Investigation of the Use of Recycled Concrete Aggregates Originating from a Single Ready-Mix Concrete Plant

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

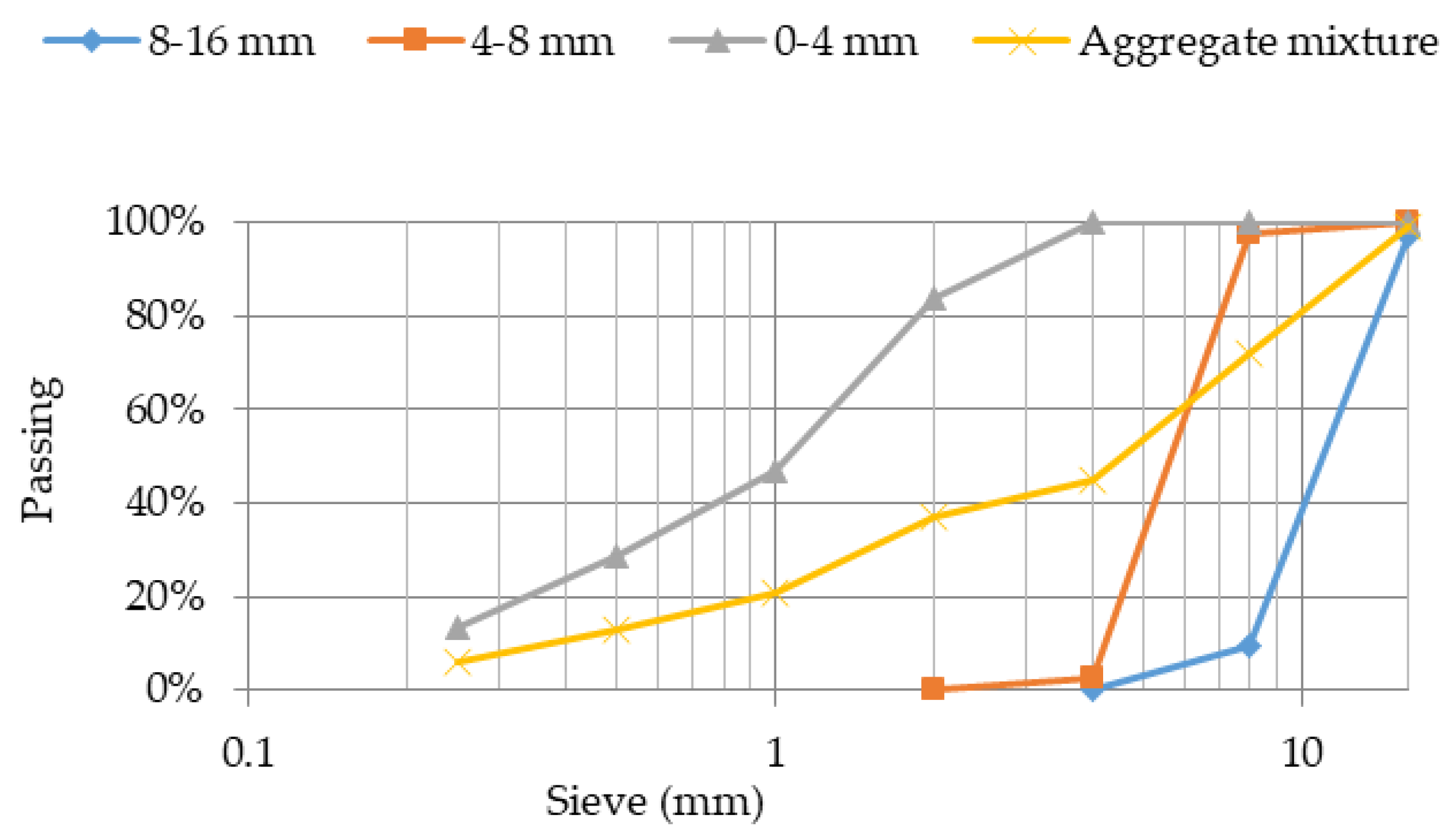

2.1. Recycled Concrete Aggregates (HR and CR)

2.1.1. Recycled Aggregate Properties Testing

2.1.2. Design of Concrete Mixtures

2.1.3. Fresh and Hardened Concrete Testing

- Open porosity according to RILEM CPC11.3 in water under vacuum;

- Seven and 28-day compressive strength test in 150 mm cubes (at least three for each testing age and mix);

- Elastic modulus in 150 × 300 mm cylinders (at least three for each testing age and mix);

- Three-point bending strength in 100 × 100 × 400 mm prisms (at least three for each testing age and mix);

- Drying shrinkage by 100 × 100 × 1000 mm, cured in 20 °C and <50% RH;

- Resistance to chloride ion penetration according to ASTM C 1202-97;

- Freeze–thaw resistance with de-icing salts after 10 cycles according to CEN/TS 12390-9.

