Risk Assessment of Drilling and Blasting Method Based on Nonlinear FAHP and Combination Weighting

Abstract

1. Introduction

2. Construction of Risk Assessment Indicators for Drilling and Blasting Method Based on the WBS—RBS Method

2.1. Developing a Work Breakdown Structure

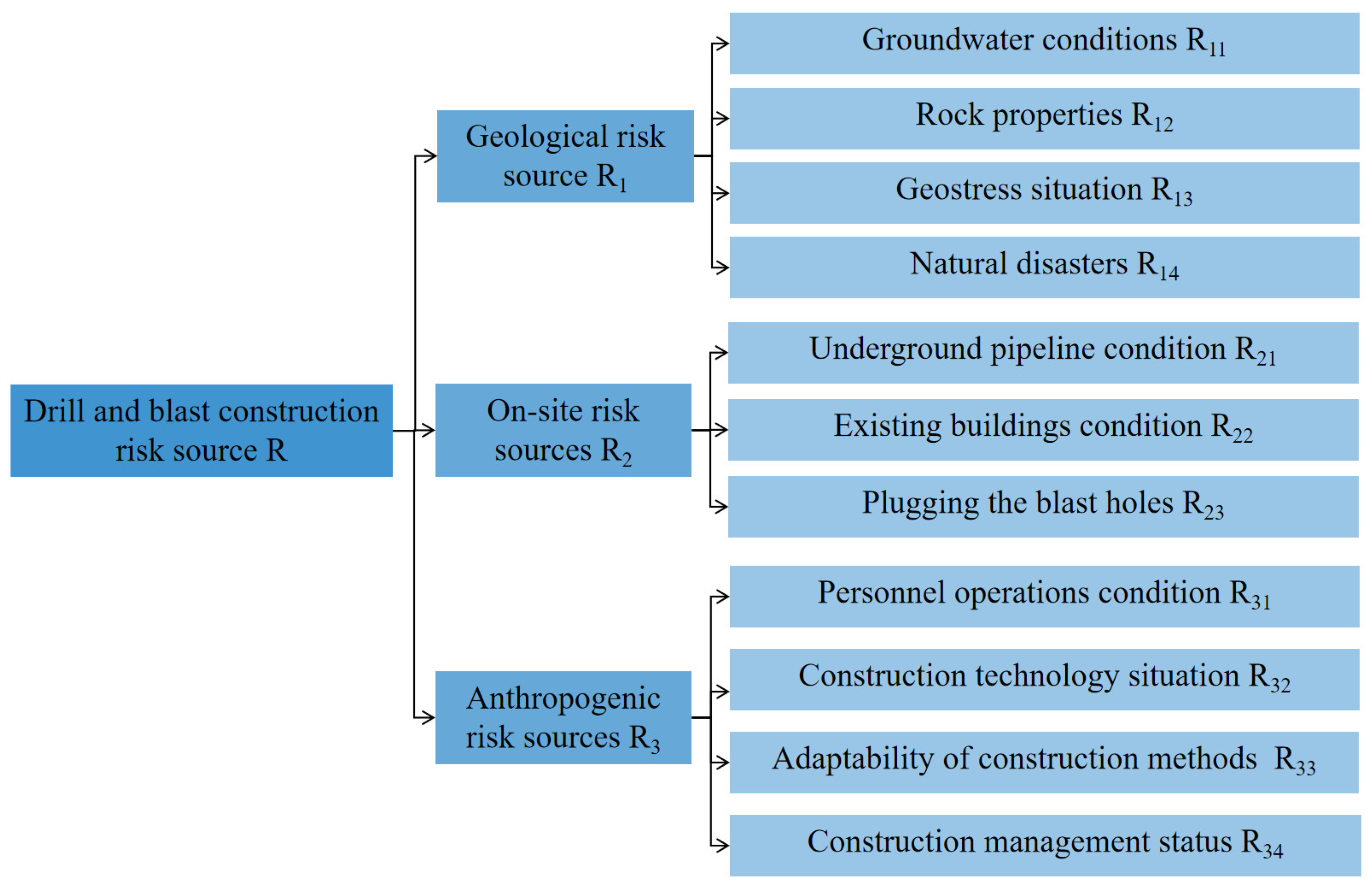

2.2. Risk Source Breakdown Structure

2.3. Risk Identification Coupling Matrix

2.4. Construction of the Risk Assessment Index System

3. Risk Assessment Methodology

3.1. Construction of the Fuzzy Relation Matrix

3.1.1. Determination of Comment Set

3.1.2. Construction of the Membership Degree Vector

3.1.3. Construction of the Fuzzy Evaluation Matrix

3.2. Determination of Weight Vectors

3.2.1. Calculation of Subjective Weight Using AHP

3.2.2. Calculation of Objective Weights Using PCA

3.2.3. Calculation of Combined Weights Using Game Theory

3.3. Nonlinear Fuzzy Comprehensive Evaluation

3.4. New Risk Assessment Model

