Potential of Waste Oyster Shells as a Novel Biofiller for Hot-Mix Asphalt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Oyster Shell Powder (OSP)

2.2. Preparation of Filler-Asphalt Mastic Samples

2.3. Fourier Transform-Infrared Spectroscopy (FT-IR)

2.4. X-ray Diffraction (XRD)

2.5. Thin-Layer Chromatography-Flame Ionization Detection (TLC-FID)

2.6. Scanning Electron Microscope (SEM)

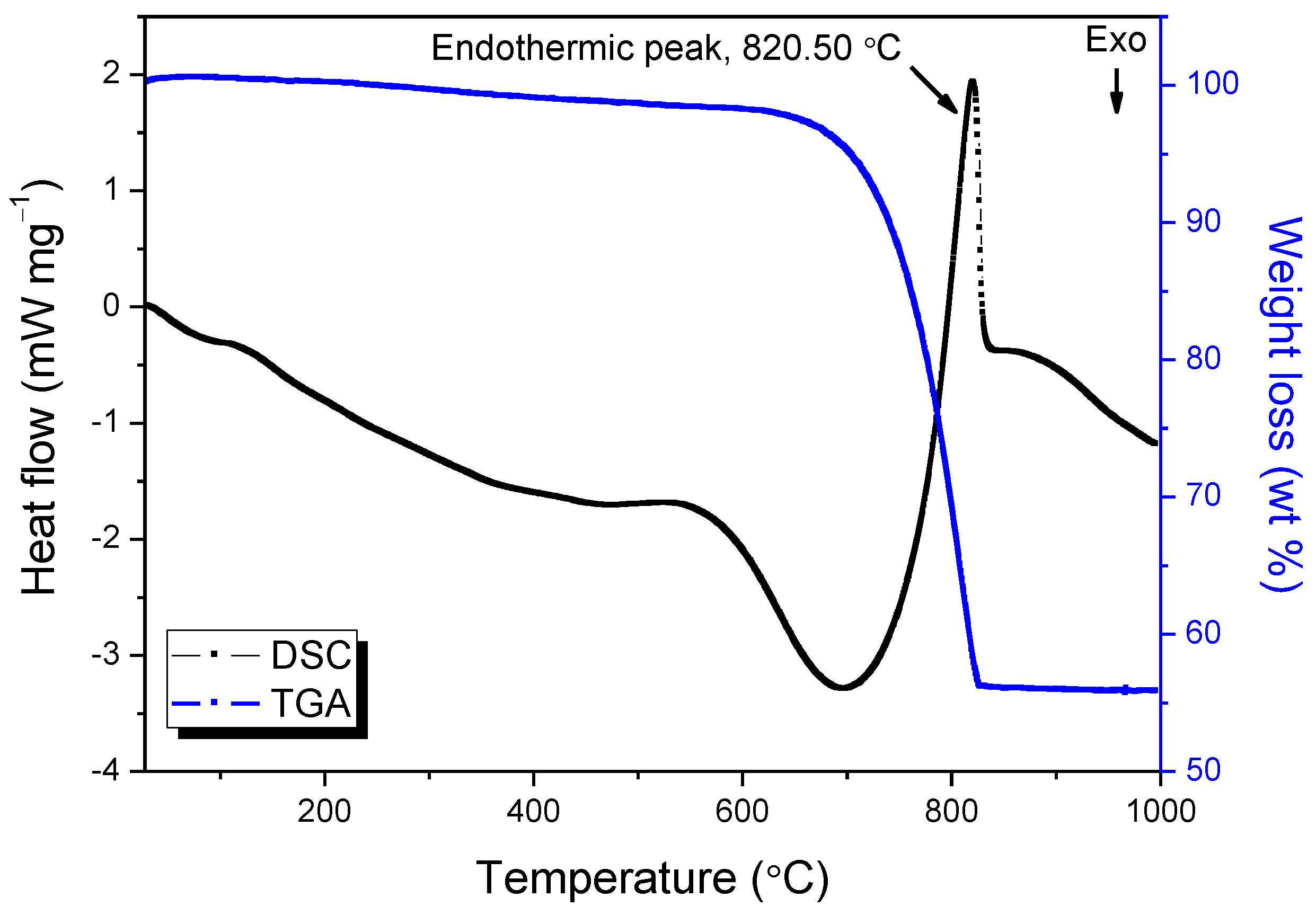

2.7. Thermogravimetric Analysis (TGA/DTGA)

2.8. Differential Scanning Calorimetry (DSC)

2.9. Conventional Asphalt Binder Tests (Penetration, Softening Point, and Ductility)

2.10. Dynamic Shear Rheometer (DSR)

3. Results

3.1. Chemical Composition of Oyster Shell Powder (OSP)

3.2. Particle-Size Distribution (PSD) of Oyster Shell Powder (OSP)

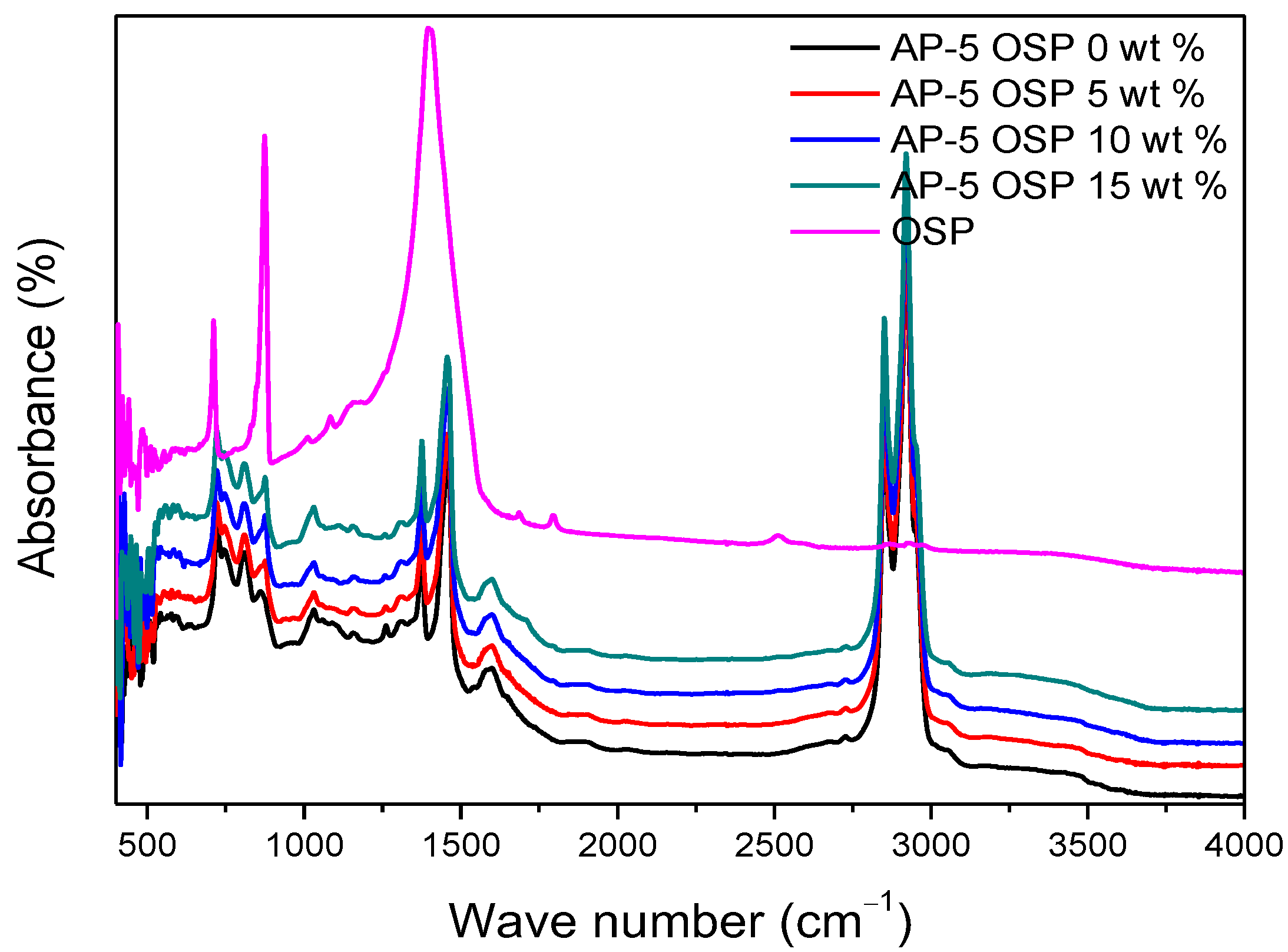

