3.1. Carbonation Depth of Cracked Concrete

Experimental results from Song et al. [

5] were used to verify the proposed model. Song et al. [

5] conducted an experimental study on the carbonation of concrete with different crack widths and mixing proportions. The concrete mixing proportions are shown in

Table 1. Concrete with high water to cement ratio represented low strength concrete. The concrete specimens were cured under water for 28 days at 20 °C. After curing, the specimens were put into a chamber at 65% RH for two weeks. Next, the concrete specimens were put into the CO

2 chamber for accelerated carbonation testing (CO

2 concentration was 10%, RH = 65%, temperature was about 25 °C). Splitting tests were used to induce 0.05 to 0.25 mm cracks into the concrete specimens.

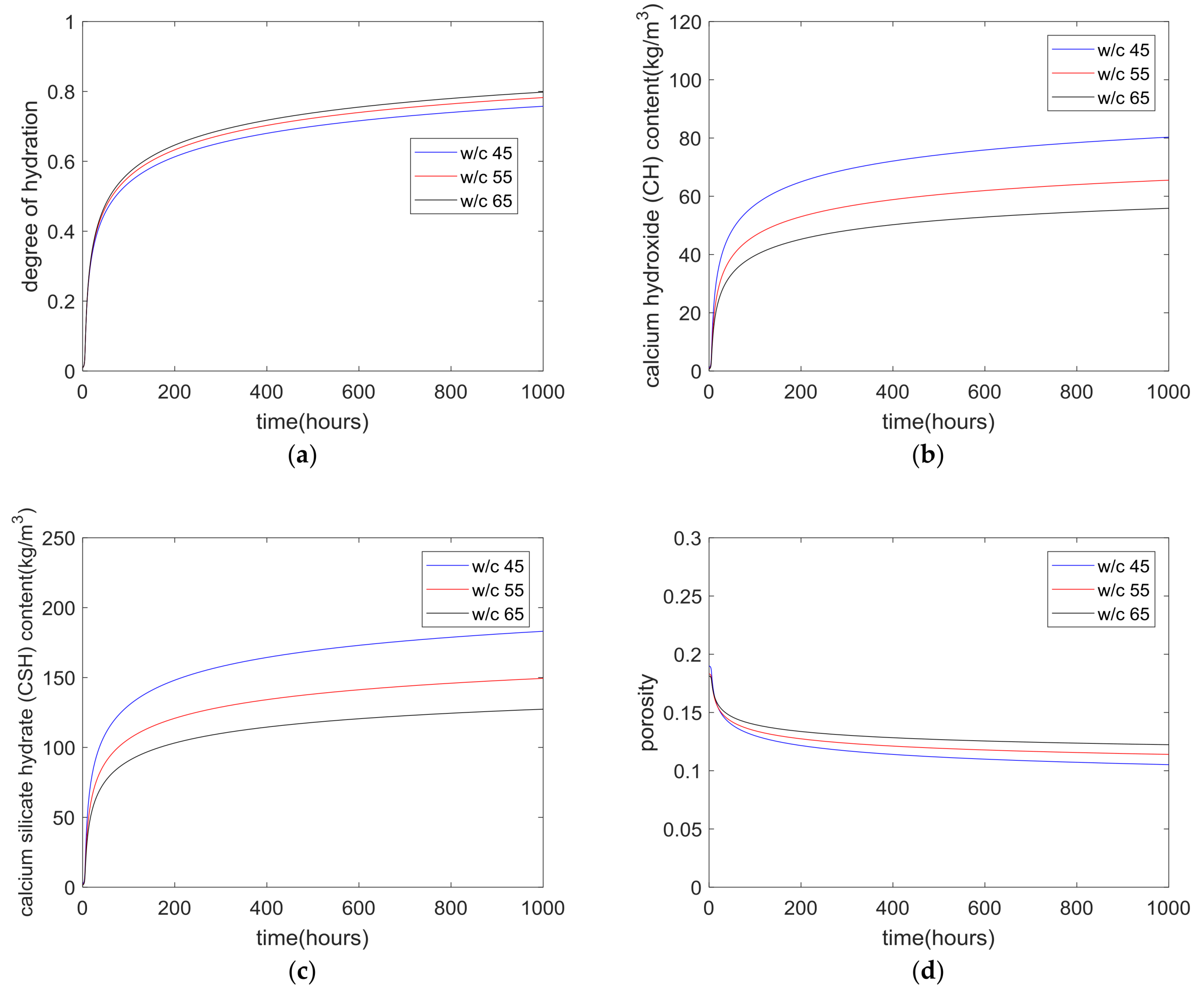

By using the kinetic cement hydration model [

9], the degree of cement hydration, CH content, CSH content and porosity of concrete were calculated and are shown in

Figure 2. With decreases in the water to cement ratios, the available depositing space of the hydration products and capillary water concentration decreased and consequently, the degree of hydration was reduced (shown in

Figure 2a). Concrete with lower water-to-cement ratios had higher CH content (shown in

Figure 2b) and CSH content (shown in

Figure 2c) and lower porosity (shown in

Figure 2d).

