Experimental Study on Drying Characteristics of Alfalfa Hay Bales Using Hot Air Convection

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

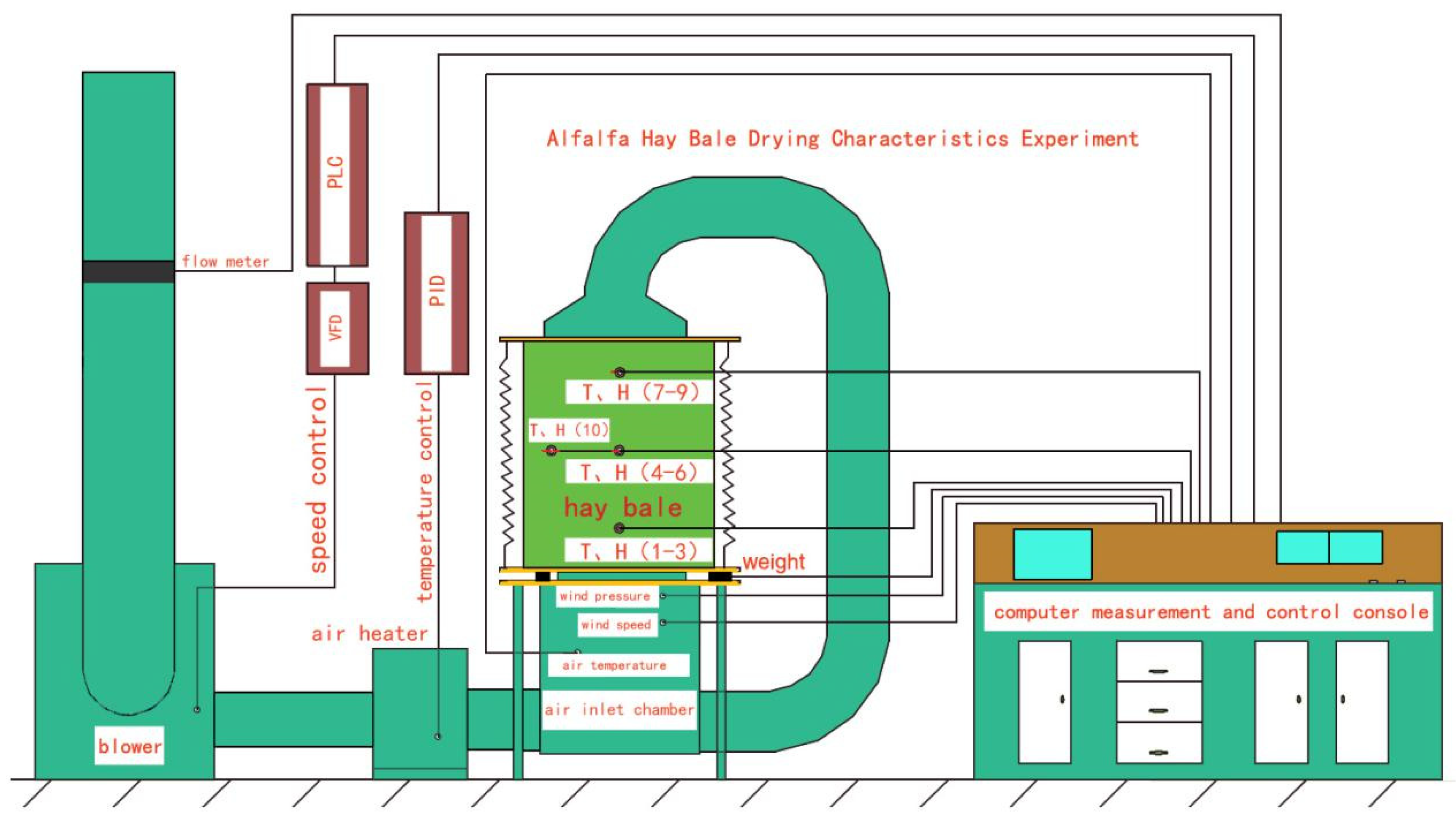

2.2. Experimental Setup