3.3. Fourier Transform-Infrared Spectroscopy (FT-IR)

3.4. X-ray Diffraction (XRD)

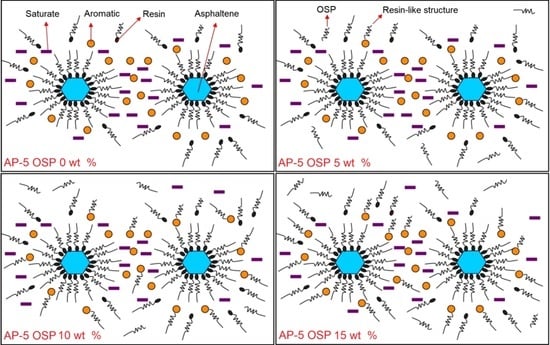

3.5. Thin-Layer Chromatography-Flame Ionization Detection (TLC-FID)

3.6. Conventional Asphalt Binder Tests (Penetration, Softening Point, and Ductility)

- (1)

- Volumetric-filling reinforcement: the stiffening caused by the presence of rigid inclusions (e.g., mineral filler) in a less rigid matrix (e.g., viscoelastic binder).

- (2)

- Physicochemical reinforcement: the stiffening caused by the interfacial effects between filler particles and asphalt, including adsorption, absorption, and selective sorption. Here, the treated asphalt efficiently creates a rigid layer, which leads to a higher net volume concentration of rigid matter, increasing thereby the mastic stiffness.

