Progress in the Synthetic Holographic Stereogram Printing Technique

Abstract

:1. Introduction

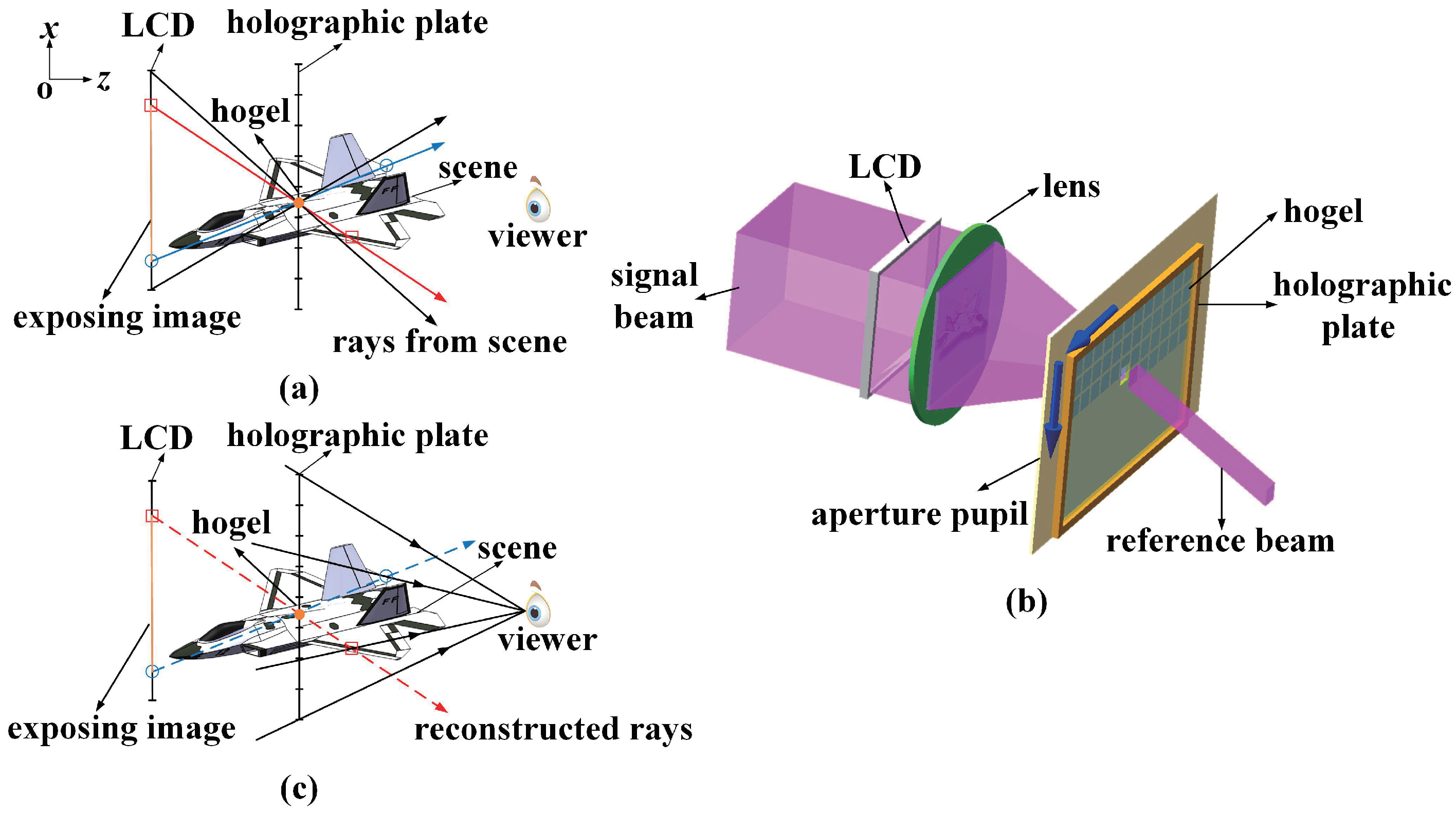

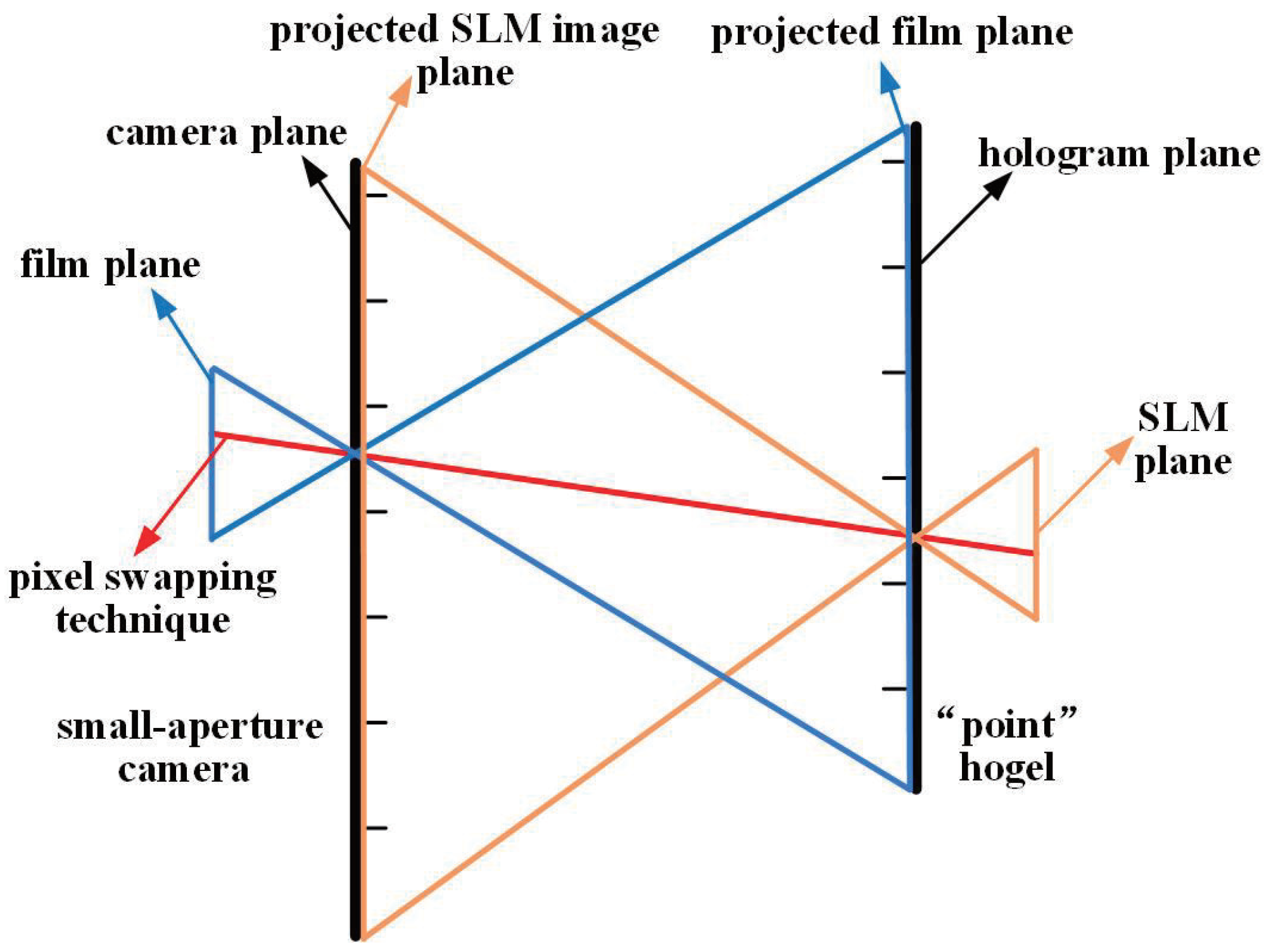

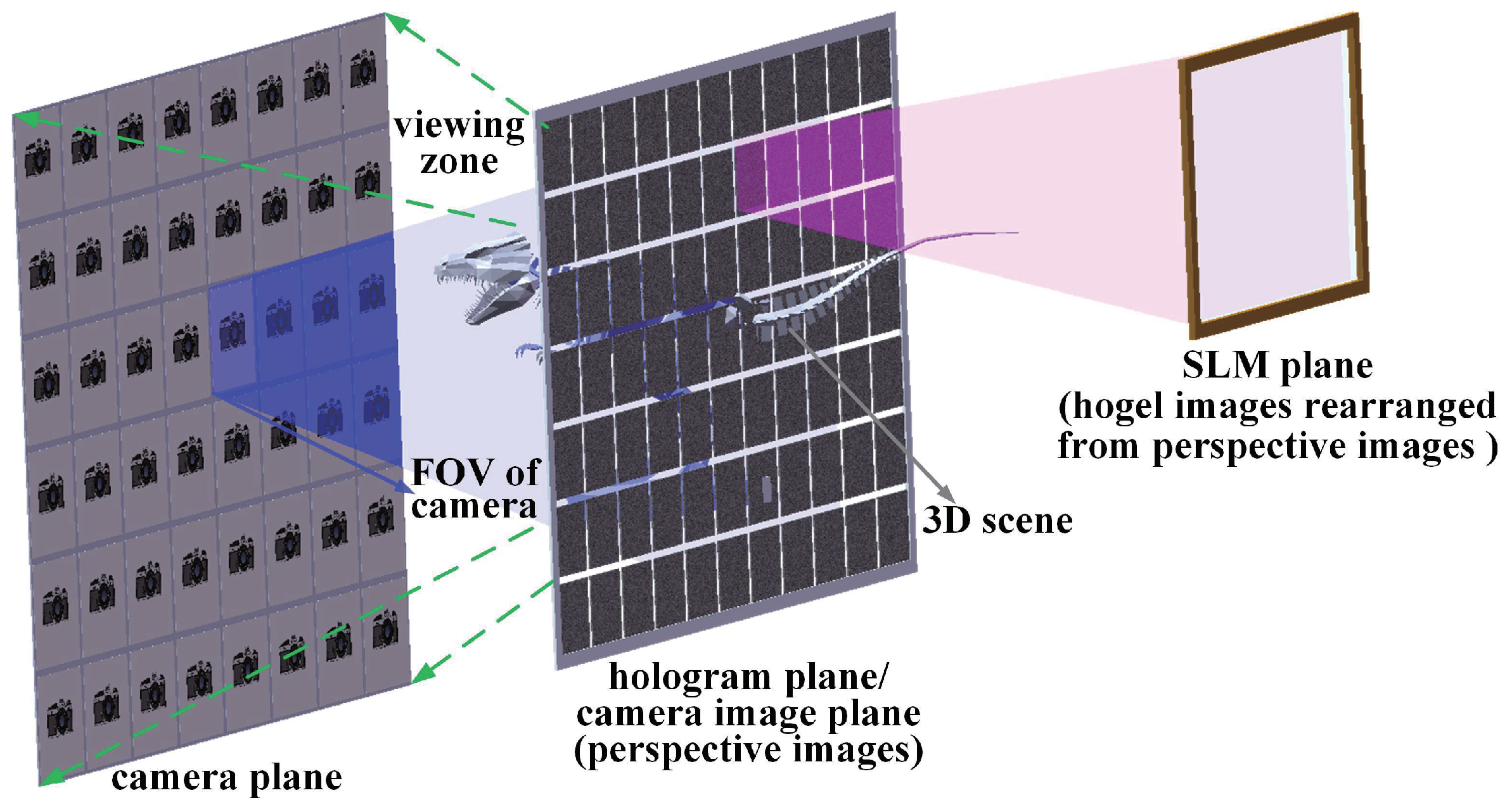

2. Development of Synthetic Holographic Stereogram Printing Technique

3. The Research Status of Synthetic Holographic Stereogram Printing

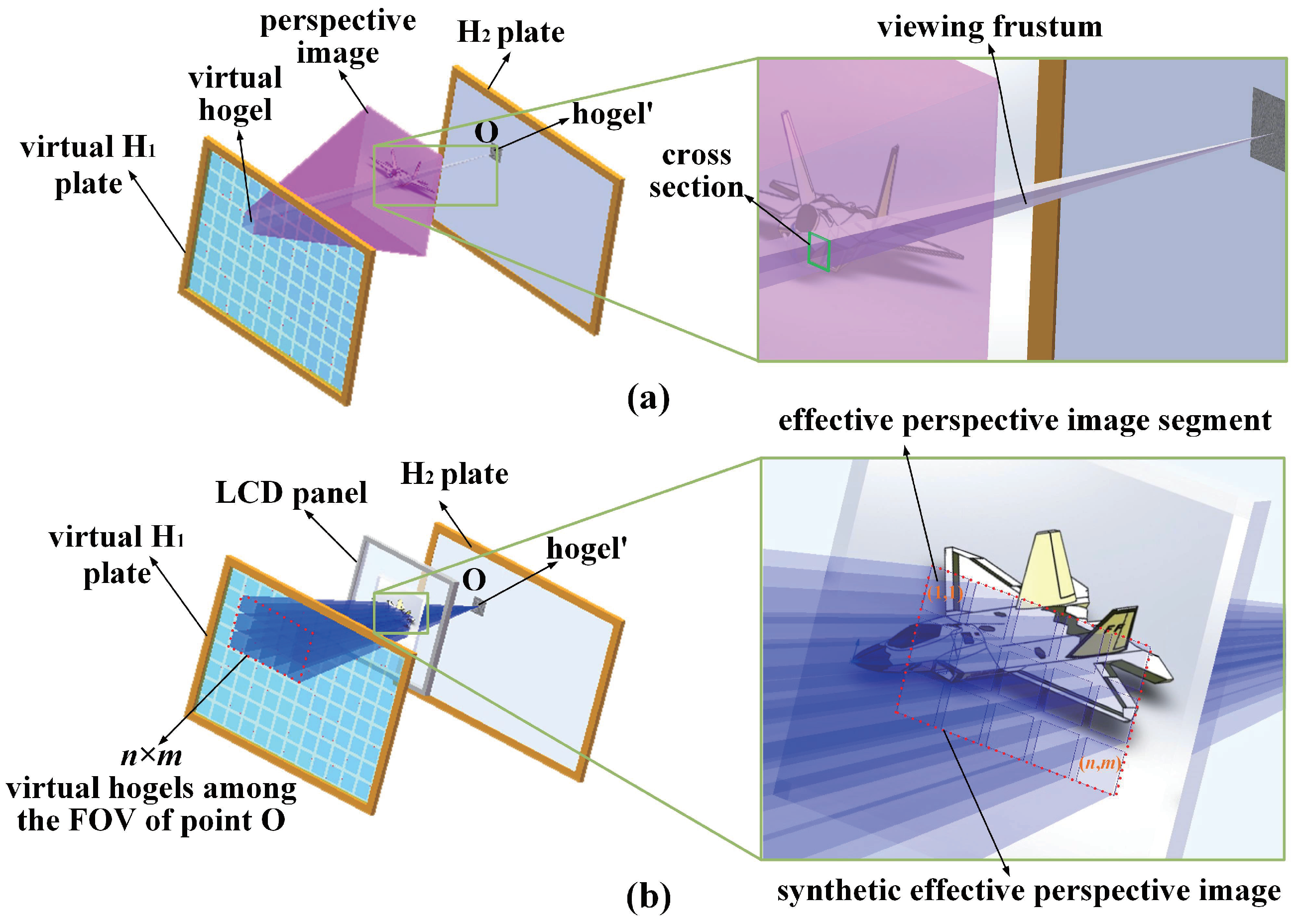

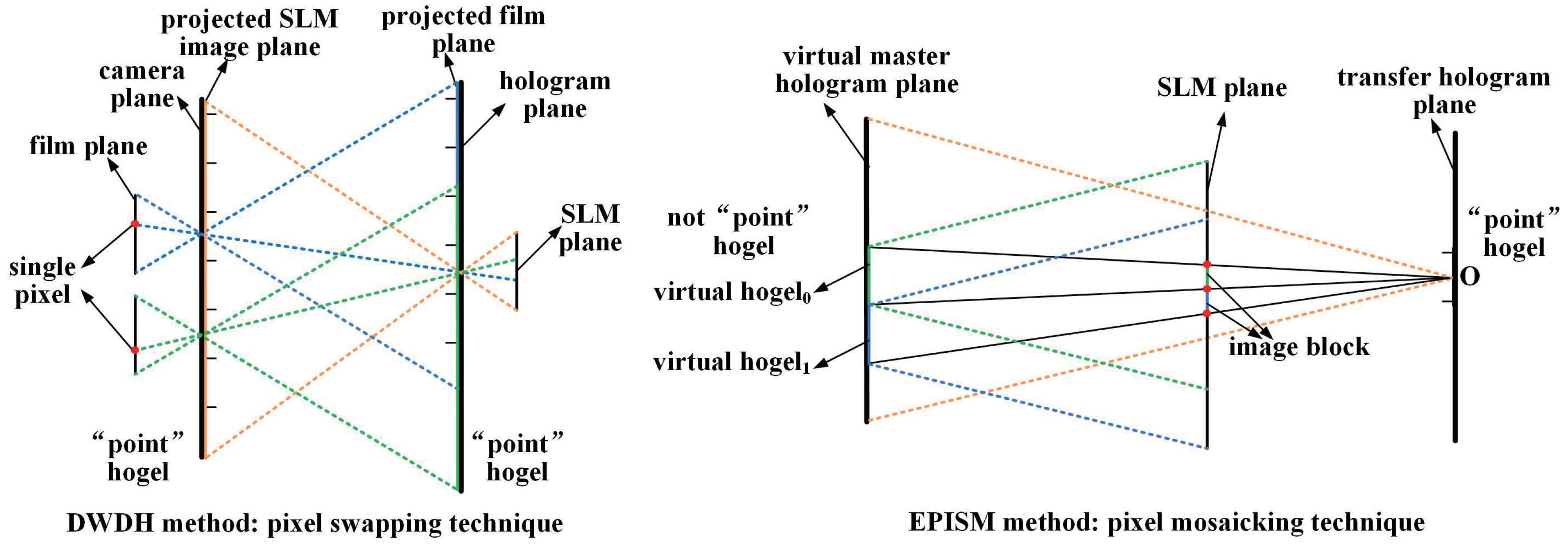

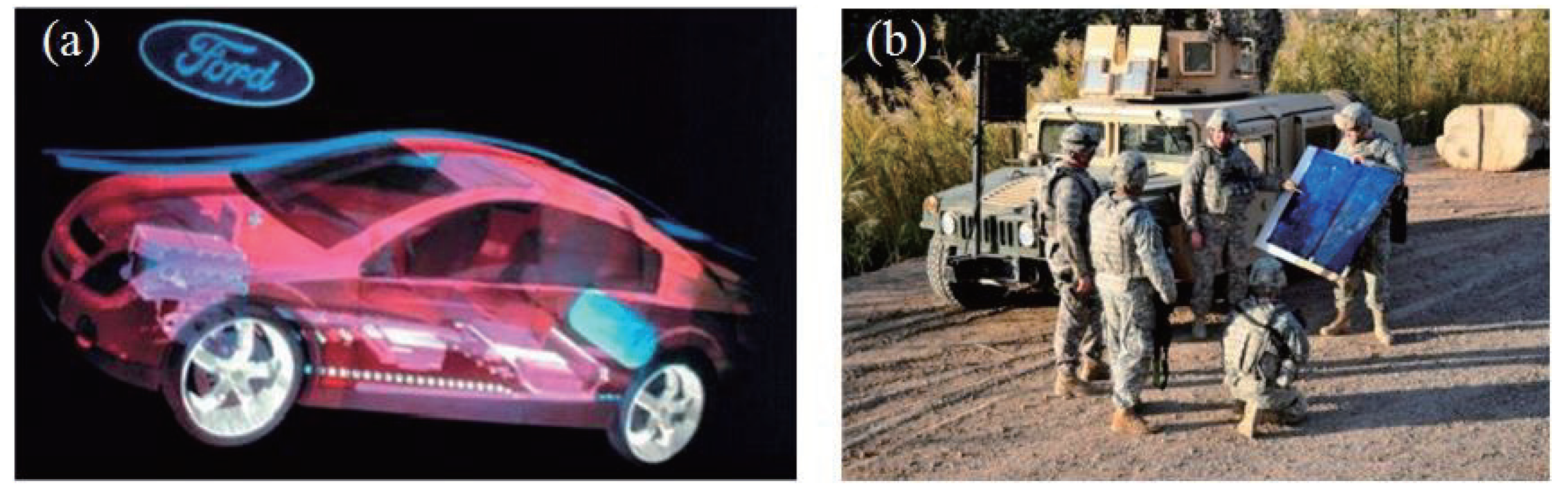

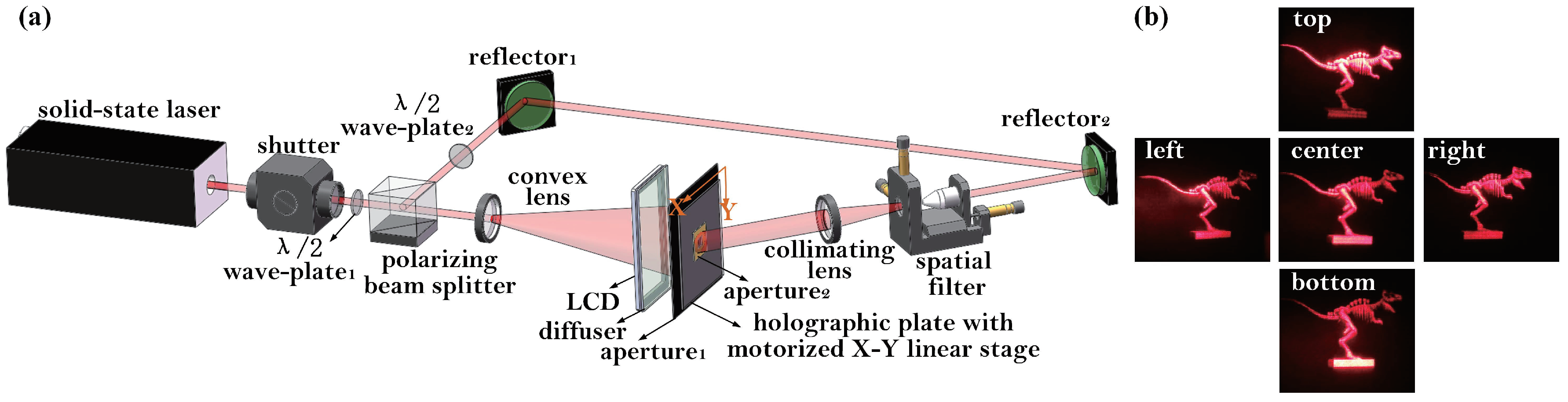

3.1. Holographic Display with a Large Format, a Large Field of View, and No Distortion

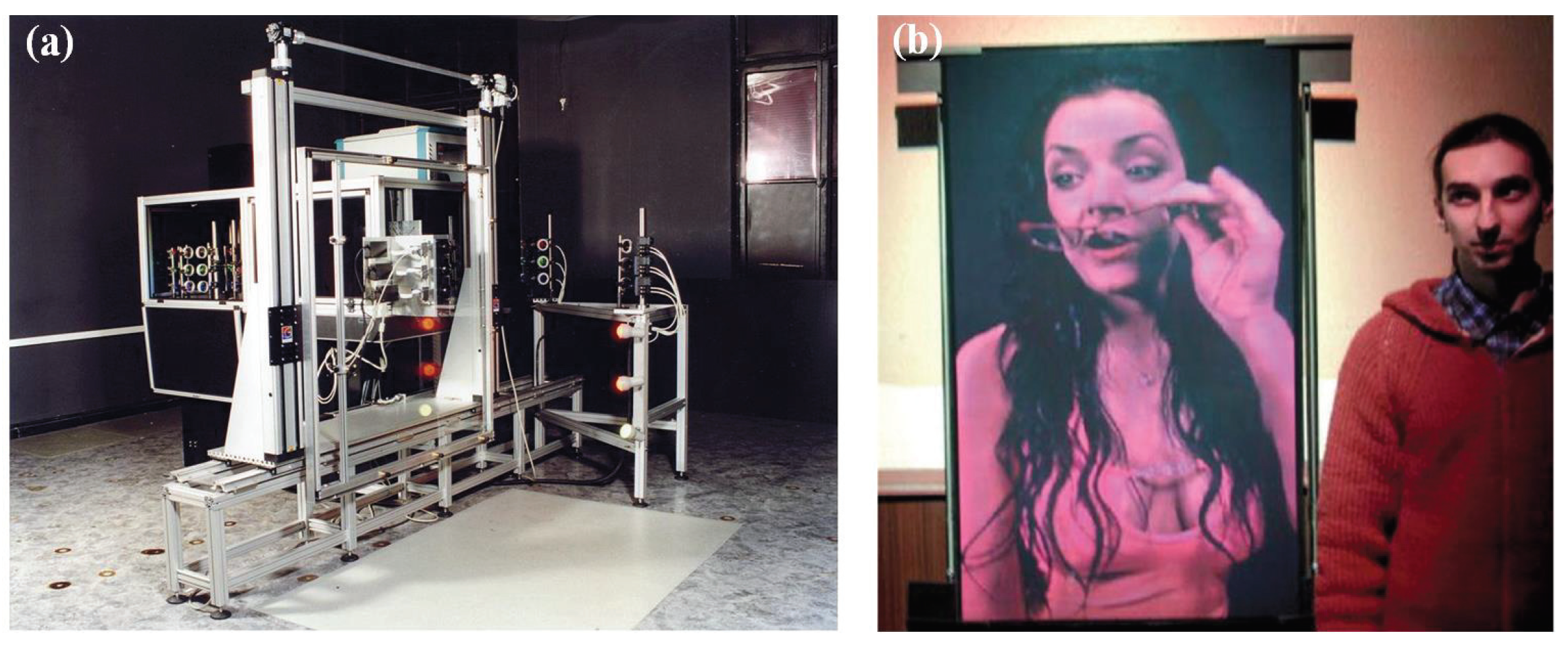

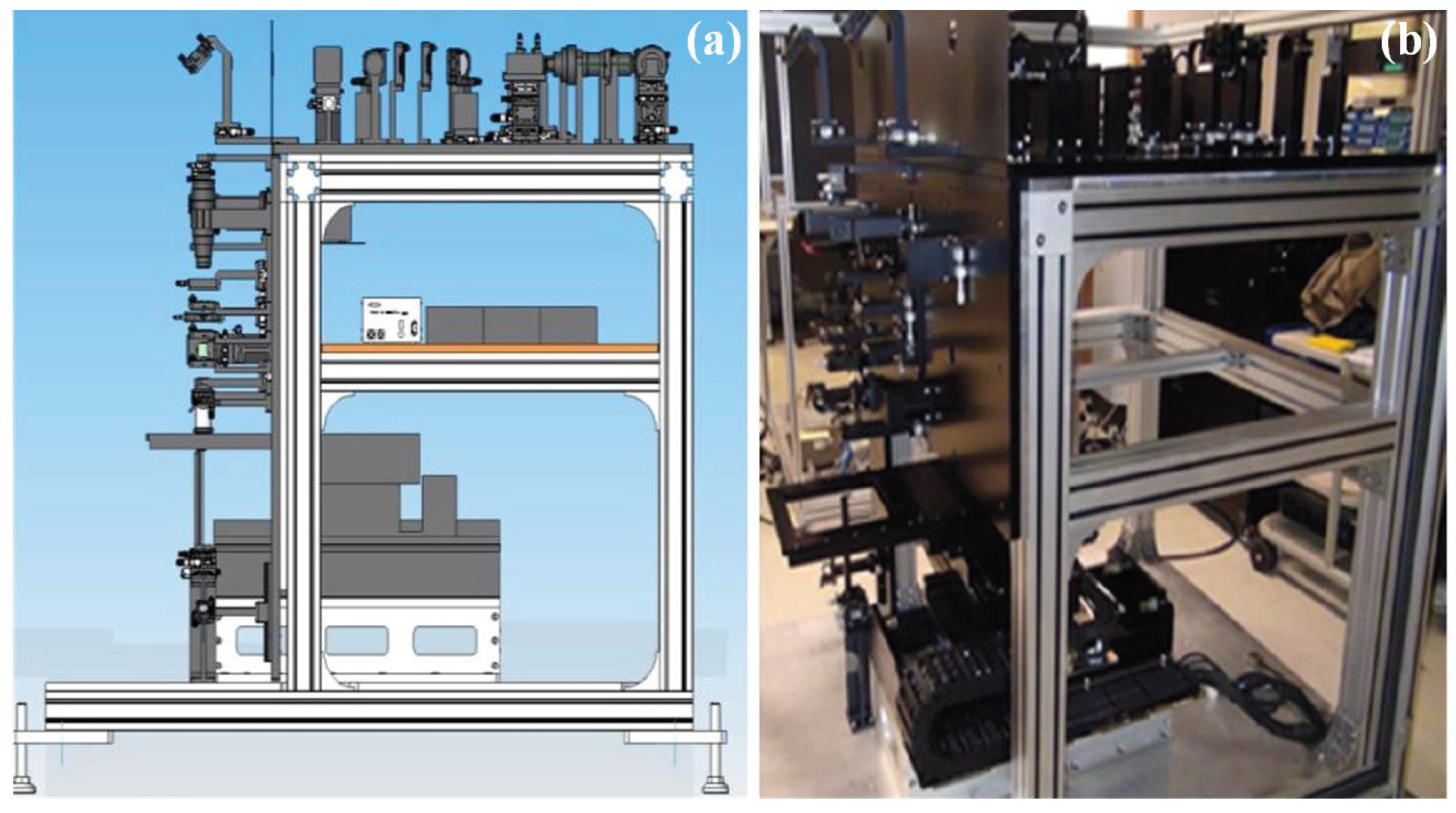

3.2. Printing Efficiency

3.3. Color Reproduction Characteristic

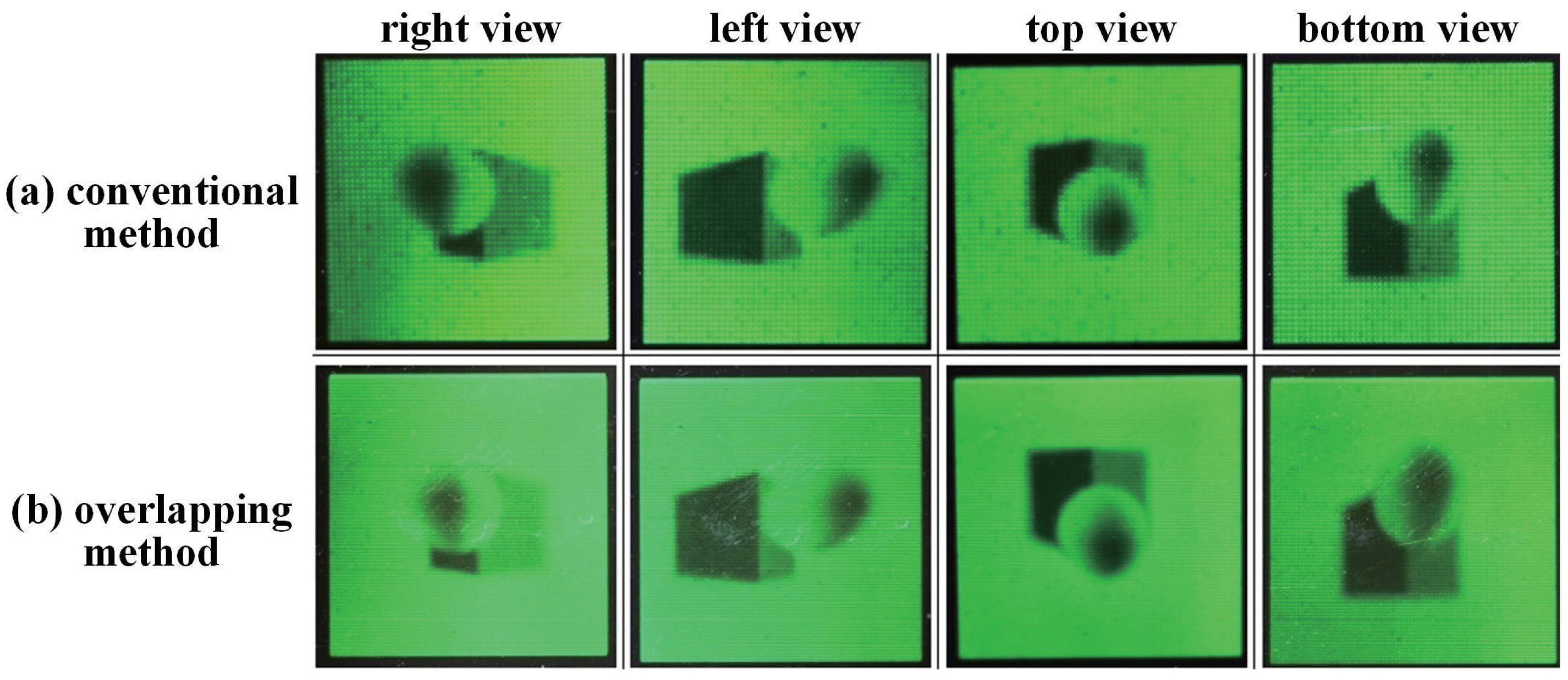

3.4. Imaging Quality

3.5. Diffraction Efficiency

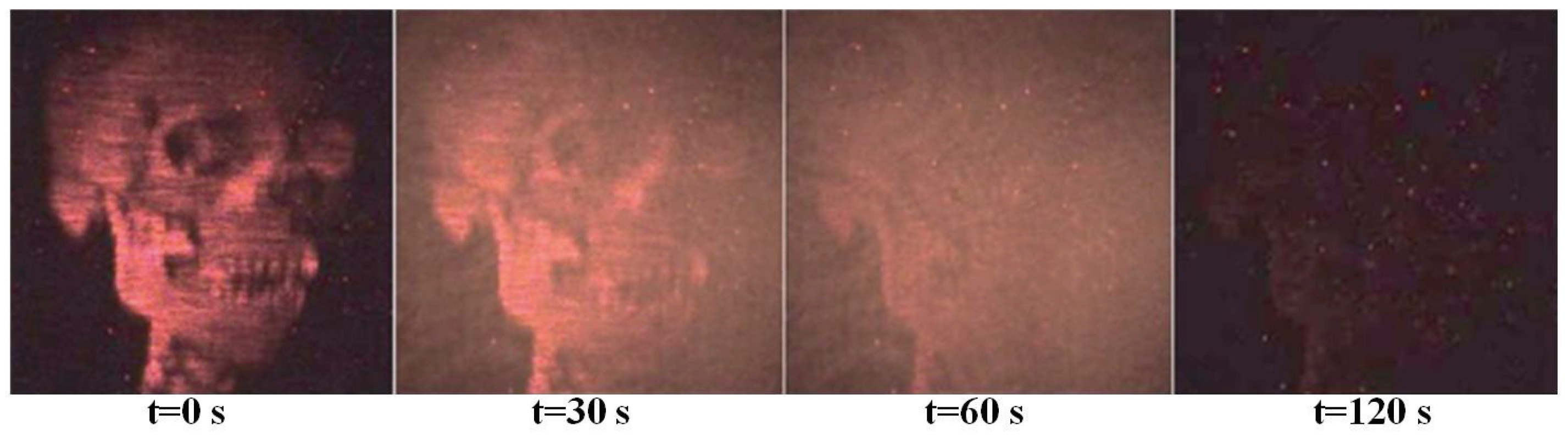

3.6. The Development of a Holographic Recording Medium

3.7. Noises Reduction

