1. Introduction

In combustion-related systems, measurements of temperature and species concentrations are necessary to fundamentally understand the combustion, optimize the operation process, and improve the combustion efficiency. In recent years, many diagnostic techniques used for measurement of combustion characterization, such as laser light scattering [

1,

2], molecular filtered Rayleigh scattering (FRS) [

3], coherent anti-stokes Raman scattering (CARS) [

4], planar laser induced fluorescence (PLIF/LIF) [

5,

6,

7], have been reported. Although these techniques mentioned above have a number of advantages compared to traditional contact measurement, there are still some inevitable limitations. The FRS and CARS have excellent monitoring capability for high-temperature and extreme conditions, but they cannot provide accurate measurements in low-pressure and low-temperature conditions. Similarly, the PLIF/LIF technique takes advantages of a high spatial resolution and a fast response time, but it has difficulties attaining absolute concentration measurements and precise calibration of free radicals. Moreover, the technology mentioned above suffers from complex optical systems and difficulties associated with expensive equipment.

Tunable diode laser absorption spectroscopy (TDLAS) has been widely used for the detection of various gases and high enthalpy flows [

8]. TDLAS usually measures path-averaged information along the laser beam and is thus restricted to flows with near-uniform properties [

9]. It was first employed for the measurement of temperature and species concentration simultaneously in combustion flows by Wang [

10]. Line-of-sight tunable diode laser absorption spectroscopy (LOS-TDLAS) sensors for gas temperature and species concentration only retrieve path-averaged information along the laser beam traditionally. Nevertheless, there are still some researchers who applied LOS-TDLAS to diagnose the non-uniformity flow fields based on multiple absorption lines with only one optical beam. For instance, Sanders developed a sensor for oxygen gas temperature distributions [

11]. Liu and Zhang studied the temperature and water vapor distributions [

12,

13]. The multi-spectral LOS-TDLAS technique can retrieve one-dimensional temperature and species distribution, but it is still limited in the application of practical combustion conditions. In recent years, TDLAS is combined with the computed tomography (CT) to form a new measurement method called tunable diode laser absorption tomography (TDLAT). The absorption spectrum effects of spatial variations can also be compensated in fluid properties. It has been developed for measuring 2D distributions of temperature and gas concentration. Many validation tests of the TDLAT have been done on the University of Virginia's Supersonic Combustion Facility and on the NASA Langley Direct-Connect Supersonic Combustion Test Facility [

14,

15,

16,

17]. For instance, Ma et al. designed a hyperspectral tomography (HT) system that can measure the 2D distribution of temperature and H

2O concentration simultaneously with a temporal resolution of 50 kHz at 225 spatial grid points [

16]. In addition, Xu developed an on-line tomography system that includes two distributed feedback (DFB) laser diodes and fan-beam illumination from five views and 60 rays measurements [

18]. In fact, the distributions of temperature and chemical species should be measured in real time and fast response to provide important feedback to the boiler-control, for example, at incinerator facilities and thermal power plants. Therefore, the above detection methods cannot be directly applied to the real-time measurement of dynamic flames systems; the reasons are as follows: (1) the rotating probing beams or target leads to a reduction in temporal responses; (2) the complicated optical and mechanical structures; (3) the powerful computer needed for off-line computation and analysis.

The object of this work is to study an on-line measurement system to monitor the 2D distributions of temperature and H2O mole fraction on the dynamic flames using TDLAT. In order to illustrate the influence of beam distribution and grid number on symmetric and asymmetric combustion field reconstruction, the numerical simulations are also introduced as important research content. Moreover, an 8 × 8 reconstruction scheme is designed with a 1395 nm DFB diode laser. Then, the combustion parameters and reconstructed image models under one and two flat flame furnaces are investigated. The measurements demonstrate the ability of TDLAT sensing to monitor temperature and gas concentration distributions in harsh practical environments.

2. Absorption Spectroscopy Fundamentals

As mentioned above, TDLAT consists of both TDLAS and CT technology. TDLAS is used to obtain the spectral information in various positions around the measurement space, and the CT technology is then used to reconstruct 2D images of the temperature and gas concentration with above transmission signals. When a laser at frequency

ν [cm

−1] enters a gas sample with a path length of

L [cm], the absorbance

αν is expressed as [

19]

where

x is the absorbing species,

P(

x) [atm] is the local total pressure,

C(

x) is the molar fraction of the absorbing species,

T(

x) [K] is the local temperature, and

φ [cm] is the normalized line shape function. For atmosphere pressure and a high temperature, the line shape is usually approximated by a Voigt profile [

20,

21]. The line strength of molecular transition

S [

T(

x)] [cm

−2atm

−1] is a function of temperature as follows [

22]:

where

Q(

T) is the partition function of the absorbing molecule [

23],

T0 [K] is the reference temperature,

k [J/K] is the Boltzmann’s constant,

h [J⋅s] is Planck’s constant,

c [cm/s] is the speed of light,

v0 [cm

−1] is the line-center frequency, and

E” [cm

−1] is the lower state energy of the transition

v0. Because the line-shape function

φ is normalized ∫

φdν ≡ 1, the integrated absorbance

Av [cm

−1] can be inferred from Equation (1).

