Fatigue Resistance Characterization of Warm Asphalt Rubber by Multiple Approaches

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation and Lab-Simulated Aging

2.1.1. Binder

2.1.2. Mortar

2.1.3. Mixture

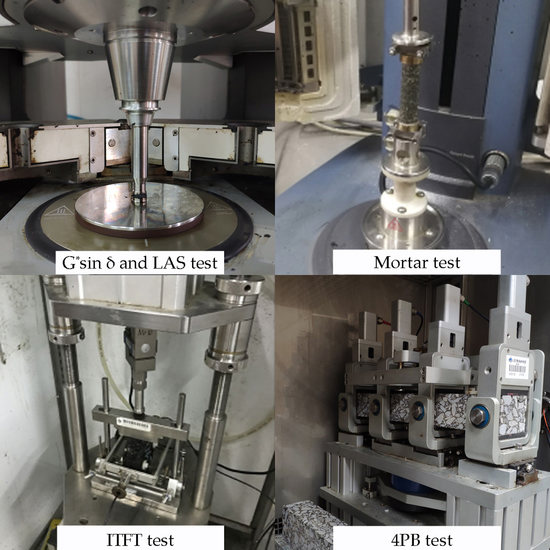

2.2. Testing Program

2.2.1. Binder

2.2.2. Mortar

2.2.3. Mixture

3. Results

3.1. Binders

3.1.1. G*sinδ

3.1.2. LAS

3.2. Mortars

3.3. Mixtures

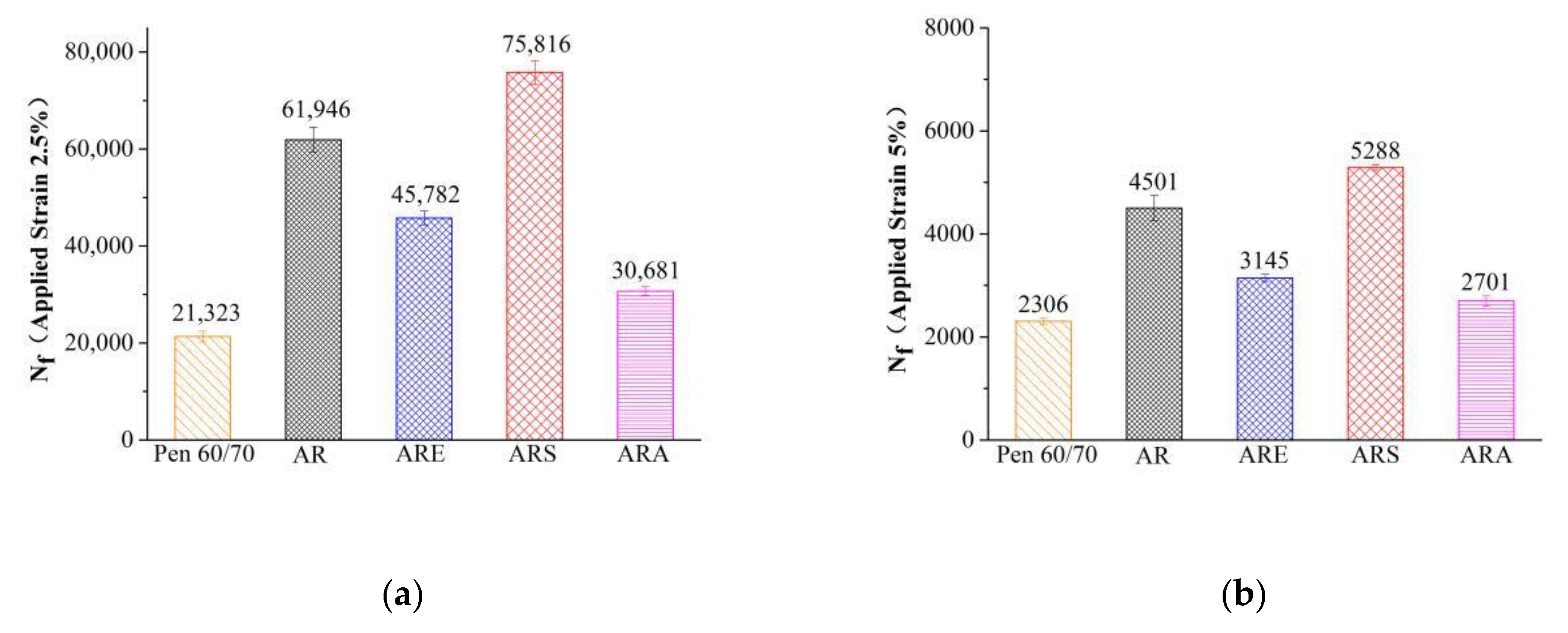

3.3.1. ITFT

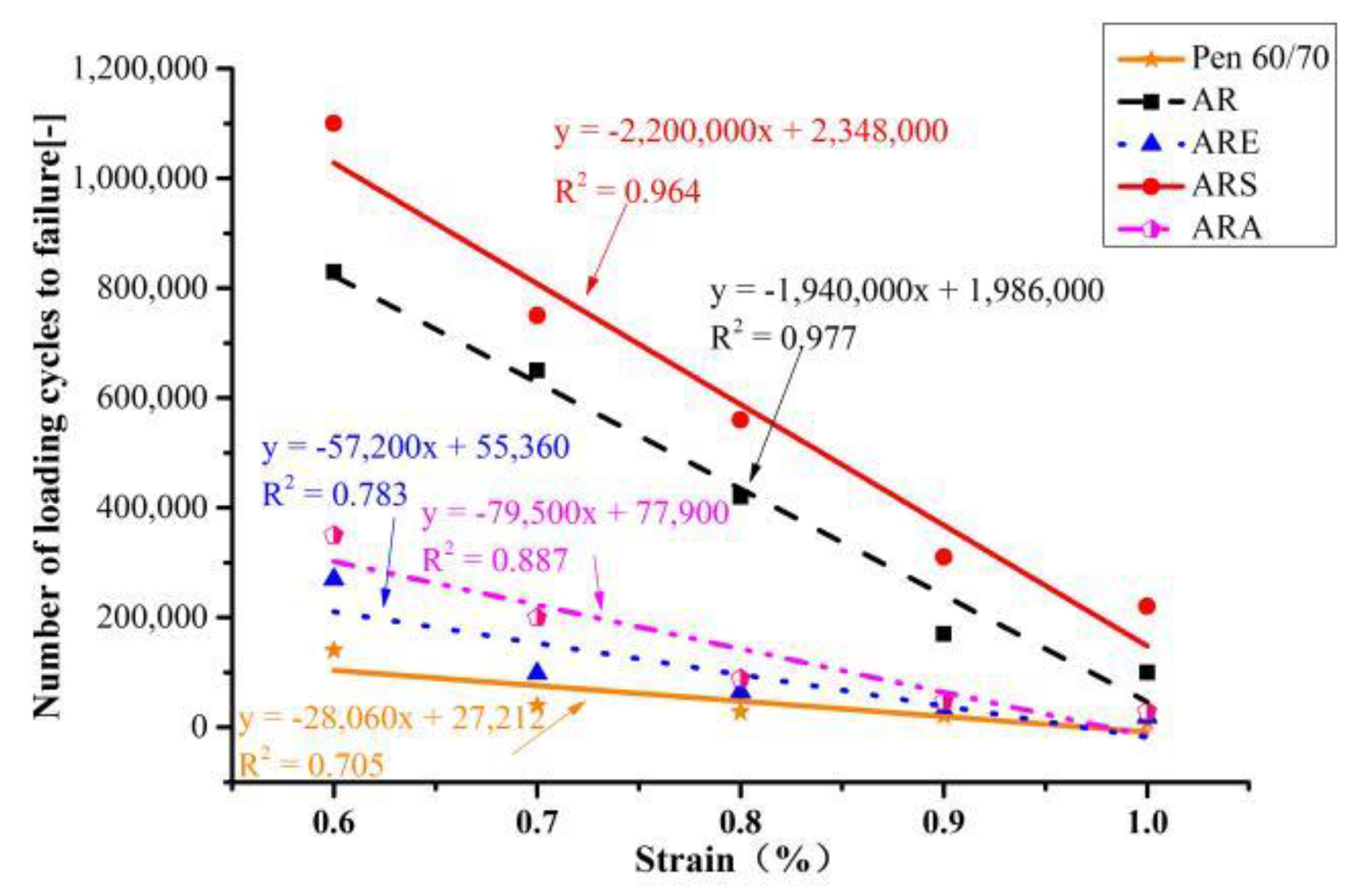

3.3.2. 4PB

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- American Association of State and Highway Transportation Officials. Grading or Verifying the performance grade (PG) of an asphalt binder. In AASHTO Standard R 29; American Association of State and Highway Transportation Officials: Washington, DC, USA, 2013. [Google Scholar]

- Association of State and Highway Transportation Officials. Estimating fatigue resistance of asphalt binders using the linear amplitude sweep. In AASHTO Standard TP 101; American Association of State and Highway Transportation Officials: Washington, DC, USA, 2013. [Google Scholar]