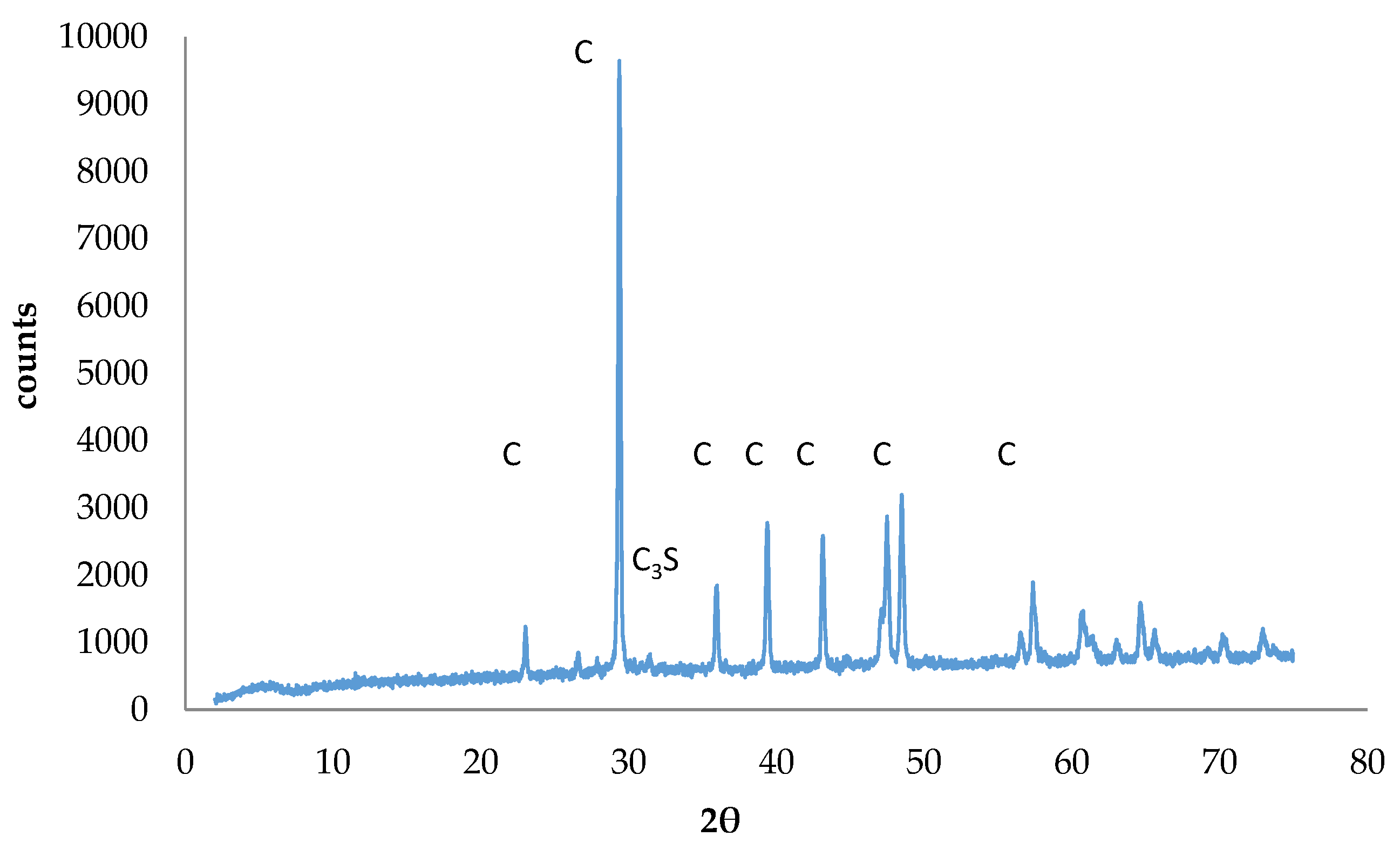

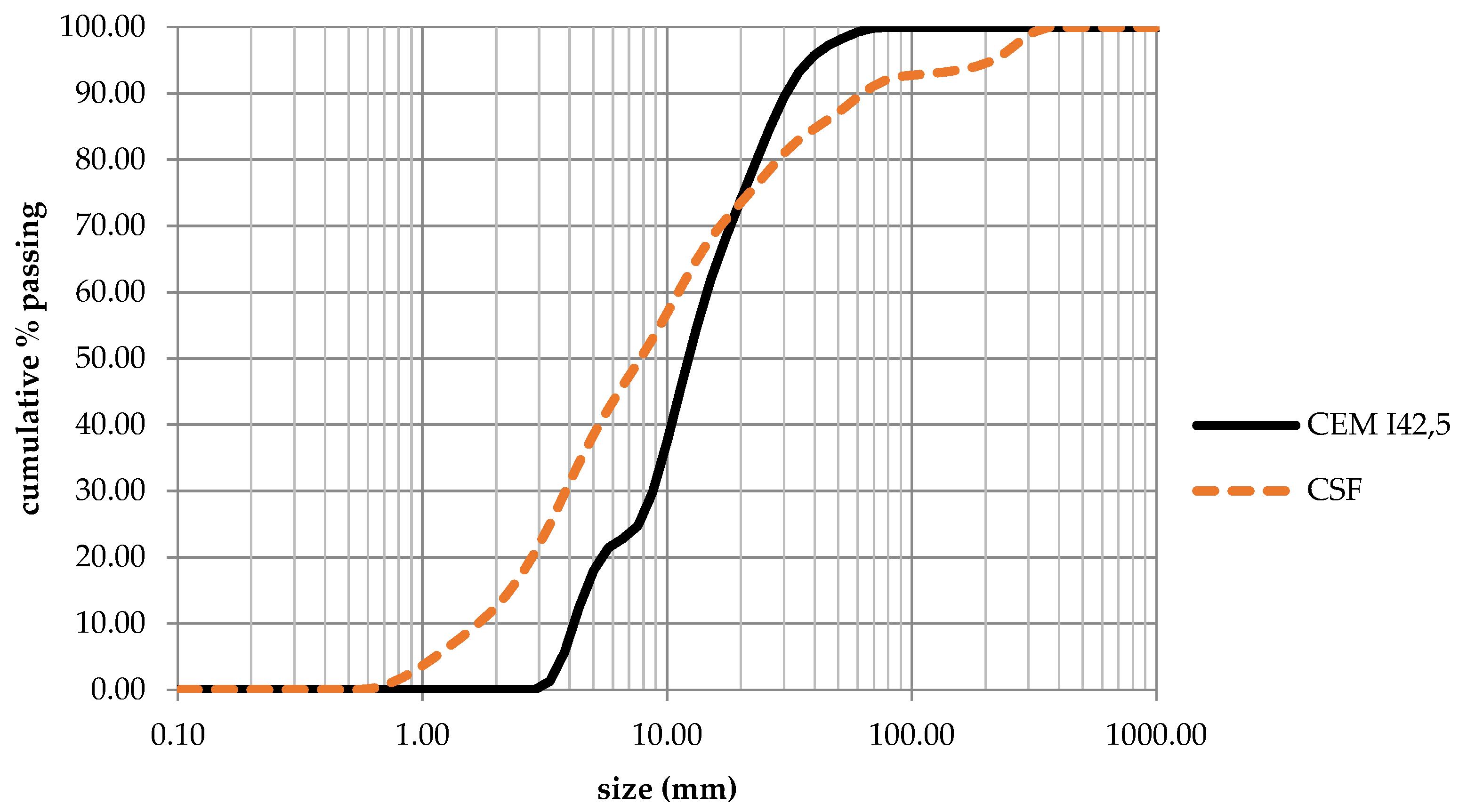

2.2. Cement Sludge Fines (CSF)

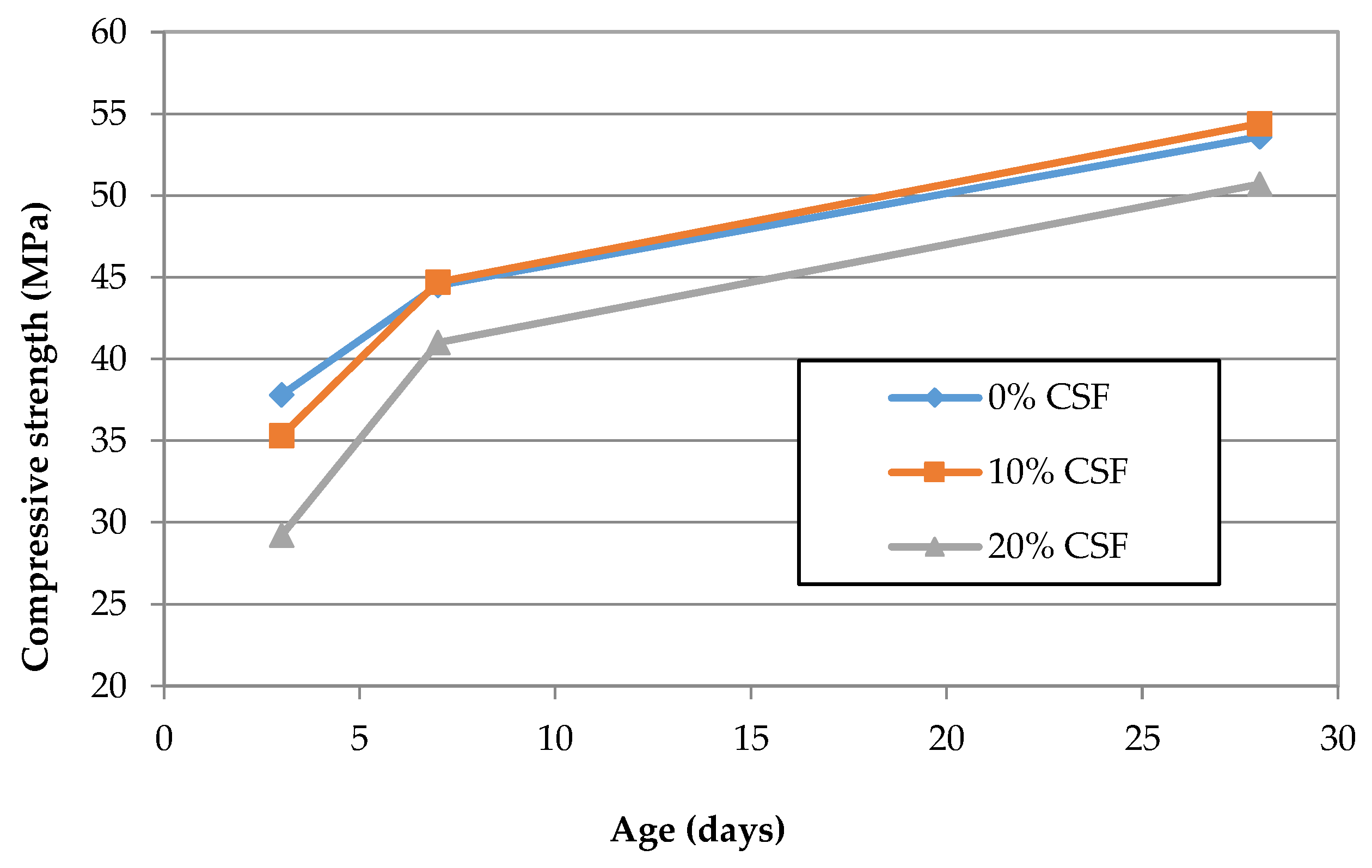

2.2.1. CSF as a Replacement of Cement in Mortars

2.2.2. CSF as an Additive for Soil Stabilization

3. Results and Discussion

3.1. Recycled Concrete Aggregates (HR and CR)

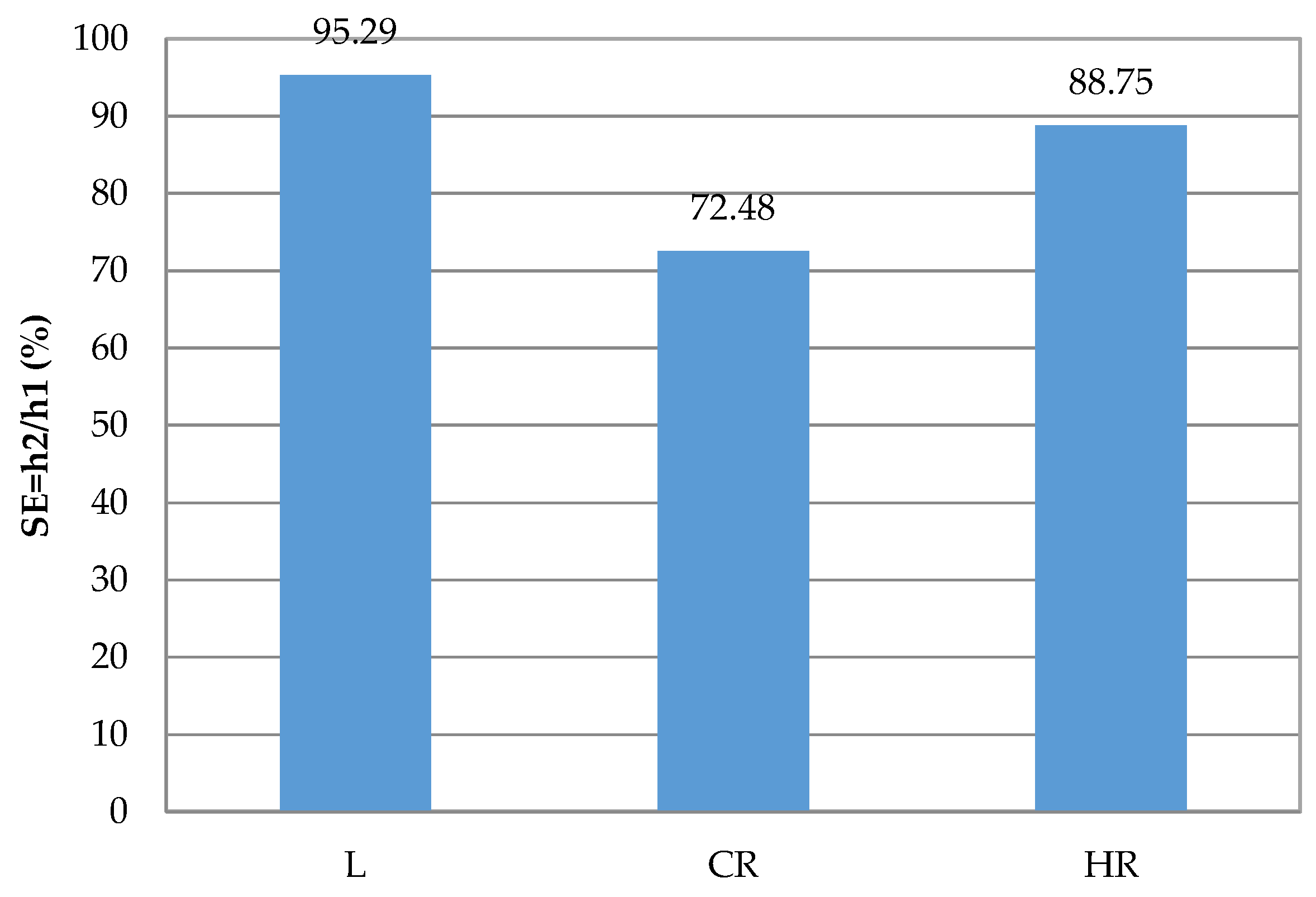

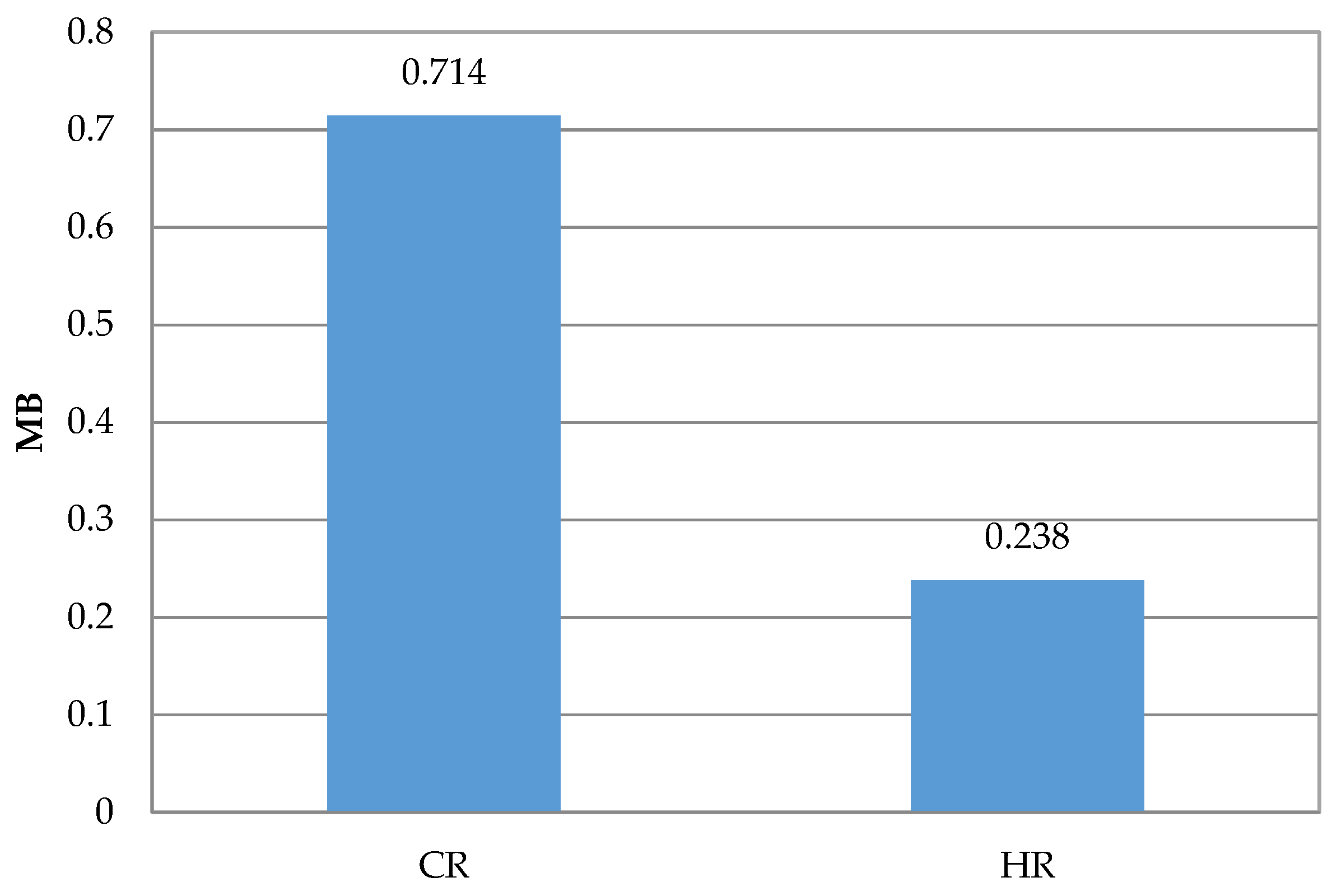

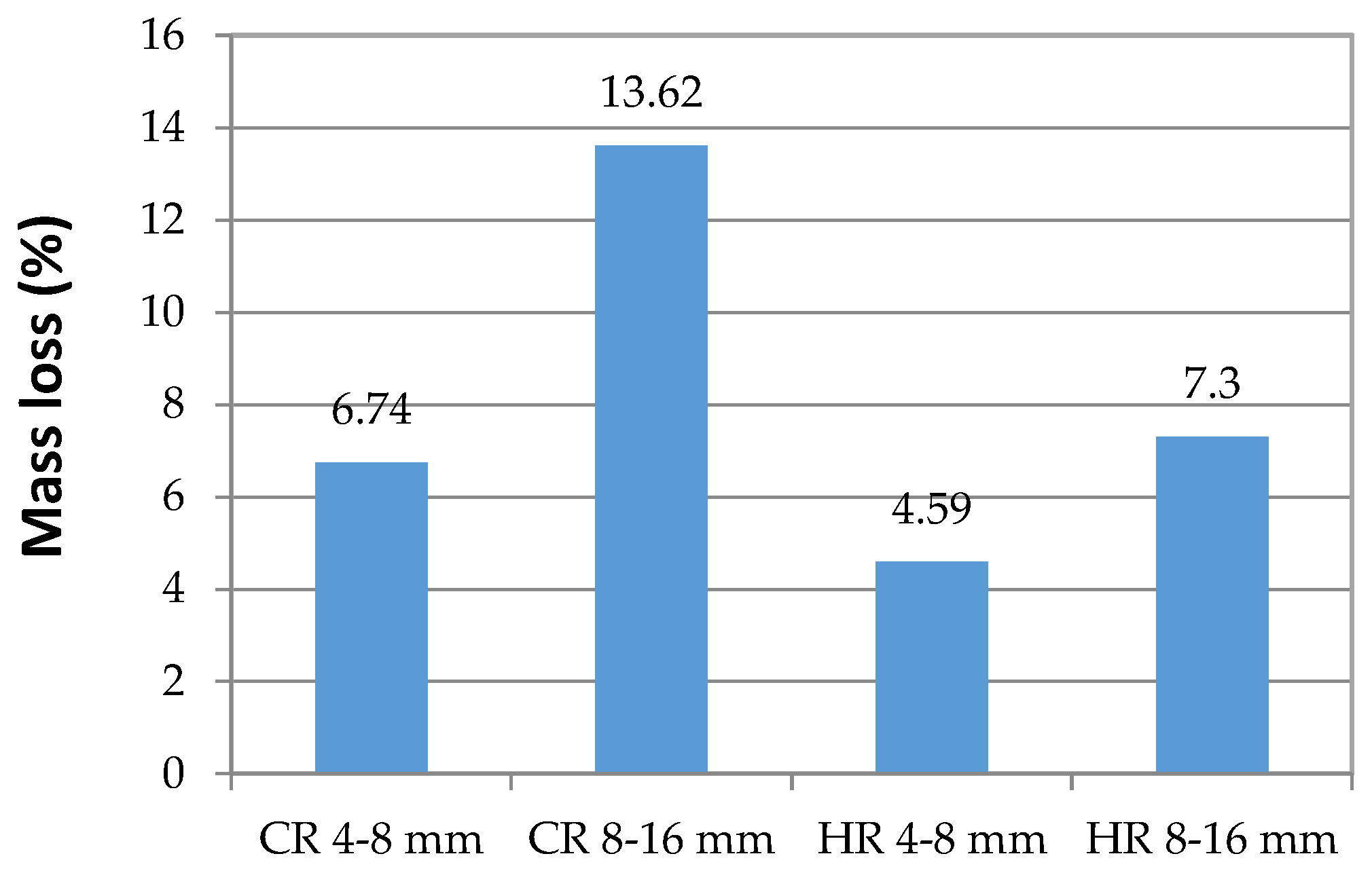

3.1.1. Recycled Aggregate Test Results

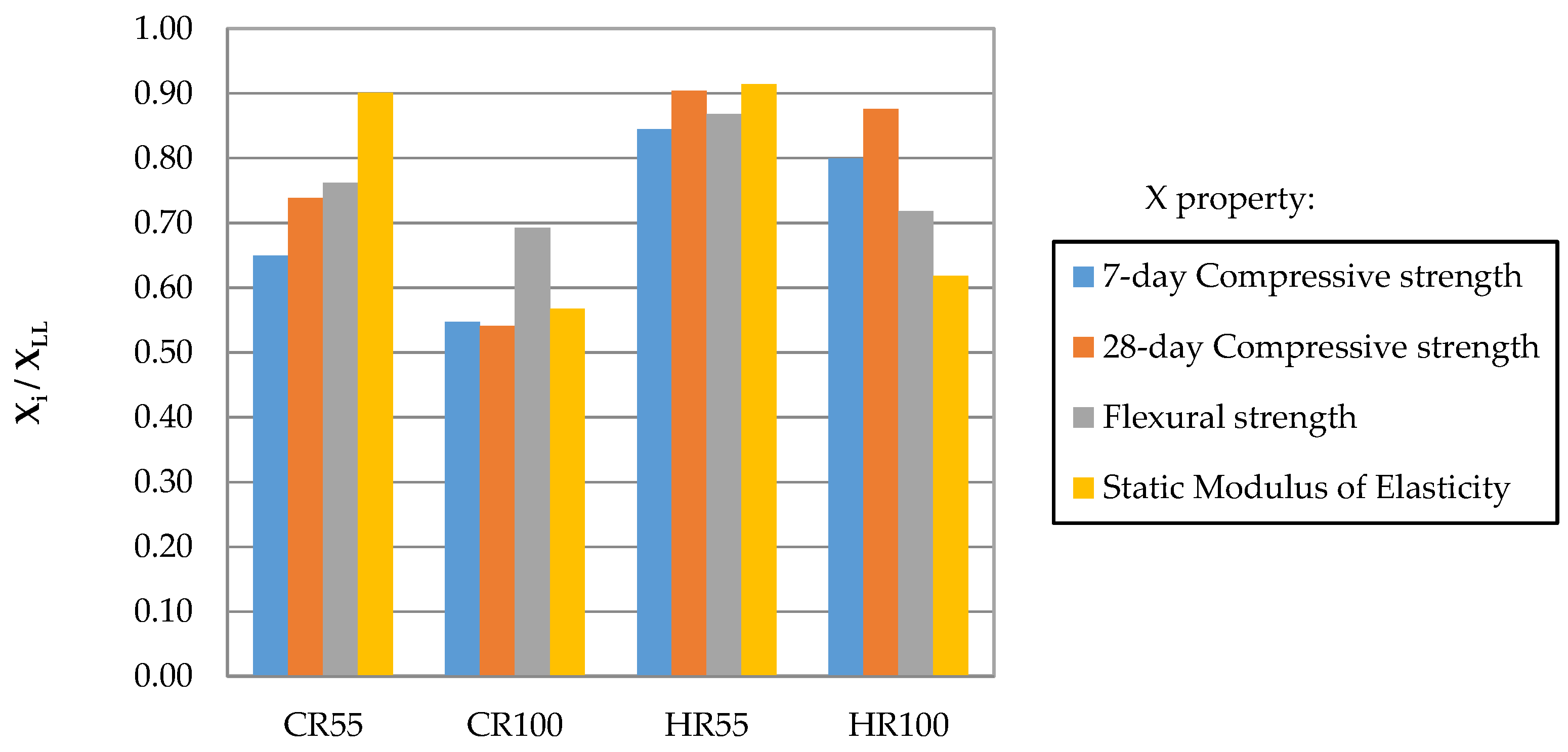

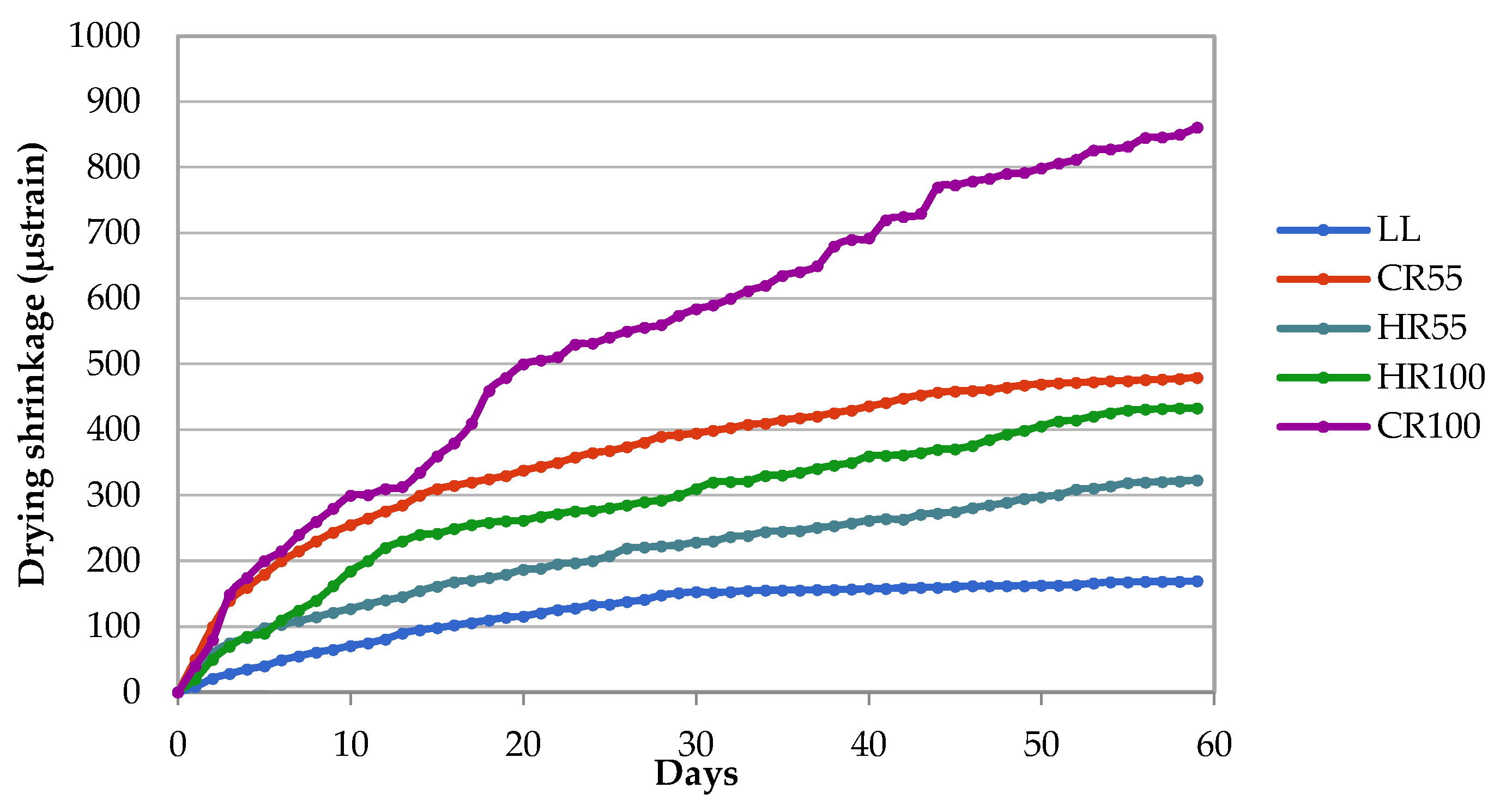

3.1.2. Concrete Test Results

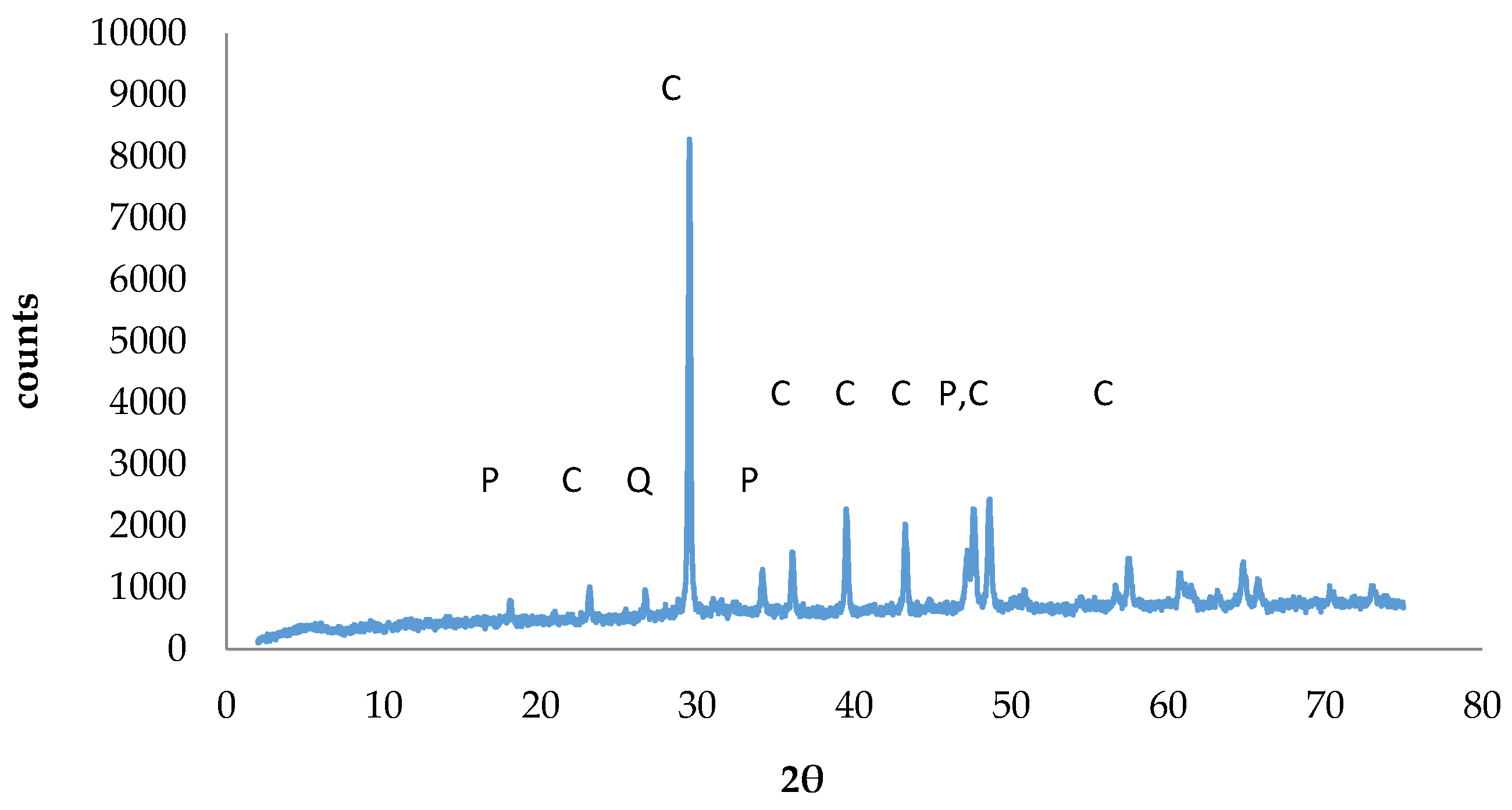

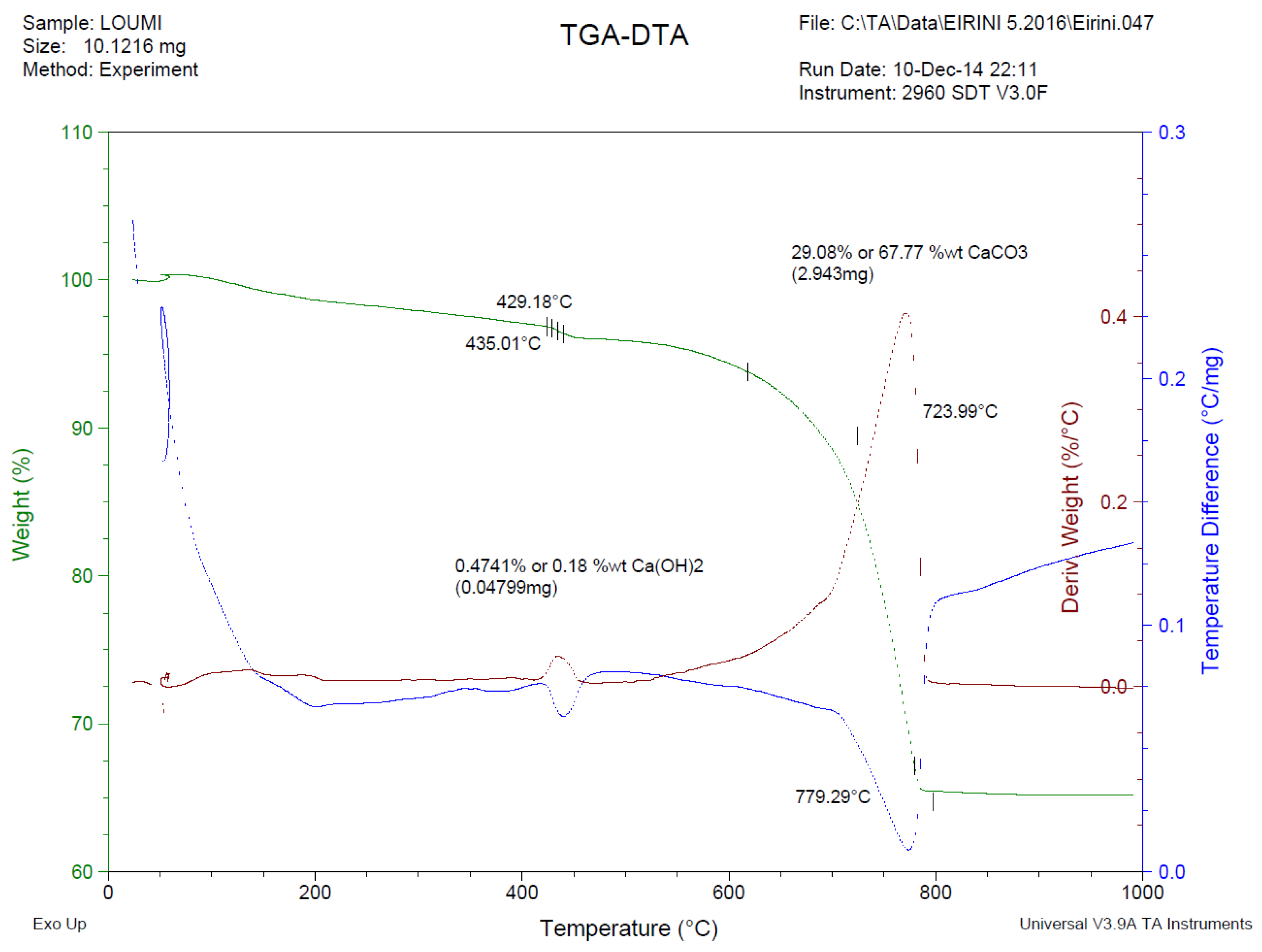

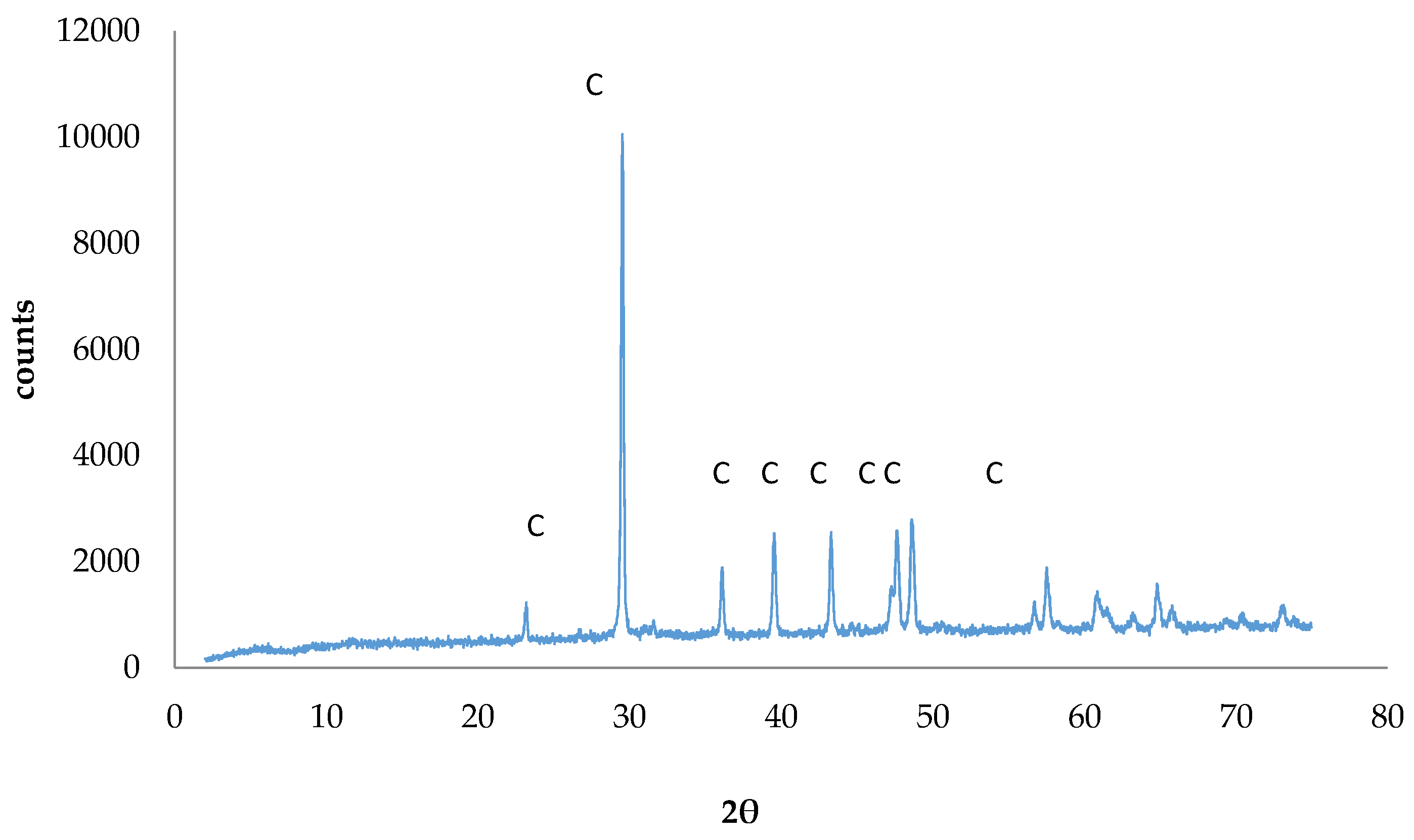

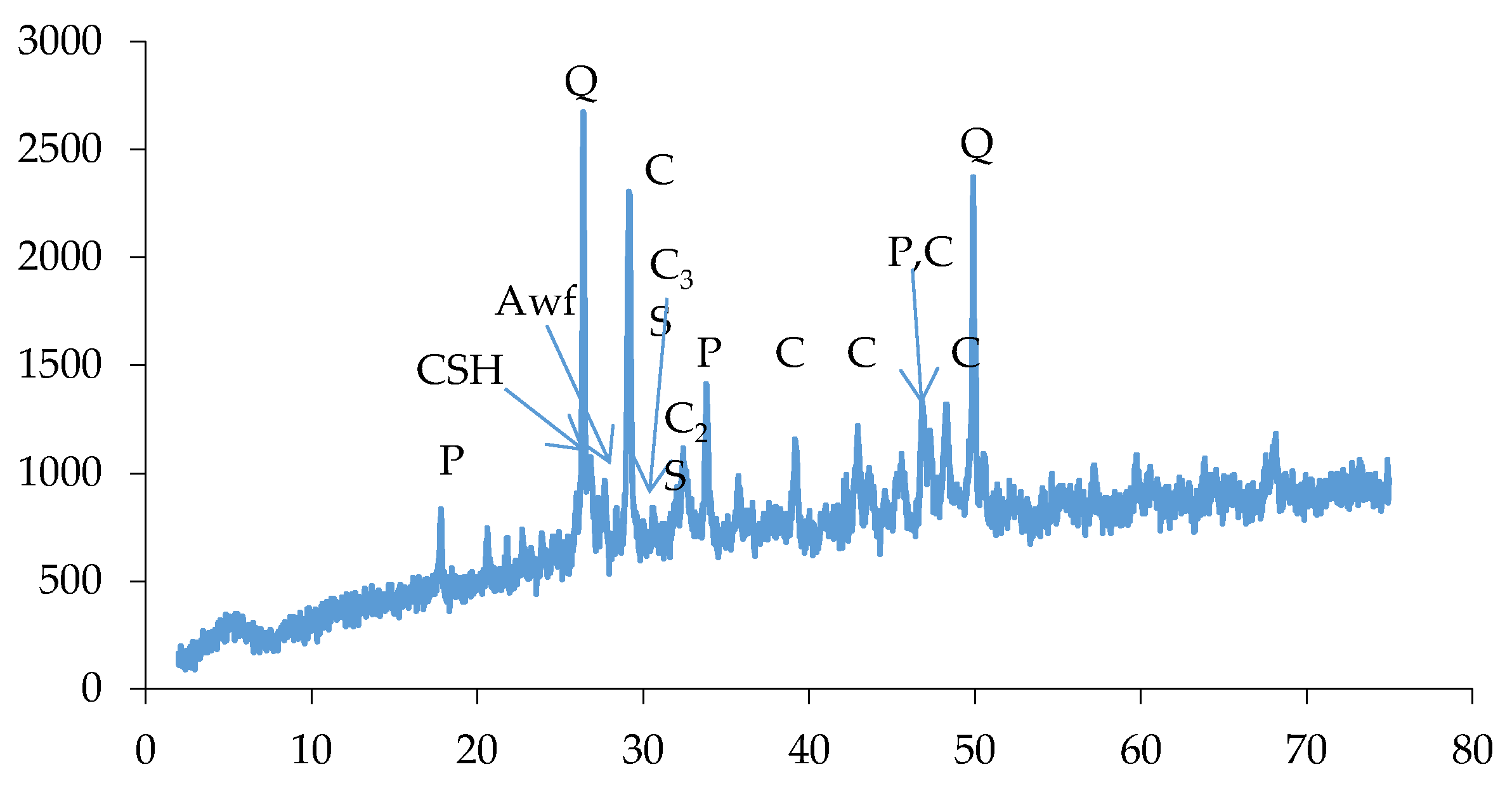

3.2. Cement Sludge Fines (CSF)

3.2.1. CSF as a Cement Replacement in Mortars

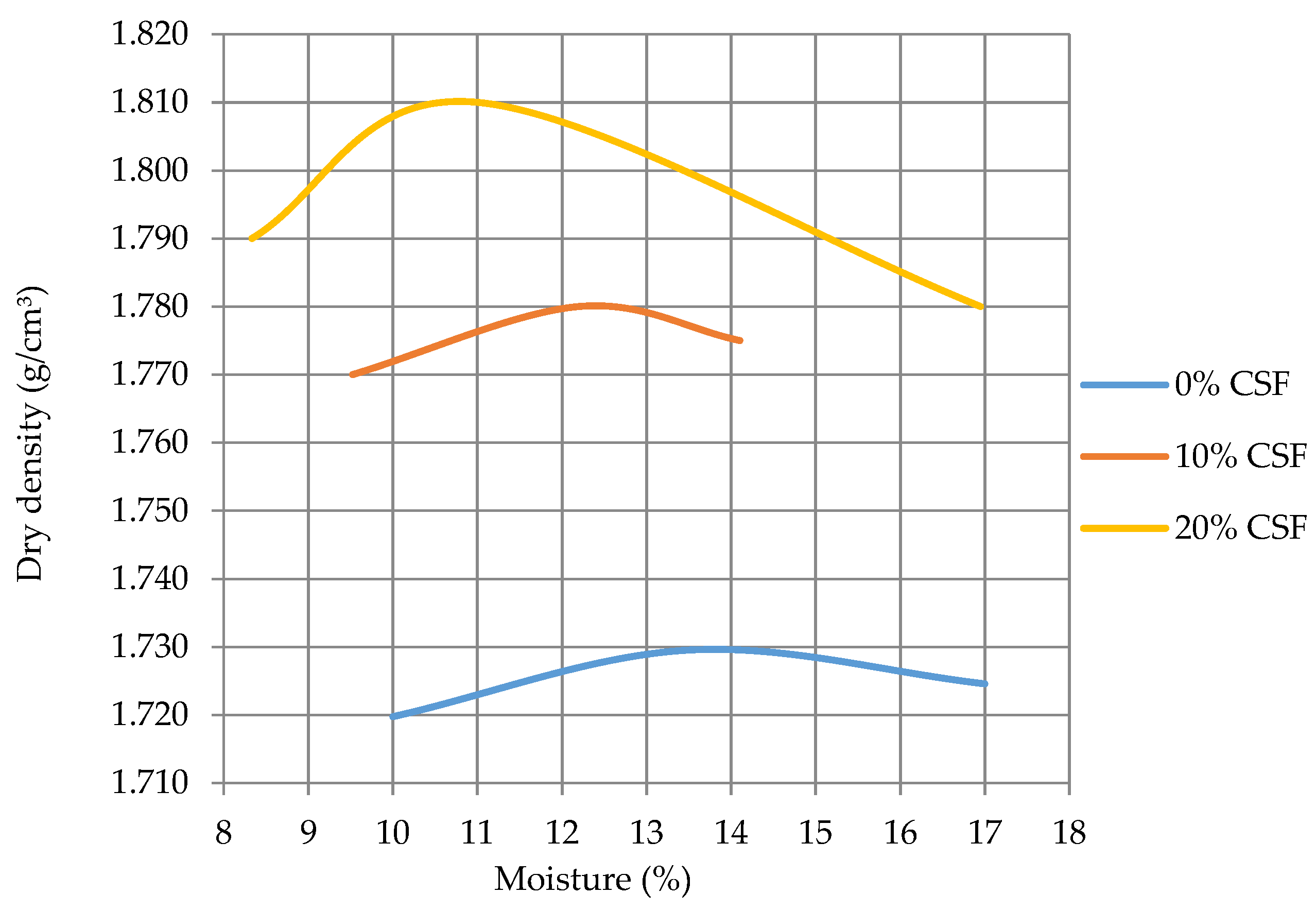

3.2.2. CSF for Soil Stabilization

4. Conclusions

- The properties of the recycled aggregates produced within a single RMC plant vary greatly, despite the fact that they are recycled concrete aggregates, without any mixed construction materials. Therefore, they should be managed separately and directed to suitable applications;