- (3)

- Particle-interaction reinforcement: the stiffening beyond physicochemical reinforcement and volume filling. This effect increases with increasing filler dosage, as rigid matter accumulates a skeletal framework form [51].

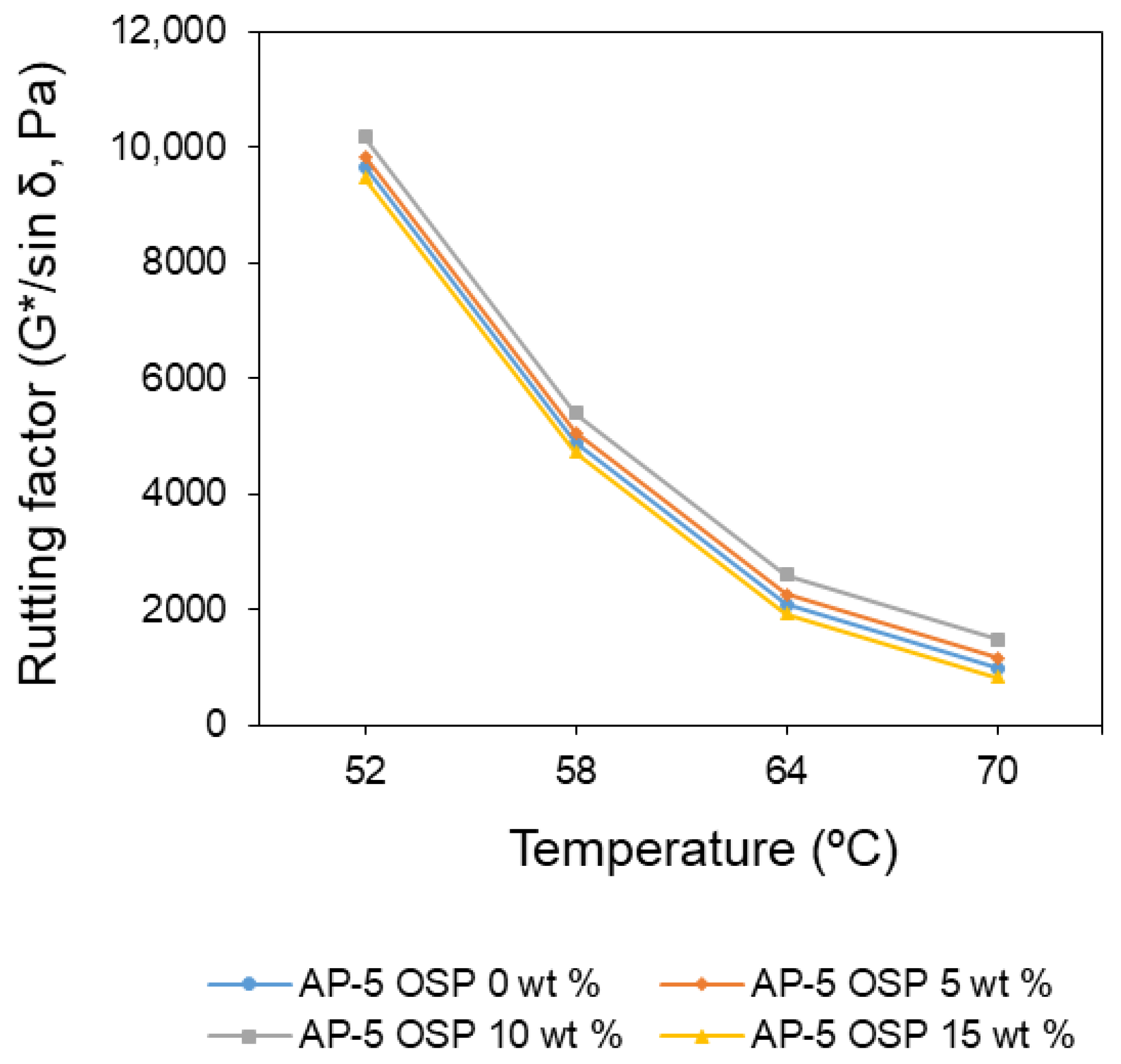

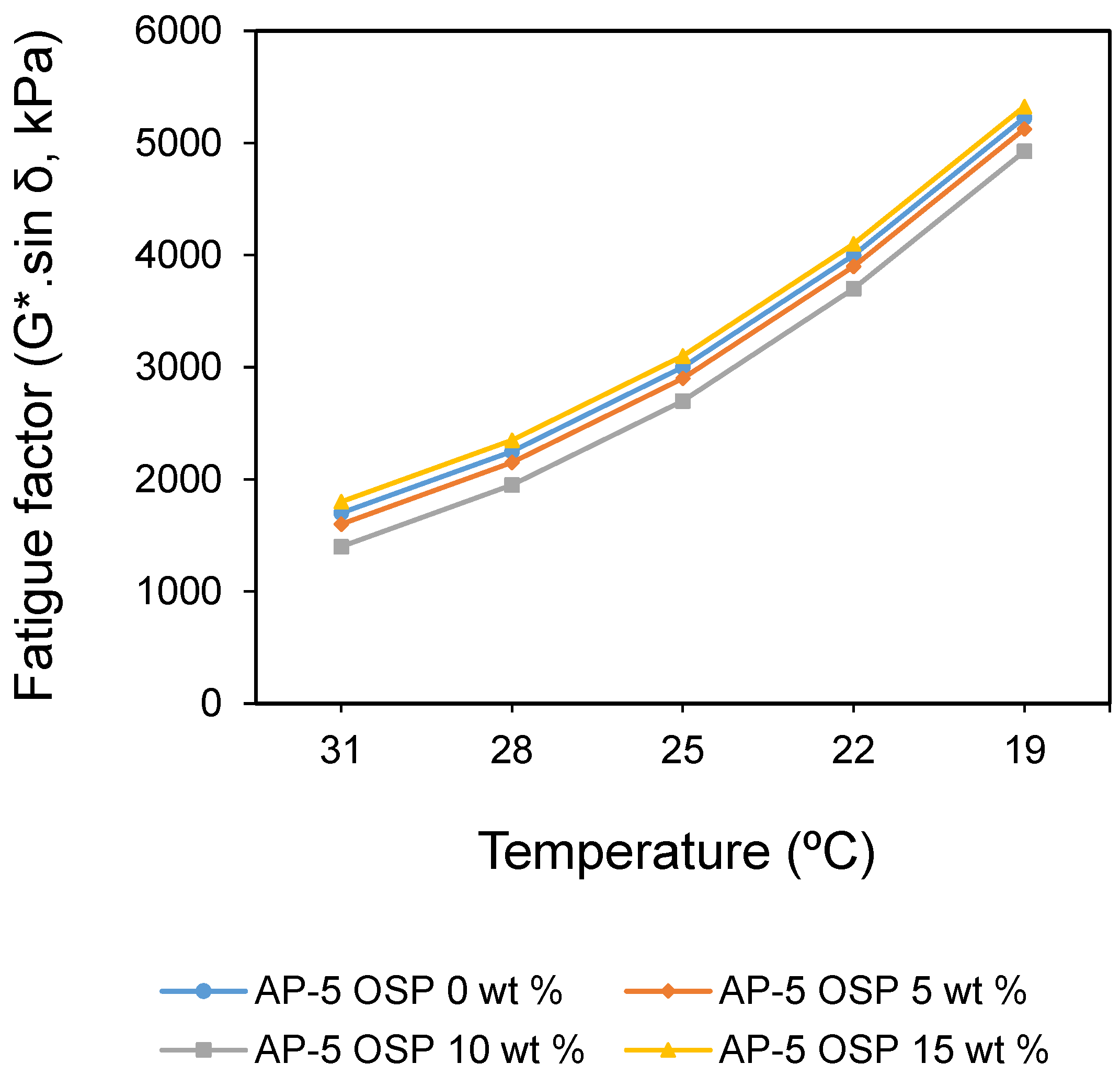

3.7. Dynamic Shear Rheometer (DSR) Test

3.7.1. Rutting Performance (G*/sin δ)

3.7.2. Fatigue Cracking Performance (G*.sin δ)

3.8. Scanning Electron Microscope (SEM)

3.9. Thermogravimetric Analysis (TGA/DTGA)

3.10. Differential Scanning Calorimetry (DSC)

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Read, J.; Whiteoak, D. The Shell Bitumen Handbook, 5th ed.; Thomas Telford Publishing: London, UK, 2003; p. 464. ISBN 13:978-0727732200. [Google Scholar]

- Transportation Research Board of the National Academies. Chapter 4. Aggregates. In NCHRP (National Cooperative Highway Research Program) REPORT 673—A Manual for Design of Hot Mix Asphalt with Commentary; National Academy of Sciences: Washington, DC, USA, 2011; pp. 28–45. ISBN 978-0-309-15564-9. [Google Scholar]

