Analysis of Vehicle–Bridge Coupling Vibration for Corrugated Steel Web Box Girder Bridges Considering Three-Dimensional Pavement Roughness

Abstract

:1. Introduction

2. Vehicle–Bridge Coupling Vibration Analysis Method Based on the Three-Dimensional Contact Constraint Method

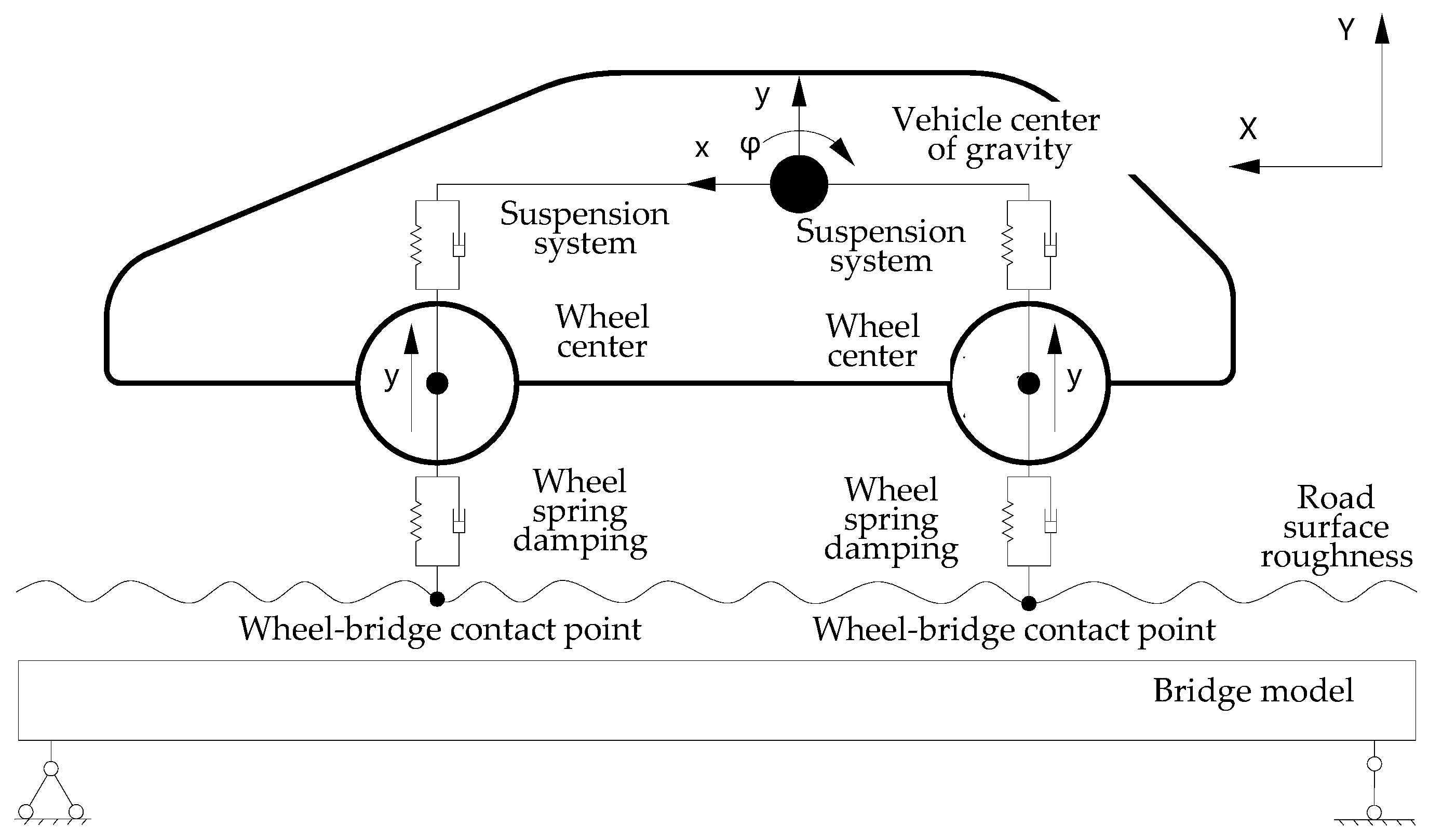

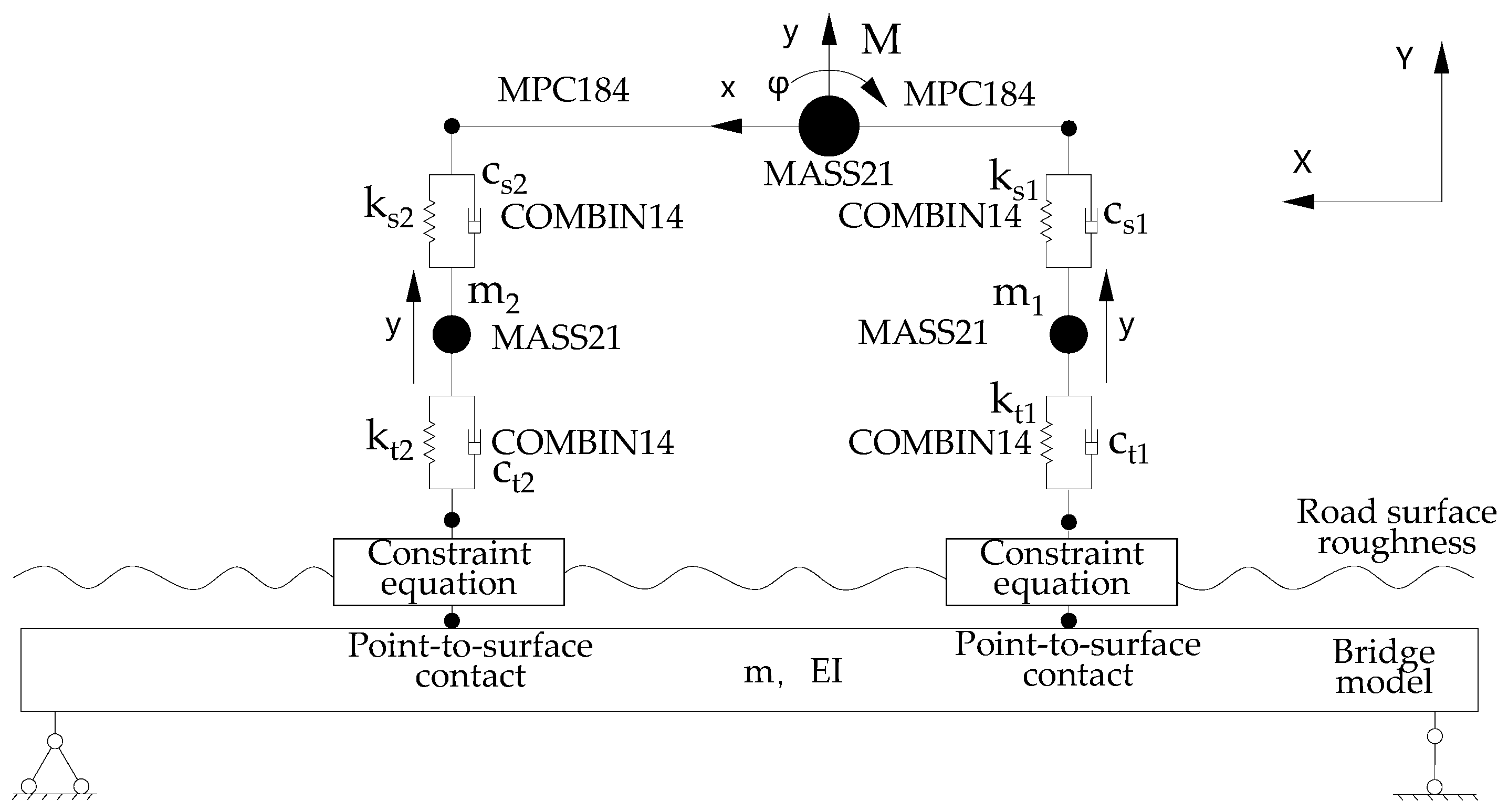

2.1. Vehicle–Highway Bridge Coupling System Model

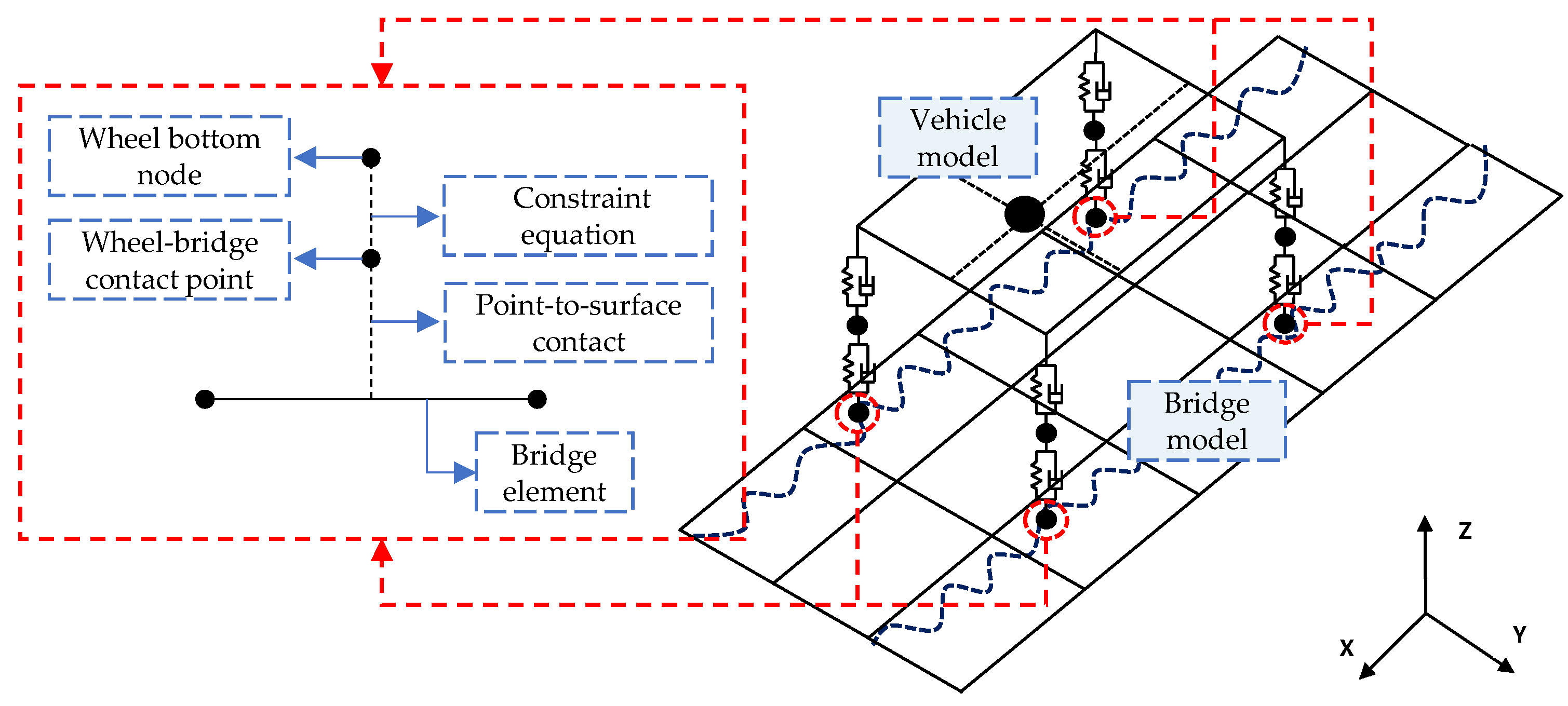

2.2. Contact Constraint Method for Three-Dimensional Pavement Roughness

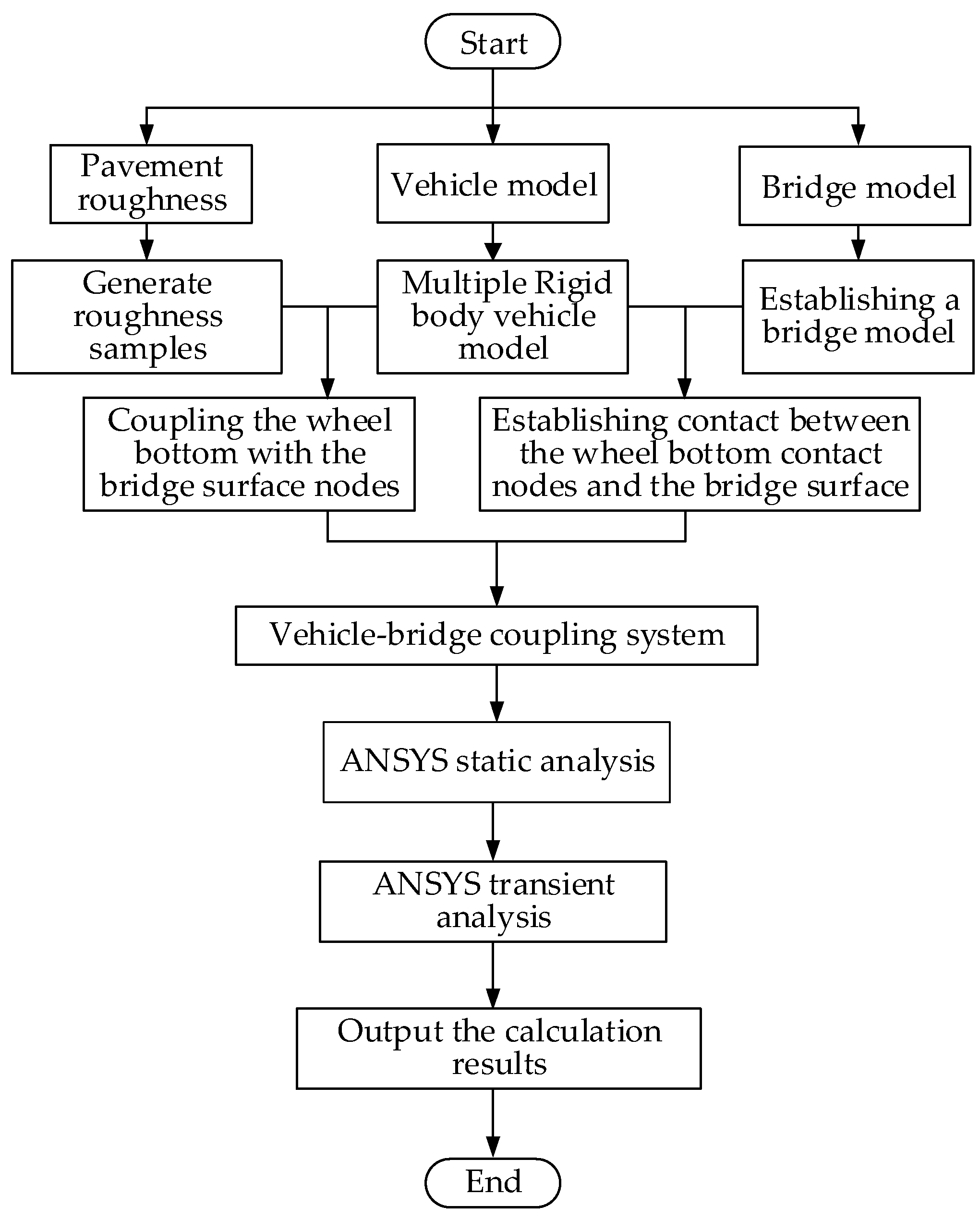

2.3. Implementation Process of the Contact Constraint Method in ANSYS

- Step 1. Establish the bridge model based on the model data.

- Step 2. Determine the lane information, including lane positions, number, and direction, and create lanes at a certain distance from both ends of the bridge to ensure vehicles enter the bridge with stable vibration states.

- Step 3. Determine the vehicle information, including the number of vehicles, types, initial positions, and vehicle speeds. Establish a multi-rigid-body vehicle model at the initial position.

- Step 4. Input the three-dimensional pavement roughness sample into ANSYS, and couple the wheel bottom nodes with the wheel–bridge deck contact points using constraint equations, with the constant term of the constraint equation being the pavement roughness value.

- Step 5. Establish point-to-surface contact between the wheel–bridge contact points and the bridge deck, forming the vehicle–bridge coupling system.

