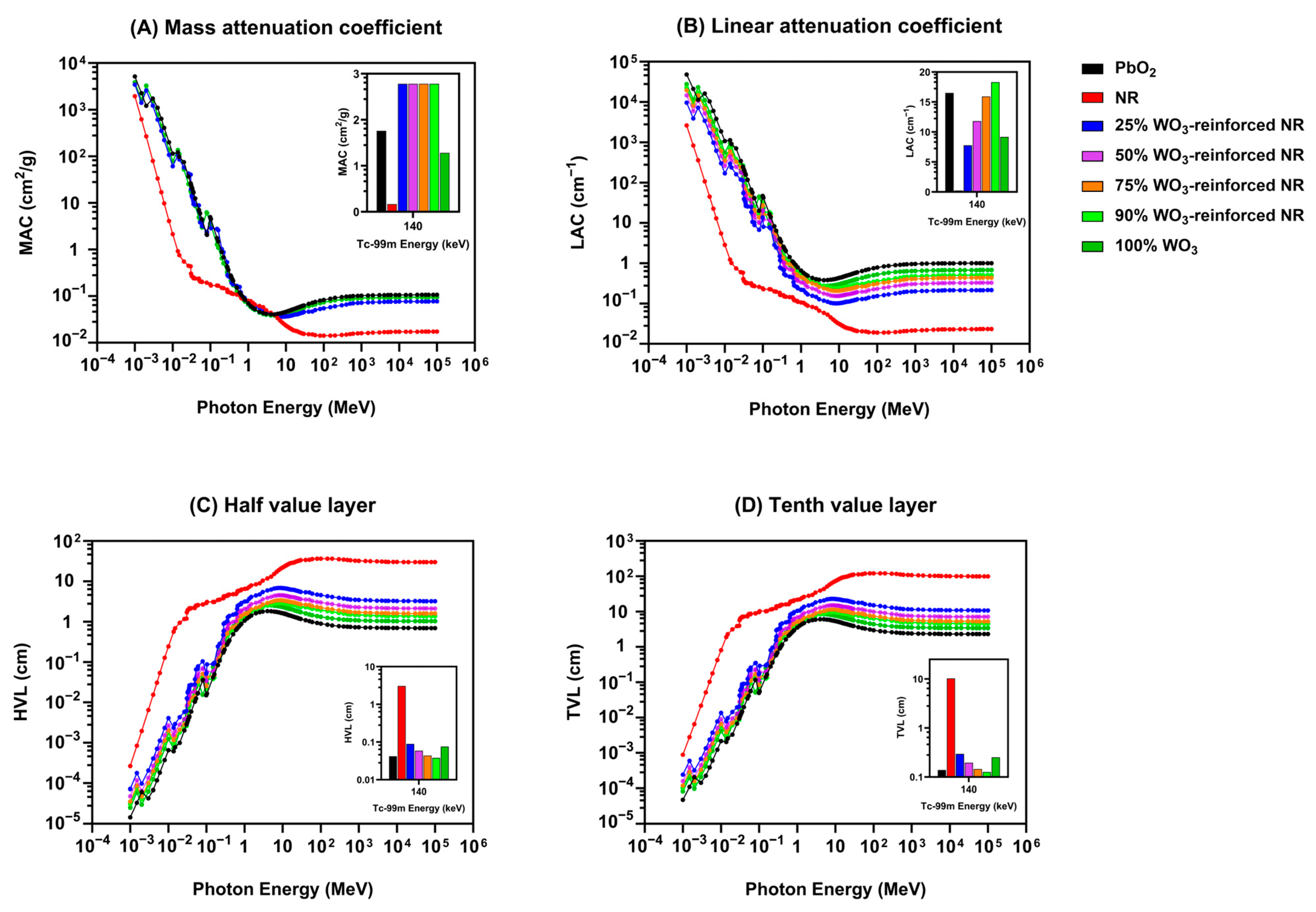

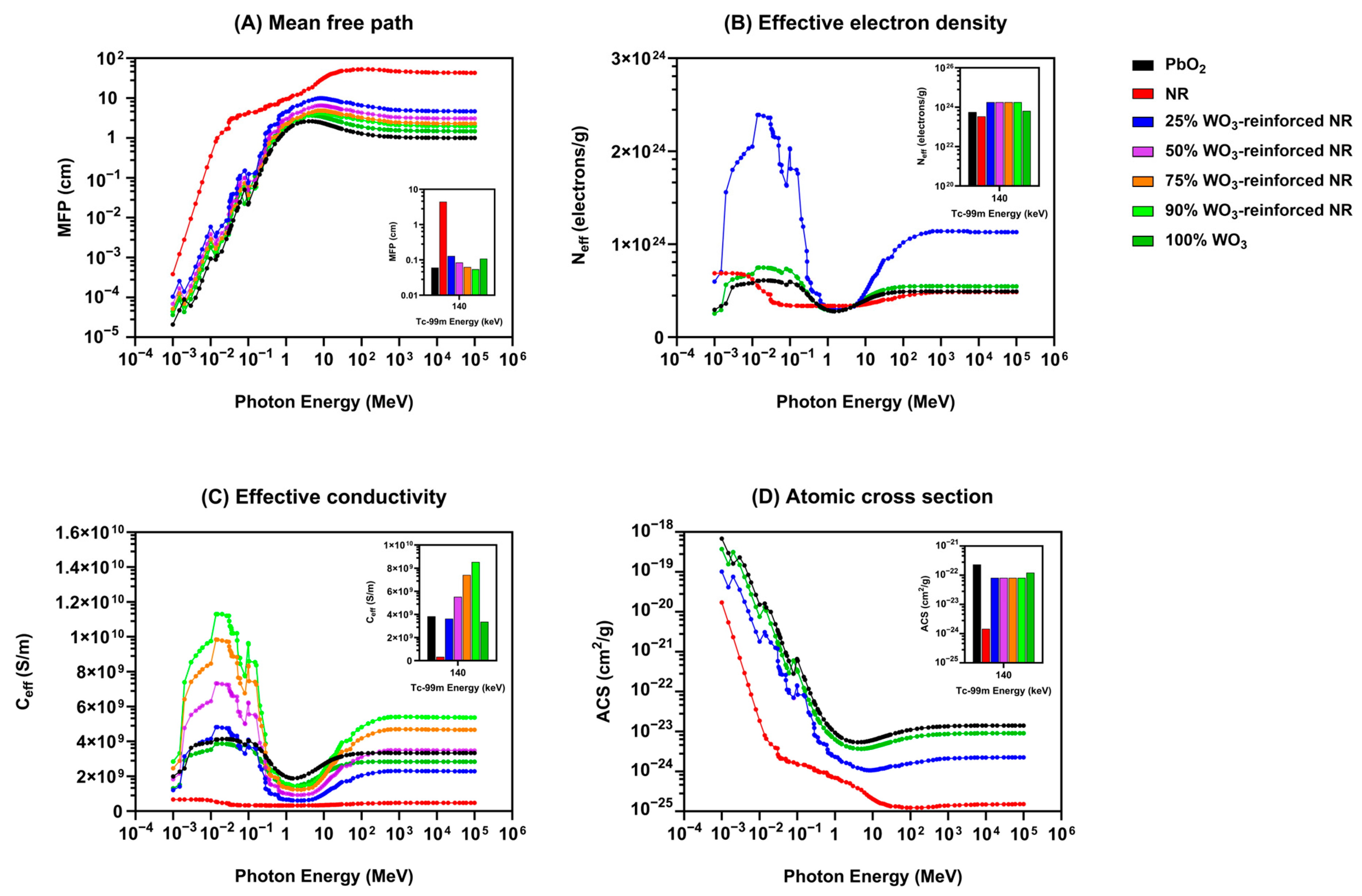

2.4.2. Computational Analysis of Radiation Shielding in Tungsten-Reinforced Polyisoprene Using Phy-X/PSD Simulations

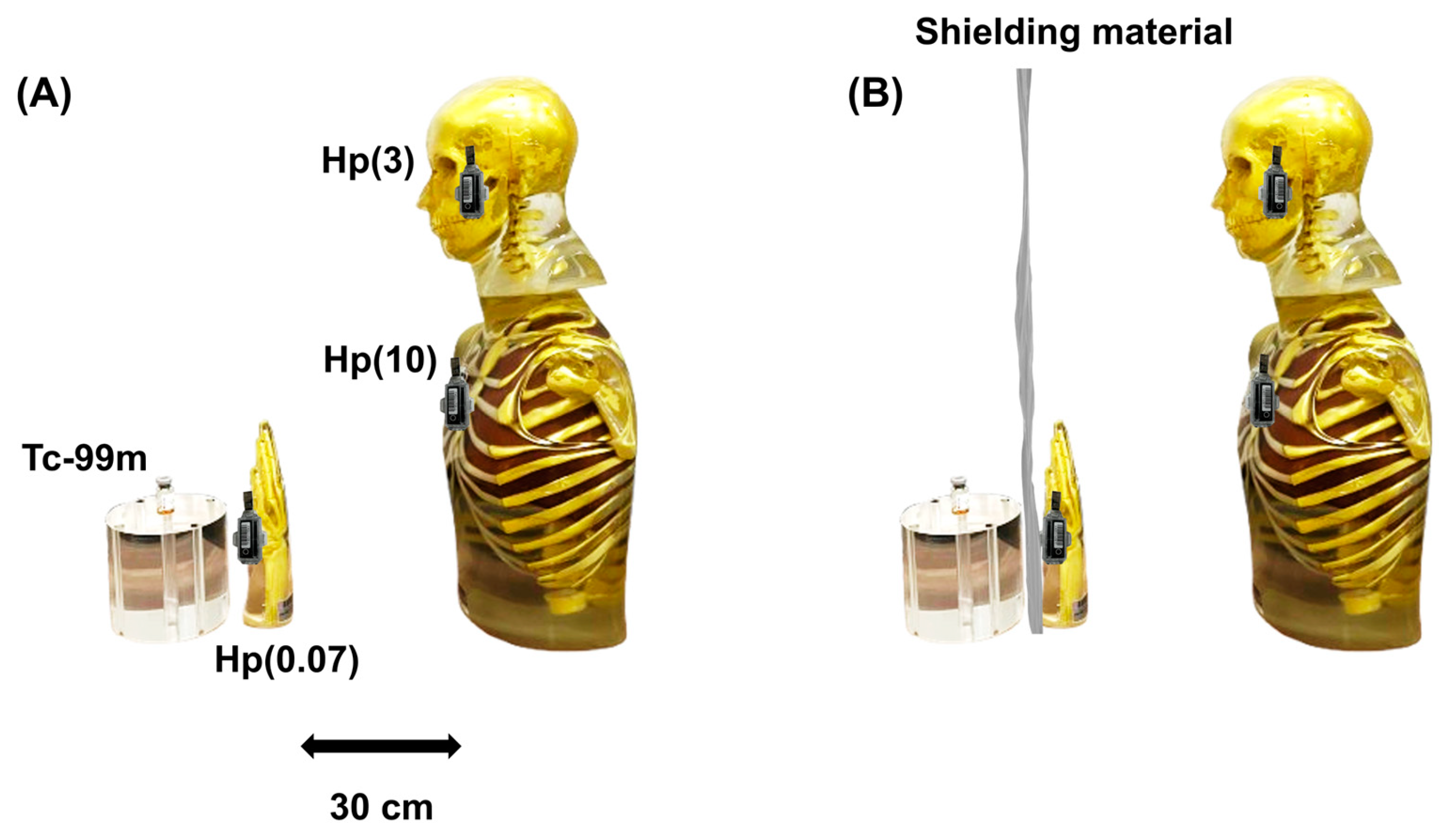

2.4.3. Experimental Investigation of Materials for Gamma Radiation Shielding of Tc-99m

2.5. Statistical Analysis

3. Results

3.1. Characterization of the Structural and Morphological Properties of Tungsten-Reinforced Polyisoprene

