Dynamic Measurement Error Modeling and Analysis in a Photoelectric Scanning Measurement Network

Abstract

:Featured Application

Abstract

1. Introduction

2. Measurement Principle and Causes of Dynamic Error

2.1. Measurement Principle

2.2. Causes of Dynamic Error

3. Dynamic Error Modeling and Uncertainty Analysis

3.1. Dynamic Error Modeling

- Divide into a lower triangular matrix and its transposed matrix: .

- Divide into the product of an orthogonal matrix and an upper triangular matrix : .

- Divide into the product of a lower triangular matrix and an upper triangular matrix : .

- Calculate matrix through , .

- Divide into the product of an orthogonal matrix and an upper triangular matrix : .

- Describe the uncertainty as: .

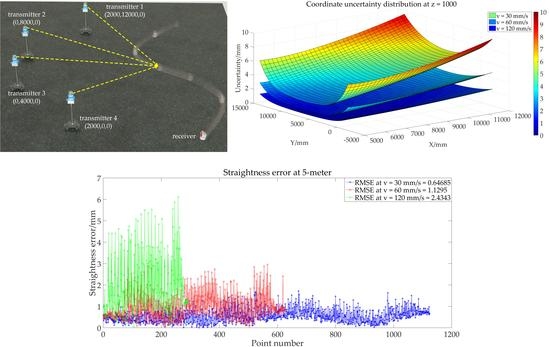

3.2. Uncertainty Simulation and Analysis

4. Experimental Verification

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhou, K.L.; Liu, T.G.; Zhou, L.F. Industry 4.0: Towards future industrial opportunities and challenges. In Proceedings of the 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent manufacturing in the context of industry 4.0: A review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Schmitt, R.H.; Peterek, M.; Morse, E.; Knapp, W.; Galetto, M.; Hartig, F.; Goch, G.; Hughes, B.; Forbes, A.; Estler, W.T. Advances in large-scale metrology—Review and future trends. CIRP Ann. 2016, 65, 643–665. [Google Scholar] [CrossRef]

- Muralikrishnan, B.; Phillips, S.; Sawyer, D. Laser trackers for large-scale dimensional metrology: A review. Precis. Eng. J. Int. Soc. Precis. Eng. Nanotechnol. 2016, 44, 13–28. [Google Scholar] [CrossRef]

- Franceschini, F.; Galetto, M.; Maisano, D.; Mastrogiacomo, L. Large-scale dimensional metrology (LSDM): From tapes and theodolites to multi-sensor systems. Precis. Eng. 2014, 15, 1739–1758. [Google Scholar] [CrossRef]

- Aguado, S.; Santolaria, J.; Samper, D.; Velazquez, J.; Javierre, C.; Fernandez, A. Adequacy of technical and commercial alternatives applied to machine tool verification using laser tracker. Appl. Sci. 2016, 6, 16. [Google Scholar] [CrossRef]

- Wang, Z.; Maropolous, P.G. Real-time error compensation of a three-axis machine tool using a laser tracker. Int. J. Adv. Manuf. Technol. 2013, 69, 919–933. [Google Scholar] [CrossRef]

- Muralikrishnan, B.; Lee, V.; Blackburn, C.; Sawyer, D.; Phillips, S.; Ren, W.; Hughes, B. Assessing ranging errors as a function of azimuth in laser trackers and tracers. Meas. Sci. Technol. 2013, 24, 6. [Google Scholar] [CrossRef]

- Hughes, B.; Forbes, A.; Lewis, A.; Sun, W.; Veal, D.; Nasr, K. Laser tracker error determination using a network measurement. Meas. Sci. Technol. 2011, 22, 12. [Google Scholar] [CrossRef]

- Luhmann, T. Close range photogrammetry for industrial applications. ISPRS J. Photogramm. Remote Sens. 2010, 65, 558–569. [Google Scholar] [CrossRef]

- Sun, B.; Zhu, J.G.; Yang, L.H.; Yang, S.R.; Guo, Y. Sensor for in-motion continuous 3d shape measurement based on dual line-scan cameras. Sensors 2016, 16, 15. [Google Scholar] [CrossRef] [PubMed]

- Jung, K.; Kim, S.; Im, S.; Choi, T.; Chang, M. A photometric stereo using re-projected images for active stereo vision system. Appl. Sci. 2017, 7, 10. [Google Scholar] [CrossRef]

- Montironi, M.A.; Castellini, P.; Stroppa, L.; Paone, N. Adaptive autonomous positioning of a robot vision system: Application to quality control on production lines. Robot. Comput. Integr. Manuf. 2014, 30, 489–498. [Google Scholar] [CrossRef]

- Huang, S.R.; Shinya, K.; Bergstrom, N.; Yamakawa, Y.; Yamazaki, T.; Ishikawa, M. Dynamic compensation robot with a new high-speed vision system for flexible manufacturing. Int. J. Adv. Manuf. Technol. 2018, 95, 4523–4533. [Google Scholar] [CrossRef]

- Di Leo, G.; Liguori, C.; Pietrosanto, A.; Sommella, P. A vision system for the online quality monitoring of industrial manufacturing. Opt. Lasers Eng. 2017, 89, 162–168. [Google Scholar] [CrossRef]

- Liu, T.; Yin, S.B.; Guo, Y.; Zhu, J.G. Rapid global calibration technology for hybrid visual inspection system. Sensors 2017, 17, 16. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.Y.; Zhu, J.G.; Lin, J.R.; Yang, L.H.; Xue, B.; Xiong, Z. Transmitter parameter calibration of the workspace measurement and positioning system by using precise three-dimensional coordinate control network. Opt. Eng. 2014, 53, 8. [Google Scholar] [CrossRef]

- Guo, F.Y.; Wang, Z.Q.; Kang, Y.G.; Li, X.N.; Chang, Z.P.; Wang, B.B. Positioning method and assembly precision for aircraft wing skin. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 317–327. [Google Scholar] [CrossRef]

- Mei, Z.Y.; Maropoulos, P.G. Review of the application of flexible, measurement-assisted assembly technology in aircraft manufacturing. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 1185–1197. [Google Scholar] [CrossRef]

- Guo, S.Y.; Lin, J.R.; Ren, Y.J.; Yang, L.H.; Zhu, J.G. Study of network topology effect on measurement accuracy for a distributed rotary-laser measurement system. Opt. Eng. 2017, 56, 8. [Google Scholar] [CrossRef]

- Golub, G.H.; Van Loan, C.F. Matrix Computations, 4th ed.; The John Hopkins University Press: Baltimore, MD, USA, 2012; pp. 63–105. [Google Scholar]

- Joint Committee for Guides in Metrology. Evaluation of Measurement Data—Supplement 2 to the “Guide to the Expression of Uncertainty in Measurement”—Extension to Any Number of Output Quantities; Joint Committee for Guides in Metrology: Paris, France, 2011. [Google Scholar]

| Straightness Error/mm | ||||||

|---|---|---|---|---|---|---|

| Simulation Experiments | Practical Experiments | Deviation | ||||

| 5 m | 7 m | 5 m | 7 m | |||

| v = 30 mm/s | 0.635 | 0.829 | 0.647 | 0.906 | 0.012 | 0.077 |

| v = 60 mm/s | 1.082 | 1.627 | 1.130 | 1.693 | 0.048 | 0.066 |

| v = 120 mm/s | 2.352 | 3.070 | 2.434 | 3.161 | 0.082 | 0.091 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, S.; Yang, L.; Lin, J.; Long, C.; Deng, R.; