Introducing Bentonite into the Environment in the Construction Stage of Linear Underground Investment Using the HDD Method

Abstract

:1. Introduction

2. Materials and Methods

- determination of the subject and selection of the study area;

- analysis of the scientific literature;

- field work and participation in the implementation of the HDD drilling;

- geomorphological analyses;

- processing of daily reports in the work on HDD in Pęciszów;

- statistical analysis of the obtained results;

- definition of dependence;

- determination of correlation; and

- conclusions.

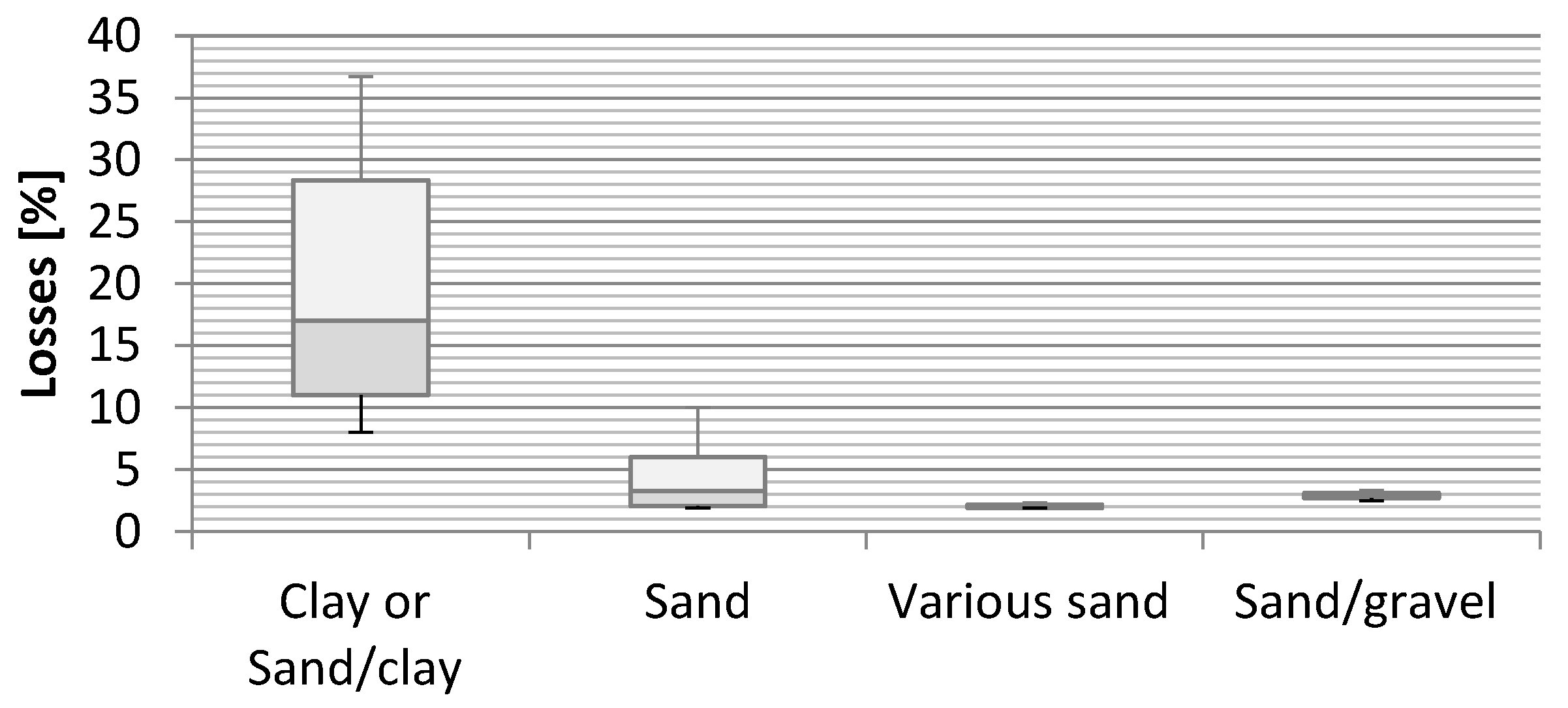

- drilling liquid is introduced to the environment on a much larger scale than that declared by investors; and

- the scale of the loss of bentonite used for directional drilling depends on the type of soil on which the construction works are conducted.

- -

- medium and fine fluvial sands and fluvial muds (cohesive dusty humic soils, locally sandy soils);

- -

- Pleistocene fine sands and lacustrine deposits (silts, dusty humic soils);

- -

- Pleistocene loam and cohesive dusty soils;

- -

- Glacial sandy soils; and

- -

- Pleistocene medium, fine and dusty sands of a fluvioglacial origin.

- the volume of treated drilling fluid per day and the soil formation (type of fraction);

- total loss of material (bentonite) during drilling, depending on the type of soil and the related fraction; and

- the percentage ratio of daily drilling fluid loss (i per 1LM) to the bentonite used.

- Kow (X,Y)—covariance between properties X and Y;

- —standard deviation of parameter X; and

- —standard deviation of parameter Y.

- a positive correlation, where high values of one variable are accompanied by high variables of the other one (and, obviously, the reverse: low values of one variable are accompanied by low values of the other one);

- negative correlation, where low values of one variable are accompanied by high values of the other one; and

- 0 correlation, where there is no linear connection between the two variables.