3.1.1. Material Characterization of Tungsten-Reinforced Polyisoprene: SEM and EDX for Microstructural and Elemental Analysis

3.1.2. Structural Properties of Tungsten-Reinforced Polyisoprene Characterized by X-Ray Diffraction

3.1.3. Characterization of Chemical Bonding and Molecular Structures in Tungsten-Reinforced Polyisoprene Using FTIR

3.1.4. Characterization of Shape Deformation in Tungsten-Reinforced Polyisoprene Under Bending: An ANSYS Simulation Study

3.2. Evaluating the Radiation-Shielding Effectiveness of Tungsten-Reinforced Polyisoprene via Simulation and Experimental Validation

3.2.1. Computational Analysis of Tungsten-Reinforced Polyisoprene as a Radiation Shielding Material Using XCOM Simulations

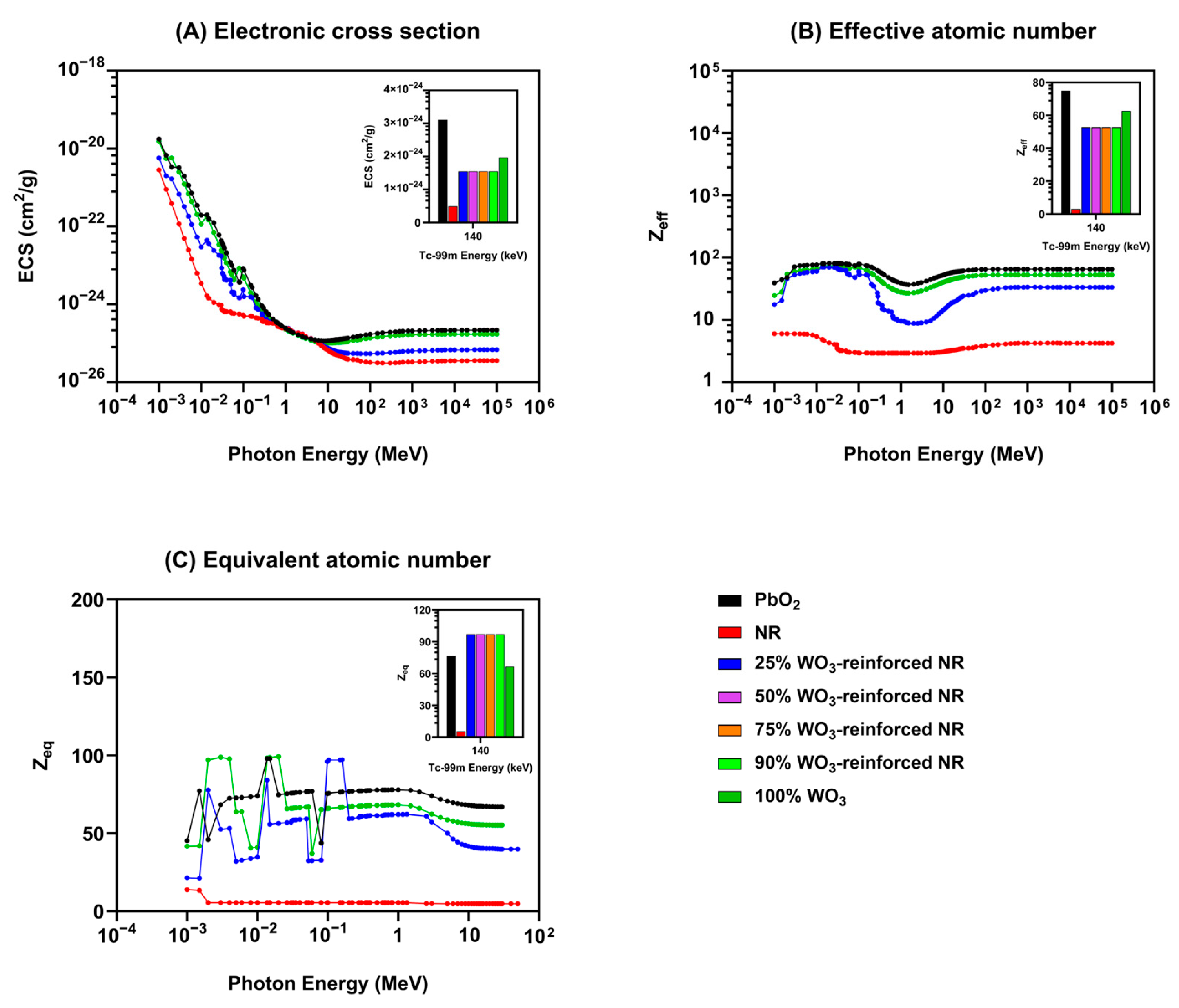

3.2.2. Computational Assessment of Tungsten-Reinforced Polyisoprene for Radiation Shielding Applications Using Phy-X/PSD Simulations