Carbonation is significantly influenced by concrete relative humidity. The carbonation of concrete tended to be the highest for environmental relative humidity of 50–70% [

9]. When the relative humidity was less than 50%, there was insufficient moisture for the progression of the carbonation reaction. While the relative humidity was higher than 70%, the diffusion of CO

2 was hindered due to the increase in the saturation degree of the concrete pores. On the other hand, the rate of cement hydration was also significantly influenced by relative humidity. Cement hydration virtually ceased at about 80% RH for concrete with various water to binder ratios and mixing proportions [

9]. In the study by Song et al. [

5], after water curing, the concrete was exposed to 65% relative humidity. The relative humidity in the surface skin of concrete approximately equaled that of the environmental relative humidity [

2,

9]. When the relative humidity in the surface skin concrete was less than 80%, the hydration of cement in the surface skin concrete stopped [

9]. Hence, further hydration in the carbonation zone of concrete was marginal and could be ignored.

The calculation results from the hydration model can be used as input parameters for evaluating the concrete carbonation depth. By using the experimental results on carbonation depth for sound concrete, the CO

2 diffusivity parameters A and a in Equation (5) were set as 2.66×10

-6 and 4.75×10

-6, respectively. These CO

2 diffusivity parameters did not change with different water to cement ratios. The calculated results regarding the carbonation depth of sound concrete are shown in

Figure 3. Concrete with lower water-to-cement ratios showed lower carbonation depths as concrete with a lower water to cement ratio has higher carbonatable material contents and lower porosity (shown in

Figure 2).

According to Song et al. [

5], cracks were induced into concrete through splitting tests. A Linear Variable Differential Transformer (LVDT) was used for measuring crack width in a fully unloaded state. It is very difficult to obtain the required crack width, so Song et al. [

5] tried to determine the crack width by 0.1 mm-division after the splitting test. In this study, 0.05 mm cracks ranged from 0 to 0.1 mm; 0.15 mm cracks ranged from 0.1 mm to 0.2 mm; and 0.25 mm crack ranged from 0.2 mm to 0.3 mm.

In Equation (7), the value of

equals the area ratio between the crack zone and total surface of concrete. The value of

was regressed based on the experimental results of the carbonation depth of cracked concrete. First, for each water to cement ratio such as 0.65, 0.55 and 0.45, based on the comparison of carbonation depths of sound concrete and cracked concrete by using the equivalent CO

2 diffusivity (Equation (8)), the value of

was determined. It was found that

was independent on crack width and was only dependent on the water to cement ratio of concrete. Second, linear regression was used to find the relationship between

and the water to cement ratio. We proposed that the relationship between

and the water-to-cement ratio was set as follows:

where

is the CO

2 diffusivity after 28 days of curing.

Figure 4 shows the ratio of

versus the crack width for different water-to-cement ratios. One hundred mm and 150 mm were used as the representative values of crack interspace. As shown in this figure, the ratio of

increased with crack width. With the decrease of water-to-cement ratios, the ratio of

increased. Hence, high strength concrete is more vulnerable due to cracking than low strength concrete. With the increase of crack interspaces, the ratio of

decreased.

It should be noted that in Equation (14), the curing period of concrete before the start of the carbonation tests was 28 days. When the concrete curing periods before the carbonation tests changed, the porosity and CO

2 diffusivity of concrete will vary correspondingly. By dividing time dependent CO

2 diffusivity

at the left- and right-hand sides of Equation (14), Equation (14) can be transformed as follows:

After this transformation, the effect of the curing period on CO

2 diffusivity was considered. By using Equation (15) and the carbonation reaction (Equation (8)), the carbonation depth of cracked concrete with different curing periods could be calculated. In this study, we used equivalent CO

2 diffusivity to calculate the carbonation depth of cracked concrete. As we considered the fundamental mechanisms involved in carbonation such as hydration, carbonation and equivalent CO

2 diffusivity, the calculation could be carried out not only within the experimental period but also in the extension period beyond the carbonation experiment.

