A Framework for 3D Plant Simulation of Meal-Kit-Packaging Robot Automation System

Abstract

:1. Introduction

2. Materials and Methods

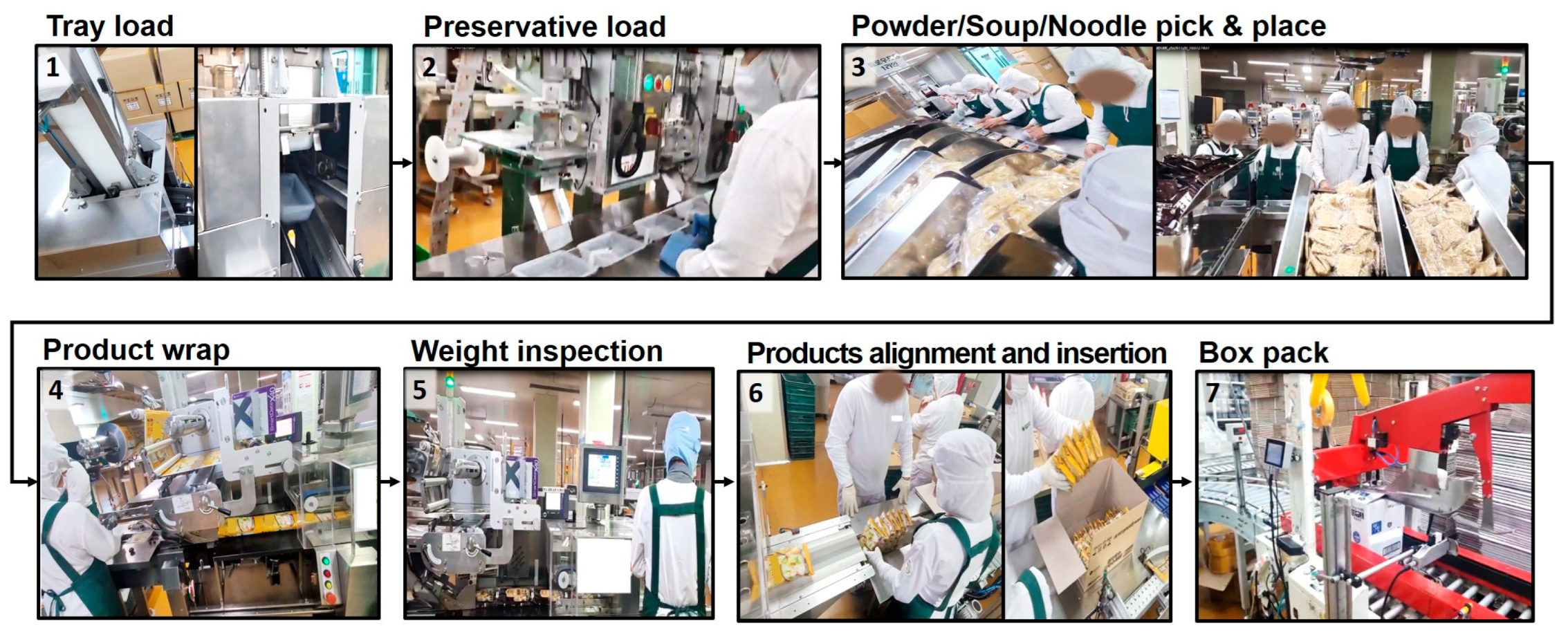

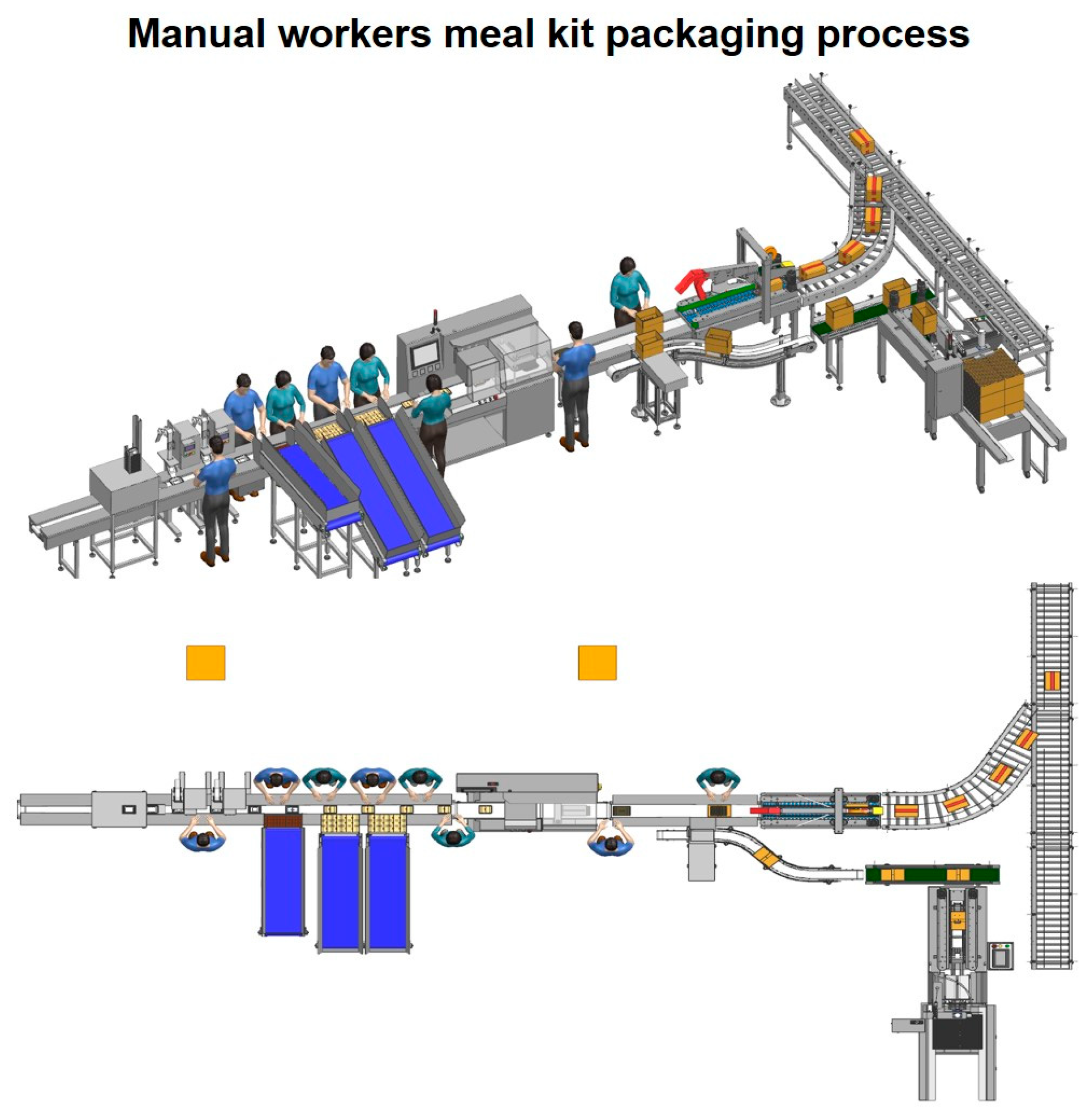