- Step 6. Enter the static analysis module, apply gravitational acceleration, and bring the spring-damping system of the vehicle model into a balanced position.

- Step 7. Enter the transient dynamic analysis module and apply displacement in the driving direction to the vehicle model. The displacement within one time step is determined by the vehicle speed. The time step is automatically adjusted by ANSYS to optimize computational accuracy and efficiency. The displacement coordination condition between the wheel and the wheel–bridge deck contact points at any moment is established by changing the constant term of the constraint equation, thus considering the effect of pavement roughness.

- Step 8. After completing the solution, enter the time history post-processing to examine the system’s dynamic response.

2.4. Verification of Method Accuracy

3. Vehicle–Bridge Coupling Analysis for Corrugated Steel Web Box Girder Bridge

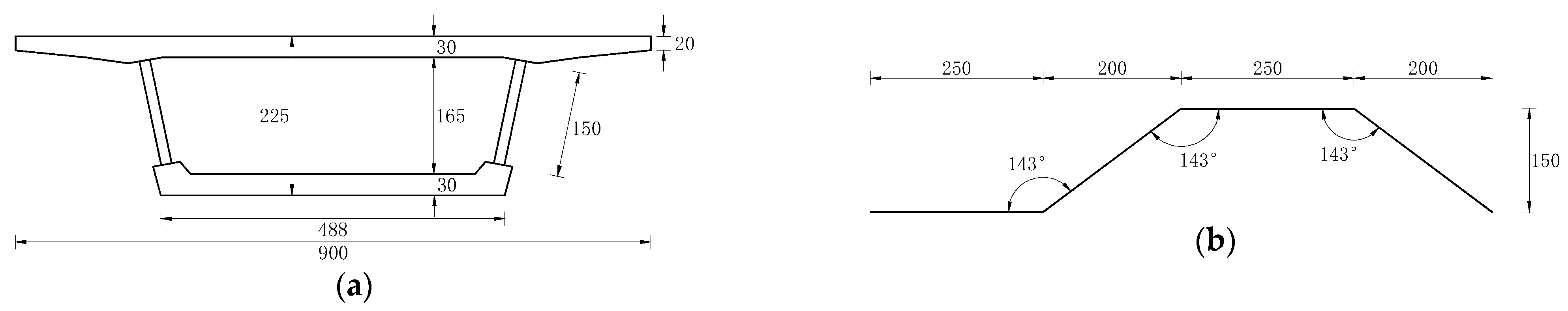

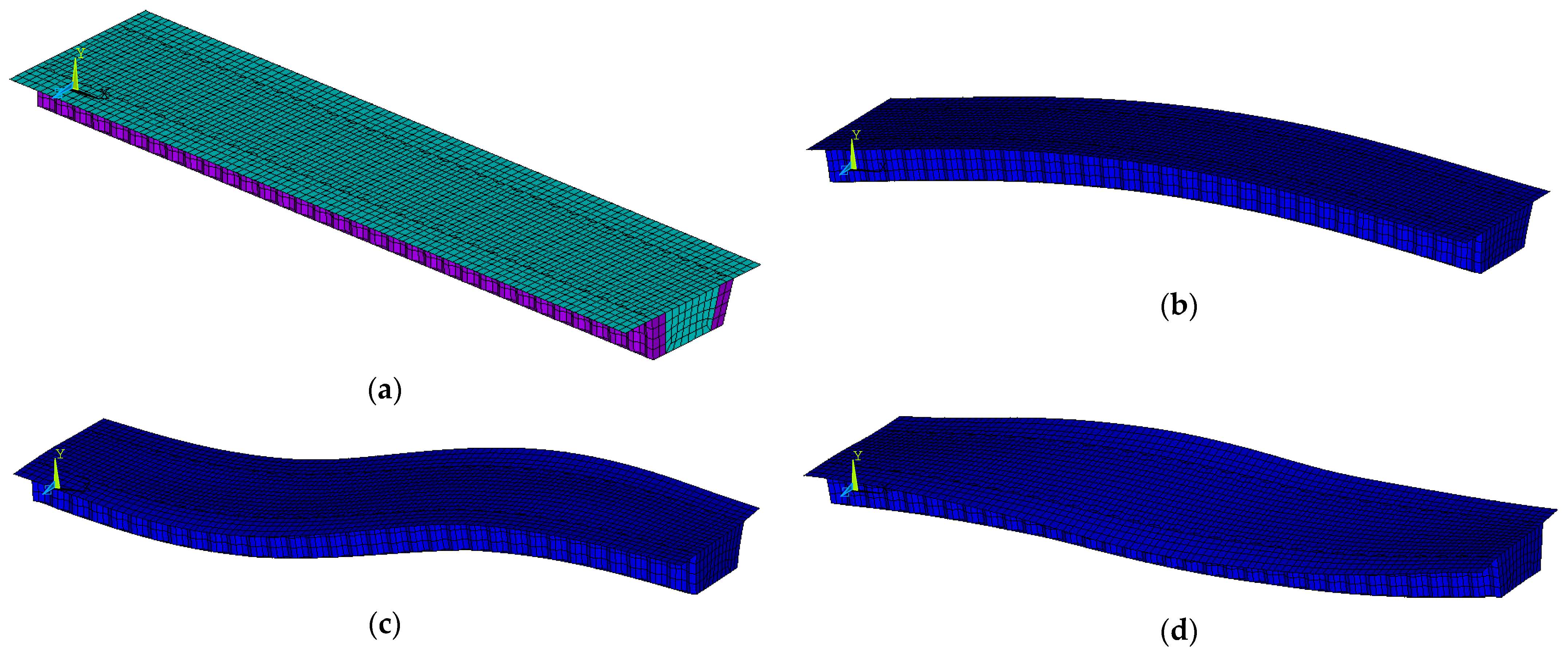

3.1. Vehicle–Bridge Coupling System Model

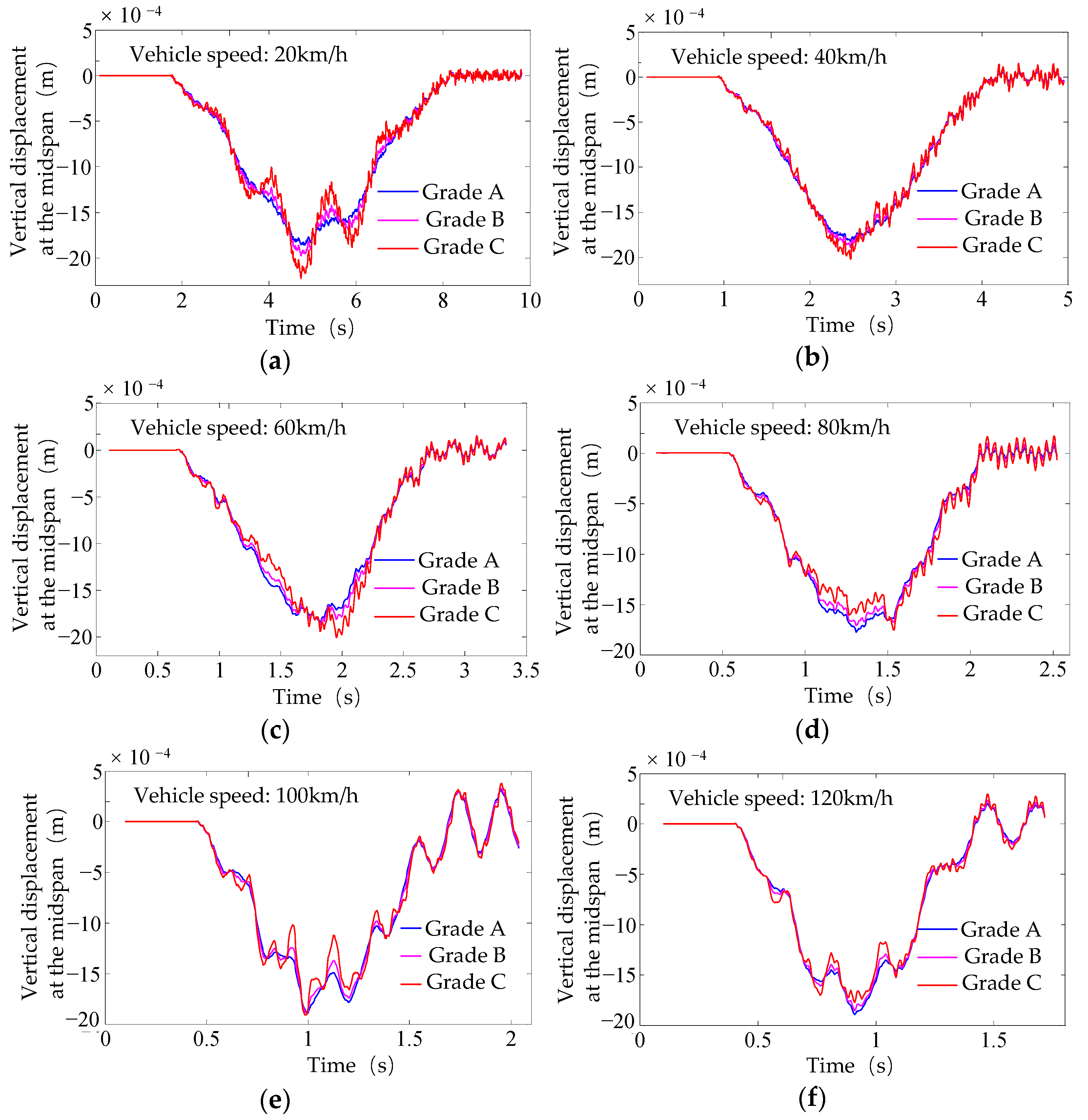

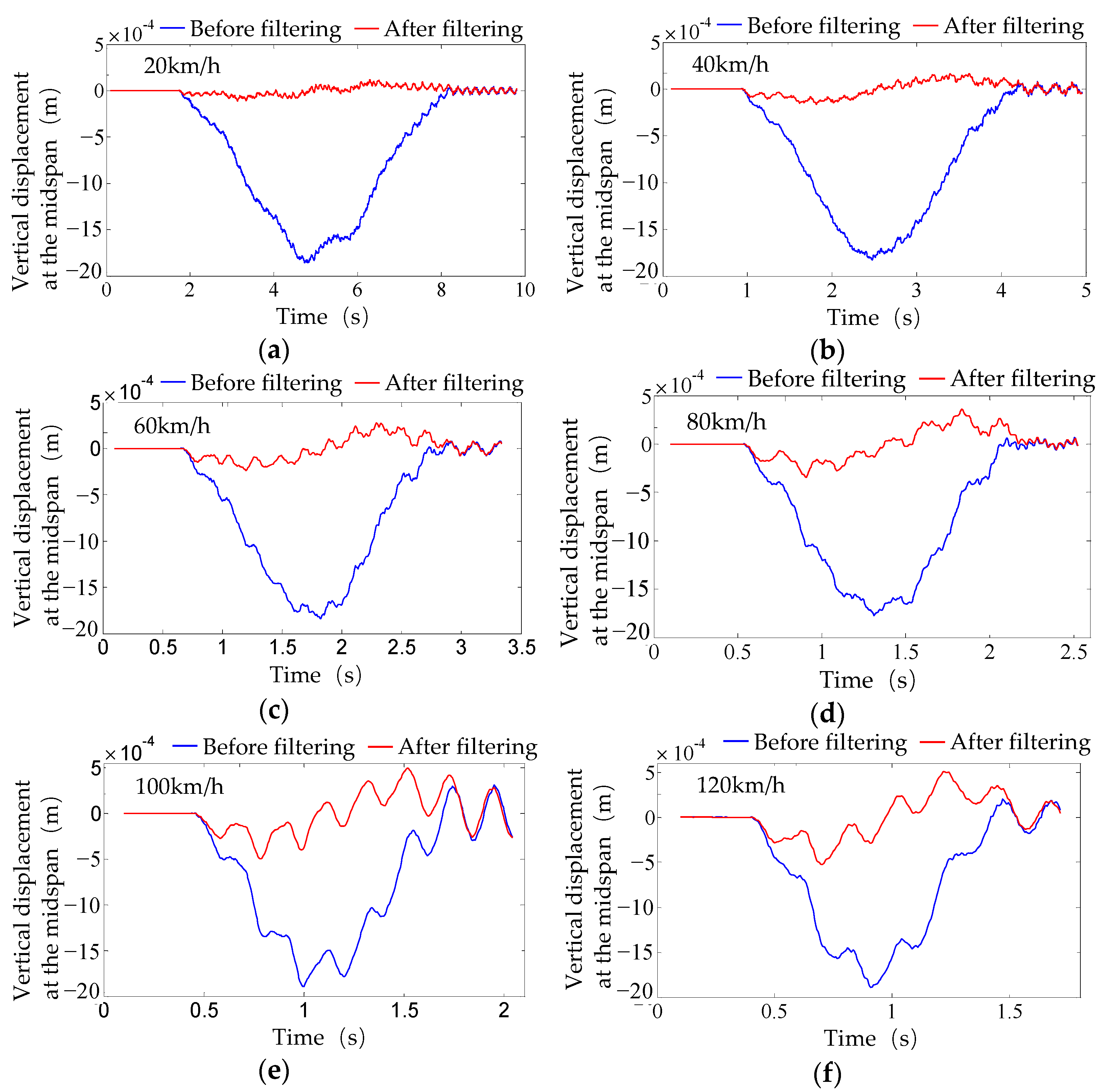

3.2. Simulation Conditions and Calculation Results

3.3. Calculate the Impact Factor

4. Analysis of Factors Affecting the Impact Factor

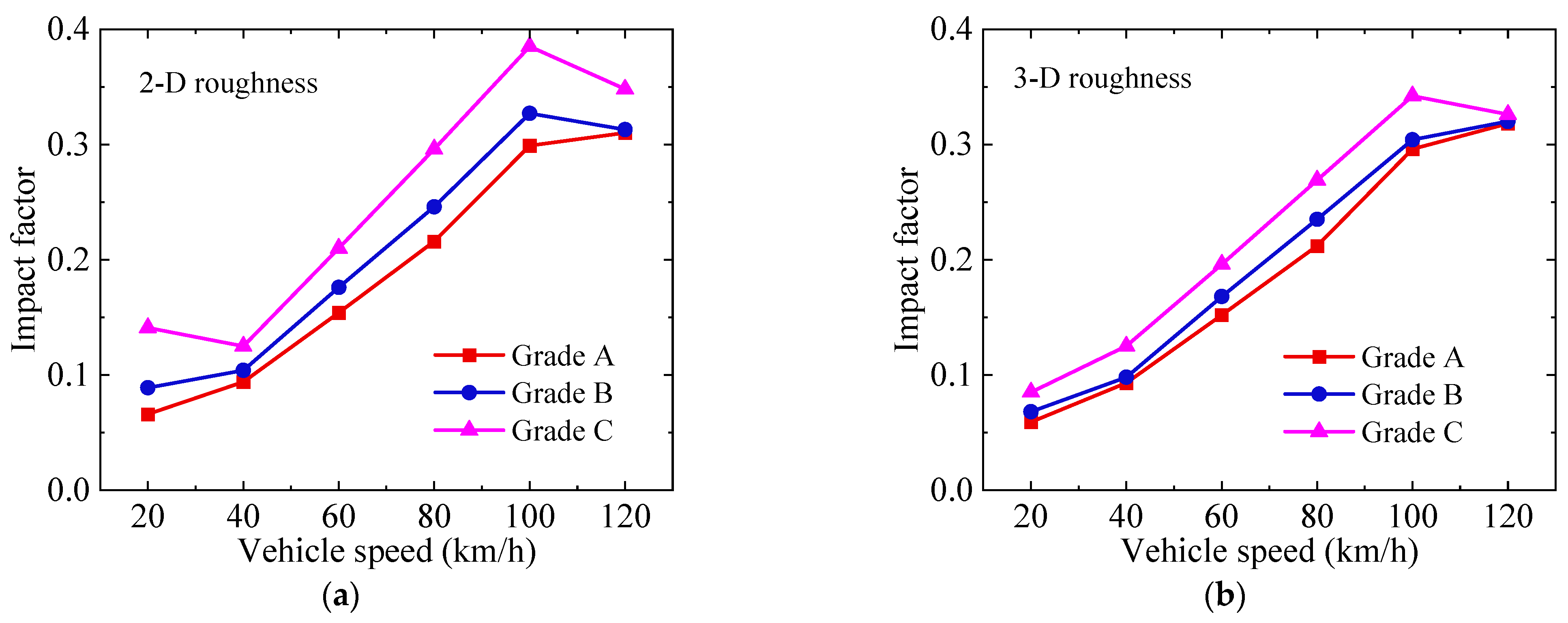

4.1. Effect of Vehicle Speed

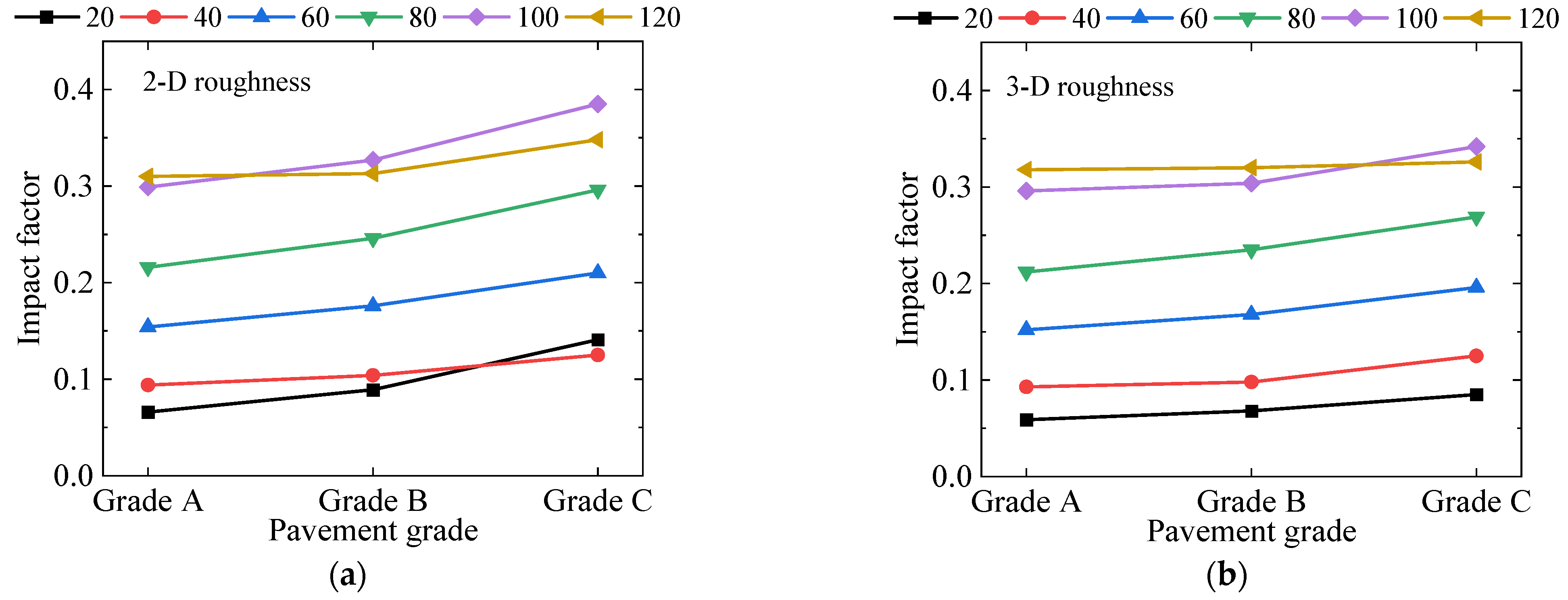

4.2. Effect of Pavement Grade

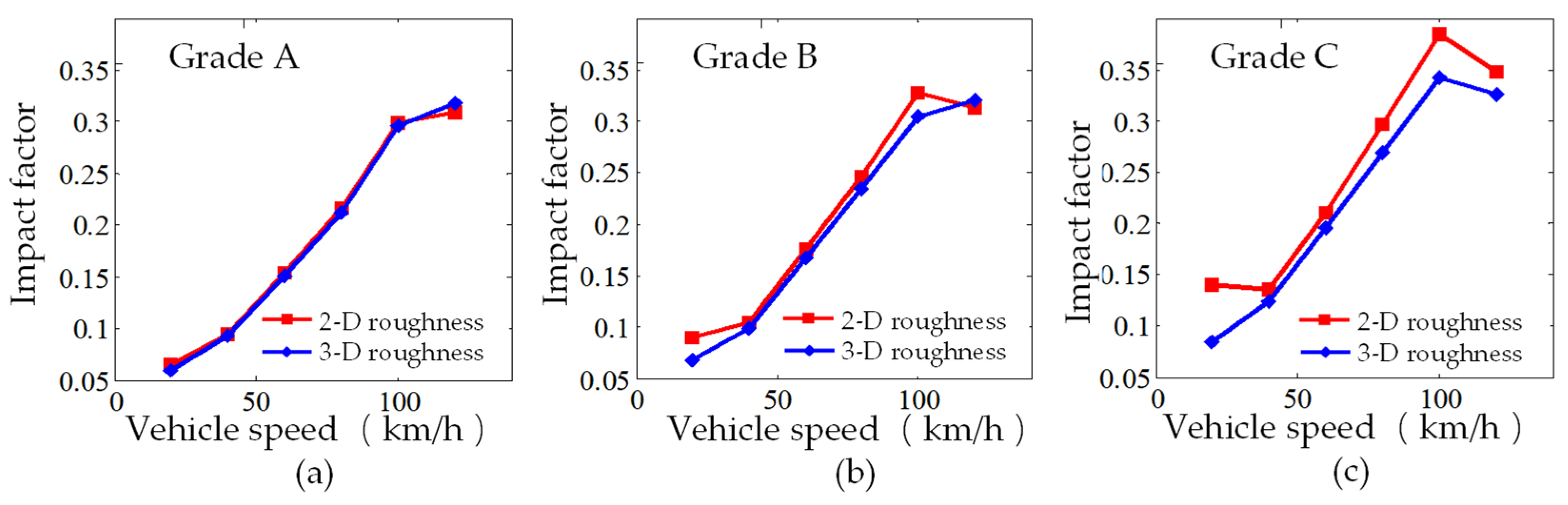

4.3. Effect of Pavement Roughness Dimensions

