Field Experiments to Evaluate Thermal Performance of Energy Slabs with Different Installation Conditions

Abstract

:1. Introduction

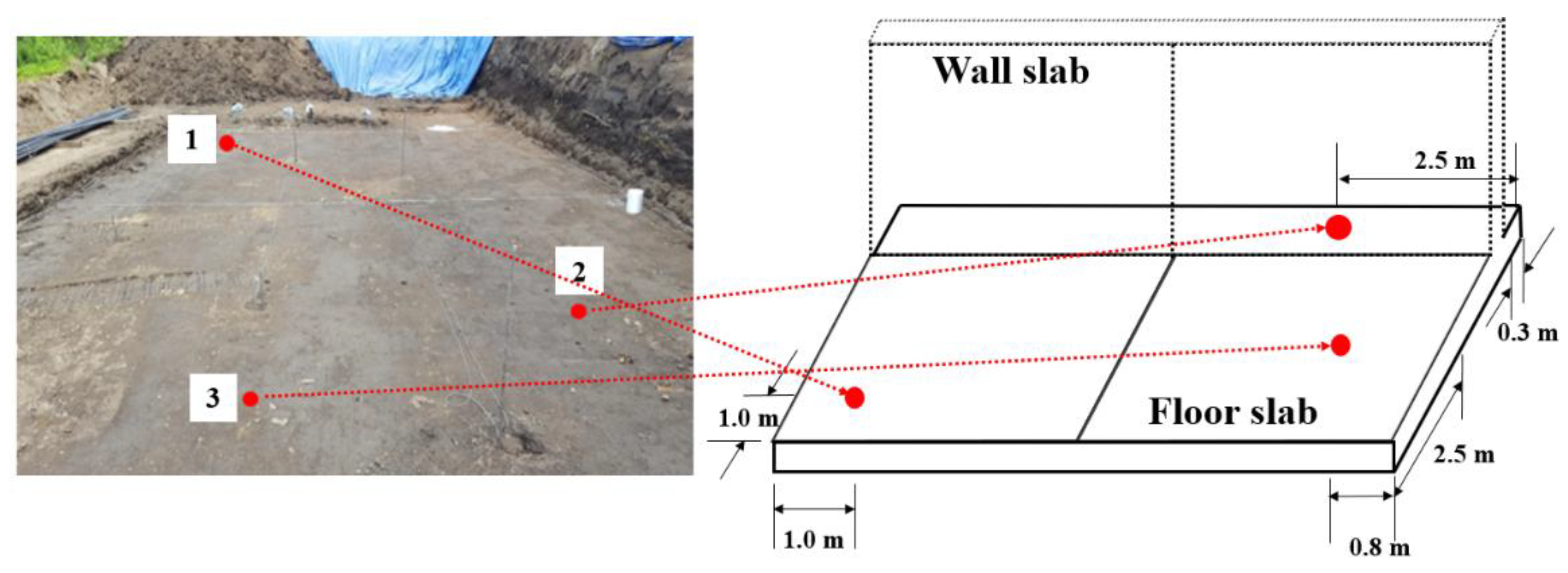

2. Construction of the Energy Slab in a Test Bed

2.1. Configuration of the Energy Slabs

2.2. Overview of Test Bed

3. Field Tests for Energy Slab

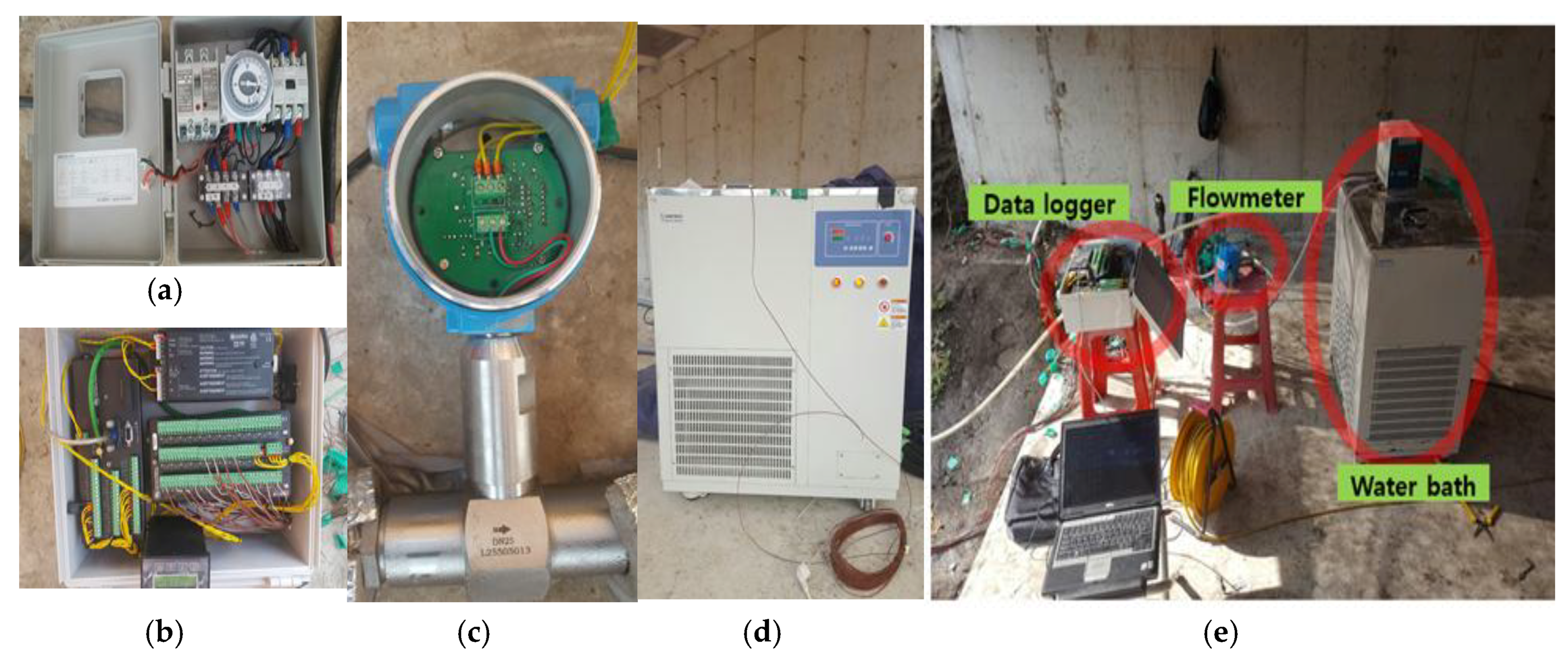

3.1. In-Situ Thermal Response Tests (TRTs)

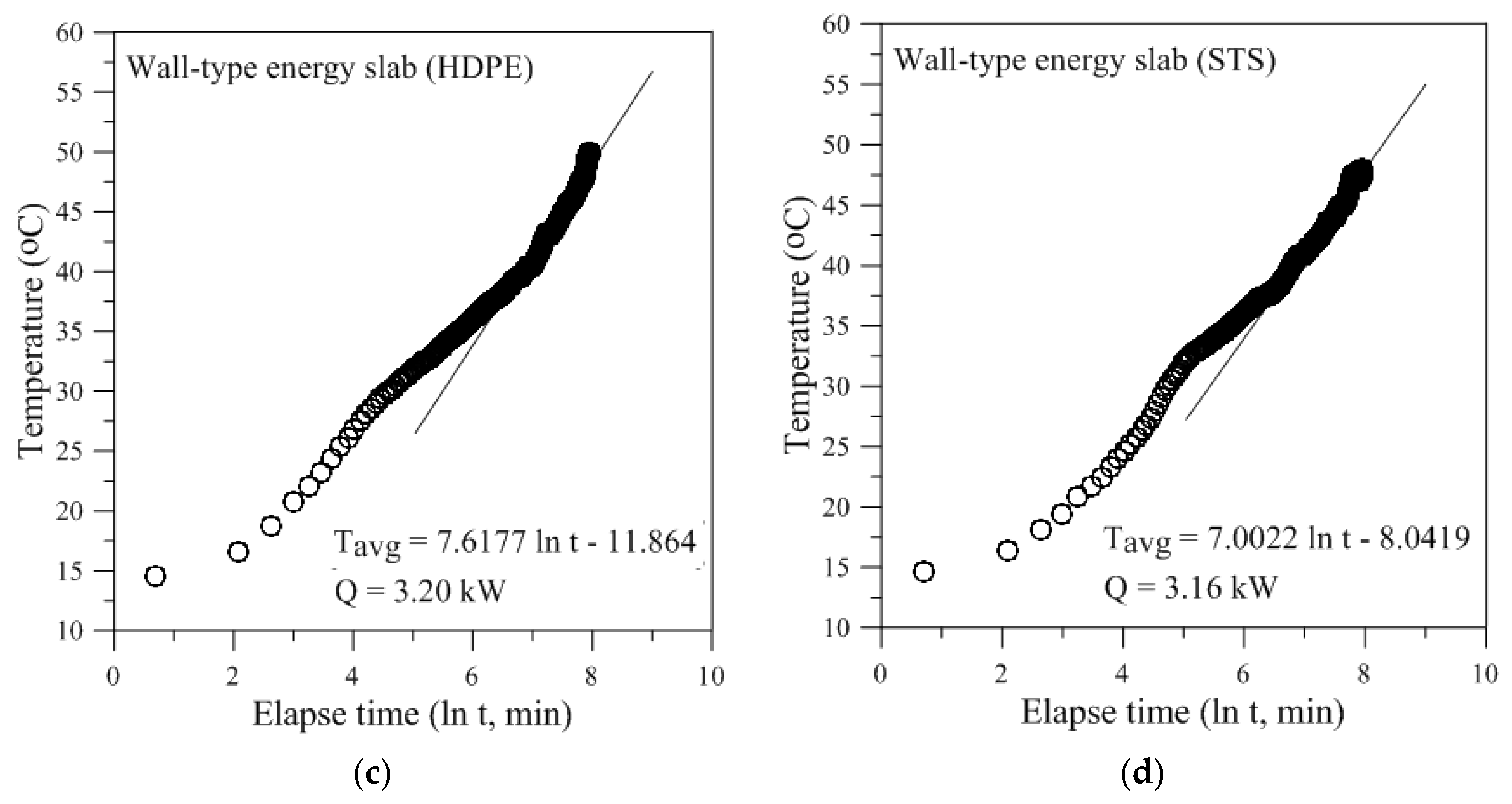

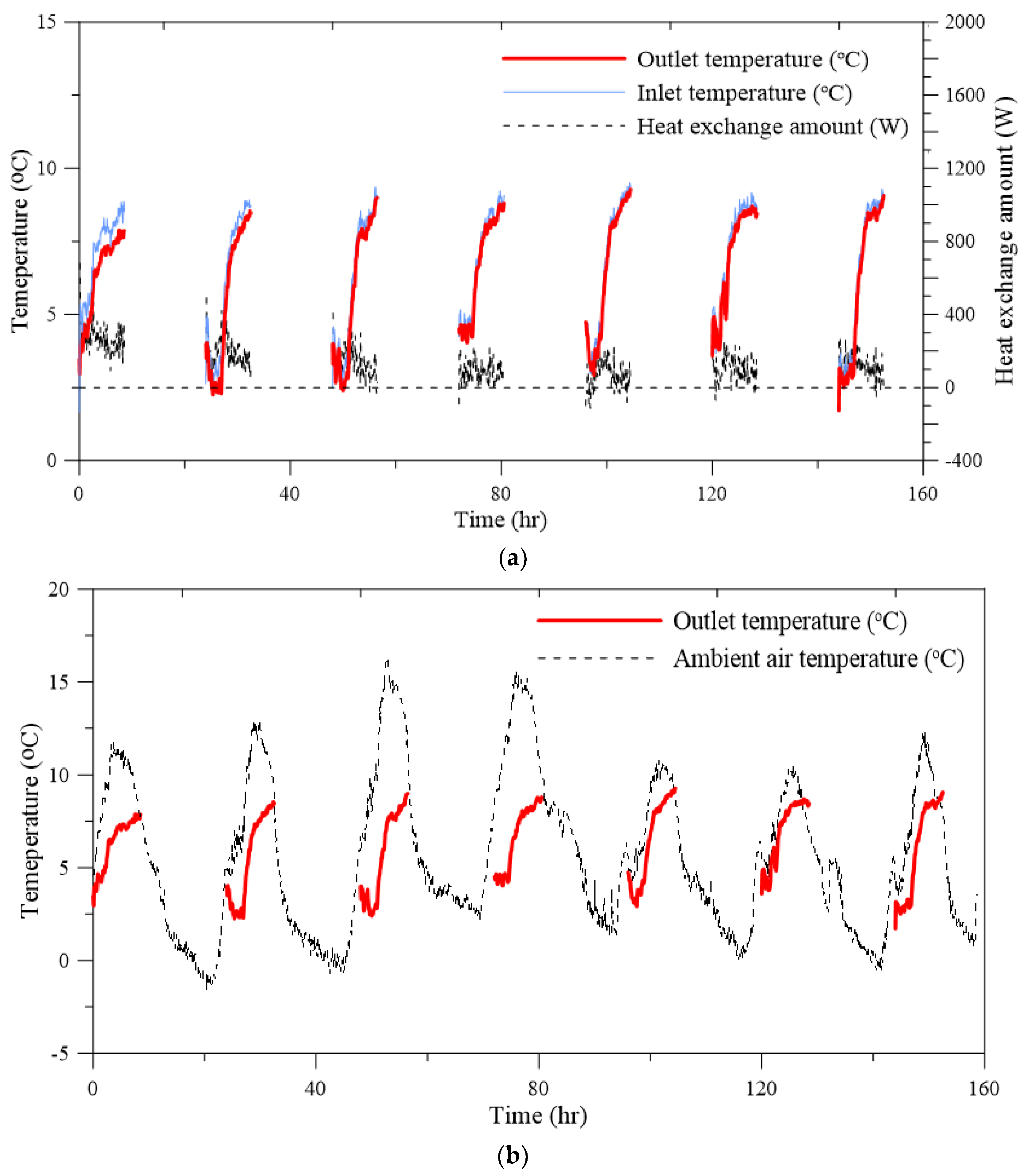

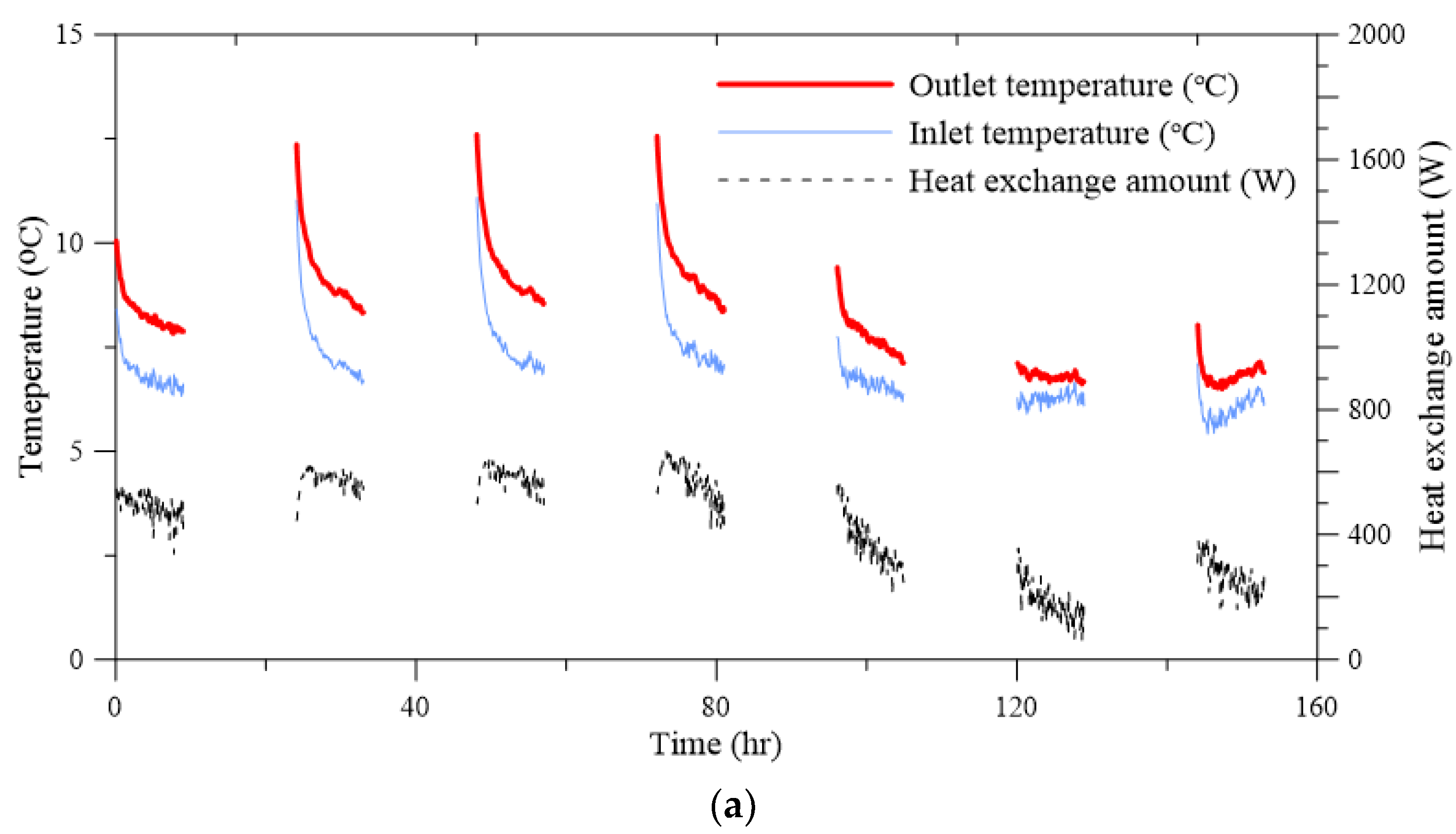

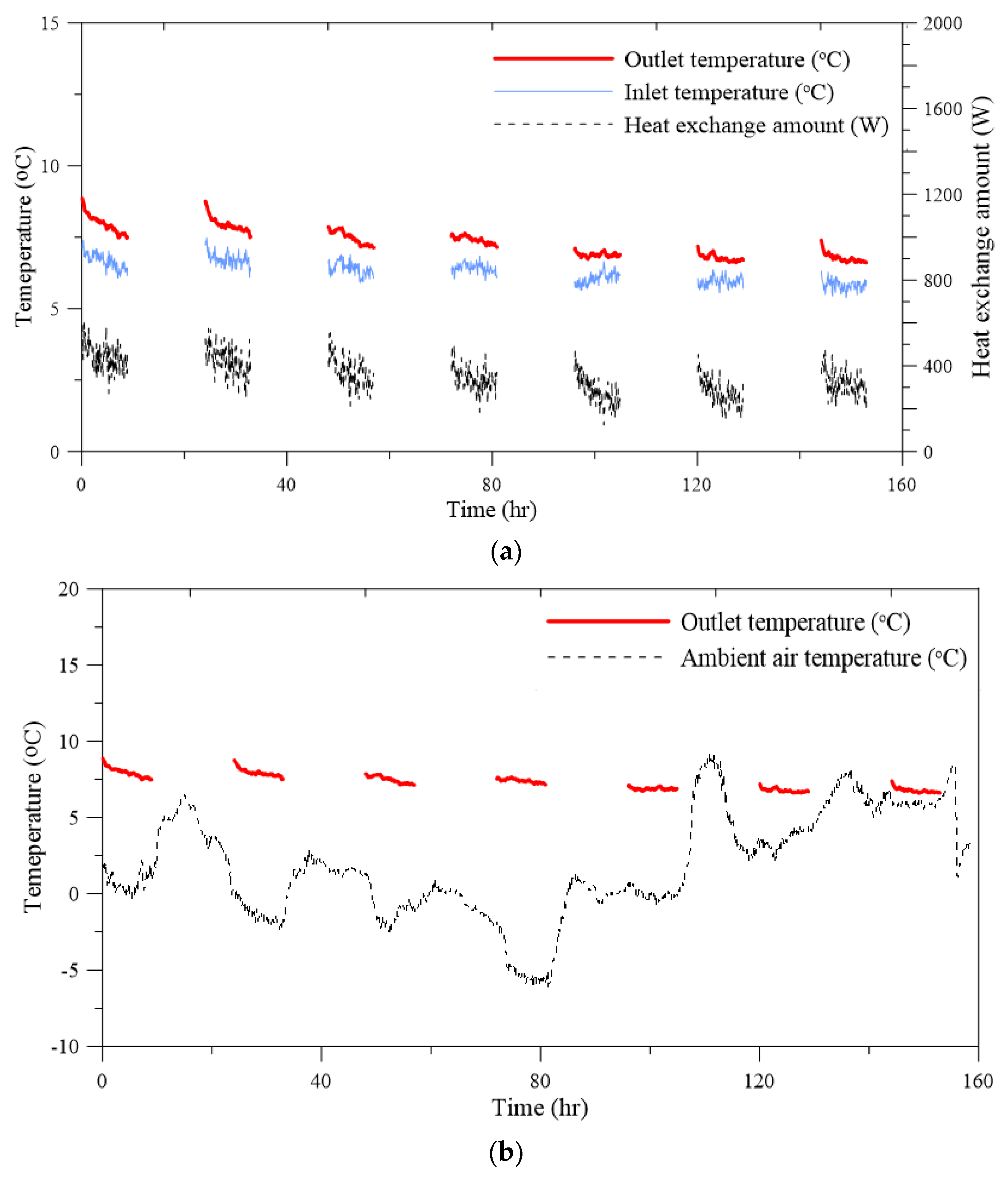

3.2. In-Situ Thermal Performance Tests (TPTs)

4. Field Test Results and Discussions

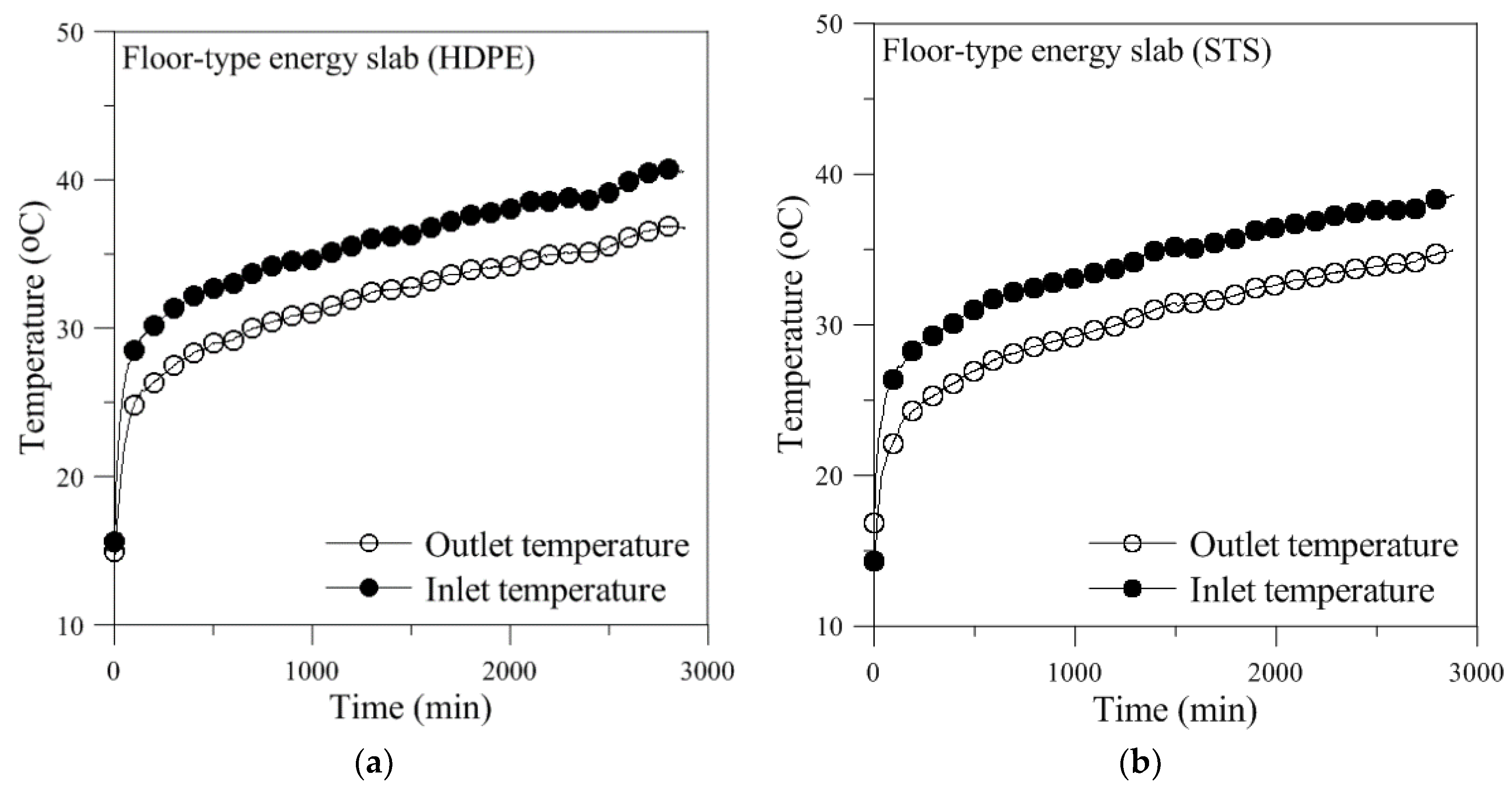

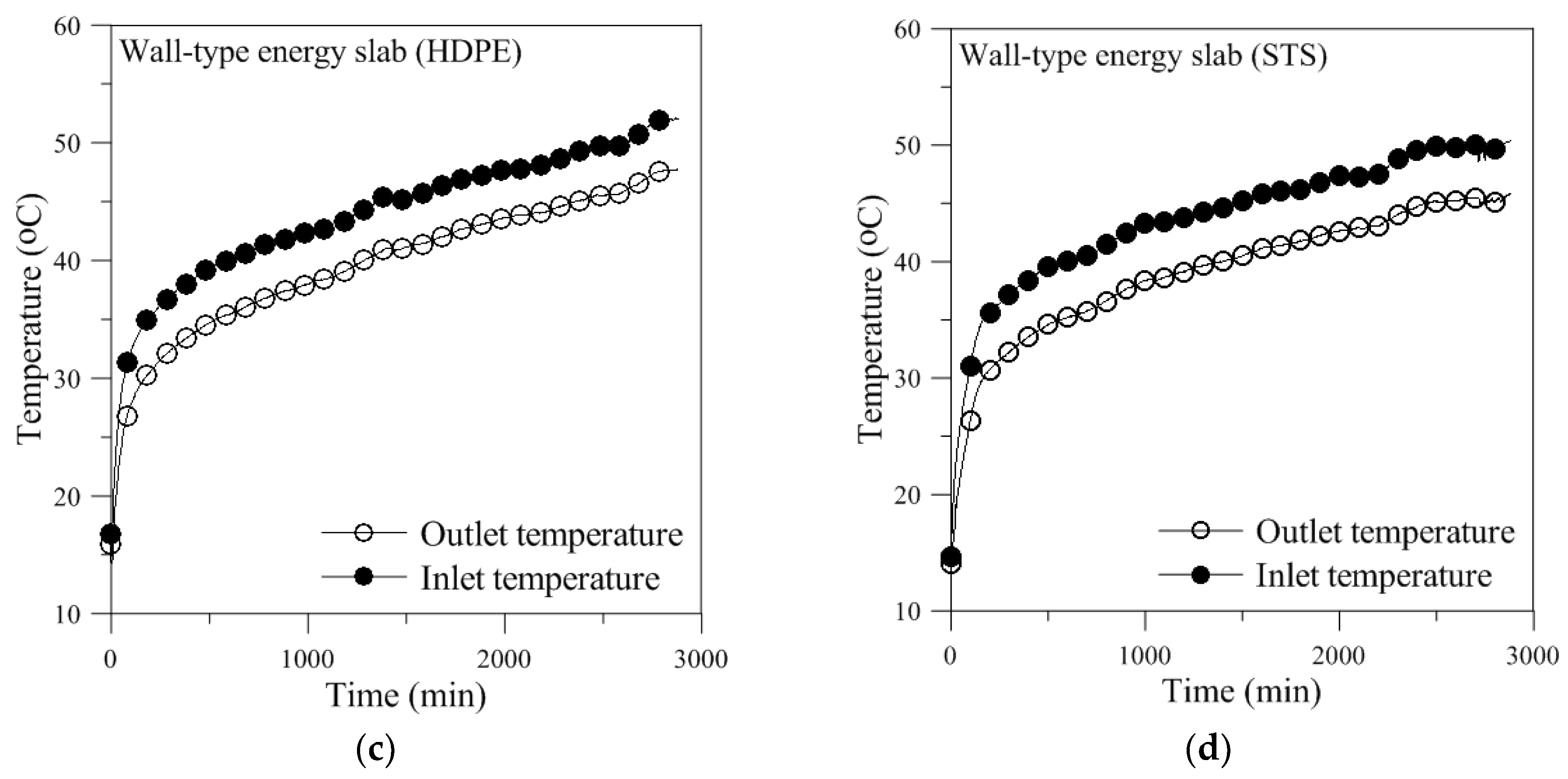

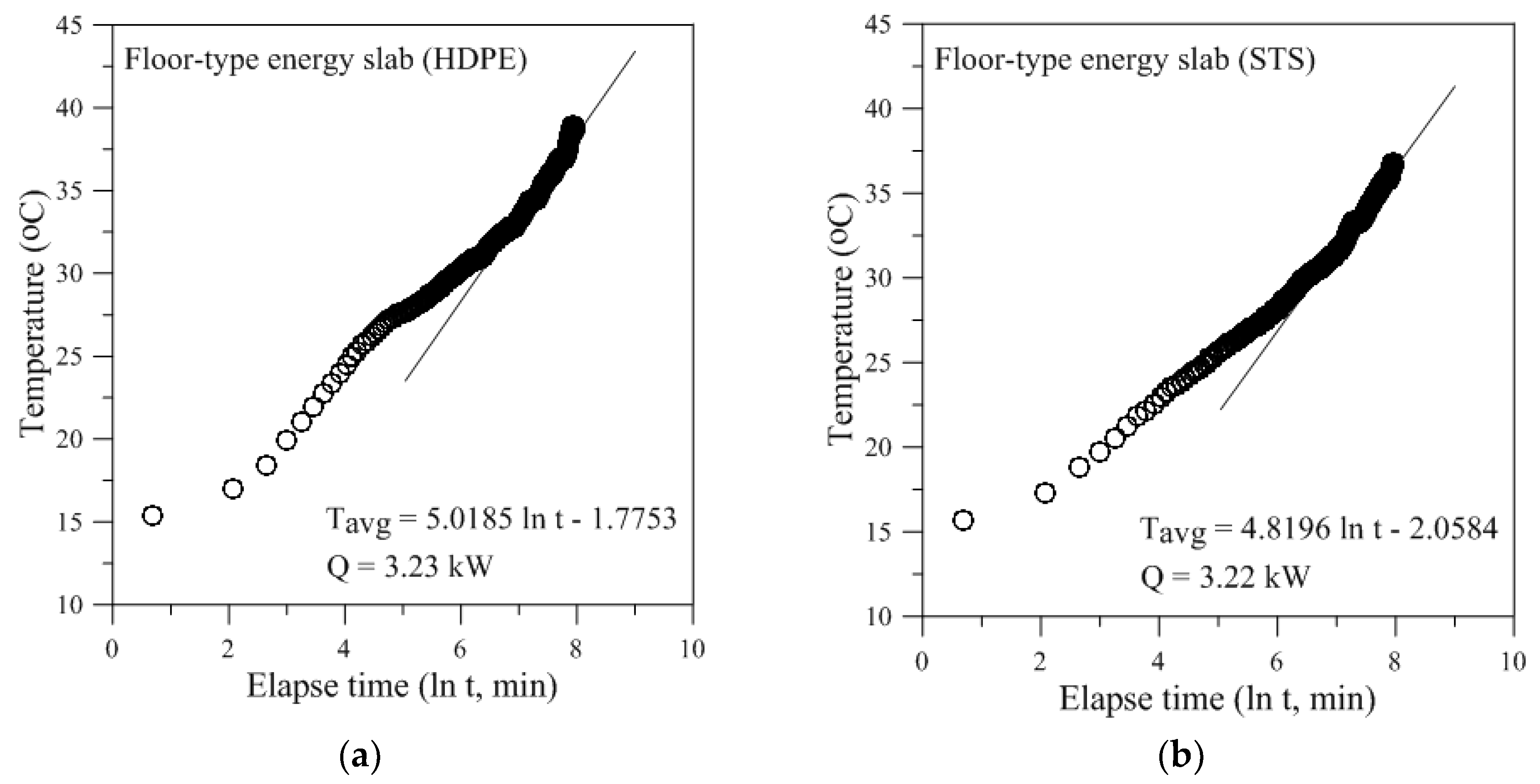

4.1. Relative Heat Exchange Efficiency from TRTs

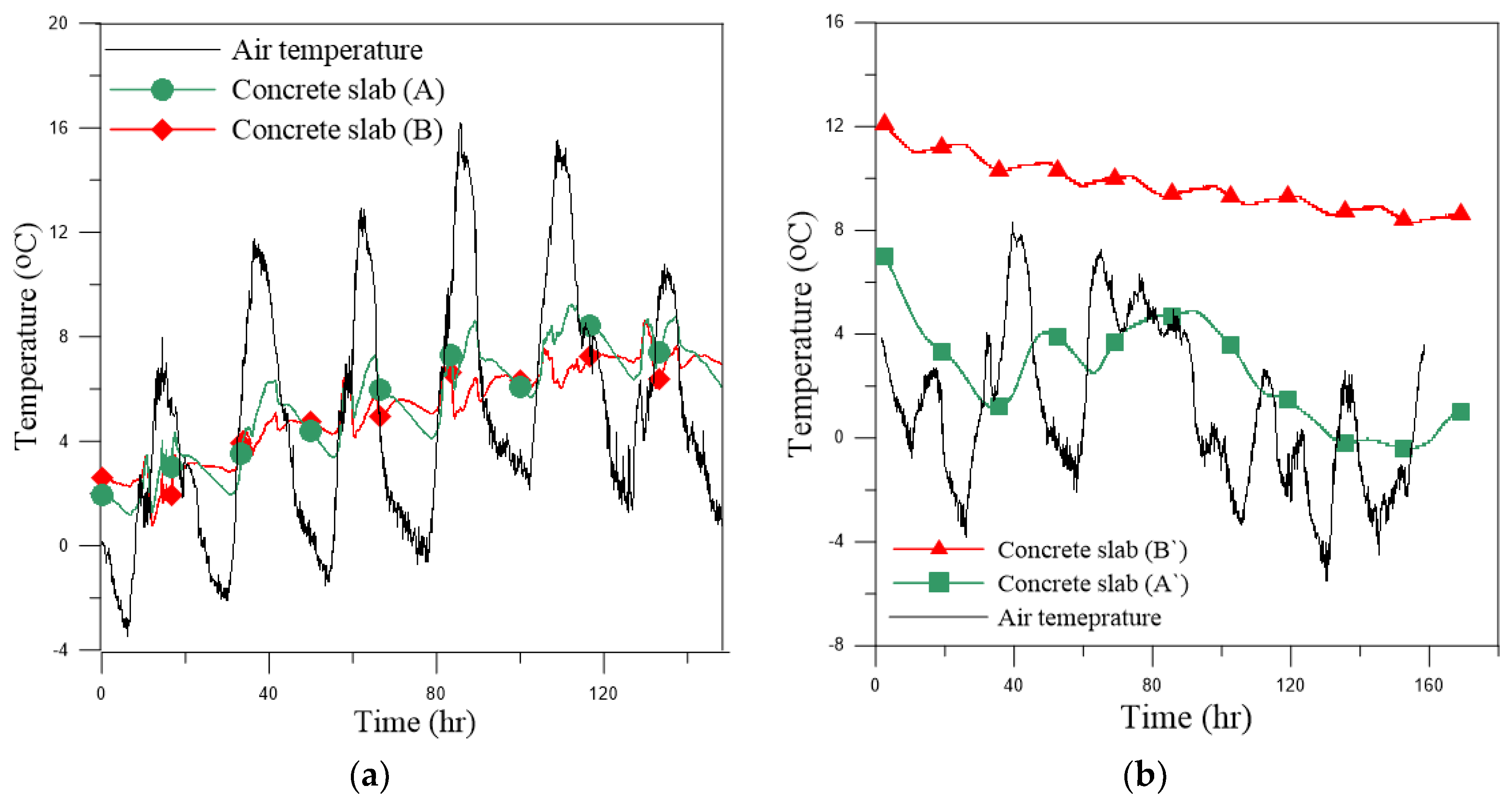