- Zhang, Y.; Leng, Z. Quantification of bituminous mortar aging and its application in ravelling evaluation of porous asphalt wearing courses. Mater. Des. 2017, 119, 1–11. [Google Scholar] [CrossRef]

- DIN Standards Committee Building and Civil Engineering. Test methods—Part 24: Resistance to fatigue (German version EN 12697-24:2018). In Bituminous Mixtures; DIN Standards Committee Building and Civil Engineering: Berlin, Germany, 2018. [Google Scholar]

- Association of State and Highway Transportation Officials. Determining the fatigue life of compacted hot mix asphalt (HMA) subjected to repeated flexural bending. In AASHTO Standard T 321; American Association of State and Highway Transportation Officials: Washington, DC, USA, 2013. [Google Scholar]

- Shu, X.; Huang, B.; Vukosavljevic, D. Laboratory evaluation of fatigue characteristics of recycled asphalt mixture. Constr. Build. Mater. 2008, 22, 1323–1330. [Google Scholar] [CrossRef]

- Leng, Z.; Yu, H.; Zhang, Z.; Tan, Z. Optimizing the mixing procedure of warm asphalt rubber with wax-based additives through mechanism investigation and performance characterization. Constr. Build. Mater. 2017, 144, 291–299. [Google Scholar] [CrossRef]

- Venudharan, V.; Biligiri, K.P.; Sousa, J.B.; Way, G.B. Asphalt-rubber gap-graded mixture design practices: A state-of-the-art research review and future perspective. Road Mater. Pavement Des. 2017, 18, 730–752. [Google Scholar] [CrossRef]

- Freitas, E.F. The effect of time on the contribution of asphalt rubber mixtures to noise abatement. Noise Control Eng. J. 2012, 60, 1–8. [Google Scholar] [CrossRef]

- Pasetto, M.; Pasquini, E.; Giacomello, G.; Baliello, A. Sustainable solutions for road pavements: A multi-scale characterization of warm mix asphalts containing steel slags. J. Clean. Prod. 2017, 166, 835–843. [Google Scholar] [CrossRef]

- Pasetto, M.; Pasquini, E.; Giacomello, G.; Baliello, A. Warm chemical additive to improve water resistance of asphalt mixtures containing steel slags: A multi-scale approach. Int. J. Pavement Eng. Infrastruct. 2017, 18, 26–39. [Google Scholar]

- Shu, X.; Huang, B. Recycling of waste tire rubber in asphalt and Portland cement concrete: An overview. Constr. Build. Mater. 2014, 67, 217–224. [Google Scholar] [CrossRef]