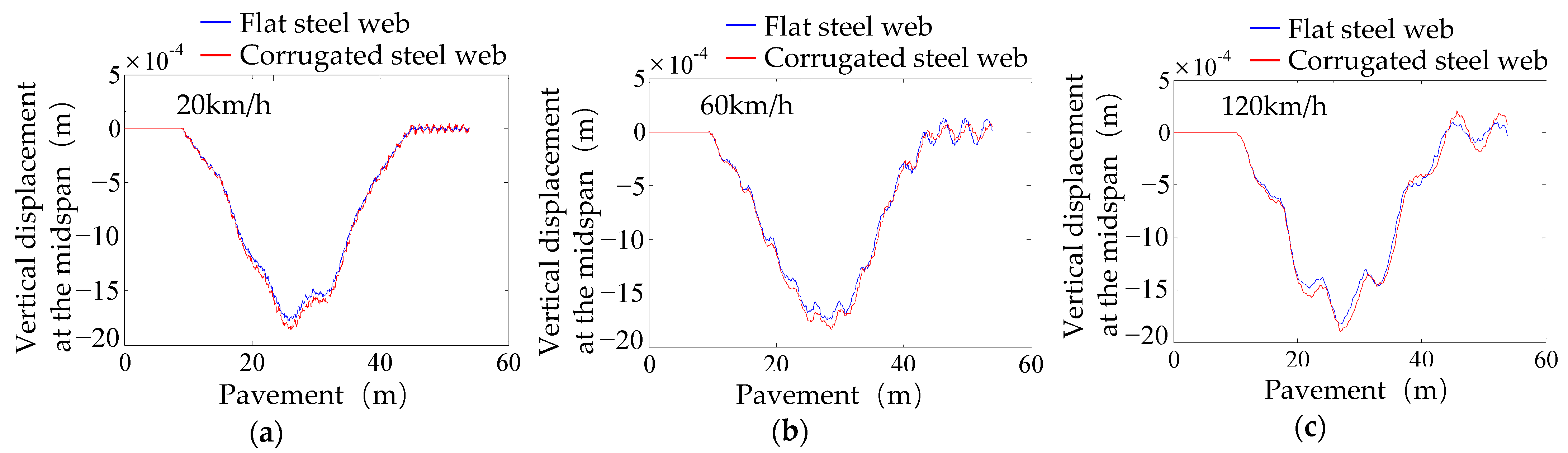

4.4. Effect of Box Girder Configurations

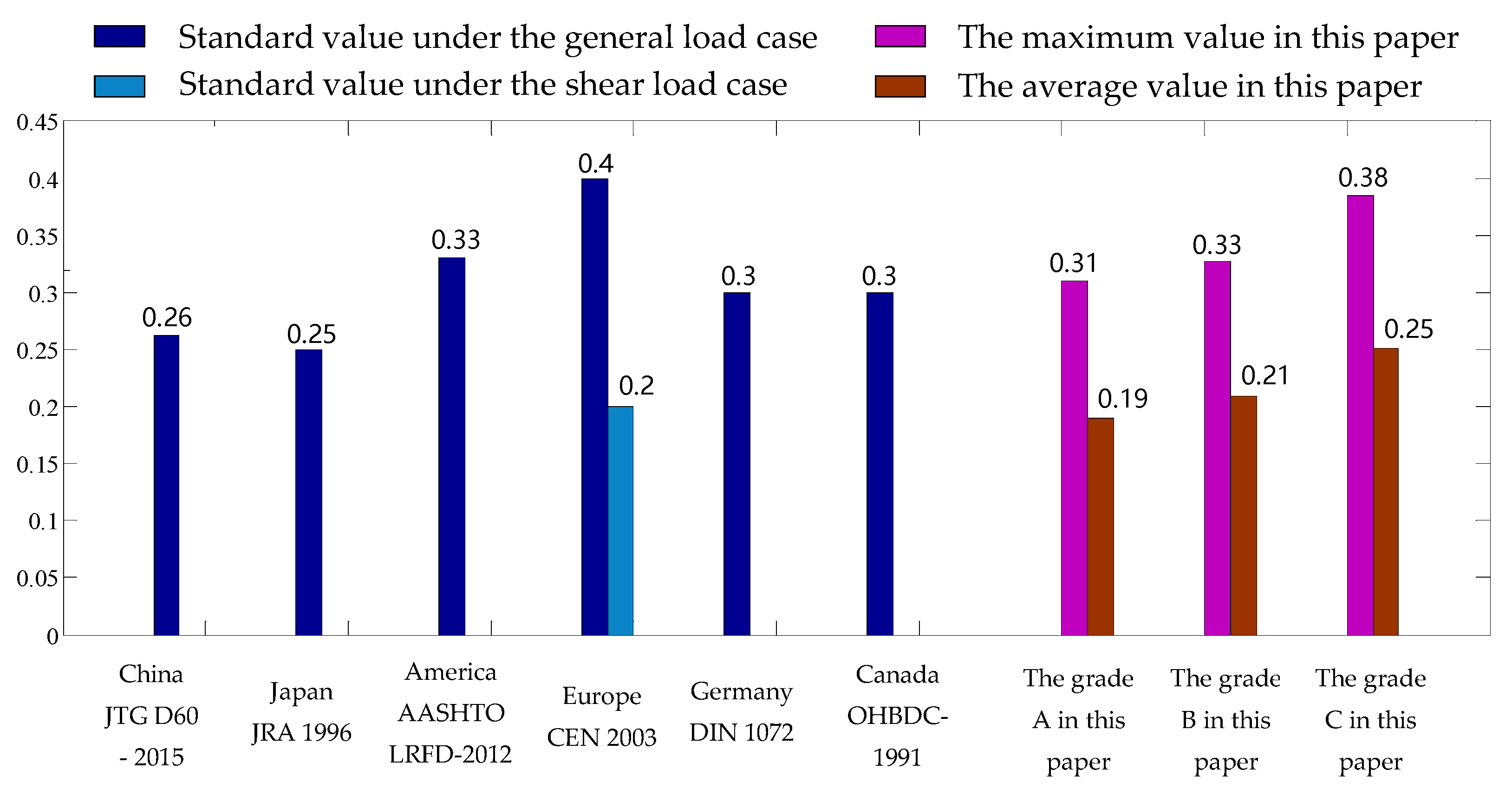

4.5. Comparison of Impact Factor in This Study with International Standards

5. Conclusions

- After verifying the correctness of the method, a vehicle–bridge coupling vibration study on corrugated steel web box girder bridges was conducted. The effect of vehicle speed on the impact factor is not entirely positively correlated and is often influenced by other factors. For example, under different pavement grades, the variation pattern of the impact factor with vehicle speed is inconsistent. Within the range of operating speeds, there is a peak value for the impact factor. It is recommended to avoid the speed corresponding to this peak during operation to reduce excessive impact vibrations on the bridge.

- At all speed levels, the influence pattern of pavement grade on the impact factor is consistent, with the impact factor increasing as pavement conditions deteriorate. For each upgrade in pavement grade, the impact factor increases by an average of 19.1%. Therefore, regular maintenance of the bridge pavement significantly promotes the service performance of the bridge.

- The comparison of impact factors between three-dimensional and two-dimensional pavement roughness reveals notable differences. In most cases, the impact factors on the three-dimensional pavement roughness are smaller than those for the two-dimensional pavement roughness. The average reduction is 2.4%, 7.3%, and 13.5% for grade A, B, and C surfaces, respectively.