2.3. Experimental Procedure

2.4. Calculation Methods for Key Parameters

3. Results and Discussion

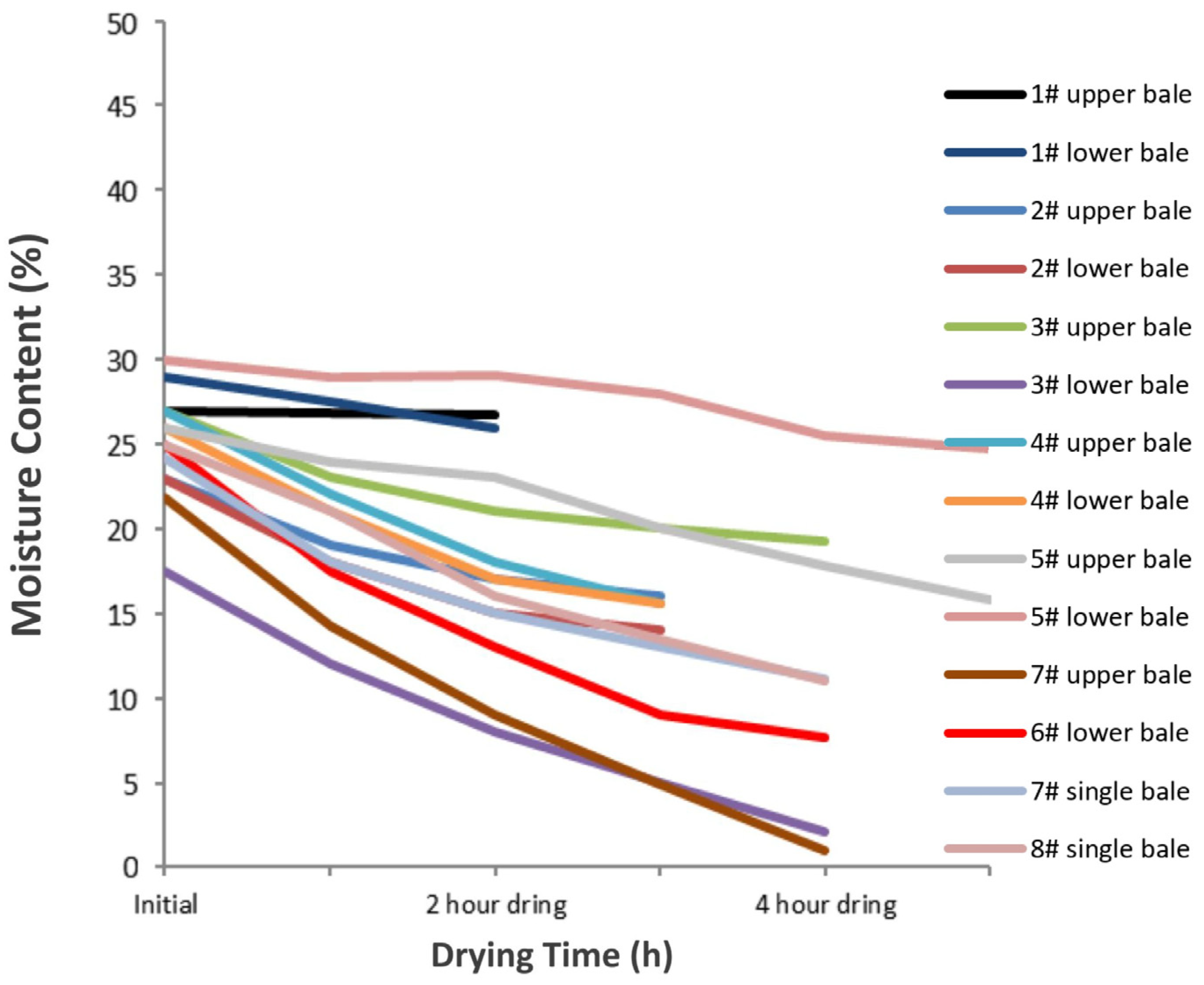

3.1. Overall Trend of the Decline in the Moisture Content of Hay Bales