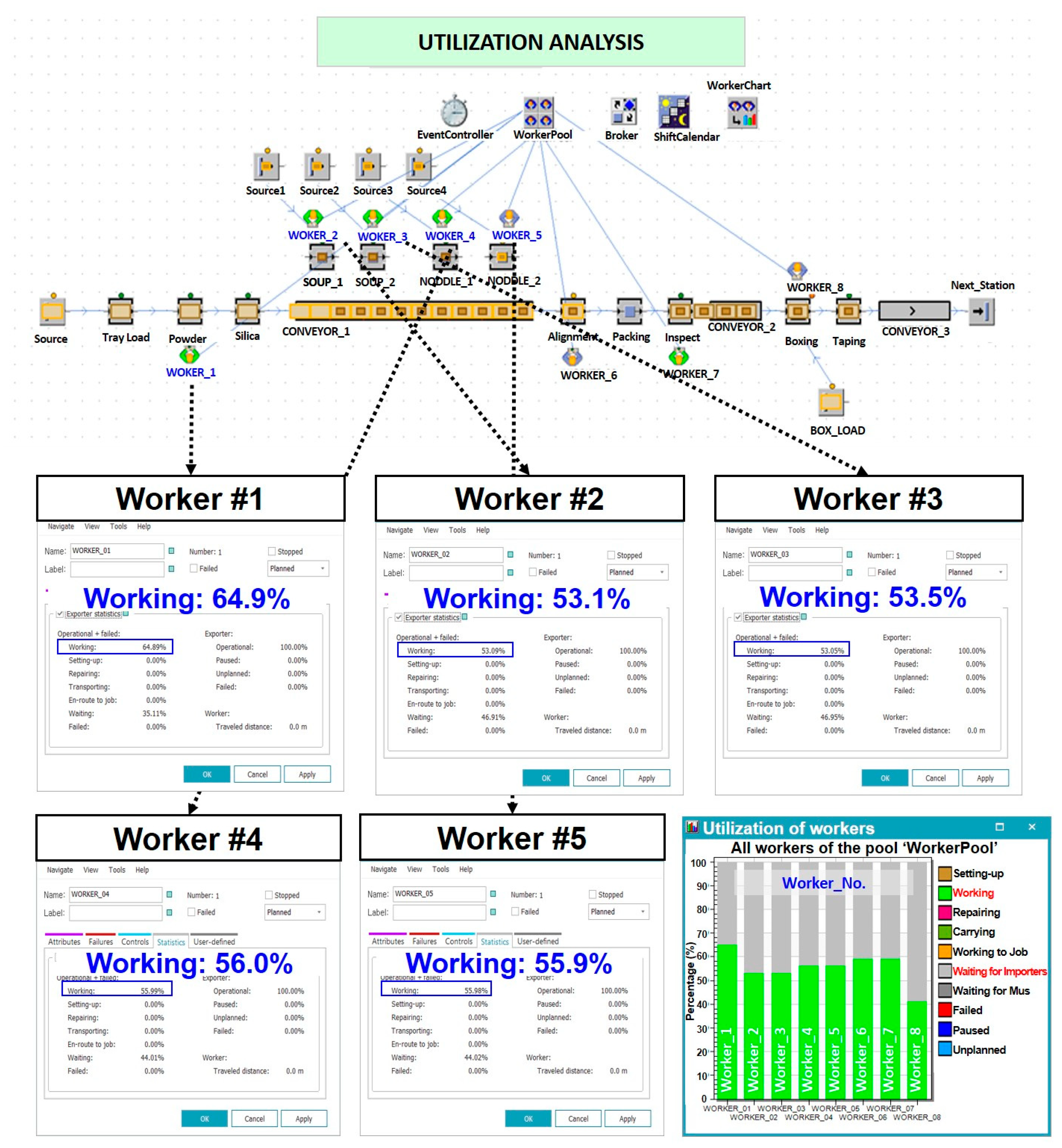

2.1. Analysis of Existing Manual Process of Packaging the Meal Kit Product

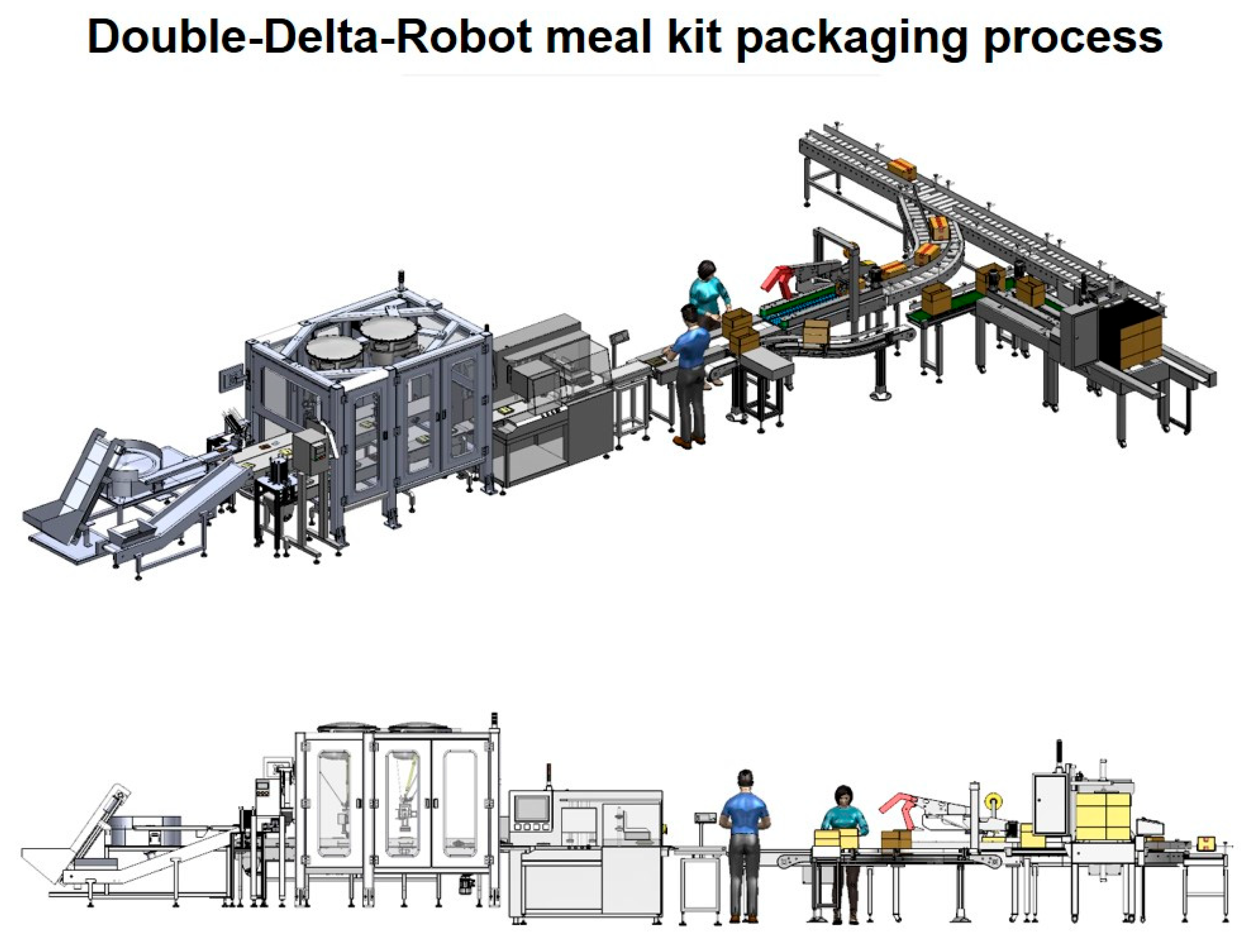

2.2. 3D-Model, Meal Kit, Robot Automation System