- Lee, D.Y. The Effect of Filler on Asphalt Cement Mastics. Ph.D. Thesis, Iowa State University of Science and Technology, Ames Iowa, USA, 1964. [Google Scholar]

- Chen, J.S. Rheological Properties of Asphalt-Mineral Filler Mastics. J. Jpn. Soc. Civil Eng. 1997, 36, 269–277. [Google Scholar] [CrossRef]

- Kim, M.; Buttlar, W. Stiffening Mechanisms of Asphalt-Aggregate Mixtures. Transp. Res. Rec. J. Transp. Res. Board 2010, 2181, 98–108. [Google Scholar] [CrossRef]

- Underwood, B.S.; Kim, Y.R. Experimental investigation into the multiscale behavior of asphalt concrete. Int. J. Pavement Eng. 2011, 12, 357–370. [Google Scholar] [CrossRef]

- Clopotel, C.; Velasquez, R.; Bahia, H. Measuring physico-chemical interaction in mastics using glass transition. Road Mater. Pavement 2012, 13, 304–320. [Google Scholar] [CrossRef]

- Rigden, P.J. The use of fillers in bituminous road surfacings. A study of filler-binder systems in relation to filler characteristics. J. Chem. Technol. Biot. 1947, 66, 299–309. [Google Scholar] [CrossRef]

