Strategic Prioritization for Sustainable Development in the Logistics Industry: A FAHP-NFAD Approach

Abstract

1. Introduction

2. Literature Review

2.1. Scientific Research on Sustainable Strategy Assessment

2.2. Identifying Research Gaps and Advancing MCDM Approaches for Sustainable Logistics Strategy Evaluation

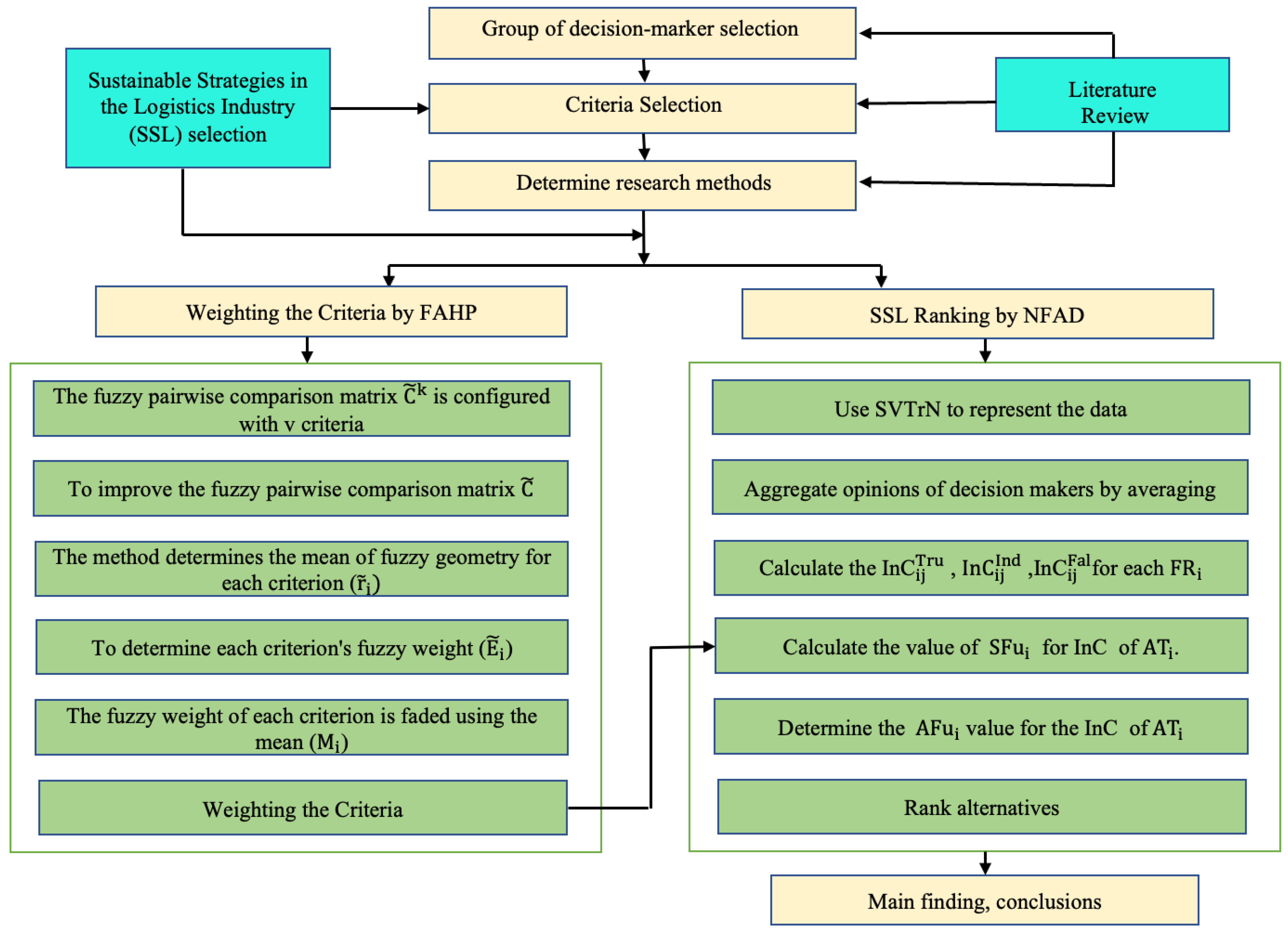

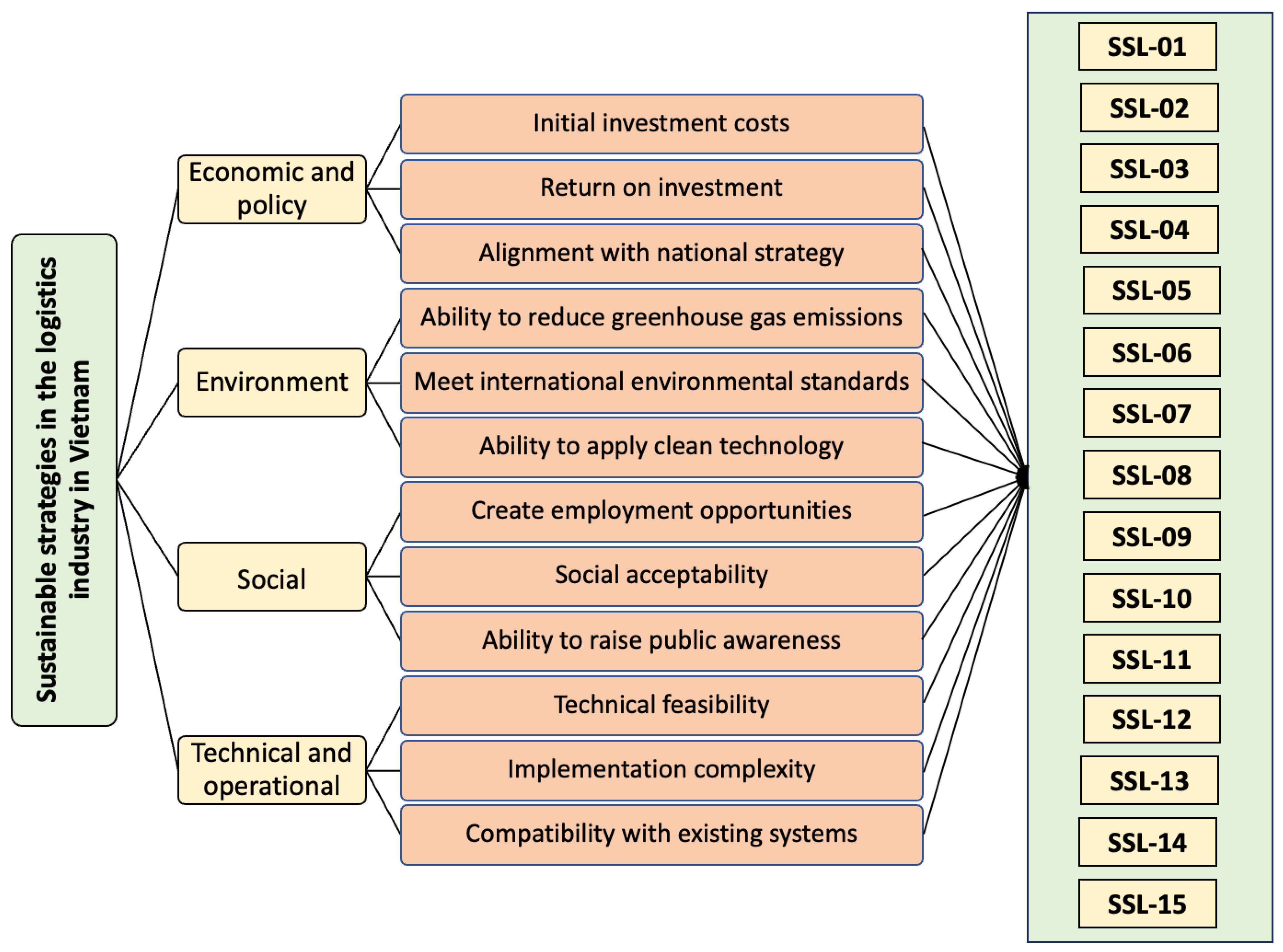

3. Methodology

3.1. Methodology Description

3.2. Fuzzy Analytical Hierarchy Process (FAHP)

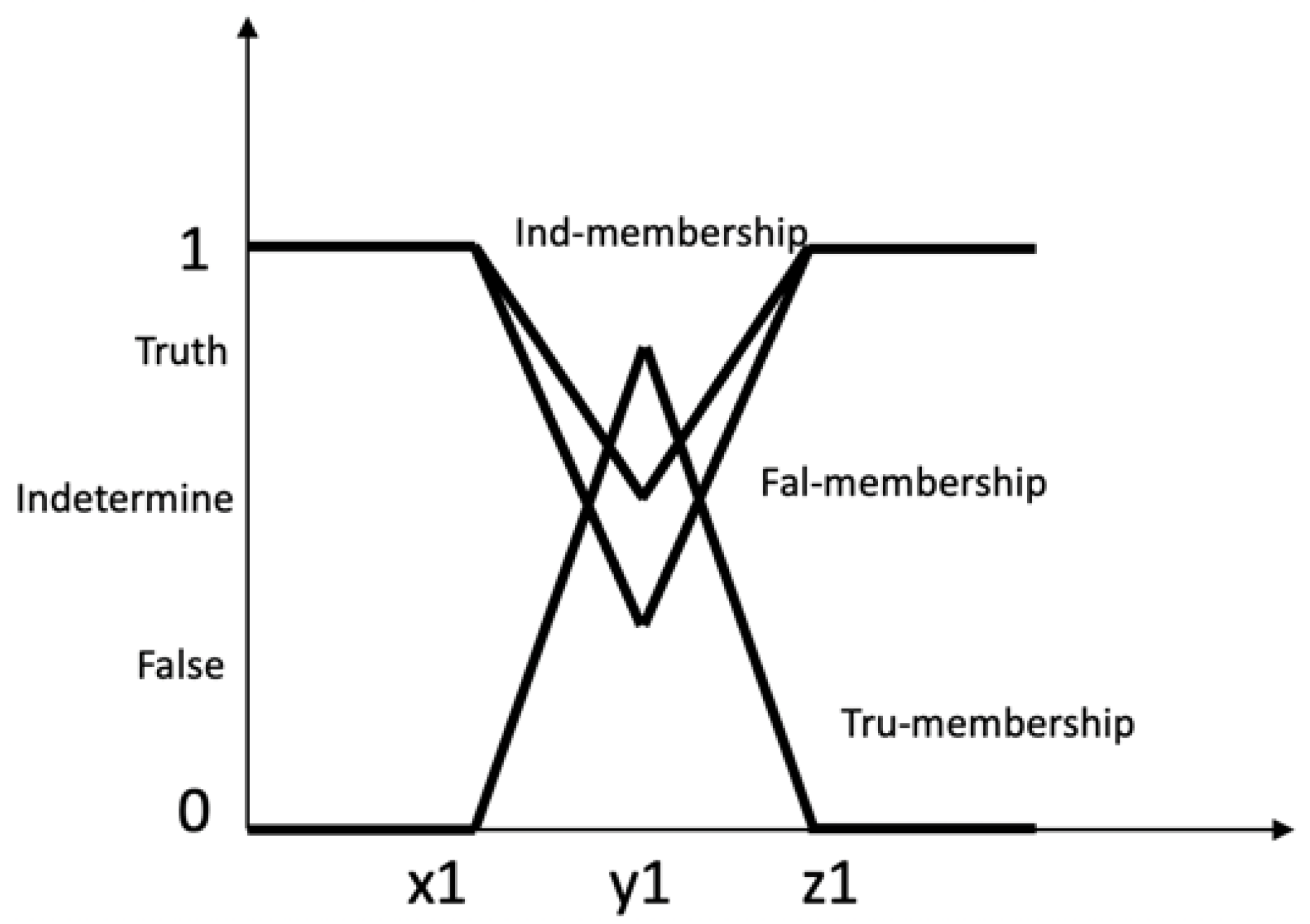

3.3. Neutrosophic Set Theory

3.4. Neutrosophic Axiomatic Design (NAD)

4. The Results

NAD Calculation Results

5. The Practical and Managerial Implications of the Study

6. Conclusions, Limitations, and Future Studies

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Evangelista, P.; Colicchia, C.; Creazza, A. Is environmental sustainability a strategic priority for logistics service providers? J. Environ. Manag. 2017, 198, 353–362. [Google Scholar] [CrossRef] [PubMed]

- Sikder, M.; Wang, C.; Yeboah, F.K.; Wood, J. Driving factors of CO2 emission reduction in the logistics industry: An assessment of the RCEP and SAARC economies. Environ. Dev. Sustain. 2022, 26, 2557–2587. [Google Scholar] [CrossRef]

- Hsu, H.-Y.; Hwang, M.-H.; Chiu, Y.-S.P. Development of a strategic framework for sustainable supply chain management. AIMS Environ. Sci. 2021, 8, 532–552. [Google Scholar] [CrossRef]

- Xie, D.; Qiu, Y.; Huang, J. Multi-Objective optimization for green logistics planning and operations management: From economic to environmental perspective. Comput. Ind. Eng. 2024, 189, 109988. [Google Scholar] [CrossRef]

- Kraus, S.; Rehman, S.U.; García, F.J.S. Corporate social responsibility and environmental performance: The mediating role of environmental strategy and green innovation. Technol. Forecast. Soc. Chang. 2020, 160, 120262. [Google Scholar] [CrossRef]

- Javed, T.; Mahmoud, A.B.; Yang, J.; Zhao, X. Green branding in fast fashion: Examining the impact of social sustainability claims on Chinese consumer behaviour and brand perception. Corp. Commun. Int. J. 2024, 29, 915–934. [Google Scholar] [CrossRef]

- Gruchmann, T. Advanced Green Logistics Strategies and Technologies. In Operations, Logistics and Supply Chain Management; Springer International Publishing: Cham, Switzerland, 2019; pp. 663–686. [Google Scholar] [CrossRef]

- Negri, M.; Cagno, E.; Colicchia, C.; Sarkis, J. Integrating sustainability and resilience in the supply chain: A systematic literature review and a research agenda. Bus. Strategy Environ. 2021, 30, 2858–2886. [Google Scholar] [CrossRef]