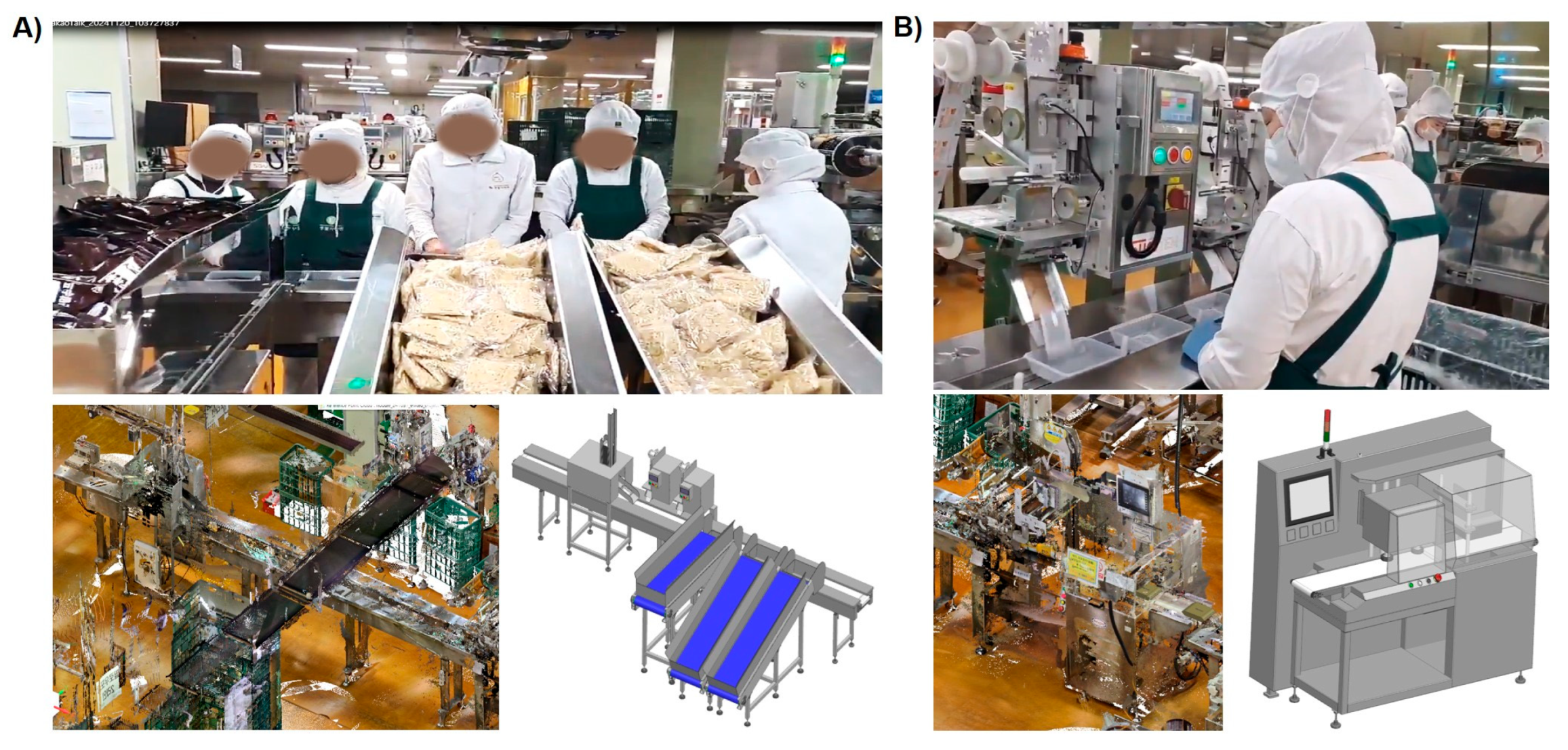

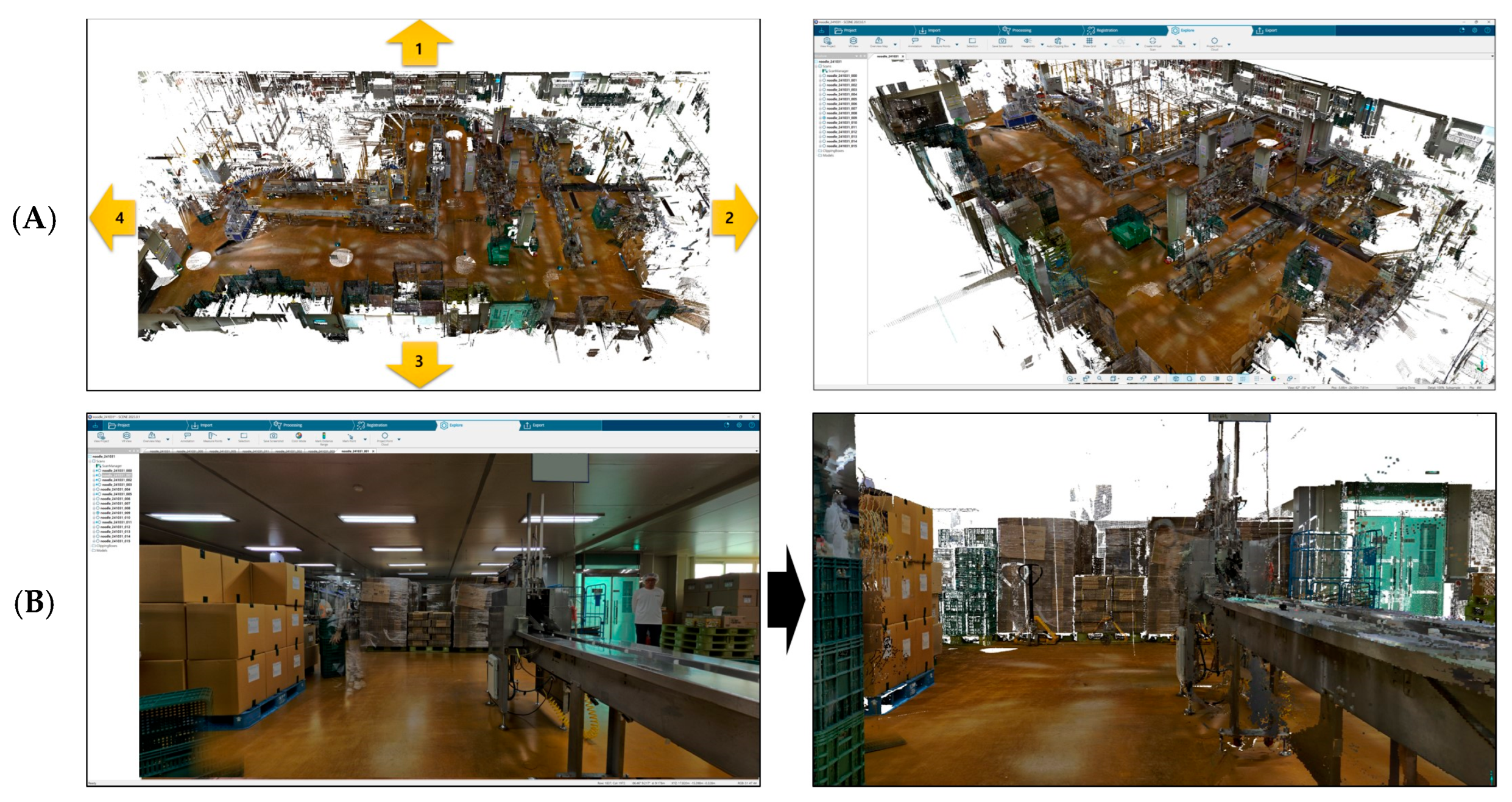

2.2.1. 3D Scanning of Existing Meal Kit Production Site

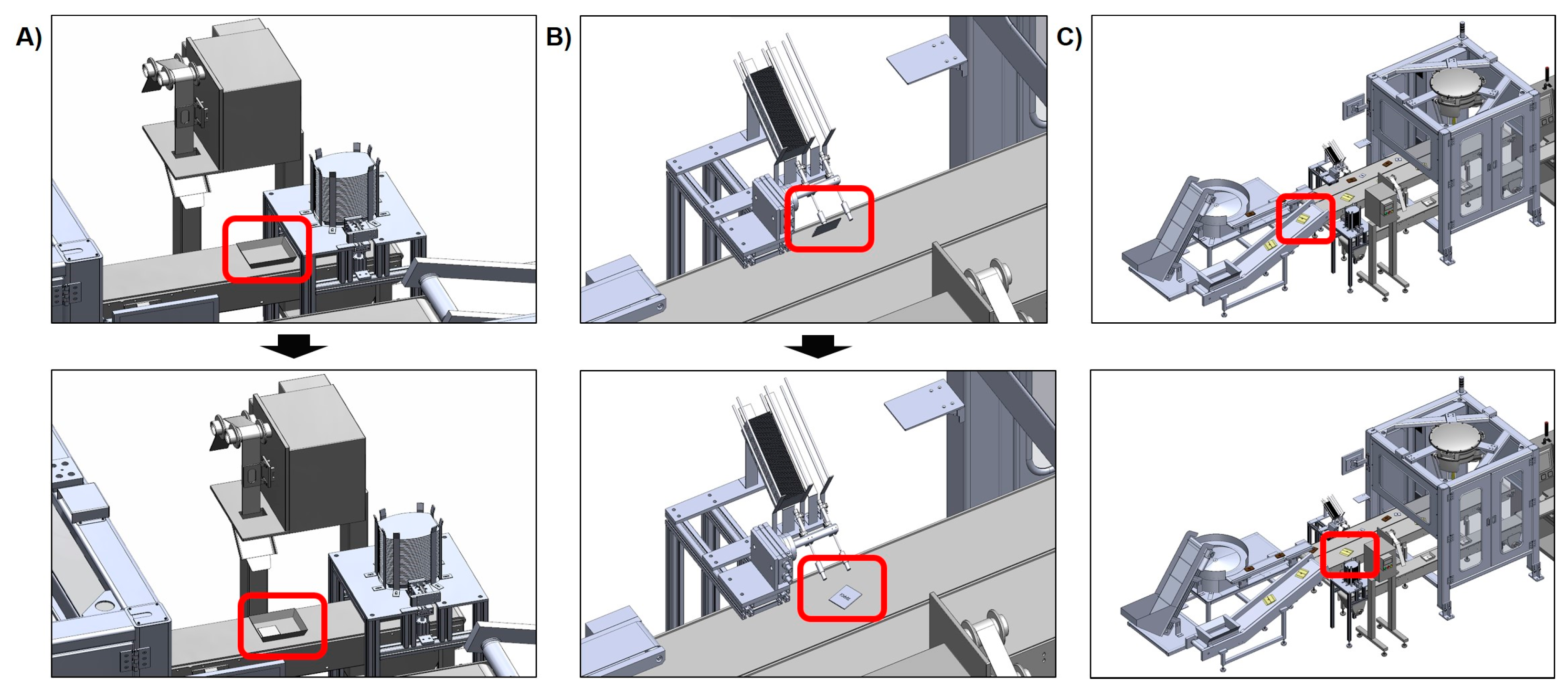

