Mechanical and Hydraulic Behaviors of Eco-Friendly Pervious Concrete Incorporating Fly Ash and Blast Furnace Slag

Abstract

:1. Introduction

2. Objective

3. Experimental Program

3.1. Materials

- Cement: P.O 42.5 cement was selected, which was from Hunan Pingtang Cement Plant in Hunan, China. P.O 42.5 means ordinary Portland cement and the 28-day cement mortar strength is 42.5 MPa when the water-cement ratio is 0.45. The chemical components of the cement is shown in Table 1.

- Aggregate: single-sized gravel aggregates with the size in 16–19 mm.

- The FA and BFS used in this study came from Xiangtan Power Plant in Hunan, China. The chemical components of FA and BFS are shown in Table 1.

3.2. Sample Preparation

3.3. Test Methods

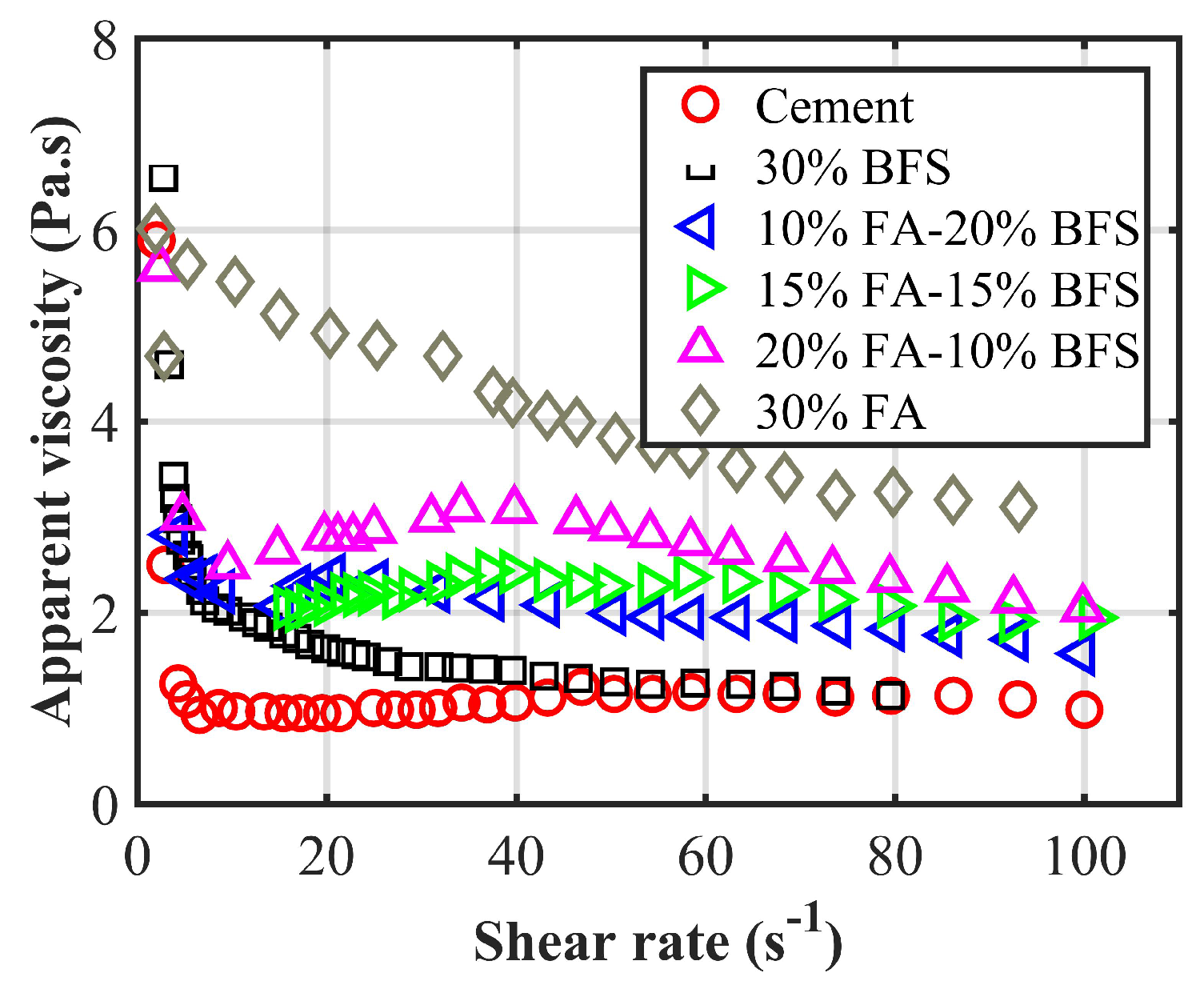

3.3.1. Rheology Test

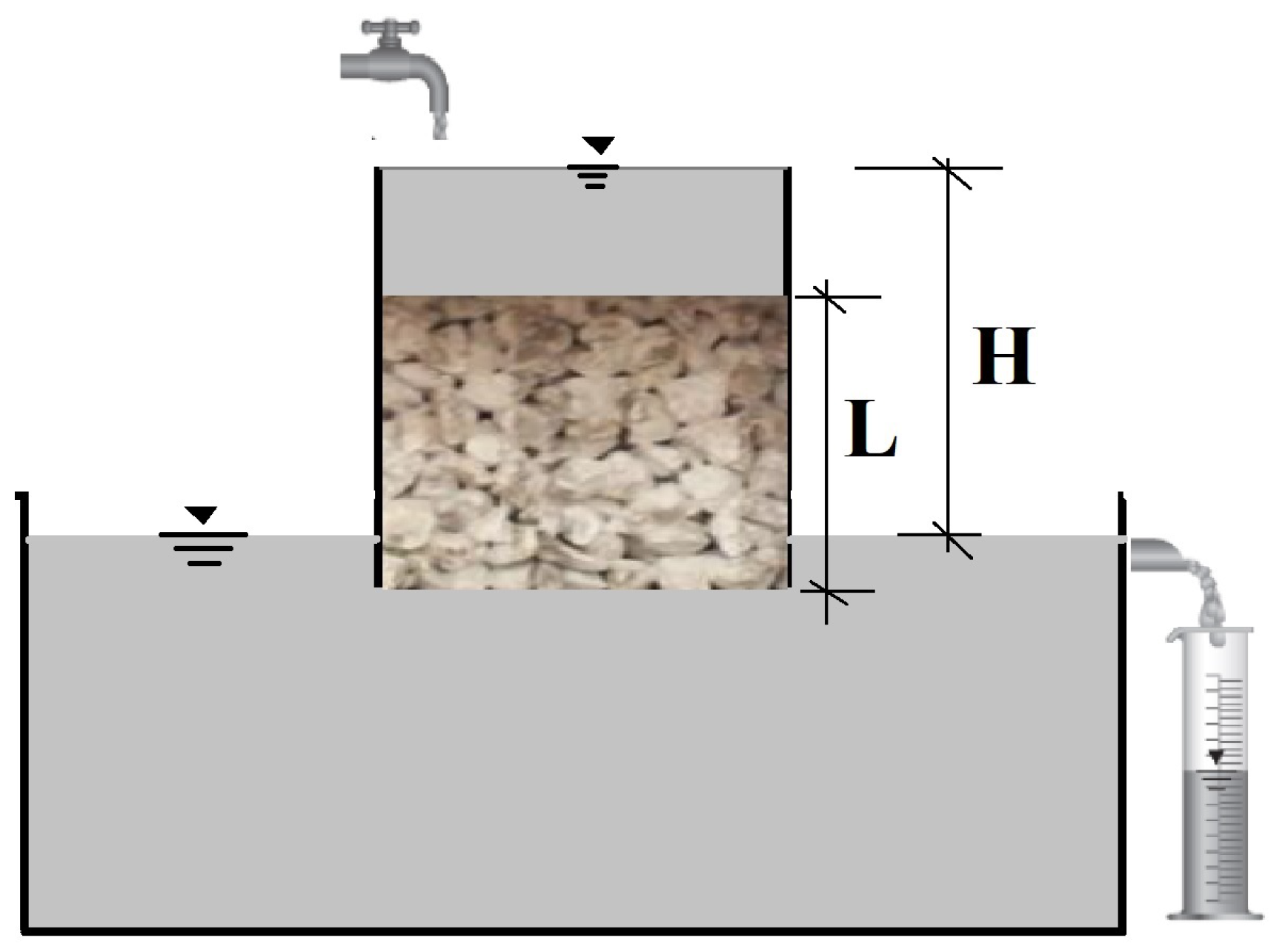

3.3.2. Hydraulic Tests

3.3.3. Mechanical Tests

4. Results and Discussions

4.1. Rheology Test

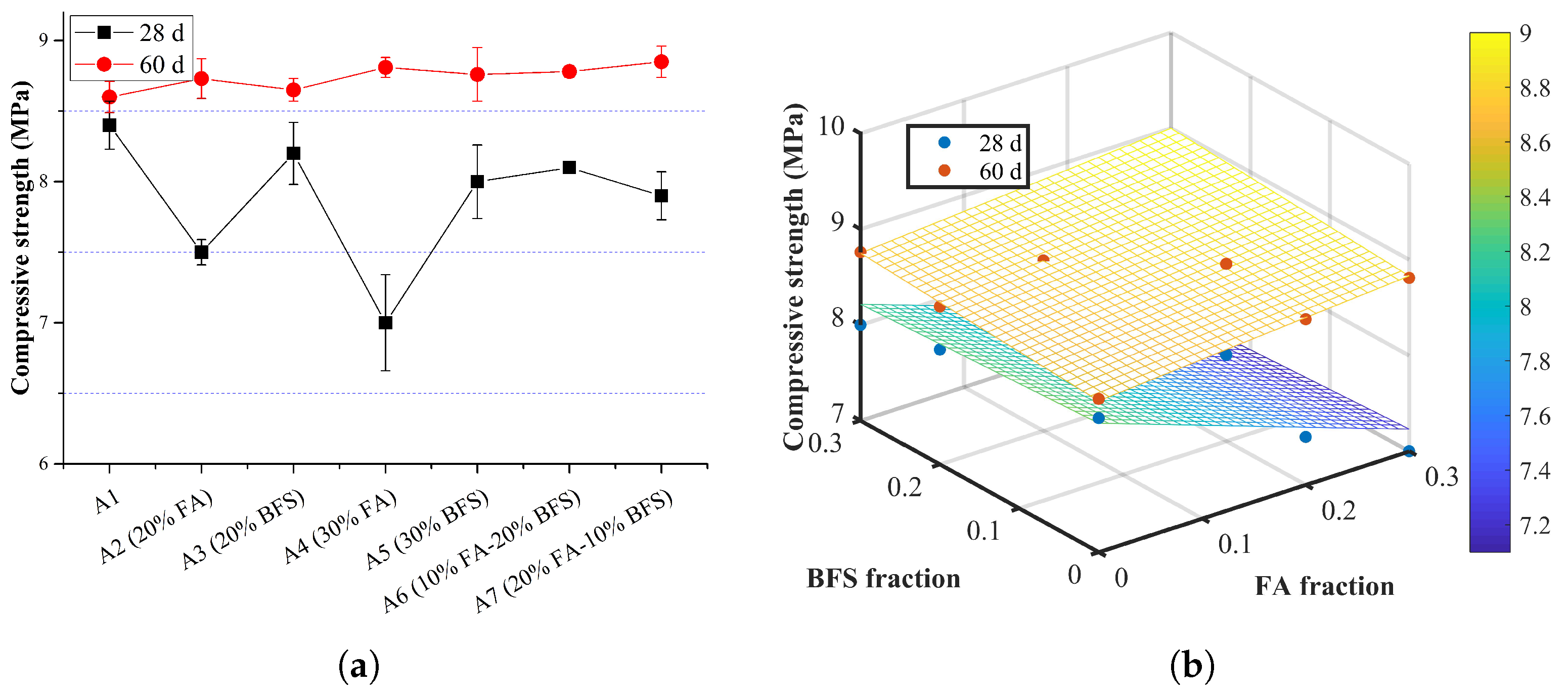

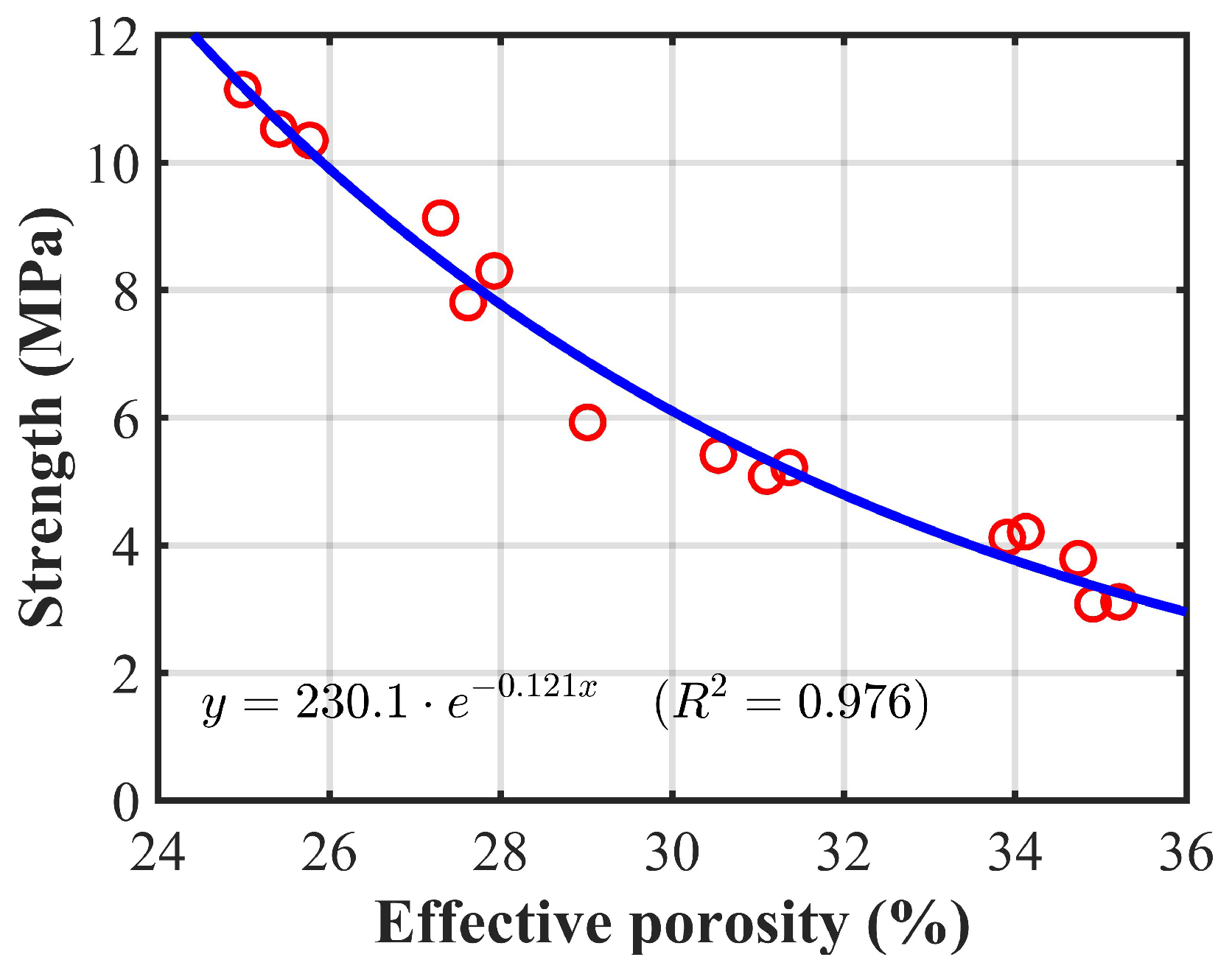

4.2. Compressive Strength

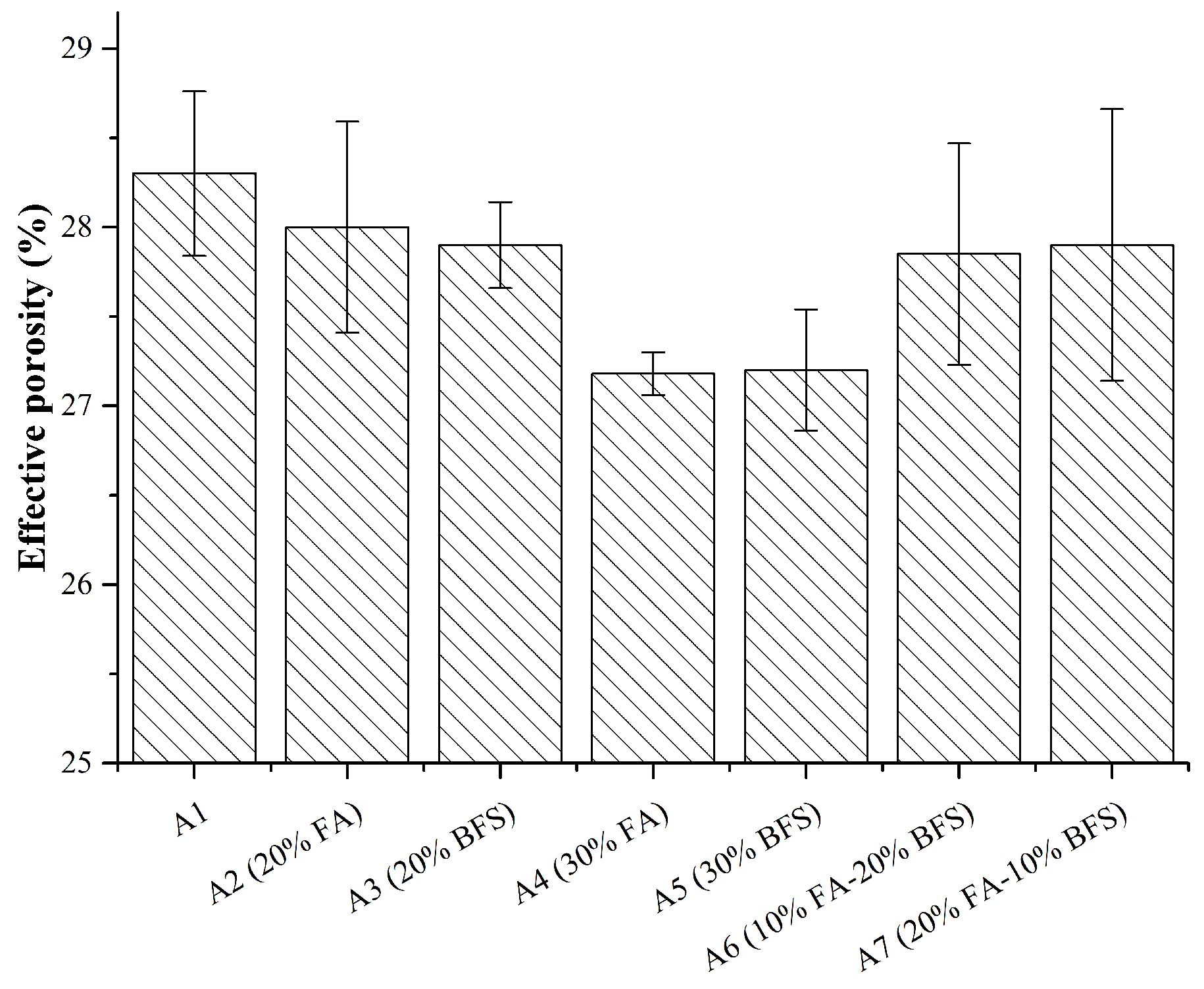