- Heukelom, W. The role of filler in bituminous mixes. J. Assoc. Asph. Paving Technol. 1965, 34, 396–429. [Google Scholar]

- Anderson, D.A. Mechanical Behavior and Reinforcement of Mineral Filler-Asphalt Mixtures. J. Assoc. Asph. Paving Technol. 1973, 42, 37–66. [Google Scholar]

- Craus, J.; Ishai, I.; Sides, A. Some physico-chemical aspects of the effect and the role of the filler in bituminous paving mixtures. J. Assoc. Asph. Paving Technol. 1978, 46, 558–588. [Google Scholar]

- Davis, C.; Castorena, C. Implications of physico-chemical interactions in asphalt mastics on asphalt microstructure. Constr. Build. Mater. 2015, 94, 83–89. [Google Scholar] [CrossRef]

- Fini, E.H.; Al-Qadi, I.L.; You, Z.; Zada, B.; Mills-Beale, J. Partial replacement of asphalt binder with bio-binder: Characterization and modification. Int. J. Pavement Eng. 2012, 13, 515–522. [Google Scholar] [CrossRef]

- Dhasmana, H.; Ozer, H.; Al-Qadi, I.L.; Zhang, Y.; Schideman, L.; Sharma, B.K.; Chen, W.T.; Minarick, M.J.; Zhang, P. Rheological and Chemical Characterization of Biobinders from Different Biomass Resources. Transp. Res. Rec. J. Transp. Res. Board 2015, 2505, 121–129. [Google Scholar] [CrossRef]

- Guarin, A.; Khan, A.; Butt, A.A.; Birgisson, B.; Kringos, N. An extensive laboratory investigation of the use of bio-oil modified bitumen in road construction. Constr. Build. Mater. 2016, 106, 133–139. [Google Scholar] [CrossRef]

- Kowalski, K.J.; Król, J.B.; Bańkowski, W.; Radziszewski, P.; Sarnowski, M. Thermal and Fatigue Evaluation of Asphalt Mixtures Containing RAP Treated with a Bio-Agent. Appl. Sci-Basel 2017, 7, 216. [Google Scholar] [CrossRef]

- Król, J.B.; Niczke, Ł.; Kowalski, K.J. Towards Understanding the Polymerization Process in Bitumen Bio-Fluxes. Materials 2017, 10, 1058. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Lin, J.; Wu, S. Potential of recycled fine aggregates powder as filler in asphalt mixture. Constr. Build. Mater. 2011, 25, 3909–3914. [Google Scholar] [CrossRef]

- Chandra, S.; Kumar, P.; Feyissa, B.A. Use of Marble Dust in Road Construction. Road Mater. Pavement 2002, 3, 317–330. [Google Scholar] [CrossRef]

- Modarres, A.; Rahmanzadeh, M. Application of coal waste powder as filler in hot mix asphalt. Constr. Build. Mater. 2014, 66, 476–483. [Google Scholar] [CrossRef]

- Saltan, M.; Öksüz, B.; Uz, V.E. Use of glass waste as mineral filler in hot mix asphalt. Sci. Eng. Compos. Mater. 2015, 22, 271–277. [Google Scholar] [CrossRef]

- Sargin, Ş.; Saltan, M.; Morova, N.; Serin, S.; Terzi, S. Evaluation of rice hush ash as filler in hot mix asphalt concrete. Constr. Build. Mater. 2013, 48, 390–397. [Google Scholar] [CrossRef]

- Jeffry, S.N.; Jaya, R.P.; Hassan, N.A.; Yaacob, H.; Mirza, J.; Drahman, S.H. Effect of nanocharcoal coconut-shell ash on the physical and rheological properties of bitumen. Constr. Build. Mater. 2018, 158, 1–10. [Google Scholar] [CrossRef]

- Kiruthiha, K.; Loshini, G.; Thivya, M. Strengthening of Flexible Pavement using Egg Shell as a Filler. Int. J. Eng. Trends Technol. (IJETT) 2015, 21, 483–486. [Google Scholar] [CrossRef]

- Arabani, M.; Babamohammadi, S.; Azarhoosh, A.R. Experimental investigation of seashells used as filler in hot mix asphalt. Int. J. Pavement Eng. 2014, 16, 502–509. [Google Scholar] [CrossRef]

- KDI (Korea Development Institute). Report of Economic Policy (in Korean); KDI (Korea Development Institute): Seoul, Korea, 2002. [Google Scholar]

- Yoon, G.L.; Kim, B.T.; Kim, B.O.; Han, S.H. Chemical–mechanical characteristics of crushed oyster-shell. Waste Manag. 2003, 23, 825–834. [Google Scholar] [CrossRef]

- Lee, J.Y.; Lee, C.H.; Ha, B.H.; Kim, S.C.; Lee, D.K.; Kim, P.J. Effect of Oyster Shell Meal on Improving Soil Microbiological Activity. Korean J. Soil Sci. Fertil. 2005, 38, 281–286. [Google Scholar]