Figure 5 shows that with the increase of water-to-cement ratio and crack width, the carbonation depth of concrete increased. As shown in

Figure 5a, for concrete with a water-to-cement ratio of 0.65 and a 0.25 mm crack, after 42 days of accelerated carbonation tests, the carbonation depth was about six times that of sound concrete. While for concrete with a water-to-cement ratio of 0.45 and a 0.25 mm crack (shown in

Figure 5c), after 42 days of accelerated carbonation tests, the carbonation depth of concrete was about ten times that of sound concrete. Hence, concrete with a lower water-to-cement ratio is more vulnerable to cracking than concrete with a higher water-to cement ratio. Given the same crack widths, for high strength concrete, when compared with sound concrete, the increase in carbonation depth was more obvious than that of low strength concrete. Additionally, as shown in

Figure 5, the theoretical and experimental outcomes showed some deviations. This may be because the crack width used in the calculation may be different from the real crack width in the experiments. For example, when the used crack width in the calculation was 0.15 mm, the real crack width was between 0.1 and 0.2 mm.

In addition, Talukdar et al. [

13] theoretically calculated the effective CO

2 diffusion coefficient of cracked concrete by considering the crack geometry factor. Crack geometry factor presents significant influence on equivalent CO

2 diffusivity of cracked concrete. The secondary fracture crack and damage to the concrete around the crack zone will contribute to CO2 transport and affect the calculation value of the crack geometry factor. To calculate the crack geometry factor, the influences of the secondary fracture crack and concrete damage should be considered. Until now, it has been difficult to find a general equation to determine the crack geometry factor of CO

2. The crack geometry factor of chloride ions may be different from that of CO

2. To accurately determine the crack geometry factor of CO

2, further experimental studies about the CO

2 diffusivity of cracked concrete with different crack widths should be undertaken. Hence in this study, for simplicity, we used the experimental regression equation to calculate

. On the other hand, in this study, the values of

A and

a in Equation (5) are 2.66×10

-6 and 4.75×10

-6, respectively, which were a little different from that found by Papadakis [

2] but their magnitude were the same [

2]. In Reference [

14], Talukdar and Banthia adapted the value of

a according to the experimental results of concrete carbonation. The difference of the values

A and

a between the current study and [

14] may be because the current study simplified the carbonation as a diffusion-controlled process.

3.2. Service Life of Cracked Concrete Considering Climate Change

Climate models project the responses of numerous climate variables such as in global environmental temperature and sea level to different scenarios of greenhouse gas emissions and other human-related emissions. Of these different scenarios, the IPCC-AR5 scenario, which was proposed by the Intergovernmental Panel on Climate Change (IPCC), is considered as one of the best models for climate change [

15].

Figure 6 shows the CO

2 concentration increase. Representative Concentration Pathways (RCP) 8.5, RCP 4.5 and RCP 2.6 scenarios were considered in this study. RCP 8.5 projected higher CO

2 concentration increases than RCP 4.5 and RCP 2.6.

Figure 7 shows the temperature increase for different climate change scenarios. Both mean temperature rises and the upper and lower 90% confidence intervals of each scenarios are included in

Figure 7.

In this section, parameter analysis was carried out to calculate the carbonation depth, probability of corrosion initiation and service life of cracked concrete. Two W/C (0.45 and 0.65), two concrete cover depths (25 mm and 35 mm) and three crack widths (0.05 mm, 0.10 mm and 0.15 mm) were used in the parameter analysis. In this study, W/C = 0.45, cover depth = 35 mm, crack width = 0.05 mm represents the upper limit of service life and W/C = 0.65, cover depth = 25 mm, crack width = 0.25 mm represents the lower limit of service life.

Table 2 shows statistical parameters. In this study, we considered the uncertainties of the

and

. The concrete cover depth was assumed to have a normal distribution [

11] and the coefficient of variance of cover depth was assumed to be 0.2 [

3]. The carbonation rate parameter at the initial time was assumed to have a normal distribution [

11] and the coefficient of variance of the carbonation rate parameter was 0.15 [

3]. For CO

2 concentration and global temperature, the coefficient of variance increased with time [

11]. At the initial time, the coefficient of variance equaled zero and at the 100-year mark, the coefficient of variance was taken to be 0.06 [

11]. In addition, in this parameter study, the relative humidity was set as 65%, the initial environmental temperature was set as 25 °C, the curing period before carbonation testing was 28 days and the interspace of the concrete crack was 100 mm.