2.2.2. 3D Modeling of Existing Meal Kit Packaging Process’s Layout

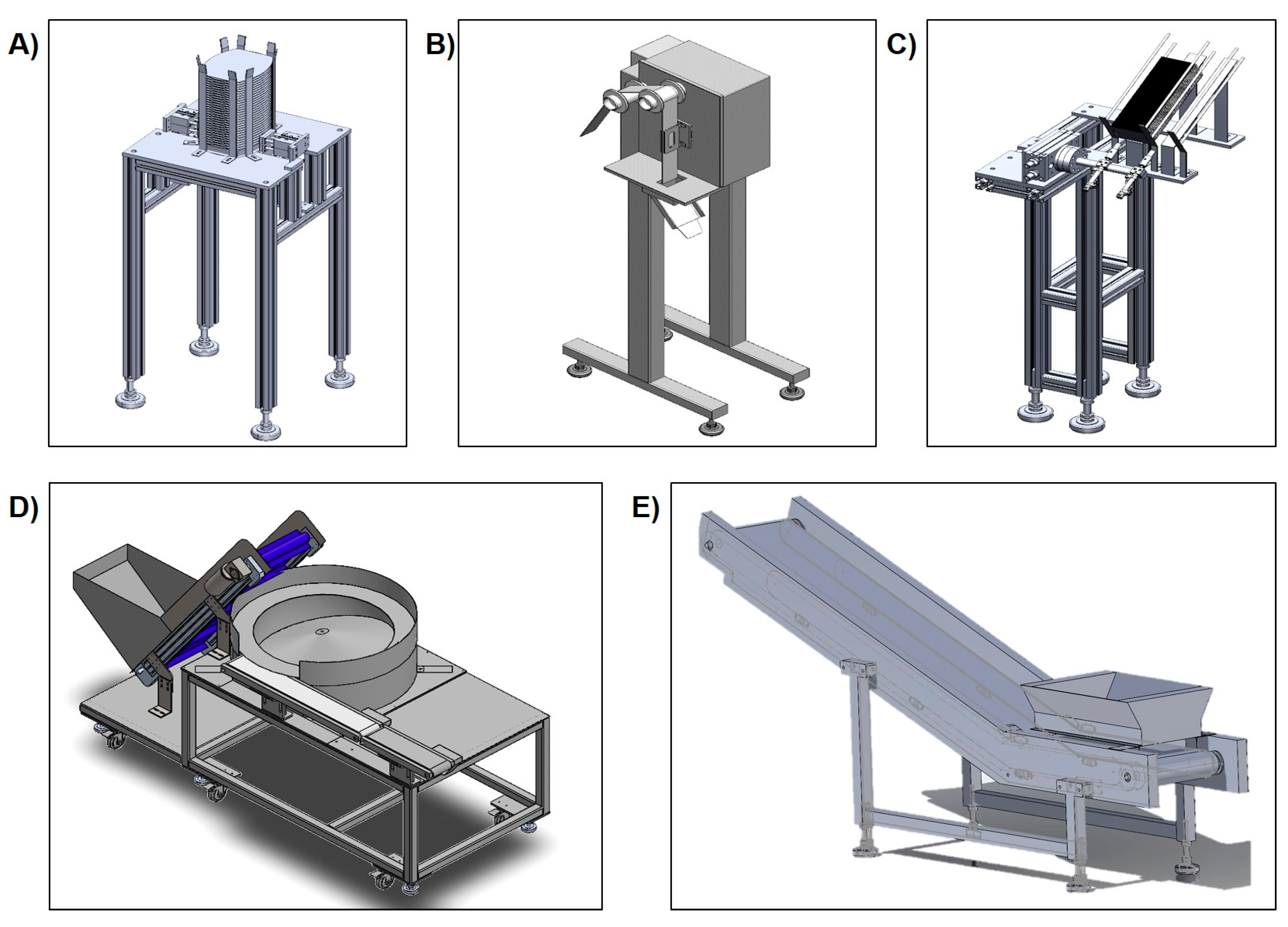

2.2.3. 3D Modeling of Robot-Implemented Meal Kit Packaging Process

2.3. Development of Robot-Automated 3D