3.8. Frequency Response Analysis of the Holographic Stereogram

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Gabor, D. A new microscopic principle. Nature 1948, 161, 777–778. [Google Scholar] [CrossRef] [PubMed]

- Lucente, M. The first 20 years of holographic video—And the next 20. In Proceedings of the SMPTE 2nd Annual International Conference on Stereoscopic 3D for Media and Entertainment, New York, NY, USA, 21–23 June 2011. [Google Scholar]

- Bjelkhagen, H.I.; Brotherton-Ratcliffe, D. Ultrarealistic imaging: The future of display holography. Opt. Eng. 2014, 53, 112310. [Google Scholar] [CrossRef]

- Yamaguchi, M. Full-parallax holographic light-field 3-D displays and interactive 3-D touch. Proc. IEEE 2017, 105, 947–959. [Google Scholar] [CrossRef]

- Park, J.S.; Stoykova, E.; Kang, H.J. White light viewable silver-halide holograms in design applications. Bulg. Chem. Commun. 2016, 48, 37–40. [Google Scholar]

- Zheng, H.; Sun, G.; Yu, Y. A review of holographic printing technologies. Laser Optoelectron. Prog. 2012, 49, 110002. (In Chinese) [Google Scholar] [CrossRef]

- Yamaguchi, M. Light-field and holographic three-dimensional displays [Invited]. J. Opt. Soc. Am. A 2016, 33, 2348–2364. [Google Scholar] [CrossRef] [PubMed]

- Kang, H.; Stoykova, E.; Berberova, N.; Park, J.; Nazarova, D.; Park, J.S.; Kim, Y.; Hong, S.; Ivanov, B.; Malinowski, N. Three-dimensional imaging of cultural heritage artifacts with holographic printers. In Proceedings of the SPIE 19th International Conference and School on Quantum Electronics: Laser Physics and Applications, Sozopol, Bulgaria, 26–30 September 2016; Volume 10226, p. 102261I. [Google Scholar]

- Yoshikawa, H.; Yamaguchi, T. Review of holographic printers for computer-generated holograms. IEEE Trans. Ind. Inform. 2016, 12, 1584–1589. [Google Scholar] [CrossRef]

- Jolly, S.; Smalley, D.E.; Barabas, J.; Bove, V.M. Direct fringe writing architecture for photorefractive polymer-based holographic displays: Analysis and implementation. Opt. Eng. 2013, 52, 055801. [Google Scholar] [CrossRef]

- Yoshikawa, H. Research activities on digital holographic displays in Japan. In Proceedings of the SPIE Three-Dimensional Imaging, Visualization, and Display 2011, Orlando, FL, USA, 25–29 April 2011; Volume 8043, p. 804305. [Google Scholar]

- Li, Y.; Wang, H.; Ma, L.; Shi, Y. Three-dimensional imaging and display of real-existing scene using fringe. In Proceedings of the SPIE International Conference on Optics in Precision Engineering and Nanotechnology (icOPEN2013), Singapore, 9–11 April 2013; Volume 8769, p. 87691I. [Google Scholar]

- Yoshikawa, H.; Yamaguchi, T. Computer-generated holograms for 3D display (Invited Paper). Chin. Opt. Lett. 2009, 7, 1079–1082. [Google Scholar]

- Su, J.; Yan, X.; Huang, Y.; Chen, Y.; Jiang, X. Resolution matching in laser direct printing of a computer-generated hologram. J. Opt. Soc. Am. B 2017, 34, B1–B8. [Google Scholar] [CrossRef]

- Yoshikawa, H.; Takei, K. Development of a compact direct fringe printer for computer-generated holograms. In Proceedings of the SPIE Practical Holography XVIII: Materials and Applications, San Jose, CA, USA, 18–22 January 2004; Volume 5290, pp. 114–121. [Google Scholar]

- Yamaguchi, T.; Yoshikawa, H. Computer-generated image hologram. Chin. Opt. Lett. 2011, 9, 120006. [Google Scholar] [CrossRef]

- Sohn, I.B.; Choi, H.K.; Yoo, D.; Noh, Y.C.; Noh, J.; Ahsan, M.S. Three-dimensional hologram printing by single beam femtosecond laser direct writing. Appl. Surf. Sci. 2018, 427, 396–400. [Google Scholar] [CrossRef]

- Kang, H.; Stoykova, E.; Yoshikawa, H.; Hong, S.; Kim, Y. Comparison of System Properties for Wave-Front Holographic Printers; Osten, W., Ed.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 851–854. ISBN 978-3-642-36359-7. [Google Scholar]

- Oi, R.; Chou, P.-Y.; Jackin, B.J.; Wakunami, K.; Ichihashi, Y.; Okui, M.; Huang, Y.-P.; Yamamoto, K. Three-dimensional reflection screens fabricated by holographic wavefront printer. Opt. Eng. 2018, 57, 061605. [Google Scholar]