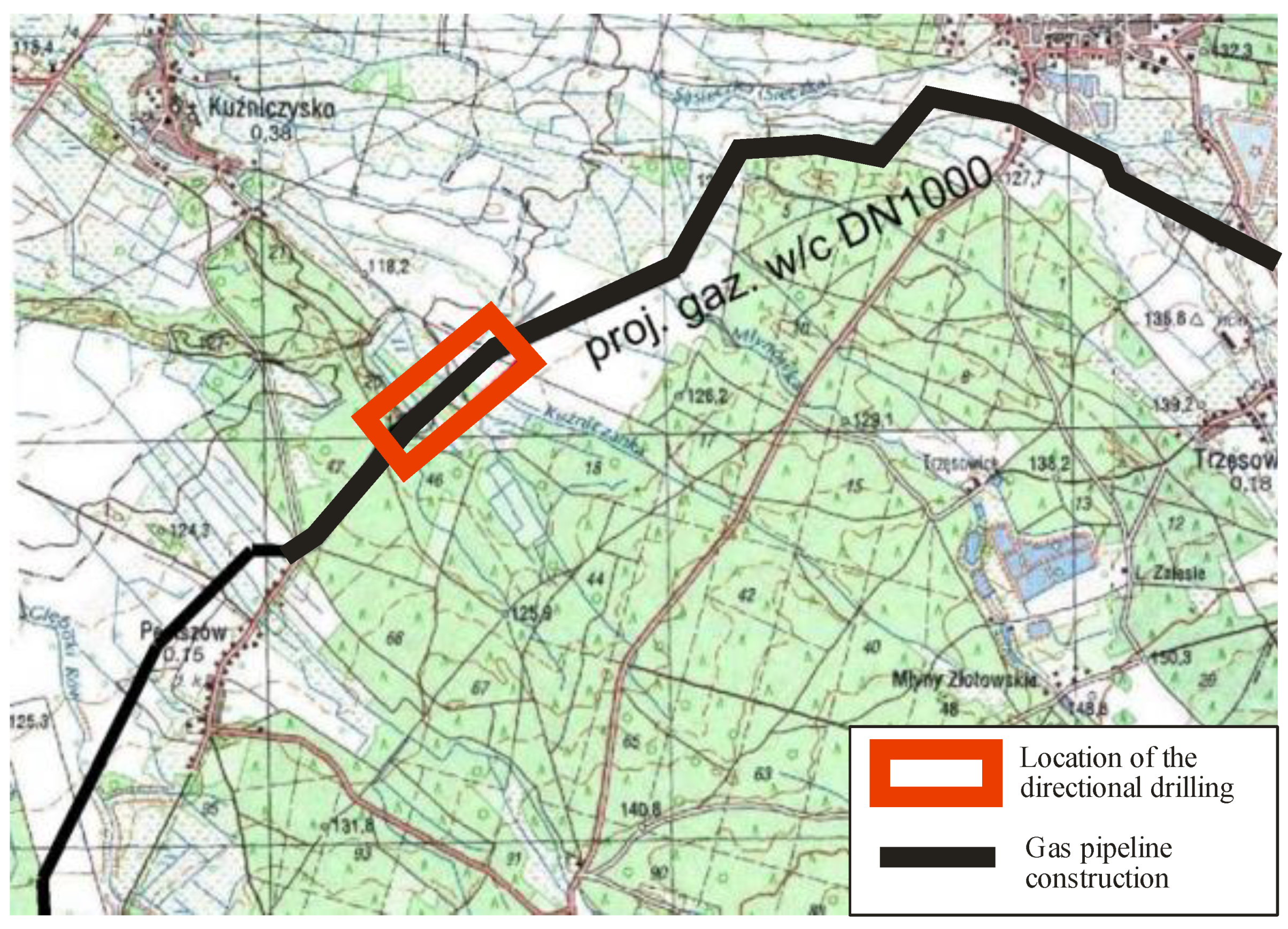

3. Realization of the Investment Using Horizontal Directional Drilling (HDD)

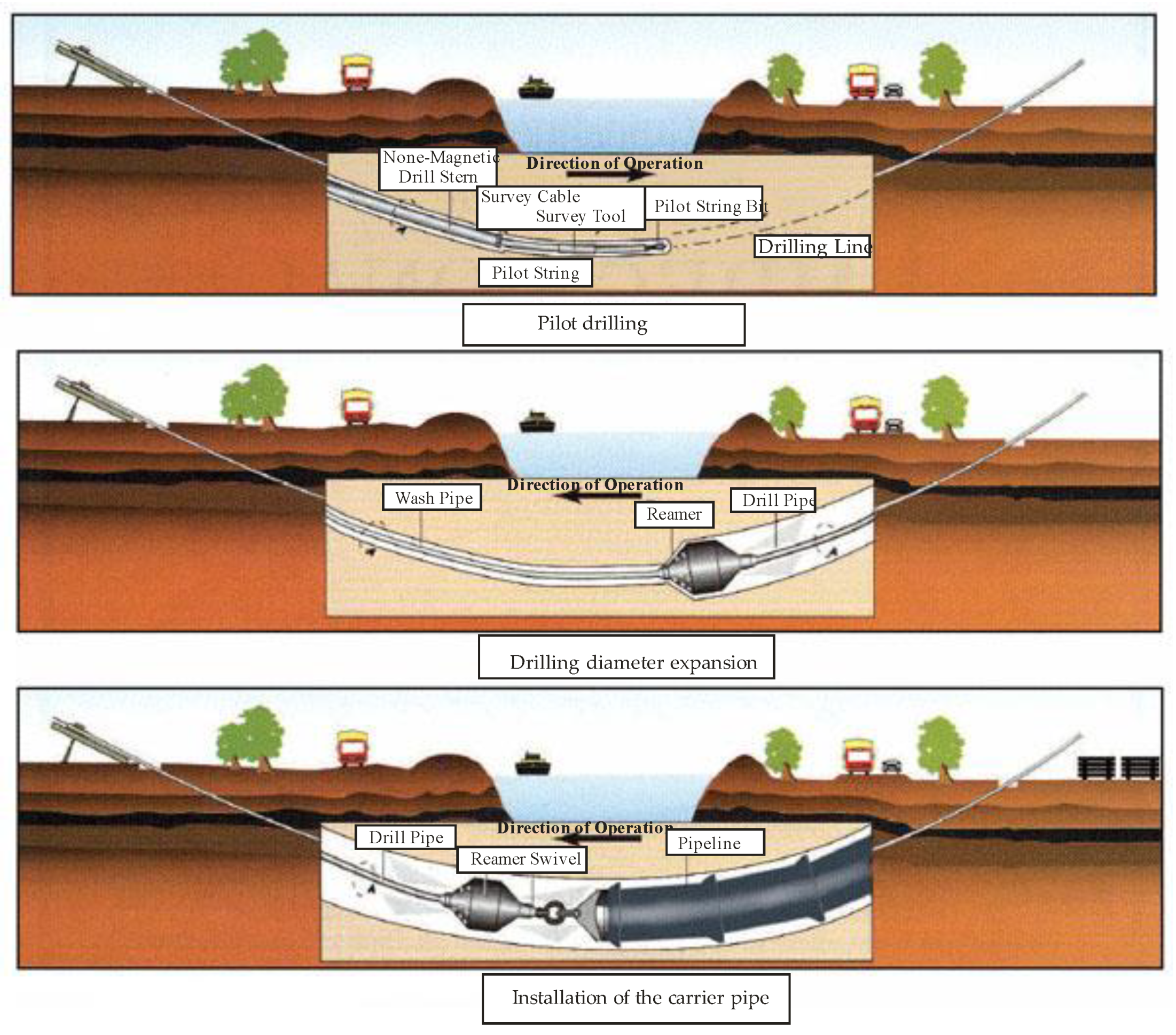

- Pilot drilling. The drilling is performed using the drilling rig, drill string, drilling tools, and a navigation system. The circulation system of the drilling fluid is closed. The borings that come out of the borehole, together with the drilling fluid, are separated, the excavated soil is stored behind the separator in waste pits, and the treated liquid is poured into the mixer. Next, the fluid of the appropriate parameters is poured into the buffer, then collected from the buffer and fed by a pump into the drill string and, later, into the drill and the wall of the drilling borehole, supporting the processing of the drilled layer.

- Drilling diameter expansion. The drilling is widened using expanding tools. The process consists of one or two stages. The diameter of the borehole provides an appropriate safety buffer for the installed carrier pipe. The drilling liquid, together with the excavated waste, is transported from the pipe using a transfer pump through a transfer pipeline to the machinery end, where it is separated.

- Installation of the carrier pipe. The pipe is placed on rollers, then fastened to a swivel and pulled into the drilling borehole using the drilling rig and the drill string. During the whole installation process, drilling fluid is fed directly into the borehole (Figure 3).

4. Amount of Drilling Fluid Loss in the Drilling Realization Stage

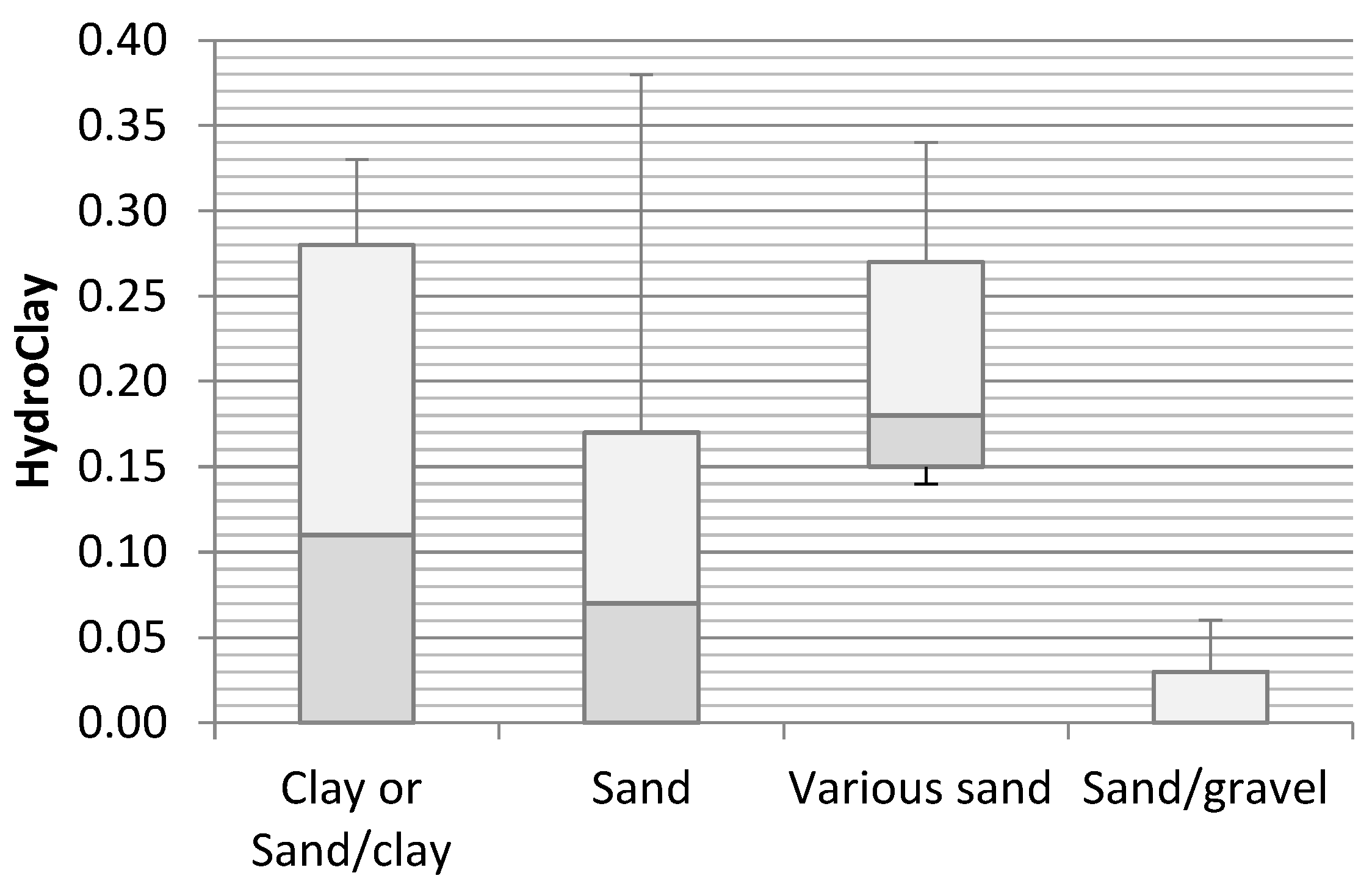

5. Discussion—Influence of Soil Substrate on the Loss of Drilling Fluid

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Explanations and Future Research

References and Notes

- Ziniewicz, M.A. Administracyjnoprawne aspekty opłat adiacenckich (Administrative and Legal Aspects of Betterment Levies); LexisNexis: Warszawa, Polska, 2012. (In Polish) [Google Scholar]

- Cymerman, R. Planowanie przestrzenne dla rzeczoznawców majątkowych, zarządców oraz pośredników w obrocie nieruchomościami (Spatial Planning for Certified Valuers, Property Managers and Real Estate Brokers); EDUCATERRA: Olsztyn, Polska, 2012. (In Polish) [Google Scholar]

- Act of March 27, 2003 on Spatial Planning and Land Development (uniform text: Journal of Laws of 2017, item 1073).

- Act of August 21, 1997 on Real Estate Management (uniform text: Journal of Laws of 2018, item 2147 incl. amendments).

- Act of July 7, 1994—Construction Law (uniform text: Journal of Laws of 2017, item 1332).

- Act of April 27, 2001—Environmental Protection Law (uniform text: Journal of Laws of 2018, item 799).

- Bąkowski, T.; Szwajder, W. Proces inwestycyjno–budowlany (The Investment and Construction Process); Zagadnienia administracyjno–prawne: Toruń, Polska, 2004. (In Polish) [Google Scholar]

- Michael, D.; Lubrecht, L.G. Horizontal Directional Drilling: A Green and Sustainable Technology for Site Remediation. Environ. Sci. Technol. 2012, 46, 2484–2489. [Google Scholar] [CrossRef]

- Bergaya, F.; Lagaly, G. Surface Modification of Clay Minerals. Appl. Clay Sci. 2001, 19, 1–30. [Google Scholar] [CrossRef]

- Srinivasan, R. Advances in application of natural clay and its composites in removal of biological, organic, and inorganic contaminants from drinking water. Adv. Mater. Sci. Eng. 2011, 2011, 872531. [Google Scholar] [CrossRef]

- Wan, D.; Li, W.; Wang, G.; Chen, K.; Lu, L.; Hu, Q. Adsorption and heterogeneous degradation of rhodamine B on the surface of magnetic bentonite material. Appl. Surf. Sci. 2015, 349, 988–996. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, D.; Liu, B.; Gao, X.; Xu, W.; Liang, P.; Xu, Y. Adsorption of fluoride from aqueous solution using low-cost bentonite/chitosan beads. Am. J. Anal. Chem. 2013, 4, 48–53. [Google Scholar] [CrossRef]

- Góra, W.; Góra, P.; Jaszczyszyn, K. Perspektywy zastosowania naturalnych bentonitów w technologii ścieków przemysłowych (Perspectives of Natural Bentonite Application in Industrial Wastewater Treatment). Available online: http://ros.edu.pl/images/roczniki/2016/No2/74_ROS_N2_V18_R2016.pdf (accessed on 7 October 2018).

