Optimization of Fluorine Plasma Treatment for Interface Improvement on HfO2/In0.53Ga0.47As MOSFETs

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussion

3.1. Optimization of CF4/O2 Plasma

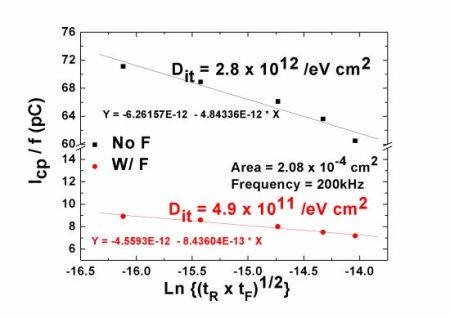

3.2. Electrical Characterization of the Interface Trap Density

| High k | Passivation method | Channel material | LG | EOT or thickness of high-k | Dit | SS (mV/dec) | Ref. |

|---|---|---|---|---|---|---|---|

| (cm−2eV−1) | |||||||

| Al2O3 * | - | In0.53Ga0.47As | - | 4.2 nm | 5 × 1011 | - | [16] |

| Al2O3 | - | In0.53Ga0.47As | - | 10 nm of Al2O3 | 2.5 × 1011 | - | [17] |

| Al2O3 | - | In0.53Ga0.47As | 1.5 µm | 8 nm of Al2O3 | 1 × 1012 | >200 | [18] |

| Al2O3 | - | In0.53Ga0.47As | 0.5 µm | 30 nm of Al2O3 | 1.4 × 1012 | 240 | [19] |

| HfO2 * | - | In0.53Ga0.47As | - | 2.1 nm | 1 × 1012 | - | [16] |

| HfO2 * | - | In0.53Ga0.47As | - | 7.8 nm of HfO2 | 2 × 1012 | - | [20] |

| HfO2 * | Al-doped | In0.53Ga0.47As | - | 8–9 nm of HfO2 | 6 × 1012 | - | [21] |

| HfO2 * | PH3 | In0.53Ga0.47As | 4 µm | 1.7 nm | 8.6 × 1011 | 103 | [22] |

| HfAlO | SiH4+NH3 | In0.53Ga0.47As | 2–10 µm | 3.8 nm | 6.5 × 1011 | 155–210 | [2] |

| ZrO2 | LaAlO3 | In0.53Ga0.47As | 5 µm | 1.63 nm | 7.5 × 1011 | 116 | [23] |

| HfO2 | CF4/O2 post treatment | In0.53Ga0.47As | 5–20 µm | 1.4 nm | 4.9 × 1011 | 109 | This work |

| HfO2 | Control | 1.35 nm | 2.8 × 1012 | 127 | This work |

4. Conclusions

References

- Shahrjerdi, D.; Tutuc, E.; Banerjee, S.K. Impact of surface chemical treatment on capacitance-voltage characteristics of GaAs metal-oxide-semiconductor capacitors with Al2O3 gate dielectric. Appl. Phys. Lett. 2007, 91, 063501. [Google Scholar]

- Chin, H.-C.; Liu, X.; Gong, X.; Yeo, Y.-C. Silane and ammonia surface passivation technology for high-mobility In0.53Ga0.47As MOSFETs. Trans. Electron. Devices 2010, 57, 973–979. [Google Scholar]

- Chen, Y.-T.; Zhao, H.; Yum, J.H.; Wang, Y.; Lee, J.C. Metal-oxide-semiconductor field-effect-transistors on indium phosphide using HfO2 and silicon passivation layer with equivalent oxide thickness of 18 Å. Appl. Phys. Lett. 2009, 94, 213505. [Google Scholar]

- CRC, Handbook of Physics and Chemistry, 84 ed; CRC: Boca Raton, FL, USA, 2003.

- Wu, W.-C.; Lai, C.-S.; Lee, S.-C.; Ma, M.-W.; Chao, T.-S.; Wang, J.-C.; Hsu, C.-W.; Chou, P.-C.; Chen, J.-H.; Kao, K.-H.; et al. Fluorinated HfO2 Gate Dielectrics Engineering for CMOS by Pre- and Post-CF4 Plasma Passivation. In Proceedings of IEEE International Electron Devices Meeting, San Francisco, CA, USA, 15-17 December 2008; pp. 1–4.

- Seo, K.; Sreenivasan, R.; McIntyre, P.C.; Saraswat, K.C. Improvement in high-k (HfO2/SiO2) reliability by incorporation of fluorine. IEEE Electron. Device Lett. 2006, 27, 821–823. [Google Scholar] [CrossRef]

- Xie, R.; He, W.; Yu, M.; Zhu, C. Effects of fluorine incorporation and forming gas annealing on high-k gated germanium metal-oxide-semiconductor with GeO2 surface passivation. Appl. Phys. Lett. 2008, 93, 073504. [Google Scholar] [CrossRef]

- Chin, H.-C.; Gong, X.; Wang, L.; Yeo, Y.-C. Fluorine incorporation in HfAlO gate dielectric for defect passivation and effect on electrical characteristics of In0.53Ga0.47As n-MOSFETs. Electrochem. Solid State Lett. 2010, 13, H440–H442. [Google Scholar]

- Chen, Y.-T.; Zhao, H.; Yum, J.H.; Wang, Y.; Xue, F.; Zhou, F.; Lee, J.C. Improved electrical characteristics of TaN/Al2O3/In0.53Ga0.47As metal-oxide-semiconductor field-effect transistors by fluorine incorporation. Appl. Phys. Lett. 2009, 95, 013501. [Google Scholar]

- Zhao, H.; Chen, Y.; Yum, J.H.; Wang, Y.; Lee, J.C. HfO2-based In0.53Ga0.47As MOSFETs (EOT ≈ 10Å) Using Various Interfacial Dielectric Layers. In Proceedings of IEEE 67th Device Research Conference, University Park, PA, USA, 22-24 June 2009; pp. 89–90.

- Zhao, H.; Yum, J.H.; Chen, Y.-T.; Lee, J.C. In0.53Ga0.47As n-metal-oxide-semiconductor field effect transistors with atomic layer deposited Al2O3, HfO2, and LaAlO3 gate dielectrics. J. Vac. Sci. Technol. B 2009, 27, 2024–2027. [Google Scholar] [CrossRef]

- Lee, S.; Park, J.-W. Effect of fluorine on dielectric properties of SiOF films. J. Appl. Phys. 1996, 80, 5260–5263. [Google Scholar]

- Tatsumi, T.; Fukuda, S.; Kadomura, S. Etch rate acceleration of SiO2 during wet treatment after gate etching. Jpn. J. Appl. Phys. 1993, 32, 6114–6118. [Google Scholar]

- Groeseneken, G.; Maes, H.E.; Beltran, N.; Dekeersmaecker, R.F. A reliable approach to charge-pumping measurements in MOS transistors. IEEE Trans. Electron. Devices 1984, 31, 42–53. [Google Scholar] [CrossRef]

- Xie, R.; Phung, T.H.; He, W.; Sun, Z.; Yu, M.; Cheng, Z.; Zhu, C. High Mobility High-k/Ge pMOSFETs with 1 nm EOT—New Concept on Interface Engineering and Interface Characterization. In Proceedings of 2008 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 15-17 December 2008; pp. 393–396.

- Zhao, H.; Huang, J.; Chen, Y.-T.; Yum, J.H.; Wang, Y.; Xue, F.; Zhou, F.; Lee, J.C. Effects of gate-first and gate-last process on interface quality of In0.53Ga0.47As metal-oxide-semiconductor capacitors using atomic-layer-deposited Al2O3 and HfO2 oxides. Appl. Phys. Lett. 2009, 95, 253501. [Google Scholar]

- Chiu, H.C.; Tung, L.T.; Chang, Y.H.; Lee, Y.J.; Chang, C.C.; Kwo, J.; Hong, M. Achieving a low interfacial density of states in atomic layer deposited Al2O3 on In0.53Ga0.47As. 53Ga0.47As. Appl. Phys. Lett. 2008, 93, 202903. [Google Scholar]

- Lin, D.; Brammertz, G.; Sioncke, S.; Fleischmann, C.; Delabie, A.; Martens, K.; Bender, H.; Conard, T.; Tseng, W.H.; Lin, J.C.; et al. Enabling the high-performance InGaAs/Ge CMOS: A common gate stack solution. In Proceedings of 2009 IEEE International Electron Devices Meeting (IEDM), Baltimore, MD, USA, 7-9 December 2009; pp. 1–4.