- In the grade A pavement condition, when passing through the box beam at speeds of 20 km/h, 60 km/h, and 120 km/h, the mid-span dynamic deflection of the flat steel web box beam is reduced by 4.2%, 4.7%, and 3.7% compared to the corrugated steel web box beam, respectively. However, the impact factors are quite similar; the difference between the two models is within 0.005. For the steel bottom plate box girder, the mid-span dynamic deflection increases by 21.7%, 30.3%, and 33.4% compared to the concrete bottom plate box girder. Meanwhile, the impact factors increase by 274.2%, 196.8%, and 116.8%, respectively. Therefore, after replacing the concrete bottom plate in the corrugated steel web box beam with a steel bottom plate, the static load-bearing capacity remains unchanged. However, the vibration problem of the box beam is significantly exacerbated.

- A comparison of impact factors calculated based on various national standards reveals that most of the standard calculated impact factors exceed the average impact factors obtained in this study. They are also closer to the maximum impact factor calculated under grade A pavement conditions. Therefore, standard methods for calculating impact factors are more applicable to new bridges and well-maintained bridges. For older bridges with poorer maintenance conditions, simulation calculations based on vehicle–bridge coupling are recommended.

- This research has not yet conducted vehicle–bridge coupling analysis under multiple vehicles, vehicle–bridge coupling analysis of continuous multi-span bridges, and wheel–bridge separation assumption analysis. Additionally, the method used in this paper has been validated through numerical simulation experiments, and bridge testing validation is also part of our future plans to enhance the applicability of the method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, B.; Huang, Q. A summary of application of prestressed concrete box-girder bridges with corrugated steel webs. Highway 2005, 7, 45–53. (In Chinese) [Google Scholar]

- Di, J.; Zhou, X.; Zhang, Z. Research on the mechanical performance of prestressed concrete corrugated steel web composite box girders. J. China Foreign Highw. 2007, 3, 79–83. (In Chinese) [Google Scholar]

- He, J.; Wang, S.; Liu, Y.; Dai, L.; Lyu, Z.; Li, C.; Xin, H.; Tan, C. The development of composite bridges with corrugated steel webs in China. Bridge Eng. 2019, 174, 1–44. [Google Scholar]

- Elgaaly, M.; Seshadri, A.; Hamilton Robert, W. Bending strength of steel beams with corrugated webs. J. Struct. Eng. 1997, 123, 772–782. [Google Scholar]

- Elgaaly, M.; Hamilton Robert, W.; Seshadri, A. Shear strength of beams with corrugated webs. J. Struct. Eng. 1996, 122, 390–398. [Google Scholar]

- Zhou, X.; Kong, X.; Hou, J.; Cheng, D.; Jin, D. Shear Mechanical Property of Composite Box Girder with Corrugated Steel Webs. China J. Highw. Transp. 2007, 2, 77–82. (In Chinese) [Google Scholar]

