Abstract

The growing global demand for sustainable energy solutions has led to increased interest in kinetic energy harvesting as a viable alternative to traditional power sources. High-foot-traffic environments, such as public spaces and religious sites, generate significant mechanical energy that often remains untapped. This study explores energy-harvesting technologies applicable to public areas with heavy foot traffic, focusing on Al-Haram Mosque in Saudi Arabia—one of the most densely populated religious sites in the world. The research investigates the potential of piezoelectric, triboelectric, and hybrid systems to convert pedestrian foot traffic into electrical energy, addressing challenges such as efficiency, durability, scalability, and integration with existing infrastructure. Piezoelectric materials, including PVDF and BaTiO3, effectively convert mechanical stress from footsteps into electricity, while triboelectric nanogenerators (TENGs) utilize contact electrification for lightweight, flexible energy capture. In addition, this study examines material innovations such as 3D-printed biomimetic structures, MXene-based composites (MXene is a two-dimensional material made from transition metal carbides, nitrides, and carbonitrides), and hybrid nanogenerators to improve the longevity and scalability of energy-harvesting systems in high-density footfall environments. Proposed applications for Al-Haram Mosque include energy-harvesting mats embedded with piezoelectric and triboelectric elements to power IoT devices, LED lighting, and environmental sensors. While challenges remain in material degradation, scalability, and cost, emerging hybrid systems and advanced composites present a promising pathway toward sustainable, self-powered infrastructure in large-scale, high-foot-traffic settings. These findings offer a transformative approach to energy sustainability, reducing reliance on traditional energy sources and contributing to Saudi Arabia’s Vision 2030 for renewable energy adoption.

1. Introduction

The demand for electrical energy is rising quickly because of our growing dependence on electrical and electronic devices [1]. Clean and renewable energy sources—such as sound, vibration, wind, sea waves, and kinetic energy [2]-can help meet this demand [3]. By relying on these sustainable and freely available sources, we can reduce our use of traditional energy [4]. In everyday environments, human footsteps are an untapped source of energy that often goes to waste [1,3]. Because of the global shortage of energy resources, finding new energy sources, such as human footsteps, is now a necessity [5].

Piezoelectric transduction is a promising technology for gathering ambient energy, with successful applications in areas such as structural engineering, transportation, wireless electronics, the Internet of Things (IoT), and wearable or implantable biomedical devices [3]. Piezoelectric materials change kinetic energy or mechanical vibrations from the environment into electrical energy [6]. Pedestrian energy harvesting applies this technology to convert the energy from walking, jogging, or jumping into electricity. This electricity can then power devices such as small sensors or street lighting and may even charge electric vehicles in the future. Proposals by researchers such as Yeboah et al. [6] show that a useful amount of electricity can be generated. However, these models should be hybrid (footsteps plus solar) when foot traffic is high (e.g., a football pitch) or at Al-Haram Mosque (our focus). Last, the growing need for sustainable energy in high-traffic public spaces points out the drawbacks of traditional manufacturing methods for energy devices, which are often expensive and time-consuming [7].

This review looks at existing energy-harvesting studies to help develop the best solutions for high-foot-traffic sites. Al-Haram Mosque in Saudi Arabia will be used as the case study. The review will include an analysis of the materials, designs, power output, and overall suitability for use at Al-Haram Mosque. Before that, a brief introduction to Al-Haram Mosque and its power needs will be presented.

2. Methodology

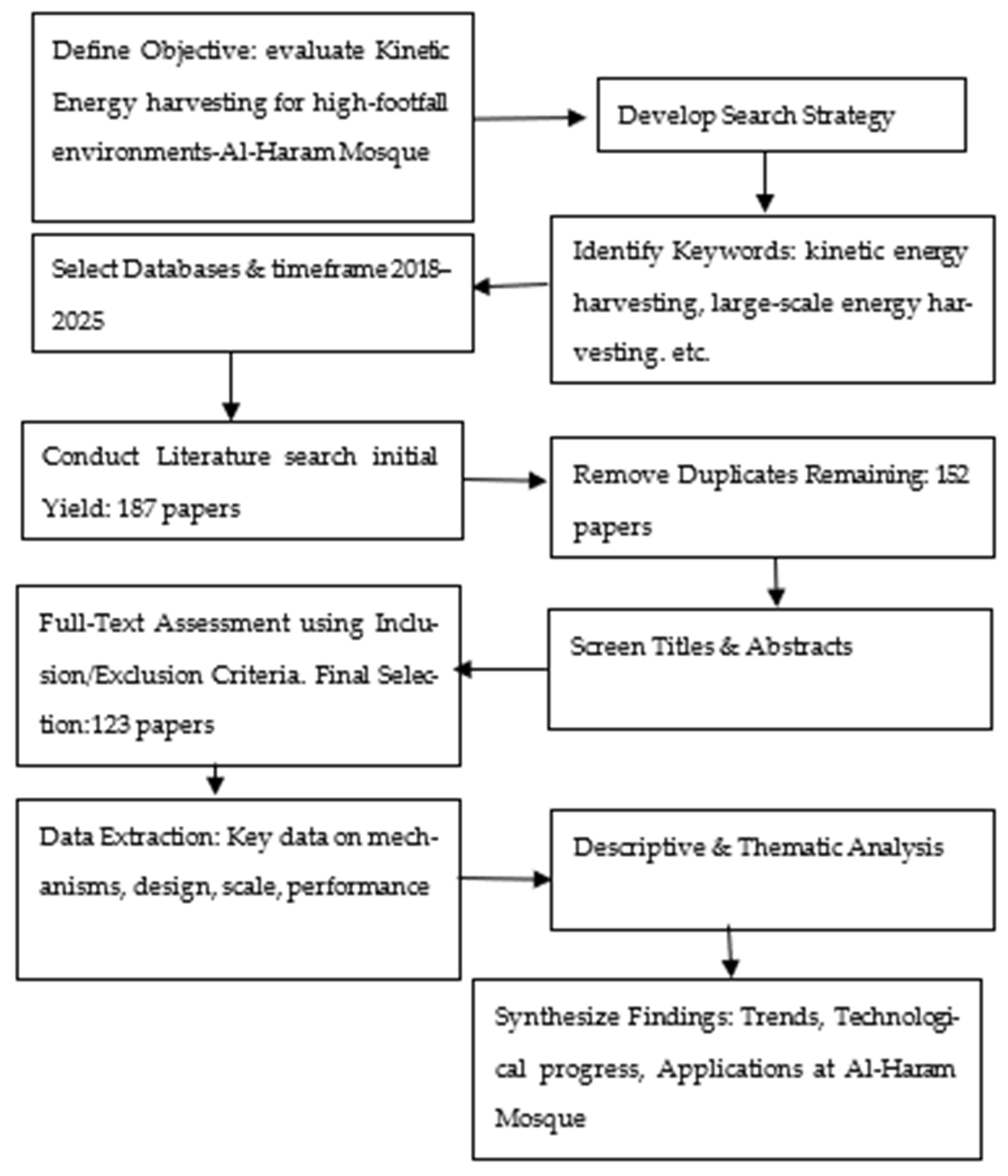

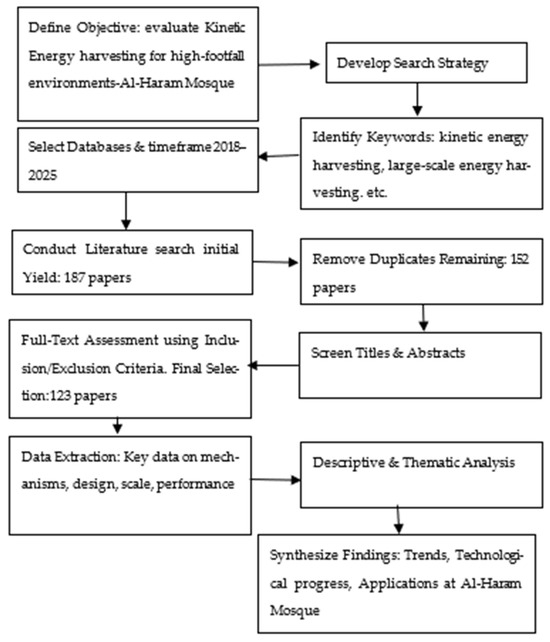

This systematic literature review investigates the potential of implementing kinetic energy harvesting solutions in high-foot-traffic settings. It examines recent developments in large-scale energy harvesting technologies to determine their suitability for crowded locations such as the Al-Haram Mosque. To ensure transparency and reliability, the review follows the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) guidelines [8,9].

A broad search strategy was used to find studies published between 2018 and 2025 in multiple academic databases. This timeframe was chosen for two reasons: (1) to capture recent trends in renewable energy (earlier periods have already been covered by other review studies [10,11]) and (2) because many renewable energy initiatives in Saudi Arabia emerged during this interval [12,13]. The search terms included “kinetic energy harvesting”, “large-scale energy harvesting”, “high footfall environments”, “energy harvesting in public spaces”, and “renewable energy in mosques”. Boolean operators (AND, OR) were used to refine the search results.

The research team established inclusion and exclusion criteria to filter studies. Eligible research had to be published between 2018 and 2025, focus on large-scale energy harvesting in high-footfall locations, and appear in peer-reviewed journals or conference proceedings. Studies were excluded if they addressed only small-scale or personal devices that did not involve kinetic energy harvesting if the full text was not available, or if they were written in languages other than English.

The initial search returned 187 papers. After removing duplicates, 152 remained. Title and abstract screening further reduced this number, and then researchers conducted a full-text review using the inclusion and exclusion criteria. This process left 123 relevant articles. The PRISMA framework maintained methodological consistency and minimized bias. The selected papers provided information on proposed harvesting methods, system design, and scale, and how these methods operate in large-scale or high-foot-traffic settings. The analysis evaluated each system’s practicality and performance, along with any associated challenges. A mix of descriptive and thematic methods was used to summarize the findings, highlight technological progress, and explore possible applications in settings such as the Al-Haram Mosque. Figure 1 presents a visual overview of this selection process.

Figure 1.

Systematic literature review steps of this work.

3. Energy Harvesting

The focus of this paper is kinetic energy harvesting. Therefore, this section looks at energy harvesting from the viewpoint of kinetic energy research. Energy harvesting is defined as converting kinetic energy—mainly mechanical energy from vibrations or applied pressure—into electrical energy by using piezoelectric materials [2]. While this definition emphasizes piezoelectric materials, other materials can also be used to capture energy from the human movement.

Zhang et al. [14] emphasize the need for sustainable, high-performance solutions that can operate under harsh conditions, addressing the limits of traditional energy-harvesting methods that rely on mechanical inputs such as vibrations or pressure. A review by Akinaga et al. [15] discusses six piezoelectric nanogenerators (PENGs), eight triboelectric pairs (TENGs), two electromagnetic generators (EMGs), and PVC coverings for footstep energy harvesting. They used a triple-hybrid design with a scattered layout of PENGs, TENGs, and EMGs across six foldable modules to allow easy transport and setup, aiming to measure how well these devices collect power from footsteps. However, the work of Akinaga et al. [15] is more theoretical, examining how advances in material science can aid energy harvesting for Internet of Things (IoT) applications. They also discuss future uses of spin caloritronic technology and thermoelectric materials in energy conversion but provide less empirical data than other studies.

This study focuses on footstep energy harvesting. Footsteps in crowded places often generate energy that goes unused. Because energy-harvesting systems are lacking, high-traffic areas have strong potential for footstep-based energy collection [5,15,16,17]. Piezoelectric materials, for instance, can capture energy from foot traffic to power low-energy devices such as streetlights or signs [5]. Atik et al. [18] developed a prototype with piezoelectric transducers that gather energy through piezoelectric tiles, convert it into electricity, and store it in a 12 V battery.

Crawley and Luo [19] explored a new piezoelectric energy-harvesting design that uses a bridge shear-force structure to transform high compressive forces into shear forces on piezoelectric discs. This approach efficiently converts mechanical stress into electrical potential along the shear axis. Li et al. [20] use advanced production methods, such as Fused Deposition Modelling (FDM) and Direct Ink Writing (DIW), with specialized materials (polymers, ceramics, and metal composites enhanced by graphene oxide, PVDF, and CNTs) to create precise biomimetic designs. In another system with magnetoelectric coupling, mechanical strain from a magnetic field or vibration triggers polarization in the piezoelectric layer, which generates electrical energy [21]. The cantilever design further improves energy output through resonance, revealing the potential for powering portable electronic devices [21].

Naifar et al. [22] offer further insight into energy-harvesting techniques, highlighting hybrid systems that combine piezoelectric, triboelectric, and electromagnetic methods to capture mechanical energy from sources such as foot traffic. Such advanced materials have shown outstanding energy conversion efficiency and durability under repeated mechanical stress [22,23]. Their high piezoelectric and triboelectric performance makes them suitable for harvesting energy from vibrations or pressure [22]. Because these materials are lightweight and flexible, they can be smoothly incorporated into a variety of applications, which favors practical and scalable deployment [11]. They also exhibit strong resistance to factors such as humidity and temperature changes, enabling long-term reliability [24]. Efforts to enhance scalability in manufacturing, as described by Zhang et al. [14] and others [22], pave the way for more widespread adoption of these systems.

3.1. Energy Harvesting Material: t-TENGs

Triboelectric nanogenerators (TENGs) have recently gained attention for generating renewable energy using the triboelectric effect, an electrostatic process where certain materials become charged when they contact and then separate [25,26,27]. Introduced by Wang [28] in 2012, TENG technology has grown quickly, with uses in wearable electronics, environmental monitoring, and healthcare devices [28,29]. Recent research has focused on creating textile-based TENGs (t-TENGs) by integrating TENGs into flexible textiles. These t-TENGs can efficiently capture energy from human motion or other everyday mechanical activities [28,29].

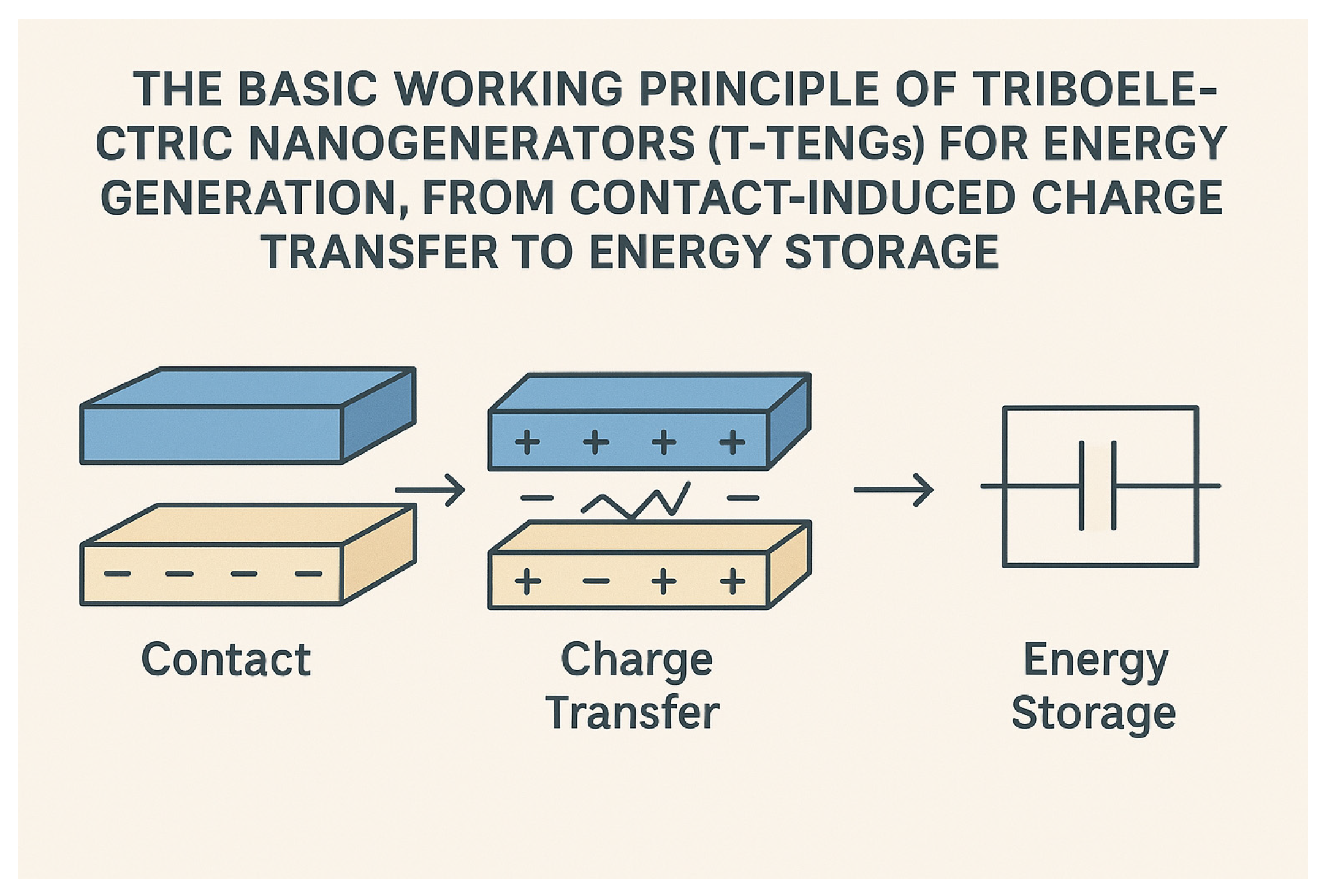

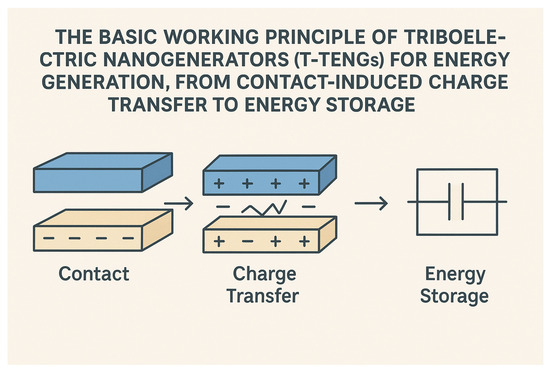

The triboelectric effect in TENGs involves the exchange of electrons between materials with different electron affinities (see Figure 2). When these materials meet and then separate, one material gains electrons while the other loses electrons, creating an electric potential [30,31]. If they are connected to an external circuit, this potential drives electrons to flow, producing electrical energy. TENGs typically operate in four primary modes: vertical contact separation, lateral sliding, single-electrode, and free-standing [32].

Figure 2.

The basic working principle of triboelectric nanogenerators (t-TENGs) for energy generation, from contact-induced charge transfer to energy storage.

Research shows that TENGs can harvest energy from a wide range of mechanical sources, including human motion, wind, water, and vibrations [33,34]. For example, Radhakrishnan et al. [35] found that TENGs can turn ocean wave energy into electricity, suggesting large-scale possibilities for marine renewable energy. Similarly, Xing et al. [36] examined how TENGs capture low-frequency mechanical energy in outdoor environments, noting their durability and adaptability. TENGs have also been miniaturized for use in self-powered sensors, microelectronics, and portable consumer electronics [36]. In contrast, single-phase magnetoelectric (ME) materials often respond weakly, making them less practical for real-world applications [20].