- Hadi, S.; Miru, S.; Kaseng, S.; Asngadi; Syamsuddin; Zahra, F. Barriers to Green Logistics Implementation in Indonesia: A Preliminary Study. In Proceedings of the 2nd International Interdisciplinary Conference on Environmental Sciences and Sustainable Developments Education and Green Economy (IICESSD EGE 2022), Palu, Indonesia, 7–8 November 2022; pp. 254–257. [Google Scholar] [CrossRef]

- An, H.; Razzaq, A.; Nawaz, A.; Noman, S.M.; Khan, S.A.R. Nexus between green logistic operations and triple bottom line: Evidence from infrastructure-led Chinese outward foreign direct investment in Belt and Road host countries. Environ. Sci. Pollut. Res. 2021, 28, 51022–51045. [Google Scholar] [CrossRef]

- Jefimovaitė, L.; Vienažindienė, M. Factors influencing the application of green logistics: Findings from the lithuanian logistics center. Pol. J. Manag. Stud. 2022, 25, 193–212. [Google Scholar] [CrossRef]

- Zhang, M.; Sun, M.; Bi, D.; Liu, T. Green Logistics Development Decision-Making: Factor Identification and Hierarchical Framework Construction. IEEE Access 2020, 8, 127897–127912. [Google Scholar] [CrossRef]

- Matić, B.; Jovanović, S.; Das, D.K.; Zavadskas, E.K.; Stević, Ž.; Sremac, S.; Marinković, M. A New Hybrid MCDM Model: Sustainable Supplier Selection in a Construction Company. Symmetry 2019, 11, 353. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Freeman, J.; Chen, T. Green supplier selection using an AHP-Entropy-TOPSIS framework. Supply Chain Manag. Int. J. 2015, 20, 327–340. [Google Scholar] [CrossRef]

- Wang, C.N.; Pham, T.D.T.; Nhieu, N.L. Applying an Ordinal Priority Approach Based Neutrosophic Fuzzy Axiomatic Design Approach to Develop Sustainable Geothermal Energy Source. Energy Eng. 2024, 121, 2039–2064. [Google Scholar] [CrossRef]

- Gimenez, C.; Sierra, V.; Rodon, J. Sustainable operations: Their impact on the triple bottom line. Int. J. Prod. Econ. 2012, 140, 149–159. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. Assessing sustainability in the supply chain: A triple bottom line approach. Appl. Math. Model. 2015, 39, 2882–2896. [Google Scholar] [CrossRef]

- Chatterjee, S.; Chaudhuri, R. Supply chain sustainability during turbulent environment: Examining the role of firm capabilities and government regulation. Oper. Manag. Res. 2022, 15, 1081–1095. [Google Scholar] [CrossRef]

- Chen, J.Y.; Dimitrov, S.; Pun, H. The impact of government subsidy on supply Chains’ sustainability innovation. Omega 2019, 86, 42–58. [Google Scholar] [CrossRef]

- Hunka, A.D.; Linder, M.; Habibi, S. Determinants of consumer demand for circular economy products. A case for reuse and remanufacturing for sustainable development. Bus. Strategy Environ. 2021, 30, 535–550. [Google Scholar] [CrossRef]