- Di, J.; Zhou, X.; You, J.; Kong, X. Torsional property of prestressed concrete composite beam with corrugated steel webs. J. Change Univ. (Nat. Sci. Ed.) 2009, 29, 58–63+76. (In Chinese) [Google Scholar]

- Ding, Y.; Jiang, K.B.; Shao, F.; Deng, A.Z. Experimental study on ultimate torsional strength of PC composite box-girder with corrugated steel webs under pure torsion. Struct. Eng. Mech. 2013, 46, 519–531. [Google Scholar] [CrossRef]

- Hassanein, M.F.; Kharoob, O.F. Shear buckling behavior of tapered bridge girders with steel corrugated webs. Eng. Struct. 2014, 74, 157–169. [Google Scholar]

- Wu, W.; Wan, S.; Ye, J.; Fang, T. Spatial Finite Element Analysis on Shear Lag Effect in Composite box Girder With Corrugated Steel Web. China Civ. Eng. J. 2004, 9, 31–36. (In Chinese) [Google Scholar]

- Wang, Y.; Zhou, Y.; Zhao, Y.; Zhao, Y.; Xue, Y.; Feng, W. Comparison of Dynamic Amplification Factor of Deflection and Bending Moment of Highway Continuous Box-Girder Bridges by Mode Superposition. Materials 2024, 17, 1041. [Google Scholar] [CrossRef] [PubMed]

- Chen, X. The Vehicle-Bridge Interaction Analysis of Corrugated Steel Web Box Girder Based on Contact-Constraint Method. Master’s Thesis, Chongqing University, Chongqing, China, 2019. [Google Scholar]

- He, G.J.; Xie, L. The Research of Dynamic Characteristic for Box-girder Bridge with Corrugated Webs. Adv. Mater. Res. 2013, 639, 554–564. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, P.; Di, J.; Zhou, X. Free vibration characteristics and experiment study of composite box girder with corrugated steel webs. J. Traffic Transp. Eng. 2008, 5, 76–80. (In Chinese) [Google Scholar]

- Liu, B.; Chen, H.; Ren, H. Improvement Study of the Dynamic Characteristics for Concrete Box-Girder with Corrugated Steel Webs. China Railw. Sci. 2008, 3, 29–33. (In Chinese) [Google Scholar]

- Li, P.; Liu, B.; Xiao, Y. Influence of Different Pier Types on Dynamic Performance of Continuous Rigid-Frame Bridges with Corrugated Steel Webs. Bridge Constr. 2011, 2, 27–29. (In Chinese) [Google Scholar]

- Yan, W. Vehicle-Bridge Coupling Vibration of Continuous Box Girder Bridge with Corrugated Steel Webs. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2012. [Google Scholar]

- Li, P.F.; Liu, B.D.; Xiao, Y.N. Influence of Variation of Damping Ratio on Vehicle-bridge Coupling Vibration Responses of Bridge with Corrugated Steel Webs. In Civil Engineering in China—Current Practice and Research Report; Aussino Academic Publishing House: Sydney, Australia, 2010; pp. 139–144. [Google Scholar]

- Ji, W.; Deng, L.; He, W.; Liu, S.; Lin, P. Local and global impact factors analysis for PC box girder bridges with corrugated steel webs. J. Vib. Shock. 2017, 36, 22–28. (In Chinese) [Google Scholar]

- Han, W.; Ma, L.; Yuan, S.; Zhao, S. Analysis of the effect of inconsistent stimulus of surface roughness on vehicle-bridge coupling vibrations. China Civ. Eng. J. 2011, 44, 81–90. (In Chinese) [Google Scholar]

- Xu, Z.-D.; Ge, T.; Miao, A. Experimental and theoretical study on a novel multi-dimensional vibration isolation and mitigation device for large-scale pipeline structure. Mech. Syst. Signal Process. 2019, 129, 546–567. [Google Scholar]

- Xu, Z.-D.; Wu, Z. Energy damage detection strategy based on acceleration responses for long-span bridge structures. Eng. Struct. 2007, 29, 609–617. [Google Scholar]

- Erduran, E.; Nordli, C.; Gonen, S. Effect of Elastomeric Bearing Stiffness on the Dynamic Response of Railway Bridges Considering Vehicle–Bridge Interaction. Appl. Sci. 2022, 12, 11952. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Jie, Z. State-of-the-Art Review and Trend of Studies on Coupling Vibration for Vehicle and Highway Bridge System. Eng. Mech. 2008, 3, 230–240. (In Chinese) [Google Scholar]

- Liu, Y.; Wang, L.; Jiang, C.; Shu, H. Research on Mechanical Performance of In-Service Continuous Rigid-Frame Bridge Based on Vehicle-Bridge Coupling Vibration. Appl. Sci. 2024, 14, 6950. [Google Scholar] [CrossRef]

- Liu, S. Research on Vehicle-Bridge Coupled Vibration of Double-Deck Highway Steel Truss Bridge. Ph.D. Thesis, Chang’an University, Xi’an, China, 2015. [Google Scholar]

- Wang, X. Structural Dynamic Analysis and Application with ANSYS; China Communications Press: Beijing, China, 2014. [Google Scholar]

- Zhao, Y.C. Analysis and Research on Coupled Vibration of Highway Vehicle Bridge Considering the Influence of Deck Irregularity. Master’s Thesis, Central South University, Changsha, China, 2011. [Google Scholar]

- Qiao, P.; Ma, C.; Duan, C.-J.; Lei, H.; Zhao, H.; He, J. Vehicle–Bridge Interaction Dynamic Analysis of Continuous Rigid Frame Composite Box Girder Bridge with Corrugated Steel Webs under Seismic Excitation. Adv. Civ. Eng. 2024, 2024, 3870669. [Google Scholar]

- Deng, L.; Yu, Y.; Zou, Q.L.; Cai, C.S. State-of-the-Art Review of Dynamic Impact Factors of Highway Bridges. J. Bridge Eng. 2015, 20, 04014080. [Google Scholar]

- Yuan, L.L. Vertical Flexural Mechanical Characteristics and Experimental Study of Composite Box Girder with Corrugated Steel Web Considering Shear Deformation. Ph.D. Thesis, Lanzhou Jiaotong University, Lanzhou, China, 2019. [Google Scholar]

- Deng, L.; Cai, C.S. Identification of parameters of vehicles moving on bridges. Eng. Struct. 2009, 31, 2474–2485. [Google Scholar]

- Michaltsos, G.T.; Konstantakopoulos, T.G. Dynamic response of a bridge with surface deck irregularities. J. Vib. Control 2000, 6, 667–689. [Google Scholar]

- Broquet, C.; Bailey, S.F.; Fafard, M.; Bruehwiler, E. Dynamic Behavior of Deck Slabs of Concrete Road Bridges. J. Bridge Eng. 2004, 9, 137–146. [Google Scholar]

- Shi, X.; Cai, C.S.; Chen, S. Vehicle induced dynamic behavior of short-span slab bridges considering effect of approach slab condition. J. Bridge Eng. 2008, 13, 83–92. [Google Scholar]

- Dodds, C.J.; Robson, J.D. The description of road surface roughness. J. Sound Vib. 1973, 31, 175–183. [Google Scholar]

- GB/T 7031-2005 C-P; Mechanical Vibration-Road Surface Profiles-Reporting of Measured Data. National Standardization Administration: Beijing, China, 2005.