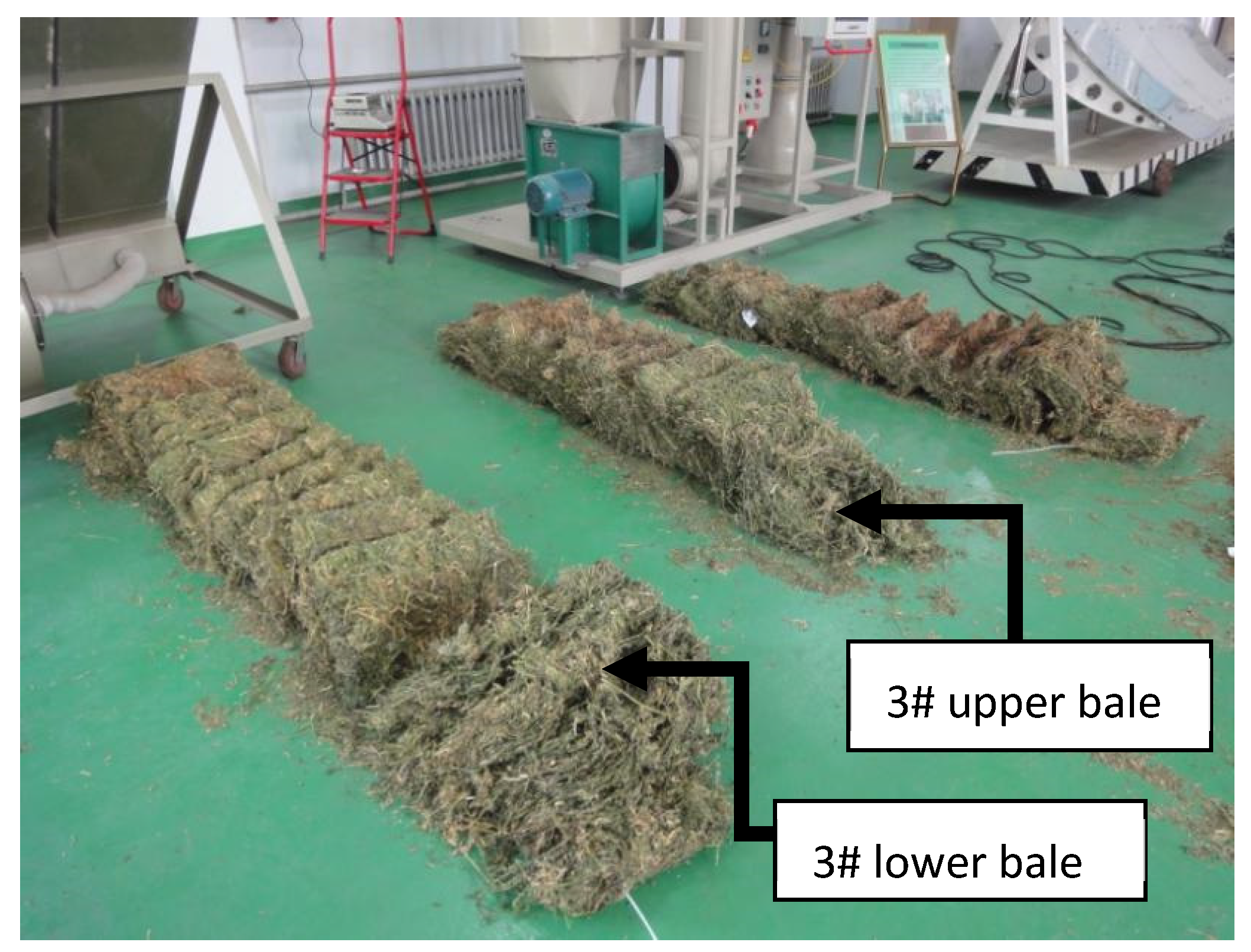

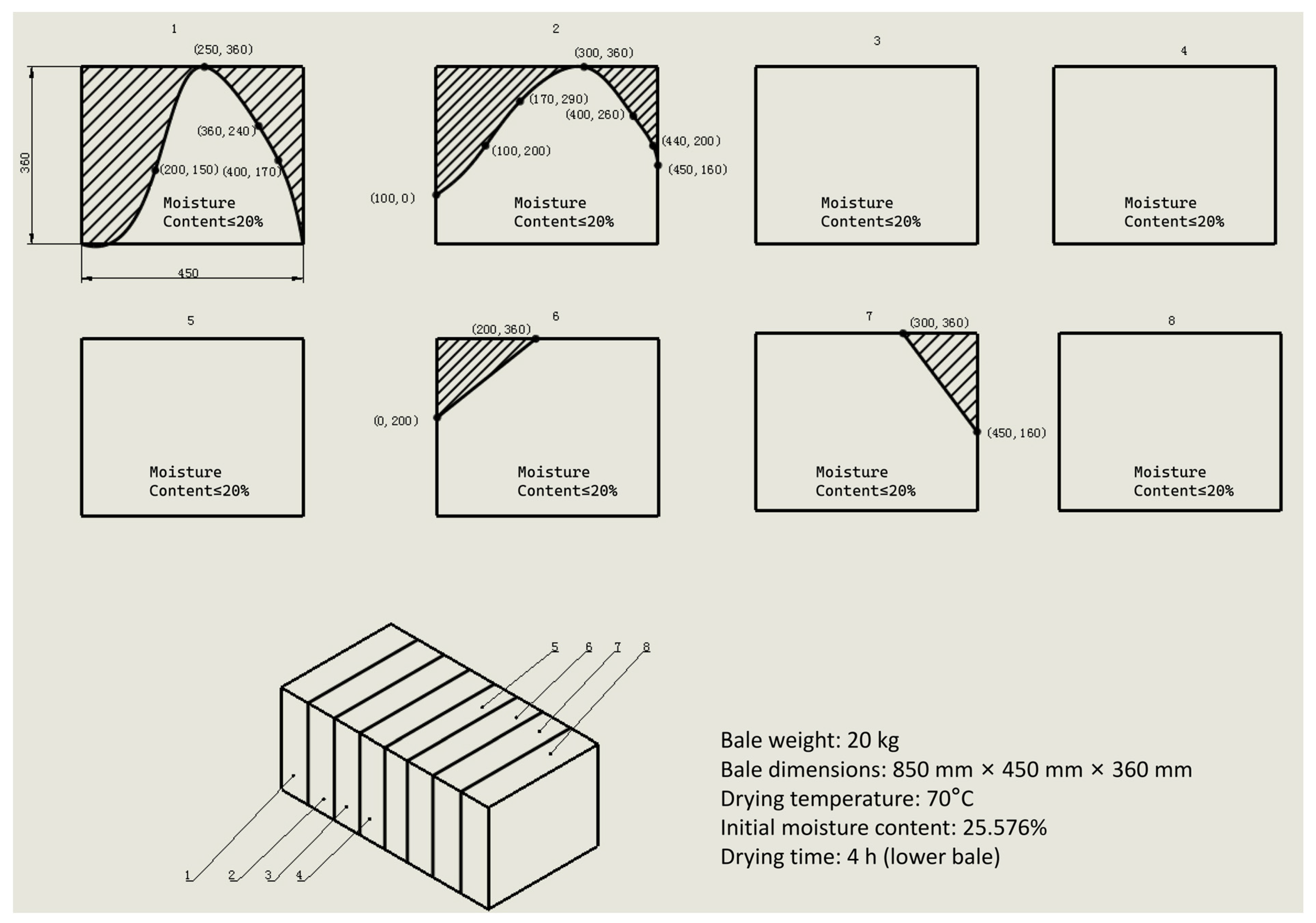

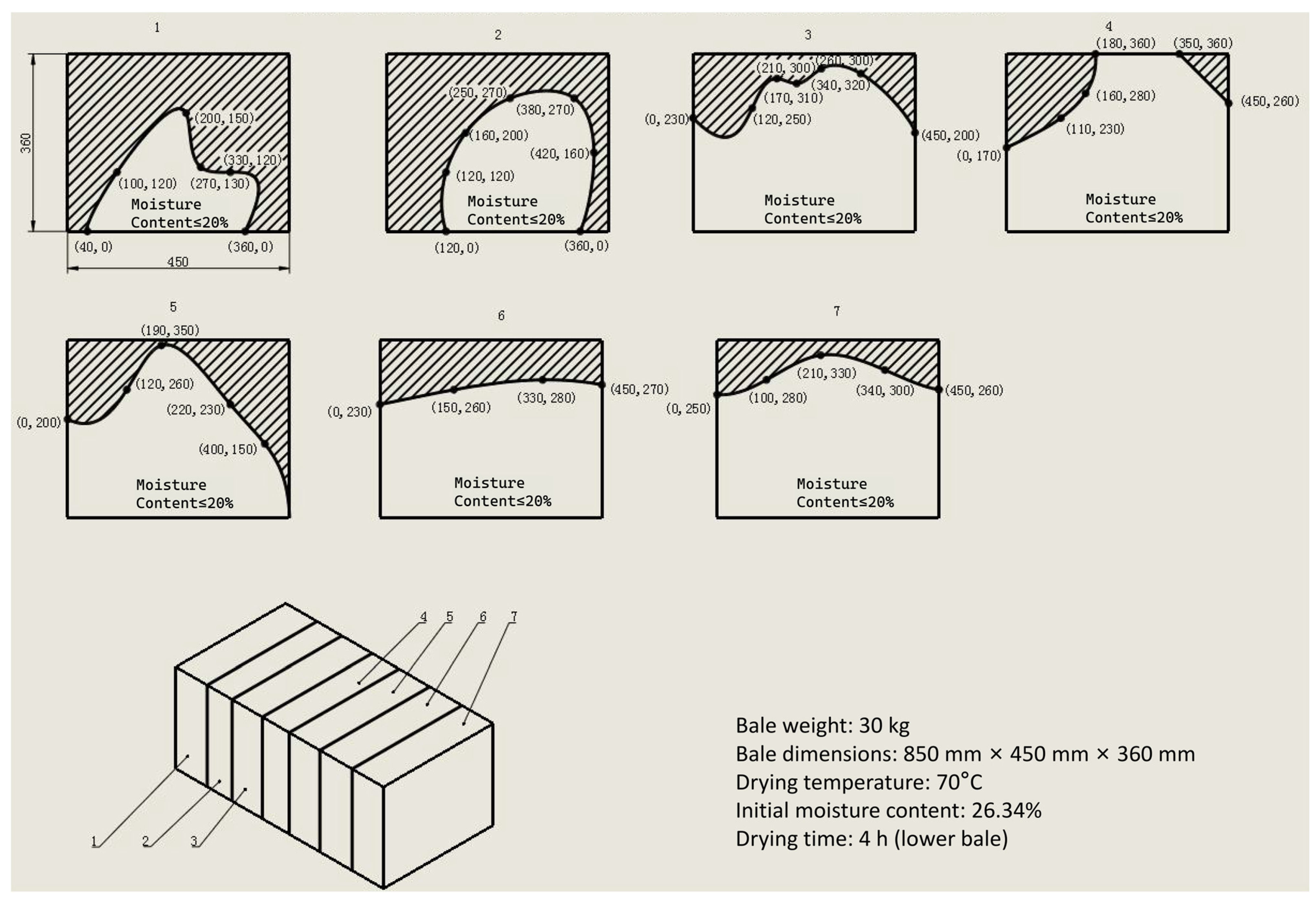

3.2. Moisture Distribution of Different Hay Bale Cross-Sections

3.3. Analysis of Drying Characteristics for Different Bales and Optimization Proposal

4. Conclusions

- (1)

- Temperature–efficiency tradeoff: At 70 °C and an air velocity of 2 m/s, bales with 25% initial moisture (w.b.) reached the target moisture (17% w.b.) within 1.5 h, achieving a drying efficiency of 26.67 kg/h. While higher temperatures (>70 °C) may further accelerate drying, they risk nutrient degradation.