- All three recycled aggregates tested can be potentially be used in construction applications, after simple processing (crushing, sieving and pre-soaking), indicating that they do not require the energy and cost for transportation outside the RMC plant;

- The recycled aggregates from hardened concrete specimens (HR) had better properties compared to recycled aggregates from concrete returns (CR) and the use of their fine fraction could also be considered for structural concrete production;

- The durability properties of concrete with HR and CR were slightly reduced when 100% of the coarse fraction was used and considerably reduced when 100% of the fine and coarse fraction was used. Future research could determine the optimum amount of natural aggregate replacement, as in all recycled aggregates;

- CSF seems to be a good-quality fine material, provided that it is crushed and sieved through the 75 μm sieve;

- CSF could potentially be used as a filler material in cement mortar production and as an additive for soil stabilization.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete—A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- European Ready Mixed Concrete Organization. Ready-Mixed Concrete Industry Statistics—Year 2016. Available online: http://ermco.eu/new/wp-content/uploads/2018/07/ERMCO-Statistics-2016-18.02.04.pdf (accessed on 28 September 2018).

- Sealey, B.J.; Hill, G.J.; Phillips, P.S. Review of Strategy for Recycling and Reuse of Waste Materials. In Recycling and Reuse of Sewage Sludge, Proceedings of the International Symposium Organised by the Concrete Technology Unit and Held at the University of Dundee, Scotland, UK, 19–20 March 2001; Dhir, R.K., Limbachiya, M.K., McCarthy, M.J., Eds.; Thomas Telford: London, UK, 2001; pp. 325–336. [Google Scholar]

- Vieira, L.D.B.P.; de Figueiredo, A.D. Evaluation of concrete recycling system efficiency for ready-mix concrete plants. Waste Manag. 2016, 56, 337–351. [Google Scholar] [CrossRef] [PubMed]

- Xuan, D.; Poon, C.S.; Zheng, W. Management and sustainable utilization of processing wastes from ready-mixed concrete plants in construction: A review. Resour. Conserv. Recycl. 2018, 136, 238–247. [Google Scholar] [CrossRef]

- Xuan, D.; Zhan, B.; Poon, C.S.; Zheng, W. Innovative reuse of concrete slurry waste from ready-mixed concrete plants in construction products. J. Hazard. Mater. 2016, 312, 65–72. [Google Scholar] [CrossRef] [PubMed]

