Artificial Neural Network-Based Constitutive Relationship of Inconel 718 Superalloy Construction and Its Application in Accuracy Improvement of Numerical Simulation

Abstract

:1. Introduction

2. Experiments

2.1. Material and Experiment Procedures

2.2. Experimental Results

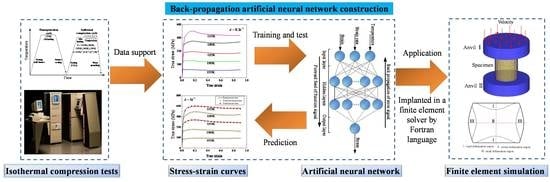

3. ANN model

3.1. Development of ANN Model

3.2. Evaluation of ANN Model

4. Continuous Mapping Relationship

5. Application

6. Conclusions

- (1)

- The true stress level of Inconel 718 superalloy decreases with increasing temperature or decreasing strain rate. The true stress varies along with strain highly non-linearly, which represents the non-linear variation of the comprehensive effects of different action mechanisms including work hardening, dynamic recovery, dynamic recrystallization, and the interaction of intermetallic precipitation phases.

- (2)

- An ANN model taking the deformation temperature (T), strain rate () and true strain (ε) as input variables and the true stress (σ) as output variable was constructed for the compression flow behaviors of Inconel 718 superalloy. The evaluation via the indicators of correlation coefficient (R), average absolute relative error (AARE) and relative error (δ) revealed that the present ANN model has admirable performance in describing and predicting the flow behaviors.

- (3)

- The continuous mapping relationship within the temperature range of 1103–1403 K, the strain rate range of 0.01–10 s−1, and the strain range of 0.05–0.9 was constructed. Such a constitutive relationship can provide abundant and accurate stress-strain data in extensive scope for the FE model of Inconel 718 superalloy.

- (4)

- The simulated isothermal compression tests under the deformation conditions of 1153 K and 0.1 s−1, 1303 K and 0.1 s−1, 1153 K and 1 s−1 and 1253 K and 1 s−1 were conducted in the FE solver. The comparisons between the simulated stroke-load curves based on the FEM-implanted ANN model and the FEM that imported the training stress-strain data revealed the fact that the FE simulation adopting the FE model-implanted ANN model describing the constitutive relationship model can significantly improve the numerical simulation accuracy of hot forming processes.

Author Contributions

Conflicts of Interest

Appendix A

Do i = 1, P Net1(1, i) = 0 DO j = 1, Q Net1(1, i) = IW21(j, i) × X(1, j) + B1(1, i) End do Y1(1, i) = f1(net1(1, i)) End do Do i = 1, Q Net2(1, i) = 0 DO j = 1, P Net2(1, i) = LW32(j, i) × Y1(1, j) + B2(1, i) End do Y2(1, i) = f2(net2(1, i)) End do Net3(1, 1) = 0 DO i = 1, Q Net3(1, 1) = LW42(i, 1) × Y2(1, i) + B3(1, 1) End do Output = f3(net3(1, 1))where P and Q are the neuron numbers of hidden layers, here, P = Q = 10; i and j are the dynamic variables for iteration; X(1, 1), X(1, 2) and X(1, 3) respectively represent the input variables, namely temperature, strain rate and strain; Net1(1, i) and Net2(1, i) are the weighted input values of ith neurons; Net3(1, 1) is the one of output neuron; Y1(1, i) and Y2(1, i) are the output values of ith neurons, namely the values of flow stress; B1, B2 and B3 are respectively the bias vectors for the hidden layers and output layer, net.b{1}, net.b{2} and net.b{3} are respectively N × 1, M × 1 and 1 × 1 cell array; IW21, LW32 and LW42 are the weight matrices of weights delivered to layers from network inputs, delivered to the second hidden layer from first hidden layer, and delivered to the out layer from second hidden layer. net.IW {2,1}, net.LW {3,2} and net.LW{4,2} are respectively N × 3, M × N and N × M cell array; f1 and f2 are tansig function, and f3 is purelin function.