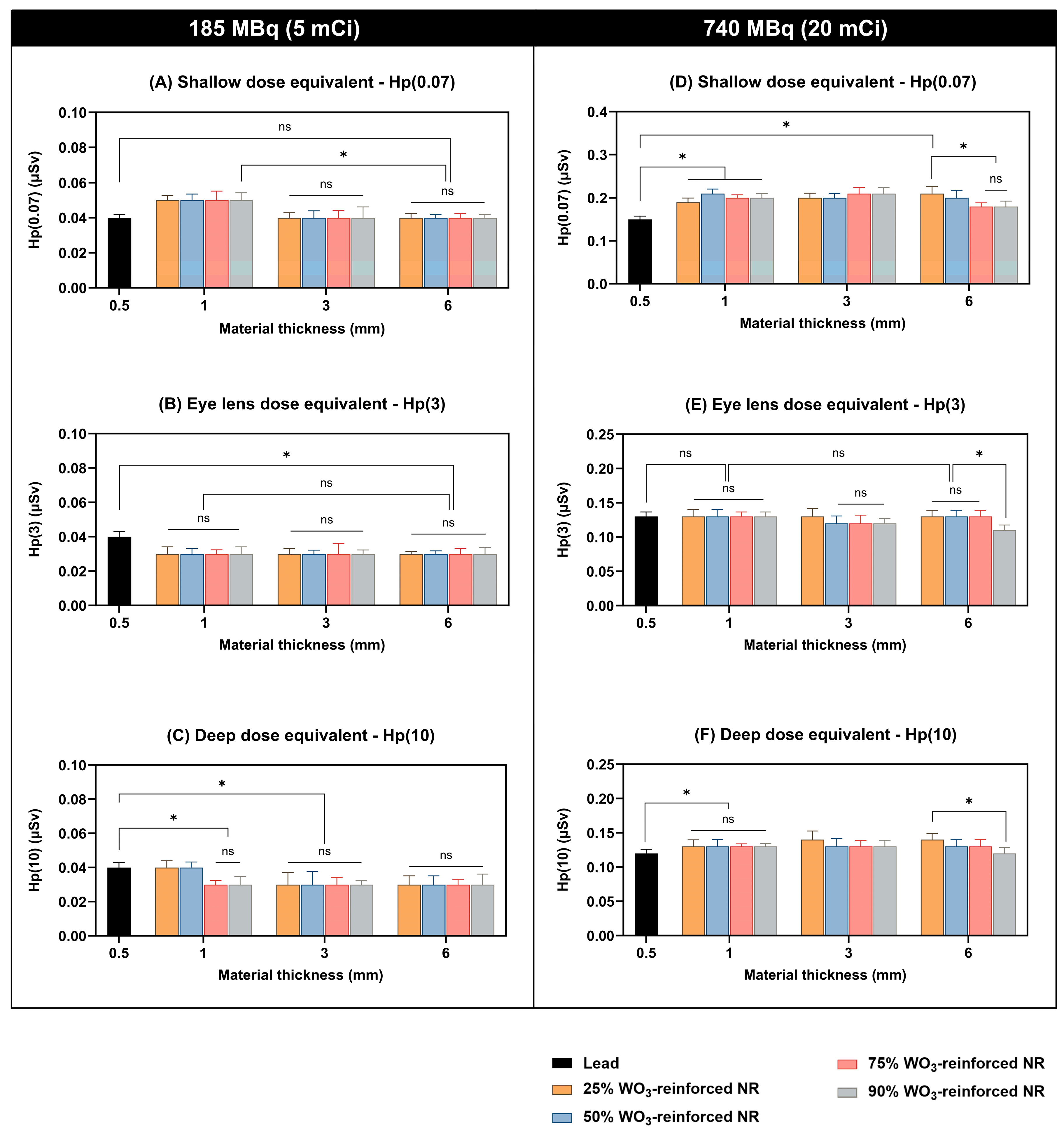

3.2.3. Experimental Evaluation of the Gamma Radiation-Shielding Efficiency of Tungsten-Reinforced Polyisoprene for Tc-99m

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brambilla, M.; Vassileva, J.; Kuchcinska, A.; Rehani, M.M. Multinational Data on Cumulative Radiation Exposure of Patients from Recurrent Radiological Procedures: Call for Action. Eur. Radiol. 2020, 30, 2493–2501. [Google Scholar] [PubMed]

- Papagiannopoulou, D. Technetium-99m Radiochemistry for Pharmaceutical Applications. J. Label. Compd. Radiopharm. 2017, 60, 502–520. [Google Scholar] [CrossRef]

- Marshall, S.K.; Prom-On, P.; Sangkue, S.; Thiangsook, W. Assessment of Radiation Exposure in a Nuclear Medicine Department during 99mTc-MDP Bone Scintigraphy. Toxics 2023, 11, 814. [Google Scholar] [CrossRef] [PubMed]

