A Fully Coupled Model for the Simulation of Gas Flow in Multiscale Shale Reservoirs Combining Multiple Effects

Abstract

:1. Introduction

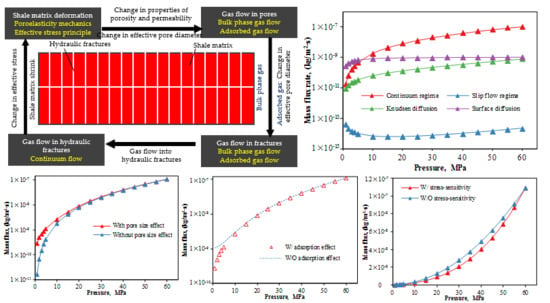

2. Mathematical Model

3. Formulation of the Mathematical Model

3.1. Pore Size Distribution within Matrix

3.2. Modified Effective Pore Diameter with Effects of Adsorption/Desorption and Stress-Sensitivity

3.2.1. Stress-Sensitivity

3.2.2. Adsorption/Desorption

3.2.3. Modified Effective Pore Diameter

3.3. Gas Flow Regimes within the Matrix

3.3.1. Bulk Phase Gas Flow Regimes

3.3.2. Adsorbed Gas Flow

3.3.3. Comprehensive Gas Flow Model

3.4. Gas Flow in Hydraulic Fractures

4. Model Validation

4.1. Comparison with Traditional Models

4.1.1. Civan Model

4.1.2. Dusty-Gas Model (DGM Model)

4.1.3. Comparison of the Models

4.2. History Matching for Marcellus Shale

5. Results and Discussion

5.1. Comparison of Mass Flux in Various Flow Regimes

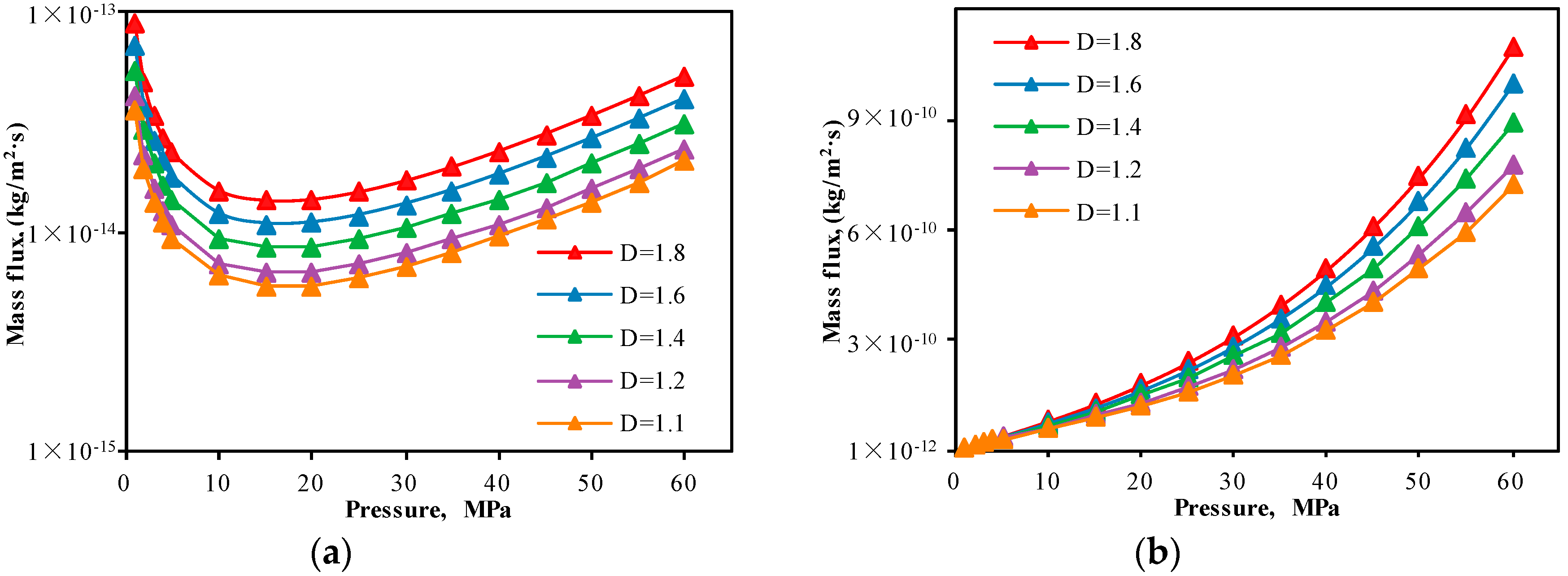

5.2. Impact of Multiscale Pores

5.3. Impact of Adsorption/Desorption

5.4. Impact of Stress-Sensitivity

5.5. Comparison of Impacts of Adsorption/Desorption and Stress-Sensitivity

6. Conclusions

- Pore size distribution has a significant influence on gas flow in shale reservoirs. Multiscale pore structure means that various bulk flow regimes may occur rather than single continuum flow dominant in shale reservoirs. The gas flow capacity will be underestimated without considering the impact of pore size distribution. Because the frequency of pores in a certain pore size scale is a positive correlation with fractal dimension. A large amount of pores in slip flow and Knudson diffusion with respect to a larger fractal dimension enhance the apparent permeability of shale reservoirs.