Table 3 shows the summary of the analyzed cases. Six cases were analyzed: the RCP 2.6, RCP 4.5, RCP 8.5, RCP 8.5 upper 90% confidence interval, RCP 8.5 at the time slice 2050 and RCP 8.5 upper 90% confidence interval at the time slice 2050. To some extent, the different analysis cases such as RCP 2.6, RCP 4.5, RCP 8.5, RCP 8.5 upper 90% confidence interval, RCP 8.5 at the time slice 2050 and RCP 8.5 upper 90% confidence interval at the 2050-time slice, can represent specific cities [

14,

16,

17].

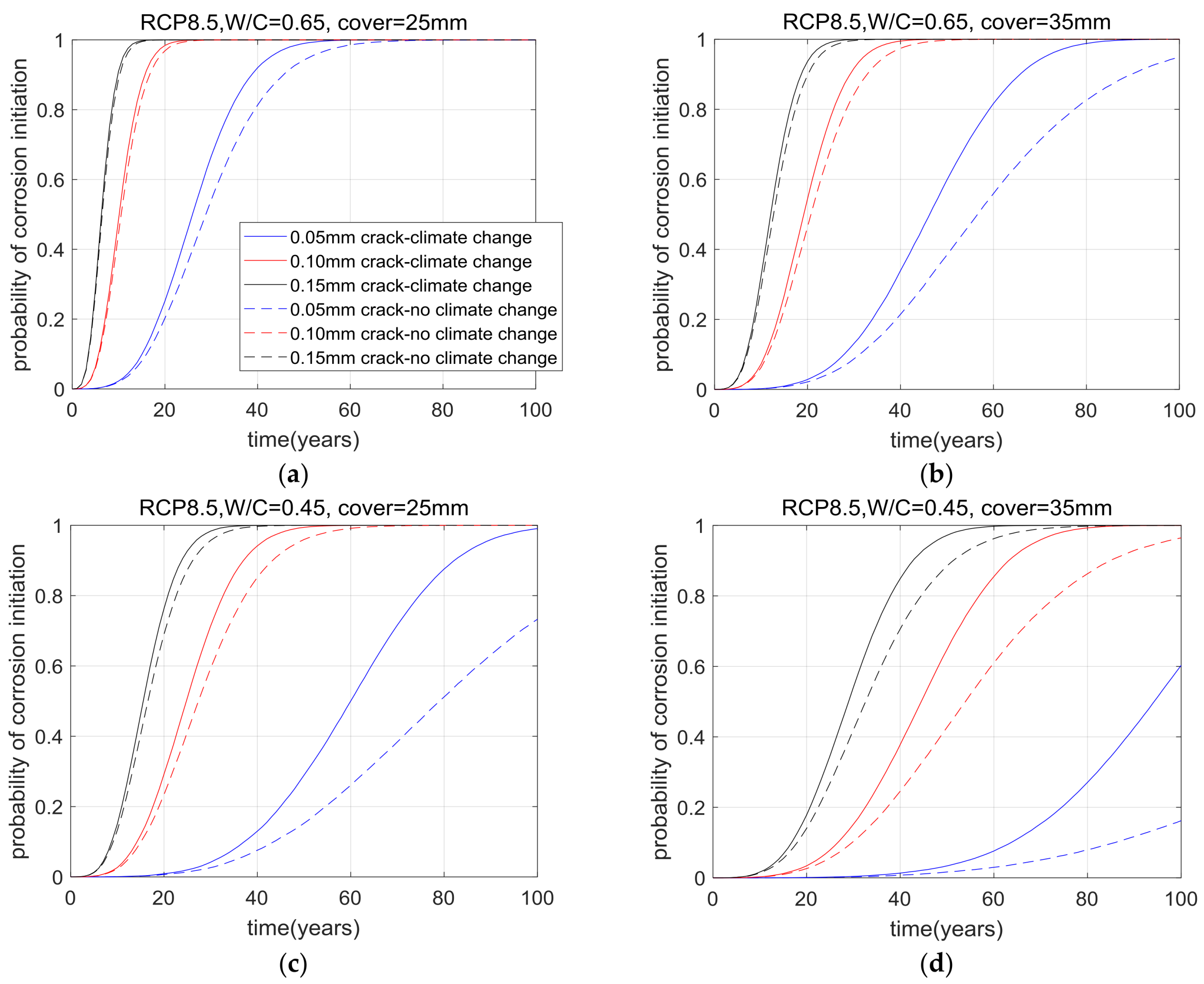

Based on the concrete hydration-carbonation integrated model, the carbonation depth of concrete could be calculated. Furthermore, by using the Monte Carlo method, the probability of corrosion initiation was determined. The probability of corrosion initiation for the analysis cases is shown in