- (2)

- Density-dependent airflow limitation: Increasing the bale density from 127.95 to 144.15 kg/m3 extended drying time by 50%, indicating the relationship between density and airflow resistance. This necessitates density control (<130 kg/m3) during baling to match dryer capacity.

- (3)

- Directional drying heterogeneity: Horizontal air supply caused severe moisture gradients, with central regions exceeding 20% (w.b.) despite surface dryness. Vertical airflow (top–bottom) partially mitigated this, suggesting directional optimization as a priority for industrial dryers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Y.; Xu, C.; Gu, Q.; Shi, Y.; Chen, J.; Wu, H.; He, J.; Li, X.; Han, L.; Su, D. Partial root-zone drying subsurface drip irrigation increased the alfalfa quality yield but decreased the alfalfa quality content. Front. Plant Sci. 2024, 15, 1297468. [Google Scholar] [CrossRef] [PubMed]

- Maira, C.; Javier, B.; Luis, R.; Alejandra, C.; Gerardo, G.; Jose, M.; Eduardo, C. A simplified feeding system did not affect milk production compared with a total mixed ration system in dairy cows. Ital. J. Anim. 2020, 19, 887–895. [Google Scholar] [CrossRef]

- Shamsi, S.-M.; Mohammad, S.; Hemad, Z. Investigation of fuel consumption and essential oil content in drying process of lemon verbena leaves using a continuous flow dryer equipped with a solar pre-heating system. J. Clean. Prod. 2019, 233, 1133–1145. [Google Scholar] [CrossRef]

- Aleksander, N.H. Nitrogen fractions and in sacco dry matter and crude protein degradability of fresh and frozen alfalfa. Anim. Feed Sci. Technol. 1998, 71, 351–355. [Google Scholar] [CrossRef]

- Khalid, A.; Gaadi, A. Impact of raking and baling patterns on alfalfa hay dry matter and quality losses. Saudi J. Biol. Sci. 2018, 25, 1040–1048. [Google Scholar] [CrossRef]

- Tuğrul, K.M.; Bozbay, C.K. Effect of two types of mowers on crop drying rate, yield, and quality of alfalfa (Medicago sativa L.). Appl. Ecol. Environ. Res. 2023, 21, 2731–2745. [Google Scholar] [CrossRef]

- Zhang, J.X.; Liu, Y.T.; Liang, W.P. Moisture and Drying Time Change Regular of Alfalfa During Field Drying. Mod. Agric. Sci. Technol. 2015, 7, 284–285. [Google Scholar]

- Luchini, N.D.; Broderick, G.A.; Muck, R.E.; Makoni, N.; Vetter, R. Effect of Storage System and Dry Matter Content on the Composition of Alfalfa Silage. J. Dairy Sci. 1997, 80, 1827–1832. [Google Scholar] [CrossRef]

- Román, D.; Hensel, O. Numerical simulations and experimental measurements on the distribution of air and drying of round hay bales. Biosys. Eng. 2014, 122, 1–15. [Google Scholar] [CrossRef]

- Gunhan, T.; Demir, V.; Hancioglu, E.; Hepbasli, A. Mathematical modelling of drying of bay leaves. Energy Convers. Manag. 2005, 46, 1667–1679. [Google Scholar] [CrossRef]

- Qian, S.; Zhe, Y.; Electrification, A. Testing Study on Solar Drying Characteristics of Alfalfa Bale. J. Agric. Mech. Res. 2017, 39, 158–161. [Google Scholar]

- Arinze, E.A.; Sokhansanj, S.; Schoenau, G.J. Simulation of natural and solar-heated air hay drying systems. Comput. Electron. Agric. 1993, 8, 325–345. [Google Scholar] [CrossRef]

- Hongyi, C.; Manquan, Z.; Wenming, W. Technological parameters optimization for improving quality of heated-air dried alfalfa. Trans. Chin. Soc. Agric. Eng. 2015, 31, 337–345. [Google Scholar] [CrossRef]