- Yang, E.I.; Yi, S.T.; Leem, Y.M. Effect of oyster shell substituted for fine aggregate on concrete characteristics: Part I. Fundamental properties. Cement Concr. Res. 2005, 35, 2175–2182. [Google Scholar] [CrossRef]

- Lee, C.H.; Lee, J.Y.; Ha, B.H.; Kim, P.J. Increased Available Phosphate by Shell Meal Fertilizer Application in Upland Soil. Korean J. Soil Sci. Fertil. 2005, 38, 52–57. [Google Scholar]

- American Association of State Highway and Transportation Officials. AASHTO T-37, Sieve Analysis of Mineral Filler for Hot Mix Asphalt (HMA); American Association of State Highway and Transportation Officials: Washington, DC, USA, 2011. [Google Scholar]

- Masson, J.F.; Price, T.; Collins, P. Dynamics of Bitumen Fractions by Thin-Layer Chromatography/Flame Ionization Detection. Energy Fuels 2001, 15, 955–960. [Google Scholar] [CrossRef]

- American Society of Testing Materials (ASTM) International. ASTM D36/D36M-14e1, Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus); American Society of Testing Materials (ASTM) International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- American Society of Testing Materials (ASTM) International. ASTM D113-07, Standard Test Method for Ductility of Bituminous Materials; American Society of Testing Materials (ASTM) International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- American Society of Testing Materials (ASTM) International. ASTM D5/D5M-13, Standard Test Method for Penetration of Bituminous Materials; American Society of Testing Materials (ASTM) International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Zhang, J.; Wang, J.; Wu, Y.; Wang, Y.; Wang, Y. Evaluation of the improved properties of SBR/weathered coal modified bitumen containing carbon back. Constr. Build. Mater. 2009, 23, 2678–2687. [Google Scholar] [CrossRef]

- Karmakar, S.; Roy, T.K. Effect of Waste Plastic and Waste Tires Ash on Mechanical Behavior of Bitumen. J. Mater. Civil Eng. 2016, 28. [Google Scholar] [CrossRef]

- American Society of Testing Materials (ASTM) International. ASTM D7175-15, Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer; American Society of Testing Materials (ASTM) International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Tan, Y.; Li, X.; Wu, J. Internal Influence Factors of Asphalt-Aggregate Filler Interactions Based on Rheological Characteristics. J. Mater. Civil Eng. 2012, 24, 1520–1528. [Google Scholar]

- Zhang, J.; Li, X.; Liu, G.; Pei, J. Effects of material characteristics on asphalt and filler interaction ability. Int. J. Pavement Eng. 2017, 1–10. [Google Scholar] [CrossRef]

- Zaniewski, J.P.; Reyes, C.H. Evaluation of the Effect of Fines on Asphalt Concrete; Technical Report; West Virginia University: Morgantown, WV, USA, 2003. [Google Scholar]

- Muniandy, R.; Aburkaba, E.; Yunus, R.; Hamid, H.; Salihudin, H. Influence of Mineral Filler Particle Size and Type on Rheological and Performance Properties of SMA Asphalt-filler Mastics. Asian J. Appl. Sci. 2012, 5, 522–537. [Google Scholar]

- Wen, H.; Zhang, K.; Hobbs, A.; Edburg, S.L. Microstructural characterization and micromechanics of asphaltic materials–II: Simulation of drying aggregate in asphalt plants. In Asphalt Pavements, 2nd ed.; Kim, R.Y., Ed.; CRC Press Taylor & Francis Group: London, UK; New York, NY, USA, 2014; Volume 1, pp. 963–970. ISBN 978-1-138-02693-3. [Google Scholar]

- Dukatz, E.L.; Anderson, D.A. The Effect of Various Fillers on the Mechanical Behavior of Asphalt and Asphaltic Concrete. J. Assoc. Asph. Pavements 1980, 49, 530–549. [Google Scholar]

- Naemchan, K.; Meejoo, S.; Onreabroy, W.; Limsuwan, P. Temperature Effect on Chicken Egg Shell Investigated by XRD, TGA, and FTIR. Adv. Mater. Res. 2008, 55–57, 333–336. [Google Scholar] [CrossRef]

- Jazie, A.A.; Pramanik, H.; Shinha, A.S.K.; Jazie, A.A. Egg Shell as Eco-friendly Catalyst for Transesterification of Rapeseed Oil: Optimization for Biodiesel Production. Int. J. Sustain. Dev. Green Econ. 2013, 2, 27–32. [Google Scholar]

- Siddiqui, M.N.; Ali, M.F.; Shirokoff, J. Use of X-ray diffraction in assessing the aging pattern of asphalt fractions. Fuel 2002, 81, 51–58. [Google Scholar] [CrossRef]

- AlHumaidan, F.S.; Hauser, A.; Rana, M.S.; Lababidi, H.M.S.; Behbehani, M. Changes in asphaltene structure during thermal cracking of residual oils: XRD study. Fuel 2015, 150, 558–564. [Google Scholar] [CrossRef]