- The gas flow capacity will be overestimated without consideration of the effect of stress-sensitivity. Matrix permeability and fracture permeability decrease with decreasing reservoir pressure because of the extrusion resulted from an increase in effective stress. The variation on gas flow within fractures permeability caused by a change of effective stress is more significant than that on gas flow within the matrix with a high compressibility. In addition, Stress-sensitivity has a significant influence on bulk phase gas flow. Because matrix shrinkage with increasing effective stress, resulting in diminution of the effective pore diameter for bulk phase gas flow.

- Gas flow capacity of bulk phase gas will be overestimated without consideration of the impacts of adsorption/desorption due to the adsorbed gas molecules along the pore walls will reduce the available pore space for bulk phase gas flow. In addition, considerable adsorbed gas contents are stored in the small pores results in surface diffusion, which enhances the transport of gas molecules along molecular concentration gradients.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, J.; Liu, H.Q.; Wang, L.; Zhang, H.L.; Luo, H.S.; Gao, Y. Apparent permeability for gas transport in nanopores of organic shale reservoirs including multiple effects. Int. J. Coal Geol. 2015, 152, 50–62. [Google Scholar] [CrossRef]

- Javadpour, F.; Fisher, D.; Unsworth, M. Nanoscale gas flow in shale gas sediments. J. Can. Pet. Technol. 2007, 46, 55–61. [Google Scholar] [CrossRef]

- Wu, K.L.; Li, X.F.; Chen, Z.X. Micro-scale effects of gas transport in organic nanopores of shale gas reservoirs. Nat. Gas Ind. 2016, 36, 51–64. [Google Scholar]

- Sun, H.; Yao, J.; Cao, Y.C.; Fan, D.Y.; Zhang, L. Characterization of gas transport behaviors in shale gas and tight gas reservoirs by digital rock analysis. Int. J. Heat Mass Transf. 2017, 104, 227–239. [Google Scholar] [CrossRef]

- Wu, K.L.; Li, X.F.; Chen, Z.X.; Li, J.; Liang, Y.F.; WU, X. Real gas transport mechanism and mathematical model through complex nanopores and microfractures in shale gas reservoirs. Sci. Sin. 2016, 46, 851–863. [Google Scholar]

- Cao, P.; Liu, J.; Leong, Y.K. A fully coupled multiscale shale deformation-gas transport model for the evaluation of shale gas extraction. Fuel 2016, 178, 103–117. [Google Scholar] [CrossRef]

- Yao, J.; Sun, H.; Fan, D.Y.; Wang, C.C.; Sun, Z.X. Numerical simulation of gas transport mechanisms in tight shale gas reservoirs. Pet. Sci. 2013, 10, 528–537. [Google Scholar] [CrossRef]

- Beskok, A.; Karniadakis, G.E. A model for flows in channels, pipes, and ducts at micro and nano scales. Microscale Thermophys. Eng. 1999, 3, 43–77. [Google Scholar]

- Yu, B.M.; Cheng, P. A fractal permeability model for bi-dispersed porous media. Int. J. Heat Mass Transf. 2002, 45, 2983–2993. [Google Scholar] [CrossRef]

- Civan, F.; Rai, C.S.; Sondergeld, C.H. Shale-gas permeability and diffusivity inferred by improved formulation of relevant retention and transport mechanisms. Transp. Porous Med. 2011, 86, 925–944. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Jensen, J.L.; Pedersen, P.K.; Freeman, M. Innovative methods for flow-unit and pore-structure analyses in a tight siltstone and shale gas reservoir. AAPG Bull. 2012, 96, 355–374. [Google Scholar] [CrossRef]

- Anderson, J.M.; Moorman, M.W.; Brown, J.R.; Hochrein, J.M.; Thornberg, S.M.; Achyuthan, K.E.; Gallis, M.A.; Torczynski, J.R.; Khraishi, T.; Manginell, R.P. Isothermal mass flow measurements in microfabricated rectangular channels over a very wide Knudsen range. J. Micromech. Microeng. 2014, 24, 308–314. [Google Scholar] [CrossRef]