- Madaleno, M.; Dogan, E.; Taskin, D. A step forward on sustainability: The nexus of environmental responsibility, green technology, clean energy and green finance. Energy Econ. 2022, 109, 105945. [Google Scholar] [CrossRef]

- Karaman, A.S.; Kilic, M.; Uyar, A. Green logistics performance and sustainability reporting practices of the logistics sector: The moderating effect of corporate governance. J. Clean. Prod. 2020, 258, 120718. [Google Scholar] [CrossRef]

- Piwowar-Sulej, K. Human resources development as an element of sustainable HRM—With the focus on production engineers. J. Clean. Prod. 2021, 278, 124008. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.; Parvaiz, G.S.; Ali, A.; Jehangir, M.; Hassan, N.; Bae, J. A Model for Understanding the Mediating Association of Transparency between Emerging Technologies and Humanitarian Logistics Sustainability. Sustainability 2022, 14, 6917. [Google Scholar] [CrossRef]

- Korucuk, S.; Aytekin, A.; Ecer, F.; Pamucar, D.S.S.; Karamaşa, Ç. Assessment of ideal smart network strategies for logistics companies using an integrated picture fuzzy LBWA–CoCoSo framework. Manag. Decis. 2023, 61, 1434–1462. [Google Scholar] [CrossRef]

- Charłampowicz, J.; Mańkowski, C.; Saikouk, T. Strategic integration of environmental sustainability in inland logistics: A multi-criteria decision-making approach. Bus. Strategy Environ. 2024, 33, 7544–7561. [Google Scholar] [CrossRef]

- Krstić, M.; Agnusdei, G.P.; Miglietta, P.P.; Tadić, S. Evaluation of the smart reverse logistics development scenarios using a novel MCDM model. Clean. Environ. Syst. 2022, 7, 100099. [Google Scholar] [CrossRef]

- Luyen, L.A.; Van Thanh, N. Logistics Service Provider Evaluation and Selection: Hybrid SERVQUAL–FAHP–TOPSIS Model. Processes 2022, 10, 1024. [Google Scholar] [CrossRef]

- Tadić, S.; Zečević, S.; Krstić, M. A novel hybrid MCDM model based on fuzzy DEMATEL, fuzzy ANP and fuzzy VIKOR for city logistics concept selection. Expert Syst. Appl. 2014, 41, 8112–8128. [Google Scholar] [CrossRef]

- Zak, J.; Węgliński, S. The Selection of the Logistics Center Location Based on MCDM/A Methodology. Transp. Res. Procedia 2014, 3, 555–564. [Google Scholar] [CrossRef]

- Wadhwa, S.; Madaan, J.; Chan, F.T.S. Flexible decision modeling of reverse logistics system: A value adding MCDM approach for alternative selection. Robot. Comput. Integr. Manuf. 2009, 25, 460–469. [Google Scholar] [CrossRef]

- Stević, Ž.; Tanackov, I.; Puška, A.; Jovanov, G.; Vasiljević, J.; Lojaničić, D. Development of Modified SERVQUAL–MCDM Model for Quality Determination in Reverse Logistics. Sustainability 2021, 13, 5734. [Google Scholar] [CrossRef]

- Chejarla, K.C.; Vaidya, O.S.; Kumar, S. MCDM applications in logistics performance evaluation: A literature review. J. Multi-Criteria Decis. Anal. 2022, 29, 274–297. [Google Scholar] [CrossRef]

- Kilic, H.S.; Kalender, Z.T.; Solmaz, B.; Iseri, D. A two-stage MCDM model for reverse logistics network design of waste batteries in Turkey. Appl. Soft Comput. 2023, 143, 110373. [Google Scholar] [CrossRef]

- Nila, B.; Roy, J. A new hybrid MCDM framework for third-party logistics provider selection under sustainability perspectives. Expert Syst. Appl. 2023, 234, 121009. [Google Scholar] [CrossRef]

- Zhang, M.; Yan, T.; Gao, W.; Xie, W.; Yu, Z. How does environmental regulation affect real green technology innovation and strategic green technology innovation? Sci. Total Environ. 2023, 872, 162221. [Google Scholar] [CrossRef]

- Tognetti, A.; Grosse-Ruyken, P.T.; Wagner, S.M. Green supply chain network optimization and the trade-off between environmental and economic objectives. Int. J. Prod. Econ. 2015, 170, 385–392. [Google Scholar] [CrossRef]

- Motla, R.; Kumar, A.; Saxena, N.; Sana, S.S. Inventory optimization in a green environment with two warehouses. Innov. Green Dev. 2023, 2, 100087. [Google Scholar] [CrossRef]

- Iwan, S. Adaptative Approach to Implementing Good Practices to Support Environmentally Friendly Urban Freight Transport Management. Procedia Soc. Behav. Sci. 2014, 151, 70–86. [Google Scholar] [CrossRef]

- Margallo, M.; Ziegler-Rodriguez, K.; Vázquez-Rowe, I.; Aldaco, R.; Irabien, Á.; Kahhat, R. Enhancing waste management strategies in Latin America under a holistic environmental assessment perspective: A review for policy support. Sci. Total Environ. 2019, 689, 1255–1275. [Google Scholar] [CrossRef]

- Law, M.M.S.; Hills, P.; Hau, B.C.H. Engaging Employees in Sustainable Development—A Case Study of Environmental Education and Awareness Training in Hong Kong. Bus. Strategy Environ. 2017, 26, 84–97. [Google Scholar] [CrossRef]

- Rahla, K.; Mateus, R.; Bragança, L. Implementing Circular Economy Strategies in Buildings—From Theory to Practice. Appl. Syst. Innov. 2021, 4, 26. [Google Scholar] [CrossRef]

- Lü, X.; Wang, P.; Meng, L.; Chen, C. Energy optimization of logistics transport vehicle driven by fuel cell hybrid power system. Energy Convers. Manag. 2019, 199, 111887. [Google Scholar] [CrossRef]

- Wang, C.; Liu, J.; Fan, R.; Xiao, L. Promotion strategies for environmentally friendly packaging: A stochastic differential game perspective. Int. J. Environ. Sci. Technol. 2023, 20, 7559–7568. [Google Scholar] [CrossRef] [PubMed]

- Nayak, D.; Saetnan, E.; Cheng, K.; Wang, W.; Koslowski, F.; Cheng, Y.F.; Zhu, W.Y.; Wang, J.K.; Liu, J.X.; Moran, D.; et al. Management opportunities to mitigate greenhouse gas emissions from Chinese agriculture. Agric. Ecosyst. Environ. 2015, 209, 108–124. [Google Scholar] [CrossRef]

- Cai, S.; Gou, Z. A comprehensive analysis of green building rating systems for data centers. Energy Build. 2023, 284, 112874. [Google Scholar] [CrossRef]

- Al-Ghaili, A.M.; Kasim, H.; Al-Hada, N.M.; Jorgensen, B.N.; Othman, M.; Wang, J. Energy Management Systems and Strategies in Buildings Sector: A Scoping Review. IEEE Access 2021, 9, 63790–63813. [Google Scholar] [CrossRef]

- Lai, Y.; Yang, F.; Meng, G.; Lu, W. Data-Driven Flexible Vehicle Scheduling and Route Optimization. IEEE Trans. Intell. Transp. Syst. 2022, 23, 23099–23113. [Google Scholar] [CrossRef]

- Lai, P.-L.; Su, D.-T.; Tai, H.-H.; Yang, C.-C. The impact of collaborative decision-making on logistics service performance for container shipping services. Marit. Bus. Rev. 2020, 5, 175–191. [Google Scholar] [CrossRef]

- Waqas, M.; Dong, Q.; Ahmad, N.; Zhu, Y.; Nadeem, M. Critical Barriers to Implementation of Reverse Logistics in the Manufacturing Industry: A Case Study of a Developing Country. Sustainability 2018, 10, 4202. [Google Scholar] [CrossRef]

- Vornhusen, B.; Kopfer, H. Emission vehicle routing problem with split delivery and a heterogeneous vehicle fleet. In Proceedings of the Computational Logistics: 6th International Conference, ICCL 2015, Delft, The Netherlands, 23–25 September 2015; Springer International Publishing: Cham, Switzerland, 2015; pp. 76–90, Proceedings 6. [Google Scholar]

