Dynamic Observer Modeling and Minimum-Variance Self-Tuning Control of EDM Interelectrode Gap

Abstract

:Featured Application

Abstract

1. Introduction

2. EDM Interelectrode Gap Model Based on Plate Capacitor

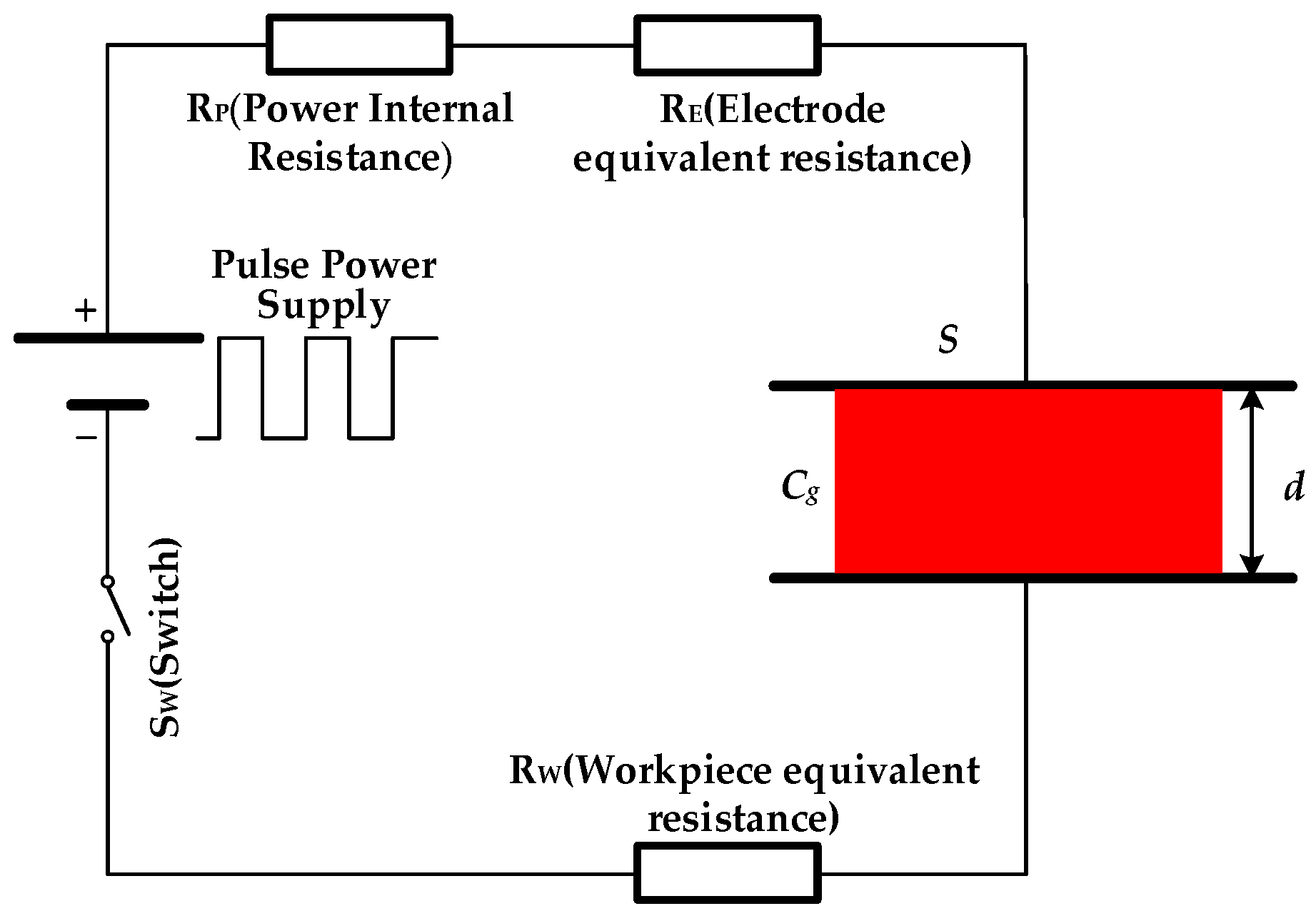

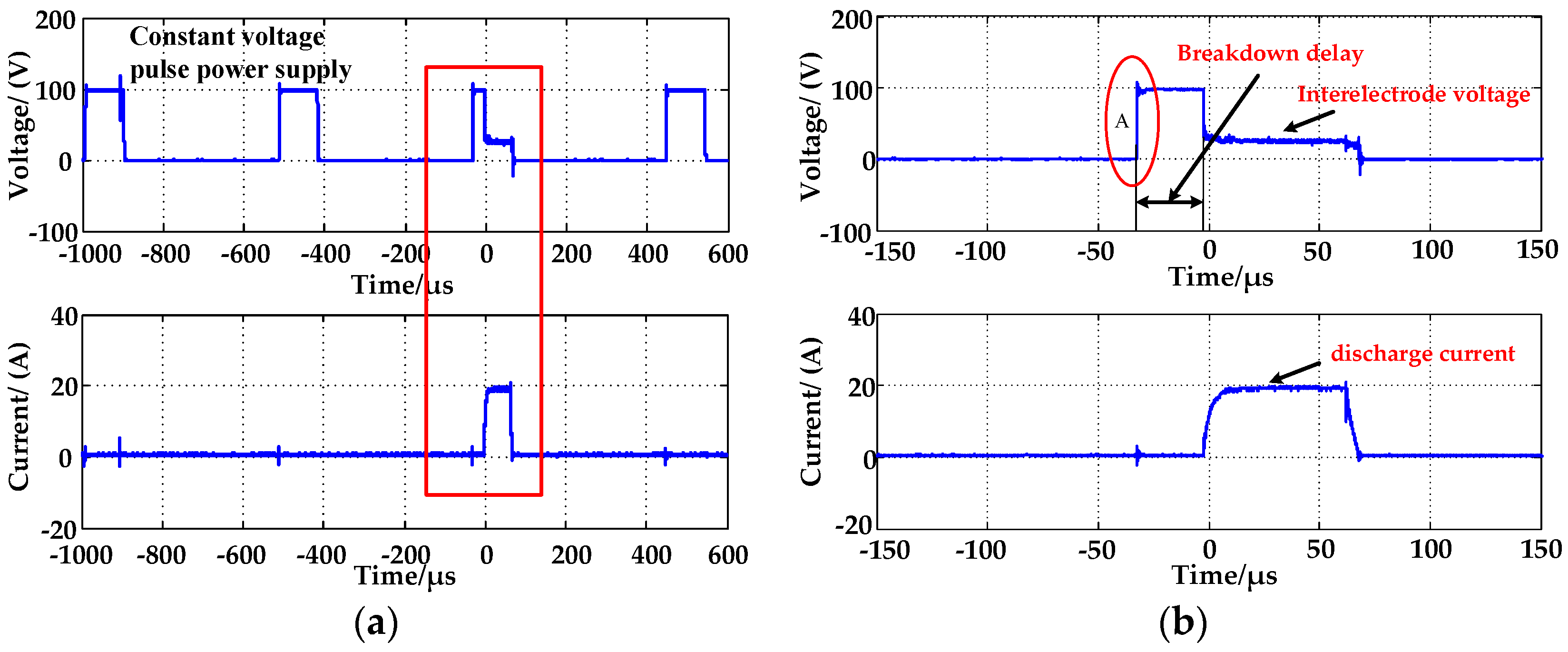

2.1. EDM Equivalent Circuit

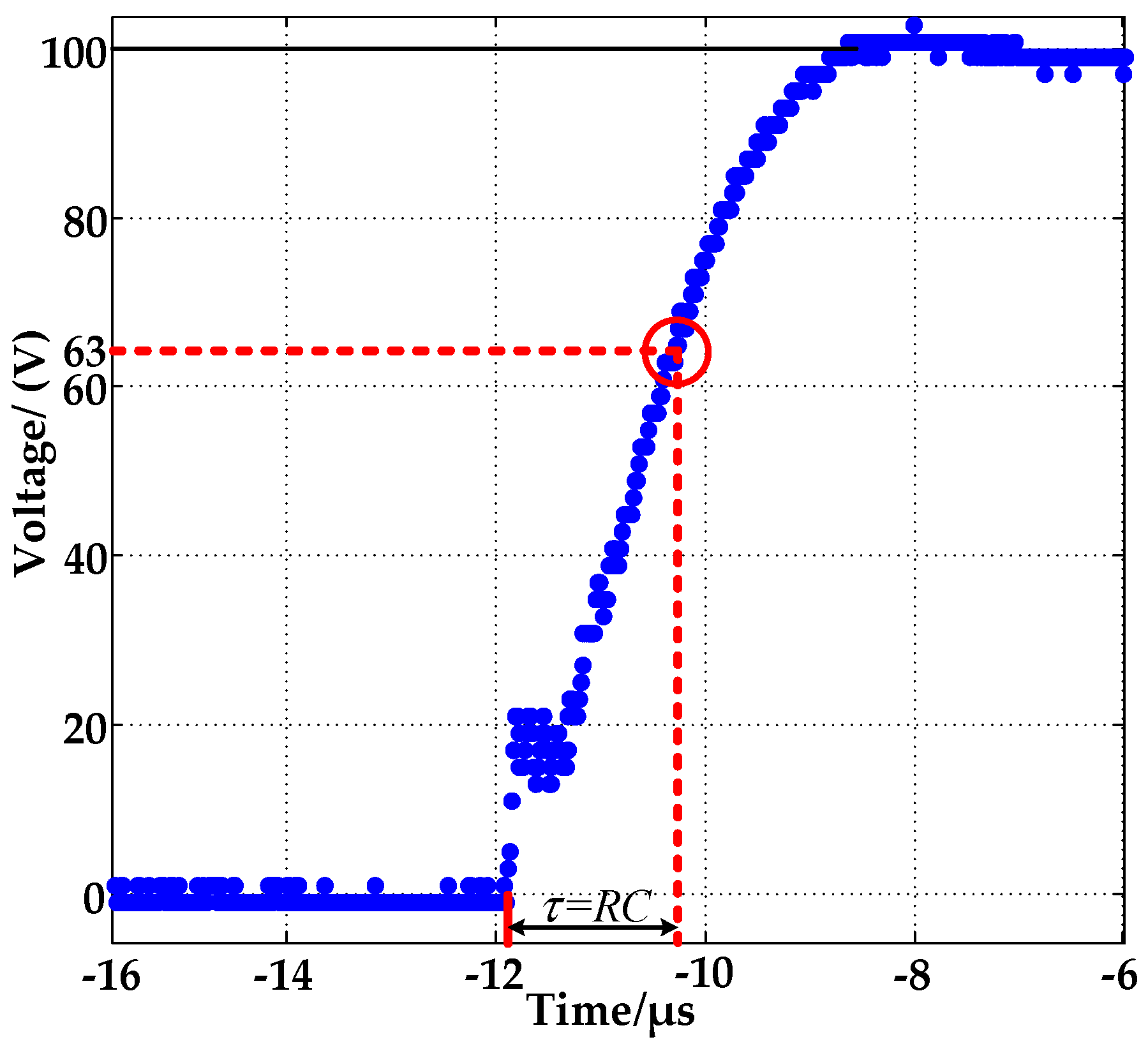

2.2. EDM Interelectrode Gap Modeling

2.3. Determination of β

2.4. Analysis of β

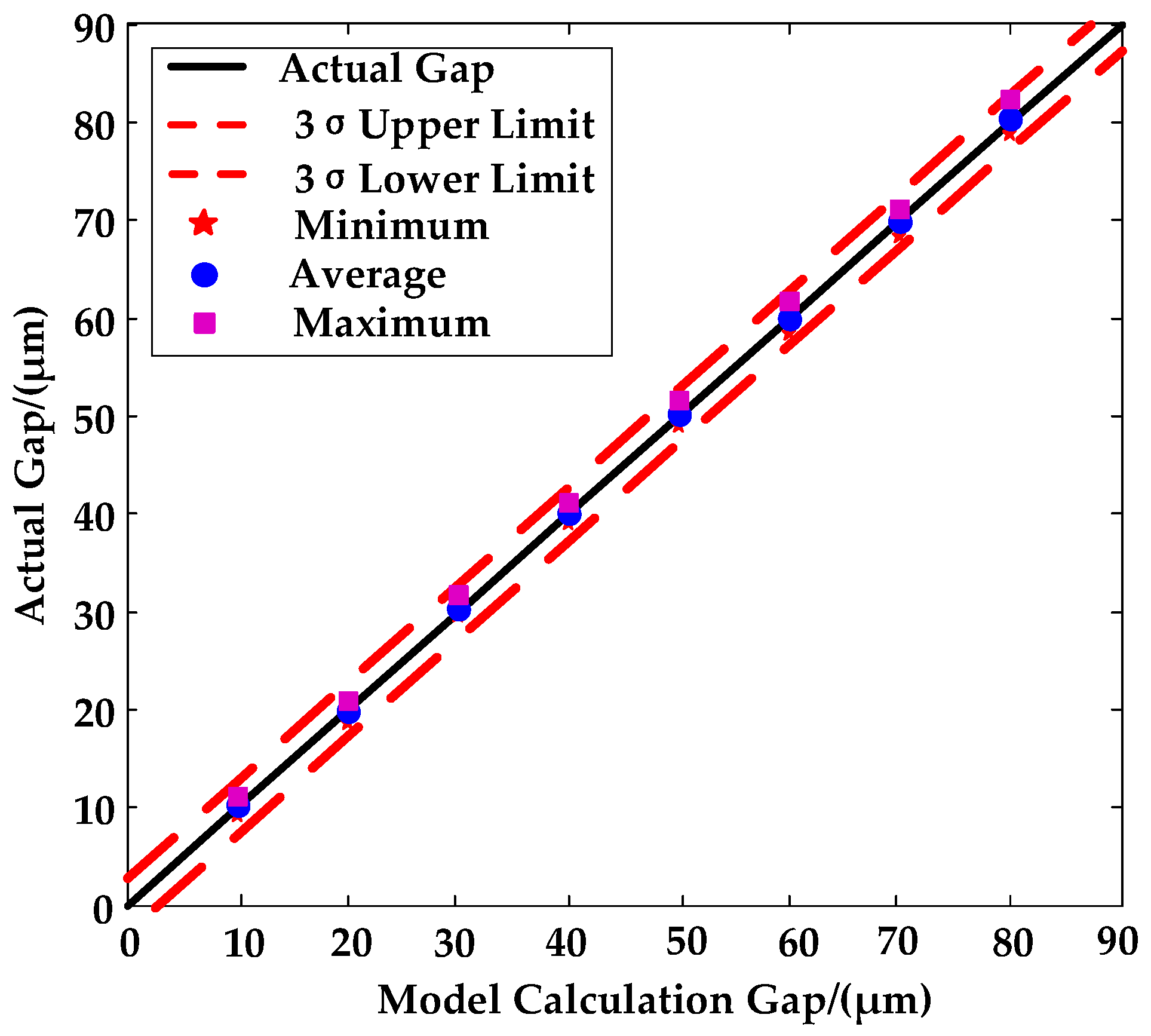

2.5. Verification of EDM Interelectrode Gap Model

3. Order Identification Based on EDM System

4. Parameter Estimation and Controller Design Based on EDM System

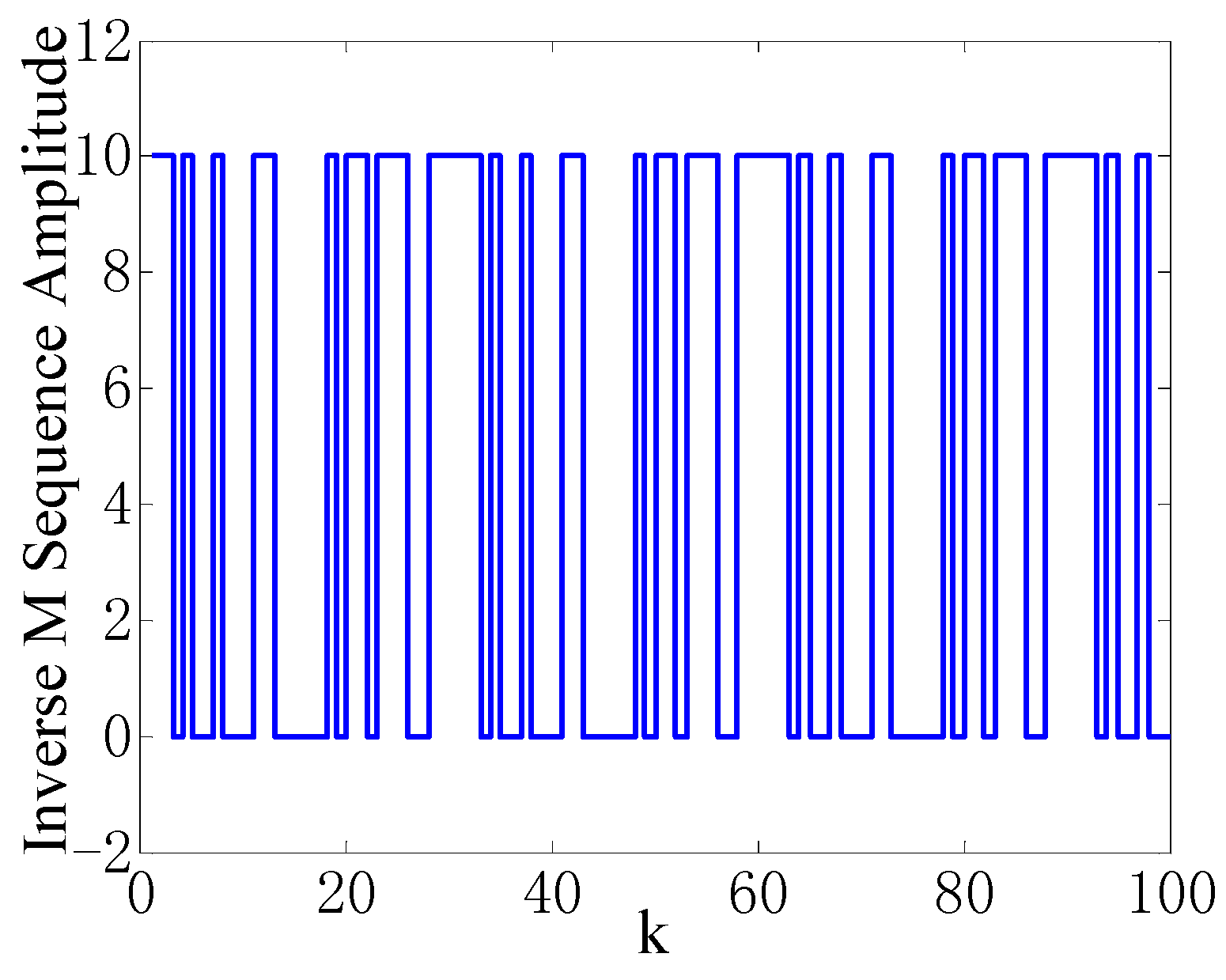

4.1. Parameter Estimation

4.2. Controller Design

