Proportioning and Characterization of Reactive Powder Concrete for an Energy Storage Pile Application

Abstract

:1. Introduction

2. Materials and Experimental Procedures

2.1. Materials

2.2. Design of Mixture Proportions Using Response Surface Method

2.3. Mixing Procedure and Preparation of Testing Specimens

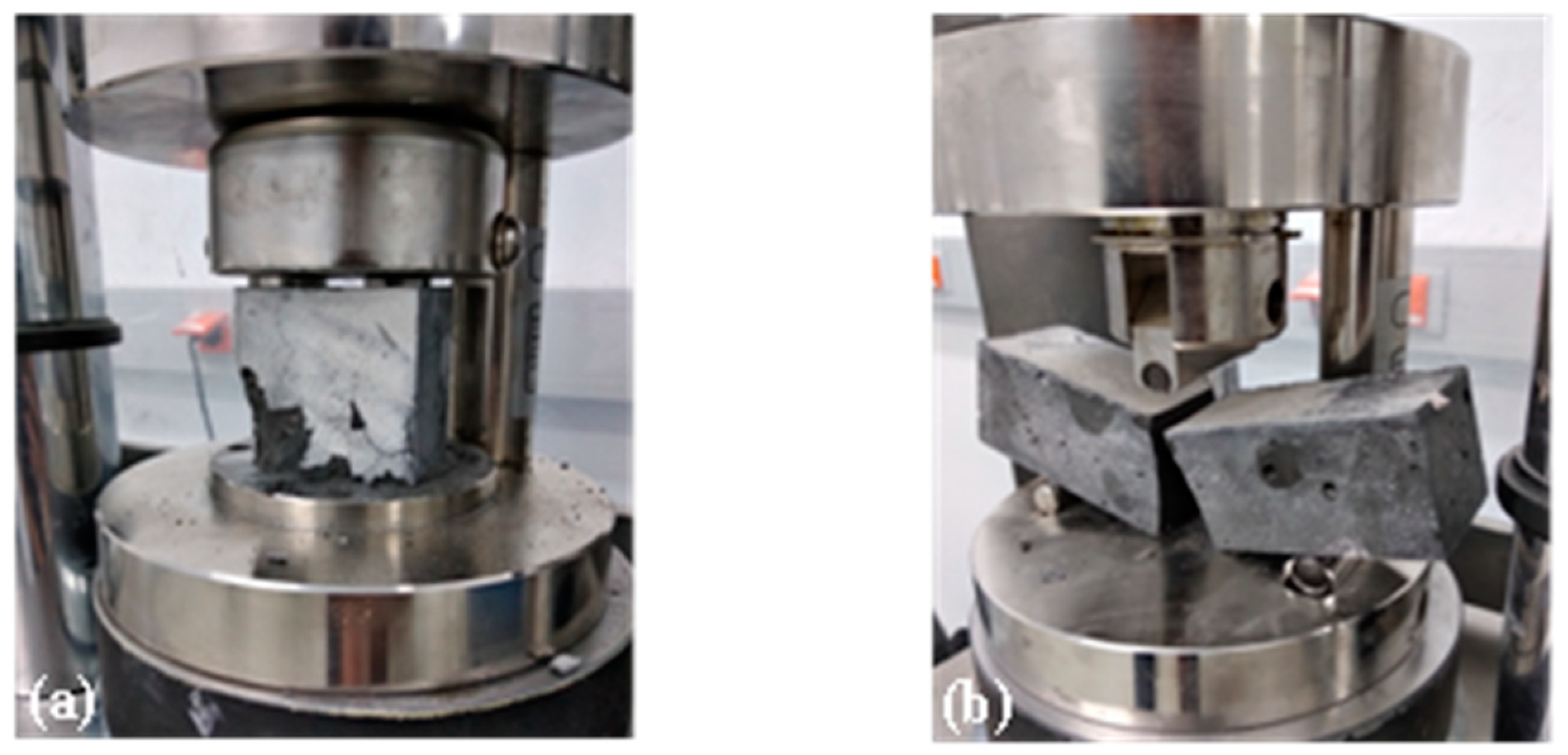

2.4. Fresh and Hardened Concrete Tests

3. Test Results

3.1. Fresh Properties of RPC

3.1.1. Flowability of RPC

3.1.2. Penetration Resistance and Setting Time

3.1.3. Relationship between Setting Time and Flowability

3.2. Hardened Properties of RPC

3.2.1. Compressive Strength Development of RPC

3.2.2. Effect of WB and Curing Temperature on Compressive and Flexural Strength

3.2.3. Effect of SF and Curing Temperature on Compressive and Flexural Strength

3.2.4. Drying Shrinkage of RPC

3.2.5. Effect of WB and Curing Temperature on Drying Shrinkage

4. Discussion

4.1. Optimization of the RPC Mix Design Component

4.2. Comparison of Test Results and Analytical Simulations

5. Conclusions

- (1)

- Except for a plain mixture (0.22WB-0SF) with a relative lower SP content (1%), the relative flowability of RPC decreased as the SF content increased for the mixtures with a constant WB. At the same time, the relative flowability of RPC decreased as the WB decreased for the mixtures with constant SF content.

- (2)

- For the RPC with a certain amount of SF, the penetration resistance increased as the SF content increased for mixtures with constant WB. For a fixed SF content, the penetration resistance increased as the WB decreased.

- (3)

- Both the initial and final setting times increased with the increase in the WB, but a higher WB plays a more critical role in controlling the setting time in the RPC mixture. At a high dosage of SF content, a further increase of SF content has no significant effect on both the initial and final set times, although increasing the SF content slightly decreases setting.

- (4)

- As the WB increased from 0.18 to 0.22, the compressive and flexural strengths of the RPC mixture increased, but a further increase of WB from 0.22 to 0.26 led to a significant drop in both strengths.