Textile-based TENGs (t-TENGs) are a major new area of TENG research. They can be used in wearable and portable energy-harvesting fabrics that convert ordinary human motions such as walking or running—into electricity. These fabrics are flexible, lightweight, and comfortable, allowing them to be easily integrated into clothing to power small devices [28,37,38]. Lu et al. [39] introduced gel-based TENGs for flexible sensing, addressing the shortcomings of standard energy-harvesting methods in terms of adaptability and performance in changing conditions.

Most t-TENG designs use woven structures made of conductive and non-conductive fibers, which produce friction during motion and generate electricity [39]. Optimizing how these fibers are arranged can increase the efficiency and power output of t-TENGs, making them more useful for real-world scenarios [40]. TENGs and t-TENGs have applications ranging from powering wearable devices to supporting large-scale environmental monitoring [41,42]. For instance, Dulal et al. [43] created “bright clothes” with built-in t-TENG technology to power small health-monitoring sensors, tracking vital signs such as heart rate and body temperature and transmitting data wirelessly. Another study by Qin et al. [44] showcased a TENG system that collects energy from raindrops and vibrations, offering an eco-friendly way to monitor environmental data. Researchers have also integrated TENGs into backpacks so that they generate power from walking or hiking, which is useful for people who spend a lot of time outdoors or work in the field [44]. Finally, Chen, Tang, and Wang [34] proposed flexible 3D-printed TENG designs that rely on triboelectric and electrostatic induction effects to harvest energy through contact separation, sliding, single-electrode, and free-standing modes. These designs can capture mechanical energy from various movements, making them suitable for wearable electronics, environmental sensors, and self-powered systems.

3.2. Energy Harvesting Material: Piezoelectric

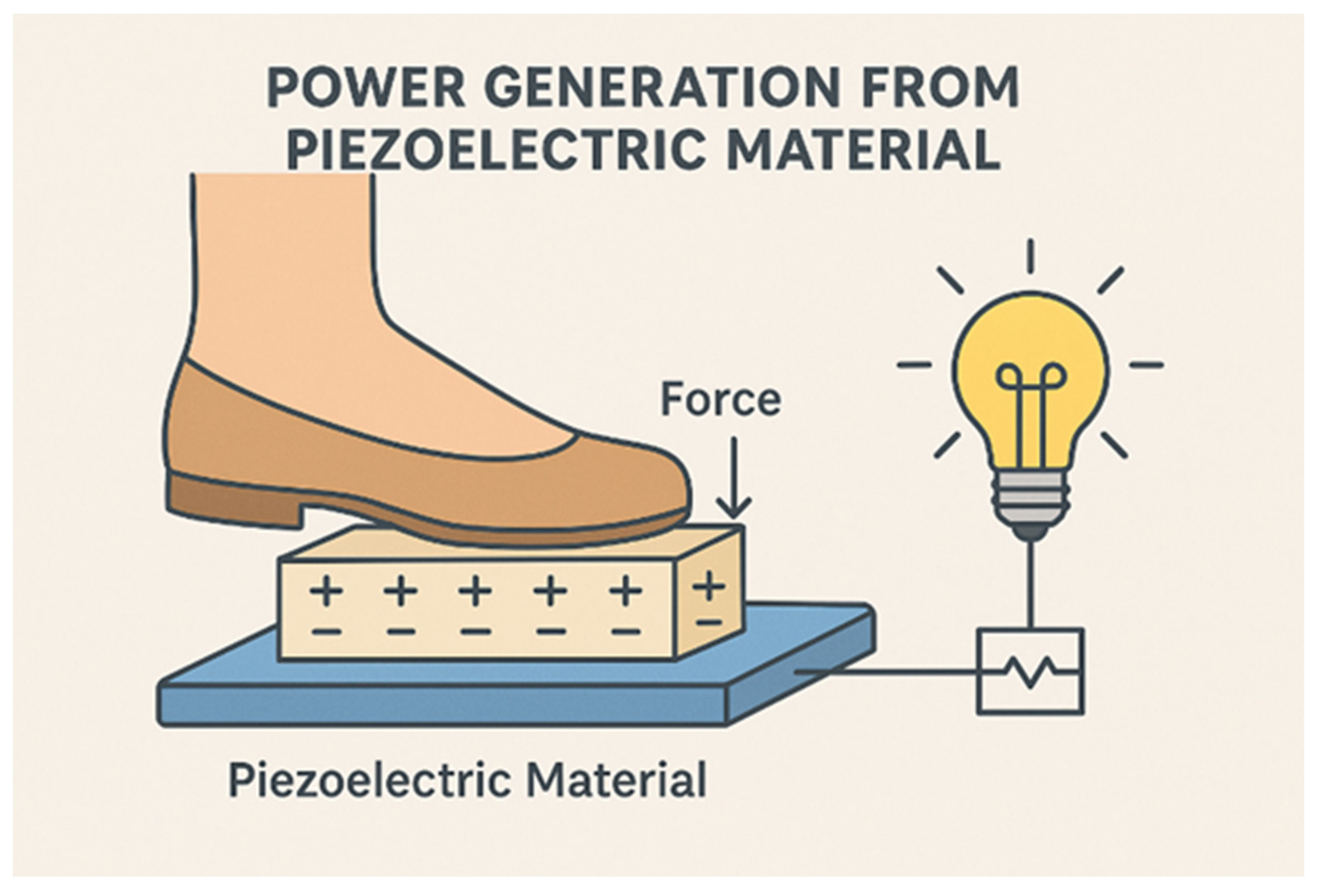

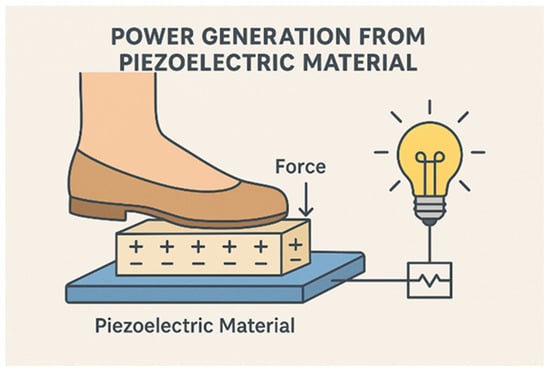

A piezoelectric diaphragm (PZT) can convert mechanical pressure, such as footsteps, into electrical energy. Figure 3 shows how piezoelectric power generation works: when mechanical pressure deforms the piezoelectric material, it produces an electric charge because of the material’s internal structure. This charge can then be harvested as usable electrical power. PZT is often chosen because of its durability and cost-effectiveness in delivering a consistent energy output [45].

Figure 3.

Power generated from piezoelectric material.

Asry et al. [5] used Lead zirconate titanate (PZT) piezoelectric transducers to convert footstep pressure into electrical energy. A related system in [15] combined 16 piezoelectric discs (arranged in series, parallel, or series–parallel) mounted on a footboard to capture energy from human footsteps, along with a 12 V solar panel to gather solar power. This setup included an AC–DC converter with different voltage doubler circuits, ensuring that the alternating current generated by the piezoelectric discs could be converted into direct current.

To enhance the energy-harvesting effectiveness of piezoelectric gyroscopes [4], researchers investigated various electric field models across multiple load resistances. However, a challenge remains: many existing models assume a constant electric field, which may not accurately capture real-world conditions for energy harvesting.

Similarly, the study in [3] explores how human footsteps can generate electrical power, focusing on piezoelectric tiles (ceramic diaphragms with specific dimensions: 20 mm diameter for the metal plate and 14 mm for the piezoelectric element) embedded in floors. After undergoing a unique process, certain ceramics have shown excellent performance in energy-related tasks, such as thermal management and absorption, and can even be tuned to match particular application needs by adjusting porosity and density [41,46]. Such a surface tension-based approach also has the advantages of being both scalable and environmentally friendly, which makes it a good candidate for combining with PZT.

Traditional ways to boost a material’s piezoelectric coefficient often require adding large amounts of ceramic, which then reduces the lightweight and flexible nature of the polymers [6,47,48]. This creates a pressing need for more sustainable, efficient, and flexible methods to create piezoelectric polymer composites [47]. Abir et al. [49] studied piezoelectricity in chalcogenide perovskites and found high sensitivity, strong energy conversion, and solid stability under changing environmental conditions, with coefficients that match or even exceed those of PZT. However, ensuring precise production control and testing long-term stability under repeated stress remains a significant hurdle for scaling up these materials in real devices.

3.3. Energy Harvesting Material: Cellulosic

Cellulosic materials, primarily obtained from plant biomass, consist of cellulose-a renewable, biodegradable, and abundant biopolymer. As sustainability concerns increase, cellulose has gained significant attention in fields such as energy storage, electronics, and sensors thanks to its environmentally friendly properties, low cost, and wide availability [50]. These qualities also make cellulosic materials ideal for green energy applications, where they serve as a low-carbon alternative to synthetic polymers often used in electronic devices [49,50]. Recent advances have focused on leveraging the natural attributes of cellulose for energy harvesting, most notably through cellulose-based nanogenerators that convert mechanical energy (for example, from human movement) into electrical energy [51,52].

Cellulose stands out for its high mechanical flexibility, robust chemical stability, and ability to undergo surface modification, all of which can enhance its triboelectric properties [51,52]. Cellulose-based triboelectric nanogenerators (TENGs) generate electricity through friction between two materials, tapping into the triboelectric effect that creates surface charges upon contact and separation. Combined with cellulose’s biodegradability, this approach offers a sustainable path toward energy-harvesting solutions in public areas such as pedestrian walkways and transportation hubs [53].

Triboelectricity in cellulosic materials can be boosted by functionalizing their surfaces to increase charge density [54,55]. Beyond triboelectricity alone, cellulose can be combined with piezoelectric and electrostatic components to form hybrid nanogenerators that capture a broader range of mechanical motions (compression, tension, and bending), further improving power output [53,56]. For instance, Nie et al. [57] demonstrated that chemically modifying cellulose surfaces can enhance electron transfer with a paired triboelectric material, doubling energy output. Zhang et al. [58] introduced a cellulose-based TENG made with micro- and nano-structured cellulose fibers, boosting the effective surface area. The increased number of contact points improved charge density and thereby boosted power generation-enough to power low-energy devices such as LEDs or small sensors. Hybrid nanogenerators incorporating cellulosic materials alongside other harvesting methods (piezoelectric or electromagnetic) provide even more ways to capture mechanical energy [52].

Luo et al. [53] combined a cellulose-based triboelectric layer with a piezoelectric polymer to create a hybrid nanogenerator, achieving a continuous power output from human motion. This design led to a 40% increase in power compared with using cellulose-based TENGs on their own. In a similar vein, Zhang et al. [58] explored blending cellulose with carbon-based nanomaterials such as graphene oxide to improve electrical conductivity and surface triboelectric properties, thus enhancing the overall efficiency of cellulose-based nanogenerators. These hybrid systems have shown promise in powering wearable devices and small IoT systems in busy public spaces such as malls and airports.

Because cellulose is flexible, it is a strong candidate for wearable applications [59]. Researchers have integrated cellulose-based nanogenerators into clothing, allowing the garments to convert everyday human motions, such as walking or hand movements, into usable electricity. Pu, Zhang, and Wang [38], as well as Das et al. [60], designed wearable TENGs embedded in textiles made of cellulose fibers, capable of storing energy in a small battery or supercapacitor. This stored energy can power low-demand sensors for health monitoring or fitness tracking. Cellulose also offers comfort and biocompatibility, as it is non-irritating to the skin and can be treated with antimicrobial agents to prevent odor [59,60]. Guan et al. [61] even developed a t-shirt equipped with cellulosic nanogenerators that generated around 10 µW/cm2 while the wearer was walking.

Despite these promising developments, cellulosic nanogenerators still face challenges. Their energy output is typically lower than that of synthetic alternatives, restricting their use to mostly low-power devices [62]. Researchers are therefore focusing on ways to boost charge density and explore hybrid systems that combine cellulose-based TENGs with other energy sources, such as solar or thermal energy [49,53,55,58,62]. Another issue arises from cellulose’s biodegradability, which is a sustainability advantage but can limit durability. In areas with heavy foot traffic, cellulose-based nanogenerators must endure constant mechanical wear and environmental exposure [50]. To address this, recent studies [49,53,55,58,62,63] have investigated using protective surface coatings or combining cellulose with sturdier materials to increase longevity. For example, Wang et al. [64] used a hydrophobic coating that protected cellulose from moisture, preventing performance degradation over time.