- Xuan, Y.; Wu, Y.; Shen, T.; Yang, T.; Ye, P. High Performance Submicron Inversion-Type Enhancement-Mode InGaAs MOSFETs with ALD Al2O3,HfO2 and HfAlO as Gate Dielectrics. In Proceedings of 2007 IEEE International Electron Devices Meeting (IEDM), Washington, DC, USA, 10-12 December 2007; pp. 637–640.

- Chang, Y.C.; Huang, M.L.; Lee, K.Y.; Lee, Y.J.; Lin, T.D.; Hong, M.; Kwo, J.; Lay, T.S.; Liao, C.C.; Cheng, K.Y. Atomic-layer-deposited HfO2 on In0.53Ga0.47As: Passivation and energy-band parameters. Appl. Phys. Lett. 2008, 92, 072901. [Google Scholar]

- Hwang, Y.; Chobpattana, V.; Zhang, J.Y.; LeBeau, J.M.; Engel-Herbert, R.; Stemmer, S. Al-doped HfO2/In0.53Ga0.47As metal-oxide-semiconductor capacitors. Appl. Phys. Lett. 2011, 98, 142901. [Google Scholar]

- Lin, J.; Lee, S.; Oh, H.-J.; Yang, W.; Lo, G.Q.; Kwong, D.L.; Chi, D.Z. Plasma PH3-Passivated High Mobility Inversion InGaAs MOSFET Fabricated with Self-Aligned Gate-First Process and HfO2/TaN Gates Stack. In Proceedings of 2008 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 15-17 December 2008; pp. 401–404.

- Huang, J.; Goel, N.; Zhao, H.; Kang, C.Y.; Min, K.S.; Bersuker, G.; Oktyabrsky, S.; Gaspe, C.K.; Santos, M.B.; Majhi, P.; et al. InGaAs MOSFET Performance and Reliability Improvement by Simultaneous Reduction of Oxide and Interface Charge in ALD (La)AlOx/ZrO2 Gate Stack. In Proceedings of 2009 IEEE International Electron Devices Meeting (IEDM), Baltimore, MD, USA, 7-9 December 2009; pp. 335–338.

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Chen, Y.-T.; Wang, Y.; Xue, F.; Zhou, F.; Lee, J.C. Optimization of Fluorine Plasma Treatment for Interface Improvement on HfO2/In0.53Ga0.47As MOSFETs. Appl. Sci. 2012, 2, 233-244. https://doi.org/10.3390/app2010233

Chen Y-T, Wang Y, Xue F, Zhou F, Lee JC. Optimization of Fluorine Plasma Treatment for Interface Improvement on HfO2/In0.53Ga0.47As MOSFETs. Applied Sciences. 2012; 2(1):233-244. https://doi.org/10.3390/app2010233

Chicago/Turabian StyleChen, Yen-Ting, Yanzhen Wang, Fei Xue, Fei Zhou, and Jack C. Lee. 2012. "Optimization of Fluorine Plasma Treatment for Interface Improvement on HfO2/In0.53Ga0.47As MOSFETs" Applied Sciences 2, no. 1: 233-244. https://doi.org/10.3390/app2010233

APA StyleChen, Y.-T., Wang, Y., Xue, F., Zhou, F., & Lee, J. C. (2012). Optimization of Fluorine Plasma Treatment for Interface Improvement on HfO2/In0.53Ga0.47As MOSFETs. Applied Sciences, 2(1), 233-244. https://doi.org/10.3390/app2010233