5. Test Verification

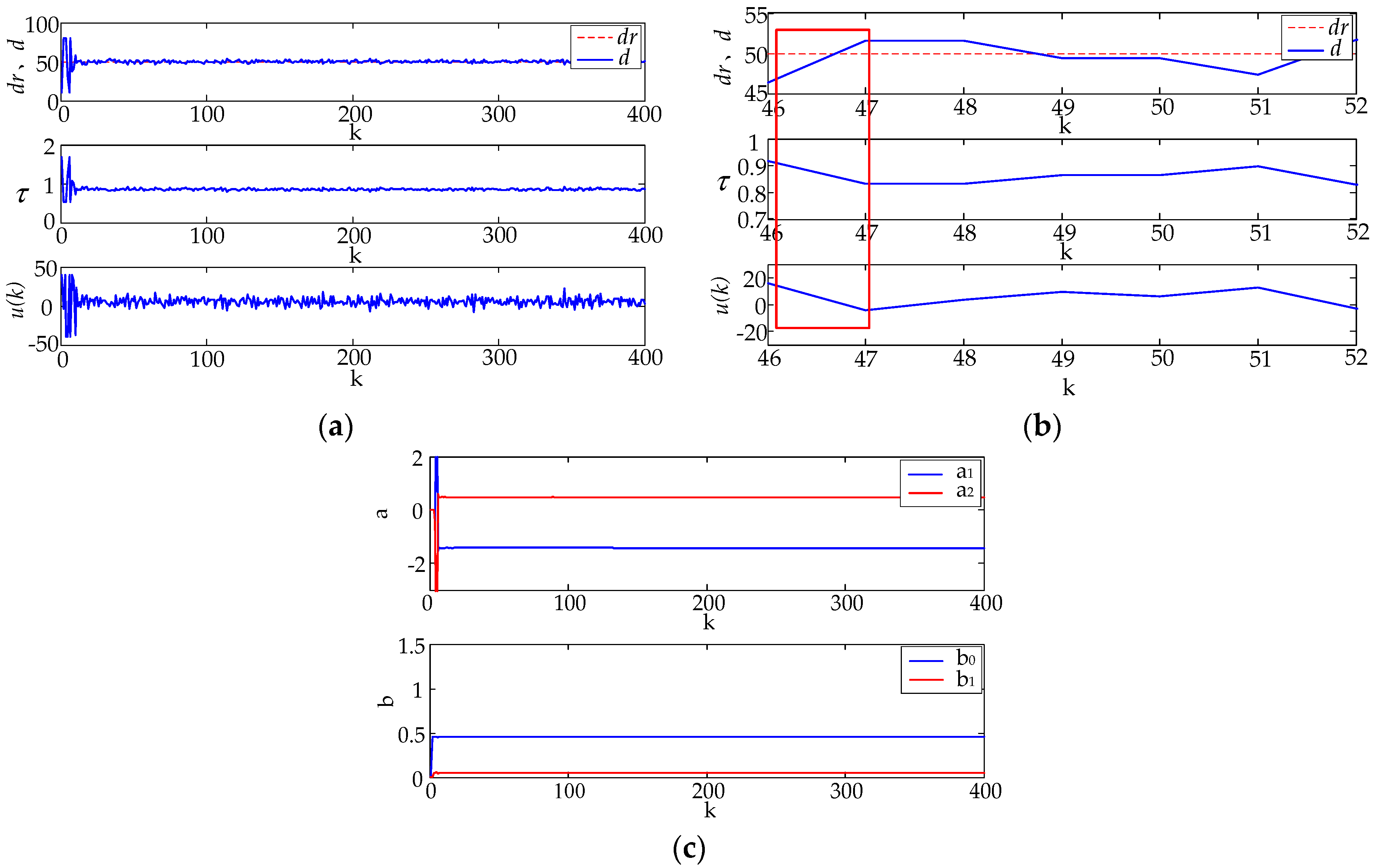

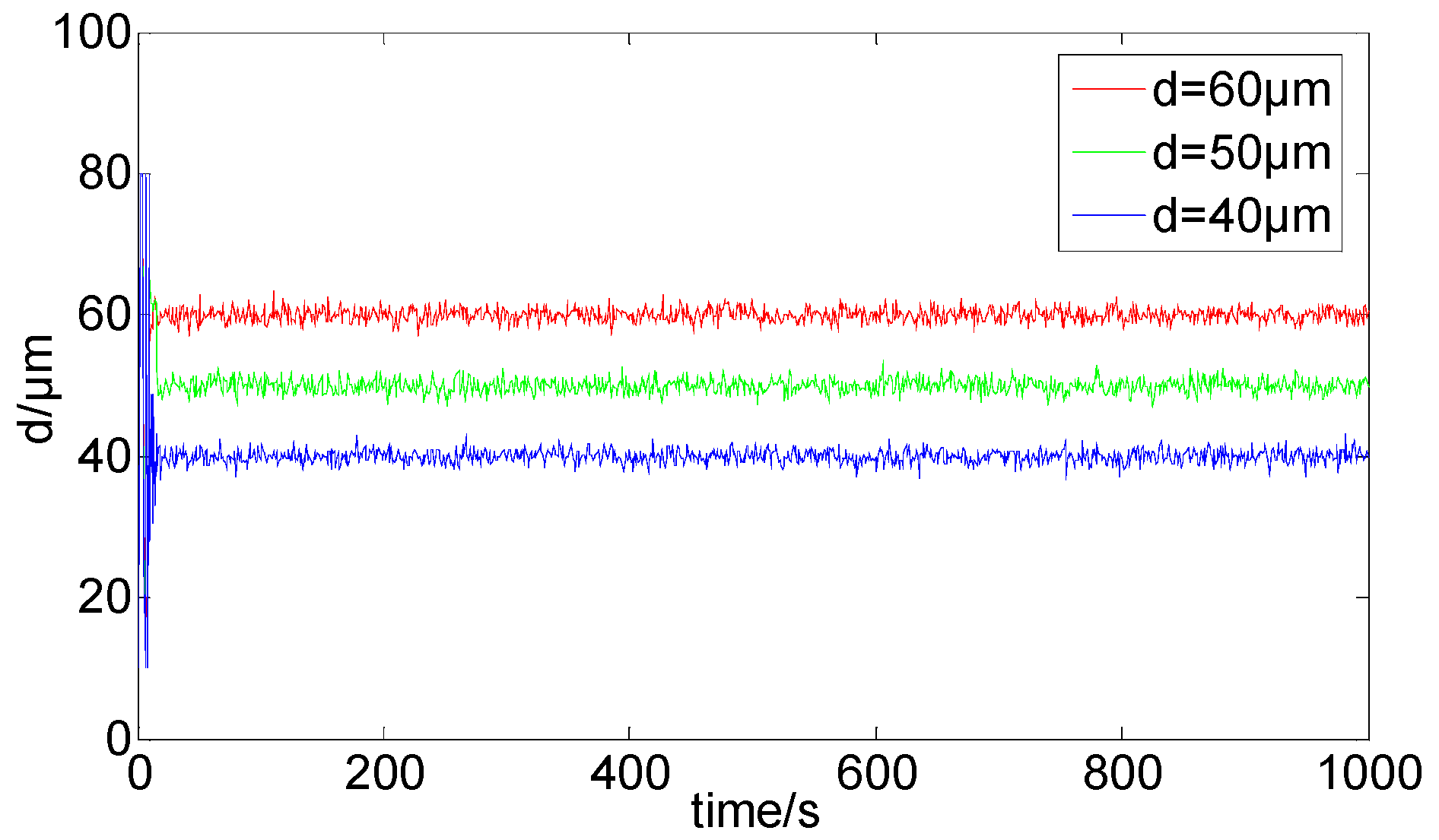

5.1. Stability Tracking Verification

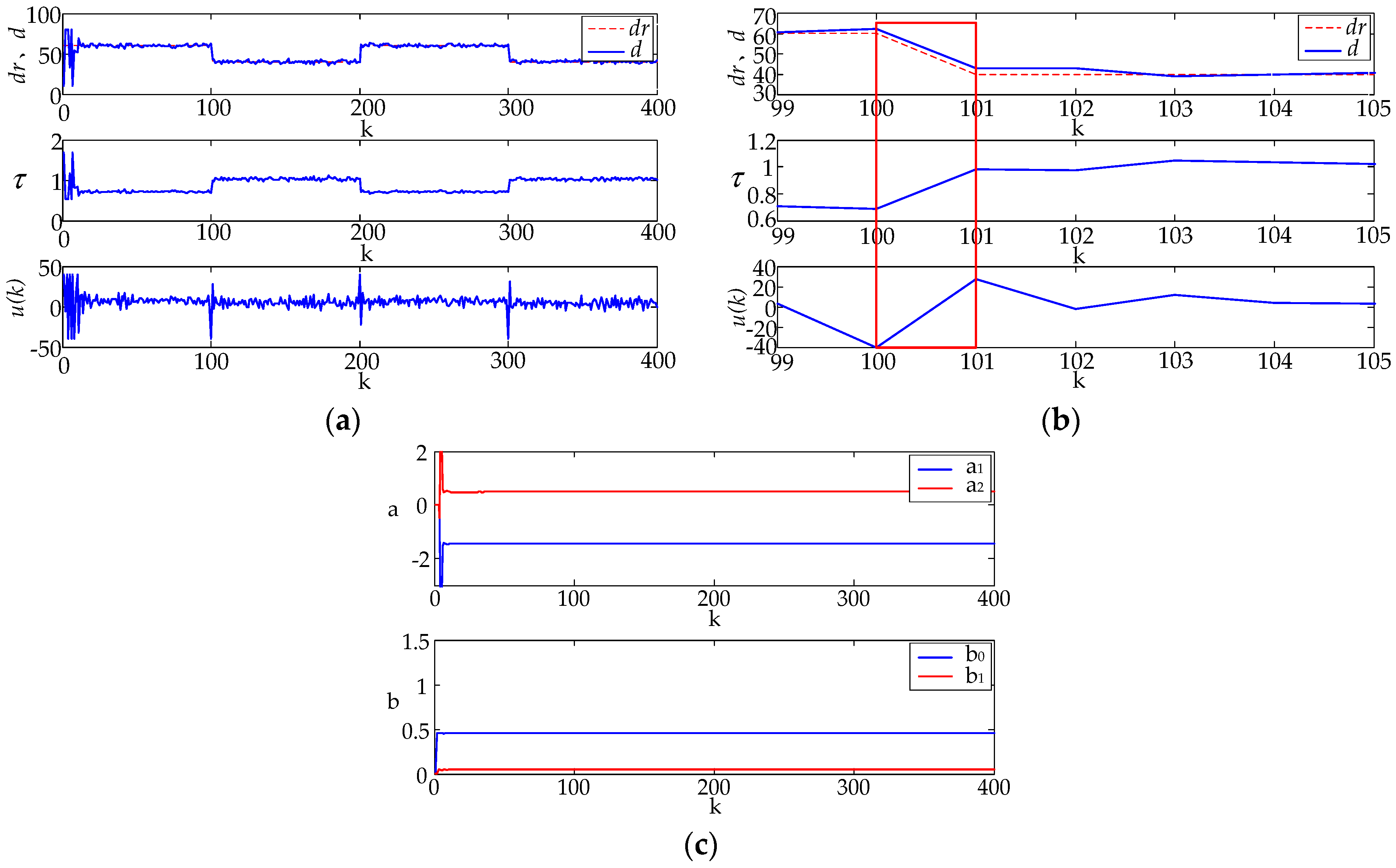

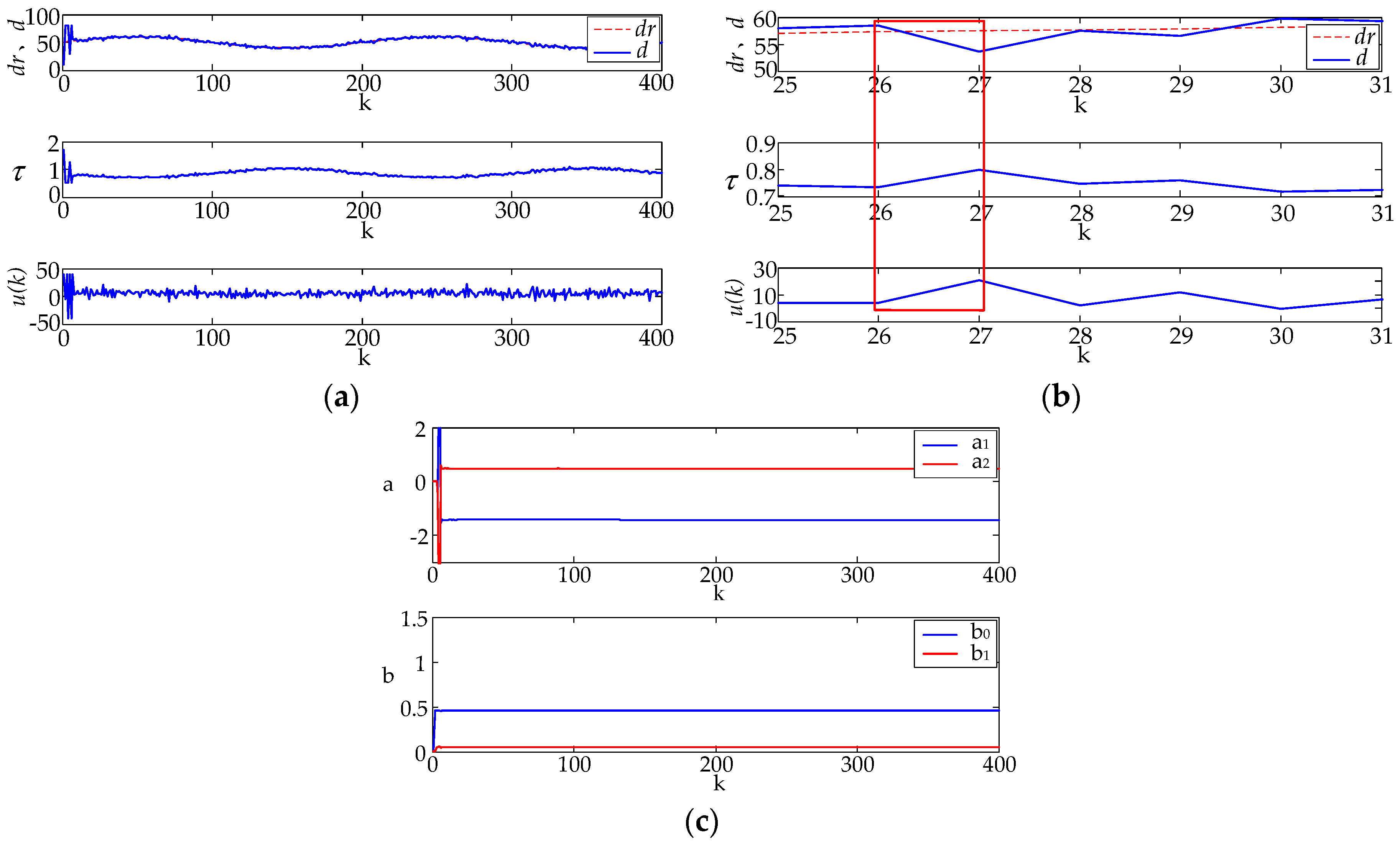

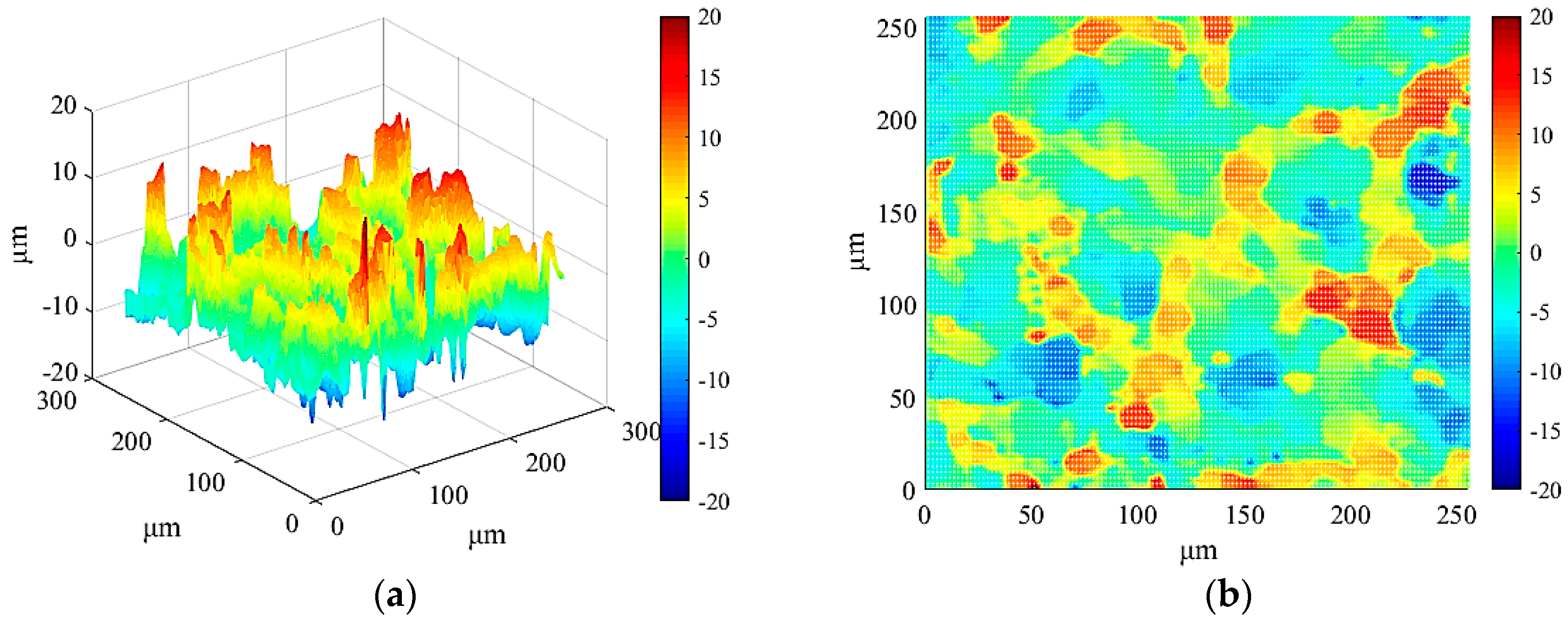

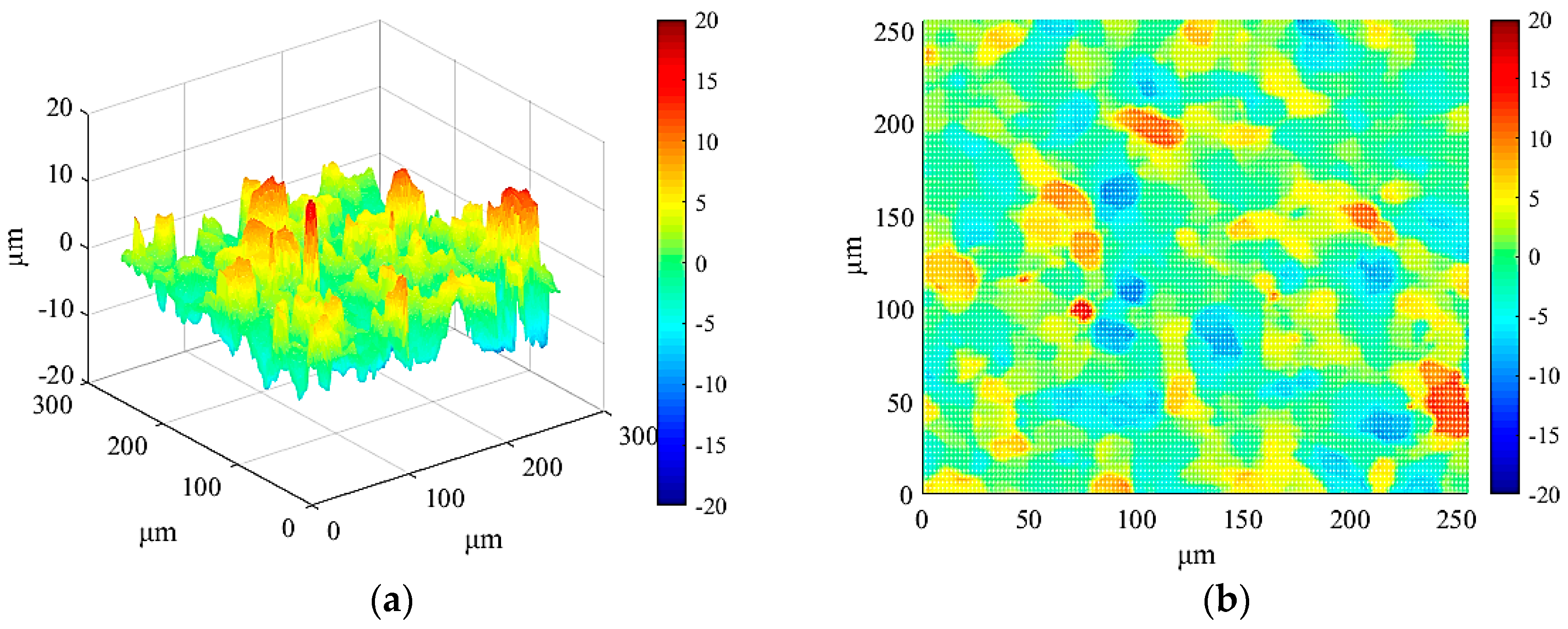

5.2. Comparison and Verification of Process Targets under Different Gap Conditions

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Egashira, K.; Mizutani, K. Micro-drilling of monocrystalline silicon using a cutting tool. Precis. Eng. 2002, 26, 263–268. [Google Scholar] [CrossRef]

- Fang, F.Z.; Wu, H.; Liu, Y.C. Modelling and experimental investigation on nanometric cutting of monocrystalline silicon. Int. J. Mach. Tools Manuf. 2005, 45, 1681–1686. [Google Scholar] [CrossRef]