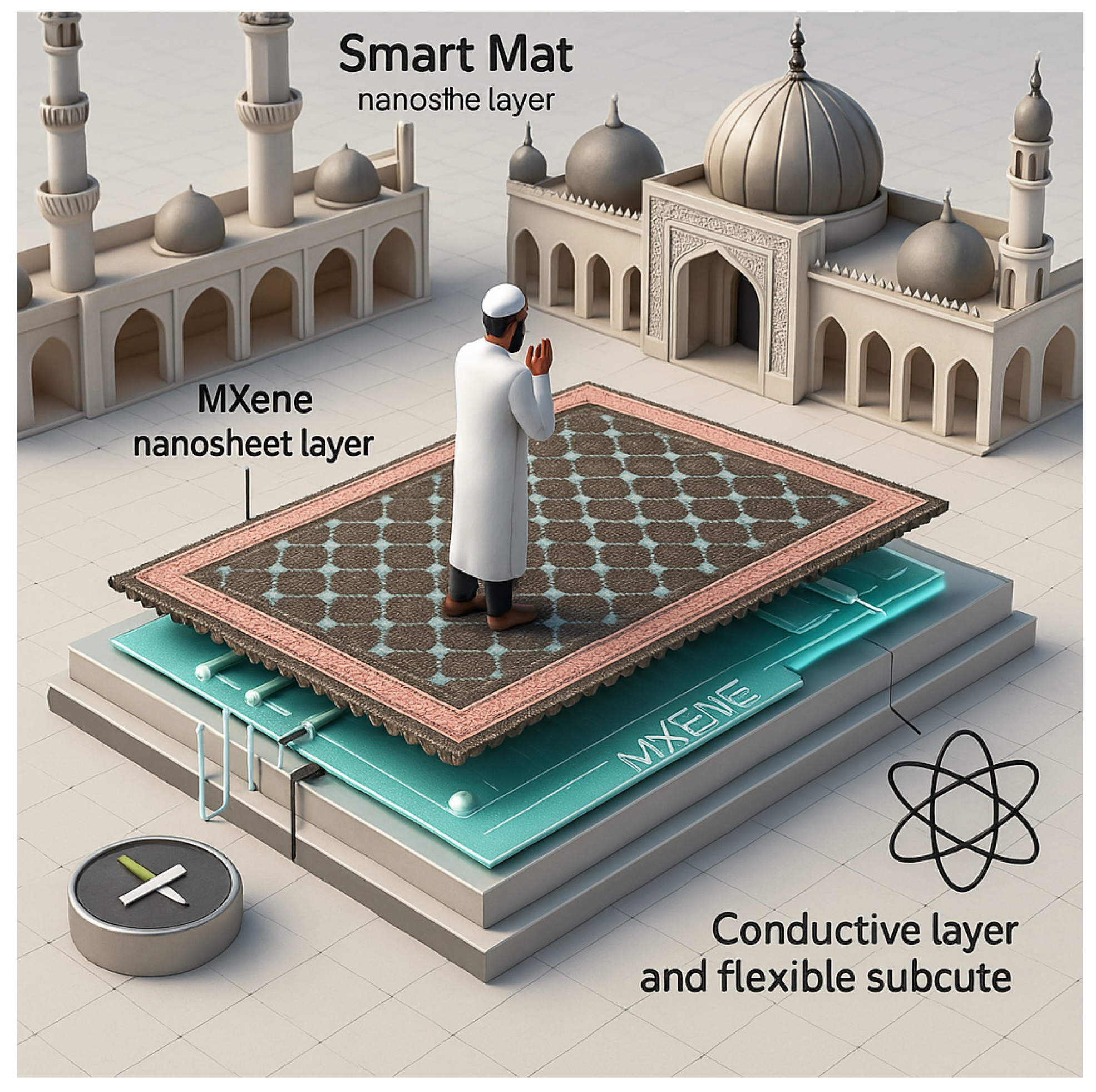

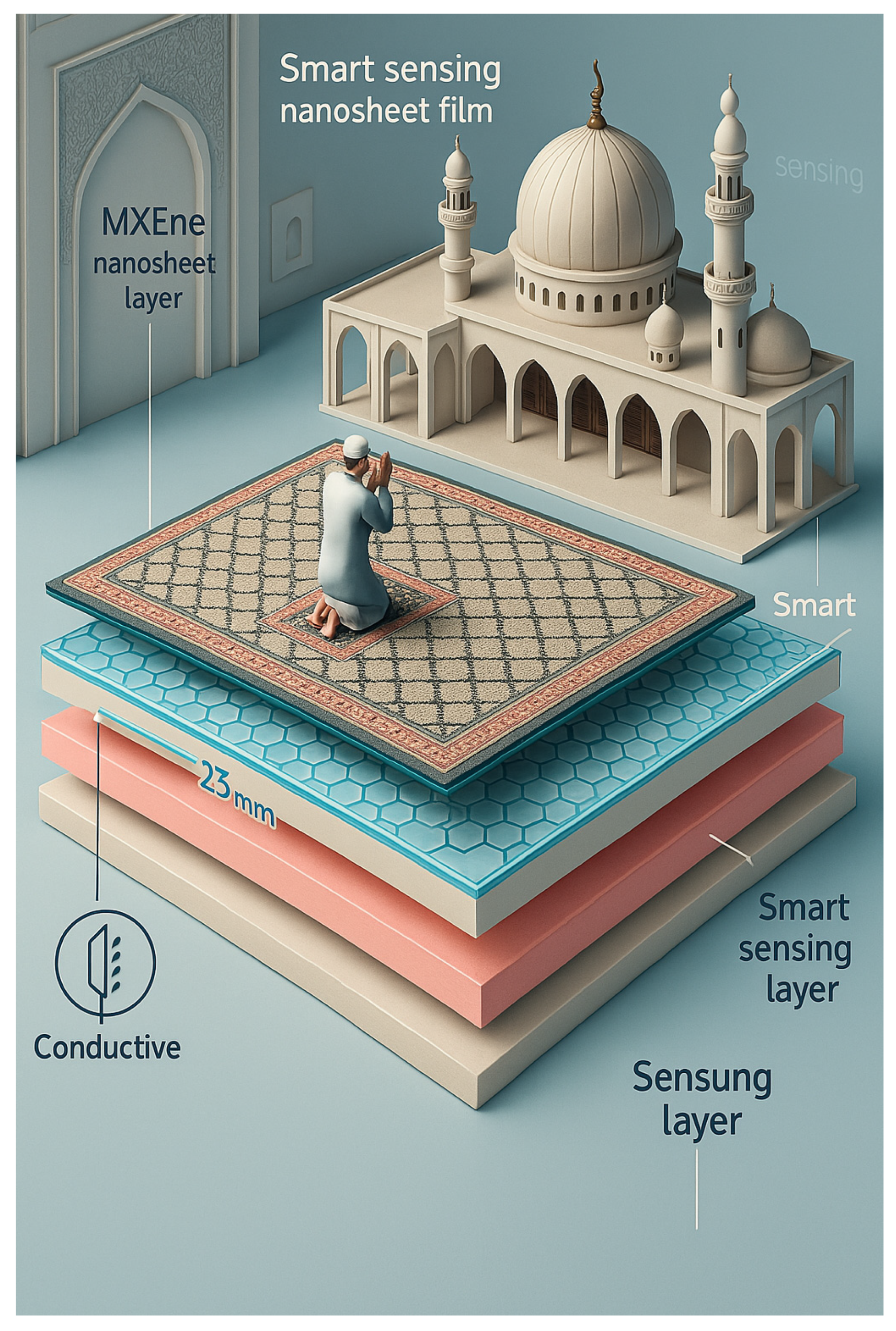

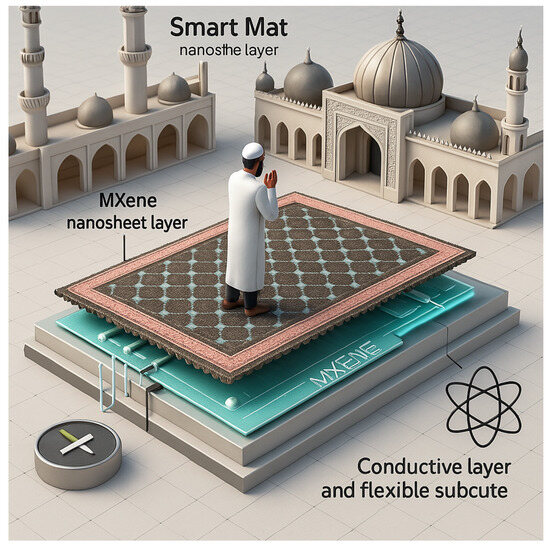

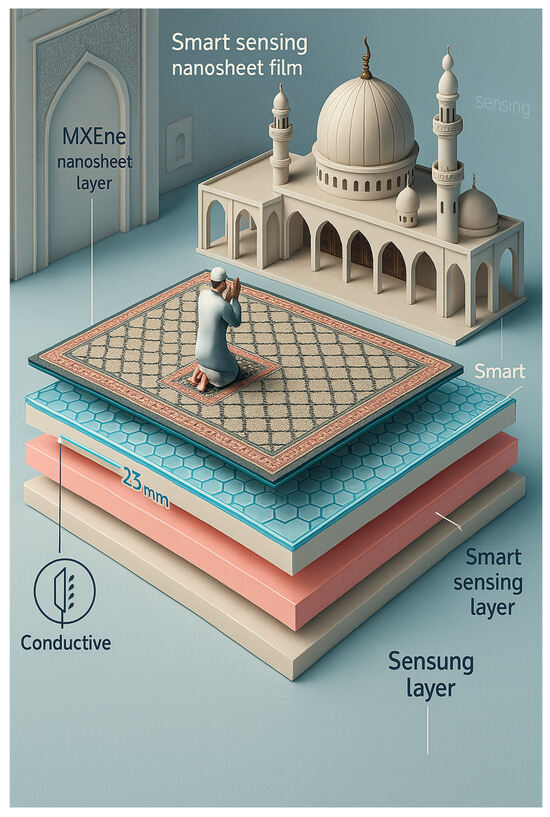

3.4. Energy Harvesting Material: MXene-Based Materials

Transition metal carbides and nitrides in the MXene family have gained attention for energy harvesting. These materials combine excellent electrical conductivity with adjustable surface chemistry and mechanical flexibility [65]. Research on how surface terminations and intercalation influence MXenes’ electronic properties has yielded insights into their broader roles in energy technologies [65]. Collectively, these studies highlight MXenes’ suitability for use in various energy-harvesting devices, including triboelectric nanogenerators (TENGs), piezoelectric systems, and supercapacitors [66].

Researchers have successfully applied the triboelectric effect with MXenes in TENGs. MXenes’ high surface charge density and conductivity significantly boost TENG performance [67]. When integrated into flexible substrates, MXenes have produced TENGs that convert mechanical energy into electrical power, offering the potential for wearable electronics and self-powered gadgets [68,69]. Their versatility also enables them to be combined with other materials, enhancing triboelectric device performance through better charge-inducing and trapping capabilities [70,71].

Beyond TENGs, MXenes show strong potential in piezoelectric energy harvesting as well. When they are incorporated into piezoelectric polymers such as poly (vinylidene fluoride) (PVDF), MXenes can greatly increase energy-conversion efficiency [72,73]. As Mankuni and Varghese [74] note, adding MXenes boosts the dielectric constant of PVDF, which in turn enhances its piezoelectric output. MXene-based flexible nanogenerators can, therefore, capture energy from low-frequency vibrations, whether from everyday human activity or environmental movement [74,75].

MXenes also contribute to energy storage and harvesting when used in supercapacitors [7]. Their large surface area and rich surface chemistry allow for quick ion transport and efficient charge storage, making them ideal materials for supercapacitor electrodes [76,77]. Recent studies report that MXene-based supercapacitors reach higher energy and power densities than traditional carbon-based supercapacitors [78,79]. Additionally, combining MXenes with materials such as metal–organic frameworks (MOFs) or conductive polymers further improves electrochemical performance and increases energy storage efficiency [80,81]. Meanwhile, MXene-based membranes can harness salinity gradients to produce electricity, thanks to improved ion selectivity and permeability—an approach especially relevant for regions with abundant saline resources [82,83,84].

Overall, MXenes’ ability to enable multiple energy-conversion processes makes them promising for a range of energy-harvesting applications. Their unique features enhance technologies such as TENGs, piezoelectric devices, supercapacitors, and osmotic energy harvesting. As research advances, exploring new ways to synthesize and functionalize MXenes will only expand their role in sustainable energy solutions.

3.5. Summary of Energy Harvesting

Various studies have tackled energy harvesting challenges through innovative piezoelectric and hybrid systems. Researchers have tested different ways to convert ambient mechanical energy—ranging from footstep pressure to vibrations and even raindrops—into electrical power that can run low-energy devices such as pedestrian signals, streetlights, and IoT sensors. Materials such as PZT, ZnO, PVDF, and advanced composites (e.g., PVDF/BaTiO3/Graphene) have been applied in setups including walkway-embedded sensors, cantilever harvesters, and multi-modal devices that capture both bending and torsional vibrations. While some configurations have generated promising voltage outputs—as high as 60.5 V- overall energy yields remain relatively small and are often sensitive to environmental conditions and inconsistent mechanical forces. Common hurdles include low power output, sensitivity to pressure and weather changes, installation challenges, and high production costs. This illustrates the potential and limitations of today’s energy-harvesting approaches, pointing to the need for further refinement to make them more reliable and scalable for sustainable power.

Studies show that hybrid energy systems using multiple materials generally outperform single-material setups. For example, Refs. [80,85] created hybrids by combining solar photovoltaic panels with piezoelectric elements. These configurations improve overall energy production by compensating for each source’s variability, resulting in peak outputs of 9.59 V [80] and 3.29 V [85], though both remain limited to low power uses. Another hybrid approach from [86] uses a composite of PVDF, BaTiO3, and graphene, achieving an open-circuit voltage of 60.5 V and a short-circuit current of 654.2 nA, retaining stability over 600 cycles. Despite increasing structural complexity and production costs, these multi-material systems hold great promise for scalable energy harvesting technologies.

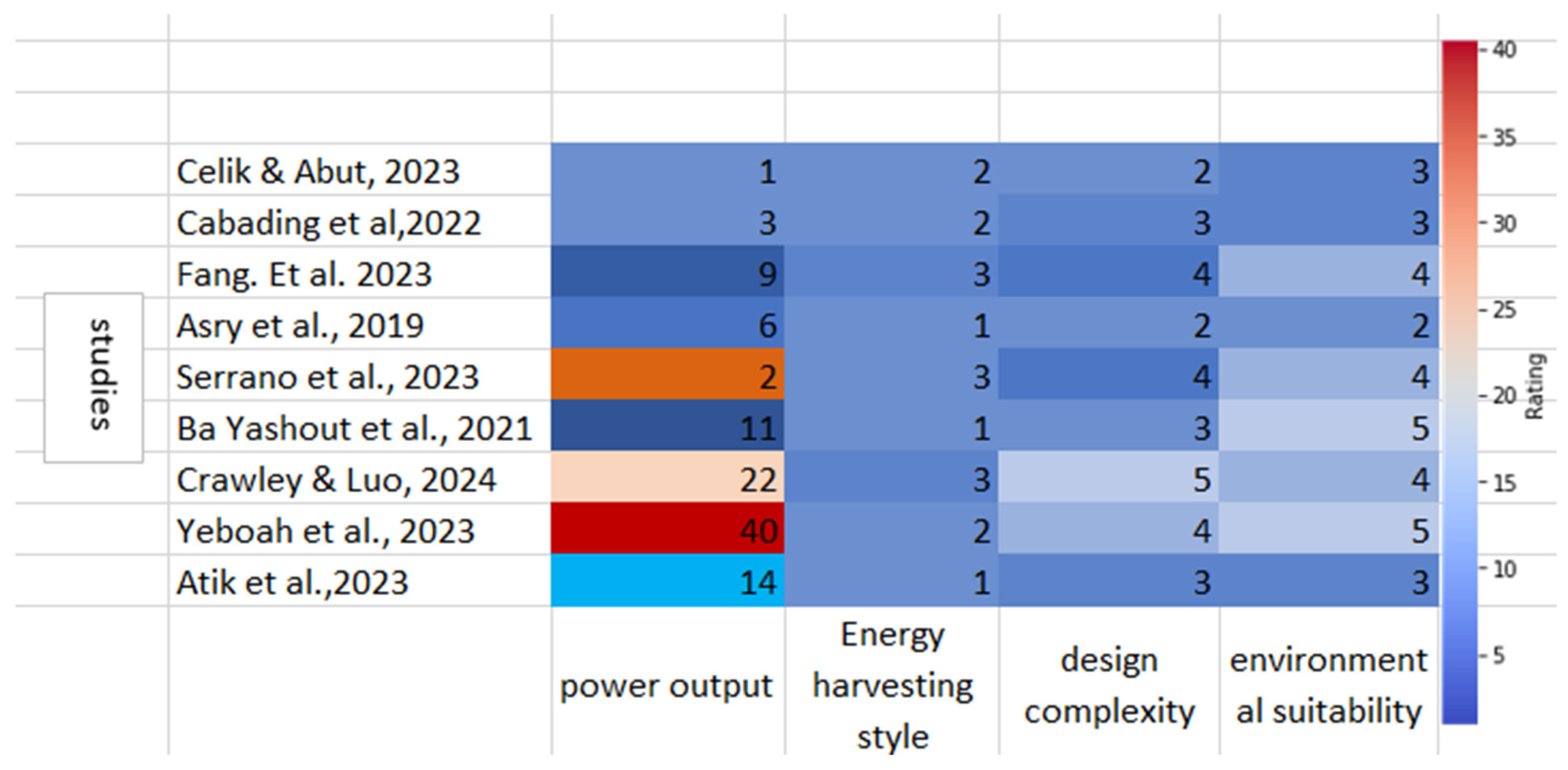

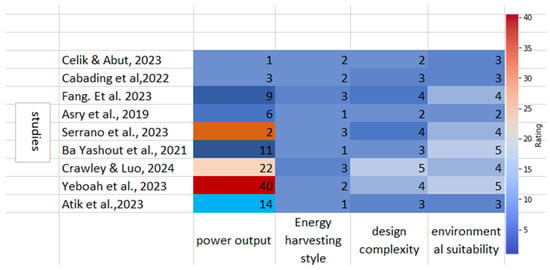

Figure 4 shows our ratings for power output, harvesting style, design complexity, and environmental suitability across the reviewed studies. The rating for energy harvesting, design complexity, and environmental suitability was based on the authors’ judgment for the context of this study (Al-Haram). Meanwhile, the power output column is based on the power output reported in this study. This heatmap relies on factors such as material resilience, device performance, and energy output. A quick look reveals which studies rank high or low in each area: deep reds and oranges highlight strong performance in a specific category, whereas darker blues mark lower scores. Yeboah et al. [6] and Selim et al. [3] achieved the top ratings overall. Piezoelectric materials, in particular, offer high conversion efficiency under cyclic mechanical stress. Modified piezoelectric polymers—such as PVDF blends—show improved flexibility and durability, making them ideal for wearable devices and structural applications [85].

Figure 4.

Comparison of the required criteria of footstep harvesting across studies (Serrano et al. [4], Asry et al. [5], Yeboah et al. [6], Fang et al. [16], Atik et al. [18], Crawley and Luo [19], Ba Yashout et al. [87], Çelik and Abut [88], Cabading et al. [89]).

One major challenge in creating effective energy-harvesting devices is finding materials that are both comfortable and efficient [33]. Recent studies [90,91] have examined textiles such as polyester, nylon, and cotton for their triboelectric properties and their compatibility with standard textile manufacturing methods [92]. For example, Neelakandan et al. [93] reported a polyester-based t-TENG capable of producing 35 µW/cm2, making it suitable for low-power applications such as health-monitoring sensors. In another study, Park et al. [94] developed a multi-layered t-TENG using interwoven conductive threads, which substantially improved both durability and energy output.

Advances in nanotechnology have further increased the effectiveness of t-TENGs. Researchers have, for instance, applied nanostructured surfaces to textile fibers to boost their contact area and, thus, their triboelectric effect [92]. Additionally, methods such as electrospinning can produce nanofiber-based TENGs with a highly textured surface, promoting greater charge density and, therefore, higher energy output [41]. Meanwhile, Chen, Tang, and Wang [34] integrated triboelectric nanogenerators (TENGs) with 3D printing—using polymers such as PDMS (polydimethylsiloxane) and PVDF (polyvinylidene fluoride) for flexible TENGs, as well as solid materials such as ABS (acrylonitrile butadiene styrene) and PLA (polylactic acid)-to address issues of scalability, cost, and design flexibility.

4. Design

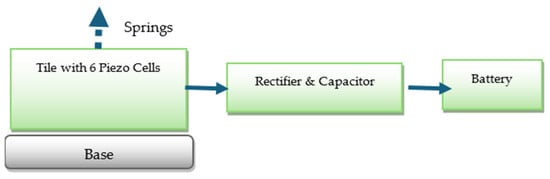

Researchers have taken various approaches to designing energy-harvesting systems using different materials and configurations. One common strategy involves arranging piezoelectric transducers in a series–parallel configuration to boost both voltage and current output. The resulting AC voltage is then converted to DC using a full-wave bridge rectifier with smoothing capacitors [5]. For instance, one design placed six piezoelectric cells between two wooden blocks, with springs allowing the upper block to return to its initial position after being stepped on. Tests with participants of different body weights showed how much voltage was generated over time [5]. By connecting the piezoelectric sensors in a series–parallel arrangement, the voltage and current outputs were maximized, enhancing energy efficiency [16]. Another approach mounted piezoelectric sensors in a series–parallel configuration on a wooden board to harness footstep energy, rectifying the AC to DC and storing it in a battery [93,94,95]. However, Suleiman and Abdulhamid [96] report that each step produces only minimal energy, limiting this design to very low-power uses.

Fang et al. [63] compared different circuit setups—series, parallel, and series–parallel —to see which yielded the most energy. Their system also employed Maximum Power Point Tracking (MPPT) to optimize solar energy collection. Serrano et al. [4] introduced a spatially varying (SV) model for the electric field in piezoelectric energy-harvesting gyroscopes. They compared this model with open-circuit (OC), constant electric field (CE), and constant electric field with coupling (CE-γ) models, testing a range of load resistances using the Differential Quadrature Method (DQM). Additionally, Serrano et al. [4] embedded a piezoelectric patch into a micro-electromechanical system (MEMS) gyroscope, modeling both energy harvesting and angular velocity sensing.

Selim et al. [3] integrated fourteen piezoelectric diaphragms into a floor tile to capture energy from footsteps. These diaphragms were connected in parallel to a rectification circuit with Schottky diodes to convert AC to DC. A filter capacitor then smoothed the output, and a DC-DC buck converter stabilized it at 5 V for small-scale applications. In contrast, Crawley and Luo [19] replaced compression-only setups with a disc spring washer, achieving up to 22% better performance under varying force and 125% better under changing velocity than a crinkle washer. Although less efficient overall, the crinkle washer showed promise for fine-tuning future designs by altering the number and distribution of its waves.

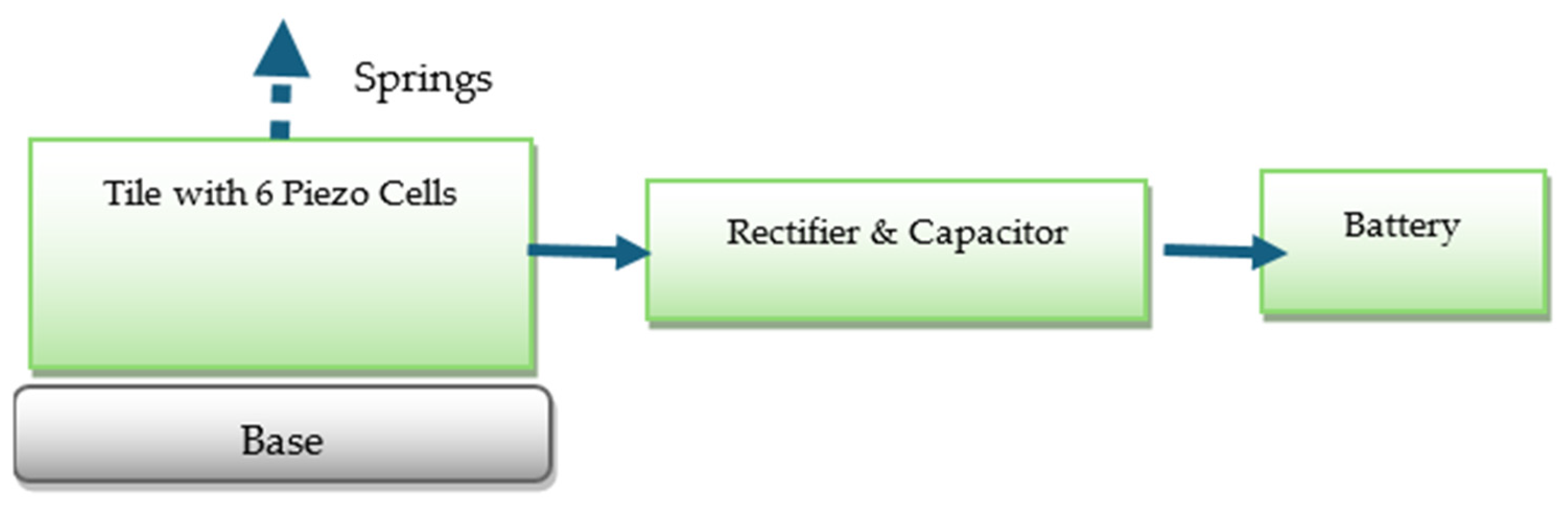

Figure 5 illustrates a typical piezoelectric tile design: six piezoelectric cells sandwiched between wooden blocks with springs to handle repeated compression. The generated AC is rectified, smoothed, and stored in a battery for use in low-power applications.

Figure 5.

A tile featuring 6 piezoelectric cells between wooden blocks with springs converts foot pressure into AC voltage, which is rectified and stored as DC energy for low-power applications.

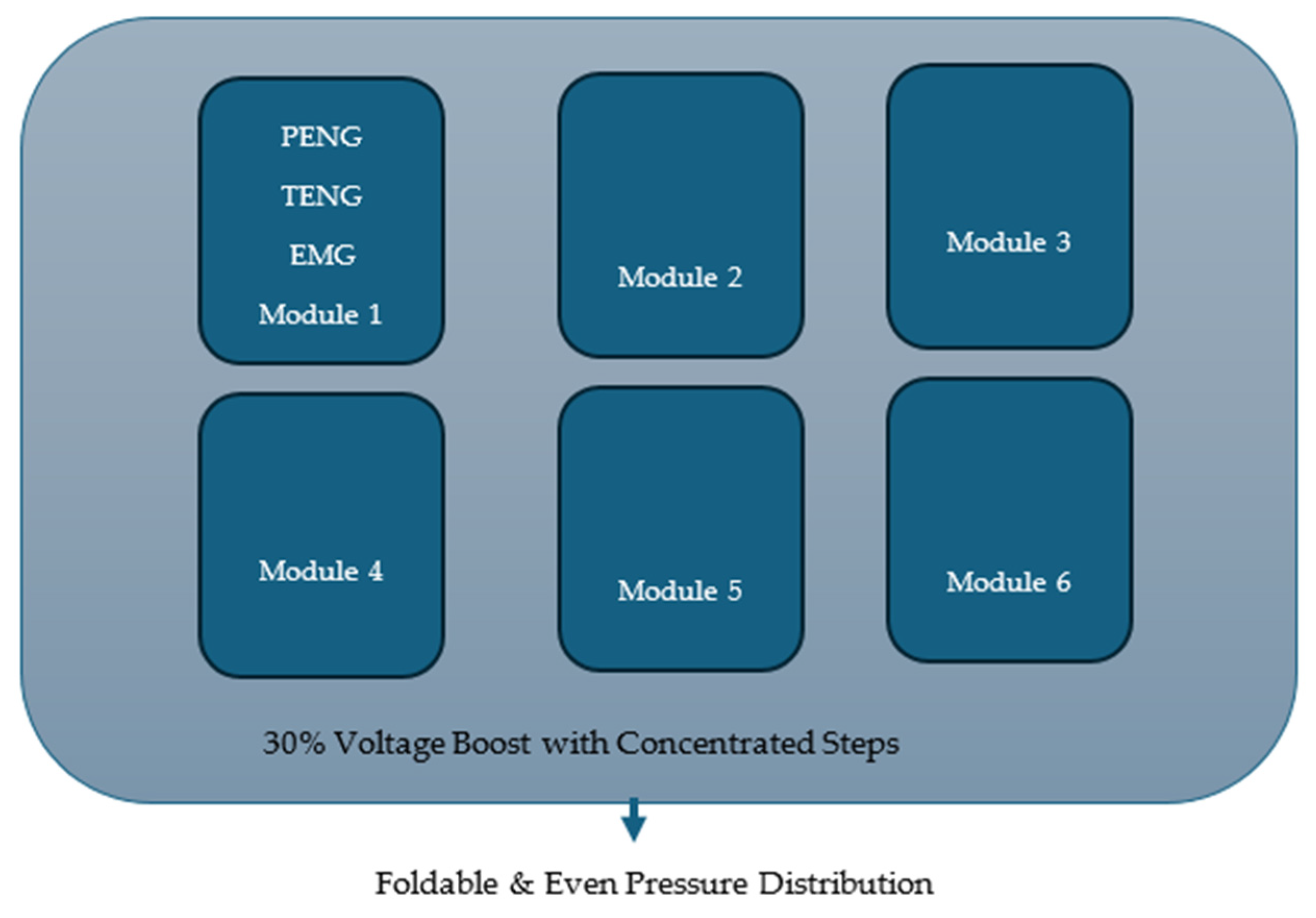

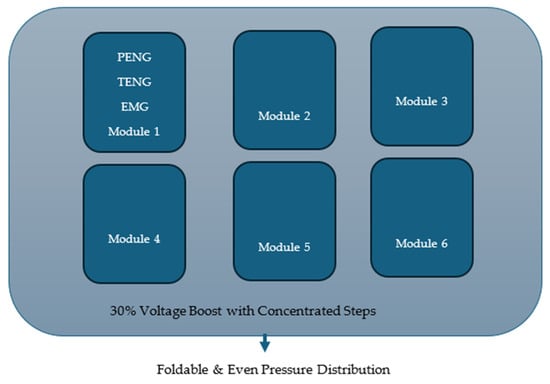

In terms of mat design, Aguarin et al. [27] focused on portability by creating six square modules that each house multiple PENGs, TENG stacks, and EMGs arranged in a scattered layout. This design increases both energy output and ease of transportation, making the mat suitable for high-foot-traffic areas. According to the authors, the scattered layout-unlike the stacked configuration often found in hybrid footwear-enables a greater number of energy harvesters to run at once, significantly increasing overall power generation [27].

Meanwhile, Yu et al. [97] took a different route, using triboelectric nanogenerator (TENG) technology and textile-TENG (t-TENG) arrays. Their mat, which features a core-shell yarn structure, can sense pressure and blend seamlessly into typical household environments. This “smart carpet” detects falls by tracking pressure changes across various TENG cells, and it uses an algorithm to tell ordinary footstep patterns apart from falls, sending an alert if a fall occurs [97].

Figure 6 illustrates one common mat design: a 2 × 3 grid of modules, each containing multiple energy-harvesting devices (PENG, TENG, and EMG). Notable features include foldability, uniform pressure distribution, and a carefully optimized design that boosts voltage output by as much as 30% when pressure is concentrated in specific areas.

Figure 6.

A modular mat arranged in a 2 × 3 grid integrates multiple energy harvesters (PENG, TENG, EMG) to capture footstep energy. The design’s foldability and even pressure distribution boost voltage output by about 30% under concentrated steps.

The mat design by Aguarin et al. [27] consists of six modular units, each measuring 12 cm × 12 cm × 2.5 cm, arranged in a 2 × 3 grid with 4.5 cm gaps between modules. This layout allows each module to operate independently, promoting flexibility and distributing foot pressure evenly. Each unit contains six piezoelectric nanogenerators (PENGs), eight triboelectric pairs (TENGs) arranged in stacks of four pairs each, and two electromagnetic generators (EMGs). A plastic stiffener helps ensure that foot pressure spreads evenly across the modules, and the entire mat is covered with PVC for durability and slip resistance.

A key advantage of this design—especially relevant for high-foot-traffic environments—is that the mat can be folded, reducing its overall size for easy transport and storage. This feature makes it well-suited for locations such as religious sites, where mats often need to be folded away for cleaning and maintenance. Another important characteristic is the need for consistent and focused pressure across the modules. Testing showed that when four of the six modules were pressed at the same time, the voltage output was about 30% higher than when all six modules were engaged only intermittently [26]. In other words, regular, concentrated stepping can boost energy storage but requires continuous foot traffic to maintain stable power generation.

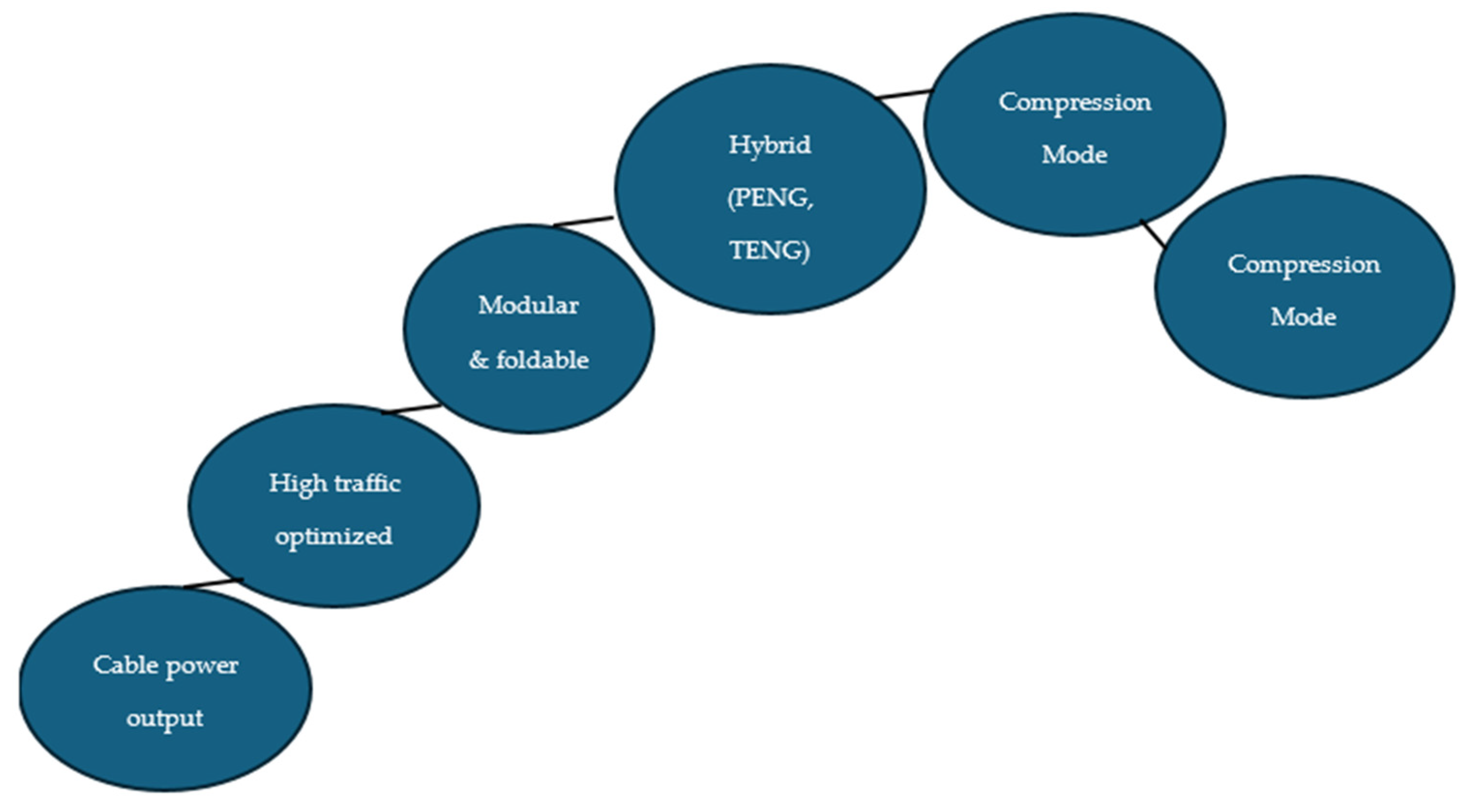

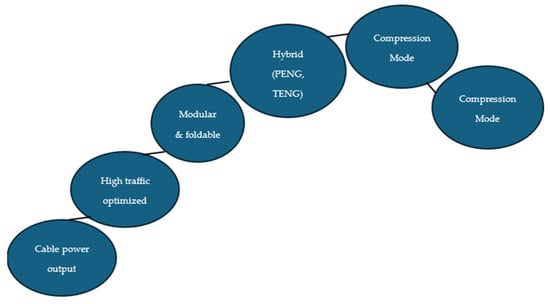

Figure 7 illustrates how the mat has evolved through several stages of development, each offering distinct benefits. Early foot-traffic energy-harvesting mats used basic cable-based outputs to carry the harvested energy to a storage device or load. While these straightforward designs successfully converted mechanical stress into electricity, they often lacked the durability and flexibility needed for heavy-use settings. The next phase of mat design introduced stronger materials and protective layers that better withstand repeated mechanical stress, making them more reliable in high-foot-traffic areas.

Figure 7.

Mat Design Evolution and Key Innovations.

Further advances led to modular and foldable mats, simplifying transport, setup, and maintenance. Hybrid systems that blend PENG, TENG, and EMG technologies can capture a wider range of mechanical energy. By altering the compression mode, these designs convert footstep force into shear or bending stress—methods that can improve energy efficiency. Arranging individual transducers in series–parallel helps balance voltage and current, meeting specific power requirements. Altogether, these innovations have produced mats that are both more portable and more efficient, consistently generating electricity through everyday walking.

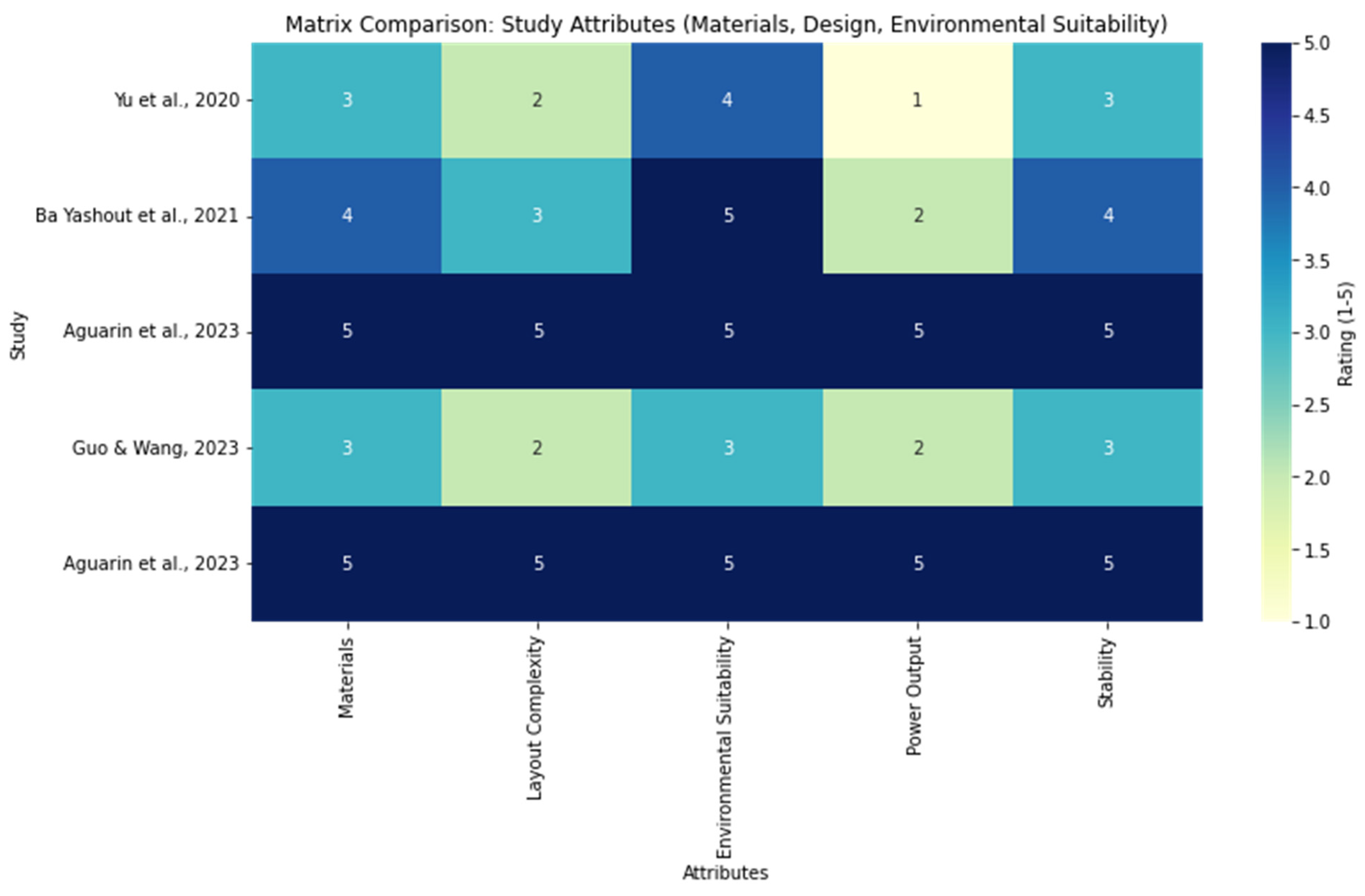

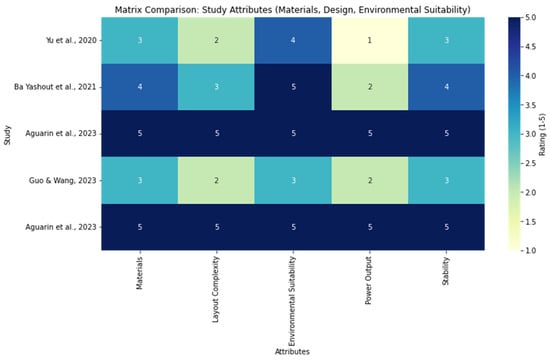

Figure 8 presents the performance analysis of various studies focusing on materials, layout complexity, environmental suitability, power output, and stability. Each study was rated on an ordinal scale from 1 to 5, reflecting the relative performance in each category. The scale is interpreted as follows: (a) low or minimal performance; (b) medium, meaning moderate or average performance; (c) high, indicating strong performance or high suitability. To arrive at these ratings, qualitative assessments were made:

Figure 8.

Rating for studies regarding the materials, layout complexity, suitability, power output [1–100], and stability (Aguarin et al. [26,27], Guo and Wang [62], Yu et al. [97], Ba Yashout et al. [87]).

Materials: Assesses the quality and type of materials used for durability and efficiency.

Layout Complexity: Considers how complex the design is, with higher ratings for more advanced or integrated components.

Environmental Suitability: Indicates how well the design can handle demanding conditions (e.g., heavy foot traffic or weather exposure).

Power Output: Measures the device’s energy-generating capability, where higher ratings mean greater output.

Stability: Reflects design features that promote consistent power output under varying conditions.

It is clear from these data that the design proposed by Aguarin et al. [26] meets all these criteria effectively. This kind of evaluation is particularly useful when creating a smart mat for high-foot-traffic locations, such as religious sites. By focusing on studies that received high ratings-for example, the work of Aguarin et al. [27]- engineers can adopt proven materials and layouts that offer strong power output and stability. This ensures the resulting smart mat will be durable, efficient, and consistently harvest energy from heavy foot traffic, aligning with the site’s requirement for a sustainable and resilient energy solution.

Megdich et al. [98] conducted a study on L-shaped bending–torsion piezoelectric energy harvesters (PEHs) that offers meaningful lessons for designing a “bright mat”, particularly for high-traffic environments. Below are key insights relevant to such applications:

- Multimodal Energy Harvesting for High Efficiency

By combining both bending and torsional energy-harvesting modes-as performed with the L-shaped PEHs-a bright mat could capture energy from the range of multidirectional forces generated by footsteps. This is especially valuable in crowded settings (such as a busy mosque) where people move in various directions and at differing speeds. Adopting multimodal energy capture would increase the mat’s power output over a wider frequency range.

- Broader Frequency Range Through d31 and d36 Modes

Employing the face shear mode (d36) alongside the conventional face extension mode (d31) significantly improves energy production across different motion types. In a bright mat, this could help capture energy more consistently from the diverse pressures and angles of footfalls, making the system more reliable even at lower frequencies.

- Better Structural Design with Coupled Bending–Torsion Mechanics

In Megdich et al. [98], the L-shaped PEH with an H1 configuration produced ten times the power of other designs. A similar layered approach using bimorph piezoelectric components could allow the mat to bend and twist under foot pressure, maximizing the range of forces it converts to electrical energy.

- Durability and Low Maintenance

The L-shaped PEH can function well under low-frequency, multimodal forces, suggesting a design that relies less on high footstep frequency. This aspect is crucial for a setting such as Al-Haram, where constant foot traffic demands a robust, low-maintenance solution. Layered structures using materials such as PZT and steel could minimize wear and reduce maintenance needs.

- Scalable Design for Large Surfaces

Since Megdich et al. [98] highlight a modular and scalable approach, a bright mat design could replicate this by using multiple PEH modules covering large surfaces. Each module can gather energy independently, connecting to a shared storage system. This modular setup allows high traffic without losing efficiency.

- Real-Time Data Collection and IoT Integration

Higher power output from combined bending–torsion and multimodal harvesting can power real-time monitoring tools for crowd flow and occupancy without external electricity. Such data could enhance crowd management and optimize how energy is stored in the bright mat system.