- Bin, X. Analysis and Application on the Vehicle-Bridge Coupling Vibration for Existing Reinforced Concrete Arch Bridges. Master’s Thesis, Central South University, Changsha, China, 2013. [Google Scholar]

- Xu, Z.-D.; Liu, M.; Wu, Z.; Zeng, X. Energy Damage Detection Strategy Based on Strain Responses for Long-Span Bridge Structures. J. Bridge Eng. 2011, 16, 644–652. [Google Scholar]

- Xu, Z.-D.; Chen, B.-B. Experimental and Numerical Study on Magnetorheological Fluids Based on Mixing Coated Magnetic Particles. J. Mater. Civ. Eng. 2016, 28, 04015198. [Google Scholar] [CrossRef]

- Tao, Y.X.; Xu, Z.D.; Wei, Y.X.; Liu, X.Y.; Dong, Y.R.; Dai, J. Integrating Deep Learning Into an Energy Framework for Rapid Regional Damage Assessment and Fragility Analysis Under Mainshock-Aftershock Sequences. Earthq. Eng. Struct. Dyn. 2025. [Google Scholar] [CrossRef]

- Xiao, H.; Huang, Y. Detection of grout sleeve defects based on the time domain dimensionless indicators of component signals. J. Build. Eng. 2023, 65, 105795. [Google Scholar] [CrossRef]

- Gohery, S.; Sharifi, S.; Burvill, C.; Mouloodi, S.; Izadifar, M.; Thissen, P. Localized failure analysis of internally pressurized laminated ellipsoidal woven GFRP composite domes: Analytical, numerical, and experimental studies. Arch. Civ. Mech. Eng. 2019, 19, 1235–1250. [Google Scholar] [CrossRef]

- Shen, H.; Xiao, X. Numerical Method for Vehicle-Bridge Coupled Vibrations. J. Southwest Jiaotong Univ. 2003, 16, 658–662. (In Chinese) [Google Scholar]

- Shinichi, M.K.K. Design and Construction of the Shinkai Bridge. Prestressed Concrete Bridge Using Corrugated Steel Webs. Bridges Found. 1994, 28, 13–20. (In Japanese) [Google Scholar]

- D60-2015 J; General Specifications for Design of Highway Bridges and Culverts. Ministry of Transport of the People’s Republic of China: Beijing, China, 2015.

- JTG/TJ21-01-2015; Load Test Ethods for Highway Bridge. Ministry of Transport of the People’s Republic of China: Beijing, China, 2015.

- Mao, Y.-N.; Ma, C.; Liu, S.-Z.; Li, L.-Y. Study on the Dynamic Response of Composite Box Girder Bridges with Corrugated Steel Webs. Adv. Civ. Eng. 2023, 2023, 5104132. [Google Scholar] [CrossRef]

- Leyi, W. Calculation Method and Experimental Study on lmpact Coefficient of Simply Supported Bridge Span Structures. Master’s Thesis, Jilin University, Jilin, China, 2009. [Google Scholar]

- JRA1996; Specifications for Highway Bridges. Japan Road Association: Tokyo, Japan, 1996.

- DIN1072; Straßen- und Wegbrücken Lastannahmen. Deutsches Institut für Normung: Berlin, Germany, 1985.

- CEN2003; Eurocode 1: Actions on Structures. Comité Européen de Normalisation: Brussels, Belgium, 2003.

- LRFDUS-6; AASHTO LRFD Bridge Design Specifications. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2012.

- OHBDC1991; Ontario Highway Bridge Design Code. Ontario Ministry of Transportation: Downsview, Canada, 1991.

| Model Parameter | Symbol | Unit | Parameter Value |

|---|---|---|---|

| Bridge line mass | Mb | kg/m | 5.41 × 103 |

| Bridge bending stiffness | EI | N·m2 | 3.5 × 1010 |

| Bridge span | Lb | m | 32 |

| Vehicle body mass | Mv | kg | 3.85 × 104 |

| vehicle pitch moment of inertia | Iα | kg·m2 | 2.466 × 106 |

| Wheelset mass | mi | kg | 4330 |

| Upper spring-damper system stiffness | Ksi | N·m−1 | 2.535 × 106 |

| Upper spring-damper system damping | Csi | kg·s−1 | 1.96 × 105 |

| Lower spring-damper system stiffness | Kti | N·m−1 | 4.28 × 106 |

| Lower spring-damper system damping | Cti | kg·s−1 | 9.8 × 104 |

| Distance between front and rear axles | Lv | m | 8.4 |

| Influence Factors | Parameter Values |

|---|---|

| Vehicle speed | 20 km/h, 40 km/h, 60 km/h, 80 km/h, 100 km/h, 120 km/h |

| Pavement roughness dimension | 2D pavement, 3D pavement |

| Pavement grade | Grade A, Grade B, Grade C |

| Speed (km/h) | 3-D Pavement Roughness | Pavement Grade | ||

|---|---|---|---|---|

| Grade A | Grade B | Grade C | ||

| 20 | No | 0.066 | 0.089 | 0.141 |

| Yes | 0.059 | 0.068 | 0.085 | |

| 40 | No | 0.094 | 0.104 | 0.125 |

| Yes | 0.093 | 0.098 | 0.125 | |

| 60 | No | 0.154 | 0.176 | 0.210 |

| Yes | 0.152 | 0.168 | 0.196 | |

| 80 | No | 0.216 | 0.246 | 0.296 |

| Yes | 0.212 | 0.235 | 0.269 | |

| 100 | No | 0.299 | 0.327 | 0.385 |

| Yes | 0.296 | 0.304 | 0.342 | |

| 120 | No | 0.310 | 0.313 | 0.348 |

| Yes | 0.318 | 0.320 | 0.326 | |

| Model Parameter | Unit | C50 Concrete Plate | Q345 Steel Plate | Prestressed Steel Reinforcement |

|---|---|---|---|---|

| Element type | - | SHELL181 | SHELL181 | LINK8 |

| Elastic modulus | MPa | 34,500 | 206,000 | 1.95 × 1010 |

| Poisson’s ratio | - | 0.2 | 0.3 | 0.3 |

| Density | kg/m3 | 2410 | 7850 | 7850 |

| Order | Frequency | Mode Characteristics |

|---|---|---|

| 1 | 4.84 Hz | First-order symmetric vertical bending |

| 2 | 12.92 Hz | First-order antisymmetric vertical bending |

| 3 | 12.94 Hz | Bending-torsion coupling |

| Model Parameter | Symbol | Unit | Parameter Value |

|---|---|---|---|

| Vehicle body mass | M1 | t | 24.81 |

| Pitching moment of inertia | Izx | kg·m2 | 172,160 |

| Rolling moment of inertia | Izy | kg·m2 | 31,496 |

| Suspension and wheel mass | mi | t | 0.73 |

| Upper spring stiffness | Ku | kN/m | 727.81 |

| Upper damping coefficient | Cu | kN·s/m | 2.19 |

| Lower spring stiffness | Kd | kN/m | 1972.9 |

| Lower damping coefficient | Cd | kN·s/m | 0 |

| Distance from the front axle to the vehicle center of mass | L1 | m | 4.56 |

| Distance from the rear axle to the vehicle center of mass | L2 | m | 1.69 |

| Box Girder Type | Working Conditions | ||

|---|---|---|---|

| 20 km/h | 60 km/h | 120 km/h | |

| Corrugated steel web box girder | 0.066 | 0.154 | 0.310 |

| Flat web box girder | 0.061 | 0.158 | 0.311 |

| Steel bottom plate box girder | 0.247 | 0.457 | 0.672 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Ma, H.; Xiao, H.; Qin, F.; Di, J.; Chen, X.; Wang, J. Analysis of Vehicle–Bridge Coupling Vibration for Corrugated Steel Web Box Girder Bridges Considering Three-Dimensional Pavement Roughness. Appl. Sci. 2025, 15, 4009. https://doi.org/10.3390/app15074009

Chen L, Ma H, Xiao H, Qin F, Di J, Chen X, Wang J. Analysis of Vehicle–Bridge Coupling Vibration for Corrugated Steel Web Box Girder Bridges Considering Three-Dimensional Pavement Roughness. Applied Sciences. 2025; 15(7):4009. https://doi.org/10.3390/app15074009

Chicago/Turabian StyleChen, Luchuan, Haixia Ma, Huaizao Xiao, Fengjiang Qin, Jin Di, Xiaodong Chen, and Jie Wang. 2025. "Analysis of Vehicle–Bridge Coupling Vibration for Corrugated Steel Web Box Girder Bridges Considering Three-Dimensional Pavement Roughness" Applied Sciences 15, no. 7: 4009. https://doi.org/10.3390/app15074009

APA StyleChen, L., Ma, H., Xiao, H., Qin, F., Di, J., Chen, X., & Wang, J. (2025). Analysis of Vehicle–Bridge Coupling Vibration for Corrugated Steel Web Box Girder Bridges Considering Three-Dimensional Pavement Roughness. Applied Sciences, 15(7), 4009. https://doi.org/10.3390/app15074009