- Rigo, V.A.; Metin, C.O.; Nguyen, Q.P.; Miranda, C.R. Hydrocarbon Adsorption on Carbonate Mineral Surfaces: A First Principles Study with van der Waals Interactions. J. Phys. Chem. C 2012, 116, 24538–24548. [Google Scholar] [CrossRef]

- Wang, H.; Grant, D.J.; Burns, P.C.; Na, C. Infrared Signature of the Cation-π Interaction between Calcite and Aromatic Hydrocarbons. Langmuir 2015, 31, 5820–5826. [Google Scholar] [CrossRef] [PubMed]

- Buttlar, W.G.; Bozkurt, D.; Al-Khateeb, G.G.; Waldhoff, A.S. Understanding Asphalt Mastic Behavior through Micromechanics. Transp. Res. Rec. J. Transp. Res. Board 1999, 1681, 157–169. [Google Scholar] [CrossRef]

- Al-Qadi, I.; Fini, E.; Elseifi, M.; Masson, J.F.; McGhee, K. Viscosity Determination of Hot-Poured Bituminous Sealants. Transp. Res. Rec. J. Transp. Res. Board 2006, 1958, 74–81. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Fini, E.H.; Elseifi, M.A.; Masson, J.F.; McGhee, K.M. Development of a Viscosity Specification for Hot-Poured Bituminous Sealants. J. Test. Eval. 2007, 35, 395–403. [Google Scholar]

- Winniford, R.S. The rheology of asphalt-filler systems as shown by the microviscometer. Am. Soc. Test. Mater. 1961, STP309, 109–120. [Google Scholar]

- Zapién-Castillo, S.; Rivera-Armenta, J.L.; Chávez-Cinco, M.Y.; Salazar-Cruz, B.A.; Mendoza-Martínez, A.M. Physical and rheological properties of asphalt modified with SEBS/montmorillonite nanocomposite. Constr. Build. Mater. 2016, 106, 349–356. [Google Scholar] [CrossRef]

- Shafabakhsh, G.H.; Ani, O.J. Experimental investigation of effect of Nano TiO2/SiO2 modified bitumen on the rutting and fatigue performance of asphalt mixtures containing steel slag aggregates. Constr. Build. Mater. 2015, 98, 692–702. [Google Scholar] [CrossRef]

- Nciri, N.; Kim, J.; Kim, N.; Cho, N. An In-Depth Investigation into the Physicochemical, Thermal, Microstructural, and Rheological Properties of Petroleum and Natural Asphalts. Materials 2016, 9, 859. [Google Scholar] [CrossRef] [PubMed]

- Asociación Española de Normalización y Certificación (AENOR). UNE-EN 13043, Aggregates for Bituminous Mixtures and Surface Treatments for Roads, Airfields and Other Trafficked Areas; Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2004. (In Spanish) [Google Scholar]

- Jahromi, S.G. Estimation of resistance to moisture destruction in asphalt mixtures. Constr. Build. Mater. 2009, 23, 2324–2331. [Google Scholar] [CrossRef]

- Woszuk, A.; Zofka, A.; Bandura, L.; Franus, W. Effect of zeolite properties on asphalt foaming. Constr. Build. Mater. 2017, 139, 247–255. [Google Scholar] [CrossRef]

- Woszuk, A.; Franus, W. A Review of the Application of Zeolite Materials in Warm Mix Asphalt Technologies. Appl. Sci-Basel 2017, 7, 293. [Google Scholar] [CrossRef]

- Zhang, Y.; Leng, Z.; Zou, F.; Wang, L.; Chen, S.S.; Tsang, D.C.W. Synthesis of zeolite A using sewage sludge ash for application in warm mix asphalt. J. Clean. Prod. 2018, 172, 686–695. [Google Scholar] [CrossRef]

- Oner, J.; Sengoz, B. Utilization of Recycled Asphalt Concrete with Warm Mix Asphalt and Cost-Benefit Analysis. PLoS ONE 2015, 10, e116180. [Google Scholar] [CrossRef] [PubMed]

- Masson, J.F.; Polomark, G.; Collins, P. Glass transitions and amorphous phases in SBS–bitumen blends. Thermochim. Acta 2005, 436, 96–100. [Google Scholar] [CrossRef]

- Nciri, N.; Kim, N.; Cho, N. New insights into the effects of styrene-butadiene-styrene polymer modifier on the structure, properties, and performance of asphalt binder: The case of AP-5 asphalt and solvent deasphalting pitch. Mater. Chem. Phys. 2017, 193, 477–495. [Google Scholar] [CrossRef]

- Clopotel, C.; Bahia, H. The effect of bitumen polar groups adsorption on mastics properties at low temperatures. Road Mater. Pavement 2013, 14, 38–51. [Google Scholar] [CrossRef]

- Guo, M.; Tan, Y.Q.; Zhang, L. Effect of Filler on Glass Transition of Asphalt Mastics. Adv. Eng. Forum 2012, 5, 376–381. [Google Scholar] [CrossRef]