Integrating these design elements can produce a bright mat capable of generating greater energy, offer enhanced durability and adaptability, and deliver consistent performance in a bustling environment with diverse foot traffic, making it practical for large-scale energy harvesting in places such as major religious sites.

5. Output Voltage and Feasibility

Koszewnik [91] notes that vibration-based energy harvesters strongly depend on the alignment of their resonance frequency with surrounding vibration frequencies. Although using flexible materials and multi-mode structures can substantially improve energy output, these systems often remain confined to specific frequency ranges, limiting their use in places with low or inconsistent vibrations. Additionally, optimizing multiple parameters at once becomes challenging for large-scale applications.

In Asry et al. [5], a maximum voltage of 6.06 V was achieved after 20 s of continuous pressure by a 60 kg individual. While this output is enough to power low-power devices (e.g., LED streetlights or small electronics), significantly more scaling would be required for larger energy needs. Combining solar PV with piezoelectric transducers helps maintain a steady power supply—even when weather changes—because the piezoelectric part can supplement energy production in high-foot-traffic periods [16]. In [17], each step generated between 1 V and 14 V, depending on the user’s weight. On average, 9600 steps were needed to charge a 12 V battery. This approach suits powering low-power streetlights in busy areas.

Likewise, Ref. [15] reported an average output of 9.46 V and 126.6 mA under test conditions, peaking at 9.59 V and 134.1 mA (with a 70 kg individual walking over piezoelectric tiles). This voltage can run small electronic devices such as sensors or mobile chargers. The hybrid system proposed in [15] is suitable for low-power operations, especially where both kinetic and solar energy are accessible. By using two energy sources, the system remains consistent even when solar is unavailable.

Serrano et al. [4] employ a Spatially Varying (SV) electric field model for piezoelectric energy-harvesting gyroscopes. At optimum load resistance (103 Ω to 108 Ω), the system achieves 1.3 mV in open-circuit and 2.1 mV in closed-circuit near 65 kHz (energies-16-02000-v2). Though these are low-power outputs (millivolt scale), they can still power small MEMS sensors. The SV model is also more accurate than constant-field models when predicting performance across different loads.

Selim et al. [3] recorded an open-circuit voltage as high as 33.7 V. However, when powering a single LED, the output dropped to 2.4 V, and two LEDs in series produced 4.8 V. Nonetheless, it is enough for low-power applications such as LEDs or other small devices. Installing 30 tiles at the entrance of a building could generate an estimated 60 Wh over 8 h—enough to power a security camera for around 11 h. Yeboah et al. [6] propose a hybrid system that is well-suited for large-scale setups, combining the continuous foot traffic during football matches with available solar power; this hybrid system ensures a reliable output even when one source is limited.

Aguarin et al. [26] report each mat module can deliver a peak open-circuit voltage of 192 V, a short-circuit current of 69.10 mA, and a maximum power of 100 mW—156% more voltage and 212% more power than equivalent hybrid shoe designs. The mat can also store 6.88 V in 10 s under steady 120 BPM stepping by a 60 kg individual, enough for short-term power. In a later design, Aguarin et al. [27] confirm the same peak performance figures (192 V, 69.10 mA, 100 mW), again highlighting a 6.88 V storage level in 10 s of continuous stepping at 120 BPM by a 60 kg person.

Although Guo and Wang [62] show promise, they do not provide detailed power results. By contrast, Aguarin et al. [26,27] report the largest increase in energy output: a 156% surge in voltage and a 212% improvement in peak power over prior systems, thanks in part to a portable, modular configuration. Still, their tri-hybrid generators were mainly tested in controlled environments. Chew et al. [99] explored biomechanical energy from walking, but they offered fewer specifics on power output than Aguarin et al. [26,27]. Chen et al. [100] found that a BP5-GFRP composite with 5 wt% BaTiO₃ (d33 ≈ −33.9 pC/N) generated up to 2 µW under 1 g sinusoidal vibration; BP5-CFRP provided 1.5 µW. Over 5,000 vibration cycles, these setups remained stable. In real-world tests, BP5-CFRP yielded 33.69 µW on an aircraft and 3.44 µW in a vehicle, suitable for structural health monitoring. Zhang et al. [67] introduced a PTNG reaching 200 V output, suggesting enough power for small devices or IoT sensors. This modular design could scale to larger surfaces (e.g., mosque floors) and stay efficient under many cycles.

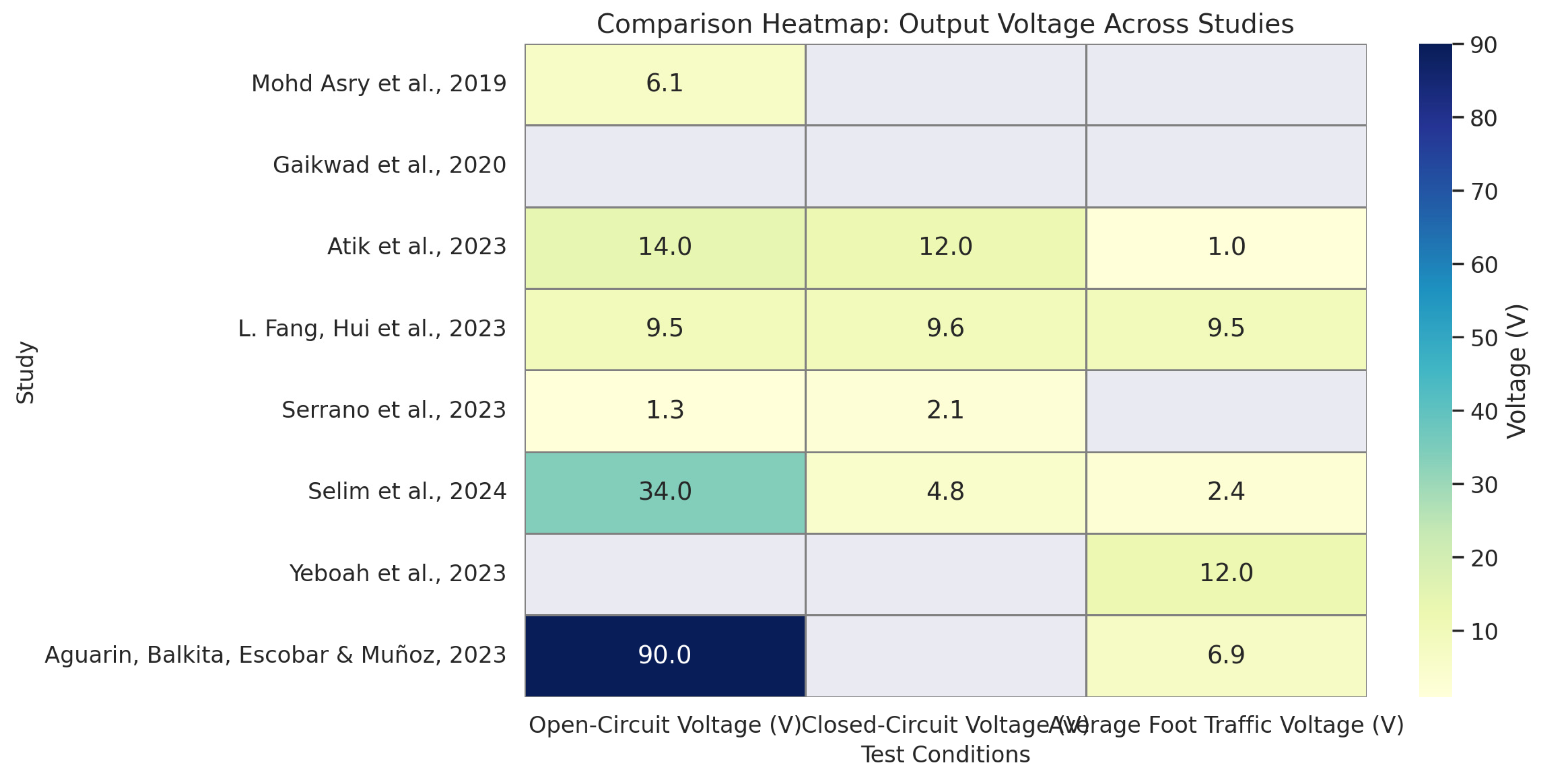

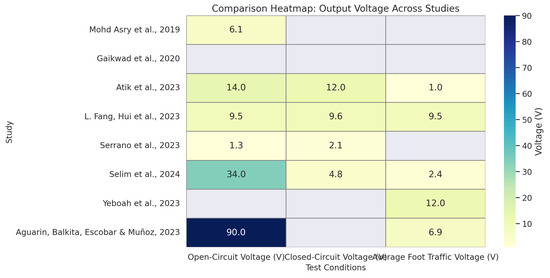

Finally, for smart mats, Yu et al. [97] highlight the importance of a textile that is home-friendly—washable, durable, and able to match interior décor—while Aguarin et al. [26] emphasize foldability, critical for venues such as religious sites that require frequent cleaning. Figure 9 compares the output voltage and circuit type across these studies, indicating that Selim et al. [3] achieved the highest voltage with an open-circuit configuration.

Figure 9.

Comparison Heatmap: Output Voltage Across Studies (Selim et al. [3], Serrano et al. [4], Asry et al. [5], Yeboah et al. [6], Fang et al. [16], Gaikwad et al. [17], Atik et al. [18], Aguarin et al. [26]).

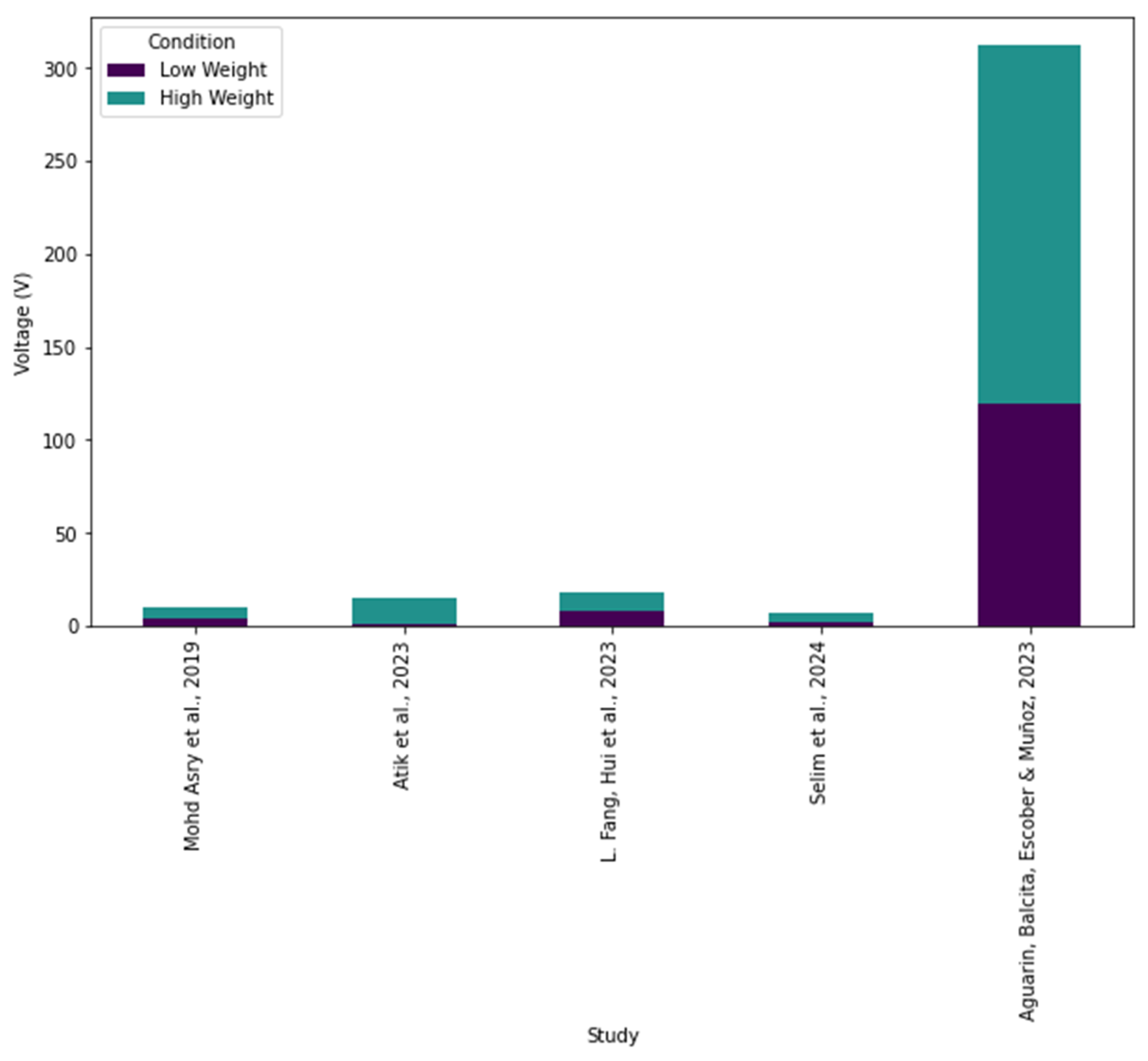

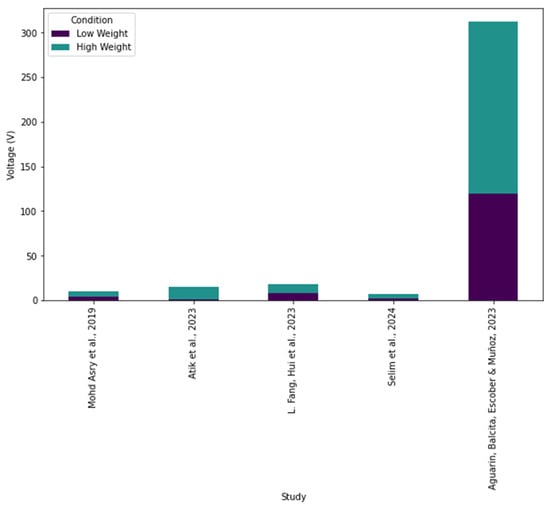

Regarding the impact of high weight on the output voltage, Figure 10 compares the reviewed studies. All studies presented in the figure reported the output voltage when weight and height were low. The work of Aguarin et al. [26] reported the highest voltage when the weight was low and high.

Figure 10.

Voltage output across different weight conditions (Selim et al. [3], Asry et al. [5], Fang et al. [16], Atik et al. [18], Aguarin et al. [27]).

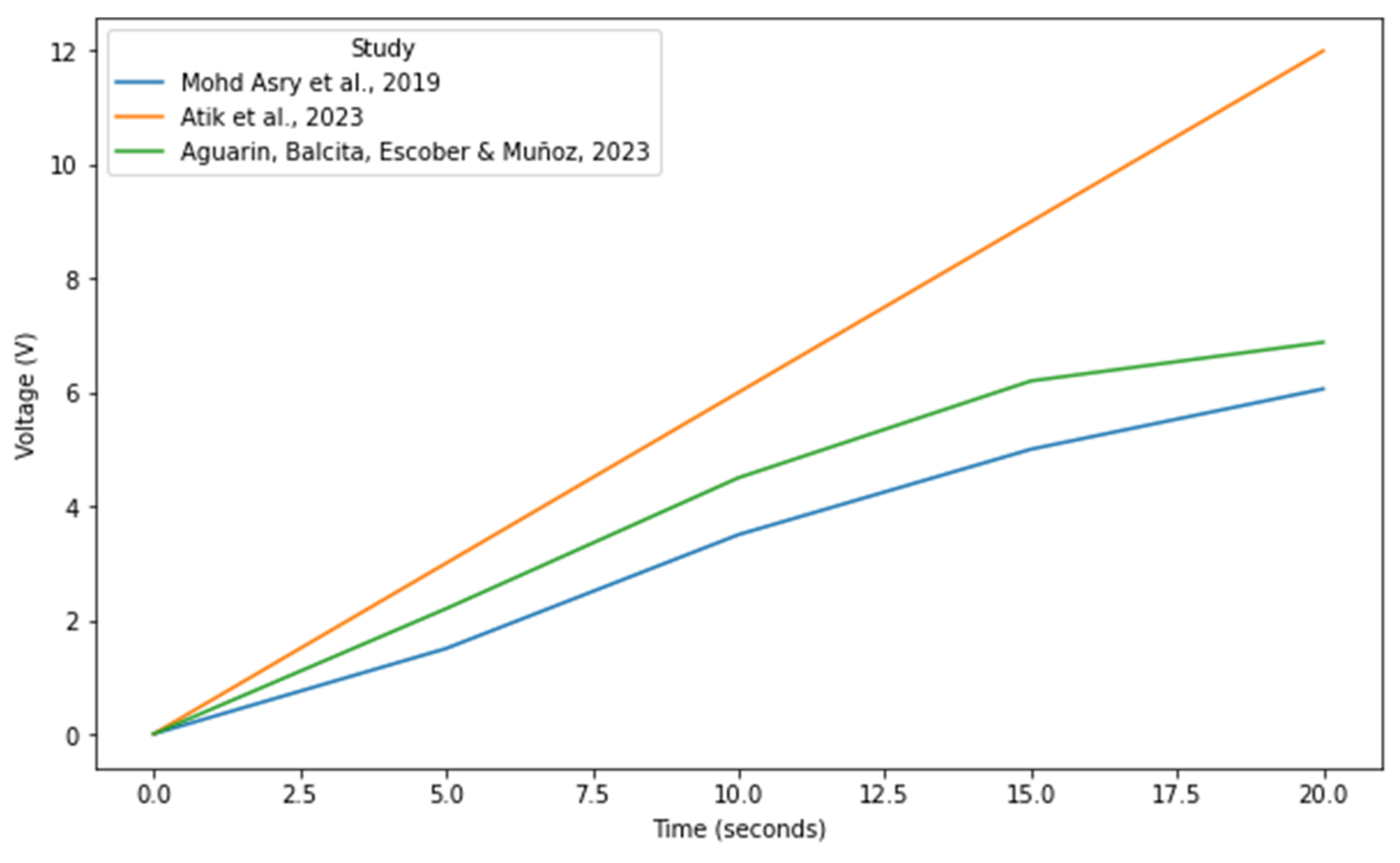

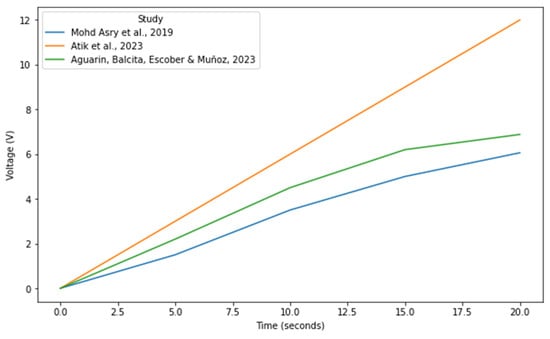

Figure 11 presents the time of continuous foot traffic and its relationship with output voltage. On average, if there are 20 s of constant foot traffic, the voltage output records its highest amount. Noticeably, the work of Atik et al. [18] shows a consistent increase in voltage while foot traffic is continuous.

Figure 11.

Voltage Output over time under continuous foot traffic (Asry et al. [5], Atik et al. [18], Aguarin et al. [26]).

