A Requirement Engineering Framework for Electric Motors Development

Abstract

:1. Introduction

2. Current Requirement Engineering Approaches on Electric Motors

2.1. Off-the-Shelf Solutions Approach

2.2. Tailor-Made Solutions Approach

3. The Framework

3.1. Stakeholders

3.2. Classification of Requirements Package

- Application essential requirements from the integrator. The requirements contained in the initial specification are classified into different non-functional groups, such as operability, serviceability, reliability, comfort, special, and standards/regulations/policies requirements packages. The satisfaction of these requirements ensures that the motor correct performance in the system application.

- Technical derived requirements. These are derived or copied from the essential requirements into the different disciplines: mechanical, electrical, control, manufacturing engineering, also additional requirements and cross-domain objectives. The satisfaction of these requirements ensures the correct design and performance of the motor during the development process and the system application integration tests.

- Specific-domain derived requirements. These are derived or copied from the technical derived requirements into the different domains that are involved in the motor development; herein emphasizing: structural, electromagnetic, vibro-acoustics, insulation, thermal, and electromagnetic compatibility (EMC). The satisfaction of these requirements ensures the correct design and performance of the motor during the development process.

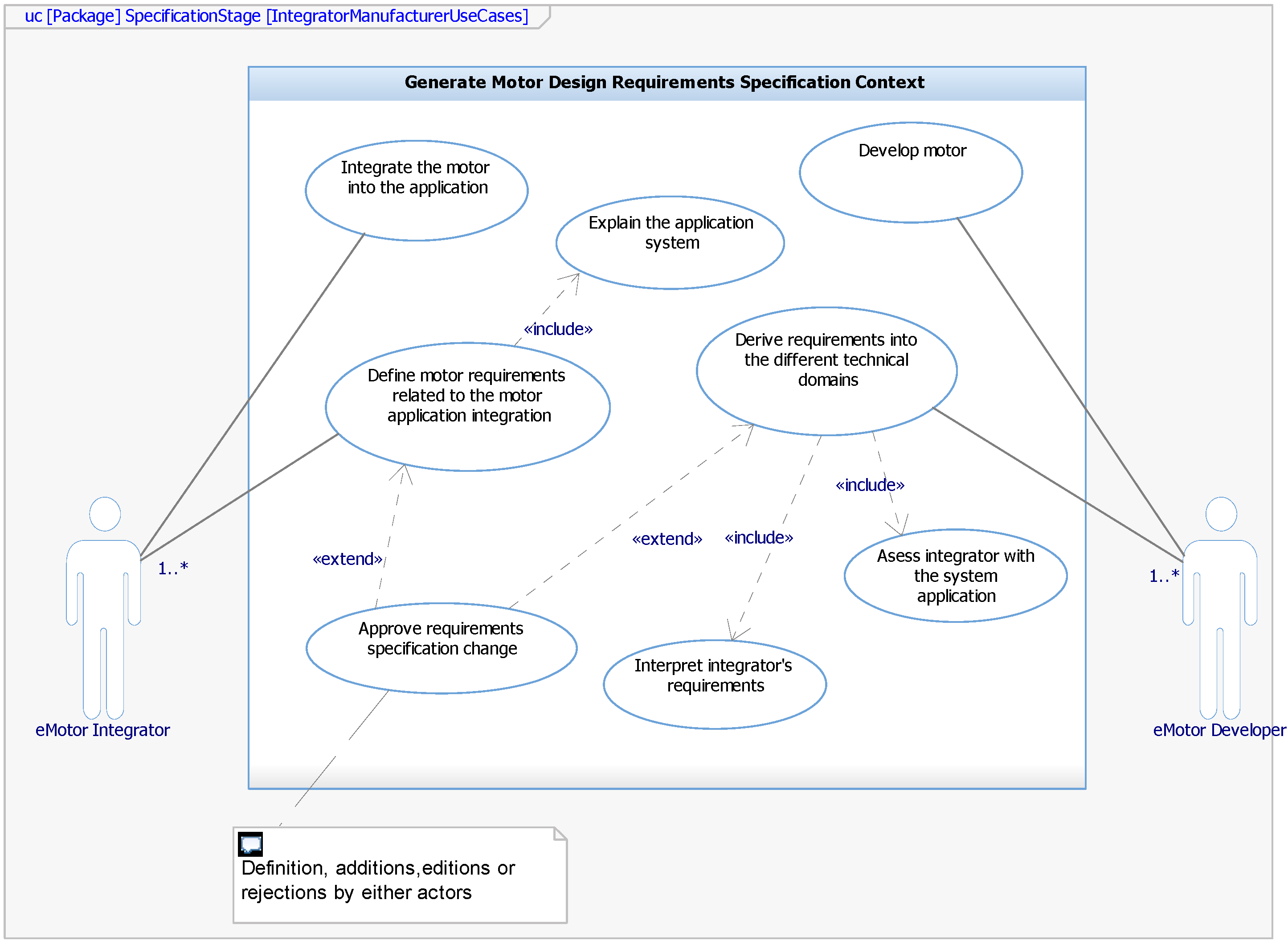

3.3. Activities

3.4. Qualification of Requirements

- Virtual prototype performance testing: These tests are done through simulations to the motor by the different domains. It should be carried out in the conceptual design phase.

- Virtual system application performance testing: These tests integrate the motor into the application, but they are also carried out through simulations during the conceptual design phase.

- Prototype performance testing: These tests are carried out on the manufactured prototype in a laboratory. These tests include type testing, routine testing, or any research testing.

- Manufacturing tolerance testing: These tests are done to components when interested in mass production.

- System application performance testing: These tests integrate the motor into the application and ensure the correct performance of the motor with the load system. Previously, factory acceptance tests may be included only if the manufactured motor is considered to be the final solution. Figure 8 illustrates the relationship among these generalized tests and the requirements packages. The realization of these tests should verify the satisfaction of the requirements within each package.