- Molinero Guerra, A.; Aimedieu, P.; Bornert, M.; Cui, Y.-J.; Tang, A.M.; Sun, Z.; Mokni, N.; Delage, P.; Bernier, F. Analysis of the structural changes of a pellet/powder bentonite mixture upon wetting by X-ray computed microtomography. Appl. Clay Sci. 2018, 165, 164–169. [Google Scholar] [CrossRef]

- Yoon, S.; Cho, W.-H.; Lee, C.; Kim, G.-Y. Thermal Conductivity of Korean ompacted Bentonite Buffer Materials for a Nuclear Waste Repository. Energies 2018, 11, 2269. [Google Scholar] [CrossRef]

- Lee, J.O.; Choi, H.; Lee, J.Y. Thermal conductivity of compacted bentonite as a buffer material for a high-level radioactive waste repository. Ann. Nucl. Energy 2016, 94, 848–855. [Google Scholar] [CrossRef]

- Gómez-Espina, R.; Villar, M.V. Geochemical and mineralogical changes in compacted MX-80 bentonite submitted to heat and water gradients. Appl. Clay Sci. 2010, 47, 400–408. [Google Scholar] [CrossRef]

- Tang, A.M.; Cui, Y.J.; Le, T.T. A study on the thermal conductivity of compacted bentonites. Appl. Clay Sci. 2008, 41, 181–189. [Google Scholar] [CrossRef] [Green Version]

- Hoffmann, C.; Alonso, E.E.; Romero, E. Hydro-mechanical behavior of bentonite pellet mixtures. Phys. Chem. Earth 2007, 32, 832–849. [Google Scholar] [CrossRef]

- Shirazi, S.M.; Wiwat, S.; Kazama, H.; Kuwano, J.; Shaaban, M.G. Salinity Effect on Swelling Characteristics of Compacted Bentonite. Environ. Prot. Eng. 2011, 37, 65–74. [Google Scholar]

- Montes, G.; Duplay, J.; Martinem, L.; Mendoza, C. Swellingshrinkage Kinetics of MX80 Bentonite. Appl. Clay Sci. 2003, 22, 279–293. [Google Scholar] [CrossRef]

- Galamboš, M.; Suchánek, P.; Rosskopfová, O. Sorption of anthropogenic radionuclides on natural and synthetic inorganic sorbents. J. Radioanal. Nucl. Chem. 2012, 293, 613–633. [Google Scholar] [CrossRef]

- Cho, W.J.; Kwon, S. An empirical model for the thermal conductivity of compacted bentonite and a bentonite-sand mixture. Heat Mass Transf. 2011, 47, 1385–1393. [Google Scholar] [CrossRef]

- Tao, Y.; Wen, X.-D.; Li, J.; Yang, L. Theoretical and Experimental Investigations on the Structures of Purified Clay and Acid-activated Clay. Appl. Surf. Sci. 2006, 252, 6154–6161. [Google Scholar] [CrossRef]

- Research and Development on Radioactive Waste Disposal; JAEA: Ibaraki, Japan, 2008.

- Ariaratnam, S.T.; Harbin, B.C.; Stauber, R.L. Modeling of annular fluid pressures in horizontal boring. Tunn. Undergr. Space Technol. 2007, 22, 610–619. [Google Scholar] [CrossRef]

- Ariaratnam, S.T.; Stauber, R.M.; Bell, J.; Harbin, B.; Canon, F. Predicting and Controling Hydraulic Fracturing during Horizontal Directional Drilling. In Proceedings of the 2013 Pipeline Engineering and Construction International Conference, Baltimore, MD, USA, 13–16 July 2013; pp. 1334–1345. [Google Scholar]

- Ma, B.S.; Najafi, M.; Shen, H.; Wu, L. Risk evaluation for maxi horizontal directional drilling crossing projects. J. Pipeline Syst. Eng. 2010, 1, 91–97. [Google Scholar] [CrossRef]

- Shu, B.; Zhang, S.; Liang, M. Estimation of the maximum allowable drilling mud pressure for a horizontal directional drilling borehole in fractured rock mass. Tunn. Undergr. Space Technol. 2018, 72, 64–72. [Google Scholar] [CrossRef]

- Zwierzchowska, A. Technologie bezwykopowej budowy sieci gazowych, wodociągowych i kanalizacyjnych; Wydawnictwo Politechniki Świetokrzyskiej: Kielce, Polska, 2006. (In Polish) [Google Scholar]

- Detailed Geological Map of Poland in a Scale of 1:50000. Czeszów char; Polish Geological Institute: Warszawa, Polska, 1956–2009.

- Ryżak, M.; Bartmiński, P.; Bieganowski, A. Metody wyznaczania rozkładu granulometrycznego gleb mineralnych (Methods of determining the granulometric distribution of mineral soils). Acta Agrophysica Monogr. 2009, 175, 9–13. [Google Scholar]

- Ferguson, G.A.; Takane, Y. Analiza statystyczna w psychologii i pedagogice (Statistical Analysis in Psychology and Education). Wydawnictwo Naukowe PWN 2009, 608. (In Polish) [Google Scholar]

- HD Drilling Contractors, HDD? What is the Process? Available online: http://www.hddrilling.co.za/what-is-horizontal-directional-trenchless-drilling (accessed on 18 October 2018).

- Osikowicz, R. Technology of Horizontal Directional Drilling Applied in the Installation of Power Supply System in the Light of Their Environmental Impact, Based on the Example of Lake Trupel. Opinia Techniczna. Available online: http://www.biuletyn.net/nt-bin/_private/biskupiec/3611.pdf (accessed on 7 October 2018).