- Foumani, M. Adaptation of a Collaborative Truck and Robotic Vehicle for Sustainable Supply Chain Operations. In Proceedings of the International Conference on Robot Intelligence Technology and Applications, Taicang, China, 6–8 December 2023; Springer Nature Switzerland: Cham, Switzerland, 2023; pp. 289–301. [Google Scholar]

| No. | SSLs | Strategies | Scource | Detailed Description |

|---|---|---|---|---|

| 1 | SSL-01 | Applying green technology | [37] | Using advanced technologies such as AI, IoT, and big data to optimize transportation routes, track goods, and reduce CO2 emissions. |

| 2 | SSL-02 | Optimizing supply chain network | [38] | Build efficient supply chain networks and minimize unnecessary travel distances, thereby saving fuel and reducing carbon emissions. |

| 3 | SSL-03 | Developing green warehouses | [39] | Apply measures such as renewable energy systems (solar, wind), improve insulation systems, and use LED lights to reduce energy consumption in warehouses. |

| 4 | SSL-04 | Applying environmentally friendly means of transport | [40] | Use electric, hybrid, or biofuel vehicles in transportation to reduce polluting emissions. |

| 5 | SSL-05 | Enhancing waste management | [41] | Provide processes for waste classification, recycling, and treatment, minimizing waste from logistics activities. |

| 6 | SSL-06 | Educating employees on sustainable development | [42] | Increase employee awareness of sustainability processes and strategies and provide training programs on green technology and sustainable management skills. |

| 7 | SSL-07 | Applying circular economy models | [43] | Encourage the reuse and recycling of packaging materials, reduce waste, and protect natural resources. |

| 8 | SSL-08 | Optimizing transport loads | [44] | Ensure vehicles are always operating at optimal load capacity to minimize the number of trips and save fuel. |

| 9 | SSL-09 | Using environmentally friendly packaging materials | [45] | Replace traditional packaging materials with materials that are recyclable, biodegradable, or made from renewable sources. |

| 10 | SSL-10 | Managing and reducing greenhouse gas emissions | [46] | Measure, monitor, and develop strategies to reduce greenhouse gas emissions throughout the supply chain. |

| 11 | SSL-11 | Building green distribution centers | [47] | Build distribution centers with energy-efficient designs, use green technology, and minimize emissions. |

| 12 | SSL-12 | Applying energy management systems | [48] | Comply with international standards on energy management to improve energy efficiency and reduce greenhouse gas emissions. |

| 13 | SSL-13 | Optimizing transport routes and schedules | [49] | Use route optimization software to minimize travel distance, thereby reducing fuel consumption and emissions. |

| 14 | SSL-14 | Promoting the use of collaborative logistics services | [50] | Cooperate with other logistics businesses to share vehicles, warehouses, and reduce operating costs, reducing traffic on the road. |

| 15 | SSL-15 | Developing reverse logistics strategies | [51] | Create efficient processes for handling returned goods, recycling defective products, and reusing components to reduce environmental impact. |

| Critical Level | Modification | TFNs |

|---|---|---|

| 1 | Equal importance | (1, 1, 1) |

| 2 | Quite importance | (1, 2, 3) |

| 3 | Weak importance | (2, 3, 4) |

| 4 | Not bad | (3, 4, 5) |

| 5 | Preferable | (4, 5, 6) |

| 6 | Rather importance | (5, 6, 7) |

| 7 | Fairly importance | (6, 7, 8) |

| 8 | Absolute | (7, 8, 9) |

| 9 | Perfect | (8, 9, 9) |

| Terms | L, M, U | |

|---|---|---|

| Exceptionally low | < (0, 0, 1) > | < (0, 1, 1) > |

| Significantly low | < (0, 1, 2) > | < (0.2, 0.8, 0.8) > |

| Low | < (1, 2, 3) > | < (0.3, 0.7, 0.7) > |

| Quite Low | < (2, 3, 4) > | < (0.5, 0.5, 0.5) > |

| High | < (3, 4, 5) > | < (0.7, 0.4, 0.4) > |

| Significantly high | < (4, 5, 6) > | < (0.8, 0.2, 0.2) > |

| Extremely high | < (5, 6, 7) > | < (0.9, 0.1, 0.1) > |

| Intensely high | < (7, 8, 9) > | < (1, 0, 0) > |

| Expert | Academic Qualification | Research Output | Expertise | Professional Experience | Rank |