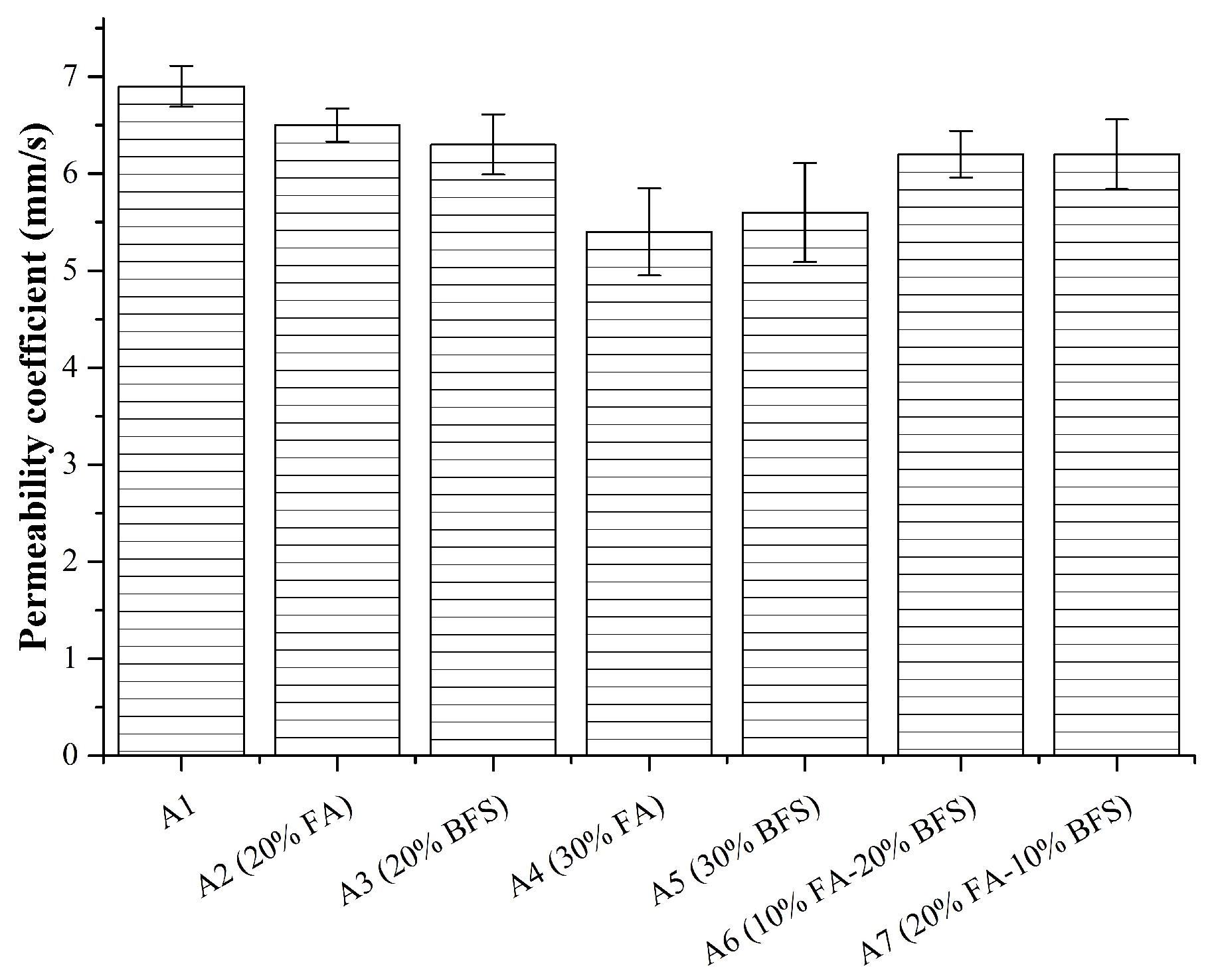

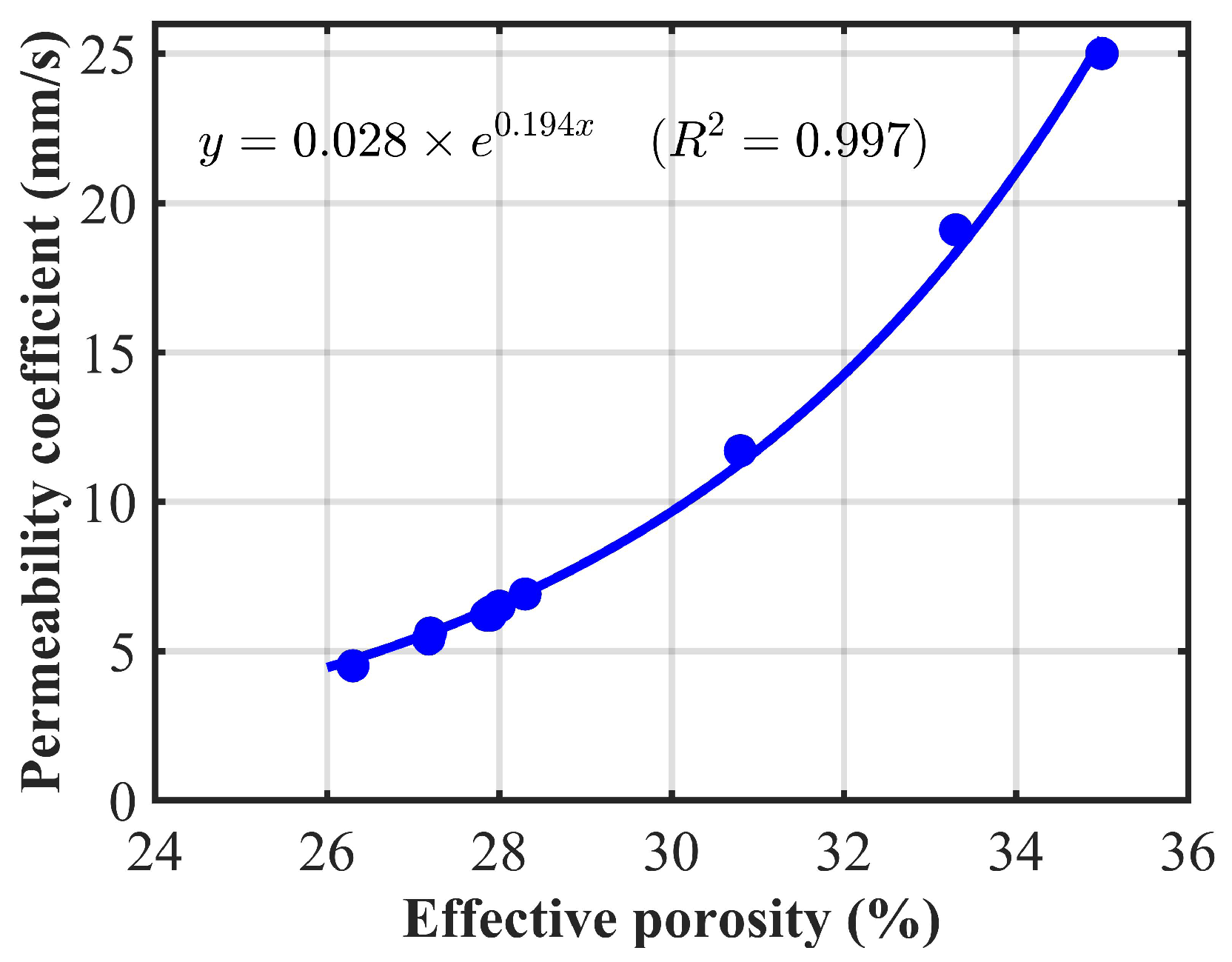

4.3. Hydraulic Performance

5. Conclusions

- FA increased the apparent viscosity, while BFS was not able to change the rheology performance significantly. Rheology performance of cementitious pastes containing FA and/or BFS belonged to the Bingham model.

- FA and BFS both decreased the compressive strength of pervious concrete at 28 d, while FA and/or BFS could slightly increase the compressive strength at 60 d. Compared to BFS, FA plays a more significant role in the compressive strength.