- Pedro, D.; De Brito, J.; Evangelista, L. Influence of the use of recycled concrete aggregates from different sources on structural concrete. Constr. Build. Mater. 2014, 71, 141–151. [Google Scholar] [CrossRef]

- Kou, S.C.; Zhan, B.J.; Poon, C.S. Feasibility study of using recycled fresh concrete waste as coarse aggregates in concrete. Constr. Build. Mater. 2012, 28, 549–556. [Google Scholar] [CrossRef]

- Audo, M.; Mahieux, P.Y.; Turcry, P. Utilization of sludge from ready-mixed concrete plants as a substitute for limestone fillers. Constr. Build. Mater. 2016, 112, 790–799. [Google Scholar] [CrossRef]

- Poon, C.S.; Chan, D. The use of recycled aggregate in concrete in Hong Kong. Resour. Conserv. Recycl. 2007, 50, 293–305. [Google Scholar] [CrossRef]

- Rao, A.; Jha, K.N.; Misra, S. Use of aggregates from recycled construction and demolition waste in concrete. Resour. Conserv. Recycl. 2007, 50, 71–81. [Google Scholar] [CrossRef]

- Yehia, S.; Abdelfatah, A. Examining the Variability of Recycled Concrete Aggregate Properties. In Proceedings of the International Conference on Civil, Architecture and Sustainable Development (CASD-2016), London, UK, 1–2 December 2016; pp. 57–60. [Google Scholar]