|---|---|---|---|---|---|

| EP-01 | Doctoral | 25 | Green Logistics Technologies | 9 years | 6 |

| EP-02 | Doctoral | 50 | Analysis in Sustainable Logistics | 17 years | 1 |

| EP-03 | Doctoral | 13 | Sustainable Logistics Models | 5 years | 7 |

| EP-04 | Doctoral | 31 | Supply Chain Management | 14 years | 4 |

| EP-05 | Doctoral | 8 | Sustainability Performance Assessment | 4 years | 9 |

| EP-06 | Doctoral | 5 | Sustainable Transportation Management | 3 years | 10 |

| EP-07 | Master | 38 | Supply Chain Risk Management | 15 years | 3 |

| EP-08 | Doctoral | 45 | Supply Chain Risk Management | 13 years | 2 |

| EP-09 | Doctoral | 29 | Supply Chain Management | 11 years | 5 |

| EP-10 | Master | 12 | Supply Chain Management | 8 years | 8 |

| Criteria | CT-1 | CT-2 | CT-3 |

| CT-1 | (1, 1, 1) | (2, 3, 4) | (3, 4, 5) |

| CT-2 | (1/4, 1/3, 1/2) | (1, 1, 1) | (2, 3, 4) |

| CT-3 | (1/5, 1/4, 1/3) | (1/4, 1/3, 1/2) | (1, 1, 1) |

| CT-4 | (1/7, 1/6, 1/5) | (1/7, 1/6, 1/5) | (1/4, 1/3, 1/2) |

| Criteria | CT-11 | CT-12 | CT-13 |

| CT-11 | (1, 1, 1) | (5, 6, 7) | (8, 9, 9) |

| CT-12 | (1/7, 1/6, 1/5) | (1, 1, 1) | (3, 4, 5) |

| CT-13 | (1/9, 1/9, 1/8) | (1/5, 1/4, 1/3) | (1, 1, 1) |

| Criteria | CT-21 | CT-22 | CT-23 |

| CT-21 | (1, 1, 1) | (3, 4, 5) | (6, 7, 8) |

| CT-22 | (1/6, 1/5, 1/4) | (1, 1, 1) | (3, 4, 5) |

| CT-23 | (1/9, 1/8, 1/7) | (1/5, 1/4, 1/3) | (1, 1, 1) |

| Criteria | CT-31 | CT-32 | CT-33 |

| CT-31 | (1, 1, 1) | (2, 3, 4) | (6, 7, 8) |

| CT-32 | (1/5, 1/4, 1/3) | (1, 1, 1) | (5, 6, 7) |

| CT-33 | (1/8, 1/7, 1/6) | (1/7, 1/6, 1/5) | (1, 1, 1) |

| Criteria | CT-41 | CT-42 | CT-43 |

| CT-41 | (1, 1, 1) | (6, 7, 8) | (7, 8, 9) |

| CT-42 | (1/8, 1/7, 1/6) | (1, 1, 1) | (2, 3, 4) |

| CT-43 | (1/9, 1/8, 1/7) | (1/4, 1/3, 1/2) | (1, 1, 1) |

| Criteria | CT-1 | CT-2 | CT-3 | CT-4 |

| CT-1 | 1.0000 | 2.8284 | 3.8730 | 5.9161 |

| CT-2 | 0.3536 | 1.0000 | 2.8284 | 5.9161 |

| CT-3 | 0.2582 | 0.3536 | 1.0000 | 2.8284 |

| CT-4 | 0.1690 | 0.1690 | 0.3536 | 1.0000 |

| 1.7808 | 4.3510 | 8.0550 | 15.6606 | |

| Criteria | CT-11 | CT-12 | CT-13 | |

| CT-1-1 | 1.0000 | 5.9161 | 8.4853 | |

| CT-1-2 | 0.1690 | 1.0000 | 3.8730 | |

| CT-1-3 | 0.1179 | 0.2582 | 1.0000 | |

| 1.2869 | 7.1743 | 13.3583 | ||

| Criteria | CT-21 | CT-22 | CT-23 | |

| CT-2-1 | 1.0000 | 3.8730 | 6.9282 | |

| CT-2-2 | 0.2582 | 1.0000 | 3.8730 | |

| CT-2-3 | 0.1443 | 0.2582 | 1.0000 | |

| 1.4025 | 5.1312 | 11.8012 | ||

| Criteria | CT-31 | CT-32 | CT-33 | |

| CT-31 | 1.0000 | 2.8284 | 6.9282 | |

| CT-32 | 0.3536 | 1.0000 | 5.9161 | |

| CT-33 | 0.1443 | 0.1690 | 1.0000 | |

| 1.4979 | 3.9975 | 13.8443 | ||

| Criteria | CT-41 | CT-42 | CT-43 | |

| CT-41 | 1.0000 | 6.9282 | 7.9373 | |

| CT-42 | 0.1443 | 1.0000 | 2.8284 | |

| CT-43 | 0.1260 | 0.3536 | 1.0000 | |

| 1.2703 | 8.2818 | 11.7657 |

| Criteria | CT-1 | CT-2 | CT-3 | CT-4 | Priority Vector |

| CT-1 | 0.5616 | 0.6501 | 0.4808 | 0.3778 | 0.5176 |

| CT-2 | 0.1985 | 0.2298 | 0.3511 | 0.3778 | 0.2893 |

| CT-3 | 0.1450 | 0.0813 | 0.1241 | 0.1806 | 0.1328 |

| CT-4 | 0.0949 | 0.0388 | 0.0439 | 0.0639 | 0.0604 |

| Criteria | CT-11 | CT-12 | CT-13 | Priority Vector | |

| CT-11 | 0.7771 | 0.8246 | 0.6352 | 0.7456 | |

| CT-12 | 0.1313 | 0.1394 | 0.2899 | 0.1869 | |

| CT-13 | 0.0916 | 0.0360 | 0.0749 | 0.0675 | |

| Criteria | CT-21 | CT-22 | CT-23 | Priority Vector | |

| CT-21 | 0.7130 | 0.7548 | 0.5871 | 0.6850 | |

| CT-22 | 0.1841 | 0.1949 | 0.3282 | 0.2357 | |

| CT-23 | 0.1029 | 0.0503 | 0.0847 | 0.0793 | |

| Criteria | CT-21 | CT-22 | CT-23 | Priority Vector | |

| CT-21 | 0.7130 | 0.7548 | 0.5871 | 0.6252 | |

| CT-22 | 0.1841 | 0.1949 | 0.3282 | 0.3045 | |

| CT-23 | 0.1029 | 0.0503 | 0.0847 | 0.0703 | |

| Criteria | CT-4-1 | CT-42 | CT-43 | Priority Vector | |

| CT-41 | 0.7872 | 0.8366 | 0.6746 | 0.7661 | |

| CT-22 | 0.1136 | 0.1207 | 0.2404 | 0.1583 | |

| CT-43 | 0.0992 | 0.0427 | 0.0850 | 0.0756 |

| Criteria | Geometric Mean |

| CT-1 | (2.340, 2.913, 3.439) |

| CT-2 | (1.257, 1.565, 1.934) |

| CT-3 | (0.562, 0.707, 0.904) |

| CT-4 | (0.267, 0.310, 0.376) |

| (4.427, 5.495, 6.654) | |

| (0.150, 0.182, 0.226) | |

| Criteria | Geometric Mean |

| CT-11 | (3.419, 3.780, 3.979) |

| CT-12 | (0.754, 0.874, 1.000) |

| CT-13 | (0.281, 0.303, 0.347) |

| (4.455, 4.956, 5.326) | |

| (0.188, 0.202, 0.224) | |

| Criteria | Geometric Mean |

| CT-21 | (2.621, 3.037, 3.420) |

| CT-22 | (0.843, 1.000, 0.186) |

| CT-33 | (0.292, 0.329, 0.382) |

| (3.757, 4.366, 4.987) | |

| (0.201, 0.229, 0.266) | |

| Criteria | Geometric Mean |

| CT-31 | (2.289, 2.759, 3.175) |

| CT-32 | (1.077, 1.260, 1.518) |

| CT-33 | (0.261, 0.288, 0.322) |

| (3.628, 4.307, 5.015) | |

| (0.199, 0.232, 0.276) | |

| Criteria | Geometric Mean |

| CT-41 | (3.476, 3.826, 4.160) |

| CT-42 | (0.630, 0.754, 0.874) |

| CT-43 | (0.303, 0.347, 0.415) |

| (4.409, 4.926, 5.449) | |

| (0.184, 0.203, 0.227) |

| Criteria | Fuzzy Weight | Sub-Criteria | Fuzzy Weight |

|---|---|---|---|