- (5)

- During the early age of curing, the compressive and flexural strengths of the RPC cured at the warm temperature are greater than that of concrete cured at a normal temperature. However, after the age of 7 days, the strength development trend of RPC became reversed.

- (6)

- Increasing the SF content from 15% to 20% increased the compressive and flexural strengths of RPC. Further increasing the SF content from 20% to 25% decreased the strength.

- (7)

- For one-day air-curing condition, plain concrete has less drying shrinkage than RPC. However, for seven-day moist-curing conditions, RPC has less drying shrinkage than plain concrete, despite its higher paste content.

- (8)

- Based on the RSM analysis, the optimum WB and SF content to achieve the highest strength was determined to be WB = 0.213 and SF = 20.0%, and the corresponding compressive strength was 84.91 MPa. This combination is similar to the tested mixture design of the WB = 0.22 and SF = 20%, which had an average strength of 84.80 MPa.

- (9)

- The RPC studied in this paper generally has a tensile strength that is higher than the maximum circumferential tensile stress demand generated from air pressure in the energy storage pile. It indicates that the RPC is potentially suitable for the energy storage pile application, since the considerable high tensile stress is a major concern for the safety of the pile.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Sun, H.; Li, Z.; Memom, S.A.; Zhang, Q.; Wang, Y.; Liu, B.; Xu, W.; Xing, F. Influence of Ultrafine 2CaO SiO2 Powder on Hydration Properties of Reactive Powder Concrete. Materials 2015, 8, 6195–6207. [Google Scholar] [CrossRef]

- Chan, Y.W.; Chu, S.H. Effect of silica fume on steel fiber bond characteristics in reactive powder concrete. Cem. Concr. Res. 2004, 34, 1167–1172. [Google Scholar] [CrossRef]

- Beglarigale, A.; Yazici, H. Pull-out behavior of steel fiber embedded in flowable RPC and ordinary mortar. Constr. Build. Mater. 2015, 75, 255–265. [Google Scholar] [CrossRef]