- Wu, B.; Qiu, C.; Guo, Y. Comparative evaluation of physicochemical properties, microstructure, and antioxidant activity of jujube polysaccharides subjected to hot air, infrared, radio frequency, and freeze drying. Agriculture 2022, 12, 1606. [Google Scholar] [CrossRef]

- Higgins, T.R.; Spooner, A.E. Microwave drying of alfalfa compared to field-and oven-drying: Effects on forage quality. Anim. Feed Sci. Technol. 1986, 16, 1–6. [Google Scholar] [CrossRef]

- Koşan, M.; Karaca Dolgun, G.; Aktekeli, B.; Sacilik, K.; Aktaş, M. Design and analysis of new solar-powered sustainable dryers: Alfalfa crop. J. Food Process Eng. 2023, 46, e14253. [Google Scholar] [CrossRef]

- Ihediwa, V.E.; Ndukwu, M.C.; Abada, U.C.; Ekop, I.E.; Bennamoun, L.; Simo-Tagne, M.; Abam, F.I. Optimization of the energy consumption, drying kinetics and evolution of thermo-physical properties of drying of forage grass for haymaking. Heat Mass Transf. 2022, 58, 1187–1206. [Google Scholar] [CrossRef]

- Kaplan, M.; Çetin, N.; Çiftci, B.; Karpuzcu, S. Comparison of drying methods for biochemical composition, energy aspects, and color properties of alfalfa hay. Biomass Convers. Biorefinery 2024, 1–16. [Google Scholar] [CrossRef]

- Friso, D. Mathematical Modelling of Rotary Drum Dryers for Alfalfa Drying Process Control. Inventions 2023, 8, 11. [Google Scholar] [CrossRef]

- Neres, M.A.; Castagnara, D.D.; Mesquita, E.E.; Zambom, M.A.; de Souza, L.C.; de Oliveira, P.S.R.; Jobim, C.C. Production of alfalfa hay under different drying methods. Rev. Bras. Zootec. 2010, 39, 1676–1683. [Google Scholar] [CrossRef]

- Wang, P.; Cen, H.; She, P.; Qin, J.; Na, R. Design of High Moisture Alfalfa Drying Experimental Bench and Thermodynamic Simulation of Drying Process. Adv. Eng. Technol. Res. 2004, 10, 146. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Patil, R.T. Kinetics of dehydration of green alfalfa. Dry. Technol. 1996, 14, 1197–1234. [Google Scholar] [CrossRef]

- Patil, R.T.; Sokhansanj, S.; Arinze, E.A.; Schoenau, G. Thin layer drying of components of fresh alfalfa. Can. Agric. Eng. 1992, 34, 343–346. Available online: https://library.csbe-scgab.ca/all-publications/976-thin-layer-drying-of-components-of-fresh-alfalfa (accessed on 26 March 2025).

- Sokhansanj, S.; Wood, H.C. Engineering aspects of forage processing for pellets, cubes, dense chops and bales. Adv. Feed Technol. 1991, 5, 6–23. [Google Scholar]

- Xu, W.X.; Islam, M.N.; Cao, X.H.; Tian, J.; Zhu, G. Effect of relative humidity on drying characteristics of microwave assisted hot air drying and qualities of dried finger citron slices. LWT-Food Sci. Technol. 2021, 137, 110413. [Google Scholar] [CrossRef]

- Babu, A.K.; Palanichamy, R.; Surya, S.B.V. Numerical and experimental analysis of a heat pump dryer for leaf drying applications. Biomass Conv. Biorefinery 2024, 14, 6321–6332. [Google Scholar] [CrossRef]