| CT-1 | (0.352, 0.53, 0.777) | CT-11 | (0.642, 0.763, 0.893) |

| CT-12 | (0.142, 0.176, 0.224) | ||

| CT-13 | (0.053, 0.061, 0.078) | ||

| CT-2 | (0.189, 0.285, 0.437) | CT-21 | (0.525, 0.696, 0.910) |

| CT-22 | (0.169, 0.229, 0.316) | ||

| CT-23 | (0.059, 0.075, 0.102) | ||

| CT-3 | (0.085, 0.129, 0.204) | CT-31 | (0.457, 0.641, 0.875) |

| CT-32 | (0.215, 0.293, 0.418) | ||

| CT-33 | (0.052, 0.067, 0.089) | ||

| CT-4 | (0.04, 0.056, 0.085) | CT-41 | (0.638, 0.777, 0.944) |

| CT-42 | (0.116, 0.153, 0.198) | ||

| CT-43 | (0.056, 0.070, 0.094) |

| Criteria | Final Fuzzy Weight | Final Weight |

|---|---|---|

| CT-11 | (0.225, 0.404, 0.694) | 0.399 |

| CT-12 | (0.049, 0.093, 0.174) | 0.093 |

| CT-13 | (0.018, 0.032, 0.061) | 0.033 |

| CT-21 | (0.099, 0.198, 0.398) | 0.199 |

| CT-22 | (0.032, 0.065, 0.138) | 0.066 |

| CT-23 | (0.011, 0.022, 0.044) | 0.022 |

| CT-31 | (0.038, 0.082, 0.179) | 0.083 |

| CT-32 | (0.018, 0.038, 0.085) | 0.039 |

| CT-33 | (0.004, 0.009, 0.018) | 0.009 |

| CT-41 | (0.025, 0.044, 0.080) | 0.045 |

| CT-42 | (0.005, 0.009, 0.017) | 0.009 |

| CT-43 | (0.002, 0.004, 0.008) | 0.004 |

| SSLs | C1-1 | C1-2 | C1-3 |

| SSL-01 | <(5.5,6.5,7.5);(0.3,0.7,0.7)> | <(3.7,4.7,5.7);(0.3,0.7,0.7)> | <(3.8,4.8,5.8);(0.3,0.7,0.7)> |

| SSL-02 | <(3.5,4.5,5.5);(0.3,0.7,0.7)> | <(3.5,4.5,5.5);(0.3,0.7,0.7)> | <(3.8,4.8,5.8);(0.3,0.7,0.7)> |

| SSL-03 | <(3.5,4.5,5.5);(0.3,0.7,0.7)> | <(4.1,5.1,6.1);(0.3,0.7,0.7)> | <(4.4,5.4,6.4);(0.3,0.7,0.7)> |

| SSL-04 | <(3.3,4.3,5.3);(0.3,0.7,0.7)> | <(3.8,4.8,5.8);(0.3,0.7,0.7)> | <(4.1,5.1,6.1);(0.3,0.7,0.7)> |

| SSL-05 | <(4.5,5.5,6.5);(0.5,0.5,0.5)> | <(4.1,5.1,6.1);(0.5,0.5,0.5)> | <(2.8,3.8,4.8);(0.3,0.7,0.7)> |

| SSL-06 | <(3.9,4.9,5.9);(0.3,0.7,0.7)> | <(4.7,5.7,6.7);(0.5,0.5,0.5)> | <(4.1,5.1,6.1);(0.3,0.7,0.7)> |

| SSL-07 | <(4.9,5.9,6.9);(0.5,0.5,0.5)> | <(3.8,4.8,5.8);(0.3,0.7,0.7)> | <(3.1,4.1,5.1);(0.3,0.7,0.7)> |

| SSL-08 | <(4.5,5.5,6.5);(0.7,0.4,0.4)> | <(3.4,4.4,5.4);(0.3,0.7,0.7)> | <(4.4,5.4,6.4);(0.3,0.7,0.7)> |

| SSL-09 | <(4.1,5.1,6.1);(0.3,0.7,0.7)> | <(3.8,4.8,5.8);(0.3,0.7,0.7)> | <(3.2,4.2,5.2);(0.3,0.7,0.7)> |

| SSL-10 | <(4.8,5.8,6.8);(0.3,0.7,0.7)> | <(4.3,5.3,6.3);(0.5,0.5,0.5)> | <(2.7,3.7,4.7);(0.5,0.5,0.5)> |

| SSL-11 | <(3.9,4.9,5.9);(0.5,0.5,0.5)> | <(3.9,4.9,5.9);(0.3,0.7,0.7)> | <(3.5,4.5,5.5);(0.5,0.5,0.5)> |

| SSL-12 | <(4.0,5.0,6.0);(0.3,0.7,0.7)> | <(4.6,5.6,6.6);(0.3,0.7,0.7)> | <(3.7,4.7,5.7);(0.3,0.7,0.7)> |

| SSL-13 | <(3.7,4.7,5.7);(0.3,0.7,0.7)> | <(3.6,4.6,5.6);(0.3,0.7,0.7)> | <(3.3,4.3,5.3);(0.3,0.7,0.7)> |

| SSL-14 | <(3.4,4.4,5.4);(0.3,0.7,0.7)> | <(4.6,5.6,6.6);(0.3,0.7,0.7)> | <(3.6,4.6,5.6);(0.3,0.7,0.7)> |

| SSL-15 | <(4.2,5.2,6.2);(0.3,0.7,0.7)> | <(3.2,4.2,5.2);(0.5,0.5,0.5)> | <(4.8,5.8,6.8);(0.3,0.7,0.7)> |

| FR | <(3.5,4.5,5.5);(0.3,0.7,0.7)> | <(2.8,3.8,4.8);(0.3,0.7,0.7)> | <(4.9,5.9,6.9);(0.3,0.7,0.7)> |

| SSLs | C2-1 | C2-2 | C2-3 |

| SSL-01 | <(4.1,5.1,6.1);(0.5,0.5,0.5)> | <(3.6,4.6,5.6);(0.3,0.7,0.7)> | <(4.2,5.2,6.2);(0.5,0.5,0.5)> |

| SSL-02 | <(3.8,4.8,5.8);(0.3,0.7,0.7)> | <(2.9,3.9,4.9);(0.7,0.4,0.4)> | <(2.6,3.6,4.6);(0.7,0.4,0.4)> |

| SSL-03 | <(4.0,5.0,6.0);(0.3,0.7,0.7)> | <(4.4,5.4,6.4);(0.5,0.5,0.5)> | <(2.5,3.5,4.5);(0.3,0.7,0.7)> |

| SSL-04 | <(4.0,5.0,6.0);(0.5,0.5,0.5)> | <(2.7,3.7,4.7);(0.3,0.7,0.7)> | <(2.5,3.5,4.5);(0.3,0.7,0.7)> |

| SSL-05 | <(4.1,5.1,6.1);(0.3,0.7,0.7)> | <(4.7,5.7,6.7);(0.3,0.7,0.7)> | <(3.8,4.8,5.8);(0.3,0.7,0.7)> |

| SSL-06 | <(3.2,4.2,5.2);(0.3,0.7,0.7)> | <(3.9,4.9,5.9);(0.3,0.7,0.7)> | <(3.5,4.5,5.5);(0.3,0.7,0.7)> |

| SSL-07 | <(4.7,5.7,6.7);(0.3,0.7,0.7)> | <(3.5,4.5,5.5);(0.3,0.7,0.7)> | <(4.2,5.2,6.2);(0.3,0.7,0.7)> |

| SSL-08 | <(3.7,4.7,5.7);(0.3,0.7,0.7)> | <(3.8,4.8,5.8);(0.3,0.7,0.7)> | <(4.2,5.2,6.2);(0.5,0.5,0.5)> |

| SSL-09 | <(3.9,4.9,5.9);(0.3,0.7,0.7)> | <(4.1,5.1,6.1);(0.3,0.7,0.7)> | <(3.0,4.0,5.0);(0.3,0.7,0.7)> |

| SSL-10 | <(4.0,5.0,6.0);(0.7,0.4,0.4)> | <(4.2,5.2,6.2);(0.3,0.7,0.7)> | <(4.2,5.2,6.2);(0.3,0.7,0.7)> |

| SSL-11 | <(3.3,4.3,5.3);(0.3,0.7,0.7)> | <(4.5,5.5,6.5);(0.3,0.7,0.7)> | <(3.4,4.4,5.4);(0.3,0.7,0.7)> |

| SSL-12 | <(4.3,5.3,6.3);(0.3,0.7,0.7)> | <(3.9,4.9,5.9);(0.3,0.7,0.7)> | <(2.9,3.9,4.9);(0.3,0.7,0.7)> |

| SSL-13 | <(3.8,4.8,5.8);(0.3,0.7,0.7)> | <(4.1,5.1,6.1);(0.3,0.7,0.7)> | <(4.6,5.6,6.6);(0.3,0.7,0.7)> |

| SSL-14 | <(4.1,5.1,6.1);(0.5,0.5,0.5)> | <(2.7,3.7,4.7);(0.5,0.5,0.5)> | <(4.9,5.9,6.9);(0.3,0.7,0.7)> |

| SSL-15 | <(4.2,5.2,6.2);(0.3,0.7,0.7)> | <(3.4,4.4,5.4);(0.3,0.7,0.7)> | <(4.1,5.1,6.1);(0.8,0.2,0.2)> |

| FR | <(4.3,5.3,6.3);(0.3,0.7,0.7)> | <(4.0,5.0,6.0);(0.3,0.7,0.7)> | <(3.1,4.1,5.1);(0.3,0.7,0.7)> |

| SSLs | C3-1 | C3-2 | C3-3 |

| SSL-01 | <(2.8,3.8,4.8);(0.5,0.5,0.5)> | <(4.6,5.6,6.6);(0.3,0.7,0.7)> | <(2.6,3.6,4.6);(0.3,0.7,0.7)> |

| SSL-02 | <(3.2,4.2,5.2);(0.3,0.7,0.7)> | <(2.5,3.5,4.5);(0.3,0.7,0.7)> | <(4.4,5.4,6.4);(0.3,0.7,0.7)> |

| SSL-03 | <(3.5,4.5,5.5);(0.3,0.7,0.7)> | <(3.6,4.6,5.6);(0.3,0.7,0.7)> | <(4.5,5.5,6.5);(0.3,0.7,0.7)> |

| SSL-04 | <(2.9,3.9,4.9);(0.3,0.7,0.7)> | <(3.8,4.8,5.8);(0.5,0.5,0.5)> | <(3.4,4.4,5.4);(0.3,0.7,0.7)> |