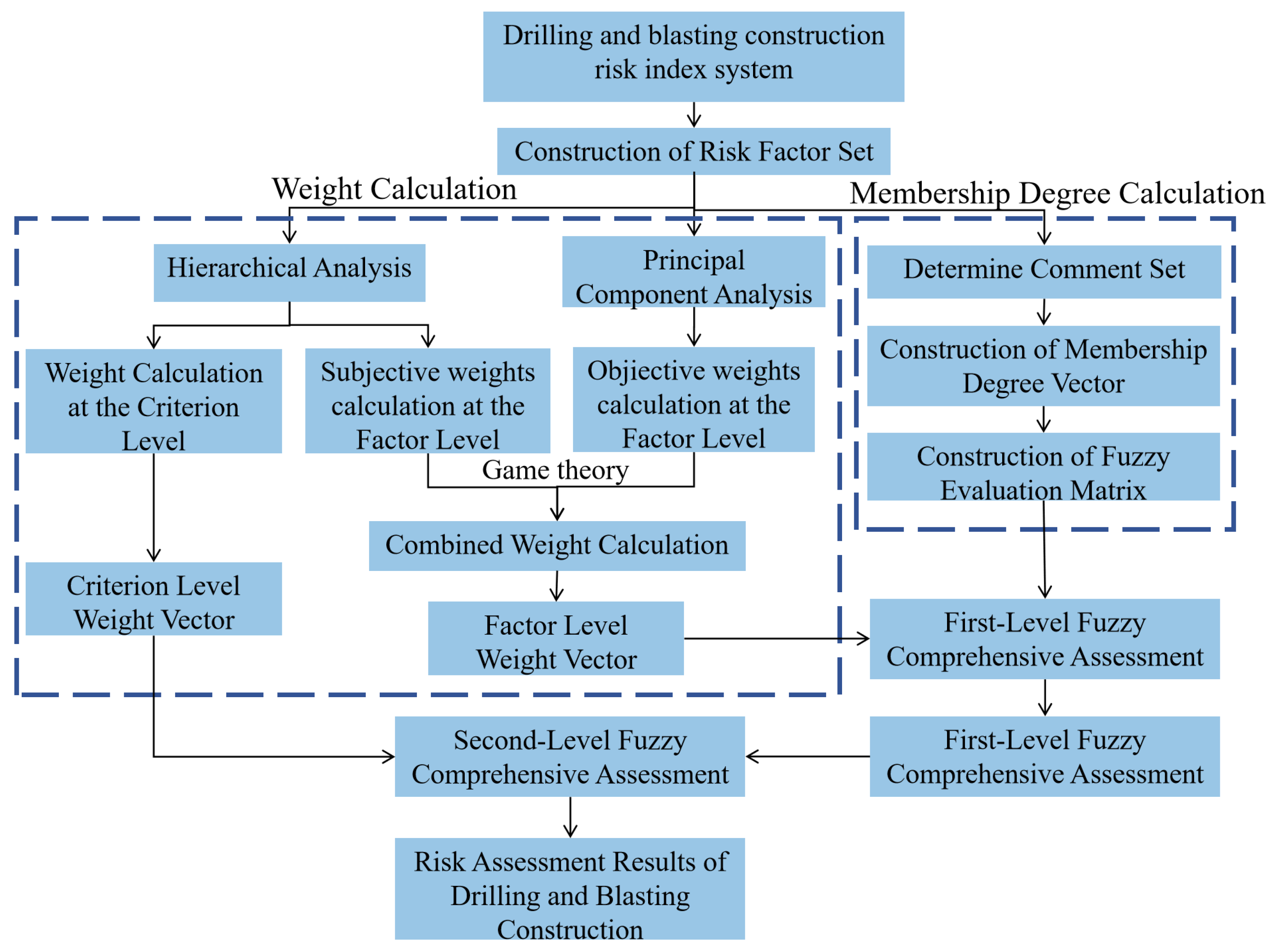

- (1)

- For the weight part, compare the importance of each risk indicator in the risk factor set using the 1–9 scale method, obtain the corresponding judgment matrix, and perform consistency testing using the consistency ratio (CR). If the consistency test is not satisfied, reconstruct the judgment matrix for adjustment. Solve the judgment matrix that satisfies the consistency test to obtain the maximum eigenvalue and corresponding eigenvector, normalize the eigenvector to obtain the subjective weights and indicator layer weights. Use PCA to extract principal components from the expert scoring data and further calculate the objective weights of each indicator. Use the game theory combined weighting method to coordinate and allocate subjective and objective weights, then combine the subjective and objective weights to obtain the combined weights of the factor layer.