- Dana, M.; Ahmadi, M.P. Studying experimentally and numerically the rate of moisture loss in conditioned alfalfa using computational fluid dynamics. J. Food Process Eng. 2022, 45, e14062. [Google Scholar] [CrossRef]

| Items | Technical Parameters |

|---|---|

| Bale size (L × W × H) | 0.85 × 0.45 × 0.36 (m) |

| Quantity of dry bales in a batch | 2 |

| Fan flow rate | 4600 m3/h |

| Fan power | 3 kW |

| Air outlet size | 500 × 160 (mm) |

| Full pressure | 1460 Pa |

| Drying air temperature | 70 °C |

| Treatment | Drying Form of Hay Bales | Drying Duration (h) | Hay Bales | Initial Weight (kg) | Initial Moisture Content (%(w.b.)) | Final Weight (kg) | Final Moisture Content (%(w.b.)) |

|---|---|---|---|---|---|---|---|

| 1 | Two bales heated from top and bottom | 2 | Upper bale | 34.96 | 27.058 | 34.78 | 26.94 |

| Lower bale | 32.92 | 29.522 | 31.54 | 26.71 | |||

| 2 | Two bales heated from top and bottom | 3.5 | Upper bale | 24.23 | 33.97 | 18.45 | 14.00 |

| Lower bale | 25.06 | 31.65 | 22.7 | 24.91 | |||

| 3 | Two bales heated from top and bottom | 2 | Upper bale | 29.09 | 27.86 | 26.3 | 20.58 |

| Lower bale | 29.53 | 26.34 | 24.9 | 13.41 | |||

| 4 | Two bales heated from top and bottom | 3 | Upper bale | 27.78 | 27.02 | 24.01 | 16.40 |

| Lower bale | 27.98 | 26.34 | 24.43 | 16.01 | |||

| 5 | Two bales heated from top and bottom | 4 | Upper bale | 17.62 | 32.02 | 13.61 | 16.90 |

| Lower bale | 19.85 | 29.27 | 16.00 | 14.00 | |||

| 6 | Two bales heated from top and bottom | 5 | Upper bale | 40.03 | 26.46 | 34.98 | 18.28 |

| Lower bale | 42.55 | 30.16 | 39.50 | 25.71 | |||

| 7 | One bale heated from top and bottom | 4 | Bale | 39.3 | 26.07 | 33.52 | 13.96 |

| 8 | One bale heated from left and right | 4 | Bale | 40.18 | 26.46 | 33.78 | 13.08 |

| Drying Time | Drying Hay Bales | Weight (kg) | Density (kg/m3) | Moisture Content (%(w.b.)) | Drying Temperature (°C) | Flow Velocity (m/s) |

|---|---|---|---|---|---|---|

| Initial | Upper Bale | 17.62 | 127.95 | 32.02 | 68.10 | 2.70 |

| Lower Bale | 19.85 | 144.15 | 29.27 | |||

| 1 h | Upper Bale | 16.07 | 116.70 | 25.82 | 73.50 | 2.90 |

| Lower Bale | 17.90 | 157.33 | 22.00 | |||

| 2 h | Upper Bale | 15.23 | 110.60 | 21.16 | 73.10 | 3.10 |

| Lower Bale | 16.96 | 123.16 | 17.94 | |||

| 3 h | Upper Bale | 14.48 | 105.15 | 18.46 | 72.70 | 3.20 |

| Lower Bale | 16.33 | 118.59 | 15.11 | |||

| 4 h | Upper Bale | 13.61 | 98.83 | 16.90 | 72.50 | 3.30 |

| Lower Bale | 16.00 | 116.19 | 14.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, J.; Liu, C. Experimental Study on Drying Characteristics of Alfalfa Hay Bales Using Hot Air Convection. Appl. Sci. 2025, 15, 3921. https://doi.org/10.3390/app15073921

Du J, Liu C. Experimental Study on Drying Characteristics of Alfalfa Hay Bales Using Hot Air Convection. Applied Sciences. 2025; 15(7):3921. https://doi.org/10.3390/app15073921

Chicago/Turabian StyleDu, Jianqiang, and Chang Liu. 2025. "Experimental Study on Drying Characteristics of Alfalfa Hay Bales Using Hot Air Convection" Applied Sciences 15, no. 7: 3921. https://doi.org/10.3390/app15073921

APA StyleDu, J., & Liu, C. (2025). Experimental Study on Drying Characteristics of Alfalfa Hay Bales Using Hot Air Convection. Applied Sciences, 15(7), 3921. https://doi.org/10.3390/app15073921