- Ahmad, S.; Zubair, A.; Maslehuddin, M. Effect of key mixture parameters on flow and mechanical properties of reactive powder concrete. Constr. Build. Mater. 2015, 99, 73–81. [Google Scholar] [CrossRef]

- Tam, C.M.; Tam, V.W.Y.; Ng, K.M. Optimal conditions for producing reactive powder concrete. Mag. Concr. Res. 2010, 62, 704–716. [Google Scholar] [CrossRef]

- Ji, T.; Chen, B.; Zhuang, Y.; Li, F.; Huang, Z.; Liang, Y. Effects of sand particle size and gradation on strength of reactive powder concrete. Adv. Mater. Res. 2011, 261–263, 208–211. [Google Scholar] [CrossRef]

- Abbas, S.; Nehdi, M.L.; Saleem, M.A. Ultra-high performance concrete: Mechanical erformance, durability, sustainability and implementation challenges. Int. J. Concr. Struct. Mater. 2016, 10, 271–295. [Google Scholar] [CrossRef]

- Vagelis, G.P. Experimental investigation and theoretical modeling of silica fume activity in concrete. Cem. Concr. Res. 1999, 29, 79–86. [Google Scholar]

- Wang, D.; Shi, C.; Wu, Z.; Xiao, J.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of ultra-high performance fibre reinforced concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Bonneau, O.; Lachemi, M.; Dallaire, E.; Dugat, J.; Aitcin, P.-C. Mechanical properties and durability of two industrial reactive powder concretes. ACI Mater. J. 1997, 94, 286–290. [Google Scholar]

- Yazici, H.; Yardimci, M.Y.; Aydin, S.; Karabulut, A.Ş. Mechanical properties of reactive powder concrete containing mineral admixtures under different curing regimes. Constr. Build. Mater. 2009, 23, 1223–1231. [Google Scholar] [CrossRef]

- Yazici, H.; Deniz, E.; Baradan, B. The effect of autoclave pressure, temperature and duration time on mechanical properties of reactive powder concrete. Constr. Build. Mater. 2013, 42, 53–63. [Google Scholar] [CrossRef]

- Ipek, M.; Yilmaz, K.; SSümer, M.; Saribiyik, M. Effect of pre-setting pressure applied to mechanical behaviours of reactive powder concrete during setting phase. Constr. Build. Mater. 2011, 25, 61–68. [Google Scholar] [CrossRef]

- Halit, Y. The effect of curing conditions on compressive strength of ultra high strength concrete with high volume mineral admixtures. Build. Environ. 2007, 42, 2083–2089. [Google Scholar]

- Cwirzen, A. The effect of the heat-treatment regime on the properties of reactive powder concrete. Adv. Cem. Res. 2007, 19, 25–33. [Google Scholar] [CrossRef]

- Hiremath, P.N.; Yaragal, S.C. Influence of mixing method, speed and duration on the fresh and hardened properties of Reactive Powder Concrete. Constr. Build. Mater. 2017, 141, 271–288. [Google Scholar] [CrossRef]

- Abbas, S.; Soliman, A.M.; Nehdi, M.L. Exploring mechanical and durability properties of ultra-high performance concrete incorporating various steel fiber lengths and dosages. Constr. Build. Mater. 2015, 75, 429–441. [Google Scholar] [CrossRef]

- Zheng, W.; Luo, B.; Wang, Y. Compressive and tensile properties of reactive powder concrete with steel fibres at elevated temperatures. Constr. Build. Mater. 2013, 41, 844–851. [Google Scholar] [CrossRef]

- Liu, S.H.; Yan, P.Y.; Feng, J.W. Research and application of RPC in the bridge engineering. Highway 2009, 58, 149–154. [Google Scholar]