- (2)

- For the membership degree part, construct the corresponding risk assessment set and risk factor set, use the expert evaluation method to evaluate the indicators of the risk factor set to obtain the membership degree vector, and then convert it into a fuzzy relation matrix.

- (3)

- Substitute the combined weights of the secondary indicators and the fuzzy relation matrix into the nonlinear fuzzy comprehensive evaluation to obtain the evaluation result vector and convert it into a fuzzy evaluation matrix. Combine the indicator layer weights for secondary nonlinear fuzzy comprehensive evaluation to obtain the secondary nonlinear fuzzy comprehensive evaluation result vector, and determine the risk level based on the membership degree. The evaluation process is shown in Figure 4.

- (4)

- Compared with existing evaluation systems, the new model improves the risk identification method and the weight part that significantly affects the evaluation results. The weights are divided into subjective and objective parts, and the game theory combined weighting method is used to integrate the subjective and objective weights, combining the advantages of both weighting methods, reducing subjectivity, and obtaining a combined weight that is more consistent with the actual situation. At the same time, a nonlinear operator is introduced for comprehensive calculation, making the evaluation results more reasonable.

4. Case Study

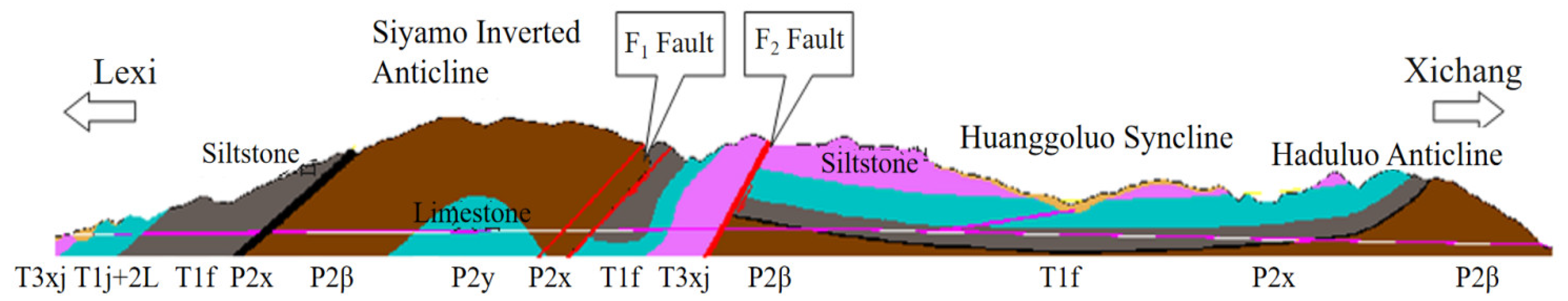

4.1. Project Overview

4.2. Calculation of Risk Indicator Weights

4.2.1. Calculation of Subjective Weight

4.2.2. Calculation of Objective Weight

4.2.3. Calculation of Combined Weights

4.3. Membership Calculation

4.4. Determination of Prominent Influence Coefficients for Risk Factors

4.5. First-Level Nonlinear Fuzzy Comprehensive Evaluation

4.6. Second-Level Nonlinear Fuzzy Comprehensive Evaluation

4.7. Countermeasures

5. Discussion

5.1. Rationality Analysis of Index Weight

- (1)

- Conventional FAHP [38] employs fuzzy numbers for pairwise comparisons by experts to construct judgment matrices and calculate weights, followed by consistency verification.

- (2)

- LFPP-FAHP [31] utilizes logarithmic fuzzy preference programming (LFPP) to determine the weights of evaluation indicators, incorporating field conditions to establish reliability functions for dynamic indicators and grading criteria for indicator rationality.

- (3)

- FAHP-SPA [39] applies triangular fuzzy analytic hierarchy process (FAHP) to determine the fuzzy weights of evaluation indicators. At the objective level, the set pair analysis (SPA) method compares the affiliation between indicator sets and standard sets to define the ranking scope of evaluation criteria. Finally, a combined subjective–objective approach determines the overall risk level of tunnel operational safety.