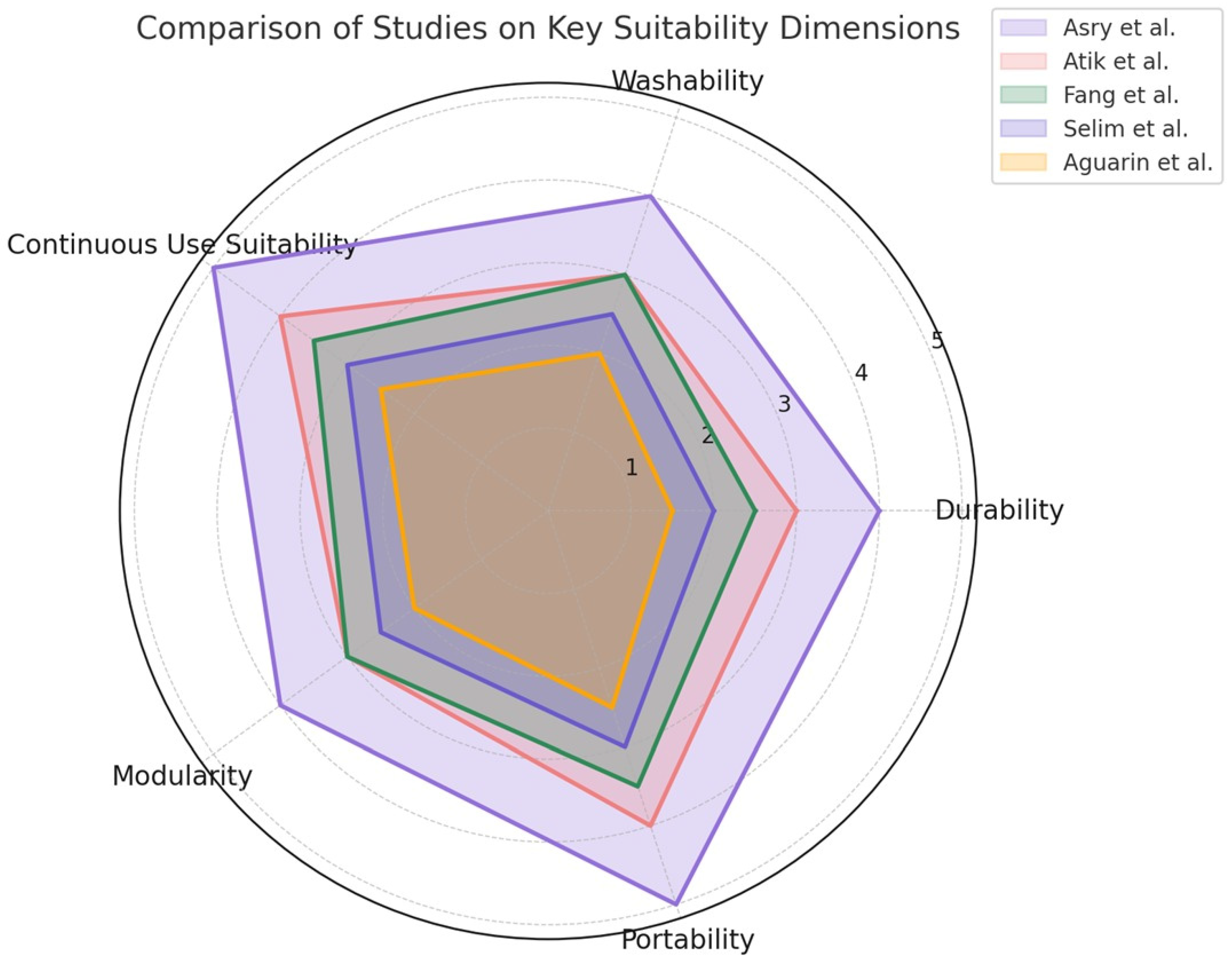

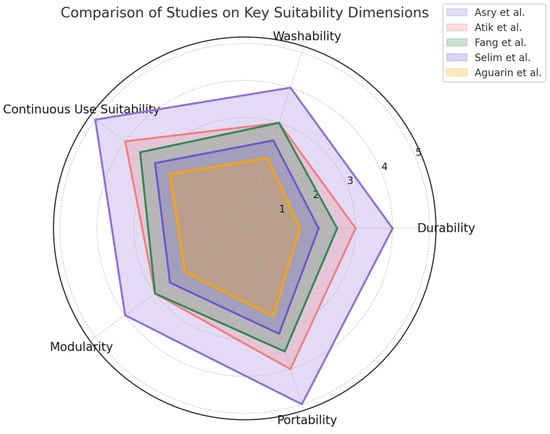

Finally, Figure 12 presents the design capability proposed in each study reviewed regarding portability, durability, washability, modularity, and continuous use suitability. It is noticeable that the work of Aguarin et al. [26] was the only design that met all those criteria.

Figure 12.

The capability of the design proposed in each study is reviewed in terms of portability, durability, washability, modularity, and continuous use. 1–5 is rating score (Selim et al [3], Asry et al. [5], Fang et al. [16], Atik et al. [18], Aguarin et al. [26]).

6. Challenges

6.1. Low Power Output

While hybrid systems hold promise, the energy produced by piezoelectric transducers remains relatively low. On its own, the power from piezoelectric harvesters is not enough for high-energy applications. Likewise, the output from a single piezoelectric tile is minimal, so powering larger or more energy-intensive devices would require significantly more tiles or additional energy sources [5]. This situation is comparable to the proposals by Selim et al. [3] and the “magic mat” of Ba Yashout et al. [87]. Meanwhile, the TENG cells in Yu et al. [97] depend on mechanical contact to create energy; although sufficient for tasks such as fall detection, they are too limited for broader energy-harvesting purposes.

6.2. Unstable Output

The energy harvested from footsteps can vary widely, mainly due to differences in a person’s weight (which compresses the piezoelectric crystals) and the number of steps taken. As a result, voltage and current outputs tend to be inconsistent [3,15,25,26]. Although Yeboah et al. [6] propose a system capable of generating a substantial amount of electricity, it relies heavily on the frequency of football matches. This limitation also applies to the designs by Aguarin et al. [26,27], and Gaikwad et al. [17]. Conversely, religious sites such as Al-Haram remain crowded day and night, making the approaches discussed in [20,21,32]—which are specifically suited to continuous foot traffic-more appropriate in that context.

6.3. Mechanical Durability

Relying on physical pressure and mechanical movements—such as springs and tiles, as seen in [3,5,16,99]-can lead to wear and tear over time, reducing the system’s long-term durability. In the proposal by Crawley and Luo [18], for instance, piezoelectric discs were subjected to high stress levels that caused material failures such as cracks and fractures. This brittleness raises concerns about practical lifespan under continuous force. Additionally, installing piezoelectric tiles under large surfaces involves considerable installation and maintenance efforts to preserve performance [96]. A tri-hybrid design similar to that in [20], which uses three different generator types, increases both complexity and the number of potential failure points. Consequently, such designs may experience greater wear and tear under extended, high-foot-traffic usage.

6.4. Dependence on Environmental Conditions and Load Resistance Sensitivity

The solar component of many hybrid systems depends heavily on weather, causing a significant drop in power output when skies are cloudy or during rainfall [15]. Although the piezoelectric aspect can help maintain some level of energy production, it is not entirely reliable. Nevertheless, continuous usage is often noted as a weak point in these designs. In the context of this study, however, Al-Haram remains busy around the clock—though there is typically lower foot traffic between midnight and 4 a.m.

Additionally, the system introduced by Serrano et al. [4] relies on finding the optimal load resistance, making it susceptible to variations in the connected electrical circuitry. Even small changes in resistance can reduce the energy harvested. Likewise, the design described in [22] requires a specific number of continuous walking hours, which can be challenging to achieve unless the setting inherently provides steady foot traffic.

6.5. Design Complexity and Sensitivity and Energy Loss in Crinkle Washers

Although using the shear mode can improve energy output [18], Crawley and Luo’s [19] system depends heavily on specific washer designs, compression forces, and how weight is distributed. This makes it difficult to scale up or apply the technology to larger projects without extensive customization. Additionally, installing piezoelectric tiles into flooring and ensuring they endure heavy foot traffic can be expensive in terms of both installation and maintenance. Likewise, even though the mat by Aguarin et al. [26] is portable, it still demands careful handling to avoid damage and relies on proper foot-pressure distribution for best results.

The crinkle washer, while offering flexibility and working well in limited spaces, showed lower energy efficiency because of uneven force distribution and occasional gaps. These factors reduced the effectiveness of energy transfer.

7. The Case Study

This case was selected for several reasons:

- (a)

- It hosts millions of pedestrians, which presents a significant opportunity for kinetic-electricity conversion. Moreover, foot traffic is consistent, meaning the large number of people (thousands at any given time) is sufficient to provide a steady flow of electricity.

- (b)

- The site consumes a tremendous amount of electricity, and kinetic energy is currently being wasted.

- (c)

- It is a challenging location for developing kinetic energy harvesting systems that are capable of remaining sustainable while enduring extreme conditions, such as high temperatures, continuous use, and frequent folding and cleaning.

On the other hand, while investigating the suitability of the aforementioned energy-harvesting materials, the following assumption was made: the term “hybrid” refers to a combination of several materials that are capable of harvesting only kinetic energy.

7.1. Background

The energy consumption of the Al-Haram Mosque (Masjid Al-Haram) in Saudi Arabia is a critical area of focus because of its vast size, continuous operation, and the immense number of visitors it attracts [101]. Located in Mecca, the Al-Haram Mosque is the largest Mosque in the world and surrounds Islam’s holiest site, the Kaaba. This section discusses the mosque’s energy demands, primary energy sources, the integration of innovative self-powered systems, and its overall sustainability approach.

The Al-Haram Mosque hosts millions of visitors annually, with peak numbers during the Hajj pilgrimage and the month of Ramadan [101]. These visitors require a consistent and reliable energy supply to ensure comfort, safety, and uninterrupted religious activities [102]. The mosque operates 24/7, with energy demands encompassing lighting, cooling, ventilation, escalators, water supply, and large-screen displays, among other needs.

Several core areas contribute to the Al-Haram Mosque’s significant energy consumption:

Lighting: The mosque is illuminated by thousands of high-intensity LED lights, both indoors and outdoors, to accommodate continuous prayer times and ensure visibility and safety [102]. This lighting is essential for guiding pilgrims at night and illuminating significant structures such as the Kaaba.

Cooling and Ventilation: Saudi Arabia’s climate is characterized by high temperatures, particularly in Mecca, where summer temperatures can exceed 40 °C (104 °F) [103]. Cooling is a significant energy consumer within the mosque, especially given the density of people congregating in one area. The cooling system includes massive air conditioning units, ventilation fans, and chillers to regulate temperatures, ensuring visitors’ comfort despite the extreme heat.

Escalators and Elevators: The Al-Haram Mosque spans multiple levels, and to facilitate the movement of millions of pilgrims, it features an extensive network of escalators and elevators. These systems are particularly beneficial for elderly and disabled visitors.

Water Supply: The provision of water for ablution areas and drinking is another critical energy component. Thousands of liters of water are required daily, with energy expended on water distribution, desalination (for drinking water), and wastewater management.

Audio–Visual Systems: Large screens and a high-quality audio system support religious activities, providing announcements and guidance to pilgrims. The audio system is extensive, covering the vast area of the mosque to ensure all worshippers can hear prayers and recitations clearly.

While exact figures for energy consumption are not frequently disclosed, reports and estimates provide insight into the mosque’s immense energy needs. The Al-Haram Mosque consumes approximately 118 MVA annually, comparable to the energy demands of a small city. Energy consumption escalates during Ramadan and Hajj because of the increased number of pilgrims, with demand rising by an estimated 20–30% [102,103].

7.2. Primary Energy Sources

Due to Saudi Arabia’s abundant hydrocarbon resources, the mosque traditionally relies on the regional grid, powered primarily by fossil fuels such as natural gas and oil [102,103]. While this energy source has proven reliable in meeting the mosque’s energy demands, the use of fossil fuels contributes to greenhouse gas emissions, making this approach less sustainable. Saudi Arabia has therefore taken significant steps toward diversifying its energy sources through initiatives such as Vision 2030 [104,105], which aims to reduce dependence on fossil fuels by increasing the use of renewable energy [106,107,108]. This strategy aligns with the country’s commitment to sustainable development and has specific implications for energy-intensive sites such as the Al-Haram Mosque.

Given the country’s high solar irradiance levels, solar power is a primary focus of Saudi Arabia’s renewable energy initiatives [104,105,106,107,108]. Solar panels have already been installed on surrounding buildings and facilities within the mosque complex [109]. However, due to space limitations and aesthetic considerations within the mosque’s main areas, the large-scale deployment of solar panels remains challenging [110]. As a result, these solar installations primarily provide supplementary power to auxiliary buildings and nearby administrative offices rather than fully replacing the primary grid supply [110,111,112].

Considering the unique requirements of the Al-Haram Mosque, there is significant potential for developing self-powered systems that harness environmental energy sources and energy from pilgrims’ movements. Emerging technologies being explored include piezoelectric energy harvesting, triboelectric nanogenerators (TENGs), and hybrid systems combining solar and kinetic energy harvesting.

Piezoelectricity, the generation of electricity through mechanical stress—has gained attention for applications in crowded areas [99]. This technology involves embedding piezoelectric materials within the flooring to convert kinetic energy from footsteps into electrical energy [25,26,88,97,99]. A piezoelectric flooring system could thus be installed in high-traffic areas of the mosque, such as entrances, prayer halls, and passageways, allowing energy to be harvested from the movement of pilgrims. Recent studies [5,25,26,97,99] indicate that piezoelectric systems could contribute to powering LED lighting or charging low-power devices, although they are unlikely to meet the mosque’s extensive energy requirements entirely. Trials conducted in other high-traffic locations have demonstrated that piezoelectric technology can effectively provide supplementary power, particularly when combined with battery storage systems that capture energy during peak usage times [97].

Triboelectric nanogenerators (TENGs) represent another promising approach for creating self-powered systems [59,62,92]. TENGs generate electricity through contact electrification, which occurs when two different materials repeatedly come into contact and separate [41]. This technology could be integrated into carpets or mats to capture energy from pilgrims’ footsteps, converting mechanical motion into electrical energy. Although TENGs are still at an experimental stage for large-scale applications, they have demonstrated potential in powering small sensors and low-energy lighting [30]. By deploying TENGs in designated walkways within the mosque, energy could be produced to power some low-energy applications. Moreover, the modular nature of TENGs allows them to be easily arranged and scaled according to specific requirements.

Last, hybrid energy systems that combine solar power with kinetic energy harvesting might provide a more robust and reliable solution. For instance, integrating piezoelectric materials with solar panels could enable energy collection during both the day (solar energy) and night (foot traffic) [6,15]. Such a hybrid system could provide a consistent power supply for the mosque’s auxiliary buildings, street lighting, and outdoor facilities. The effectiveness of hybrid systems was previously demonstrated by a project in Ghana [6], where solar energy and kinetic energy from footsteps were combined to power lighting and small devices in a public football stadium. Such hybrid systems show considerable promise for large-scale applications and could be suitably adapted to the Al-Haram Mosque, particularly in outdoor or shaded areas where solar power alone would be insufficient.

7.3. Sustainability and Future Directions for Al-Haram

The Al-Haram Mosque’s energy strategy is shifting towards a more sustainable model, aligning with broader Saudi initiatives to adopt renewable and eco-friendly energy sources [87]. Several sustainable practices have already been implemented or are under consideration [103,112]:

- (a)

- LED Lighting Upgrades: The shift from traditional lighting to LED technology has significantly reduced the mosque’s lighting energy consumption [88]. LEDs are more energy-efficient and have a longer lifespan, making them particularly suitable for high-use environments [87].

- (b)

- Cooling Innovations: To address the high energy demands associated with cooling, the mosque may consider adopting district cooling systems or high-efficiency chillers to lower electricity usage [113]. Additionally, advanced air distribution and heat exchange systems could help manage cooling more efficiently [87].

- (c)

- Energy Storage Solutions: Battery energy storage could enhance the integration of renewable sources, especially solar power, by storing excess energy generated during the day [100]. This stored energy can then be utilized during peak demand periods or at night when solar energy is unavailable.

Despite the potential benefits of renewable and self-powered systems, several challenges hinder the complete adoption of these technologies at the Al-Haram Mosque:

First, the Scale of Energy Demand: The mosque’s enormous energy requirements, particularly for cooling and ventilation, make it difficult for renewable and self-powered systems alone to fulfill the entire demand [101]. Supplementary renewable systems may be feasible, but traditional energy sources will likely remain essential for meeting the primary load [109,112].

Second, Aesthetic and Spatial Constraints: Given the mosque’s historical and religious significance, any new installations must be carefully considered [102,103]. Large-scale solar panels [110] or visible piezoelectric systems could conflict with the mosque’s aesthetics [113], requiring creative and unobtrusive integration methods.

Third, Cost and Maintenance: Implementing and maintaining renewable energy systems, especially in a high-traffic environment, can result in substantial costs [100]. Advanced energy-harvesting technologies such as TENGs and piezoelectric flooring may also require frequent maintenance due to wear and tear, potentially disrupting mosque operations [114].

Fourth, Environmental Conditions: The harsh climate in Mecca, characterized by high temperatures and dust, poses durability challenges for solar and piezoelectric systems [115]. Ensuring these technologies can withstand environmental conditions without frequent replacement or repairs is essential for their long-term viability [116].

The Al-Haram Mosque’s energy consumption is immense because of its scale, continuous operations, and the comfort and safety requirements of millions of pilgrims [101]. Although traditional fossil fuel-based energy sources have reliably powered the mosque, there is an ongoing shift towards renewable and self-powered energy systems [117]. Therefore, further exploration of solar power, piezoelectric energy harvesting, and hybrid systems combining solar and kinetic energy is necessary to reduce reliance on non-renewable sources and enhance sustainability.

While current self-powered technologies such as piezoelectric flooring and TENGs might not fully satisfy the mosque’s extensive energy needs, they provide valuable supplementary solutions that could alleviate demand on the primary grid, particularly for low-power applications. As these technologies continue to advance, the potential for renewable and self-powered systems to significantly contribute to the mosque’s energy infrastructure will likely increase, supporting Saudi Arabia’s vision for a sustainable future [118].