The integrated absorbance of two transition lines is measured simultaneously with the same species mole fraction, the same pressure, the same mole fraction, and the same path length. The above two absorbance ratios can be further simplified to the ratio of line strengths

R, which is a function of temperature only as expressed Equation (4) named double-line thermometry [

24].

Then, the temperature can be calculated at different temperature dependences:

The integrated absorbance areas

Aν for each line can be calculated by Voigt line-shape fitting methods. The gas mole fraction can in turn be obtained from the absorption of either transition with the known temperature, pressure, and path-length in Equation (3). However, this double-line thermometry actually obtains a path-averaged value because of the inherent assumption of a uniform temperature distribution along the line of sight. For the 2D distributions of temperature and gas concentration, the test section is divided into

M ×

N grids, as shown in

Figure 1. Meanwhile, the target gas concentration and temperature are assumed to be uniform in each small grid. The optical path length

Li,j of the

i-th laser beam within the

j-th grid can be calculated according to the two intersecting position of the grid and beam. It should be noted that the numbers of discretized grids, views, and laser beams are important for the accuracy of the tomographic image.

According to Equation (3), the integrated absorbance of the

i-th laser beam

Av,i can be expressed as

where

αν,i is the absorption coefficient in the

j-th grid.

M ×

N and

I are the total grid and beams number, respectively. If using two wavelengths with

I laser beams, then Equation (6) can be rewritten in matrix equation as

The matrix

L can be determined by geometrical arrangement. The integrated absorbance

Av1 and

Av2 are obtained with measurements. In this work, the absorption coefficients

αν can be calculated by solving the linear equation, Equation (7). The linear equation is iteratively solved using the algebraic reconstruction technique (ART) [

25] as

where

k is the iteration index in the ART procedure, and

λ (0 <

λ < 2) is the relaxation coefficient that plays an important role in accuracy performance and determining convergence rate [

26]. It is evident that the

λ represents the contribution of the absorption at

j-grid to the integral

i-th beam. Therefore, the

λ of conventional ART should be replaced by an automatic adjustment relaxation parameter during the reconstruction process, named the modified adaptive algebraic reconstruction technique (MAART) [

27]. The

λ of Equation (8) is expressed as

where

β is a constant during the calculation. The

β value would be recommended for selection from 0.1 to 0.3, which depends on the number of grids and beams. The reconstruction is terminated when the change of absorption coefficient

ε in Equation (10) between two consecutive iterations is less than 1 × 10

−6.

The absorbances

αv1,j and

αv2,j in the

j-th grid are obtained by performing the tomographic reconstruction. Finally, the temperature

Tj in

j-th grid can be retrieved from Equations (4) and (5), the H

2O mole fraction can be calculated from Equation (11).

3. Numerical Simulation and Analysis

In order to evaluate the efficiency of the MAART and assess the influences of the view angles and numbers, numerical simulations are carried out. Four stationary phantom flames and a square geometry of 8 × 8 grids are considered for simultaneous combustion imaging reconstructions. The different flame temperature imaging

Tset and the H

2O concentration imaging

Cset are generated using a Gaussian function and a Random function as shown in

Figure 2 and

Figure 3, respectively.

Including one flame to four flames, the set temperature distribution

Tset are set at 1500 K ± 50 K in the high temperature region and 400 K ± 50 K in the low temperature region. Typically, the H

2O concentration distribution is generally well correlated with the temperature distribution in a hydrocarbon flame. Therefore, the set volume fractions of H

2O

Cset in the measurement grids are assumed to be 0.17 ± 0.005 and 0.015 ± 0.005, correspondingly. It is known that the orientation of the view and the number of rays per view has a significant bearing on the quality of reconstruction [

28,

29]. Therefore, we assumed four different laser beams distributions to study the influence on the reconstruction in simulations. As shown in

Figure 4, the number of laser beams included is 16, 18, 32, and 44 with multi-projection. The integrated absorbance is obtained by simulated line-of-sight integration for two water vapor (H

2O) absorption lines 7165.82 cm

−1 and 7164.91 cm

−1. Spectroscopic parameters for the absorption transitions such as line-strengths, lower state energy, coefficients for their temperature dependency, and broadening coefficients are selected from the HITRAN (High Resolution Transmission) 2008 database, as shown in

Table 1. Meanwhile, in order to select the most suitable spectral line couples, the numerical simulation is carried out using the above database. The two absorption lines simulations are shown in

Figure 5, and the known parameter constants as

P = 1 atm,

L = 32 cm,

T = 500 K,

C = 0.2%, and

T = 1500 K,

C = 15%. Simulated line-of-sight data are inverted using the MAART, which is introduced in the above theoretical section.