5.2. Rationality of Evaluation Results

5.3. Limitations and Future Work

6. Conclusions

- (1)

- A comprehensive risk evaluation system was established by coupling work breakdown structure (WBS) and risk breakdown structure (RBS), effectively linking construction tasks with potential risks. This approach minimized omissions and overlaps in risk identification, providing a structured framework for assessing drilling and blasting construction risks.

- (2)

- The game theory combined weighting method was used to integrate the subjective weights calculated by the analytic hierarchy process and the objective weights calculated by principal component analysis. By applying group decision-making principles, a more reliable combined weight for the evaluation results was established, improving the rationality of the risk assessment results for drilling and blasting methods of construction and addressing the limitations inherent in single weighting methods.

- (3)

- Based on the combined weights, a nonlinear operator was introduced to perform a nonlinear fuzzy comprehensive evaluation of the drilling and blasting method construction section at the flat guide entrance of the Daliangshan No. 1 Tunnel. The prominent influence coefficients were determined subjectively, balancing the potential weakening of significant risk factors in traditional linear weighted averages. The results of the linear FAHP and nonlinear FAHP were compared, validating the rationality of the nonlinear FAHP evaluation results.

- (4)

- The model was applied to the Daliangshan No. 1 Tunnel, identifying the overall risk level as high. Key secondary risk factors, such as detonation network reliability and ventilation system performance, were highlighted. Comparative analysis demonstrated the model’s superior accuracy in weight determination and risk classification over conventional methods.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, D.; Song, Z.; Xu, T.; Zhang, Y.; Ding, L. Coupling Analysis of Tunnel Construction Risk in Complex Geology and Construction Factors. J. Constr. Eng. Manag. 2022, 148, 13. [Google Scholar] [CrossRef]

- Huo, R.; Li, S.; Song, Z.; Fujii, Y.; Lei, S.; Mao, J.; Tian, S.; Miao, Z. Analysis of Vibration Response Law of Multistory Building under Tunnel Blasting Loads. Adv. Civ. Eng. 2019, 2019, 6452657. [Google Scholar] [CrossRef]

- Tian, X.; Song, Z.; Wang, J. Study on the propagation law of tunnel blasting vibration in stratum and blasting vibration reduction technology—ScienceDirect. Soil Dyn. Earthq. Eng. 2019, 126, 105813. [Google Scholar] [CrossRef]

- Song, Z.P.; Li, S.H.; Wang, J.B.; Sun, Z.Y.; Liu, J.; Chang, Y.Z. Determination of equivalent blasting load considering millisecond delay effect. Geomech. Eng. 2018, 15, 745–754. [Google Scholar]

- Ou, G.Z.; Jiao, Y.Y.; Zhang, G.H.; Zou, J.P.; Tan, F.; Zhang, W.S. Collapse risk assessment of deep-buried tunnel during construction and its application. Tunn. Undergr. Space Technol. 2021, 115, 17. [Google Scholar] [CrossRef]

- Wu, B.; Zeng, J.; Zhu, R.; Zheng, W.; Liu, C. A Multi-Source Data Fusion Method for Assessing the Tunnel Collapse Risk Based on the Improved Dempster–Shafer Theory. Appl. Sci. 2023, 13, 5606. [Google Scholar] [CrossRef]

- Xu, T.; Song, Z.P.; Guo, D.S.; Song, Y.C. A Cloud Model-Based Risk Assessment Methodology for Tunneling-Induced Damage to Existing Tunnel. Adv. Civ. Eng. 2020, 2020, 11. [Google Scholar] [CrossRef]

- Meng, G.W.; Liu, J.L.; Qiu, W.X.; Wu, B.; Xu, S.X. A Failure Probability Evaluation Method for the Collapse of Drill-Blast Tunnels Based on a Multistate Cloud Bayesian Network. Front. Earth Sci. 2022, 10, 9. [Google Scholar] [CrossRef]

- Ou, X.D.; Wu, Y.F.; Wu, B.; Jiang, J.; Qiu, W.X. Dynamic Bayesian Network for Predicting Tunnel-Collapse Risk in the Case of Incomplete Data. J. Perform. Constr. Facil. 2022, 36, 12. [Google Scholar] [CrossRef]

- Jiang, J.; Liu, G.Y.; Ou, X.D. Risk Coupling Analysis of Deep Foundation Pits Adjacent to Existing Underpass Tunnels Based on Dynamic Bayesian Network and N-K Model. Appl. Sci. 2022, 12, 10467. [Google Scholar] [CrossRef]