- Cui, X.; Bustin, A.M.M.; Bustin, R.M. Measurements of gas permeability and diffusivity of tight reservoir rocks: Different approaches and their applications. Geofluids 2009, 9, 208–223. [Google Scholar] [CrossRef]

- Javadpour, F. Nanopores and apparent permeability of gas flow in mudrocks (shales and siltstones). J. Can. Pet. Technol. 2009, 48, 16–21. [Google Scholar] [CrossRef]

- Freeman, C.M.; Moridis, G.J.; Blasingame, T.A. A numerical study of microscale flow behavior in tight gas and shale gas reservoir systems. Transp. Porous Med. 2011, 90, 253–268. [Google Scholar] [CrossRef]

- Deng, J.; Zhu, W.; Ma, Q. A new seepage model for shale gas reservoir and productivity analysis of fractured well. Fuel 2014, 124, 232–240. [Google Scholar] [CrossRef]

- Heller, R.; Vermylen, J.; Zoback, M. Experimental investigation of matrix permeability of gas shales. AAPG Bull. 2014, 98, 975–995. [Google Scholar] [CrossRef]

- Song, F.Q.; Zhang, X.; Huang, X.H.; Long, Y.Q. The flow characteristics of shale gas through shale rock matrix in nano-scale and water imbibition on shale sheets. Sci. Sin. 2016, 46, 120–126. [Google Scholar] [CrossRef]

- Chen, D.; Pan, Z.J.; Ye, Z.H. Dependence of gas shale fracture permeability on effective stress and reservoir pressure: Model match and insights. Fuel 2015, 139, 383–392. [Google Scholar] [CrossRef]

- Mi, L.D.; Jiang, H.Q.; Li, J.J. Shale gas apparent permeability model coupling the transport mechanisms in matrix and natural fractures. Sci. Sin. 2016, 46, 1064–1070. [Google Scholar]

- Zhang, R.; Ning, Z.F.; Yang, F. Experimental study on microscopic pore structure controls on shale permeability under compaction process. Nat. Gas Geosci. 2014, 25, 1284–1289. [Google Scholar]

- Moghaddam, R.N.; Aghabozorgi, S.; Foroozesh, J. Numerical simulation of gas production from tight, ultratight and shale gas reservoirs: Flow regimes and geomechanical effects. In Proceedings of the EUROPEC 2015, Madrid, Spain, 1–4 June 2015. [Google Scholar]

- Warren, J.E.; Root, P.J. The behavior of naturally fractured reservoirs. Soc. Pet. Eng. J. 1963, 3, 245–255. [Google Scholar] [CrossRef]

- Liu, J.; Bodvarsson, G.S.; Wu, Y.S. Analysis of flow behavior in fractured lithophysal reservoirs. J. Contam. Hydrol. 2003, 62–63, 189–211. [Google Scholar] [CrossRef]

- Wu, Y.S.; Liu, H.H.; Bodvarsson, G.S. A triple-continuum approach for modeling flow and transport processes in fractured rock. J. Contam. Hydrol. 2004, 73, 145–179. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hou, X.W.; Zhu, Y.M.; Chen, S.B.; Wang, Y. Gas flow mechanisms under the effects of pore structures and permeability characteristics in source rocks of coal measures in Qinshui Basin, China. Energ Explor. Exploit. 2017, 35, 338–355. [Google Scholar] [CrossRef] [Green Version]

- Civan, F. Effective correlation of apparent gas permeability in tight porous media. Transp. Porous Med. 2010, 82, 375–384. [Google Scholar] [CrossRef]

- Yeager, B.B.; Meyer, B.R. Injection/fall-off testing in the Marcellus shale: Using reservoir knowledge to improve operational efficiency. In Proceedings of the SPE Eastern Regional Meeting, Morgantown, WV, USA, 13–15 October 2010; Society of Petroleum Engineers: Richardson, TX, USA, 2010. [Google Scholar]

- Johnson, J.D.; Graney, J.R. Fingerprinting Marcellus Shale waste products from Pb isotope and trace metal perspectives. Appl. Geochem. 2015, 60, 104–115. [Google Scholar] [CrossRef]

- Kargbo, D.M.; Wilhelm, R.G.; Campbell, D.J. Natural Gas Plays in the Marcellus Shale: Challenges and Potential Opportunities. Environ. Sci. Technol. 2010, 44, 5679–5684. [Google Scholar] [CrossRef] [PubMed]

- Yu, W.; Zhang, T.; Du, S.; Sepehrnoori, K. Numerical study of the effect of uneven proppant distribution between multiple fractures on shale gas well performance. Fuel 2015, 142, 189–198. [Google Scholar] [CrossRef]

- Yu, B.M.; Liu, W. Fractal analysis of permeabilities for porous media. AIChE J. 2004, 50, 46–57. [Google Scholar] [CrossRef] [Green Version]