4.2. Evaluation of Thermal Performance from TPT

5. Conclusions

- The field experiments indicate that increasing the thermal conductivity of pipe materials can desirably enhance the thermal performance of energy slabs when the other construction conditions are predetermined. However, the extremely high thermal conductivity of the heat exchange pipe could lead to excessive heat transfer through the surrounding media, which may impair the long-term thermal performance of energy slabs.

- There was no difference in heat exchange performance between the wall-type energy slab and the floor-type energy slab. Therefore, the energy slabs can be used in both the wall and floor slab in the underground structures to maximize the use of geothermal energy in a limited underground space.

- It is hard to expect sufficient heat exchange performance in energy slabs installed without a thermal insulation layer, because the temperature in the concrete slab containing heat exchangers is naturally governed by the ambient air temperature if there is no appropriate thermal insulation. This result implies that the installation of a thermal insulation layer in energy slabs is essential, and a thermal insulation material with suitable thermal conductivity to minimize the influence of ambient air should be used.

- The results of the TPTs showed that the average heat exchange amount of the energy slab was estimated to be about 400 W for 25 m2 of the energy slab unit. This value is not comparable to the conventional GHEXs because the field test conditions were not favorable. If energy slabs are installed in an actual underground structure, a larger heat exchange amount would be expected with the aid of the higher thermal conductivity of ground formation and less influence of the ambient air temperature. Additionally, the