- The effective porosity and permeability coefficient both decreased with the incorporation of FA and/or BFS in the pervious concrete. As the content of FA or BFS increased, the reduction was larger. However, when the replacement rate was 30%, concretes with ternary blends presented larger porosity than binary blends.

- Permeability coefficient and compressive strength both decreased with the increase of effective porosity.

- The use of FA and BFS is a sustainable approach in pervious concrete that considers both the mechanical properties and hydraulic properties.

Author Contributions

Funding

Conflicts of Interest

References

- Neithalath, N.; Sumanasooriya, M.S.; Deo, O. Characterizing pore volume, sizes, and connectivity in pervious concretes for permeability prediction. Mater. Charact. 2010, 61, 802–813. [Google Scholar] [CrossRef]

- Huang, B.; Wu, H.; Shu, X.; Burdette, E.G. Laboratory evaluation of permeability and strength of polymer-modified pervious concrete. Constr. Build. Mater. 2010, 24, 818–823. [Google Scholar] [CrossRef]

- Haselbach, L.; Boyer, M.; Kevern, J.; Schaefer, V. Cyclic heat island impacts on traditional versus pervious concrete pavement systems. Transp. Res. Rec. J. Transp. Res. Board 2011, 107–115. [Google Scholar] [CrossRef]

- Pratt, C.; Newman, A.; Bond, P. Mineral oil bio-degradation within a permeable pavement: Long term observations. Water Sci. Technol. 1999, 39, 103–109. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. Stormwater Technology Fact Sheet: Porous Pavement; USEPA: Washington, DC, USA, 1999.