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13. With the increase in cover depth (seen in a comparison between

Figure 8a,b and between

Figure 8c,d), the probability of corrosion initiation decreased. With the decrease in water-to-cement ratio (based on a comparison between

Figure 8a,c and between

Figure 8b,d, the probability of corrosion initiation also decreased. Higher W/C with a lower crack width may present a lower probability of corrosion than a lower W/C with a higher crack width. In this study, we treated the water-to-cement ratio and crack width separately and did not consider the effect of water content on the chance of cracking.

When cracks increased from 0.05 mm to 0.15 mm, the service life of concrete reduced significantly. As the service life reduced, the changing extent of the climate scenario during service life became smaller and the effect of climate change on the cumulative probability function became much weaker. Hence, the cumulative probability functions with cracks of 0.15 mm were very similar, regardless of climate change and the cumulative probability functions with cracks of 0.05 mm were quite different. For concrete with 0.05mm cracks, different climate change scenarios and time slices lead to different probabilities, especially when the probability exceeds 0.8.

In this study, the former service life was defined as the service life of concrete for the condition of no climate change; the modified service life was the service life of concrete after considering climate change and the relative service life was defined as the ratio of modified service life to former service life. Based on the interpolation between the probability of corrosion initiation and time (shown in

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13), the former service life and revised service life could be determined. Furthermore, the relative service life of concrete was calculated.

Table 4,

Table 5,

Table 6,

Table 7,

Table 8 and

Table 9 show the former service life, revised service life and relative service life of concrete of each analysis case. It shows that with an increase in former service life after considering climate change, reductions on the former service life also increased.