successful application of energy slabs in large-scale underground structures, such as underground shopping centers and subway stations, would be suitable for replacing the conventional GHEXs.

Author Contributions

Acknowledgments

Conflicts of Interest

Nomenclature

| C | specific heat of circulating fluid (J/kgK) |

| D | Pipe diameter (mm) |

| relative heat exchange efficiency per unit pipe length | |

| L | borehole length (m) |

| Lpipe | total length of heat exchange pipe (m) |

| mass flux of circulating fluid (kg/s) | |

| Q | heat exchange amount (W) |

| amount of heat injection (W) | |

| constant heat injection rate (W) | |

| Re | Reynolds number |

| slope | relationship between average of inlet and outlet temperatures, and natural logarithm of time |

| ΔT | Temperature difference (°C) |

| inlet fluid temperature (°C) | |

| outlet fluid temperature (°C) | |

| Greek Symbols | |

| α | effective thermal diffusivity (m2/s) |

| γ | Euler constant |

| λ | effective thermal conductivity of ground formation (W/mK) |

| μ | Coefficient of viscosity (g/cm s) |

| ρ | Density of working fluid (g/cm3) |

References

- Boënnec, O. Shallow ground energy systems. Proc. Inst. Civ. Eng.-Energy 2008, 161, 57–61. [Google Scholar]

- Lee, C.; Park, S.; Won, J.; Jeoung, J.; Sohn, B.; Choi, H. Evaluation of thermal performance of energy textile installed in Tunnel. Renew. Energy. 2012, 42, 11–22. [Google Scholar] [CrossRef]

- Zhang, G.; Xia, C.; Yang, Y.; Sun, M.; Zou, Y. Experimental study on the thermal performance of tunnel lining ground heat exchangers. Energy Build. 2014, 77, 149–157. [Google Scholar] [CrossRef]

- Zhang, G.; Xia, C.; Sun, M.; Zou, Y.; Xiao, S. A new model and analytical solution for the heat conduction of tunnel lining ground heat exchangers. Cold Reg. Sci. Technol. 2013, 88, 59–66. [Google Scholar] [CrossRef]