- Swiercz, R.; Oniszczuk-Swiercz, D. Experimental investigation of surface layer properties of high thermal conductivity tool steel after electrical discharge machining. Metals 2017, 7, 550. [Google Scholar] [CrossRef]

- Furutani, K.; Hiraoka, D. Condition Monitoring in concurrent micro-hole electrical discharge machining with electrode feeding devices employing AZARASHI (Seal) mechanism. Procedia CIRP 2014, 14, 424–429. [Google Scholar] [CrossRef]

- Abidi, M.H.; Al-Ahmari, A.M.; Siddiquee, A.N.; Main, S.H.; Mohammed, M.K.; Rasheed, S.M. An Investigation of the Micro-Electrical Discharge Machining of Nickel-Titanium Shape Memory Alloy Using Grey Relations Coupled with Principal Component Analysis. Metals 2017, 7, 486. [Google Scholar] [CrossRef]

- Chen, H.R.; Liu, Z.D.; Huang, S.J.; Pan, H.J.; Qiu, M.B. Study of the mechanism of multi-channel discharge in semiconductor processing by WEDM. Mater. Sci. Semicond. Process. 2015, 32, 125–130. [Google Scholar] [CrossRef]

- Puertas, I.; Luis, C.J.; Villa, G. Spacing roughness parameters study on the EDM of silicon carbide. J. Mater. Process. Technol. 2005, 164, 1590–1596. [Google Scholar] [CrossRef]

- Luis, C.J.; Puertas, I.; Villa, G. Material removal rate and electrode wear study on the EDM of silicon carbide. J. Mater. Process. Technol. 2005, 164, 889–896. [Google Scholar] [CrossRef]

- Ji, R.; Liu, Y.; Zhang, Y.; Cai, B.; Li, X. High-speed end electric discharge milling of silicon carbide ceramics. Mater. Manuf. Processes 2011, 26, 1050–1058. [Google Scholar] [CrossRef]