- Yamaguchi, T.; Miyamoto, O.; Yoshikawa, H. Volume hologram printer to record the wavefront of three-dimensional objects. Opt. Eng. 2012, 51, 075802. [Google Scholar] [CrossRef]

- Kim, Y.; Stoykova, E.; Kang, H.; Hong, S.; Park, J.; Park, J.; Hong, J. Seamless full color holographic printing method based on spatial partitioning of SLM. Opt. Express 2015, 23, 172–182. [Google Scholar] [CrossRef] [PubMed]

- Kang, H.; Stoykova, E.; Kim, Y.; Hong, S.; Park, J.; Hong, J. Color holographic wavefront printing technique for realistic representation. IEEE Trans. Ind. Inform. 2017, 12, 1590–1598. [Google Scholar] [CrossRef]

- Kang, H.; Stoykova, E.; Kim, Y.; Hong, S.; Park, J.; Hong, J. Color wavefront printer with mosaic delivery of primary colors. Opt. Commun. 2015, 350, 47–55. [Google Scholar] [CrossRef]

- Cao, L.; Wang, Z.; Zhang, H.; Jin, G.; Gu, C. Volume holographic printing using unconventional angular multiplexing for three-dimensional display. Appl. Opt. 2016, 55, 6046–6051. [Google Scholar] [CrossRef] [PubMed]