- Yu, H.; Leng, Z.; Dong, Z.; Tan, Z.; Guo, F.; Yan, J. Workability and mechanical property characterization of asphalt rubber mixtures modified with various warm mix asphalt additives. Constr. Build. Mater. 2018, 175, 392–401. [Google Scholar] [CrossRef]

- Wang, H.; Dang, Z.; You, Z.; Cao, D. Effect of warm mixture asphalt (WMA) additives on high failure temperature properties for crumb rubber modified (CRM) binders. Constr. Build. Mater. 2012, 35, 281–288. [Google Scholar] [CrossRef]

- Akisetty, C.; Xiao, F.; Gandhi, T.; Amirkhanian, S. Estimating correlations between rheological and engineering properties of rubberized asphalt concrete mixtures containing warm mix asphalt additive. Constr. Build. Mater. 2011, 25, 950–956. [Google Scholar] [CrossRef]

- Rodríguez-Alloza, A.M.; Gallego, J.; Perez, I. Study of the effect of four warm mix asphalt additives on bitumen modified with 15% crumb rubber. Constr. Build. Mater. 2013, 43, 300–308. [Google Scholar] [CrossRef] [Green Version]

- Akisetty, C.K.; Lee, S.J.; Amirkhanian, S.N. High temperature properties of rubberized binders containing warm asphalt additives. Constr. Build. Mater. 2009, 23, 565–573. [Google Scholar] [CrossRef]

- Yu, H.; Leng, Z.; Xiao, F.; Gao, Z. Rheological and chemical characteristics of rubberized binders with non-foaming warm mix additives. Constr. Build. Mater. 2016, 111, 671–678. [Google Scholar] [CrossRef]

- Oliveira, J.R.M.; Silva, H.M.R.D.; Abreu, L.P.F.; Fernandes, S.R.M. Use of a warm mix asphalt additive to reduce the production temperatures and to improve the performance of asphalt rubber mixtures. J. Clean. Prod. 2013, 41, 15–22. [Google Scholar] [CrossRef]

- Xiao, F.; Zhao, P.E.W.; Amirkhanian, S.N. Fatigue behavior of rubberized asphalt concrete mixtures containing warm asphalt additives. Constr. Build. Mater. 2009, 23, 3144–3151. [Google Scholar] [CrossRef]

- Zhou, F.; Mogawer, W.; Li, H.; Andriescu, A.; Copeland, A. Evaluation of fatigue tests for characterizing asphalt binders. J. Mater. Civ. Eng. 2012, 25, 610–617. [Google Scholar] [CrossRef]

- Yu, H.; Leng, Z.; Zhou, Z.; Shih, K.; Xiao, F.; Gao, Z. Optimization of preparation procedure of liquid warm mix additive modified asphalt rubber. J. Clean. Prod. 2017, 141, 336–345. [Google Scholar] [CrossRef]

- American Association of State and Highway Transportation Officials. Effect of heat and air on a moving film of asphalt binder (rolling thin-film oven test). In AASHTO Standard T 240; American Association of State and Highway Transportation Officials: Washington, DC, USA, 2013. [Google Scholar]

- American Association of State and Highway Transportation Officials. Accelerated aging of asphalt binder using a pressurized aging vessel. In AASHTO Standard R 28; American Association of State and Highway Transportation Officials: Washington, DC, USA, 2013. [Google Scholar]

- American Association of State and Highway Transportation Officials. Standard practice for mixture conditioning of hot mix asphalt (HMA). In AASHTO Standard R30; American Association of State and Highway Transportation Officials: Washington, DC, USA, 2002. [Google Scholar]

- Sabouri, M.; Mirzaeian, D.; Moniri, A. Effectiveness of linear amplitude sweep (LAS) asphalt binder test in predicting asphalt mixtures fatigue performance. Constr. Build. Mater. 2018, 171, 281–290. [Google Scholar] [CrossRef]