- Yang, C.T.; Zhang, R.P.; Liu, D.W.; Tang, Y.; Huang, R.D.; Qiu, W.C. Evaluation of Excavation Ergonomics of Drill and Blast Method Based on Game Theory G2-EW-TOPSIS Model. Appl. Sci. 2023, 13, 7205. [Google Scholar] [CrossRef]

- Zhang, G.H.; Chen, W.; Jiao, Y.Y.; Wang, H.; Wang, C.T. A failure probability evaluation method for collapse of drill-and-blast tunnels based on multistate fuzzy Bayesian network. Eng. Geol. 2020, 276, 105752. [Google Scholar] [CrossRef]

- Liu, G.F.; Feng, X.T.; Feng, G.L.; Chen, B.R.; Chen, D.F.; Duan, S.Q. A Method for Dynamic Risk Assessment and Management of Rockbursts in Drill and Blast Tunnels. Rock Mech. Rock Eng. 2016, 49, 3257–3279. [Google Scholar] [CrossRef]

- Saaty, T.L. Analytic hierarchy process. In Encyclopedia of Operations Research and Management Science; Gass, S.I., Harris, C.M., Eds.; Springer: New York, NY, USA, 2001. [Google Scholar] [CrossRef]

- Wang, J.X.; Cao, A.S.; Wu, Z.; Sun, Z.P.; Lin, X.; Sun, L.; Liu, W.J.; Liu, X.T.; Li, H.B.Q.; Sun, Y.W.; et al. Dynamic Risk Assessment of Ultra-Shallow-Buried and Large-Span Double-Arch Tunnel Construction. Appl. Sci. 2021, 11, 11721. [Google Scholar] [CrossRef]

- Ding, X.B.; Xie, A.Y.; Yang, H.T.; Li, S.J. Quantifying Multifactor Effects on Mud Cake Formation Risk for a Tunnel Boring Machine with the Analytical Hierarchy Process. Buildings 2023, 13, 355. [Google Scholar] [CrossRef]

- Kim, J.; Kim, C.; Kim, G.; Kim, I.; Abbas, Q.; Lee, J. Probabilistic tunnel collapse risk evaluation model using analytical hierarchy process (AHP) and Delphi survey technique. Tunn. Undergr. Space Technol. 2022, 120, 12. [Google Scholar] [CrossRef]

- Meng, G.W.; Ye, Y.C.; Wu, B.; Luo, G.J.; Zhang, X.; Zhou, Z.Q.; Sun, W.T. Risk Assessment of Shield Tunnel Construction in Karst Strata Based on Fuzzy Analytic Hierarchy Process and Cloud Model. Shock Vib. 2021, 2021, 16. [Google Scholar] [CrossRef]

- Nezarat, H.; Sereshki, F.; Ataei, M. Ranking of geological risks in mechanized tunneling by using Fuzzy Analytical Hierarchy Process (FAHP). Tunn. Undergr. Space Technol. 2015, 50, 358–364. [Google Scholar] [CrossRef]

- Ren, X.; He, T.H.; He, P.F.; Yue, F.; Yang, B. A Case Study on Fuzzy Analytic Hierarchy Process Analysis of Factors Influencing the Stability of Surrounding Rock in Water-Rich Loess Tunnels and Corresponding Disposal Strategies. Appl. Sci. 2025, 15, 1835. [Google Scholar] [CrossRef]

- Habashneh, M.; Cucuzza, R.; Aela, P.; Rad, M.M. Reliability-based topology optimization of imperfect structures considering uncertainty of load position. Structures 2024, 69, 14. [Google Scholar] [CrossRef]

- Hyun, K.C.; Min, S.; Choi, H.; Park, J.; Lee, I.M. Risk analysis using fault-tree analysis (FTA) and analytic hierarchy process (AHP) applicable to shield TBM tunnels. Tunn. Undergr. Space Technol. 2015, 49, 121–129. [Google Scholar] [CrossRef]

- Chankham, W. Risk Analysis of Underground Tunnel Construction with Tunnel Boring Machine by Using Fault Tree Analysis and Fuzzy Analytic Hierarchy Process. Safety 2024, 10, 68. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, J.; Zhu, K.; Guo, P.; Shen, C.; Xiong, Z. The Safety Risk Assessment of Mine Metro Tunnel Construction Based on Fuzzy Bayesian Network. Buildings 2023, 13, 1605. [Google Scholar] [CrossRef]

- Zheng, W.Q.; Xu, S.X.; Wang, Z.C. Fuzzy Comprehensive Evaluation of Collapse Risk in Mountain Tunnels Based on Game Theory. Appl. Sci. 2024, 14, 5163. [Google Scholar] [CrossRef]

- Ma, J.F.; Cui, G.Y.; He, S.H.; Ling, X.K. Assessment and Control of Construction Risk for a Super-Sized Quasi-Rectangular Pipe-Jacking Tunnel Adjacently to High-Speed Railways: A Case Study. Ksce J. Civ. Eng. 2023, 27, 4520–4533. [Google Scholar] [CrossRef]

- Kong, H.Q.; Zhang, N. Risk assessment of water inrush accident during tunnel construction based on FAHP-I-TOPSIS. J. Clean Prod. 2024, 449, 15. [Google Scholar] [CrossRef]

- Deng, X.; Wang, R.; Xu, T. Risk Assessment of Tunnel Portals in the Construction Stage Based on Fuzzy Analytic Hierarchy Process. Arch. Civ. Eng. 2018, 64, 69–87. [Google Scholar] [CrossRef]

- Liu, S.H.; Song, Z.P.; Zhang, Y.; Guo, D.S.; Sun, Y.H.; Zeng, T.; Xie, J.S. Risk assessment of deep excavation construction based on combined weighting and nonlinear FAHP. Front. Earth Sci. 2023, 11, 13. [Google Scholar] [CrossRef]

- Liu, K.; Chen, Y.C.; Wang, H.R.; Xie, H.; Liu, Z.W. Reducing inconsistencies of FAHP in structural safety assessment of diversion tunnels. Appl. Soft. Comput. 2023, 146, 14. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Zhang, Y.D.; Song, Z.P.; Pan, H.W. A LFPP-FAHP based evaluation model of blasting scheme for tunnel undercrossing existing buildings. Tunn. Undergr. Space Technol. 2024, 153, 15. [Google Scholar] [CrossRef]

- Yanmin, H. Risk Pre-diagnosis in Urban Rail Transit Engineering Using the WBS-RBS Method. Urban Rapin Rail Transit 2004, 4, 9–12. [Google Scholar]

- Fu, T.; Shi, K.B.; Shi, R.Y.; Lu, Z.P.; Zhang, J.M. Risk Assessment of TBM Construction Based on a Matter-Element Extension Model with Optimized Weight Distribution. Appl. Sci. 2024, 14, 5911. [Google Scholar] [CrossRef]

- Song, Z.P.; Mao, J.C.; Tian, X.X.; Zhang, Y.W.; Wang, J.B. Optimization Analysis of Controlled Blasting for Passing through Houses at Close Range in Super-Large Section Tunnels. Shock Vib. 2019, 2019, 16. [Google Scholar] [CrossRef]

- Satty, T.L. The Fundamentals of Decision Making and Priority Theory with the Analytic Hierarchy Process; RWS Publications: New York, NY, USA, 2000. [Google Scholar]

- Wold, S.; Esbensen, K.; Geladi, P. Principal Component Analysis. Chemom. Intell. Lab. Syst. 1986, 14, 231–246. [Google Scholar] [CrossRef]

- Kuhn, H.W. Classics in Game Theory; Princeton University Press: Princeton, NJ, USA, 1997. [Google Scholar]

- Naghadehi, M.Z.; Mikaeil, R.; Ataei, M. The application of fuzzy analytic hierarchy process (FAHP) approach to selection of optimum underground mining method for Jajarm Bauxite Mine, Iran. Expert Syst. Appl. 2009, 36, 8218–8226. [Google Scholar] [CrossRef]

- Zhao, Y.F.; Qiu, R.; Chen, M.; Xiao, S. Research on Operational Safety Risk Assessment Method for Long and Large Highway Tunnels Based on FAHP and SPA. Appl. Sci. 2023, 13, 9151. [Google Scholar] [CrossRef]

| Primary Indicator | Secondary Indicator | W1 | W2 | W3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W11 | W12 | W13 | W21 | W22 | W23 | W24 | W31 | W32 | W33 | W34 | W35 | ||

| R1 | R11 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 |

| R12 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | |

| R13 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | |

| R14 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | |

| R2 | R21 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| R22 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | |

| R23 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | |

| R3 | R31 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 |

| R32 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | |

| R33 | 0 | 1 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | |

| R34 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| Scale | Explanation |

|---|---|

| 1 | Both elements have the same level of contribution to the goal. |

| 3 | One element has a slightly higher contribution compared to the other. |

| 5 | One element has a significantly stronger contribution than the other. |

| 7 | One element overwhelmingly dominates the other in terms of contribution. |

| 9 | One element’s contribution is so dominant that the other’s role is almost insignificant. |