Furthermore, the tomographic images have been compared with the four simulated flames, which are discretized into

M × N grids (

M =

N = 8). The quality of reconstructed results for distributions of both temperature and H

2O concentration are evaluated by the mean relative error

eT and

eC as Equations (11) and (12), respectively.

where

Tcal and

Ccal denote the calculated temperature and the H

2O concentration of reconstructed distributions. Similarly,

Tset and

Cset stand for the set temperature and the H

2O concentration, respectively.

Figure 6 shows the

eT and

eC variation curves for different simulation flames under four beam distributions. The value of

eT and

eC are reduced with increasing the numbers of views and laser beams. The relative errors of temperatures are less than the concentration reconstruction results. The reason is that the integral area errors caused a greater impact on concentration results from the weak absorption in the peripheral low temperature regions of flame. For the centrosymmetry phantoms of flame as shown in

Figure 2a,b,d, we have better reconstruction results when the laser beam paths are vertical and parallel to the symmetry axis of the flame as shown in

Figure 4a and the beam number is 16. However, for the non-centrosymmetric phantoms of flame, like in

Figure 2c and

Figure 3c, we do not have an acceptable and practical reconstruction result when the beam number is 16 and the beam paths are not vertical and parallel to the symmetry axis of the flame. Increasing the number of views and beams,

eT and

eC are reduced to less than 0.05 and 0.1, respectively, when the number of beams are 32 and 44, as shown in

Figure 4c,d. Therefore, the better spatial resolution could be gained only when the laser beam paths are vertical and parallel to the symmetry axis of the combustion field under the limited number of light paths.

4. Experiment Process and Analysis

The TDLAS-based tomography system is shown in

Figure 7a.

Figure 7b shows a photograph of the optical test section and the configuration of the probe beams: 8 horizontally and 8 vertically, and with a spacing of 4 cm between neighboring probe beams. To be specific, the diode laser controller and function generator provide stable temperature and precise current controlling signals for a DFB laser. Thus, two vapor transitions

v1 = 7165.84 cm

−1 and

v2 = 7164.91 cm

−1 can be covered by the saw tooth scanning current. The output laser is split into 16 channels with a 1 × 16 fiber coupler. Each separated output beam is firstly collimated by a collimator and then guided through the interest region. Finally, the laser beam comprising absorption information is sampled by two arrays that contain 16 equally spaced photodiodes. Each signal is transferred into the Personal Computer to reconstruct the 2D distributions of temperature and H

2O mole fraction by the on-line manner modified ART. The sampling data of the photodetector output and the data processing are performed using a LabVIEW 2014 (National Instruments, Austin, TX, USA) program.

In order to online get the integrated absorbance

Av, the output wavelength is measured by a wavelength meter 621B-IR (Bristol Instruments, Victor, NY, USA). The output wave number is inversely proportional to the laser drive current, and the variation is 0.032 cm

−1/mA obtained by linear fitting. The relationship between the output wavenumber and the laser drive current at different temperatures is shown in

Figure 8. In our tomography experiments, the laser temperature is set to 31 °C and the drive current from 63 mA to 118 mA aims to scan over the two vapor absorptions from 7164.64 cm

−1 to 7166.40 cm

−1. The wavenumber tuning speed of the DFB laser is 10 Hz, and the average of 10 measurements has been done to remove the white noise. A 16-channel synchronous A/D (Analog to Digital) acquisition card is used in this condition, so that the time to record 16 sets of photodetector signal is 1 s including all beam positions. In principle, a more accurate analysis of the integrated absorbance areas at atmospheric pressures can be achieved by fitting the experimental spectra with a Voigt functions, for instance, the standard Humlíček algorithm [

30]. It is worth noting that the homogeneous temperature distribution is assumed along the paths of each beam. However, in these experiments, there is no observed improvement in the accuracy of the Voigt fitting, and it will be computationally more intensive than Lorentzian functions. Therefore, the Lorentzian line-shape function is used to fit all the absorption spectrums.

Figure 9 shows the final direct absorption signals in flame (red solid line) and in room air (black dot line) for two transitions at

v1 = 7164.91 cm

−1 and

v2 = 7165.82 cm

−1, respectively. The two integrated absorbance for each channel can be calculated by fitting and the modified ART. In the case of computing efficiency, it takes less than 1 s to reconstruct the images of temperature and H

2O mole fraction. Therefore, the reconstructed 2D distributions of temperature and H

2O mole fraction can be updated and displayed only every 1 s. If we need to analyze the change of combustion more quickly, we need to increase the scanning frequency (hundred or thousand times) to meet the requirements.