- Brandl, H. Energy foundations and other thermo-active ground structures. Geotechnique 2006, 56, 81–122. [Google Scholar] [CrossRef]

- De Moel, M.; Bach, P.M.; Bouazza, A.; Singh, R.M.; Sun, J.O. Technological advances and applications of geothermal energy pile foundations and their feasibility in Australia. Renew. Sustain. Energy Rev. 2010, 14, 2683–2696. [Google Scholar] [CrossRef]

- Morino, K.; Oka, T. Study on heat exchanged in soil by circulating water in a steel pile. Energy Build. 1994, 21, 65–78. [Google Scholar] [CrossRef]

- Park, S.; Lee, S.; Oh, K.; Kim, D.; Choi, H. Engineering chart for thermal performance of cast-in-place energy pile considering thermal resistance. Appl. Therm. Eng. 2018, 130, 899–921. [Google Scholar] [CrossRef]

- Moon, C.E.; Choi, J.M. Heating performance characteristics of the ground source heat pump system with energy-piles and energy-slabs. Energy 2015, 81, 27–32. [Google Scholar] [CrossRef]

- Hwang, K.I.; Woo, S.W.; Kim, J.H.; Shin, S.H.; Kim, Y.S. A study on the seasonal performances evaluation of the horizontal-type geothermal heat exchanger installed in the foundation slabs of complex building. J. Korean Sol. Energy Soc. 2007, 27, 11–17. [Google Scholar]

- Choi, J.-M. Heating and cooling performance of a ground coupled heat pump system with energy-slab. Korean J. Air-Cond. Refrig. Eng. 2012, 24, 196–203. [Google Scholar]

- Choi, J.-M.; Sohn, B.-H. Performance analysis of energy-slab ground-coupled heat exchanger. Korean J. Air-Cond. Refrig. Eng. 2012, 24, 487–496. [Google Scholar]

- Sung, C.; Park, S.; Lee, S.; Oh, K.; Choi, H. Thermo-mechanical behavior of cast-in-place energy piles. Energy. 2018, 161, 920–938. [Google Scholar] [CrossRef]