- Wu, H.; Liu, Z.; Yang, Y.; Bai, S. Characterizing Thermal Impacts of Pavement Materials on Urban Heat Island (UHI) Effect. DEStech Trans. Eng. Technol. Res. 2016. [Google Scholar] [CrossRef]

- Wu, H.; Liu, Z.; Sun, B.; Yin, J. Experimental investigation on freeze–thaw durability of Portland cement pervious concrete (PCPC). Constr. Build. Mater. 2016, 117, 63–71. [Google Scholar] [CrossRef]

- Obla, K.H. Pervious concrete for sustainable development. In Proceedings of the Recent Advances in Concrete Technology, Washington, DC, USA, 19–21 September 2007; pp. 1–6. [Google Scholar]

- Joshaghani, A.; Ramezanianpour, A.A.; Ataei, O.; Golroo, A. Optimizing pervious concrete pavement mixture design by using the Taguchi method. Constr. Build. Mater. 2015, 101, 317–325. [Google Scholar] [CrossRef]

- Tennis, P.D.; Leming, M.L.; Akers, D.J. Pervious Concrete Pavements; Number PCA Serial No. 2828; Portland ceMent Association: Skokie, IL, USA, 2004. [Google Scholar]

- Schaefer, V.R.; Wang, K.; Suleiman, M.T.; Kevern, J.T. Mix Design Development for Pervious Concrete in Cold Weather Climates; Technical Report; National Concrete Pavement Technology Center: Ames, IA, USA, 2006. [Google Scholar]

- Ibrahim, A.; Mahmoud, E.; Yamin, M.; Patibandla, V.C. Experimental study on Portland cement pervious concrete mechanical and hydrological properties. Constr. Build. Mater. 2014, 50, 524–529. [Google Scholar] [CrossRef]

- Lim, E.; Tan, K.H.; Fwa, T.F. Effect of mix proportion on strength and permeability of pervious concrete for use in pavement. J. East. Asia Soc. Transp. Stud. 2013, 10, 1565–1575. [Google Scholar]

- Deo, O. Influence of Material Structure on the Structural and Environmental Properties of Pervious Concretes. Ph.D. Thesis, Clarkson University, Potsdam, NY, USA, 2011. [Google Scholar]

- Torres, A.; Hu, J.; Ramos, A. The effect of the cementitious paste thickness on the performance of pervious concrete. Constr. Build. Mater. 2015, 95, 850–859. [Google Scholar] [CrossRef]

- Statista. Cement Production Globally and in the U.S. from 2010 to 2017. Available online: www.statista.com/statistics/219343/cement-production-worldwide/ (accessed on 24 May 2018).

- Mehta, P.K. Concrete: Structure, Properties and Materials; Prentice-Hall: Englewood Cliffs, NJ, USA, 1986. [Google Scholar]

- Li, G.; Zhao, X. Properties of concrete incorporating fly ash and ground granulated blast-furnace slag. Cem. Concr. Compos. 2003, 25, 293–299. [Google Scholar] [CrossRef]

- Deb, P.S.; Nath, P.; Sarker, P.K. The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Mater. Des. (1980–2015) 2014, 62, 32–39. [Google Scholar] [CrossRef]

- Song, W.; Yin, J. Hybrid effect evaluation of steel fiber and carbon fiber on the performance of the fiber reinforced concrete. Materials 2016, 9, 704. [Google Scholar] [CrossRef] [PubMed]

- Leng, F.; Feng, N.; Lu, X. An experimental study on the properties of resistance to diffusion of chloride ions of fly ash and blast furnace slag concrete. Cem. Concr. Res. 2000, 30, 989–992. [Google Scholar] [CrossRef]

- Glinicki, M.A.; Jóźwiak-Niedźwiedzka, D.; Gibas, K.; Dąbrowski, M. Influence of blended cements with Calcareous fly ash on chloride ion migration and carbonation resistance of concrete for durable structures. Materials 2016, 9, 18. [Google Scholar] [CrossRef] [PubMed]

- Muthaiyan, U.M.; Thirumalai, S. Studies on the properties of pervious fly ash–cement concrete as a pavement material. Cogent Eng. 2017, 4, 1318802. [Google Scholar] [CrossRef]

- Lee, J.W.; Jang, Y.I.; Park, W.S.; Kim, S.W. A study on mechanical properties of porous concrete using cementless binder. Int. J. Concr. Struct. Mater. 2016, 10, 527–537. [Google Scholar] [CrossRef]

- She, B.; Ming, Y. GT/B 50081-2002: Standard for Test Method of Mechanical Properties in Ordinary Concrete; Standard; Ministry of Housing and Urban-Rural Development of China: Beijing, China, 2002.

- Chindaprasirt, P.; Hatanaka, S.; Chareerat, T.; Mishima, N.; Yuasa, Y. Cement paste characteristics and porous concrete properties. Constr. Build. Mater. 2008, 22, 894–901. [Google Scholar] [CrossRef]

- ASTM C1754/C1754M-12: Standard Test Method for Density and Void Content of Hardened Pervious Concrete; Standard; ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D2434: Standard Test Method for Permeability of Granular Soils (Constant Head); Standard; ASTM International: West Conshohocken, PA, USA, 2006.