- Song, J.; Liu, S. Properties of reactive powder concrete and its application in highway bridge. Adv. Mater. Sci. Eng. 2016, 2016, 5460241. [Google Scholar] [CrossRef]

- Tulebekova, S.; Saliyev, D.; Zhang, D.; Kim, J.R.; Karabay, A.; Turlybek, A.; Kazybayeva, L. Preliminary Analytical Study on the Feasibility of Using Reinforced Concrete Pile Foundations for Renewable Energy Storage by Compressed Air Energy Storage Technology. In IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: London, UK, 2017; Volume 271, pp. 12–23. [Google Scholar] [CrossRef]

- Bektimirova, U.; Tleuken, A.; Satekenova, E.; Shon, C.S.; Zhang, D.; Kim, J.R. Preliminary Experimental Investigation on the Strength and Air Permeability of Reactive Powder Concrete. Mater. Sci. Forum 2018, 917, 321–328. [Google Scholar] [CrossRef]

- Sabirova, A.; Zhang, D.; Kim, J.R.; Nguyen, M.; Shon, C.S. Development of a Reinforced Concrete Foundation System for Renewable Energy Storage. In Challenges and Innovations in Geotechnics—Proceedings of the 8th Asian Young Geotechnical Engineers Conference, Astana, Kazakhstan, 5–7 August 2016; 8AYGEC 2016; CRC Press: Boca Raton, FL, USA, 2016; pp. 119–122. [Google Scholar]

- Zhang, D.; Kim, J.; Tulebekova, S.; Saliyev, D.; Lee, D.H. Structural Responses of Reinforced Concrete Pile Foundations Subjected to Pressures from Compressed Air for Renewable Energy Storage. Int. J. Concr. Struct. Mater. 2018, 12, 1–16. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars; ASTM C109; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- American Society for Testing and Materials. Standard Test Method for Flow of Hydraulic Cement Mortar; ASTM C1437; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- American Society for Testing and Materials. Standard Test Method for Time of Setting of Concrete Mixtures by Penetration Resistance; ASTM C403; ASTM International: West Conshohocken, PA, USA, 2001. [Google Scholar]

- American Society for Testing and Materials. Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading); ASTM C293; ASTM International: West Conshohocken, PA, USA, 2001. [Google Scholar]

- American Society for Testing and Materials. Standard Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete; ASTM C157; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- American Society for Testing and Materials. Standard Practice for Use of Apparatus for the Determination of Length Change of Hardened Cement Paste, Mortar, and Concrete; ASTM C490; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Lohtia, R.P.; Joshi, R.C. Mineral admixtures. In Concrete Admixture Handbook; Ramachandran, V.S., Ed.; Noyes Publications: Park Ridge, NJ, USA, 1996; 1153p. [Google Scholar]

- Elaty, M.A.A.; Ghazy, M.F. Performance of Portland cement mixes containing silica fume and mixed with lime-water. HBRC J. 2014, 10, 247–257. [Google Scholar] [CrossRef]

- Rao, G.A. Investigations on the performance of silica fume-incorporated cement pastes and mortars. Cem. Concr. Res. 2003, 33, 1765–1770. [Google Scholar] [CrossRef]

- Dave, N.; Misra, A.K.; Srivastava, A.; Kaushik, S.K. Setting time and standard consistency of quaternary binders: The influence of cementitious material addition and mixing. Int. J. Sustain. Built Environ. 2017, 6, 30–36. [Google Scholar] [CrossRef]

- Soroka, I. Portland Cement Paste and Concrete; The Macmillan Press Ltd.: London, UK, 1979; pp. 87–91. [Google Scholar]

- Verbeck, G.J.; Helmuth, R.H. Structure and physical properties of cement paste. In Proceedings of the Fifth International Symposium on the Chemistry of Cement, Tokyo, Japan, 7–11 October 1968; Part III. pp. 1–32. [Google Scholar]