- Wakunami, K.; Oi, R.; Senoh, T.; Ichihashi, Y.; Yamamoto, K. Wavefront printing technique with overlapping approach toward high definition holographic image reconstruction. In Proceedings of the SPIE Three-Dimensional Imaging, Visualization, and Display 2016, Baltimore, MD, USA, 17–21 April 2016; Volume 9867, p. 98670J. [Google Scholar]

- Ichihashi, Y.; Yamamoto, K.; Wakunami, K.; Oi, R.; Okui, M.; Senoh, T. An analysis of printing conditions for wavefront overlapping printing. In Proceedings of the SPIE Practical Holography XXXI: Materials and Applications, San Francisco, CA, USA, 28 January–2 February 2017; Volume 10127, p. 101270L. [Google Scholar]

- DeBitetto, D.J. Holographic panoramic stereograms synthesized from white light recordings. Appl. Opt. 1969, 8, 1740–1741. [Google Scholar] [CrossRef] [PubMed]

- King, M.C.; Noll, A.M.; Berry, D.H. A new approach to computer-generated holography. Appl. Opt. 1970, 9, 471–476. [Google Scholar] [CrossRef] [PubMed]

- Su, J.; Yuan, Q.; Huang, Y.; Jiang, X.; Yan, X. Method of single-step full parallax synthetic holographic stereogram printing based on effective perspective images’ segmentation and mosaicking. Opt. Express 2017, 25, 23523–23544. [Google Scholar] [CrossRef] [PubMed]

- Kang, H.; Stoykova, E.; Park, J.; Hong, S.; Kim, Y. Holographic Printing of White-Light Viewable Holograms and Stereograms; Mihaylova, E., Ed.; InTech: London, UK, 2013; pp. 171–201. ISBN 978-953-51-1117-7. [Google Scholar]

- Halle, M.W.; Benton, S.A.; Klug, M.A.; Underkoffler, J.S. Ultrgram: A generalized holographic stereogram. In Proceedings of the SPIE Practical Holography V, San Jose, CA, USA, 1–7 February 1991; Volume 1461, pp. 142–155. [Google Scholar]

- Halle, M.W. The Generalized Holographic Stereogram. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1991. [Google Scholar]

- Yamaguchi, M.; Ohyama, N.; Honda, T. Holographic three-dimensional printer: New method. Appl. Opt. 1992, 31, 217–222. [Google Scholar] [CrossRef] [PubMed]

- Yamaguchi, M.; Endoh, H.; Honda, T.; Ohyama, N. High-quality recording of a full-parallax holographic sterogram with a digital diffuser. Opt. Lett. 1994, 19, 135–137. [Google Scholar] [CrossRef] [PubMed]

- Bjelkhagen, H.I.; Brotherton-Ratcliffe, D. Ultra-Realistic Imaging: Advanced Techniques in Analogue and Digital Colour Holography; CRC Press: Boca Raton, FL, USA, 2013; ISBN 978-1-4398-2800-7. [Google Scholar]

- Brotherton-Ratcliffe, D.; Rodin, A. Holographic Printer. U.S. Patent 7,161,722, 9 January 2007. [Google Scholar]

- Halle, M.W.; Kropp, A.B. Fast computer graphics rendering for full parallax spatial displays. In Proceedings of the SPIE Practical Holography XI and Holographic Materials III, San Jose, CA, USA, 8–14 February 1997; Volume 3011, pp. 105–112. [Google Scholar]

- Su, J.; Yan, X.; Jiang, X.; Huang, Y.; Chen, Y.; Zhang, T. Characteristic and optimization of the effective perspective images’ segmentation and mosaicking (EPISM) based holographic stereogram: An optical transfer function approachg. Sci. Rep. 2018, 8, 4488. [Google Scholar] [CrossRef] [PubMed]

- Sánchez, A.M.; Prieto, D.V. Design, development and implementation of a low-cost full-parallax holoprinter. In Proceedings of the SPIE Practical Holography XXXII: Displays, Materials, and Applications, San Francisco, CA, USA, 27 January–1 February 2018; Volume 10558, p. 105580H. [Google Scholar]

- Benton, S.A.; Bove, V.M. Holographic Imaging; John Wiley & Sons: Hoboken, NJ, USA, 2008; ISBN 978-0-470-06806-9. [Google Scholar]

- Newswanger, C.; Klug, M. Holograms for the masses. In Proceedings of the 9th International Symposium on Display Holography (ISDH), Cambridge, MA, USA, 25–29 June 2012; Volume 415, p. 012082. [Google Scholar]

- Zherdev, A.Y.; Odinokov, S.B.; Lushnikov, D.S.; Shishova, M.V.; Gurylev, O.A.; Kaytukov, C.B. High-aperture diffractive lens for holographic printer. In Proceedings of the SPIE, Holography, Diffractive Optics, and Applications VII, Beijing, China, 12–14 October 2016; Volume 10022, p. 100220I. [Google Scholar]

- Park, J.; Kang, H.; Stoykova, E.; Kim, Y.; Hong, S.; Choi, Y.; Kwon, S.; Lee, S. Numerical reconstruction of a full parallax holographic stereogram with radial distortion. Opt. Express 2014, 22, 20776–20788. [Google Scholar] [CrossRef] [PubMed]

- Morozov, A.V.; Putilin, A.N.; Kopenkin, S.S.; Borodin, Y.P.; Druzhin, V.V.; Dubynin, S.E.; Dubinin, G.B. 3D holographic printer: Fast printing approach. Opt. Express 2014, 22, 2193–2206. [Google Scholar] [CrossRef] [PubMed]

- Rong, X.; Yu, X.; Guan, C. Multichannel holographic recording method for three-dimensional displays. Appl. Opt. 2011, 50, B77–B80. [Google Scholar] [CrossRef] [PubMed]

- Yamaguchi, M.; Endoh, H.; Koyama, T.; Ohyama, N. High-speed recording of full-parallax holographic stereograms by a parallel exposure system. Opt. Eng. 1996, 35, 1556–1559. [Google Scholar] [CrossRef]

- Brotherton-Ratcliffe, D.; Zacharovas, S.J.; Bakanas, R.J.; Pileckas, J.; Nikolskij, A.; Kuchin, J. Digital holographic printing using pulsed RGB lasers. Opt. Eng. 2011, 50, 091307. [Google Scholar]

- Bakanas, R.; Jankauskaitė, V.; Bulanovs, A.; Zacharovas, S.; Vilkauskas, A. Comparison of diffraction patterns exposed by pulsed and CW lasers on positive-tone photoresist. Appl. Opt. 2017, 56, 2241–2249. [Google Scholar] [CrossRef] [PubMed]

- Brotherton-Ratcliffe, D.; Vergnes, F.M.R.; Rodin, A.; Grichine, M. Holographic Printer. U.S. Patent 7,800,803, 21 September 2010. [Google Scholar]

- Wu, Q.; Wang, H.; Shi, Y.; Li, Y. Color reproduction quantitative analysis of color reflection holography. Chin. J. Lasers 2016, 43, 213–221. (In Chinese) [Google Scholar]