| 2, 4, 6, 8 | Take the median value between the two adjacent degrees of the above comparison. |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| RI | 0.00 | 0.00 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.46 |

| Scale | Definition |

|---|---|

| 1.5 | The influence of the indicator factor is minimal and hardly significant. |

| 2.5 | The indicator factor has a modest but discernible influence. |

| 3.5 | The impact of the indicator factor is clearly noticeable and somewhat significant. |

| 4.5 | The indicator factor has a substantial and highly noticeable influence. |

| 5.5 | The impact of the indicator factor is overwhelmingly significant and dominant. |

| 2.0, 3.0, 4.0, 5.0 | The median between adjacent scales, indicating the scale at times when it falls somewhere in between two adjacent scales |

| Geological Risk | On-Site Risk | Equipment Risk | Blasting Risk | Weight | |

|---|---|---|---|---|---|

| Geological risk | 1 | 1/3 | 1/9 | 1/5 | 0.0569 |

| On-site risk | 3 | 1 | 1/3 | 1/2 | 0.1852 |

| Equipment risk | 9 | 3 | 1 | 2 | 0.5016 |

| Blasting risk | 5 | 2 | 1/2 | 1 | 0.2562 |

| PC | Eigenvalue | Variance Contribution Rate | Cumulative Variance Contribution Rate | PC | Eigenvalue | Variance Contribution Rate | Cumulative Variance Contribution Rate |

|---|---|---|---|---|---|---|---|

| 1 | 434.493 | 32.953 | 32.953 | 12 | 22.023 | 1.67 | 92.266 |

| 2 | 156.07 | 11.837 | 44.789 | 13 | 20.833 | 1.58 | 93.847 |

| 3 | 118.968 | 9.023 | 53.812 | 14 | 18.606 | 1.411 | 95.258 |

| 4 | 102.347 | 7.762 | 61.574 | 15 | 14.473 | 1.098 | 96.355 |

| 5 | 92.1688 | 6.99 | 68.565 | 16 | 12.448 | 0.944 | 97.299 |

| 6 | 64.385 | 4.883 | 73.448 | 17 | 10.545 | 0.888 | 98.099 |

| 7 | 61.541 | 4.667 | 78.115 | 18 | 9.474 | 0.719 | 98.818 |

| 8 | 60.042 | 4.554 | 82.669 | 19 | 7.961 | 0.604 | 99.422 |

| 9 | 45.549 | 3.455 | 86.124 | 20 | 5.032 | 0.382 | 99.803 |

| 10 | 31.628 | 2.399 | 88.522 | 21 | 2.595 | 0.197 | 100 |

| 11 | 27.347 | 2.074 | 90.596 |

| Indicator Layer | Indicator Weight | Factor Layer | Subjective Weight | Objective Weight | Combined Weight |

|---|---|---|---|---|---|

| Geological risk T1 | 0.0569 | Tunnel collapse t11 | 0.0474 | 0.2322 | 0.1115 |

| Water and sand inrush t12 | 0.2201 | 0.1843 | 0.2077 | ||

| Rock burst t13 | 0.0666 | 0.3359 | 0.1600 | ||

| Borehole collapse t14 | 0.6658 | 0.2476 | 0.5208 | ||

| On-site risk T2 | 0.1852 | Underground pipeline failure t21 | 0.7085 | 0.1071 | 0.5000 |

| Existing buildings deformation t22 | 0.0603 | 0.4552 | 0.1973 | ||

| Surface subsidence t23 | 0.2311 | 0.4376 | 0.3027 | ||

| Equipment risk T3 | 0.5016 | Supporting structure deformation t31 | 0.0282 | 0.2730 | 0.1131 |