- Lee, C.; Park, M.; Nguyen, T.B.; Sohn, B.; Choi, J.M.; Choi, H. Performance evaluation of closed-loop vertical ground heat exchangers by conducting in-situ thermal response tests. Renew. Energy 2012, 42, 77–83. [Google Scholar] [CrossRef]

- Kim, D.; Kim, G.; Kim, D.; Baek, H. Experimental and numerical investigation of thermal properties of cement-based grouts used for vertical ground heat exchanger. Renew. Energy 2017, 112, 260–267. [Google Scholar] [CrossRef]

- Yoon, S.; Lee, S.R.; Kim, M.J.; Kim, W.J.; Kim, G.Y.; Kim, K. Evaluation of stainless steel pipe performance as a ground heat exchanger in ground-source heat-pump system. Energy 2016, 113, 328–337. [Google Scholar] [CrossRef]

- ASTM D 5334. Standard Test Method for Determination of Thermal Conductivity of Soil and Soft Rock by Needle Probe Procedure; Annual Book of ASTM Standards. 04.09; ASTM International: West Conshohocken, PA, USA, 1995; pp. 225–229. [Google Scholar]

- ASTM C 1113-90. Test Method for Thermal Conductivity of Refractories by Hot Wire (Platinum Resistance Thermometer Technique); ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- Carslaw, H.S.; Jaeger, J.C. Conduction of H eat in Solids, 2nd ed.; Oxford Science Publications: Oxford, UK, 1959. [Google Scholar]

- Sharqawy, M.; Mokheimer, E.; Habib, M.; Badr, H.; Said, S.; Al Shayea, N. Energy, exergy and uncertainty analyses of the thermal response test for a ground heat exchanger. Int. J. Energy Res. 2009, 33, 582–592. [Google Scholar] [CrossRef]

- Wagner, R.; Clauser, C. Evaluating thermal response tests using parameter estimation for thermal conductivity and thermal capacity. J. Geophys. Eng. 2005, 2, 349. [Google Scholar] [CrossRef]

- Park, S. Performance of Evaluation and Design method for Cast-In-Place Energy Piles. Ph.D. Thesis, Korea University, Seoul, Korea, 2016. [Google Scholar]

- Zhang, C.; Chen, P.; Liu, Y.; Sun, S.; Peng, D. An improved evaluation method for thermal performance of borehole heat exchanger. Renew. Energy 2015, 77, 142–151. [Google Scholar] [CrossRef]

- Miyara, A.; Tsubaki, K.; Inoue, S.; Yoshida, K. Experimental study of several types of ground heat exchanger using a steel pile foundation. Renew. Energy 2011, 36, 764–771. [Google Scholar] [Green Version]

- Wood, C.J.; Liu, H.; Riffat, S.B. Comparative performance of ‘U-tube’ and ‘coaxial’ loop designs for use with a ground source heat pump. Appl. Therm. Eng. 2012, 37, 190–195. [Google Scholar] [CrossRef]

- Zarrella, A.; De Carli, M.; Galgaro, A. Thermal performance of two types of energy foundation pile: Helical pipe and triple U-tube. Appl. Therm. Eng. 2013, 61, 301–310. [Google Scholar] [CrossRef]

| Type | Material | Thermal Conductivity (W/mK) | Length (m) | Pipe Diameter (mm) |

|---|---|---|---|---|

| Floor-type energy slab | High density polyethylene (HDPE) | 0.4 | 85 | 40 |

| Wall-type energy slab | 58 | |||

| Floor-type energy slab | Stainless steel (STS) | 16 | 53 | |

| Wall-type energy slab | 35 |

| Type | KD2-Pro | QTM-500 |

|---|---|---|

| Measuring method | Transient hot probe method | Transient hot wire method |

| Measuring range (Thermal conductivity, W/mK) | 0.02~2 | 0.023~12 |

| Sensing error | ±5%~10% | ±5% |

| Measuring time | 90 sec | 60 sec |

| Concrete Type | Thermal Conductivity (W/mK) | |

|---|---|---|

| Dry Condition | Saturated Condition | |

| Floor slab concrete | 1.992 | 2.257 |

| Wall slab concrete | 1.960 | 2.010 |

| Type | Specification |

|---|---|

| Bath size (dimension, W × D × H mm) | 350 × 400 × 300 mm |

| Bath capacity | 42 L |

| Power of heater/cooler | 4.0 kW/0.6 kW |

| Range of temperature capacity | −10 °C~98 °C |

| Temperature uniformity | ±1 °C |

| Capacity of circulation pump | 20 L/min |

| Electric requirement | 220 VAC, 60 Hz |

| Type | Pipe Material | Pipe Length (m) | effpipe |

|---|---|---|---|

| Floor-type energy slab | HDPE | 85 | 7.57 |

| Wall-type energy slab | 58 | 7.26 | |

| Floor-type energy slab | STS | 53 | 12.61 |

| Wall-type energy slab | 35 | 12.89 |

| Type | Condition |

|---|---|

| Operation type | 8 h operation–16 h pause (intermittent operation) |

| Flow rate | 5 L/min |

| Inlet temperature | 5 °C (heating condition) |

| Sample interval | 5 min |

| Total test duration | 7 days |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.; Park, S.; Kang, M.; Choi, H. Field Experiments to Evaluate Thermal Performance of Energy Slabs with Different Installation Conditions. Appl. Sci. 2018, 8, 2214. https://doi.org/10.3390/app8112214

Lee S, Park S, Kang M, Choi H. Field Experiments to Evaluate Thermal Performance of Energy Slabs with Different Installation Conditions. Applied Sciences. 2018; 8(11):2214. https://doi.org/10.3390/app8112214

Chicago/Turabian StyleLee, Seokjae, Sangwoo Park, Minkyu Kang, and Hangseok Choi. 2018. "Field Experiments to Evaluate Thermal Performance of Energy Slabs with Different Installation Conditions" Applied Sciences 8, no. 11: 2214. https://doi.org/10.3390/app8112214

APA StyleLee, S., Park, S., Kang, M., & Choi, H. (2018). Field Experiments to Evaluate Thermal Performance of Energy Slabs with Different Installation Conditions. Applied Sciences, 8(11), 2214. https://doi.org/10.3390/app8112214