- Yang, F.; Murakami, Y.; Yamaguchi, M. Digital color management in full-color holographic three-dimensional printer. Appl. Opt. 2012, 51, 4343–4352. [Google Scholar] [CrossRef] [PubMed]

- Takano, M.; Shigeta, H.; Nishihara, T.; Yamaguchi, M.; Takahashi, S.; Ohyama, N.; Kobayashi, A.; Iwata, F. Full-color holographic 3D printer. In Proceedings of the SPIE Practical Holography XVII and Holographic Materials IX, Santa Clara, CA, USA, 20–24 January 2003; Volume 5005, pp. 126–136. [Google Scholar]

- Bjelkhagen, H.I.; Mirlis, E. Color holography to produce highly realistic three-dimensional images. Appl. Opt. 2008, 47, 123–133. [Google Scholar] [CrossRef]

- Maruyama, S.; Ono, Y.; Yamaguchi, M. High-density recording of full-color full-parallax holographic stereogram. In Proceedings of the SPIE, Practical Holography XXII: Materials and Applications, San Jose, CA, USA, 19–24 January 2008; Volume 6912, p. 69120N. [Google Scholar]

- Lucente, M. Diffraction-Specific Fringe Computation for Electro-Holography. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1994. [Google Scholar]

- Hong, K.; Park, S.-G.; Yeom, J.; Kim, J.; Chen, N.; Pyun, K.; Choi, C.; Kim, S.; An, J.; Lee, H.-S.; et al. Resolution enhancement of holographic printer using a hogel overlapping method. Opt. Express 2013, 21, 14047–14055. [Google Scholar] [CrossRef] [PubMed]

- Utsugi, T.; Yamaguchi, M. Reduction of the recorded speckle noise in holographic 3D printer. Opt. Express 2013, 21, 662–674. [Google Scholar] [CrossRef] [PubMed]

- Klug, M.A.; Halle, M.W.; Lucente, M.; Plesniak, W.J. A compact prototype one-step Ultragram printer. In Proceedings of the SPIE Practical Holography VII: Imaging and Materials, San Jose, CA, USA, 31 January–5 February 1993; Volume 1914, pp. 15–24. [Google Scholar]

- Suzuki, N.; Tomita, Y. Silica-nanoparticle-dispersed methacrylate photopolymers with net diffraction efficiency near 100%. Appl. Opt. 2004, 43, 2125–2129. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Cao, L.; Wang, Z.; Jin, G. Hybrid polarization-angle multiplexing for volume holography in gold nanoparticle-doped photopolymer. Opt. Lett. 2014, 39, 6891–6894. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Cao, L.; Li, J.; He, Q.; Jin, G.; Zhang, S.; Zhang, F. Improvement of volume holographic performance by plasmon-induced holographic absorption grating. Appl. Phys. Lett. 2013, 102, 061108. [Google Scholar] [CrossRef]

- Tay, S.; Blanche, P.-A.; Voorakaranam, R.; Tunç, A.V.; Lin, W.; Rokutanda, S.; Gu, T.; Flores, D.; Wang, P.; Li, G.; et al. An updatable holographic three-dimensional display. Nature 2008, 451, 694–698. [Google Scholar] [CrossRef] [PubMed]

- Blanche, P.-A.; Bablumian, A.; Voorakaranam, R.; Christenson, C.; Lin, W.; Gu, T.; Flores, D.; Wang, P.; Hsieh, W.-Y.; Kathaperumal, M.; et al. Holographic three-dimensional telepresence using large-area photorefractive polymer. Nature 2010, 468, 80–83. [Google Scholar] [CrossRef] [PubMed]

- Tsutsumi, N.; Kinashi, K.; Tada, K.; Fukuzawa, K.; Kawabe, Y. Fully updatable three-dimensional holographic stereogram display device based on organic monolithic compound. Opt. Express 2013, 21, 19880–19884. [Google Scholar] [CrossRef] [PubMed]

- Tsutsumi, N.; Kinashi, K.; Sakai, W.; Nishide, J.; Kawabe, Y.; Sasabe, H. Real-time three-dimensional holographic display using a monolithic organic compound dispersed film. Opt. Mater. Express 2012, 2, 1003–1010. [Google Scholar] [CrossRef]

- Gao, H.; Liu, P.; Liu, J.; Zheng, Z.; Yao, Q.; Zhou, W.; Xu, F.; Yu, Y.; Zheng, H. Study on permanent holographic recording in trimethylol propane triacrylate-based photopolymer films with high diffraction efficiency. J. Opt. Soc. Am. B 2017, 34, B22–B27. [Google Scholar] [CrossRef]

- Gao, H.; Liu, P.; Zeng, C.; Yao, Q.; Zheng, Z.; Liu, J.; Zheng, H.; Yu, Y.; Zeng, Z.; Sun, T. Holographic storage of three-dimensional image and data using photopolymer and polymer dispersed liquid crystal films. Chin. Phys. B 2016, 25, 094205. [Google Scholar] [CrossRef]

- Lee, B.; Kim, J.-H.; Moon, K.; Kim, I.-J.; Kim, J. Holographic stereogram printing under the non-vibration environment. In Proceedings of the SPIE Three-Dimensional Imaging, Visualization, and Display 2014, Baltimore, MD, USA, 5–9 May 2014; Volume 9117, p. 911704. [Google Scholar]

- Plesniak, W.; Halle, M.; Bove, V.M.; Barabas, J.; Pappu, R. Reconfigurable image projection holograms. Opt. Eng. 2006, 45, 2365–2372. [Google Scholar] [CrossRef]

- St Hilaire, P. Modulation transfer function and optimum sampling of holographic stereograms. Appl. Opt. 1994, 33, 768–774. [Google Scholar] [CrossRef] [PubMed]

- Helseth, L.E. Optical transfer function of three-dimensional display systems. J. Opt. Soc. Am. A 2006, 23, 816–820. [Google Scholar] [CrossRef]

- Jiang, X.; Pei, C.; Liu, J.; Zhao, K.; Yan, X. Optimization of exit pupil function: Improvement on the OTF of full parallax holographic stereograms. J. Opt. 2013, 15, 125402. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, J.; Yan, X.; Huang, Y.; Jiang, X.; Chen, Y.; Zhang, T. Progress in the Synthetic Holographic Stereogram Printing Technique. Appl. Sci. 2018, 8, 851. https://doi.org/10.3390/app8060851

Su J, Yan X, Huang Y, Jiang X, Chen Y, Zhang T. Progress in the Synthetic Holographic Stereogram Printing Technique. Applied Sciences. 2018; 8(6):851. https://doi.org/10.3390/app8060851

Chicago/Turabian StyleSu, Jian, Xingpeng Yan, Yingqing Huang, Xiaoyu Jiang, Yibei Chen, and Teng Zhang. 2018. "Progress in the Synthetic Holographic Stereogram Printing Technique" Applied Sciences 8, no. 6: 851. https://doi.org/10.3390/app8060851

APA StyleSu, J., Yan, X., Huang, Y., Jiang, X., Chen, Y., & Zhang, T. (2018). Progress in the Synthetic Holographic Stereogram Printing Technique. Applied Sciences, 8(6), 851. https://doi.org/10.3390/app8060851