- Katz, A. Properties of concrete made with recycled aggregate from partially hydrated old concrete. Cem. Concr. Res. 2003, 33, 703–711. [Google Scholar] [CrossRef]

- Rahal, K. Mechanical properties of concrete with recycled coarse aggregate. Build. Environ. 2007, 42, 407–415. [Google Scholar] [CrossRef]

- Sagoe-Crentsil, K.K.; Brown, T.; Taylor, A.H. Performance of concrete made with commercially produced coarse recycled concrete aggregate. Cem. Concr. Res. 2001, 31, 707–712. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance enhancement of recycled concrete aggregate—A review. J. Clean. Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- De Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Dimitriou, G.; Savva, P.; Petrou, M.F. Enhancing mechanical and durability properties of recycled aggregate concrete. Constr. Build. Mater. 2018, 158, 228–235. [Google Scholar] [CrossRef]

- Pepe, M.; Toledo Filho, R.D.; Koenders, E.A.; Martinelli, E. Alternative processing procedures for recycled aggregates in structural concrete. Constr. Build. Mater. 2014, 69, 124–132. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Availability and processing of recycled aggregates within the construction and demolition supply chain: A review. J. Clean. Prod. 2017, 143, 598–614. [Google Scholar] [CrossRef]

- Oikonomou, N.D. Recycled concrete aggregates. Cem. Concr. Compos. 2005, 27, 315–318. [Google Scholar] [CrossRef]

- Agrela, F.; De Juan, M.S.; Ayuso, J.; Geraldes, V.L.; Jiménez, J.R. Limiting properties in the characterisation of mixed recycled aggregates for use in the manufacture of concrete. Constr. Build. Mater. 2011, 25, 3950–3955. [Google Scholar] [CrossRef]

- Padmini, A.K.; Ramamurthy, K.; Mathews, M.S. Influence of parent concrete on the properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 829–836. [Google Scholar] [CrossRef]

- Yang, K.H.; Chung, H.S.; Ashour, A. Influence of type and replacement level of recycled aggregates on concrete properties. ACI Mater. J. 2008, 3, 289–296. [Google Scholar] [CrossRef]

- Audo, M.; Mahieux, P.Y.; Turcry, P.; Chateau, L.; Churlaud, C. Characterization of ready-mixed concrete plants sludge and incorporation into mortars: Origin of pollutants, environmental characterization and impacts on mortars characteristics. J. Clean. Prod. 2018, 183, 153–161. [Google Scholar] [CrossRef]