Simulation of Meal Kit Packaging Process

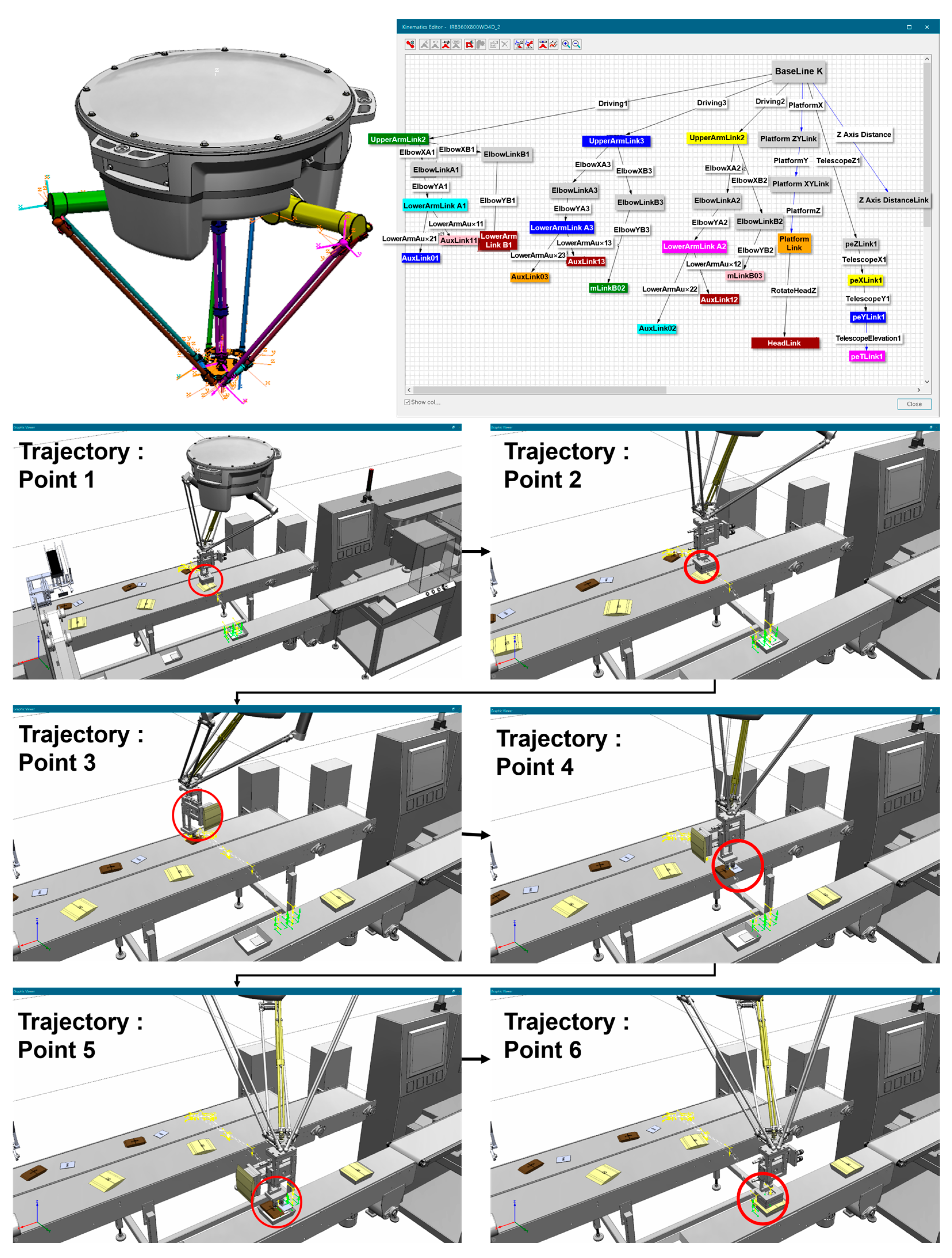

Application of Delta Robot to Novel, Hybrid 3D Simulation of the Assembly Line for Robot Automation Packaging of Meal Kits