- Teymourpour, P.; Hanz, A.J.; Mandal, T.; Bahia, H.; Rizzutto, S.J. Effect of parallel plate gap height on repeatability in DSR measurements of crumb-rubber modified binders. J. Mater. Civ. Eng. 2016, 28, 04016047. [Google Scholar] [CrossRef]

- Mannan, U.A.; Islam, M.R.; Tarefder, R.A. Effects of recycled asphalt pavements on the fatigue life of asphalt under different strain levels and loading frequencies. Int. J. Fatigue 2015, 78, 72–80. [Google Scholar] [CrossRef]

- Hintz, C.; Bahia, H. Understanding mechanisms leading to asphalt binder fatigue in the dynamic shear rheometer. Road Mater. Pavement Des. 2013, 14, 231–251. [Google Scholar] [CrossRef]

| Properties | Evotherm-DAT | Sasobit | Aspha-Min |

|---|---|---|---|

| Ingredients | Fatty amine derivatives, alkylamines | Solid saturated hydrocarbons | Zeolite, water |

| State | Liquid | Solid | Solid |

| Color | Caramel | Milky-white | White |

| Odor | Amine-like | None | None |

| Density | >1.0 g/cm3 | 0.622 g/cm3 | 1.57 g/cm3 |

| PH value | 9–10 | N/A | N/A |

| Boiling point | 150–170 °C | N/A | N/A |

| Melting point | N/A | 105–110 °C | N/A |

| Water solubility | Partially soluble | Insoluble | Insoluble |

| Dosage | 5 wt% of AR binder | 3wt% of AR binder | 5 wt% of AR binder |

| Mixture Types | or | Failure Cycles | ||||

|---|---|---|---|---|---|---|

| logk1 | k1 | k2 | R2 | Microstrain = 100 | Microstrain = 200 | |

| Pen60/70 | 7.7886 | 6.14611 × 107 | −1.8937 | 0.97460 | 1.03 × 104 | 2.70 × 103 |

| AR | 15.00943 | 1.02195 × 1015 | −4.41648 | 0.84440 | 1.50 × 106 | 7.03 × 104 |

| ARE | 13.05896 | 1.14541 × 1013 | −3.37453 | 0.95901 | 2.04 × 106 | 1.97 × 105 |

| ARS | 11.90274 | 7.99356 × 1011 | −3.18268 | 0.96721 | 3.45 × 105 | 3.80 × 104 |

| ARA | 11.46023 | 2.88556 × 1011 | −2.90851 | 0.80283 | 4.40 × 105 | 5.86 × 104 |

| Binder Type | Ranking by Different Evaluating Approaches | ||||

|---|---|---|---|---|---|

| G*sinδ | LAS | Mortar | ITFT | 4PB | |

| Pen60/70 | 5 | 5 | 5 | 5 | 5 |

| AR | 1 | 2 | 2 | 2 | 2 |

| ARE | 4 | 3 | 3 | 1 | 3 |

| ARS | 2 | 1 | 1 | 4 | 1 |

| ARA | 3 | 4 | 4 | 3 | 4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, J.; Yu, X.; Gao, Z.; Guo, F.; Wang, D.; Yu, H. Fatigue Resistance Characterization of Warm Asphalt Rubber by Multiple Approaches. Appl. Sci. 2018, 8, 1495. https://doi.org/10.3390/app8091495

Yu J, Yu X, Gao Z, Guo F, Wang D, Yu H. Fatigue Resistance Characterization of Warm Asphalt Rubber by Multiple Approaches. Applied Sciences. 2018; 8(9):1495. https://doi.org/10.3390/app8091495

Chicago/Turabian StyleYu, Jiangmiao, Xianshu Yu, Zheming Gao, Feng Guo, Duanyi Wang, and Huayang Yu. 2018. "Fatigue Resistance Characterization of Warm Asphalt Rubber by Multiple Approaches" Applied Sciences 8, no. 9: 1495. https://doi.org/10.3390/app8091495