3.5. Tools

4. Use Case Example: Deriving Electromagnetic Requirements for An Elevator Application

4.1. Requirements within the Elevator System Application Scope

4.2. Deriving Requirements into Disciplines

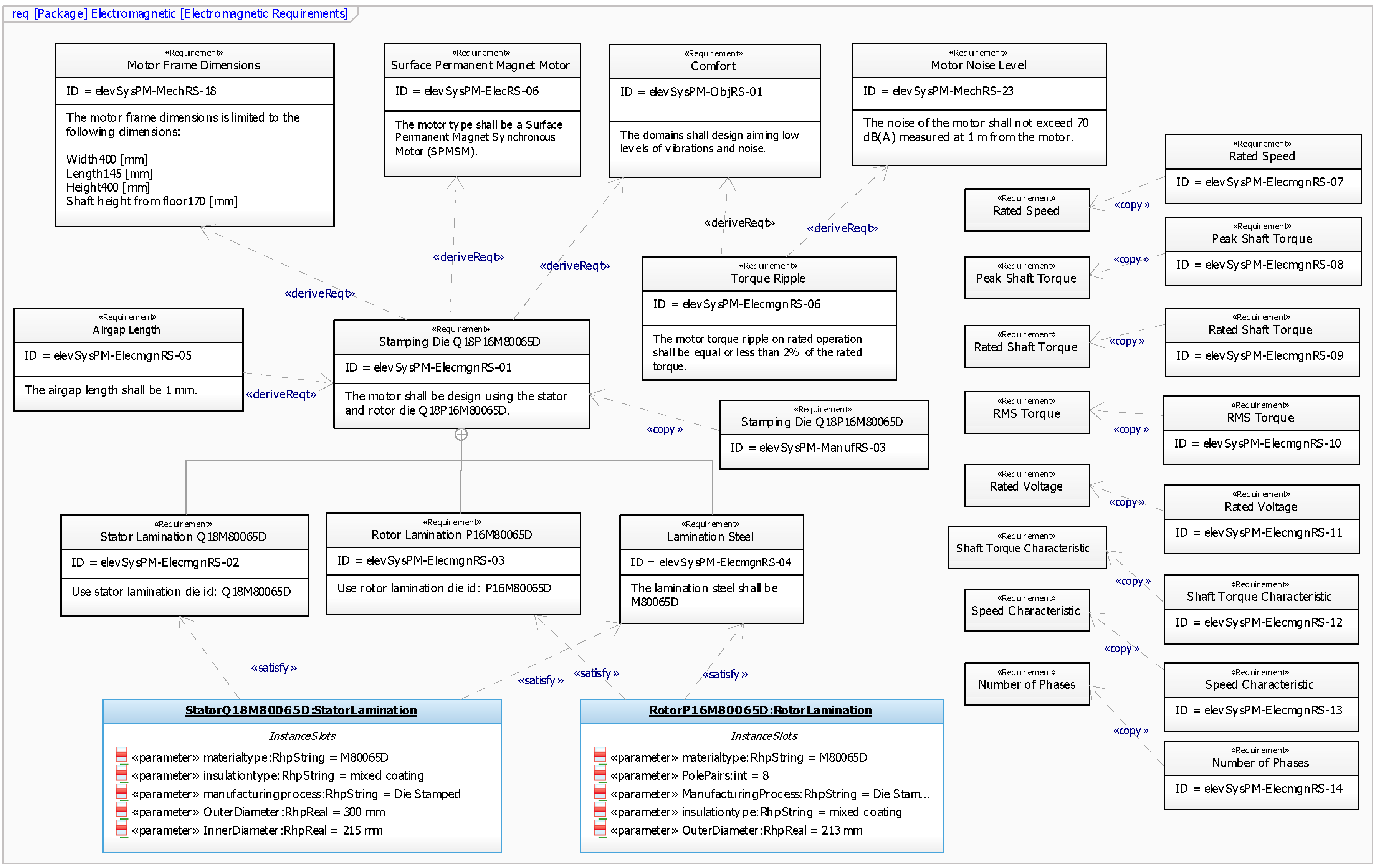

4.3. Deriving Electromagnetic Requirements

5. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bahill, A.T.; Henderson, S.J. Requirements Development, Verification, and Validation Exhibited in Famous Failures. Syst. Eng. 2005, 8, 1–14. [Google Scholar] [CrossRef]

- ABB. Low Voltage Motors Motor Guide; ABB: Zurich, Switzerland, 2018. [Google Scholar]

- WEG. Specification of Electric Motors; WEG: Jaraguá du Sol, Brazil, 2016. [Google Scholar]

- Jones, T. Motor Efficiency, Selection, and Management A Guidebook for Industrial Efficiency Programs; Consortium for Energy Efficiency: Boston, MA, USA, 2013. [Google Scholar]

- Chausovsky, A. Motor Market Update. In Proceedings of the Motor Summit, Zurich, Switzerland, 7–9 October 2014. [Google Scholar]