References

- Sugihara, T.; nomoto, T. High Speed Machining of Inconel 718 Focusing on Tool Surface Topography of CBN Tool. Procedia Manuf. 2015, 1, 675–682. [Google Scholar] [CrossRef]

- Zhang, H.; Li, C.; Liu, Y.; Guo, Q.; Li, H. Precipitation behavior during high-temperature isothermal compressive deformation of Inconel 718 alloy. Mater. Sci. Eng. A 2016, 677, 515–521. [Google Scholar] [CrossRef]

- Ning, Y.; Huang, S.; Fu, M.W.; Dong, J. Microstructural characterization, formation mechanism and fracture behavior of the needle δ phase in Fe–Ni–Cr type supseralloys with high Nb content. Mater. Charact. 2015, 109, 36–42. [Google Scholar] [CrossRef]

- Abbasi, S.M.; Shokuhfar, A. Prediction of hot deformation behaviour of 10Cr–10Ni–5Mo–2Cu steel. Mater. Lett. 2007, 61, 2523–2526. [Google Scholar] [CrossRef]

- Mao, P.L.; Su, G.Y.; Yang, K. Dynamic recrystallisation of as cast austenite in 18–8 stainless steel. Mater. Sci. Technol. 2002, 18, 892–896. [Google Scholar] [CrossRef]

- Huang, K.; Logé, R.E. A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Hallberg, H. Approaches to modeling of recrystallization. Metals 2011, 1, 16–48. [Google Scholar] [CrossRef]

- Liu, Y.; Ning, Y.; Nan, Y.; Liang, H.; Li, Y.; Zhao, Z. Characterization of hot deformation behavior and processing map of FGH4096–GH4133B dual alloys. J. Alloys Compd. 2015, 633, 505–515. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Bhaduri, A.K.; Venugopal, S.; Sivaprasad, P.V. Analysis and mathematical modelling of elevated temperature flow behaviour of austenitic stainless steels. Mater. Sci. Eng. A 2011, 528, 1937–1943. [Google Scholar] [CrossRef]

- Ayala, H.V.H.; Habineza, D.; Rakotondrabe, M.; Klein, C.E.; Coelho, L.S. Nonlinear Black-box System Identification through Neural Networks of a Hysteretic Piezoelectric Robotic Micromanipulator. IFAC-PapersOnLine 2015, 48, 409–414. [Google Scholar] [CrossRef]

- Gallo, C.; Contò, F.; La Sala, P.; Antonazzo, A.P. A neural network model for classifying olive farms. Proc. Technol. 2013, 8, 593–599. [Google Scholar] [CrossRef]

- Gallo, I.; Vanetti, M.; Albertini, S.; Nodari, A. Multi-net System Configuration for Visual Object Segmentation by Error Backpropagation. In Pattern Recognition and Image Analysis; Sanches, J.M., Micó, L., Cardoso, J.S., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 468–475. [Google Scholar]

- Yao, X. Evolving artificial neural networks. IEEE Proc. 1999, 87, 1423–1447. [Google Scholar]

- Bilgehan, M.; Turgut, P. Artificial neural network approach to predict compressive strength of concrete through ultrasonic pulse velocity. Res. Nondestruct. Eval. 2010, 21, 1–17. [Google Scholar] [CrossRef]

- Liu, J.; Chang, H.; Hsu, T.Y.; Ruan, X. Prediction of the flow stress of high-speed steel during hot deformation using a BP artificial neural network. J. Mater. Process. Technol. 2000, 103, 200–205. [Google Scholar] [CrossRef]

- Phaniraj, M.P.; Lahiri, A.K. The applicability of neural network model to predict flow stress for carbon steels. J. Mater. Process. Technol. 2003, 141, 219–227. [Google Scholar] [CrossRef]