- Kayali, O.; Haque, M.N.; Zhu, B. Drying shrinkage of fibre-reinforced lightweight aggregate concrete containing fly ash. Cem. Concr. Res. 1999, 29, 1835–1840. [Google Scholar] [CrossRef]

- Kim, J.J.; Taha, M.R. Experimental and Numerical Evaluation of Direct Tension Test for Cylindrical Concrete Specimens. Adv. Civ. Eng. 2014, 2014, 156926. [Google Scholar] [CrossRef]

| Components | Cement (by Mass) | SF (by Mass) |

|---|---|---|

| CaO [%] | 63.81 | 0.47 |

| SiO2 [%] | 21.45 | 95.6 |

| Al2O3 [%] | 4.45 | 0.45 |

| Fe2O3 [%] | 3.07 | 0.05 |

| SO3 [%] | 2.46 | - |

| MgO [%] | 2.42 | - |

| K2O [%] | 0.83 | - |

| Others | 1.02 | 1.53 |

| Loss on Ignition [%] | 0.49 | 1.90 |

| No. | Mixture ID | WB | Coded values of WB | SF [%] | Coded values of SF | Cement kg/m3 (m3) | SF kg/m3 (m3) | Sand kg/m3 (m3) | Water kg/m3 (m3) | Total Vol. m3 | SP [%] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.18WB-20SF | 0.18 | −1.41 | 20 | 0 | 1000 (0.317) | 200 (0.090) | 903 (0.376) | 216 (0.216) | 1.00 | 2 |

| 2 | 0.1917WB-23.54SF | 0.1917 | −1 | 23.54 | 1 | 971 (0.308) | 229 (0.103) | 861 (0.359) | 230 (0.230) | 1.00 | 2.5 |

| 3 | 0.22WB-25SF | 0.22 | 0 | 25 | 1.41 | 960 (0.305) | 240 (0.108) | 776 (0.323) | 264 (0.264) | 1.00 | 1.5 |

| 4 | 0.22WB-20SF | 0.22 | 0 | 20 | 0 | 1000 (0.317) | 200 (0.090) | 788 (0.328) | 264 (0.264) | 1.00 | 1.5 |

| 5 | 0.2483WB-23.54SF | 0.2483 | 1 | 23.54 | 1 | 971 (0.308) | 229 (0.103) | 698 (0.291) | 298 (0.298) | 1.00 | 1.125 |

| 6 | 0.26WB-20SF | 0.26 | 1.41 | 20 | 0 | 1000 (0.317) | 200 (0.090) | 673 (0.280) | 312 (0.312) | 1.00 | 1.5 |

| 7 | 0.2483WB-16.46SF | 0.2483 | 1 | 16.46 | −1 | 1030 (0.327) | 170 (0.077) | 716 (0.298) | 298 (0.298) | 1.00 | 1 |

| 8 | 0.22WB-15SF | 0.22 | 0 | 15 | −1.41 | 1043 (0.331) | 157 (0.071) | 802 (0.334) | 264 (0.264) | 1.00 | 1.5 |

| 9 | 0.1917WB-16.46SF | 0.1917 | −1 | 16.46 | −1 | 1030 (0.327) | 170 (0.077) | 879 (0.366) | 230 (0.230) | 1.00 | 2.50 |