- Yu, B.M.; Li, J.H. Some fractal characters of porous media. Fractals 2011, 9, 365–372. [Google Scholar] [CrossRef]

- Yu, W.; Sepehrnoori, K. Simulation of gas desorption and geomechanics effects for unconventional gas reservoirs. Fuel 2013, 116, 455–464. [Google Scholar] [CrossRef]

- Alramahi, B.; Sundberg, M.I. Proppant embedment and conductivity of hydraulic fractures in shales. In Proceedings of the 46th US Rock Mechanics/Geomechanics Symposium, Chicago, IL, USA, 24–27 June 2012. [Google Scholar]

- Dong, J.J.; Hsu, J.Y.; Wu, W.J.; Shimamoto, T.; Hung, J.H.; Yeh, E.C.; Wu, Y.H.; Sone, H. Stress-dependence of the permeability and porosity of sandstone and shale from TCDP Hole-A. Int. J. Rock Mech. Min. Sci. 2010, 47, 1141–1157. [Google Scholar] [CrossRef]

- Langmuir, I. The adsorption of gases on plane surface of glass, mica and platinum. J. Am. Chem. Soc. 1918, 40, 1361–1403. [Google Scholar] [CrossRef]

- Kast, W.; Hohenthanner, C.R. Mass transfer within the gas-phase of porous media. Int. J. Heat Mass Transf. 2000, 43, 807–823. [Google Scholar] [CrossRef]

- Ziarani, A.S.; Aguilera, R. Knudsen’s permeability correction for tight porous media. Transp. Porous Med. 2012, 91, 239–260. [Google Scholar] [CrossRef]

- Clifford, K.H.; Webb, S.W. Gas transport in Porous Media. Transp. Porous Med. 1996, 14, 3576–3582. [Google Scholar]

| Parameters | Value | Unit |

|---|---|---|

| Reservoir depth | 2619.1 | m |

| Initial reservoir pressure gradient | 1.40 × 104 | Pa/m |

| Initial reservoir pressure | 3.26 × 107 | Pa |

| Reservoir temperature | 352.55 | K |

| Gas viscosity | 2.01 × 10−5 | Pa·s |

| Initial matrix permeability | 0.0006 | mD |

| Initial hydraulic fracture permeability | 30 | mD |

| Initial matrix porosity | 0.065 | fraction |

| Surface diffusion coefficient | 1.0 × 10−8 | m2/s |

| Langmuir pressure | 3.0 × 106 | Pa |

| Langmuir volume | 2.5 | m3/t |

| Initial gas saturation | 0.70 | fraction |

| Drainage Area | 80 | acres |

| Wellbore radius | 0.3646 | ft |

| Number of fractures | 17 | Dimensionless |

| Horizontal well length | 426.7 | m |

| Parameters | Value | Unit |

|---|---|---|

| Reservoir depth | 2500 | m |

| Initial reservoir pressure gradient | 1.0 × 104 | Pa/m |

| Initial reservoir pressure | 6.0 × 107 | Pa |

| Reservoir temperature | 323 | K |

| Gas viscosity | 2.01 × 10−5 | Pa·s |

| Initial matrix porosity | 0.06 | fraction |

| Initial permeability | 0.006 | mD |

| Pore tortuosity factor | 1.5 | fraction |

| Compressibility for permeability | 6.0 × 10−7 | Pa−1 |

| Compressibility for porosity | 4.0 × 10−7 | Pa−1 |

| Pore area fractal dimension | 1.8 | fraction |

| Langmuir pressure | 3.0 × 106 | Pa |

| Langmuir volume | 2.5 | m3/t |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, X.; Zhu, Y.; Liu, Y.; Wang, Y. A Fully Coupled Model for the Simulation of Gas Flow in Multiscale Shale Reservoirs Combining Multiple Effects. Appl. Sci. 2018, 8, 1063. https://doi.org/10.3390/app8071063

Hou X, Zhu Y, Liu Y, Wang Y. A Fully Coupled Model for the Simulation of Gas Flow in Multiscale Shale Reservoirs Combining Multiple Effects. Applied Sciences. 2018; 8(7):1063. https://doi.org/10.3390/app8071063

Chicago/Turabian StyleHou, Xiaowei, Yanming Zhu, Yu Liu, and Yang Wang. 2018. "A Fully Coupled Model for the Simulation of Gas Flow in Multiscale Shale Reservoirs Combining Multiple Effects" Applied Sciences 8, no. 7: 1063. https://doi.org/10.3390/app8071063

APA StyleHou, X., Zhu, Y., Liu, Y., & Wang, Y. (2018). A Fully Coupled Model for the Simulation of Gas Flow in Multiscale Shale Reservoirs Combining Multiple Effects. Applied Sciences, 8(7), 1063. https://doi.org/10.3390/app8071063