- Wenzl, M.; Colombo, F.; Guanais, F.; Lopert, R.; Paris, V.; Pearson, M.; Charlton, K.; Demeter, S.J.; Bilbao y Leon, S.; Pike, C. The Supply of Medical Isotopes: An Economic Diagnosis and Possible Solutions; Organisation for Economic Co-Operation and Development: Paris, France, 2019. [Google Scholar]

- Marshall, S.K.; Hayeeabdunromae, A.; Noomad, N.; Durawee, W.; Sirieak, N.; Karnkorn, P.; Keawtong, V. Evaluation of Environmental Radiation Exposure and Algorithms for Determining the Occupational Effective Dose During 99mTc-MDP Bone Scintigraphy: A Comprehensive Analysis. Appl. Sci. 2024, 14, 11211. [Google Scholar] [CrossRef]

- Lee, W.J.; Choi, Y.; Ko, S.; Cha, E.S.; Kim, J.; Kim, Y.M.; Kong, K.A.; Seo, S.; Bang, Y.J.; Ha, Y.W. Projected Lifetime Cancer Risks from Occupational Radiation Exposure among Diagnostic Medical Radiation Workers in South Korea. BMC Cancer 2018, 18, 1206. [Google Scholar] [CrossRef]

- Güngördü, N.; Kurtul, S.; Özdil, A.; Erdoğan, M.S. Does Occupational Ionizing Radiation Exposure in Healthcare Workers Affect Their Hematological Parameters? Arch. Environ. Occup. Health 2023, 78, 80–87. [Google Scholar] [CrossRef]

- Boice, J.D.; Cohen, S.S.; Mumma, M.T.; Howard, S.C.; Yoder, R.C.; Dauer, L.T. Mortality among Medical Radiation Workers in the United States, 1965–2016. In The Million Person Study of Low-Dose Radiation Health Effects; CRC Press: Boca Raton, FL, USA, 2024; pp. 255–279. [Google Scholar]

- de Gonzalez, A.B.; Darby, S. Risk of Cancer from Diagnostic X-Rays: Estimates for the UK and 14 Other Countries. Lancet 2004, 363, 345–351. [Google Scholar] [CrossRef]

- Picano, E.; Vano, E. Updated Estimates of Radiation Risk for Cancer and Cardiovascular Disease: Implications for Cardiology Practice. J. Clin. Med. 2024, 13, 2066. [Google Scholar] [CrossRef]

- Richardson, D.B.; Leuraud, K.; Laurier, D.; Gillies, M.; Haylock, R.; Kelly-Reif, K.; Bertke, S.; Daniels, R.D.; Thierry-Chef, I.; Moissonnier, M. Cancer Mortality after Low Dose Exposure to Ionising Radiation in Workers in France, the United Kingdom, and the United States (INWORKS): Cohort Study. BMJ 2023, 382, e074520. [Google Scholar]

- Rühm, W.; Laurier, D.; Wakeford, R. Cancer Risk Following Low Doses of Ionising Radiation–Current Epidemiological Evidence and Implications for Radiological Protection. Mutat. Res. Toxicol. Environ. Mutagen. 2022, 873, 503436. [Google Scholar]

- Adelodun, M.O.; Anyanwu, E.C. Health Effects of Radiation: An Epidemiological Study on Populations near Nuclear Medicine Facilities. Health 2024, 13, 228–239. [Google Scholar]

- Calabrese, E.J. Linear Non-Threshold (LNT) Fails Numerous Toxicological Stress Tests: Implications for Continued Policy Use. Chem. Biol. Interact. 2022, 365, 110064. [Google Scholar]

- Calabrese, E.J.; Selby, P.B. Muller Mistakes: The Linear No-Threshold (LNT) Dose Response and US EPA’s Cancer Risk Assessment Policies and Practices. Chem. Biol. Interact. 2023, 383, 110653. [Google Scholar] [CrossRef] [PubMed]

- Allam, S.M.E.; Algany, M.M.A.; Khider, Y.I.A. Radiation Safety Compliance Awareness among Healthcare Workers Exposed to Ionizing Radiation. BMC Nurs. 2024, 23, 208. [Google Scholar] [CrossRef]

- Shubayr, N. Operating Room Radiation Safety Measures: Awareness, Compliance, and Perceived Risks among Nurses and Other Healthcare Workers. Int. Nurs. Rev. 2024; ahead of print. [Google Scholar] [CrossRef]

- Galli, E.; Soliman-Aboumarie, H.; Gargani, L.; Szymański, P.; Gimelli, A.; Petersen, S.E.; Sade, L.E.; Stankovic, I.; Donal, E.; Cosyns, B. EACVI Survey on Radiation Exposure in Interventional Echocardiography. Eur. Heart J.-Cardiovasc. Imaging 2024, 25, 727–734. [Google Scholar]

- Clarke, R.; Valentin, J. A History of the International Commission on Radiological Protection. Health Phys. 2005, 88, 407–422. [Google Scholar]

- Wu, Y.; Wang, Z. Progress in Ionizing Radiation Shielding Materials. Adv. Eng. Mater. 2024, 26, 2400855. [Google Scholar] [CrossRef]

- More, C.V.; Alsayed, Z.; Badawi, M.S.; Thabet, A.A.; Pawar, P.P. Polymeric Composite Materials for Radiation Shielding: A Review. Environ. Chem. Lett. 2021, 19, 2057–2090. [Google Scholar] [CrossRef]