| 10 | 0.18WB-0SF | 0.18 | NA | 0 | NA | 1200 (0.381) | 0 (0) | 967 (0.403) | 216 (0.216) | 1.00 | 1.5 |

| 11 | 0.22WB-0SF | 0.22 | NA | 0 | NA | 1200 (0.381) | 0 (0) | 852 (0.355) | 264 (0.264) | 1.00 | 1.0 |

| 12 | 0.26WB-0SF | 0.26 | NA | 0 | NA | 1200 (0.381) | 0 (0) | 737 (0.307) | 312 (0.312) | 1.00 | 0.5 |

| No. | Mixture ID | Before Dropping | After Dropping | Γm | Porosity | ||||

|---|---|---|---|---|---|---|---|---|---|

| d1 (mm) | d2 (mm) | 7-d | 28-d | 56-d | |||||

| 1 | 0.18WB-20SF | 110 | 110 | 150 | 150 | 1.25 | 3.84 | 4.14 | 5.28 |

| 2 | 0.1917WB-23.54SF | 100 | 107 | 195 | 200 | 2.90 | 5.27 | 5.77 | 5.44 |

| 3 | 0.22WB-25SF | 105 | 100 | 165 | 165 | 1.72 | 6.72 | 6.66 | 5.40 |

| 4 | 0.22B-20SF | 125 | 120 | 205 | 200 | 3.10 | 5.60 | 5.27 | 4.04 |

| 5 | 0.2483WB-23.54SF | 115 | 115 | 200 | 190 | 2.80 | 9.18 | 7.43 | 7.98 |

| 6 | 0.26WB-20SF | 120 | 125 | 250 | 250 | 5.25 | 12.95 | 15.05 | 10.80 |

| 7 | 0.2483WB-16.46SF | 110 | 110 | 150 | 155 | 1.33 | 8.43 | 8.77 | 7.13 |

| 8 | 0.22WB-15SF | 120 | 125 | 210 | 205 | 3.10 | 9.24 | 8.65 | 11.34 |

| 9 | 0.1917WB-16.46SF | 110 | 110 | 175 | 165 | 1.89 | 10.15 | 5.58 | 3.59 |

| 10 | 0.18WB-0SF | 100 | 105 | 130 | 135 | 0.76 | 11.74 | 7.27 | 2.95 |

| 11 | 0.22WB-0SF | 100 | 100 | 160 | 165 | 1.64 | 10.17 | 13.47 | 8.61 |

| 12 | 0.26WB-0SF | 100 | 100 | 165 | 160 | 1.64 | 14.77 | 16.20 | 9.60 |

| No. | Mixture | Density (g/cm3) | Porosity * | Porosity/Density | |||

|---|---|---|---|---|---|---|---|

| Normal Curing | Warm Curing | Normal Curing | Warm Curing | Normal Curing | Warm Curing | ||

| 1 | 0.18WB-20SF | 2.23 | 2.19 | 4.14 | 5.75 | 1.85 | 2.62 |

| 2 | 0.22WB-0SF | 2.26 | 2.24 | 13.47 | 13.10 | 5.95 | 5.84 |

| 3 | 0.22WB-15SF | 2.21 | 2.24 | 8.65 | 8.16 | 3.92 | 3.65 |

| 4 | 0.22B-20SF | 2.17 | 2.20 | 5.27 | 11.35 | 2.43 | 5.15 |

| 5 | 0.22WB-25SF | 2.19 | 2.18 | 6.66 | 10.73 | 3.03 | 4.92 |

| 6 | 0.26WB-20SF | 2.18 | 2.20 | 15.05 | 13.30 | 6.89 | 6.04 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bektimirova, U.; Shon, C.-S.; Zhang, D.; Sharafutdinov, E.; Kim, J.R. Proportioning and Characterization of Reactive Powder Concrete for an Energy Storage Pile Application. Appl. Sci. 2018, 8, 2507. https://doi.org/10.3390/app8122507

Bektimirova U, Shon C-S, Zhang D, Sharafutdinov E, Kim JR. Proportioning and Characterization of Reactive Powder Concrete for an Energy Storage Pile Application. Applied Sciences. 2018; 8(12):2507. https://doi.org/10.3390/app8122507

Chicago/Turabian StyleBektimirova, Umut, Chang-Seon Shon, Dichuan Zhang, Eldar Sharafutdinov, and Jong R. Kim. 2018. "Proportioning and Characterization of Reactive Powder Concrete for an Energy Storage Pile Application" Applied Sciences 8, no. 12: 2507. https://doi.org/10.3390/app8122507