7.4. Kinetic Energy Harvesting Materials Assessment

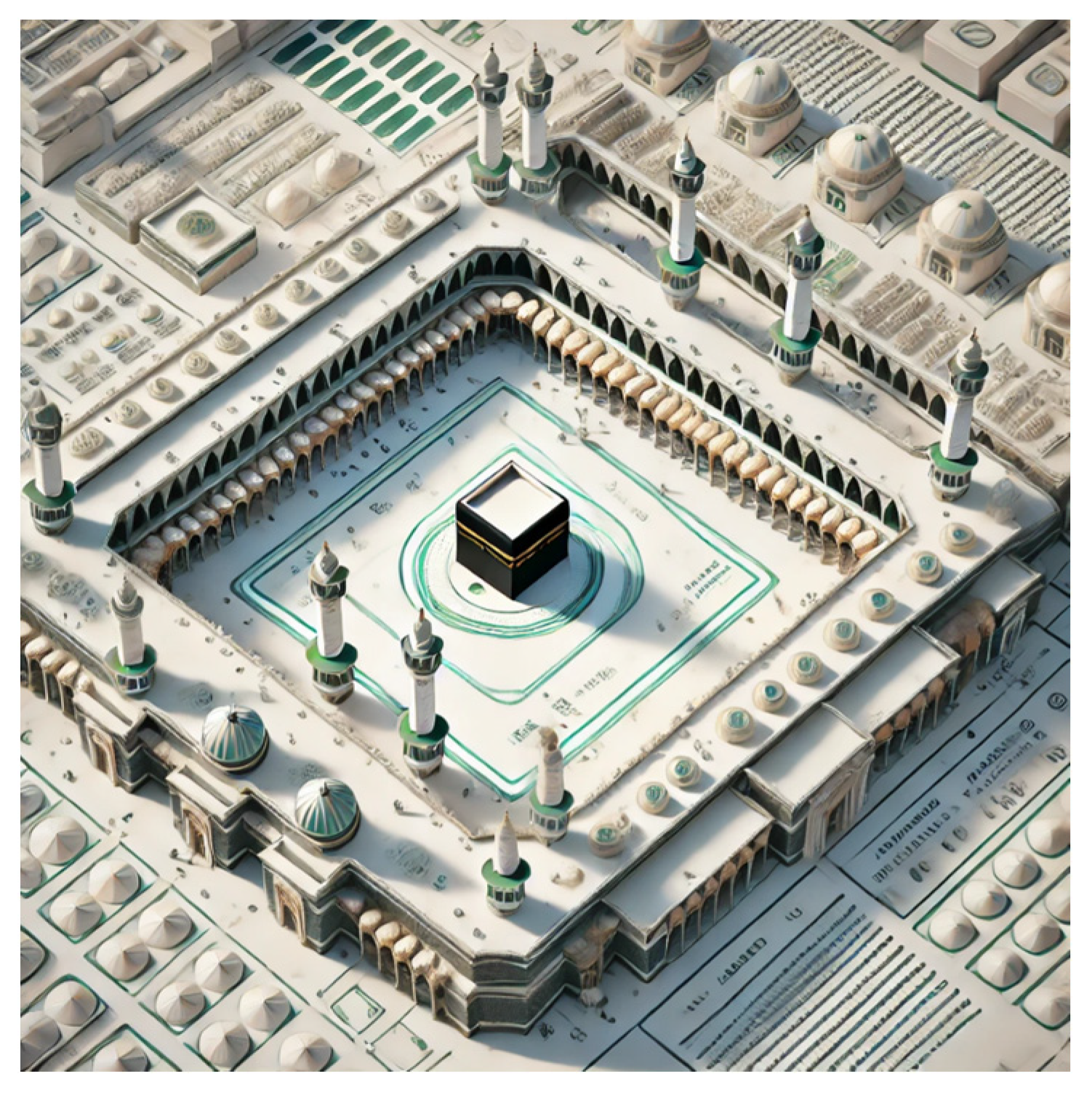

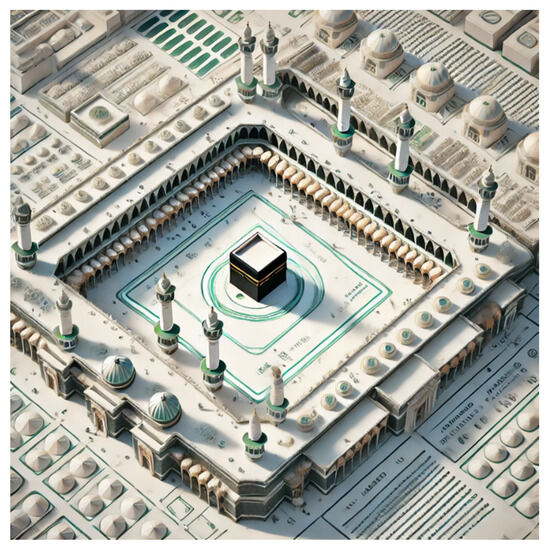

To appreciate the large space available in the Al-Haram Mosque to be utilized for kinetic-based energy harvesting, an illustration is provided in Figure 13. The illustration shows a simplified 3D-style top-down view of Masjid Al-Haram in Mecca, with the Kaaba located centrally within the Mataf area (the open white circular zone surrounding the Kaaba). The image highlights designated blank areas where smart mats can be placed. These areas include Main courtyards—open spaces outside the covered prayer halls, shown in light beige, typically used during peak prayer times or overflow situations. Terrace levels—upper-level flat zones along the mosque’s structure, represented in lighter tones and labeled with arrows. These areas are accessible and provide extra capacity for smart mat placement. Peripheral open zones—labeled blank spaces along the outer mosque walls, commonly used by pilgrims, especially during non-peak hours. The colored arrows and labels clearly indicate mat-eligible zones while helping differentiate between the core sacred area (darker or highlighted central sections) and general-use prayer areas (lighter open spaces). The minarets and covered halls are shown in raised 3D shapes to illustrate the layout. The light color palette is intentionally used to keep the focus on open zones and maintain clarity for academic or instructional use.

Figure 13.

A 3D-Style Top-Down View of Al-Haram Mosque with Highlighted Mat Placement Areas.

7.4.1. t-TENGs Materials

Textile-based Triboelectric Nanogenerators (t-TENGs) present a promising material solution for generating electricity from the movement of large crowds, making them especially suitable for high-foot-traffic areas such as the Al-Haram Mosque in Saudi Arabia [119]. While an analogy can be drawn between crowded sports complexes, as discussed in [119], and the mosque, Al-Haram experiences a significantly higher and continuous flow of millions of pilgrims, particularly during peak periods such as Hajj and Ramadan. This constant foot traffic provides a substantial and consistent source of mechanical energy, which could be harnessed by integrating t-TENG materials into the flooring to power lighting or low-energy devices within the mosque. The inherent modularity of textile-based TENGs allows them to be engineered into flexible and customizable mats or carpets that can seamlessly blend with the mosque’s aesthetic design. These textile modules can cover extensive foot-traffic areas and are easily folded or stored during cleaning and maintenance, aligning well with the mosque’s regular upkeep routines.

Regarding the suitability of t-TENG materials for the mosque’s environmental conditions, recent advancements have significantly improved their durability and resistance to environmental challenges. Research involving polyester-based TENGs and advanced coating techniques has enhanced their ability to withstand repeated mechanical stress and harsh conditions such as high humidity, temperature fluctuations, and dust exposure [120]. These conditions are common in the climate surrounding the Al-Haram Mosque. Such improvements in material properties underscore the potential of t-TENGs as a robust and reliable energy-harvesting solution in heavily used areas. Although t-TENG materials may not currently produce enough electricity to operate heavy electrical systems, they are ideal for powering low-energy applications, such as lighting systems, sensors for air-quality monitoring, or small digital displays. Furthermore, integrating t-TENG-powered sensors could enable autonomous monitoring of environmental parameters such as temperature, humidity, and CO2 levels, thereby enhancing comfort and safety without relying on external power sources.

Despite these advantages, several challenges remain for the practical implementation of t-TENG materials. The current power output of these textiles remains relatively limited, suggesting that combining them with other energy sources may be necessary to satisfy higher energy demands. Moreover, although recent advancements have improved durability, textile-based TENGs remain susceptible to wear under continuous heavy foot traffic. Addressing this issue may require the application of high-durability coatings or the selection of more robust materials. Additionally, the extreme conditions at the Al-Haram Mosque—including high temperatures, dust, and humidity—could negatively impact the efficiency of t-TENG materials.

Hybrid triboelectric systems incorporating polymers with conductive fillers have demonstrated enhanced charge generation and retention capabilities [89,120]. Their flexibility and lightweight characteristics make this composite material ideal for integration into thin, large-area devices, further reinforcing the potential of textile-based TENGs as a viable solution for kinetic energy harvesting in environments with substantial foot traffic.

Therefore, to estimate the power harvesting using this material within the Al-Haram space, the following assumptions are set: (a) Energy per footstep is ~0.1 Joule (conservative estimate), energy per full prayer cycle is ~1.0 Joule (due to multiple postures), average people per day is ~500,000 (can exceed 2 million in Hajj and Ramadhan), average prayer cycles/day/person is 5 (compulsory) + 2 (optional) = 7, mat-covered area (example) is 10,000 m2 (selected prayer area), people per m2 in congregation is ~2.5.

Therefore, total Energy Harvested (Prayer):

Per day: Total energy/day = people × prayer cycles × energy per cycle

= 500,000 × 7 × 1.0 = 3,500,00 Joules/day

In watt/hour, it will be 3,500,000 J ÷ 3600 = ~972 Wh/day

This equates to nearly 1 kWh/day from just prayer movements, and we have not yet included walking energy.

The total energy harvested (walking)-with the assumption that each person walks ~500 steps inside the mosque daily (entry, tawaf, sa’I, etc.) is 500,000 ×500 × 0.1 J = 6944 Wh. Then, the walking + prayer total = ~7.9 kWh/day, and much more during Hajj and Ramadhan.