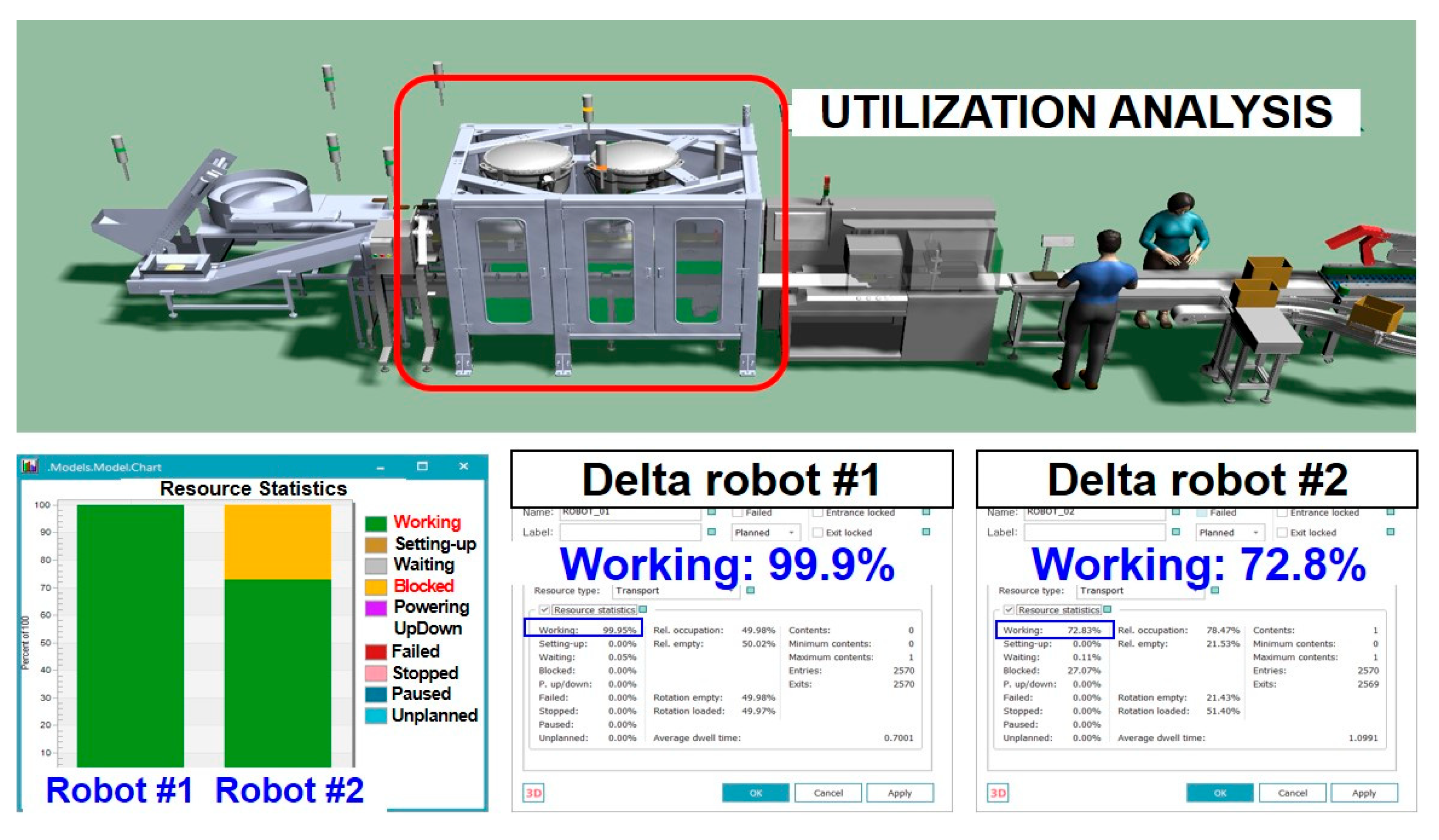

2.4. Performance Analysis of Robot Automation System

3. Results and Discussion

3.1. Result of 3D Scanning of Existing Production Site

3.2. Result of Manual Meal Kit Packaging Process

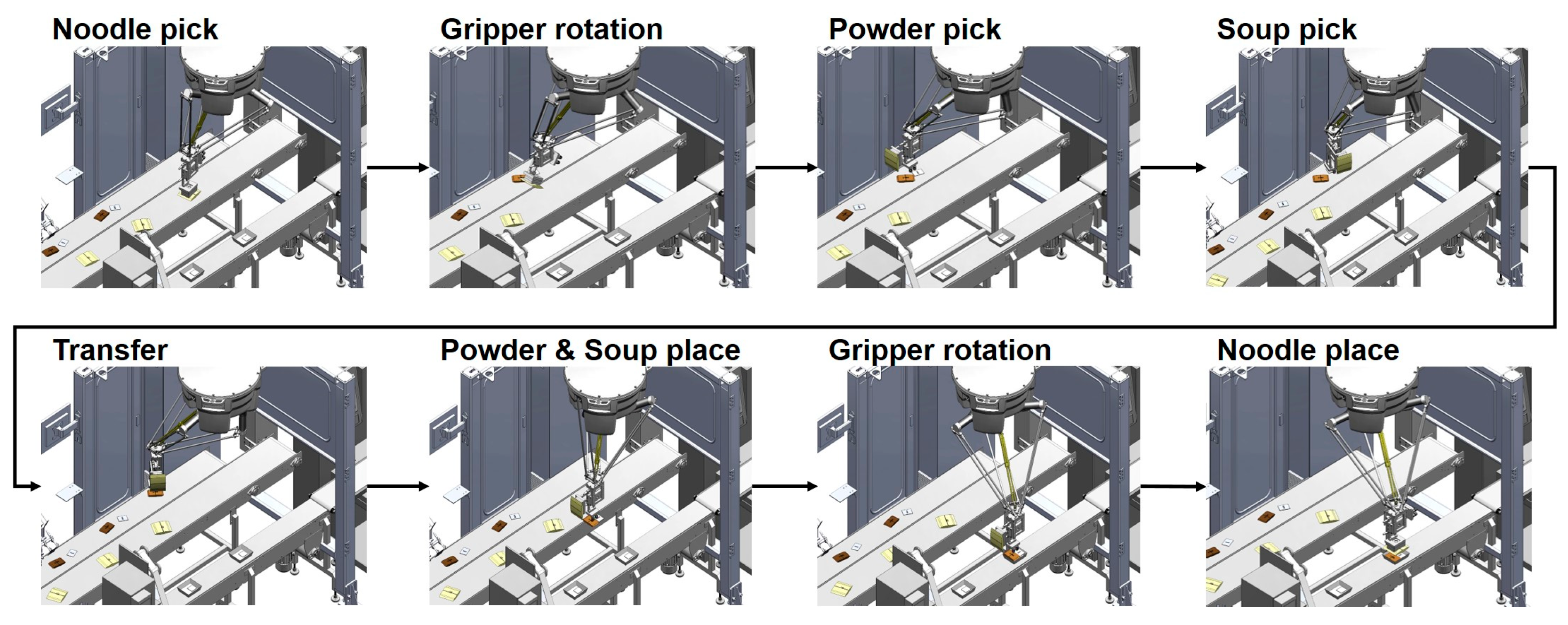

3.3. Result of Single-Delta-Robot-Implemented Meal Kit Packaging Process

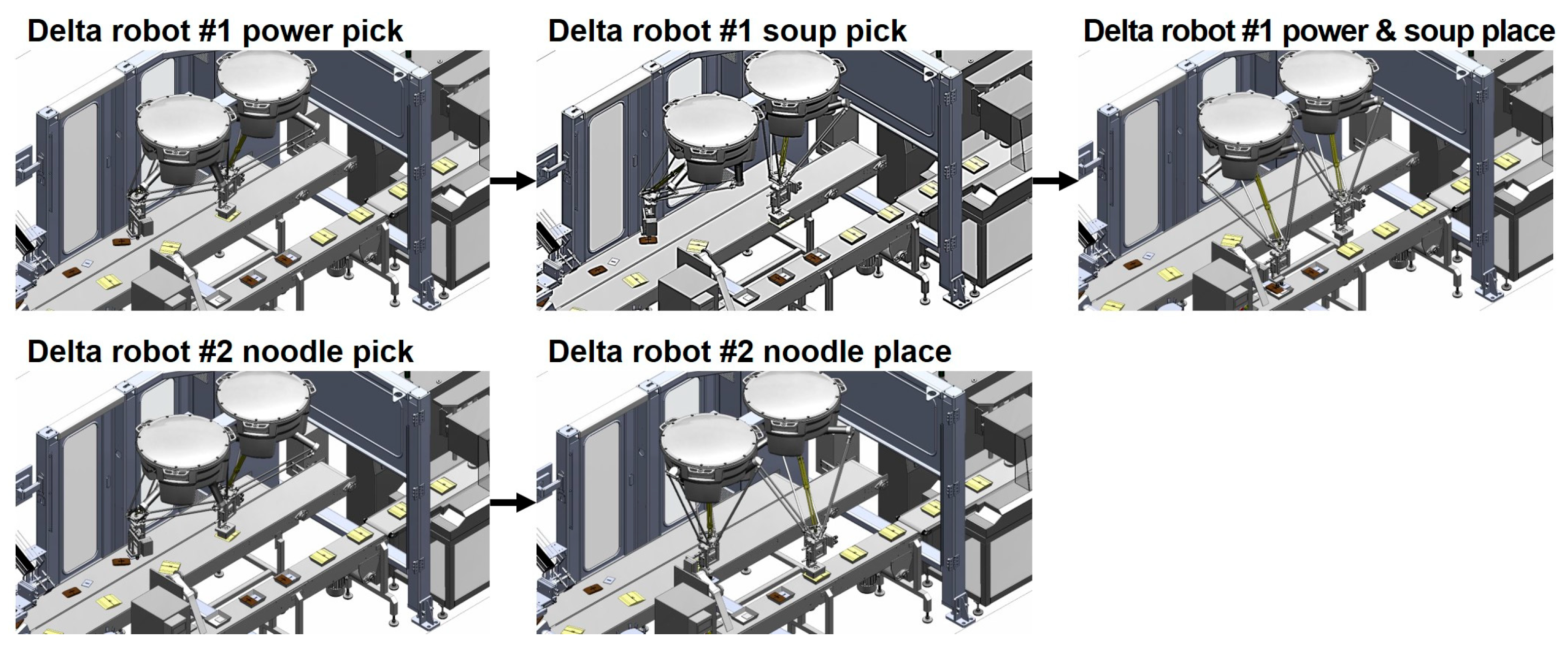

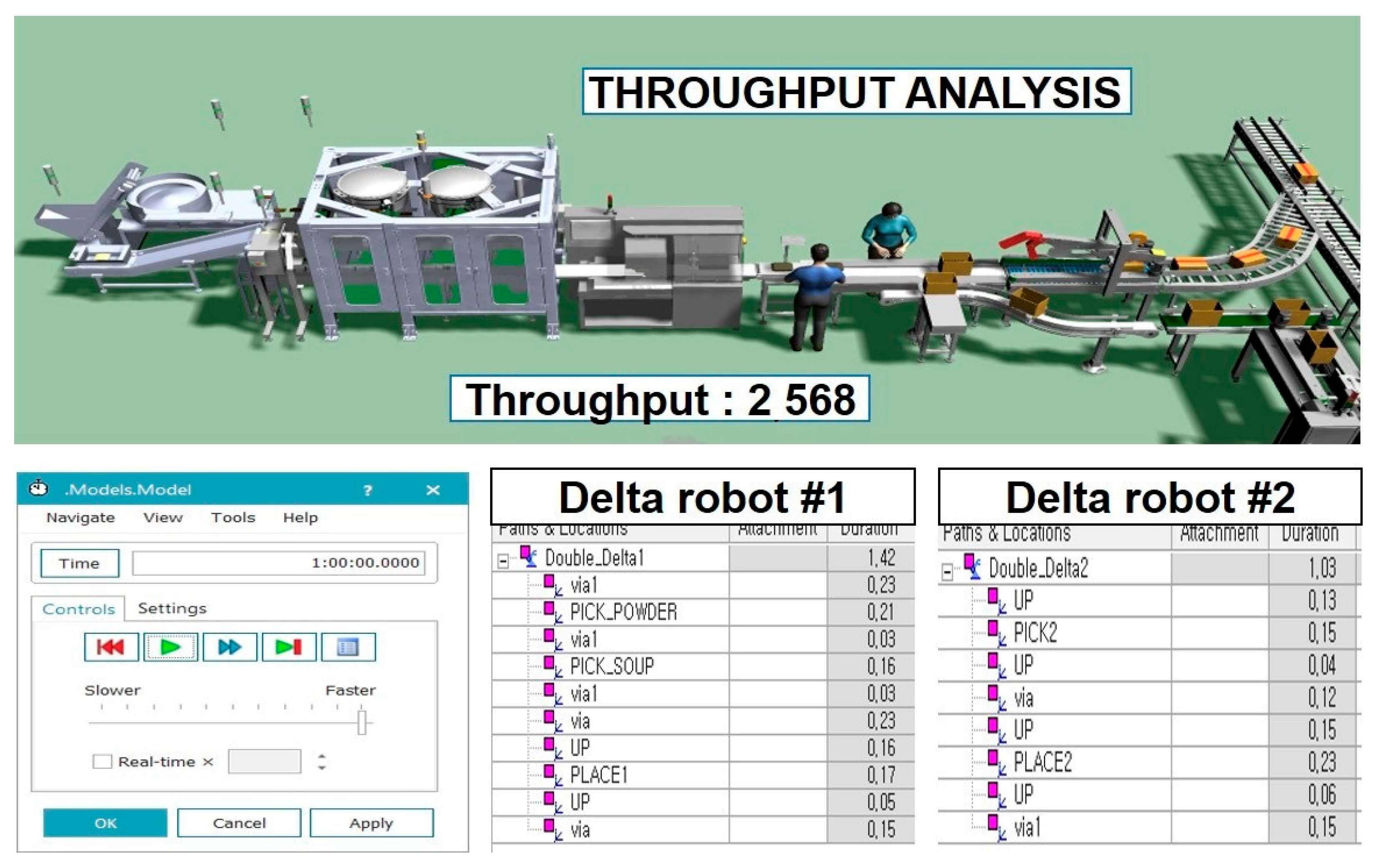

3.4. Result of Double-Delta-Robot-Implemented Meal Kit Packaging Process

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HMR | Home Meal Replacement |

| TPS | Tecnomatix Process Simulate |

| CAD | Computer-Aided Design |

| KPI | Key Performance Indicators |

References

- Bumbudsanpharoke, N.; Ko, S. Packaging technology for home meal replacement: Innovations and future prospective. Food Control 2022, 132, 108470. [Google Scholar] [CrossRef]

- Rha, J.Y.; Lee, H.; Kim, S.; Nam, Y. A study on the relationship between purchases of meal kits and home meal replacements. Nutr. Res. Pract. 2024, 18, 425–435. [Google Scholar] [CrossRef] [PubMed]

- Mahalik, N.P. Processing and packaging automation systems: A review. Sens. Instrum. Food Qual. Saf. 2009, 3, 12–25. [Google Scholar] [CrossRef]

- Mahalik, N.P.; Yen, M. Extending fieldbus technology to food processing industry: A review. Comput. Stand. Interfaces 2009, 31, 586–598. [Google Scholar] [CrossRef]