- Chini, S.A.; Mbwambo, W.J. Environmentally friendly solutions for the disposal of concrete wash water from ready mixed concrete operations. In Proceedings of the CIB W89 Beijing International Conference, Beijing, China, 21–24 October 1996; pp. 21–24. [Google Scholar]

- Mashaly, A.O.; El-Kaliouby, B.A.; Shalaby, B.N.; El-Gohary, A.M.; Rashwan, M.A. Effects of marble sludge incorporation on the properties of cement composites and concrete paving blocks. J. Clean. Prod. 2016, 112, 731–741. [Google Scholar] [CrossRef]

- Galetakis, M.; Soultana, A. A review on the utilisation of quarry and ornamental stone industry fine by-products in the construction sector. Constr. Build. Mater. 2016, 102, 769–781. [Google Scholar] [CrossRef]

- Cardoso, R.; Silva, R.V.; de Brito, J.; Dhir, R. Use of recycled aggregates from construction and demolition waste in geotechnical applications: A literature review. Waste Manag. 2016, 49, 131–145. [Google Scholar] [CrossRef] [PubMed]

- De Brito, J.; Saikia, N. Recycled Aggregate in Concrete: Use of Industrial, Construction and Demolition Waste; Springer: London, UK, 2012; ISBN 9781447145394. [Google Scholar]

- Kazaz, A.; Ulubeyli, S.; Er, B.; Arslan, V.; Atici, M.; Arslan, A. Fresh ready-mixed concrete waste in construction projects: A planning approach. Organ. Technol. Manag. Constr. Int. J. 2015, 7, 1280–1288. [Google Scholar] [CrossRef]

- Ferreira, L.; De Brito, J.; Barra, M. Influence of the pre-saturation of recycled coarse concrete aggregates on concrete properties. Mag. Concr. Res. 2011, 63, 617–627. [Google Scholar] [CrossRef]

- Zhao, Z.; Remond, S.; Damidot, D.; Xu, W. Influence of fine recycled concrete aggregates on the properties of mortars. Constr. Build. Mater. 2015, 81, 179–186. [Google Scholar] [CrossRef]

- Evangelista, L.; Guedes, M.; De Brito, J.; Ferro, A.C.; Pereira, M.F. Physical, chemical and mineralogical properties of fine recycled aggregates made from concrete waste. Constr. Build. Mater. 2015, 86, 178–188. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Evangelista, L.; De Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Berodier, E.; Scrivener, K. Understanding the Filler Effect on the Nucleation and Growth of C-S-H. J. Am. Ceram. Soc. 2014, 97, 3764–3773. [Google Scholar] [CrossRef]

- De Weerdt, K.; Haha, M.B.; Le Saout, G.; Kjellsen, K.O.; Justnes, H.; Lothenbach, B. Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash. Cem. Concr. Res. 2011, 41, 279–291. [Google Scholar] [CrossRef]

- Nehdi, M.; Mindess, S.; Aïtcin, P.C. Optimization of high strength limestone filler cement mortars. Cem. Concr. Res. 1996, 26, 883–893. [Google Scholar] [CrossRef]

- Manasseh, J.; Olufemi, A.I. Effect of lime on some geotechnical properties of Igumale shale. Electron. J. Geotech. Eng. 2008, 13, 1–12. [Google Scholar]

- Amu, O.O.; Fajobi, A.B.; Oke, B.O. Effect of eggshell powder on the stabilizing potential of lime on an expansive clay soil. J. Appl. Sci. 2005, 5, 1474–1478. [Google Scholar] [CrossRef]

| Mixture | Designation |

|---|---|

| LL | Reference (100% of aggregates limestone) |

| CR55 | Recycled fresh concrete returns as coarse aggregates |

| CR100 | 100% of aggregates recycled fresh concrete returns |

| HR55 | Recycled concrete of high compressive strength as coarse aggregates |

| HR100 | 100% of aggregates recycled concrete of high compressive strength |

| Concrete Composition | LL | CR55 | CR100 | HR55 | HR100 |

|---|---|---|---|---|---|

| Cement CEM II32.5 | 300 | 300 | 300 | 300 | 300 |

| Tap water | 165 | 165 | 165 | 165 | 165 |

| Fine aggregate 0–4 mm | 842 | 843 | 528 | 843 | 499 |

| Coarse aggregate 4–8 mm | 478 | 478 | 300 | 478 | 283 |

| Coarse aggregate 8–16 mm | 576 | 525 | 525 | 542 | 542 |

| Superplasticizer | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| CR Fine | CR Coarse | HR Fine | HR Coarse | |

|---|---|---|---|---|

| WA24 (%) | 6.13 | 5.45 | 5.88 | 3.21 |

| pa (kg/m³) | 1723 | 2604 | 1617 | 2610 |

| prd (kg/m³) | 1558 | 2281 | 1477 | 2409 |

| pssd (kg/m³) | 1654 | 2405 | 1563 | 2486 |

| LA | - | 31.1% | - | 36.5% |

| LL | CR55 | CR100 | HR55 | HR100 | |

|---|---|---|---|---|---|

| Air content (%) | 2 | 2 | 2.3 | 2.2 | 2 |

| Slump (cm) | 6.5 | 11 | 17 | 15 | 18 |

| Density (kg/m³) | 2418 | 2318 | 2165 | 2378 | 2157 |

| LL | CR55 | CR100 | HR55 | HR100 | ||

|---|---|---|---|---|---|---|

| Open porosity (%) | 13 | 11 | 21 | 10 | 22 | |

| Compressive strength (MPa) | 7-day | 33 | 22 | 18 | 28 | 27 |

| 28-day | 38 | 28 | 20 | 34 | 33 | |

| 28-day flexural strength (MPa) | 7.03 | 5.36 | 4.87 | 6.10 | 5.05 | |

| 28-day elastic Modulus (GPa) | 44.7 | 40.2 | 25.3 | 40.8 | 27.6 | |

| 28-day drying shrinkage (μstrain) | 180 | 400 | 590 | 220 | 300 | |

| Resistance to chloride Ion penetration | Charge passed | 2491 | 3912 | 8284 | 2913 | 9342 |

| Chloride ion penetrability | MODERATE | MODERATE | HIGH | MODERATE | HIGH | |

| Freeze–thaw mass loss (wt %) | 0.422 | 0.362 | 0.845 | 0.412 | 0.890 | |

| (wt %) | Na2O | K2O | CaO | MgO | Fe2O3 | Al2O3 | SiO2 | L.I.% | Cl− | NO3− | SO3 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CSF | 0.19 | 0.21 | 32.09 | 1.05 | 1.26 | 2.45 | 36.51 | 25.22 | 0.01 | <0.01 | 0.05 |

| CEM I42.5 N | 0.57 | 1.08 | 66.84 | 3.91 | 2.40 | 3.74 | 19.55 | 1.91 | 0.03 | 0.02 | 1.49 |

| Soil | 0.90 | 0.98 | 8.67 | 5.39 | 3.79 | 6.88 | 63.14 | 10.25 | 0.08 | 0.02 | 0.02 |

| 0% CSF | 10% CSF | 20% CSF | |

|---|---|---|---|

| Maximum dry density (g/cm³) | 1.73 | 1.78 | 1.81 |

| Optimum moisture content (%) | 14.0 | 12.4 | 10.6 |

| CBR (%) | 5 | 12 | 33 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anastasiou, E.; Papachristoforou, M.; Anesiadis, D.; Zafeiridis, K.; Tsardaka, E.-C. Investigation of the Use of Recycled Concrete Aggregates Originating from a Single Ready-Mix Concrete Plant. Appl. Sci. 2018, 8, 2149. https://doi.org/10.3390/app8112149

Anastasiou E, Papachristoforou M, Anesiadis D, Zafeiridis K, Tsardaka E-C. Investigation of the Use of Recycled Concrete Aggregates Originating from a Single Ready-Mix Concrete Plant. Applied Sciences. 2018; 8(11):2149. https://doi.org/10.3390/app8112149

Chicago/Turabian StyleAnastasiou, Eleftherios, Michail Papachristoforou, Dimitrios Anesiadis, Konstantinos Zafeiridis, and Eirini-Chrysanthi Tsardaka. 2018. "Investigation of the Use of Recycled Concrete Aggregates Originating from a Single Ready-Mix Concrete Plant" Applied Sciences 8, no. 11: 2149. https://doi.org/10.3390/app8112149

APA StyleAnastasiou, E., Papachristoforou, M., Anesiadis, D., Zafeiridis, K., & Tsardaka, E.-C. (2018). Investigation of the Use of Recycled Concrete Aggregates Originating from a Single Ready-Mix Concrete Plant. Applied Sciences, 8(11), 2149. https://doi.org/10.3390/app8112149