- Dick, J.; Hull, E.; Jackson, K. Requirements Engineering; Springer: Berlin, Germany, 2017; ISBN 978-3-319-61072-6. [Google Scholar]

- Arayici, Y.; Ahmed, V.; Aouad, G. A Requirements Engineering Framework for Integrated Systems Development for the Construction Industry. J. Inf. Technol. Constr. 2006, 11, 35–55. [Google Scholar]

- Rehman, S.; Gruhn, V. An Effective Security Requirements Engineering Framework for Cyber-Physical Systems. Technologies 2018, 6, 65. [Google Scholar] [CrossRef]

- Abo, R. Introduction to a Requirements Engineering Framework for Aeronautics. J. Softw. Eng. Appl. 2010, 3, 894–900. [Google Scholar] [CrossRef]

- Rivera, C.A.; Poza, J.; Ugalde, G.; Almandoz, G. A Knowledge Based System architecture to manage and automate the electrical machine design process. In Proceedings of the 2017 IEEE International Workshop of Electronics, Control, Measurement, Signals and Their Application to Mechatronics, ECMSM 2017, Donostia-San Sebastian, Spain, 24–26 May 2017. [Google Scholar]

- ABB Optimizer. Available online: http://www145.abb.com/selection (accessed on 14 November 2018).