- Bader, F.; Rahimifard, S. Challenges for industrial robot applications in food manufacturing. In Proceedings of the 2nd International Symposium on Computer Science and Intelligent Control, Stockholm, Sweden, 21–23 September 2018; pp. 1–8. [Google Scholar]

- Mahmoodi, E.; Fathi, M.; Tavana, M.; Ghobakhloo, M.; Ng, A.H. Data-driven simulation-based decision support system for resource allocation in industry 4.0 and smart manufacturing. J. Manuf. Syst. 2024, 72, 287–307. [Google Scholar] [CrossRef]

- Florescu, A. Digital twin for flexible manufacturing systems and optimization through simulation: A case study. Machines 2024, 12, 785. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Digital twin for smart manufacturing, A review. Sustain. Manuf. Serv. Econ. 2023, 2, 100017. [Google Scholar] [CrossRef]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Srasrisom, K.; Srinoi, P.; Chaijit, S.; Wiwatwongwana, F. Improvement of an Automated CAN Packaging System Based on Modeling and Analysis Approach through Robot Simulation Tools. Int. J. Robot. Autom. 2020, 9, 178–189. [Google Scholar] [CrossRef]

- Jha, A.; Soni, M.; Suhaib, M. Simulation and Kinematic Analysis of KUKA KR5 Arc Robot. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1149, p. 012005. [Google Scholar]

- Gui, W.; Zhou, F.; Tang, F. Research on Motion Simulation of Stacking Robot Workstation Based on RobotStudio. In Proceedings of the 2023 IEEE 3rd International Conference on Power, Electronics and Computer Applications (ICPECA), Shenyang, China, 29–31 January 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 301–305. [Google Scholar]

- Vasudevan, S.; Mekhalfi, M.L.; Blanes, C.; Lecca, M.; Poiesi, F.; Chippendale, P.I.; Lastra, J.L.M. Robotics and Machine Vision for Primary Food Manipulation and Packaging: A Survey. IEEE Access 2024, 12, 152579–152613. [Google Scholar] [CrossRef]

- Afizul, N.A.; Selimin, M.A.; Pagan, N.A.; Ng, K.Y. Modelling an Assembly Line Using Tecnomatix Plant Simulation Software. Res. Manag. Technol. Bus. 2024, 5, 1048–1055. [Google Scholar]

- Janekova, J.; Fabianova, J.; Kadarova, J. Optimization of the automated production process using software simulation tools. Processes 2023, 11, 509. [Google Scholar] [CrossRef]

- Fedorko, G.; Molnár, V.; Strohmandl, J.; Horváthová, P.; Strnad, D.; Cech, V. Research on Using the Tecnomatix Plant Simulation for Simulation and Visualization of Traffic Processes at the Traffic Node. Appl. Sci. 2022, 12, 12131. [Google Scholar] [CrossRef]

- Fusto, C.; Longo, F.; Muraca, A.; Rudi, L.; Timpani, T.; Veltri, P. Enhancing Efficiency in the Food Industry: A Simulation Model for Optimizing Production Processes. In Proceedings of the 9th International Food Operations & Processing Simulation Workshop (FOODOPS 2023), Athens, Greece, 18–20 September 2023. [Google Scholar]

- Wang, J.; Yi, T.; Liang, X.; Ueda, T. Application of 3D Laser Scanning Technology Using Laser Radar System to Error Analysis in the Curtain Wall Construction. Remote Sens. 2022, 15, 64. [Google Scholar] [CrossRef]

- Di Stefano, F.; Chiappini, S.; Gorreja, A.; Balestra, M.; Pierdicca, R. Mobile 3D scan LiDAR: A literature review. Geomat. Nat. Hazards Risk 2021, 12, 2387–2429. [Google Scholar] [CrossRef]

- Kim, T.H.; Byoung, G.; Kwon, K.H.; Kim, A.N. Plant Simulation for Robot Automation System of Deep-Frying Process of Kimbugak. Food Sci. Biotechnol. 2025, 34, 503–514. [Google Scholar] [CrossRef]

- Cheng, H.; Li, W. Reducing the frame vibration of delta robot in pick and place application: An acceleration profile optimization approach. Shock Vib. 2018, 2018, 2945314. [Google Scholar] [CrossRef]

- Kansal, S.; Mukherjee, S. Vision-Based Kinematic Analysis of the Delta Robot for Object Catching. Robotica 2022, 40, 2010–2030. [Google Scholar] [CrossRef]

- Gholami, A.; Homayouni, T.; Ehsani, R.; Sun, J.Q. Inverse Kinematic Control of a Delta Robot Using Neural Networks in Real-Time. Robotics 2021, 10, 115. [Google Scholar] [CrossRef]

- Aliev, K.; Antonelli, D.; Awouda, A.; Chiabert, P. Key performance indicators integrating collaborative and mobile robots in the factory networks. In Proceedings of the Collaborative Networks and Digital Transformation: 20th IFIP WG 5.5 Working Conference on Virtual Enterprises, PRO-VE 2019, Turin, Italy, 23–25 September 2019; Springer International Publishing: New York, NY, USA; pp. 635–642. [Google Scholar]

- Frohlich, C.; Mettenleiter, M. Terrestrial laser scanning–new perspectives in 3D surveying. Int. Arch. Photogramm. Remote Sens. Spatial Inf. Sci. 2004, 36, W2. [Google Scholar]

- Yilmaz, A.; Sumer, E.; Temeltas, H. A precise scan matching based localization method for an autonomously guided vehicle in smart factories. Robot. Comput. Integr. Manuf. 2022, 75, 102302. [Google Scholar] [CrossRef]

| KPI Index | Manual | Robot Automation | |

|---|---|---|---|

| Single Delta Robot | Double Delta Robot | ||

| Utilization rate (%) | 64.8, 53.1, 53.1, 56.0, 55.9 | 99.9 | 98.0, 78.5 |

| Throughput (ea/h) | 2112 | 1510 | 2568 |

| Number of employee | 8 | 2 | 2 |

| 1 Cycle time (s) | - | 2.36 | 1.42, 1.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, T.H.; Gu, B.I.; Kwon, K.H.; Kim, A.-N. A Framework for 3D Plant Simulation of Meal-Kit-Packaging Robot Automation System. Appl. Sci. 2025, 15, 4116. https://doi.org/10.3390/app15084116

Kim TH, Gu BI, Kwon KH, Kim A-N. A Framework for 3D Plant Simulation of Meal-Kit-Packaging Robot Automation System. Applied Sciences. 2025; 15(8):4116. https://doi.org/10.3390/app15084116

Chicago/Turabian StyleKim, Tae Hyong, Byoung Il Gu, Ki Hyun Kwon, and Ah-Na Kim. 2025. "A Framework for 3D Plant Simulation of Meal-Kit-Packaging Robot Automation System" Applied Sciences 15, no. 8: 4116. https://doi.org/10.3390/app15084116

APA StyleKim, T. H., Gu, B. I., Kwon, K. H., & Kim, A.-N. (2025). A Framework for 3D Plant Simulation of Meal-Kit-Packaging Robot Automation System. Applied Sciences, 15(8), 4116. https://doi.org/10.3390/app15084116