- Prabhu, S.; Bubbly, S.G.; Gudennavar, S.B. X-Ray and γ-Ray Shielding Efficiency of Polymer Composites: Choice of Fillers, Effect of Loading and Filler Size, Photon Energy and Multifunctionality. Polym. Rev. 2023, 63, 246–288. [Google Scholar] [CrossRef]

- Marshall, S.K.; Boonpeng, K.; Buapud, N.; Chimhashat, S.; Chuaymuang, J.; Kwandee, P.; Songphum, N. Bismuth Oxide Nanoparticle-Enhanced Poly (Methyl Methacrylate) Composites for I-131 Radiation Shielding: A Combined Simulation and Experimental Investigation. Polymers 2025, 17, 590. [Google Scholar] [CrossRef]

- Intom, S.; Kalkornsurapranee, E.; Johns, J.; Kaewjaeng, S.; Kothan, S.; Hongtong, W.; Chaiphaksa, W.; Kaewkhao, J. Mechanical and Radiation Shielding Properties of Flexible Material Based on Natural Rubber/Bi2O3 Composites. Radiat. Phys. Chem. 2020, 172, 108772. [Google Scholar]

- Yasmin, S.; Kamislioglu, M.; Sayyed, M.I. Assessment of Radiation Shielding Performance of Li2O-BaO-Bi2O3-P2O5 Glass Systems within the Energy Range from 0.081 MeV to 1.332 MeV via MCNP6 Code. Optik 2023, 274, 170529. [Google Scholar]

- Gamal, R.; Salama, E.; Elshimy, H.; El-Nashar, D.E.; Bakry, A.; Ehab, M. Gamma Attenuation and Mechanical Characteristics of a Lead/NBR/SBR Rubber Composite with Black Nanocarbon Reinforcement. Sustainability 2023, 15, 2165. [Google Scholar] [CrossRef]

- Toyen, D.; Rittirong, A.; Poltabtim, W.; Saenboonruang, K. Flexible, Lead-Free, Gamma-Shielding Materials Based on Natural Rubber/Metal Oxide Composites. Iran. Polym. J. 2018, 27, 33–41. [Google Scholar] [CrossRef]

- Ali, A.; Zhang, N.; Santos, R.M. Mineral Characterization Using Scanning Electron Microscopy (SEM): A Review of the Fundamentals, Advancements, and Research Directions. Appl. Sci. 2023, 13, 12600. [Google Scholar] [CrossRef]

- Belz, G.T.; Auchterlonie, G.J. An Investigation of the Use of Chromium, Platinum and Gold Coating for Scanning Electron Microscopy of Casts of Lymphoid Tissues. Micron 1995, 26, 141–144. [Google Scholar]

- Holder, C.F.; Schaak, R.E. Tutorial on Powder X-Ray Diffraction for Characterizing Nanoscale Materials. ACS Nano 2019, 13, 7359–7365. [Google Scholar] [CrossRef]

- Fawcett, T.G.; Kabekkodu, S.N.; Blanton, J.R.; Blanton, T.N. Chemical Analysis by Diffraction: The Powder Diffraction FileTM. Powder Diffr. 2017, 32, 63–71. [Google Scholar]

- Chan, K.A.; Kazarian, S.G. Attenuated Total Reflection Fourier-Transform Infrared (ATR-FTIR) Imaging of Tissues and Live Cells. Chem. Soc. Rev. 2016, 45, 1850–1864. [Google Scholar]

- Smith, T.L. Ultimate Tensile Properties of Elastomers. II. Comparison of Failure Envelopes for Unfilled Vulcanizates. Rubber Chem. Technol. 1964, 37, 792–807. [Google Scholar]

- Wood, L.A. Uniaxial Extension and Compression in Stress-Strain Relations of Rubber. J. Res. Natl. Bur. Stand. 1977, 82, 57. [Google Scholar]

- Bokobza, L.; Rapoport, O. Reinforcement of Natural Rubber. J. Appl. Polym. Sci. 2002, 85, 2301–2316. [Google Scholar] [CrossRef]

- James, H.M.; Guth, E. Theory of the Elastic Properties of Rubber. J. Chem. Phys. 1943, 11, 455–481. [Google Scholar]

- Brown, D.A.; Chadwick, M.B.; Capote, R.; Kahler, A.C.; Trkov, A.; Herman, M.W.; Sonzogni, A.A.; Danon, Y.; Carlson, A.D.; Dunn, M. ENDF/B-VIII.0: The 8th Major Release of the Nuclear Reaction Data Library with CIELO-Project Cross Sections, New Standards and Thermal Scattering Data. Nucl. Data Sheets 2018, 148, 1–142. [Google Scholar]

- Berger, M.J.; Hubbell, J.H. XCOM: Photon Cross Sections on a Personal Computer; U.S. Department of Commerce, National Bureau of Standards: Gaithersburg, MD, USA, 1987. [Google Scholar]

- Gerward, L.; Guilbert, N.; Jensen, K.B.; Levring, H. X-Ray Absorption in Matter. Reengineering XCOM. Radiat. Phys. Chem. 2001, 60, 23–24. [Google Scholar]

- Şakar, E.; Özpolat, Ö.F.; Alım, B.; Sayyed, M.I.; Kurudirek, M. Phy-X/PSD: Development of a User Friendly Online Software for Calculation of Parameters Relevant to Radiation Shielding and Dosimetry. Radiat. Phys. Chem. 2020, 166, 108496. [Google Scholar]

- Bellamy, M.B.; Bernstein, J.L.; Cullings, H.M.; French, B.; Grogan, H.A.; Held, K.D.; Little, M.P.; Tekwe, C.D. Recommendations on Statistical Approaches to Account for Dose Uncertainties in Radiation Epidemiologic Risk Models. Int. J. Radiat. Biol. 2024, 100, 1393–1404. [Google Scholar] [CrossRef]

- ISO 4037-3-2019; Radiological Protection—X and Gamma Reference Radiation for Calibrating Dosemeters and Dose Rate Meters and for Determining Their Response as a Function of Photon Energy—Part 3: Calibration of Area and Personal Dosemeters and the Measurement of Their Response as a Function of Energy and Angle of Incidence. ISO: Geneva, Switzerland, 2019.