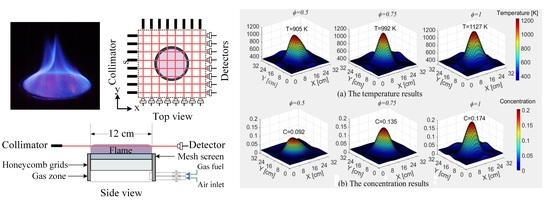

In the experiment, a premixed flame is generated by a circular flat flame burner (Holthuis & Associates, Sebastopol, CA, USA).

Figure 10 shows the schematic of the burner. The gas fuel and air were mixed in a buffering zone and then passed through the honeycomb grids before flew in to the flame region. In order to build a flat flame, the burner was equipped with a mesh screen. The volumetric flow-rates of the gas fuel and air were accurately controlled by two float-type flowmeters (Shuanghuan, Changzhou, China). The diameter of burner is 12 cm, and the side length of the square measurement region is 32 cm. The height of the laser beams 8 × 8 grids is adjusted 2 cm above the burner surface, as shown in

Figure 11. That is to say, the 2D distributions of temperature and H

2O mole fraction on the cross section of the flame at H = 2 cm are reconstructed per second in this experiment. In the combustion process, the air flow rate is set to 20 L/min and three different combustion states are operated by setting the gas fuel (CH

4) flow rates to 1.0 L/min, 1.6 L/min, and 2.1 L/min, which resulted in the fuel–air equivalence ratio (

ϕ) approximate to 0.5, 0.75, and 1, respectively. When the flame is stabilized, the 2D distributions of temperature

Tcal and H

2O mole fraction

Ccal are obtained. In order to smooth the reconstructed image, the cubic spline interpolating function is applied to the final image data process [

31]. In the core of the flame, the value of

Tcal and

Ccal are larger than beside value in case of a higher equivalent ratio. As shown in

Figure 12a, their temperature peaks are 955 K, 992 K, and 1127 K under three different kinds of equivalence ratios, respectively. Based on the analysis, the combustion temperature reaches the highest when the equivalence ratio of the premixed flow is exactly stoichiometric. At the same time, the core flame temperatures have been recorded by a B-type thermocouple, and the measurement results are 905 K, 970 K, and 1066 K, respectively. Therefore, the temperature relative errors between the peaks value of

Tcal and the B-type thermocouple (Huakong, Beijing, China) are less than 5.6%. The same effect is observed in the case of the H

2O mole fraction distribution

Ccal as in the case of

Tcal, as seen in

Figure 12b. The core flame theoretical value of H

2O mole fraction is 0.190 when calculated with chemical equilibrium method for a fuel-air equivalence ratio of 1. The H

2O mole fraction

Ccal of the other two combustion states, whose equivalent ratio are 0.75 and 0.5, are 0.146 and 0.099 from theoretical estimates. The experimental measurements are 0.174, 0.135, and 0.092 in the core flame of three combustion states. Therefore, the relative errors between theoretical value and reconstruction

Ccal are less than 8.6%. Because the flame region is smaller than the measurement region and the flow disturbance mixes the boundary air into the flame, these cause the H

2O concentration to be lower than its theoretical value. At the boundary of the flame,

Tcal and

Ccal gradually decrease to surrounding values because of heat transfer and gas mixing between the combustion products and the surrounding air.

In order to verify the performance of the tomographic sensor and algorithm, the distributions of temperature and H

2O mole fraction are reconstructed with two circular flat flames burners as is shown in

Figure 13. The divided laser beam grids are also 2 cm high above the two flat flames. In the process of combustion, the air velocity of Burner 1 and Burner 2 are set to 20 L/min and their fuel velocity are set to 1.8 L/min and 2.0 L/min for different combustion states, respectively. Similarly, the images of 2D distribution of temperature

Tcal and H

2O mole fraction

Ccal are shown in

Figure 14. The double temperature peaks are 927 K and 996 K at the center of Burner 1 and Burner 2, respectively. Meanwhile, the distribution of

Ccal corresponds to the

Tcal, and the peak values are 0.094 and 0.134. The

Tcal and

Ccal out of the combustion area are just above ambient temperature and humidity. The experimental results are well coincident with the theoretical calculation, and yet, the errors are close to 10%. Because the area of effective measurement is larger than the combustion region of interest, the air around the flow has great effects on the results. Although we have obtained good imaging results using the cubic spline interpolating function, the practical image quality is still limited by the finite number of laser beams.