| SSL-05 | <(2.1,3.1,4.1);(0.3,0.7,0.7)> | <(4.0,5.0,6.0);(0.3,0.7,0.7)> | <(3.4,4.4,5.4);(0.3,0.7,0.7)> |

| SSL-06 | <(3.7,4.7,5.7);(0.3,0.7,0.7)> | <(4.1,5.1,6.1);(0.3,0.7,0.7)> | <(3.6,4.6,5.6);(0.3,0.7,0.7)> |

| SSL-07 | <(3.8,4.8,5.8);(0.3,0.7,0.7)> | <(3.5,4.5,5.5);(0.3,0.7,0.7)> | <(3.9,4.9,5.9);(0.3,0.7,0.7)> |

| SSL-08 | <(3.4,4.4,5.4);(0.3,0.7,0.7)> | <(3.5,4.5,5.5);(0.3,0.7,0.7)> | <(4.0,5.0,6.0);(0.5,0.5,0.5)> |

| SSL-09 | <(3.2,4.2,5.2);(0.3,0.7,0.7)> | <(3.4,4.4,5.4);(0.3,0.7,0.7)> | <(5.2,6.2,7.2);(0.3,0.7,0.7)> |

| SSL-10 | <(3.7,4.7,5.7);(0.3,0.7,0.7)> | <(4.2,5.2,6.2);(0.3,0.7,0.7)> | <(3.3,4.3,5.3);(0.5,0.5,0.5)> |

| SSL-11 | <(3.2,4.2,5.2);(0.3,0.7,0.7)> | <(3.6,4.6,5.6);(0.3,0.7,0.7)> | <(4.6,5.6,6.6);(0.3,0.7,0.7)> |

| SSL-12 | <(4.0,5.0,6.0);(0.3,0.7,0.7)> | <(5.3,6.3,7.3);(0.5,0.5,0.5)> | <(4.1,5.1,6.1);(0.5,0.5,0.5)> |

| SSL-13 | <(4.2,5.2,6.2);(0.3,0.7,0.7)> | <(4.6,5.6,6.6);(0.7,0.4,0.4)> | <(4.7,5.7,6.7);(0.3,0.7,0.7)> |

| SSL-14 | <(3.4,4.4,5.4);(0.5,0.5,0.5)> | <(5.7,6.7,7.7);(0.3,0.7,0.7)> | <(3.2,4.2,5.2);(0.3,0.7,0.7)> |

| SSL-15 | <(4.8,5.8,6.8);(0.3,0.7,0.7)> | <(4.0,5.0,6.0);(0.3,0.7,0.7)> | <(4.7,5.7,6.7);(0.5,0.5,0.5)> |

| FR | <(3.8,4.8,5.8);(0.3,0.7,0.7)> | <(3.5,4.5,5.5);(0.3,0.7,0.7)> | <(3.8,4.8,5.8);(0.3,0.7,0.7)> |

| SSLs | C4-1 | C4-2 | C4-3 |

| SSL-01 | <(3.7,4.7,5.7);(0.3,0.7,0.7)> | <(3.1,4.1,5.1);(0.3,0.7,0.7)> | <(2.4,3.4,4.4);(0.3,0.7,0.7)> |

| SSL-02 | <(3.6,4.6,5.6);(0.3,0.7,0.7)> | <(3.9,4.9,5.9);(0.3,0.7,0.7)> | <(4.4,5.4,6.4);(0.3,0.7,0.7)> |

| SSL-03 | <(3.1,4.1,5.1);(0.3,0.7,0.7)> | <(3.9,4.9,5.9);(0.3,0.7,0.7)> | <(4.4,5.4,6.4);(0.3,0.7,0.7)> |

| SSL-04 | <(3.4,4.4,5.4);(0.3,0.7,0.7)> | <(3.7,4.7,5.7);(0.5,0.5,0.5)> | <(3.2,4.2,5.2);(0.7,0.4,0.4)> |

| SSL-05 | <(3.5,4.5,5.5);(0.5,0.5,0.5)> | <(3.3,4.3,5.3);(0.3,0.7,0.7)> | <(3.5,4.5,5.5);(0.5,0.5,0.5)> |

| SSL-06 | <(3.2,4.2,5.2);(0.3,0.7,0.7)> | <(3.8,4.8,5.8);(0.3,0.7,0.7)> | <(3.1,4.1,5.1);(0.3,0.7,0.7)> |

| SSL-07 | <(4.8,5.8,6.8);(0.3,0.7,0.7)> | <(4.5,5.5,6.5);(0.3,0.7,0.7)> | <(3.7,4.7,5.7);(0.5,0.5,0.5)> |

| SSL-08 | <(3.4,4.4,5.4);(0.3,0.7,0.7)> | <(2.4,3.4,4.4);(0.3,0.7,0.7)> | <(3.6,4.6,5.6);(0.3,0.7,0.7)> |

| SSL-09 | <(3.5,4.5,5.5);(0.3,0.7,0.7)> | <(3.7,4.7,5.7);(0.3,0.7,0.7)> | <(4.0,5.0,6.0);(0.3,0.7,0.7)> |

| SSL-10 | <(3.9,4.9,5.9);(0.3,0.7,0.7)> | <(3.6,4.6,5.6);(0.3,0.7,0.7)> | <(3.1,4.1,5.1);(0.3,0.7,0.7)> |

| SSL-11 | <(3.4,4.4,5.4);(0.3,0.7,0.7)> | <(4.1,5.1,6.1);(0.3,0.7,0.7)> | <(3.3,4.3,5.3);(0.3,0.7,0.7)> |

| SSL-12 | <(3.0,4.0,5.0);(0.5,0.5,0.5)> | <(3.0,4.0,5.0);(0.3,0.7,0.7)> | <(3.1,4.1,5.1);(0.5,0.5,0.5)> |

| SSL-13 | <(3.2,4.2,5.2);(0.3,0.7,0.7)> | <(4.1,5.1,6.1);(0.3,0.7,0.7)> | <(2.4,3.4,4.4);(0.3,0.7,0.7)> |

| SSL-14 | <(3.9,4.9,5.9);(0.5,0.5,0.5)> | <(2.6,3.6,4.6);(0.5,0.5,0.5)> | <(4.4,5.4,6.4);(0.3,0.7,0.7)> |

| SSL-15 | <(4.2,5.2,6.2);(0.3,0.7,0.7)> | <(3.6,4.6,5.6);(0.5,0.5,0.5)> | <(3.4,4.4,5.4);(0.3,0.7,0.7)> |

| FR | <(3.7,4.7,5.7);(0.3,0.7,0.7)> | <(3.2,4.2,5.2);(0.3,0.7,0.7)> | <(3.9,4.9,5.9);(0.3,0.7,0.7)> |

| IC T | C1-1 | C1-2 | C1-3 | C2-1 | C2-2 | C2-3 | C3-1 | C3-2 | C3-3 | C4-1 | C4-2 | C4-3 |

| SSL-01 | 0.00 | 1.72 | 2.30 | 0.72 | 0.64 | 2.72 | 2.42 | 2.30 | 2.64 | 0.00 | 0.15 | 4.00 |

| SSL-02 | 0.00 | 1.24 | 2.30 | 0.83 | 3.04 | 1.57 | 1.03 | 2.00 | 1.03 | 0.15 | 1.24 | 0.83 |

| SSL-03 | 0.00 | 3.03 | 0.83 | 0.47 | 1.06 | 1.03 | 0.47 | 0.15 | 1.24 | 1.03 | 1.24 | 0.83 |

| SSL-04 | 0.30 | 2.00 | 1.47 | 0.88 | 3.03 | 1.03 | 1.72 | 0.88 | 0.64 | 0.47 | 1.25 | 1.98 |

| SSL-05 | 2.42 | 3.44 | 0.00 | 0.30 | 1.24 | 1.24 | 5.47 | 0.83 | 0.64 | 0.72 | 0.15 | 1.06 |

| SSL-06 | 0.64 | 9.06 | 1.47 | 2.30 | 0.15 | 0.64 | 0.15 | 1.03 | 0.30 | 0.83 | 1.03 | 1.47 |

| SSL-07 | 3.89 | 2.00 | 6.64 | 0.64 | 0.83 | 2.30 | 0.00 | 0.00 | 0.15 | 2.30 | 3.03 | 0.72 |

| SSL-08 | 2.74 | 1.03 | 0.83 | 1.03 | 0.30 | 2.72 | 0.64 | 0.00 | 0.72 | 0.47 | 1.47 | 0.47 |

| SSL-09 | 1.03 | 2.00 | 5.47 | 0.64 | 0.15 | 0.15 | 1.03 | 0.15 | 3.47 | 0.30 | 0.83 | 0.15 |

| SSL-10 | 3.03 | 4.42 | 0.00 | 1.21 | 0.30 | 2.30 | 0.15 | 1.24 | 1.25 | 0.30 | 0.64 | 1.47 |

| SSL-11 | 1.06 | 2.30 | 3.89 | 2.00 | 0.83 | 0.47 | 1.03 | 0.15 | 1.47 | 0.47 | 1.72 | 1.03 |

| SSL-12 | 0.83 | 6.64 | 2.64 | 0.00 | 0.15 | 0.30 | 0.30 | 7.06 | 0.88 | 1.66 | 0.30 | 1.89 |

| SSL-13 | 0.30 | 1.47 | 4.64 | 0.83 | 0.15 | 4.00 | 0.64 | 3.04 | 1.72 | 0.83 | 1.72 | 4.00 |

| SSL-14 | 0.15 | 6.64 | 3.03 | 0.72 | 3.44 | 6.64 | 1.06 | 0.00 | 1.03 | 0.72 | 1.44 | 0.83 |

| SSL-15 | 1.24 | 1.06 | 0.15 | 0.15 | 1.03 | 2.87 | 2.00 | 0.83 | 2.14 | 0.83 | 1.06 | 0.83 |

| IC I | C1-1 | C1-2 | C1-3 | C2-1 | C2-2 | C2-3 | C3-1 | C3-2 | C3-3 | C4-1 | C4-2 | C4-3 |

| SSL-01 | 0.00 | 1.72 | 2.30 | 0.08 | 0.64 | 2.08 | 1.78 | 2.30 | 2.64 | 0.00 | 0.15 | 4.00 |

| SSL-02 | 0.00 | 1.24 | 2.30 | 0.83 | 1.96 | 0.48 | 1.03 | 2.00 | 1.03 | 0.15 | 1.24 | 0.83 |

| SSL-03 | 0.00 | 3.03 | 0.83 | 0.47 | 0.42 | 1.03 | 0.47 | 0.15 | 1.24 | 1.03 | 1.24 | 0.83 |

| SSL-04 | 0.30 | 2.00 | 1.47 | 0.25 | 3.03 | 1.03 | 1.72 | 0.25 | 0.64 | 0.47 | 0.61 | 0.90 |