- Kampker, A.; Kreisköther, K.; Büning, M.K.; Treichel, P.; Theelen, J. Automotive quality requirements and process capability in the production of electric motors. In Proceedings of the 2017 7th International Electric Drives Production Conference (EDPC), Würzburg, Germany, 5–6 December 2017. [Google Scholar]

- Dufrene, M. A methodological Framework to Support Integrated Ecodesign for Companies: Requirements and Conceptualization Towards a Software Platform. Ph.D. Thesis, University Grenoble Alpes, Saint-Martin-d’Hères, France, 2015. [Google Scholar]

- Jufer, M. Electric Drives: Design Methodology; Wiley-ISTE Press: London, UK, 2013; ISBN 9781848212176. [Google Scholar]

- Yilmaz, M. Limitations/capabilities of electric machine technologies and modeling approaches for electric motor design and analysis in plug-in electric vehicle applications. Renew. Sustain. Energy Rev. 2015, 52, 80–99. [Google Scholar] [CrossRef]

- Mccoy, G.A.; Douglass, J.G. Premium Efficiency Motor Selection and Application Guide—A Handbook for Industry; U.S. Department of Energy: Washington, DC, USA, 2014.

- Boteler, R.B.; Moore, M.E.; Turner, M.J. An evaluation and comparison of advanced motor technologies. In Proceedings of the 9th International Conference on Energy Efficiency in Motor Driven Systems, EEMODS 2015, Helsinki, Finland, 15–17 September 2015; pp. 412–423. [Google Scholar]

| Package | Requirements Examples |

|---|---|

| Application Essential Requirements Package | |

| Operability | Power sources, ratings, torque, speed, efficiency, service factor, duty cycle, environmental conditions, insulation, mounting, frame size. |

| Serviceability | Requirements related to ease of maintenance, ease of recycling, monitoring sensors (e.g., resistance temperature detectors (RTDs)). |

| Comfort | Noise and Vibrations, dynamic smoothness control, continuous operation smoothness. |

| Reliability | Life expectancy, permissible design or manufacturing tolerances, lead times, fault tolerances, tests. |

| Special | Transportation, training, mounting, assembly (e.g., on site), commissioning. |

| Regulations/standards/policies | Regulations, standards or policies that the motor must accomplish or follow. |

| Technical Derived Requirements Package | |

| Mechanical | Shaft torque, vibration and noise levels, types of bearings, rotor inertia, speed, shaft design, frame design, stresses, thermal constraints, cooling systems options, mounting constraints, enclosure type with the environment, insulation, size constraints, materials, sensors, related standards/regulations/policies, and others. |

| Electrical | Electromagnetic torque, winding arrangement, power factor, efficiency, voltage constraints, current constraints, size constraints, number of phases, insulation, thermal constraints, losses, torque density, electric motor type, materials, duty cycle or speed vs. torque curve, inductances, electromagnetic interferences, sensors, converter type, converter power ratings, related standards/regulations/policies, and others. |

| Control | Control strategy, switching frequency, converter type, sensors, phases, related standards/regulations/policies, and others. |

| Manufacturing | Machined lamination, stamped lamination, coil formation, encapsulation, impregnation, interference fit, rotor balancing, winding process, magnets mounting, magnets retention, magnetization, winding process, machined shaft, forged shaft, stack assembly, tolerances, related standards/regulations/policies, and others. |

| Motor General or Specific Objectives | Cost, materials, efficiency, lead time manufacturing, lead time design, motor type, life cycle, and others not included in other requirements classification. |

| Requirement Package ID | Package Name |

|---|---|

| InRS | Integrator’s requirements |

| MechRS | Mechanical engineering requirements |

| ElecRS | Electrical engineering requirements |

| ControlRS | Control engineering requirements |

| ManufRS | Manufacturing engineering requirements |

| ObjRS | Set objectives during the development process |

| ElecmgnRS | Electromagnetic requirements |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rivera, C.A.; Poza, J.; Ugalde, G.; Almandoz, G. A Requirement Engineering Framework for Electric Motors Development. Appl. Sci. 2018, 8, 2391. https://doi.org/10.3390/app8122391

Rivera CA, Poza J, Ugalde G, Almandoz G. A Requirement Engineering Framework for Electric Motors Development. Applied Sciences. 2018; 8(12):2391. https://doi.org/10.3390/app8122391

Chicago/Turabian StyleRivera, Christian A., Javier Poza, Gaizka Ugalde, and Gaizka Almandoz. 2018. "A Requirement Engineering Framework for Electric Motors Development" Applied Sciences 8, no. 12: 2391. https://doi.org/10.3390/app8122391