- Mandal, S.; Sivaprasad, P.V.; Venugopal, S.; Murthy, K.P.N. Artificial neural network modeling to evaluate and predict the deformation behavior of stainless steel type AISI 304L during hot torsion. Appl. Soft Comput. 2009, 9, 237–244. [Google Scholar] [CrossRef]

- Sabokpa, O.; Zarei-Hanzaki, A.; Abedi, H.R.; Haghdadi, N. Artificial neural network modeling to predict the high temperature flow behavior of an AZ81 magnesium alloy. Mater. Des. 2012, 39, 390–396. [Google Scholar] [CrossRef]

- Meo, S.; Zohoori, A.; Vahedi, A. Optimal design of permanent magnet flux switching generator for wind applications via artificial neural network and multi-objective particle swarm optimization hybrid approach. Energy Convers. Manag. 2016, 110, 230–239. [Google Scholar] [CrossRef]

- Guarize, R.; Matos, N.A.F.; Sagrilo, L.V.S.; Lima, E.C.P. Neural networks in the dynamic response analysis of slender marine structures. Appl. Ocean Res. 2007, 29, 191–198. [Google Scholar] [CrossRef]

- Aoki, K.; Izumi, O. Flow and fracture behaviour of Ni3 (Al-Ti) single crystals tested in tension. J. Mater. Sci. 1979, 14, 1800–1806. [Google Scholar] [CrossRef]

- Zhu, Y.; Zeng, W.; Sun, Y.; Feng, F.; Zhou, Y. Artificial neural network approach to predict the flow stress in the isothermal compression of as-cast TC21 titanium alloy. Comput. Mater. Sci. 2011, 50, 1785–1790. [Google Scholar] [CrossRef]

- Meissner, M.; Schmuker, M.; Schneider, G. Optimized Particle Swarm Optimization (OPSO) and its application to artificial neural network training. BMC Bioinform. 2006, 7, 125. [Google Scholar] [CrossRef] [PubMed]

- Mandal, S.; Rakesh, V.; Sivaprasad, P.V.; Venugopal, S.; Kasiviswanathan, K.V. Constitutive equations to predict high temperature flow stress in a Ti-modified austenitic stainless steel. J. Mater. Sci. Eng. A 2009, 500, 114–121. [Google Scholar] [CrossRef]

- Vickram, A.S.; Das, R.; Srinivas, M.S.; Rao, K.A.; Jayaraman, G.; Sridharan, T.B. Prediction of Zn concentration in human seminal plasma of Normospermia samples by Artificial Neural Networks (ANN). J. Assist. Reprod. Genet. 2013, 30, 453–459. [Google Scholar] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, J.; Ren, H.; Gao, K. Artificial Neural Network-Based Constitutive Relationship of Inconel 718 Superalloy Construction and Its Application in Accuracy Improvement of Numerical Simulation. Appl. Sci. 2017, 7, 124. https://doi.org/10.3390/app7020124

Lv J, Ren H, Gao K. Artificial Neural Network-Based Constitutive Relationship of Inconel 718 Superalloy Construction and Its Application in Accuracy Improvement of Numerical Simulation. Applied Sciences. 2017; 7(2):124. https://doi.org/10.3390/app7020124

Chicago/Turabian StyleLv, Junya, Huiyu Ren, and Kai Gao. 2017. "Artificial Neural Network-Based Constitutive Relationship of Inconel 718 Superalloy Construction and Its Application in Accuracy Improvement of Numerical Simulation" Applied Sciences 7, no. 2: 124. https://doi.org/10.3390/app7020124

APA StyleLv, J., Ren, H., & Gao, K. (2017). Artificial Neural Network-Based Constitutive Relationship of Inconel 718 Superalloy Construction and Its Application in Accuracy Improvement of Numerical Simulation. Applied Sciences, 7(2), 124. https://doi.org/10.3390/app7020124