Application of FBG Based Sensor in Pipeline Safety Monitoring

Abstract

:1. Introduction

2. Pipeline Safety Monitoring Theory

2.1. Hoop Strain Theory

2.2. Leakage Monitoring

2.3. Corrosion Monitoring

2.4. Leakage and Corrosion Distinction

3. Sensor Introduction

3.1. Sensor Design

3.2. Sensor Calibration Test

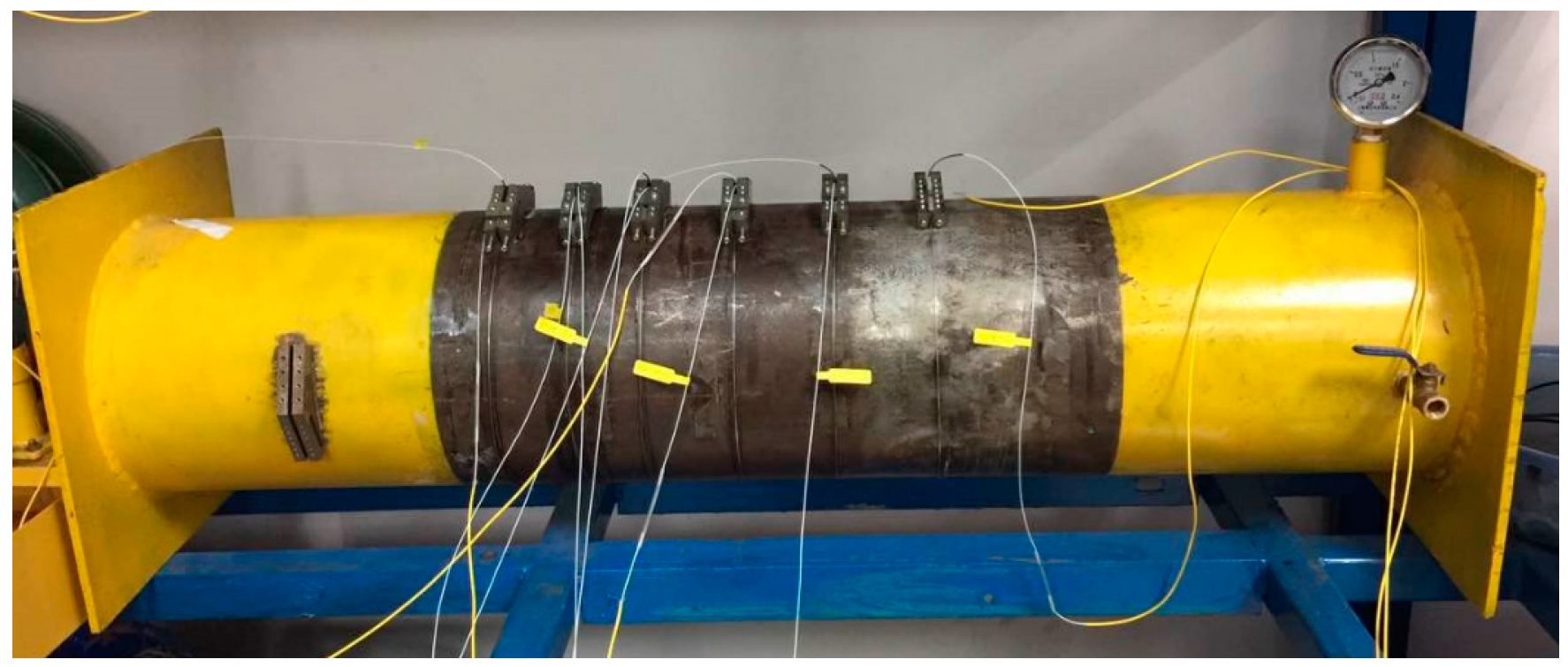

4. Experimental Pipeline and Sensor Installation

4.1. Experimental Pipeline Introduction

4.2. Sensor Installation

5. Experimental Results

5.1. Leakage Monitoring

5.2. Corrosion Detection Results

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Laurentys, C.; Bomfim, C.; Menezes, B.; Caminhas, W. Design of a pipeline leakage detection using expert system: A novel approach. Appl. Soft Comput. 2011, 11, 1057–1066. [Google Scholar] [CrossRef]

- Frings, J.; Walk, T. Distributed fiber optic sensing enhances pipeline safety and security. Oil Gas Eur. Mag. 2011, 3, 132–136. [Google Scholar]

- Bartolini, C.; Cioccolanti, L.; Comodi, G.; Caresana, F. Distributed stirling engines for pipeline corrosion protection. In Proceedings of the 15th International Stirling Engine Conference, Dubrovnik, Croatia, 27–29 September 2012. [Google Scholar]

- Skjelvareid, M.; Birkelund, Y.; Larsen, Y. Internal pipeline inspection using virtual source synthetic aperture ultrasound imaging. NDT E Int. 2013, 54, 151–158. [Google Scholar] [CrossRef]

- Tavakoli, M.; Marques, L.; de Almeida, A. Development of an industrial pipeline inspection robot. Ind. Robot Int. J. 2010, 37, 309–322. [Google Scholar] [CrossRef]