| SSL-05 | 1.78 | 2.81 | 0.00 | 0.30 | 1.24 | 1.24 | 5.47 | 0.83 | 0.64 | 0.08 | 0.15 | 0.42 |

| SSL-06 | 0.64 | 8.42 | 1.47 | 2.30 | 0.15 | 0.64 | 0.15 | 1.03 | 0.30 | 0.83 | 1.03 | 1.47 |

| SSL-07 | 3.25 | 2.00 | 6.64 | 0.64 | 0.83 | 2.30 | 0.00 | 0.00 | 0.15 | 2.30 | 3.03 | 0.08 |

| SSL-08 | 1.65 | 1.03 | 0.83 | 1.03 | 0.30 | 2.08 | 0.64 | 0.00 | 0.08 | 0.47 | 1.47 | 0.47 |

| SSL-09 | 1.03 | 2.00 | 5.47 | 0.64 | 0.15 | 0.15 | 1.03 | 0.15 | 3.47 | 0.30 | 0.83 | 0.15 |

| SSL-10 | 3.03 | 3.78 | 0.00 | 0.12 | 0.30 | 2.30 | 0.15 | 1.24 | 0.61 | 0.30 | 0.64 | 1.47 |

| SSL-11 | 0.42 | 2.30 | 3.25 | 2.00 | 0.83 | 0.47 | 1.03 | 0.15 | 1.47 | 0.47 | 1.72 | 1.03 |

| SSL-12 | 0.83 | 6.64 | 2.64 | 0.00 | 0.15 | 0.30 | 0.30 | 6.42 | 0.25 | 1.02 | 0.30 | 1.25 |

| SSL-13 | 0.30 | 1.47 | 4.64 | 0.83 | 0.15 | 4.00 | 0.64 | 1.96 | 1.72 | 0.83 | 1.72 | 4.00 |

| SSL-14 | 0.15 | 6.64 | 3.03 | 0.08 | 2.81 | 6.64 | 0.42 | 0.00 | 1.03 | 0.08 | 0.81 | 0.83 |

| SSL-15 | 1.24 | 0.42 | 0.15 | 0.15 | 1.03 | 1.36 | 2.00 | 0.83 | 1.50 | 0.83 | 0.42 | 0.83 |

| IC F | C1-1 | C1-2 | C1-3 | C2-1 | C2-2 | C2-3 | C3-1 | C3-2 | C3-3 | C4-1 | C4-2 | C4-3 |

| SSL-01 | 0.00 | 1.72 | 2.30 | 0.08 | 0.64 | 2.08 | 1.78 | 2.30 | 2.64 | 0.00 | 0.15 | 4.00 |

| SSL-02 | 0.00 | 1.24 | 2.30 | 0.83 | 1.96 | 0.48 | 1.03 | 2.00 | 1.03 | 0.15 | 1.24 | 0.83 |

| SSL-03 | 0.00 | 3.03 | 0.83 | 0.47 | 0.42 | 1.03 | 0.47 | 0.15 | 1.24 | 1.03 | 1.24 | 0.83 |

| SSL-04 | 0.30 | 2.00 | 1.47 | 0.25 | 3.03 | 1.03 | 1.72 | 0.25 | 0.64 | 0.47 | 0.61 | 0.90 |

| SSL-05 | 1.78 | 2.81 | 0.00 | 0.30 | 1.24 | 1.24 | 5.47 | 0.83 | 0.64 | 0.08 | 0.15 | 0.42 |

| SSL-06 | 0.64 | 8.42 | 1.47 | 2.30 | 0.15 | 0.64 | 0.15 | 1.03 | 0.30 | 0.83 | 1.03 | 1.47 |

| SSL-07 | 3.25 | 2.00 | 6.64 | 0.64 | 0.83 | 2.30 | 0.00 | 0.00 | 0.15 | 2.30 | 3.03 | 0.08 |

| SSL-08 | 1.65 | 1.03 | 0.83 | 1.03 | 0.30 | 2.08 | 0.64 | 0.00 | 0.08 | 0.47 | 1.47 | 0.47 |

| SSL-09 | 1.03 | 2.00 | 5.47 | 0.64 | 0.15 | 0.15 | 1.03 | 0.15 | 3.47 | 0.30 | 0.83 | 0.15 |

| SSL-10 | 3.03 | 3.78 | 0.00 | 0.12 | 0.30 | 2.30 | 0.15 | 1.24 | 0.61 | 0.30 | 0.64 | 1.47 |

| SSL-11 | 0.42 | 2.30 | 3.25 | 2.00 | 0.83 | 0.47 | 1.03 | 0.15 | 1.47 | 0.47 | 1.72 | 1.03 |

| SSL-12 | 0.83 | 6.64 | 2.64 | 0.00 | 0.15 | 0.30 | 0.30 | 6.42 | 0.25 | 1.02 | 0.30 | 1.25 |

| SSL-13 | 0.30 | 1.47 | 4.64 | 0.83 | 0.15 | 4.00 | 0.64 | 1.96 | 1.72 | 0.83 | 1.72 | 4.00 |

| SSL-14 | 0.15 | 6.64 | 3.03 | 0.08 | 2.81 | 6.64 | 0.42 | 0.00 | 1.03 | 0.08 | 0.81 | 0.83 |

| SSL-15 | 1.24 | 0.42 | 0.15 | 0.15 | 1.03 | 1.36 | 2.00 | 0.83 | 1.50 | 0.83 | 0.42 | 0.83 |

| SF | C1-1 | C1-2 | C1-3 | C2-1 | C2-2 | C2-3 | C3-1 | C3-2 | C3-3 | C4-1 | C4-2 | C4-3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SSL-01 | 0.27 | 0.01 | 0.00 | 0.17 | 0.03 | 0.00 | 0.02 | 0.00 | 0.00 | 0.03 | 0.01 | 0.00 |

| SSL-02 | 0.27 | 0.02 | 0.00 | 0.08 | 0.02 | 0.02 | 0.03 | 0.00 | 0.00 | 0.03 | 0.00 | 0.00 |

| SSL-03 | 0.27 | −0.03 | 0.01 | 0.10 | 0.05 | 0.01 | 0.04 | 0.02 | 0.00 | 0.01 | 0.00 | 0.00 |

| SSL-04 | 0.23 | 0.00 | 0.01 | 0.16 | −0.02 | 0.01 | 0.01 | 0.03 | 0.00 | 0.02 | 0.01 | 0.00 |

| SSL-05 | 0.11 | −0.01 | 0.02 | 0.11 | 0.02 | 0.01 | −0.10 | 0.01 | 0.00 | 0.04 | 0.01 | 0.00 |

| SSL-06 | 0.18 | −0.18 | 0.01 | −0.02 | 0.04 | 0.01 | 0.05 | 0.01 | 0.00 | 0.02 | 0.00 | 0.00 |

| SSL-07 | −0.08 | 0.00 | −0.05 | 0.09 | 0.03 | 0.00 | 0.06 | 0.03 | 0.01 | 0.00 | 0.00 | 0.00 |

| SSL-08 | 0.19 | 0.03 | 0.01 | 0.06 | 0.04 | 0.00 | 0.04 | 0.03 | 0.01 | 0.02 | 0.00 | 0.00 |

| SSL-09 | 0.13 | 0.00 | −0.04 | 0.09 | 0.04 | 0.01 | 0.03 | 0.02 | 0.00 | 0.03 | 0.00 | 0.00 |

| SSL-10 | −0.14 | −0.04 | 0.02 | 0.20 | 0.04 | 0.00 | 0.05 | 0.01 | 0.01 | 0.03 | 0.00 | 0.00 |

| SSL-11 | 0.29 | −0.01 | −0.01 | 0.00 | 0.03 | 0.01 | 0.03 | 0.02 | 0.00 | 0.02 | 0.00 | 0.00 |

| SSL-12 | 0.16 | −0.14 | −0.01 | 0.13 | 0.04 | 0.01 | 0.05 | −0.05 | 0.01 | 0.02 | 0.00 | 0.00 |

| SSL-13 | 0.23 | 0.02 | −0.03 | 0.08 | 0.04 | −0.01 | 0.04 | 0.01 | 0.00 | 0.02 | 0.00 | 0.00 |

| SSL-14 | 0.25 | −0.14 | −0.01 | 0.17 | 0.00 | −0.03 | 0.06 | 0.03 | 0.00 | 0.04 | 0.01 | 0.00 |

| SSL-15 | 0.10 | 0.07 | 0.02 | 0.12 | 0.02 | 0.02 | 0.00 | 0.01 | 0.00 | 0.02 | 0.01 | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Le, M.-T. Strategic Prioritization for Sustainable Development in the Logistics Industry: A FAHP-NFAD Approach. Appl. Sci. 2025, 15, 4364. https://doi.org/10.3390/app15084364

Le M-T. Strategic Prioritization for Sustainable Development in the Logistics Industry: A FAHP-NFAD Approach. Applied Sciences. 2025; 15(8):4364. https://doi.org/10.3390/app15084364

Chicago/Turabian StyleLe, Minh-Tai. 2025. "Strategic Prioritization for Sustainable Development in the Logistics Industry: A FAHP-NFAD Approach" Applied Sciences 15, no. 8: 4364. https://doi.org/10.3390/app15084364

APA StyleLe, M.-T. (2025). Strategic Prioritization for Sustainable Development in the Logistics Industry: A FAHP-NFAD Approach. Applied Sciences, 15(8), 4364. https://doi.org/10.3390/app15084364