- Allouche, E.N.; Ariaratnam, S.T.; Lueke, J.S. Horizontal directional drilling: profile of an emerging industry. J. Constr. Eng. Manag. 2000, 126, 68–76. [Google Scholar] [CrossRef]

- Atalah, A.; Kariuki, J. Cost Comparison between Horizontal Directional Drilling and Open-Cut Construction Methods in Nairobi, Kenya. In Proceedings of the International Conference on Pipelines and Trenchless Technology (ICPTT) 2009, Shanghai, China, 18–21 October 2009. [Google Scholar] [CrossRef]

- Sarireh, M.; Tarawneh, S. Modeling of Productivity for Horizontal Directional Drilling (HDD) Operation and Applications. Eur. J. Bus. Manag. 2014, 6, 1905–2222. [Google Scholar]

- Manacorda, G.; Miniati, M.; Bracciali, S.; Dei, D.; Scott, H.F.; Koch, E.; Pinchbeck, D.; Murgier, S. Development of a bore-head GPR for Horizontal Directional Drilling (HDD) equipment. In Proceedings of the 13th International Conference on Ground Penetrating Radar, Lecce, Italy, 21–25 June 2010. [Google Scholar]

- Kazak, J.; Van Hoof, J.; Szewranski, S. Challenges in the wind turbines location process in Central Europe—The use of spatial decision support systems. Renew. Sust. Energ. Rev. 2017, 76, 425–433. [Google Scholar] [CrossRef]

- Płuciennik, M.; Hełdak, M.; Szczepański, J.; Patrzałek, C. Application of Spatial Models in Making Location Decisions of Wind Power Plant in Poland. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2014. [Google Scholar]

| Abbreviation | Name | Explanation |

|---|---|---|

| HDD | Horizontal Directional Drilling | Modern technology (classified as one of the so-called trenchless methods) that consists in conducting horizontal directional drilling. Horizontal drilling is a type of directional drilling. Horizontal directional drilling enables the construction of various types of installations (water supply pipes, sewage systems, gas supply pipes, and power supply lines) using the trenchless method in all locations, where it is impossible to construct an open trench for pipes or cables. |

| IM, IR | Impact Moling Impact Ramming | This method consists in directing a pneumatic piercing tool (the so-called mole) through the soil at a specific distance. Pneumatic impact-ramming of steel pipes. In this technology, steel pipes are rammed into the soil using a hammer head, placed in the starting trench in a special bed, which is also referred to as the cradle or platform. |

| PJ | Pipe Jacking | Trenchless method of constructing underground pipelines. This hydraulic jacking technology consists in ramming steel casing pipes into the soil using hydraulic motors. |

| MTM | Microtunneling | Trenchless method of constructing underground pipelines, consisting in the pneumatic jacking of carrier pipes, following the equipment, called the head, which is placed on the front and digs the tunnel, while being pushed. Microtunneling is defined as a remotely-controlled, guided, pipe-jacking operation that provides continuous support to the excavation face by applying mechanical or fluid pressure to balance groundwater and earth pressures. |

| - | Drilling liquid | Drilling liquid used in the realization of HDD projects is always a water dispersion fluid. The drilling liquid performs vital functions related to the process based on the balance of pressure and flow:

|

| - | Pilot drilling. | The stage that precedes the widening of the pilot hole and the installation of the technological pipe using the HDD method. Works are conducted using drilling equipment and the techniques of soil washing, mining with a stream of drilling liquid or the use of a depth engine with a roller drill. |

| Item | Name of Fraction and Sub-Fraction | Grain Diameter (d) in Mm | Soil Name and Grain Diameter in mm adopted for Research Purposes |

|---|---|---|---|

| 1 | Pebbles:

| 2 < d ≤ 76

|

|

| 2 | Sand:

| 0.05 < d ≤ 2.0

|

|

| 3 | Silt:

| 0.002 < d ≤ 0.05

| |

| 4 | Clay:

| d ≤ 0.002

|

|

| Application and Properties of the Technology | HDD | IM, IR | PJ | MPM |

|---|---|---|---|---|

| Deviations from the designed route of the system. | The trajectory of the constructed drilling and the position of the exit point are nearly identical to the designed ones. |

| It is assumed that the horizontal accuracy of the pipeline construction is 1 to 2% of the length of pipes constructed at one time. | The trajectory of the constructed drilling and the position are nearly identical to the designed ones. |

| Drilling length Ramming length | 2900 m |

| In one step, up to 80 m of pipeline may be constructed (when borings are transported with a screw conveyor) or up to 50 m (with drilling liquid system). | Depending on the soil and water conditions and the diameter of the pipeline, with the hydraulic transport of borings, the length may reach up to 500 m. |

| External diameter of the drilling ramming or of the integrated pipe. | Max. pipe diameter: 1400mm | Maximum external diameter of the pipeline is only up to 200 mm. For directional ramming with a pneumatic piercing tool (the so-called mole), it is possible to install a pipe with a diameter of up to 63 mm. | The scope of the constructed diameters is 150 to 600 mm. | 300 to 3000 mm. |

| Usability of the application of the technology in urban areas. | Drillings may be conducted in strongly urbanized areas. | It is possible to construct short sections of horizontal drilling under construction objects. | It is possible to construct with horizontal drilling under construction objects on short sections. | Drillings may be conducted in strongly urbanized areas. |

| Usability of the technology for crossing linear obstacles, transportation routes (heavy traffic roads, tramways and railway tracks). | It is possible to construct with horizontal drilling under construction objects. | It is possible to construct with horizontal drilling under construction objects on short sections. | It is possible to construct with horizontal drilling under construction objects on short sections. | It is possible to construct with horizontal drilling under construction objects. |