- Tan, Y.; Guo, M. Study on the phase behavior of asphalt mastic. Constr. Build. Mater. 2013, 47, 311–317. [Google Scholar] [CrossRef]

| Elemental Analysis | |

|---|---|

| C (carbon) | 84.62 wt % |

| H (hydrogen) | 10.39 wt % |

| N (nitrogen) | 0.65 wt % |

| S (sulfur) | 3.69 wt % |

| O (oxygen) | 0.65 wt % |

| SARA Generic Fractions | |

| Saturates | 4.47 wt % |

| Aromatics | 17.45 wt % |

| Resins | 45.18 wt % |

| Asphaltenes | 32.90 wt % |

| Physical Properties | |

| Penetration at 25 °C | 60.00 dmm |

| Softening point | 50.00 °C |

| Ductility at 25 °C | 110.50 cm |

| Organic Compounds | Concentration (wt %) |

|---|---|

| C (carbon) | 12.072 |

| H (hydrogen) | 0.092 |

| N (nitrogen) | 0.189 |

| S (sulfur) | 0.000 |

| O (oxygen) | 34.023 |

| Total | 46.376 |

| Inorganic Compounds | Percentage (wt %) |

| CaO (calcium oxide) | 99.033 |

| SO3 (sulfur trioxide) | 0.518 |

| SrO (strontium oxide) | 0.311 |

| Fe2O3 (ferric oxide) | 0.086 |

| CuO (cupric oxide) | 0.030 |

| MnO (magnesium oxide) | 0.023 |

| Total | 100.00 |

| Parameter | Value |

|---|---|

| Span | 4.273 µm |

| Weighted residual | 0.12% |

| Specific surface area | 0.7582 m2 g−1 |

| D [3,2] | 7.91 µm |

| D [4,3] | 117 µm |

| Dv (10) | 2.98 µm |

| Dv (50) | 71.10 µm |

| Dv (90) | 307 µm |

| Mode | 162 µm |

| Sample | Penetration at 25 °C (dmm) | Penetration Index (PI) | Softening Point (°C) | Ductility at 25 °C (cm) |

|---|---|---|---|---|

| AP-5 OSP 0 wt % | 60.00 | −0.77 | 50.00 | 110.50 |

| AP-5 OSP 5 wt % | 58.20 | −0.11 | 53.00 | 103.33 |

| AP-5 OSP 10 wt % | 55.10 | +0.80 | 57.70 | 95.10 |

| AP-5 OSP 15 wt % | 52.50 | +1.24 | 60.50 | 89.50 |

| Sample | TGA/DTGA (°C) | −ΔW (wt %) | |||||

|---|---|---|---|---|---|---|---|

| Stage 1 | Stage 2 | Stage 3 | Tonset | Toffset | Tmax | ||

| OSP | 25.21–641.31 | 641.31–710.76 | 710.76–999.98 | 641.31 | 710.76 | 695.89 | 54.91 |

| AP-5 OSP 0 wt % | 25.39–362.23 | 362.23–457.56 | 457.56–999.97 | 362.23 | 457.56 | 432.27 | 14.29 |

| AP-5 OSP 5 wt % | 25.25–369.64 | 369.64–460.60 | 460.60–999.98 | 369.64 | 460.60 | 437.14 | 13.01 |

| AP-5 OSP 10 wt % | 25.14–374.47 | 347.47–460.72 | 460.72–999.98 | 374.47 | 460.72 | 437.80 | 14.11 |

| AP-5 OSP 15 wt % | 25.15–362.42 | 362.42–458.33 | 458.33–999.98 | 362.42 | 458.33 | 433.65 | 12.56 |

| Sample | Thermal Parameter | |||

|---|---|---|---|---|

| Tg1 (°C) | ΔCp1 (J g·°C−1) | Tg2 (°C) | ΔCp2 (J g·°C−1) | |

| OSP | † | † | † | † |

| AP-5 OSP 0 wt % | −26.70 | 0.1946 | 5.17 | 0.2360 |

| AP-5 OSP 5 wt % | −25.61 | 0.2083 | 9.37 | 0.2554 |

| AP-5 OSP 10 wt % | −28.91 | 0.2343 | 6.08 | 0.2559 |

| AP-5 OSP 15 wt % | −28.12 | 0.2077 | 5.74 | 0.2469 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nciri, N.; Shin, T.; Lee, H.; Cho, N. Potential of Waste Oyster Shells as a Novel Biofiller for Hot-Mix Asphalt. Appl. Sci. 2018, 8, 415. https://doi.org/10.3390/app8030415

Nciri N, Shin T, Lee H, Cho N. Potential of Waste Oyster Shells as a Novel Biofiller for Hot-Mix Asphalt. Applied Sciences. 2018; 8(3):415. https://doi.org/10.3390/app8030415

Chicago/Turabian StyleNciri, Nader, Taesub Shin, Haksoo Lee, and Namjun Cho. 2018. "Potential of Waste Oyster Shells as a Novel Biofiller for Hot-Mix Asphalt" Applied Sciences 8, no. 3: 415. https://doi.org/10.3390/app8030415

APA StyleNciri, N., Shin, T., Lee, H., & Cho, N. (2018). Potential of Waste Oyster Shells as a Novel Biofiller for Hot-Mix Asphalt. Applied Sciences, 8(3), 415. https://doi.org/10.3390/app8030415