| Poor ventilation t32 | 0.2610 | 0.0476 | 0.1870 | ||

| Water accumulation t33 | 0.0829 | 0.2494 | 0.1407 | ||

| Lining leakage t34 | 0.1046 | 0.1710 | 0.1276 | ||

| Blasting network failure t35 | 0.5233 | 0.2590 | 0.4317 | ||

| Blasting risk T4 | 0.2562 | Borehole spacing t41 | 0.2240 | 0.1712 | 0.2057 |

| Borehole depth t42 | 0.1549 | 0.1384 | 0.1491 | ||

| Number or type of borehole t43 | 0.0935 | 0.0446 | 0.0766 | ||

| Drilling equipment t44 | 0.0953 | 0.0817 | 0.0906 | ||

| Blasting charge structure t45 | 0.0280 | 0.1422 | 0.0676 | ||

| Discontinuous slag discharge t46 | 0.0248 | 0.0824 | 0.0448 | ||

| Blast jet lag t47 | 0.0659 | 0.0678 | 0.0666 | ||

| Misfire or residual blasting t48 | 0.0175 | 0.1984 | 0.0802 | ||

| Poor blasting effect t49 | 0.2960 | 0.0733 | 0.2188 |

| Risk Level | t11 | t12 | t13 | t14 | t21 | t22 | t23 | t31 | t32 | t33 | t34 | t35 | t41 | t42 | t43 | t44 | t45 | t46 | t47 | t48 | t49 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Level 1 | 0 | 0 | 0 | 0.6 | 0 | 0 | 0 | 0 | 0.1 | 0.1 | 0 | 0 | 0.2 | 0 | 0.2 | 0.4 | 0 | 0 | 0 | 0 | 0.1 |

| Level 2 | 0 | 0 | 0 | 0.3 | 0 | 0 | 0.3 | 0.3 | 0.6 | 0.6 | 0.2 | 0.3 | 0.6 | 0.2 | 0.5 | 0.3 | 0 | 0 | 0 | 0 | 0.7 |

| Level 3 | 0.3 | 0.8 | 0.2 | 0.1 | 0.7 | 0.3 | 0.6 | 0.6 | 0.3 | 0.3 | 0.6 | 0.5 | 0.2 | 0.4 | 0.3 | 0.3 | 0.1 | 0.2 | 0.3 | 0.3 | 0.2 |

| Level 4 | 0.6 | 0.2 | 0.7 | 0 | 0.2 | 0.6 | 0.1 | 0.1 | 0 | 0 | 0.2 | 0.2 | 0 | 0.4 | 0 | 0 | 0.6 | 0.5 | 0.6 | 0.4 | 0 |

| Level 5 | 0.1 | 0 | 0.1 | 0 | 0.1 | 0.1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.3 | 0.3 | 0.1 | 0.3 | 0 |

| Primary Indicator | T1 | T2 | T3 | T4 | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3.5 | 3 | 2 | 3.5 | ||||||||||||||||||

| Secondary Indicator | t11 | t12 | t13 | t14 | t21 | t22 | t23 | t31 | t32 | t33 | t34 | t35 | t41 | t42 | t43 | t44 | t45 | t46 | t47 | t48 | t49 |

| 4.5 | 3 | 4.5 | 1.5 | 3 | 4 | 3.5 | 3.5 | 2 | 2.5 | 2.5 | 2.5 | 2 | 1.5 | 2 | 2 | 4.5 | 4.5 | 2.5 | 4.5 | 1.5 | |

| Calculation Model | Evaluation Result | Risk Level |

|---|---|---|

| Conventional FAHP | [0.0924, 0.2052, 0.2847, 0.3196, 0.0981] | Level 4 |

| This study | [0.1061, 0.1883, 0.2625, 0.3001, 0.1429] | Level 4 |

| LFPP-FAHP | [0.0753, 0.1698, 0.3095, 0.3497, 0.0957] | Level 4 |

| FAHP-SPA | [0.1152, 0.1749, 0.2448, 0.2796, 0.1855] | Level 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, C.; Luo, D.; Shen, X.; Xu, L.; Pan, H.; Liu, Y. Risk Assessment of Drilling and Blasting Method Based on Nonlinear FAHP and Combination Weighting. Appl. Sci. 2025, 15, 4239. https://doi.org/10.3390/app15084239

Ji C, Luo D, Shen X, Xu L, Pan H, Liu Y. Risk Assessment of Drilling and Blasting Method Based on Nonlinear FAHP and Combination Weighting. Applied Sciences. 2025; 15(8):4239. https://doi.org/10.3390/app15084239

Chicago/Turabian StyleJi, Cheng, Dong Luo, Xiaole Shen, Leilei Xu, Hongwei Pan, and Yuwei Liu. 2025. "Risk Assessment of Drilling and Blasting Method Based on Nonlinear FAHP and Combination Weighting" Applied Sciences 15, no. 8: 4239. https://doi.org/10.3390/app15084239

APA StyleJi, C., Luo, D., Shen, X., Xu, L., Pan, H., & Liu, Y. (2025). Risk Assessment of Drilling and Blasting Method Based on Nonlinear FAHP and Combination Weighting. Applied Sciences, 15(8), 4239. https://doi.org/10.3390/app15084239