| Usability of the technology in areas with a dense water supply, sewage network, power supply and telecommunication lines. | It is possible to construct with horizontal drilling under the network systems. | If the soil is mobile enough, this technology allows motorways to be crossed and home gas or water connections to be installed, etc. | It is possible to construct with horizontal drilling under construction objects on short sections. | It is possible to construct with horizontal drilling under the network systems. |

| Possibility to cross navigable rivers and channels. | Possibility to install facilities below the bottom of rivers or channels. | Application is generally impossible due to the limitations created by the ramming length. | The technology may also be used for constructing pipelines below the ground water level. | The technology may also be used for constructing pipelines below the ground water level. |

| Possibility to cross mountains and hills. | Possibility to install facilities below the rock mass. | Application is generally impossible due to the limitations created by the ramming length. This method may be ineffective in water-saturated soils in low surface friction conditions. | Application is generally impossible due to the limitations created by the ramming length. | Possibility to install facilities below the rock mass. |

| Economic aspects. | The method enables a fast pace of works. | The method enables a fast pace of works. | The method enables a fast pace of works and low construction costs. | The method enables a fast pace of works. |

| Environmental impact during the realization of drilling. | The technology allows the impact in areas that should stay intact due to their natural and landscape values to be minimized. | Application is generally impossible due to the limitations created by the ramming length. | Application is generally impossible due to the limitations created by the ramming length. | The technology allows the impact in areas that should stay intact due to their natural and landscape values to be minimized. |

| Formation | Daily Pro-Gress (m) | Losses per 1 LM (m3) | Drilling Fluid Stream (L/min) | Delivery Pressure (bar) | Speed in PP (m/min) | Time of Discharge from the Bottom (min) | Circula-Tion Time (min) | Rey-Nolds Num-Ber | shearing Rate | Total Circulation/Daily Circulation (m3) |

|---|---|---|---|---|---|---|---|---|---|---|

| Sand | 10 | 2 | 800 | 9 | 10 | 19 | 120 | 2 | 13.4 s−1 | 199/197 |

| Clay | 20 | 2.5 | 800 | 12 | 10 | 29 | 153 | 2 | 13.4 s−1 | 151/350 |

| Clay | 24 | 4.2 | 800 | 11 | 10 | 29 | 153 | 2 | 13.4 s−1 | 112/462 |

| Sand/clay | 27 | 6.6 | 3200 | 25 | 2.6 | 22 | 106 | 1 | 0.31 s−1 | 804/1273 |

| Sand/clay | 30 | 6 | 3200 | 22 | 2.6 | 48 | 146 | 1 | 0.31 s−1 | 941/2214 |

| Sand | 28 | 6.4 | 3200 | 19 | 2.6 | 58 | 169 | 1 | 0.31 s−1 | 464/2678 |

| Sand | 30 | 6 | 3200 | 18 | 2.6 | 73 | 294 | 1 | 0.31 s−1 | 630/3308 |

| Sand | 28 | 6.4 | 3200 | 17 | 2.6 | 91 | 235 | 1 | 0.31 s−1 | 832/4140 |

| Sand/gravel | 26 | 6.9 | 3200 | 16 | 2.6 | 117 | 286 | 1 | 0.31 s−1 | 1171/5311 |

| Sand/gravel | 34 | 5.3 | 3200 | 15 | 2.6 | 142 | 335 | 1 | 0.31 s−1 | 870/6181 |

| Sand/gravel | 30 | 6 | 3200 | 15 | 2.6 | 160 | 370 | 1 | 0.31 s−1 | 719/5603 |

| Various sand | 33 | 5.4 | 3300 | 15 | 2.6 | 182 | 407 | 1 | 0.31 s−1 | 774/7752 |

| Sand | 29 | 6.1 | 3000 | 14 | 2.6 | 205 | 477 | 1 | 0.31 s−1 | 372/8124 |

| Sand | 25 | 7.2 | 3300 | 18 | 2.5 | 42 | 125 | 1 | 0.31 s−1 | 198/8322 |

| Various sand | 27 | 6.6 | 3300 | 15 | 2.5 | 137 | 316 | 1 | 0.31 s−1 | 438/8760 |

| Various sand | 22 | 8.1 | 3300 | 13 | 2.5 | 82 | 350 | 1 | 0.31 s−1 | 356/9116 |

| Sand | 25 | 7.8 | 3300 | 17 | 2.5 | 76 | 186 | 1 | 0.31 s−1 | 365/9481 |

| Various sand | 27 | 7.2 | 3300 | 11 | 2.5 | 190 | 424 | 1 | 0.31 s−1 | 448/9929 |

| Sand | 27 | 7.2 | 3000 | 10 | 2.5 | 24 | 85 | 1 | 0.31 s−1 | 126/10,055 |

| Sand | 20 | 9.7 | 3200 | 10 | 2.5 | 214 | 897 | 1 | 0.31 s−1 | 86/10,141 |

| Fraction Separation Set | Solid Fraction | Product | ||||||

|---|---|---|---|---|---|---|---|---|

| Daily Treated Volume [m3] | Total Treated Volume [m3] | Water: Borehole Volume | Drillings borehole VOLUME | Bentonite | Soda Ash | ClayCutter | Detergent | HydroClay |