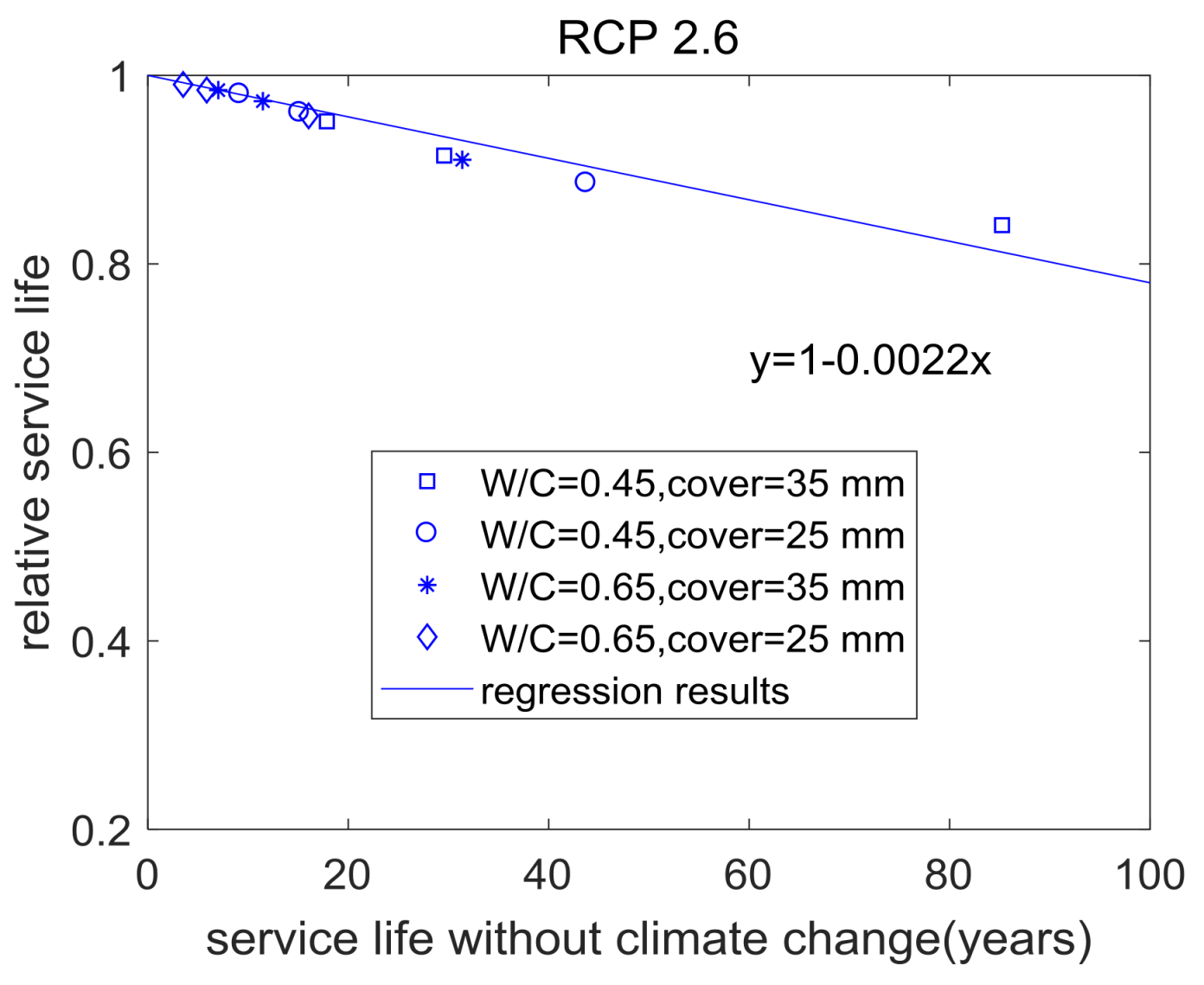

Figure 14,

Figure 15,

Figure 16,

Figure 17,

Figure 18 and

Figure 19 show the relative service life for each case. Relative service life is expressed as a function of former service life. Given a certain analysis case, for concrete with different water-to-cement ratios, different cover depths and different crack widths, the relationships between relative service life and former service life were similar. When former service life increased, relative service life also almost linearly decreased. Hence, climate change presents more significant influence on the service life of more durable concrete.

The summary of the analysis results for various cases is shown as follows. First, in the RCP 8.5, RCP 4.5 and RCP 2.6 climate change scenarios for concrete structures with a time slice 2000 and a 50-year service life, after considering climate change, service life will reduce by 16%, 14.5% and 11%, respectively. The reduction trend of service life was similar to the increase trends of CO

2 concentration and global temperature. Second, with a time slice 2000, as the climate change scenario changed from RCP 8.5 to RCP 8.5 upper 90% confidence interval, service life loss slightly increased from 16% to 16.5%. This was due to the increase in global temperature. While with a time slice 2050, as the climate change scenario changed from RCP 8.5 to RCP 8.5 upper 90% confidence interval, service life loss slightly increased from 24% to 25%. The service life loss may have more uncertainty in the near future than in the present. Third, in the case of the RCP 8.5 climate change scenario, for concrete structures with a 50-year service life, when the time slice changed from 2000 to 2050, service life loss increased from 16% to 24%. This was because the increase of CO

2 concentration and temperature were much higher in the 2050–2100 range than the 2000–2050 range of RCP 8.5. In addition, as shown in

Table 4 and

Table 8, when the time slice changed from 2000 to 2050, the service life was reduced because of the increase in CO

2 concentration and temperature.

The proposed model considered the influences of material properties (mixing proportions and curing periods), crack characteristics (crack width and crack interspace) and environmental conditions (CO

2 concentration, temperatures and relative humidity) on carbonation resistance and the service life of concrete structures. The calculated results regarding corrosion initiation time and service life can be combined with structural health monitoring technology for the design and maintenance of concrete structures [

18,

19]. However, the proposed model has its limitations. First, the CO

2 diffusivity in the cracked zone was not analyzed in detail. The crack geometry shape such as equal width cracks or tapered cracks were not taken into account [

5]. Second, the interaction between moisture diffusion, thermal diffusion, carbonation reaction and CO

2 diffusion were also not taken into account [

20]. In this study, only a simplified equation (Equation (4)) was employed to calculate the carbonation depth of concrete. Third, the defined service life in this study was too conservative. The corrosion propagation period should be included in the service life of concrete structures [

21]. In addition, the effect of other atmospheric variables on carbonation such as wind pressure, especially at the surface of concrete buildings, should also be considered in further studies [

22]. By combining the penetration-reaction carbonation model [

22] with the Monte Carlo method, the influence of wind pressure on carbonation service life can be found.