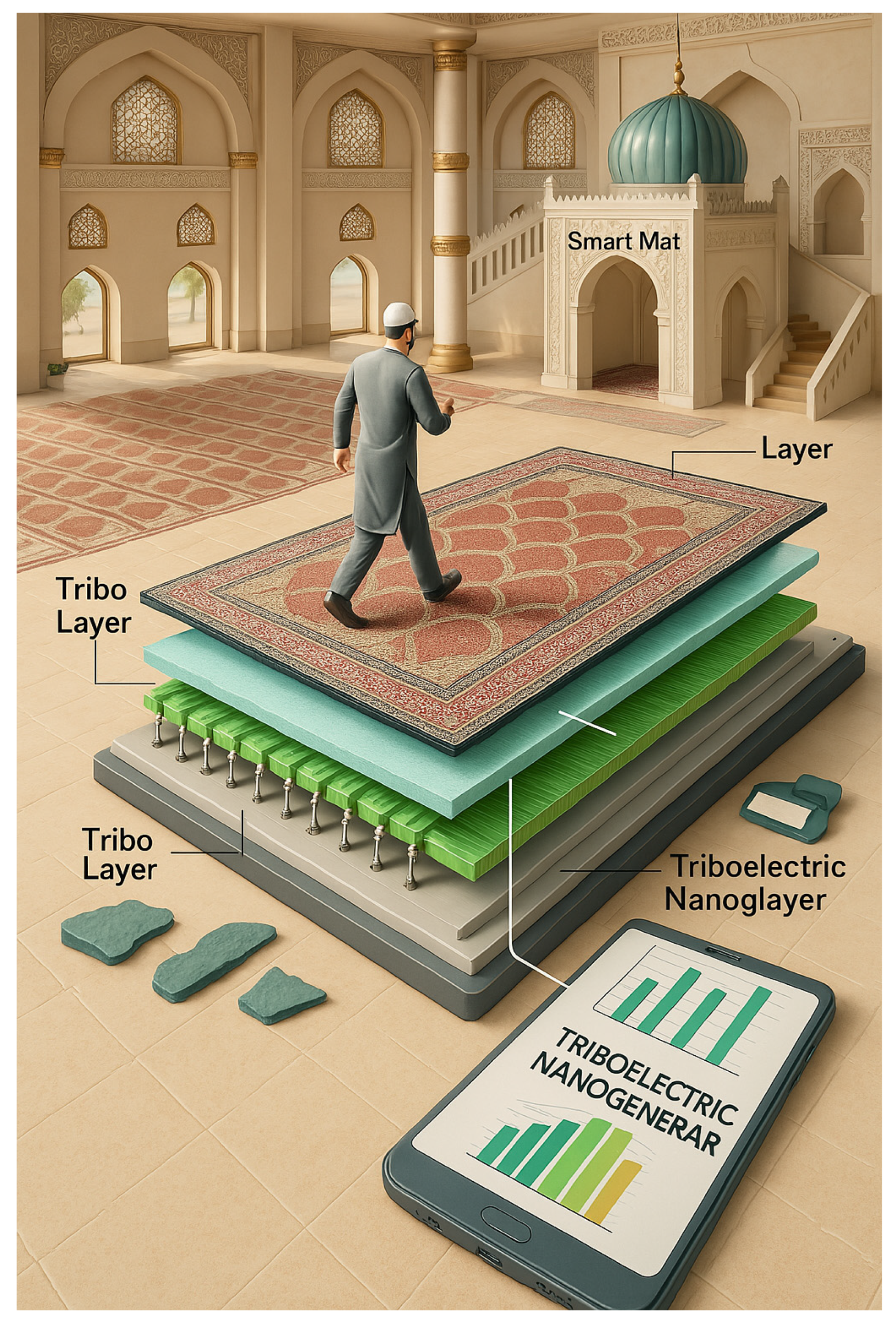

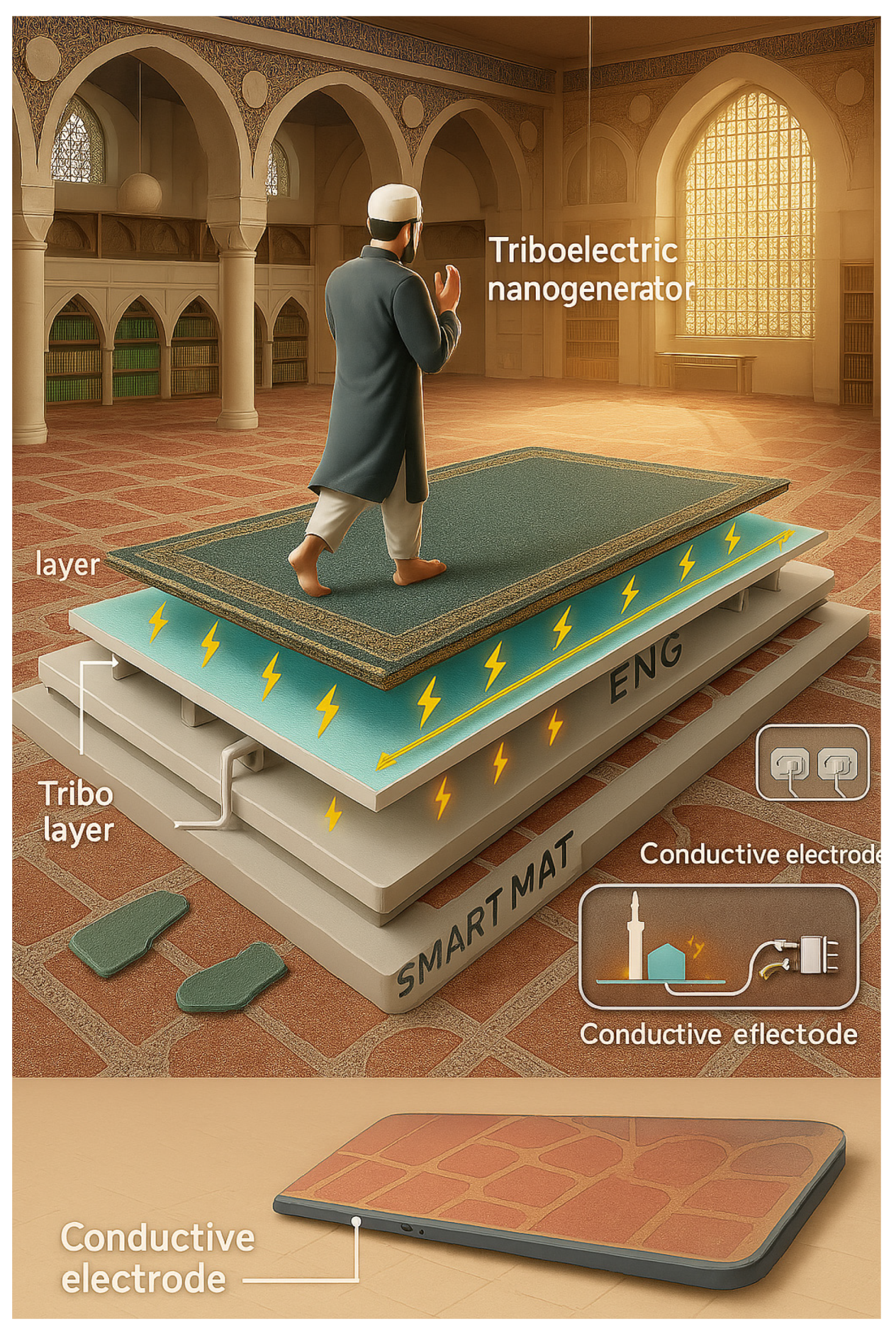

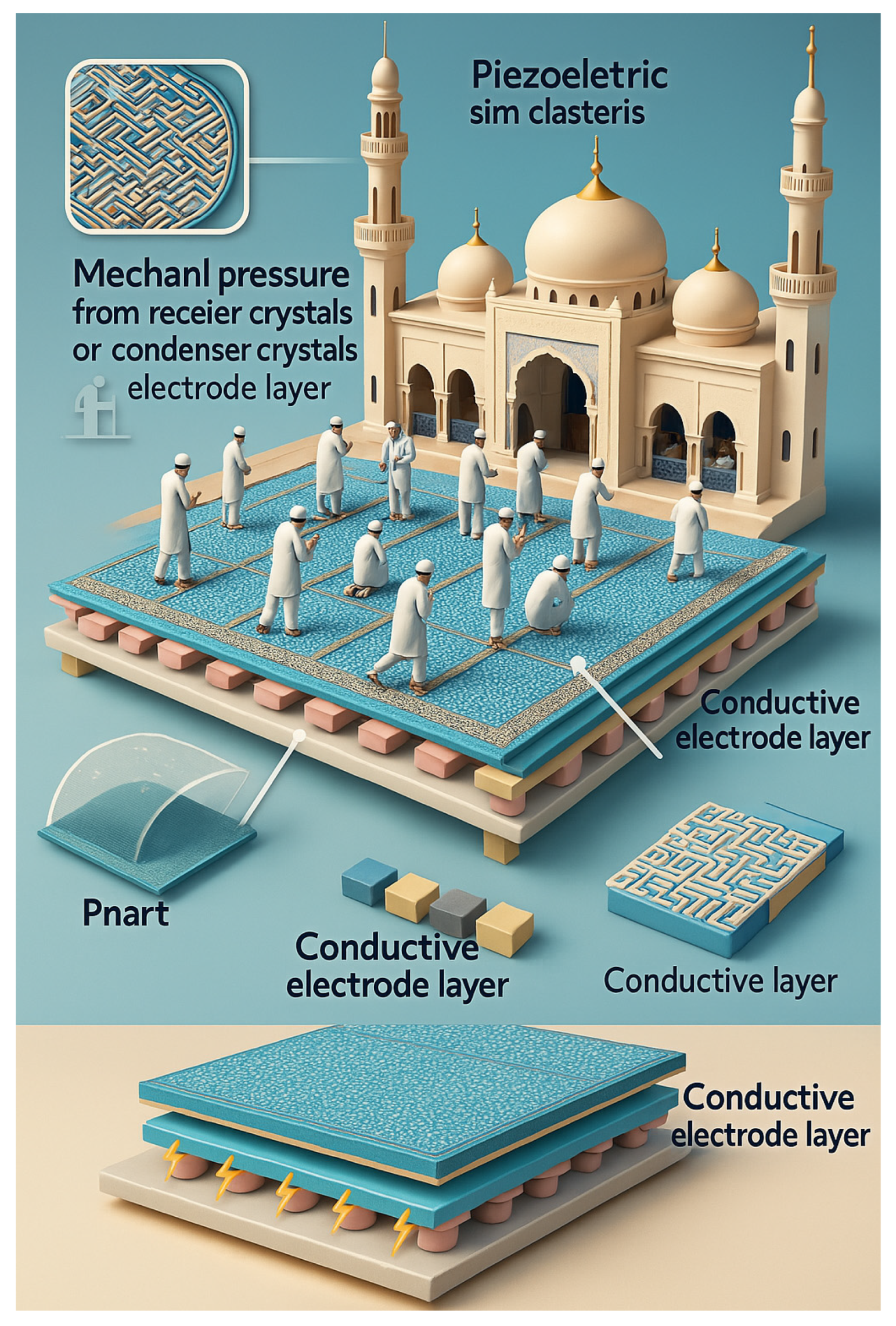

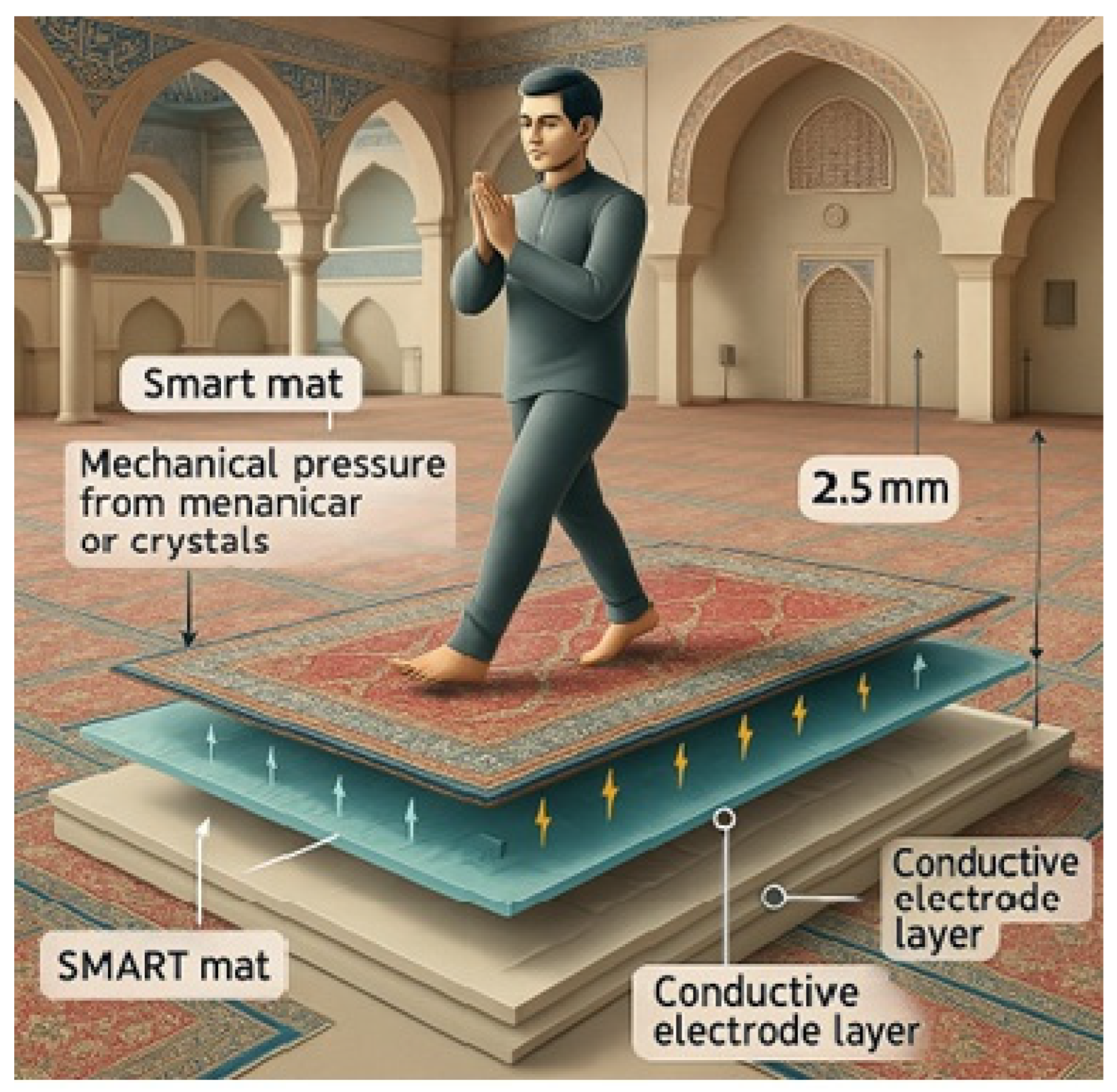

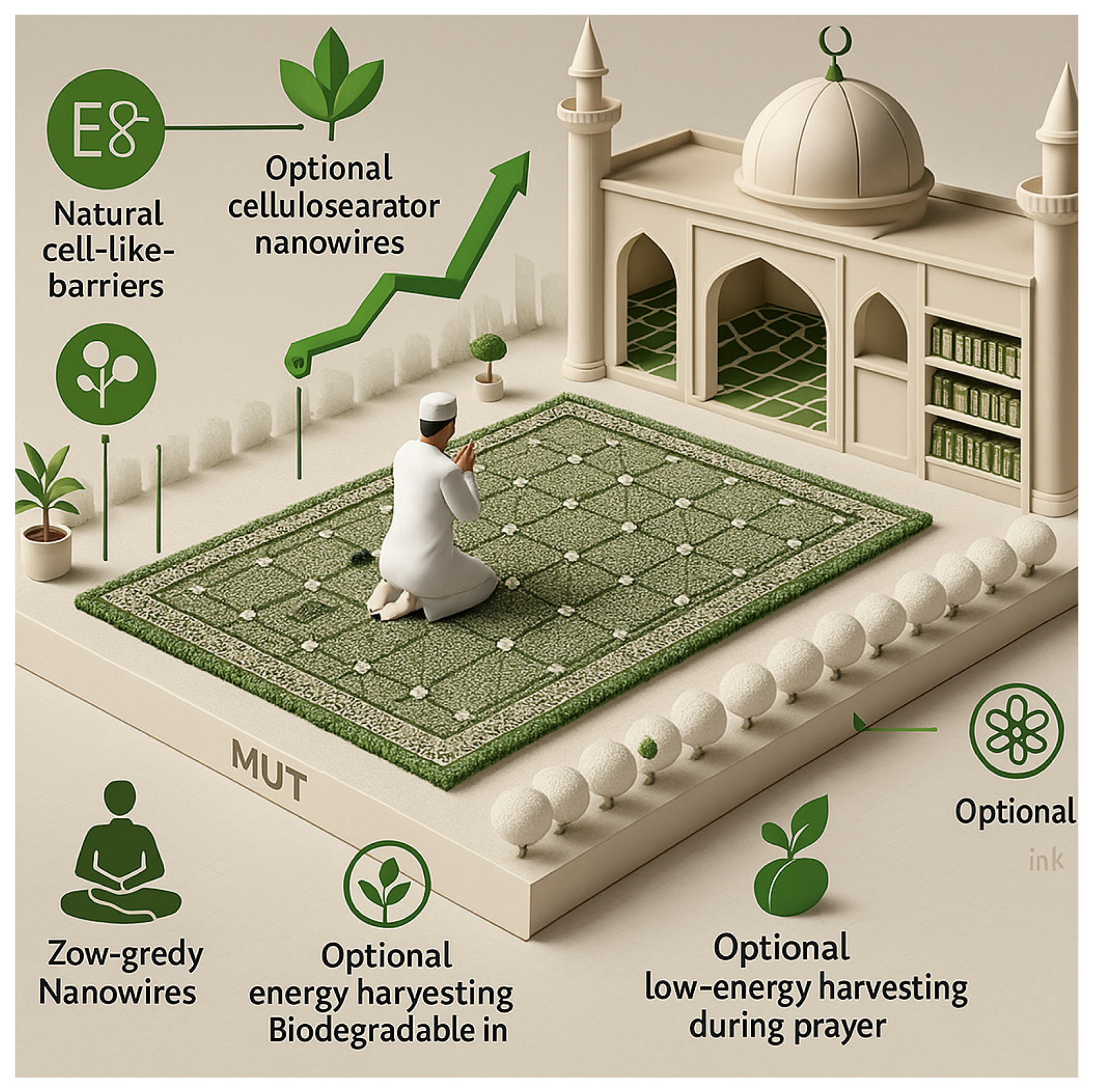

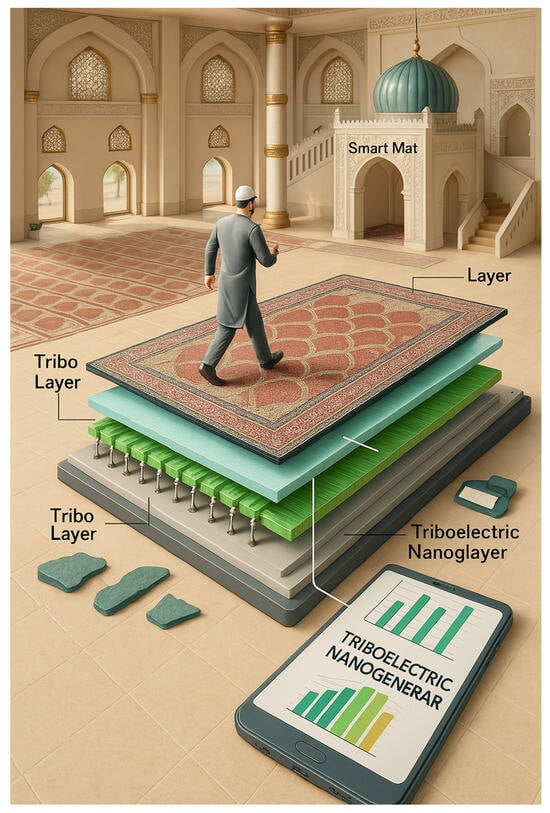

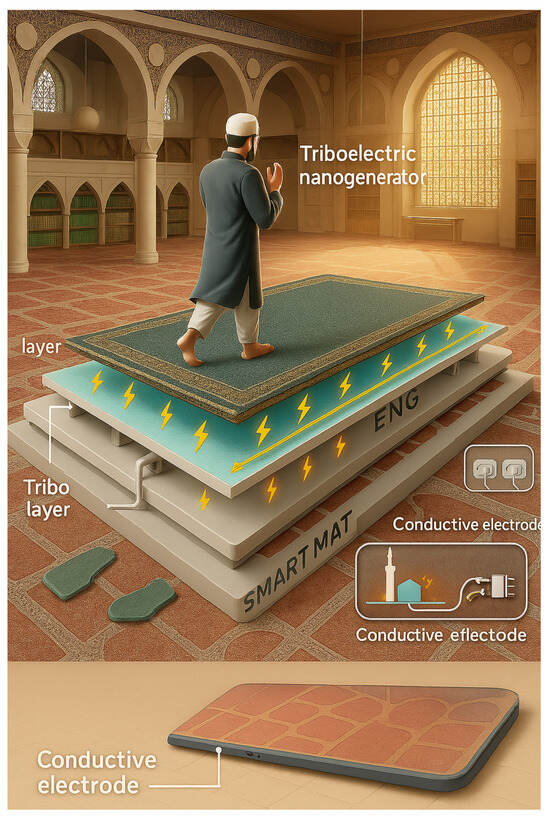

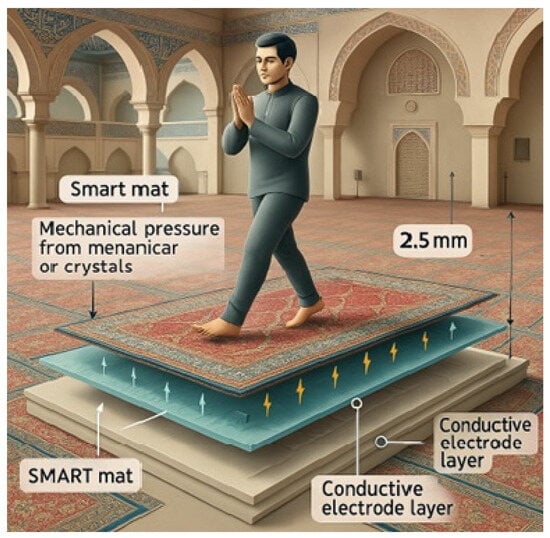

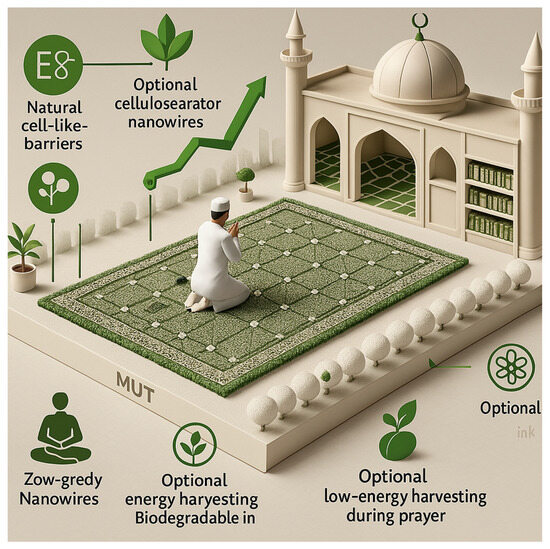

Additionally, the two illustrations (Figure 14 and Figure 15) show how T-TENG smart mats can harvest energy from worshippers walking and praying. The labeled layers of the smart mat are the Triboelectric Layer, Conductive Electrode, and Substrate. The energy flow arrows show mechanical-to-electrical conversion. Finally, a small energy output indicator. In Figure 14, as the individual moves and applies pressure during prayer, the mechanical energy is converted into electrical energy through triboelectric and electrostatic induction. Arrows show the directional flow of energy, and a small indicator highlights the approximate energy output per cycle. In Figure 15, as worshippers walk across the surface, repeated foot strikes generate charge through the triboelectric effect. The layered structure includes (1) a surface triboelectric film generating static charge, (2) a conductive electrode collecting charge, and (3) a substrate providing mechanical support. Energy flow arrows demonstrate real-time power generation, and an energy meter visually represents potential output. With thousands of steps daily in mosque environments, such systems offer a sustainable solution for harvesting clean, ambient energy.

Figure 14.

A worshipper performing prayer movements (such as sujood and standing) on a smart mat made from Triboelectric Nanogenerator (T-TENG) materials. The mat includes three key layers: a triboelectric active surface, a conductive electrode layer, and a flexible substrate.

Figure 15.

The application of T-TENG smart mats within mosque walkways, capturing energy from foot traffic.

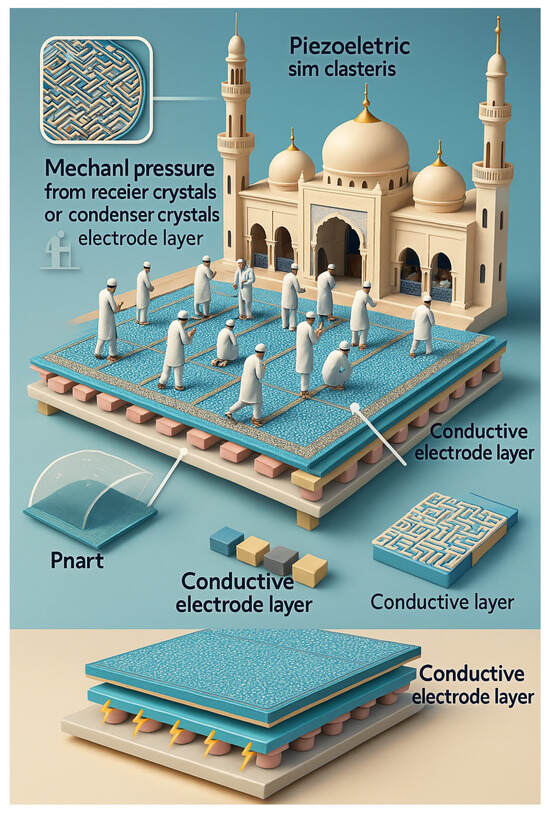

7.4.2. Piezoelectric Materials

Many studies provide significant insights that can inform the design of energy-harvesting mats for the Al-Haram Mosque. For example, chalcogenide perovskites exhibit high piezoelectric sensitivity and structural stability [49], making them highly suitable for converting the mechanical energy from pilgrims’ foot traffic into electrical energy. Their resistance to environmental stress aligns well with the conditions at the mosque, characterized by high temperatures and humidity. Additionally, the scalability and sustainability of these materials support their application in large-scale installations. Smart mats incorporating chalcogenide perovskites could efficiently power low-energy applications such as LED lighting, sensors, or portable charging stations, aligning with the mosque’s innovation and sustainability goals.

Lead zirconate titanate (PZT) is another attractive material for harvesting energy from foot traffic, especially in busy pedestrian areas. Its combination of durability, efficient energy conversion, and affordability positions it as an ideal solution for converting footstep pressure into electrical energy, presenting sustainable and innovative opportunities for urban infrastructure. Research [5] has demonstrated the effectiveness of PZT transducers in capturing energy from human footsteps, establishing a strong foundation for their implementation in public infrastructure. PZT stands out particularly because of its stable power output under repetitive mechanical loading. These characteristics benefit high-foot-traffic areas, as continuous pedestrian movement can serve as a reliable source of electricity. For instance, a previous study [3] embedded piezoelectric ceramic diaphragms inside floor tiles, successfully maintaining the durability of PZT under continuous use, thereby ensuring that energy harvesting systems operate effectively over extended periods.

Beyond standalone PZT systems, researchers have explored hybrid approaches, integrating additional materials or techniques to enhance total energy collection. Fang et al. [16] combined piezoelectric transducers with photovoltaic (PV) cells to simultaneously harness kinetic and solar energy, thus overcoming the limitations of low energy generation per footstep. The inherent flexibility of PZT technology makes it particularly suitable for multi-modal energy harvesting systems designed for urban settings with variable environmental conditions.

However, implementing PZT-based energy harvesting walkways introduces several challenges. Individual piezoelectric elements typically generate limited energy, making it necessary to arrange them into arrays or configurations to achieve practical power outputs. Additionally, designs must account for variations in foot pressure and environmental factors, such as moisture and temperature, which significantly influence piezoelectric performance. Ensuring efficient and reliable system operation requires careful engineering, including integration with low-forward-voltage Schottky diodes and the use of series–parallel configurations.

PZT-based systems also provide broader advantages for urban infrastructure, contributing to environmental sustainability and energy self-sufficiency. When installed in pedestrian walkways, these systems capture otherwise unused kinetic energy, supplying power to smart-city applications such as sensors and lighting. Recent research [95] indicates that multimodal designs using coupled bending and torsional modes can further enhance energy-harvesting capabilities, expanding the practical applications of PZT systems. Due to its efficient energy conversion and consistent performance under repetitive loads, PZT is particularly suited to walkways and high-foot-traffic areas, and it offers opportunities for hybridization with other renewable energy technologies.

To illustrate the potential implementation of PZT-based energy harvesting, the following assumptions are made:

Energy generated per footstep (piezoelectric): approximately 0.2 Joules.

Energy per prayer cycle: approximately 1.5 Joules (due to compression/bending).

Average number of visitors per day: 500,000.

Prayer cycles per day per visitor: 7.

Walking steps per day per visitor: 500.

From these assumptions, the calculated daily energy potential is as follows:

Prayer movement energy: 500,000 visitors × 7 cycles/day × 1.5 J = 5,250,000 J/day (approximately 1458 Wh/day).

Walking energy: 500,000 visitors × 500 steps/day × 0.2 J = 50,000,000 J/day (approximately 13,889 Wh/day).

Thus, the total daily energy (prayer + walking) harvested from piezoelectric mats is approximately 15.3 kWh/day. This output significantly exceeds the energy generated by textile-based triboelectric nanogenerators (t-TENGs), particularly in high-density usage scenarios.