- Singhal, R.K.; Samariya, A.; Xing, Y.-T.; Kumar, S.; Dolia, S.N.; Deshpande, U.P.; Shripathi, T.; Saitovitch, E.B. Electronic and magnetic properties of Co-doped ZnO diluted magnetic semi-conductor. J. Alloys Compd. 2010, 496, 324. [Google Scholar]

- McMurdie, H.F.; Morris, M.C.; Evans, E.H.; Paretzkin, B.; Wong-Ng, W.; Ettlinger, L.; Hubbard, C.R. Standard X-ray diffraction powder patterns from the JCPDS research associateship. Powder Diffr. 1986, 1, 64–77. [Google Scholar]

- Han, W.; Gao, M. Investigations on iron sulfide nanosheets prepared via a single-source precursor approach. Cryst. Growth Des. 2008, 8, 1023–1030. [Google Scholar]

- Ahn, W.; Kim, K.B.; Jung, K.N.; Shin, K.H.; Jin, C.S. Synthesis and electrochemical properties of a sulfur–multi-walled carbon nanotubes composite as a cathode material for lithium–sulfur batteries. J. Power Sources 2012, 202, 394–399. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Wang, G.Y.; Hu, X.Y.; Shi, Q.F.; Qiao, T.; Yang, Y. Phase-controlled synthesis of ZnS nanocrystallites by mild solvothermal decomposition of an air-stable single-source molecular precursor. J. Cryst. Growth 2005, 284, 554–560. [Google Scholar] [CrossRef]

- Onwudiwe, D.C.; Ajibade, P.A. Synthesis, characterization and thermal studies of Zn(II), Cd(II), and Hg(II) complexes of N-methyl-N-phenyldithiocarbamate: The single crystal structure of [(C6H5)(CH3)NCS2]4Hg2. Int. J. Mol. Sciences 2011, 12, 1964–1978. [Google Scholar] [CrossRef] [PubMed]

- DiMarco, J. ICDD Grant-in-Aid 1990; JCPDS code 00-041-1876; Physics Department, The Polytechnic University: Brooklyn, NY, USA, 1990. [Google Scholar]

- Parks, J.; McCarthy, G. ICDD Grant-in-Aid 1993; JCPDS code 00-047-0064; North Dakota State University: Fargo, ND, USA, 1993. [Google Scholar]

- Diehl, R.; Brandt, G.; Salje, E. The crystal structure of triclinic WO3. Acta Crystallogr., Sect. B Struct. Crystallogr. Cryst. Chem. 1978, 34, 1105. [Google Scholar] [CrossRef]

- Biondi, M.; Bortoli, E.; Avitabile, R.; Bartoli, A.; Busatti, E.; Tozzi, A.; Cimmino, M.C.; Pini, A.; Guasti, A. Radiation Shielding Calculation for Interventional Radiology: An Updated Workload Survey Using a Dose Monitoring Software. Phys. Med. 2024, 125, 104509. [Google Scholar] [CrossRef]

- Jayasinghe, J.; De Silva, R.T.; de Silva, K.N.; de Silva, R.M.; Silva, V.A. Titanium Carbide Ceramic Nanocrystals to Enhance the Physicochemical Properties of Natural Rubber Composites. RSC Adv. 2020, 10, 19290–19299. [Google Scholar] [CrossRef]

- AbuAlRoos, N.J.; Azman, M.N.; Amin, N.A.B.; Zainon, R. Tungsten-Based Material as Promising New Lead-Free Gamma Radiation Shielding Material in Nuclear Medicine. Phys. Med. 2020, 78, 48–57. [Google Scholar] [CrossRef]

- Kim, S.-C. Evaluation of Shielding Performance of Gamma Ray Shielding Tungsten Polymer Composite with LBL-Type Layered Structure. Coatings 2023, 14, 36. [Google Scholar] [CrossRef]

- Tishkevich, D.I.; Rotkovich, A.A.; German, S.A.; Zhaludkevich, A.L.; Vershinina, T.N.; Bondaruk, A.A.; Razanau, I.U.; Dong, M.; Sayyed, M.I.; Leonchik, S.V. Heavy Alloy Based on Tungsten and Bismuth: Fabrication, Crystal Structure, Morphology, and Shielding Efficiency against Gamma-Radiation. RSC Adv. 2023, 13, 24491–24498. [Google Scholar] [CrossRef]

- Taniguchi, Y.; Wakabayashi, H.; Yoneyama, H.; Chen, Z.; Morino, K.; Otosaki, A.; Yamada, M.; Inaki, A.; Kayano, D.; Kinuya, S. Application of a Tungsten Apron for Occupational Radiation Exposure in Nursing Care of Children with Neuroblastoma during 131I-Meta-Iodo-Benzyl-Guanidine Therapy. Sci. Rep. 2022, 12, 47. [Google Scholar] [CrossRef]