- Kwon, Y.; Yi, B. Design and motion planning of a two-module collaborative indoor pipeline inspection robot. IEEE Trans. Robot. 2012, 28, 681–696. [Google Scholar] [CrossRef]

- Murayama, R.; Makiyama, S.; Kodama, M.; Taniguchi, Y. Development of an ultrasonic inspection robot using an electromagnetic acoustic transducer for a Lamb wave and an SH-plate wave. Ultrasonics 2004, 42, 825–829. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Wang, P.; Vuran, M.; Al-Rodhaan, M.; Al-Dhelaan, A.; Akyildiz, I. MISE-PIPE: Magnetic induction-based wireless sensor networks for underground pipeline monitoring. Ad Hoc Netw. 2011, 9, 218–227. [Google Scholar] [CrossRef]

- Li, H.N.; Li, D.S.; Song, G.B. Recent applications of fiber optic sensors to health monitoring in civil engineering. Eng. Struct. 2004, 26, 1647–1657. [Google Scholar] [CrossRef]

- Grosswig, S.; Graupner, A.; Hurtig, E.; Kühn, K.; Trostel, A. Distributed fibre optical temperature sensing technique—A variable tool for monitoring tasks. In Proceedings of the 8th International Symposium on Temperature and Thermal Measurements in Industry and Science, Berlin, Germany, 19–21 June 2001. [Google Scholar]

- Niklès, M.; Vogel, B.; Briffod, F.; Grosswig, S.; Sauser, F.; Luebbecke, S.; Pfeiffer, T. Leakage detection using fiber optics distributed temperature monitoring. Smart Struct. Mater. 2004, 18–25. [Google Scholar] [CrossRef]

- Zou, L.; Sezerman, O.; Revie, W. Pipeline corrosion monitoring by fiber optic distributed strain and temperature sensors. In Proceedings of the NACE International Corrosion Conference and Expo, New Orleans, LA, USA, 16–20 March 2008. [Google Scholar]

- Alhandawi, K.; Vahdati, N.; Shiryayev, O.; Lawand, L. Corrosion monitoring along infrastructures using distributed fiber optic sensing. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, Las Vegas, NV, USA, 20–24 March 2016. [Google Scholar]

- Li, W.; Bao, X. High Spatial Resolution Distributed Fiber Optic Technique for Strain and Temperature Measurements in Concrete Structures. In Proceedings of the International Workshop on Smart Materials, Structures NDT in Canada 2013 Conference & NDT for the Energy Industry, Calgary, AB, Canada, 7–10 October 2013. [Google Scholar]

- Li, H.; Yi, T.; Ren, L.; Li, D.; Huo, L. Reviews on innovations and applications in structural health monitoring for infrastructures. Struct. Monit. Maint. 2014, 1, 1–45. [Google Scholar] [CrossRef]

- Ren, L.; Jia, Z.; Li, H.; Song, G. Design and experimental study on FBG hoop-strain sensor in pipeline monitoring. Opt. Fiber Technol. 2014, 20, 15–23. [Google Scholar] [CrossRef]

- Jia, Z.; Ren, L.; Li, H.; Ho, S.; Song, G. Experimental study of pipeline leak detection based on hoop strain measurement. Struct. Control Health Monit. 2015, 22, 799–812. [Google Scholar] [CrossRef]

- Felli, F.; Paolozzi, A.; Vendittozzi, C.; Paris, C.; Asanuma, H. Use of FBG sensors for health monitoring of pipelines. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, Las Vegas, NV, USA, 20–24 March 2016. [Google Scholar]

- Zhou, J.; Sun, L.; Li, H. Study on dynamic response measurement of the submarine pipeline by full-term FBG sensors. Sci. World J. 2014, 2014. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Sohn, H. Damage detection for pipeline structures using optic-based active sensing. Smart Struct. Syst. 2012, 9, 461–472. [Google Scholar] [CrossRef]

- Hou, Q.; Jiao, W.; Zhan, S.; Ren, L.; Jia, Z. Natural gas pipeline leakage detection based on FBG strain sensor. In Proceedings of the Fifth International Conference on Measurements and Mechatronics Automation, Hong Kong, China, 16–17 January 2013. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, T.; Ren, L.; Jia, Z.; Li, D.; Li, H. Application of FBG Based Sensor in Pipeline Safety Monitoring. Appl. Sci. 2017, 7, 540. https://doi.org/10.3390/app7060540

Jiang T, Ren L, Jia Z, Li D, Li H. Application of FBG Based Sensor in Pipeline Safety Monitoring. Applied Sciences. 2017; 7(6):540. https://doi.org/10.3390/app7060540

Chicago/Turabian StyleJiang, Tao, Liang Ren, Ziguang Jia, Dongsheng Li, and Hongnan Li. 2017. "Application of FBG Based Sensor in Pipeline Safety Monitoring" Applied Sciences 7, no. 6: 540. https://doi.org/10.3390/app7060540

APA StyleJiang, T., Ren, L., Jia, Z., Li, D., & Li, H. (2017). Application of FBG Based Sensor in Pipeline Safety Monitoring. Applied Sciences, 7(6), 540. https://doi.org/10.3390/app7060540