- Wallevik, J.E. Rheology of Particle Suspensions: Fresh Concrete, Mortar and cEment Paste with Various Types of Lignosulfonates; Fakultet for Ingeniørvitenskap og Teknologi: Trondheim, Norway, 2003. [Google Scholar]

- Bingham, E.C. Fluidity and Plasticity; McGraw-Hill: Columbus, OH, USA, 1922; Volume 2. [Google Scholar]

- Bentz, D.P.; Ferraris, C.F.; Galler, M.A.; Hansen, A.S.; Guynn, J.M. Influence of particle size distributions on yield stress and viscosity of cement–fly ash pastes. Cem. Concr. Res. 2012, 42, 404–409. [Google Scholar] [CrossRef]

- Monteiro, P. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Publishing: Columbus, OH, USA, 2006. [Google Scholar]

- Transport of the People’s Republic of China. Code for Design of Highway Reinforced Concrete and Prestressed Concrete Bridges and Culverts; China Communications Press: Beijing, China, 2004.

- CEB-FIP. CEB-FIP Model Code 1990: Design Code; Thomas Telford: London, UK, 1993. [Google Scholar]

- Mehta, P. Studies on the mechanisms by which condensed silica fume improves the properties of concrete: Durability aspects. In Proceedings of the International Workshop on Condensed Silica Fume in Concrete, Ottawa, ON, Canada, 1987; Volume 17. [Google Scholar]

- Anastasiou, E.; Filikas, K.G.; Stefanidou, M. Utilization of fine recycled aggregates in concrete with fly ash and steel slag. Constr. Build. Mater. 2014, 50, 154–161. [Google Scholar] [CrossRef]

- Gencel, O.; Koksal, F.; Ozel, C.; Brostow, W. Combined effects of fly ash and waste ferrochromium on properties of concrete. Constr. Build. Mater. 2012, 29, 633–640. [Google Scholar] [CrossRef]

- Haselbach, L.M.; Valavala, S.; Montes, F. Permeability predictions for sand-clogged Portland cement pervious concrete pavement systems. J. Environ. Manag. 2006, 81, 42–49. [Google Scholar] [CrossRef] [PubMed]

- Montes, F.; Haselbach, L. Measuring hydraulic conductivity in pervious concrete. Environ. Eng. Sci. 2006, 23, 960–969. [Google Scholar] [CrossRef]

- Lian, C.; Zhuge, Y.; Beecham, S. The relationship between porosity and strength for porous concrete. Constr. Build. Mater. 2011, 25, 4294–4298. [Google Scholar] [CrossRef]

| Components | Cement (%) | FA (%) | BFS (%) |

|---|---|---|---|

| SiO | 21.38 | 50.15 | 30.7 |

| AlO | 5.63 | 30.51 | 9.8 |

| FeO | 3.56 | 2.08 | 2.1 |

| CaO | 63.72 | 12.5 | 47.5 |

| MgO | 2.15 | 0.088 | 3.8 |

| SO | 1.75 | 0.4 | 4.4 |

| NaO | 1.02 | 1.32 | 1.07 |

| LOI | 0.79 | 1.13 | 0.63 |

| Total | 100 | 98.2 | 100 |

| No. | Mass Percentage | W-C Ratio | ||

|---|---|---|---|---|

| C | FA | BFS | ||

| M1 | 100 | 0 | 0 | 0.35 |

| M2 | 70 | 0 | 30 | 0.35 |

| M3 | 70 | 10 | 20 | 0.35 |

| M4 | 70 | 15 | 15 | 0.35 |

| M5 | 70 | 20 | 10 | 0.35 |

| M6 | 70 | 30 | 0 | 0.35 |

| Cement (kg) | Compressive Strength (MPa) | Effective Porosity (%) | Permeability Coefficient (Cm/s) |

|---|---|---|---|

| 160 | 3.3 | 35.0 | 25.0 |

| 210 | 4.5 | 33.3 | 19.1 |

| 240 | 5.5 | 30.8 | 11.7 |

| 280 | 8.4 | 28.3 | 6.9 |

| 320 | 10.6 | 26.3 | 4.5 |

| No. | C (kg/m) | FA (kg/m) | BFS (kg/m) |

|---|---|---|---|

| C | 280 | 0 | 0 |

| A1 | 224 | 56 () | 0 |

| A2 | 224 | 0 | 56 () |

| A3 | 196 | 84 () | 0 |

| A4 | 196 | 0 | 84 () |

| A5 | 196 | 28 () | 56 () |

| A6 | 196 | 56 () | 28 () |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, H.; Yin, J.; Song, W. Mechanical and Hydraulic Behaviors of Eco-Friendly Pervious Concrete Incorporating Fly Ash and Blast Furnace Slag. Appl. Sci. 2018, 8, 859. https://doi.org/10.3390/app8060859

Peng H, Yin J, Song W. Mechanical and Hydraulic Behaviors of Eco-Friendly Pervious Concrete Incorporating Fly Ash and Blast Furnace Slag. Applied Sciences. 2018; 8(6):859. https://doi.org/10.3390/app8060859

Chicago/Turabian StylePeng, Hua, Jian Yin, and Weimin Song. 2018. "Mechanical and Hydraulic Behaviors of Eco-Friendly Pervious Concrete Incorporating Fly Ash and Blast Furnace Slag" Applied Sciences 8, no. 6: 859. https://doi.org/10.3390/app8060859