- El-Khatib, A.M.; Alabsy, M.T.; El-Khatib, A.Y.; Dib, M.F.; Abbas, M.I. Superiority of Micro/Nano Tungsten Carbide Reinforced Poly-Methyl Methacrylate Composites in Shielding Gamma Radiation. Nucl. Eng. Technol. 2024, 56, 4103–4114. [Google Scholar]

- Kassim, H.; Aldawood, S.; Prasad, S.; Asemi, N.N.; Aziz, A.A.; AlSalhi, M.S. Advanced Polymeric Matrix Utilizing Nanostructured Bismuth and Tungsten Oxides for Gamma Rays Shielding. Heliyon 2024, 10, e37289. [Google Scholar] [PubMed]

- Karabul, Y.; İçelli, O. The Assessment of Usage of Epoxy Based Micro and Nano-Structured Composites Enriched with Bi2O3 and WO3 Particles for Radiation Shielding. Results Phys. 2021, 26, 104423. [Google Scholar]

- Eyssa, H.M.; Sadek, R.F.; Mohamed, W.S.; Ramadan, W. Structure-Property Behavior of Polyethylene Nanocomposites Containing Bi2O3 and WO3 as an Eco-Friendly Additive for Radiation Shielding. Ceram. Int. 2023, 49, 18442–18454. [Google Scholar]

- Kim, D.H.; Cho, Y.I. Evaluation of Shielding Performance of Polymer-Tungsten Composites in High-Energy Electron Beam Therapy. J. Korean Soc. Radiol. 2024, 18, 783–791. [Google Scholar]

- Kim, S.-C. Tungsten-Based Hybrid Composite Shield for Medical Radioisotope Defense. Materials 2022, 15, 1338. [Google Scholar] [CrossRef]

- Al Hassan, M.; Liu, W.B.; Wang, J.; Ali, M.M.M.; Rawashdeh, A. Monte Carlo Simulations of Gamma-Rays Shielding with Phthalonitrile-Tungsten Borides Composites. Int. J. Radiat. Res. 2022, 20, 621–626. [Google Scholar]

- Gilys, L.; Griškonis, E.; Griškevičius, P.; Adlienė, D. Lead Free Multilayered Polymer Composites for Radiation Shielding. Polymers 2022, 14, 1696. [Google Scholar] [CrossRef]

- Bijanu, A.; Arya, R.; Agrawal, V.; Tomar, A.S.; Gowri, V.S.; Sanghi, S.K.; Mishra, D.; Salammal, S.T. Metal-Polymer Composites for Radiation Protection: A Review. J. Polym. Res. 2021, 28, 392. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, W.; Zhang, X.; Gao, Y.; Guo, S. High-Efficiency, Flexibility and Lead-Free X-Ray Shielding Multilayered Polymer Composites: Layered Structure Design and Shielding Mechanism. Sci. Rep. 2021, 11, 4384. [Google Scholar] [CrossRef]

| Ingredient | Content (phr) * | Chemical Role | Role in Composite |

|---|---|---|---|

| Natural rubber (NR) | 100 (part) | Elastomer | Primary matrix providing flexibility, elasticity, and mechanical strength. |

| Zinc Oxide (ZnO) | 10 | Vulcanization activator | Activator for sulfur vulcanization, enhances cross-linking efficiency. |

| Stearic acid | 2 | Vulcanization co-activator | Processing aid and activator, improves dispersion of fillers. |

| Tetramethylthiuram disulfide (TMTD) | 2 | Secondary accelerator and sulfur donor | Accelerator, speeds up vulcanization, improves cross-linking. |

| Sulfur (S) | 5 | Vulcanizing agent | Cross-linking agent, enhances elasticity and strength. |

| WO3 | 0, 25, 50, 75, 90 wt% | Reinforcing filler and radiation-shielding additive | Reinforcing filler, provides radiation-shielding, and increases density. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marshall, S.K.; Chuaymuang, J.; Kwandee, P.; Songphum, N. Shielding Efficacy of Tungsten Oxide-Reinforced Polyisoprene in Attenuating Technetium-99m Gamma Radiation: An Alternative Shielding Solution for Occupational Safety in Nuclear Medicine. Appl. Sci. 2025, 15, 3892. https://doi.org/10.3390/app15073892

Marshall SK, Chuaymuang J, Kwandee P, Songphum N. Shielding Efficacy of Tungsten Oxide-Reinforced Polyisoprene in Attenuating Technetium-99m Gamma Radiation: An Alternative Shielding Solution for Occupational Safety in Nuclear Medicine. Applied Sciences. 2025; 15(7):3892. https://doi.org/10.3390/app15073892

Chicago/Turabian StyleMarshall, Suphalak Khamruang, Jarasrawee Chuaymuang, Poochit Kwandee, and Nueafa Songphum. 2025. "Shielding Efficacy of Tungsten Oxide-Reinforced Polyisoprene in Attenuating Technetium-99m Gamma Radiation: An Alternative Shielding Solution for Occupational Safety in Nuclear Medicine" Applied Sciences 15, no. 7: 3892. https://doi.org/10.3390/app15073892

APA StyleMarshall, S. K., Chuaymuang, J., Kwandee, P., & Songphum, N. (2025). Shielding Efficacy of Tungsten Oxide-Reinforced Polyisoprene in Attenuating Technetium-99m Gamma Radiation: An Alternative Shielding Solution for Occupational Safety in Nuclear Medicine. Applied Sciences, 15(7), 3892. https://doi.org/10.3390/app15073892