| 141 | 141 | 6.6 | 0.91 | 11.60 | 0.13 | 0.09 | 0.13 | 0.13 |

| 83 | 224 | 6.5 | 0.79 | 13.20 | 0.00 | 0.18 | 0.17 | 0.33 |

| 83 | 224 | 6.8 | 0.70 | 0.00 | 0.00 | 0.00 | 0.00 | 0.22 |

| 713 | 937 | 3.3 | 1.00 | 3.70 | 0.03 | 0.00 | 0.00 | 0.00 |

| 821 | 1758 | 2.4 | 1.16 | 8.20 | 0.08 | 0.00 | 0.00 | 0.00 |

| 821 | 1758 | 2.3 | 1.02 | 9.30 | 0.00 | 0.00 | 0.00 | 0.00 |

| 549 | 2307 | 2.1 | 1.07 | 6.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| 754 | 3061 | 1.9 | 1.00 | 7.20 | 0.00 | 0.00 | 0.00 | 0.00 |

| 1062 | 4123 | 1.7 | 1.00 | 4.70 | 0.00 | 0.00 | 0.00 | 0.00 |

| 761 | 4884 | 1.6 | 0.99 | 4.00 | 0.02 | 0.00 | 0.00 | 0.00 |

| 719 | 5603 | 1.5 | 0.99 | 3.10 | 0.00 | 0.00 | 0.00 | 0.06 |

| 661 | 6264 | 1.4 | 1.00 | 5.80 | 0.00 | 0.00 | 0.00 | 0.19 |

| 281 | 6545 | 1.4 | 0.91 | 16.10 | 0.00 | 0.00 | 0.00 | 0.13 |

| 178 | 6723 | 1.4 | 0.95 | 10.10 | 0.00 | 0.00 | 0.00 | 0.38 |

| 393 | 7116 | 1.5 | 0.95 | 1.40 | 0.05 | 0.00 | 0.00 | 0.34 |

| 304 | 7420 | 1.4 | 0.92 | 1.90 | 0.07 | 0.00 | 0.00 | 0.14 |

| 330 | 7750 | 1.4 | 0.93 | 6.80 | 0.20 | 0.00 | 0.00 | 0.20 |

| 413 | 8163 | 1.5 | 0.97 | 2.80 | 0.05 | 0.00 | 0.00 | 0.16 |

| 96 | 8259 | 1.5 | 0.97 | 0.40 | 0.00 | 0.00 | 0.00 | 0.00 |

| 75 | 8334 | 1.5 | 0.98 | 0.40 | 0.00 | 0.00 | 0.00 | 0.00 |

| Variable | N | M | SD | Min | Max | Q1 | Mdn | Q3 | Skew | K | S-W | p |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bentonite | 19 | 6.12 | 4.44 | 0.00 | 16.10 | 2.80 | 5.80 | 9.30 | 0.66 | −0.12 | 0.96 | 0.533 |

| Soda Ash | 20 | 0.03 | 0.05 | 0.00 | 0.20 | 0.00 | 0.00 | 0.05 | 2.10 | 4.49 | 0.67 | <0.001 |

| HydroClay | 20 | 0.11 | 0.13 | 0.00 | 0.38 | 0.00 | 0.10 | 0.20 | 0.80 | −0.53 | 0.83 | 0.002 |

| Time of discharge from the bottom [min] | 20 | 97.00 | 66.38 | 19.00 | 214.00 | 32.25 | 79.00 | 155.50 | 0.48 | −1.19 | 0.90 | 0.048 |

| Circula-tion time [min] | 20 | 281.70 | 187.11 | 85.00 | 897.00 | 147.75 | 260.50 | 365.00 | 1.93 | 5.33 | 0.82 | 0.002 |

| Losses [%] | 20 | 6.60 | 8.56 | 1.90 | 36.70 | 2.00 | 2.70 | 7.65 | 2.72 | 8.08 | 0.61 | <0.001 |

| Variable | Fraction | n | Q1 | Mdn | Q3 | Min | Max | M | SD | H | p | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Time of outflow from the bottom [min] | Clay or sand/clay | 4 | 4.50 | 25.50 | 29.00 | 38.50 | 22.00 | 48.00 | 32.00 | 11.17 | 8.06 | 0.045 |

| Sand | 9 | 9.78 | 33.00 | 65.50 | 83.50 | 19.00 | 214.00 | 89.11 | 72.29 | |||

| Various sand | 4 | 15.00 | 109.50 | 159.50 | 186.00 | 82.00 | 190.00 | 147.75 | 49.65 | |||

| Sand/gravel | 3 | 14.67 | 129.50 | 142.00 | 151.00 | 117.00 | 160.00 | 139.67 | 21.59 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwast-Kotlarek, U.; Hełdak, M.; Szczepański, J. Introducing Bentonite into the Environment in the Construction Stage of Linear Underground Investment Using the HDD Method. Appl. Sci. 2018, 8, 2210. https://doi.org/10.3390/app8112210

Kwast-Kotlarek U, Hełdak M, Szczepański J. Introducing Bentonite into the Environment in the Construction Stage of Linear Underground Investment Using the HDD Method. Applied Sciences. 2018; 8(11):2210. https://doi.org/10.3390/app8112210

Chicago/Turabian StyleKwast-Kotlarek, Urszula, Maria Hełdak, and Jakub Szczepański. 2018. "Introducing Bentonite into the Environment in the Construction Stage of Linear Underground Investment Using the HDD Method" Applied Sciences 8, no. 11: 2210. https://doi.org/10.3390/app8112210

APA StyleKwast-Kotlarek, U., Hełdak, M., & Szczepański, J. (2018). Introducing Bentonite into the Environment in the Construction Stage of Linear Underground Investment Using the HDD Method. Applied Sciences, 8(11), 2210. https://doi.org/10.3390/app8112210