- Salcedo, A.T.; Arbizu, I.P.; Pérez, C.J.L. Analytical modelling of energy density and optimization of the EDM machining parameters of Inconel 600. Metals 2017, 7, 166. [Google Scholar] [CrossRef]

- Kunieda, M.; Lauwers, B.; Rajurkar, K.P.; Schumacher, B.M. Advancing EDM through fundamental insight into the process. CIRP Ann. 2005, 54, 64–87. [Google Scholar] [CrossRef]

- Mahardika, M.; Mitsui, K. A new method for monitoring micro-electric discharge machining processes. Int. J. Mach. Tools Manuf. 2008, 48, 446–458. [Google Scholar] [CrossRef]

- Mahardika, M.; Tsujimoto, T.; Mitsui, K. A new approach on the determination of ease of machining by EDM processes. Int. J. Mach. Tools Manuf. 2008, 48, 746–760. [Google Scholar] [CrossRef]

- Rajurkar, K.P.; Wang, W.M.; Lindsay, R.P. A new model reference adaptive control of EDM. CIRP Ann. 1989, 38, 183–186. [Google Scholar] [CrossRef]

- Behrens, A.W.; Ginzel, J.; Bruhns, F.L. Threshold technology and its application for gap status detection. J. Mater. Process. Technol. 2004, 149, 310–315. [Google Scholar] [CrossRef]

- Han, F.; Wachi, S.; Kunieda, M. Improvement of machining characteristics of micro-EDM using transistor type isopulse generator and servo feed control. Precis. Eng. 2004, 28, 378–385. [Google Scholar] [CrossRef]

- Tarng, Y.S.; Tseng, C.M.; Chung, L.K. A fuzzy pulse discriminating system for electrical discharge machining. Int. J. Mach. Tools Manuf. 1997, 37, 511–522. [Google Scholar] [CrossRef]

- Kao, J.Y.; Tarng, Y.S. A neutral-network approach for the on-line monitoring of the electrical discharge machining process. J. Mater. Process. Technol. 1997, 69, 112–119. [Google Scholar] [CrossRef]

- Rajurkar, K.P.; Wang, W.M. Improvement of EDM performance with advanced monitoring and control systems. J. Manuf. Sci. Eng. 1997, 119, 770–775. [Google Scholar] [CrossRef]

- Rajurkar, K.P.; Wang, W.M.; Lindsay, R.P. Real-time stochastic model and control of EDM. CIRP Ann. 1990, 39, 187–190. [Google Scholar] [CrossRef]

- Weck, M.; Dehmer, J.M. Analysis and adaptive control of EDM sinking process using the ignition delay time and fall time as parameter. CIRP Ann. 1992, 41, 243–246. [Google Scholar] [CrossRef]

- Kao, C.C.; Shih, A.J. Design and tuning of a fuzzy logic controller for micro-hole electrical discharge machining. J. Manuf. Processes 2008, 10, 61–73. [Google Scholar] [CrossRef]

- Kao, C.C.; Shih, A.J.; Miller, S.F. Fuzzy logic control of microhole electrical discharge machining. J. Manuf. Sci. Eng. 2008, 130, 1786–1787. [Google Scholar] [CrossRef]

- Kaneko, T.; Onodera, T. Improvement in machining performance of die-sinking EDM by using self-adjusting fuzzy control. J. Mater. Process. Technol. 2004, 149, 204–211. [Google Scholar] [CrossRef]

- Shabgard, M.R.; Badamchizadeh, M.A.; Ranjbary, G.; Amini, K. Fuzzy approach to select machining parameters in electrical discharge machining (EDM) and ultrasonic-assisted EDM processes. J. Manuf. Syst. 2013, 32, 32–39. [Google Scholar] [CrossRef]

- Li, S.; Du, S.; Tang, A.; Landers, G.L.; Zhang, Y. Force modeling and control of SiC monocrystal wafer processing. J. Manuf. Sci. Eng. 2015, 137, 061003. [Google Scholar] [CrossRef]

- Kojima, A.; Natsu, W.; Kunieda, M. Spectroscopic measurement of arc plasma diameter in EDM. CIRP Ann. 2008, 57, 203–207. [Google Scholar] [CrossRef]

- Li, M.H. Electric discharge machining surface characteristics. In EDM Theoretical Basis; National Defense Industry Press: Beijing, China, 1989. [Google Scholar]

- Ikai, T.; Hashigushi, K. Heat input for crater formation in EDM. In Proceedings of the International Symposium for Electro-Machining (ISEM XI), EPFL, Lausanne, Switzerland, 17–21 April 1995; pp. 163–170. [Google Scholar]

| P-Type Monocrystalline Silicon | Diameter (1 in) | Growth Mode | Straight Pull Single Crystal (CZ) |

|---|---|---|---|

| Thickness of Si wafer | 5 mm | Doping type | Boron doping |

| Crystal orientation | <111> | Resistivity | 0.1 Ω cm |

| Melting point | 1410 °C | Boiling point | 2355 °C |

| Density | 2.33 g/cm³ |

| Actual Gap (μm) | β1 | β2 | β3 | ||||

|---|---|---|---|---|---|---|---|

| 10 | 1.62 | 16.2 | 1.63 | 16.3 | 1.64 | 16.4 | 16.3 |

| 15 | 1.58 | 23.7 | 1.57 | 23.55 | 1.57 | 23.55 | 23.6 |

| 20 | 1.51 | 30.2 | 1.52 | 30.4 | 1.49 | 29.8 | 30.13 |

| 25 | 1.37 | 34.3 | 1.39 | 34.75 | 1.36 | 34 | 34.35 |

| 30 | 1.23 | 36.9 | 1.22 | 36.6 | 1.24 | 37.2 | 36.9 |

| 35 | 1.1 | 38.5 | 1.13 | 39.55 | 1.12 | 39.2 | 39.08 |

| 40 | 1.02 | 40.8 | 1.05 | 42 | 1.04 | 41.6 | 41.47 |

| 45 | 0.95 | 42.75 | 0.93 | 41.85 | 0.94 | 42.3 | 42.3 |

| 50 | 0.86 | 43 | 0.88 | 44 | 0.87 | 43.5 | 43.5 |

| 55 | 0.78 | 42.6 | 0.77 | 42.35 | 0.77 | 42.35 | 42.43 |

| 60 | 0.71 | 42.75 | 0.72 | 43.2 | 0.70 | 42.0 | 42.65 |

| 65 | 0.66 | 42.9 | 0.65 | 42.25 | 0.65 | 42.25 | 42.47 |

| 70 | 0.61 | 42.7 | 0.62 | 43.4 | 0.60 | 42.0 | 42.7 |

| 75 | 0.57 | 42.75 | 0.58 | 43.5 | 0.57 | 42.75 | 43 |

| 80 | 0.54 | 42.4 | 0.55 | 44 | 0.54 | 43.2 | 43.2 |

| Actual Gap (μm) | Model-Calculated Gap (μm) | Model-Calculated Mean Gap | δmax | |

|---|---|---|---|---|

| 10 | 9.1562 | 10.2138 | 1.2168 | 1.10 |

| 11.1022 | ||||

| 20 | 18.5918 | 19.8764 | 1.1365 | 1.41 |

| 20.7725 | ||||

| 30 | 29.4844 | 30.3362 | 1.0687 | 1.61 |

| 31.6051 | ||||

| 40 | 39.0474 | 40.0568 | 0.9165 | 1.14 |

| 41.1400 | ||||

| 50 | 48.8590 | 50.2152 | 0.9862 | 1.57 |

| 51.5708 | ||||

| 60 | 58.3669 | 59.8568 | 0.9676 | 1.73 |

| 61.7297 | ||||

| 70 | 68.1800 | 69.7634 | 1.2043 | 1.82 |

| 71.1806 | ||||

| 80 | 78.7784 | 80.2652 | 1.1862 | 2.31 |

| 82.3050 |

| Interelectrode Gap (μm) | Material Removal Rate (mg/min) | Surface Roughness (μm) |

|---|---|---|

| 40 | 51 | 7.35 |

| 50 | 46 | 5.66 |

| 60 | 39 | 4.58 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xin, B.; Li, S.; Yin, X.; Lu, X. Dynamic Observer Modeling and Minimum-Variance Self-Tuning Control of EDM Interelectrode Gap. Appl. Sci. 2018, 8, 1443. https://doi.org/10.3390/app8091443

Xin B, Li S, Yin X, Lu X. Dynamic Observer Modeling and Minimum-Variance Self-Tuning Control of EDM Interelectrode Gap. Applied Sciences. 2018; 8(9):1443. https://doi.org/10.3390/app8091443

Chicago/Turabian StyleXin, Bin, Shujuan Li, Xincheng Yin, and Xiong Lu. 2018. "Dynamic Observer Modeling and Minimum-Variance Self-Tuning Control of EDM Interelectrode Gap" Applied Sciences 8, no. 9: 1443. https://doi.org/10.3390/app8091443

APA StyleXin, B., Li, S., Yin, X., & Lu, X. (2018). Dynamic Observer Modeling and Minimum-Variance Self-Tuning Control of EDM Interelectrode Gap. Applied Sciences, 8(9), 1443. https://doi.org/10.3390/app8091443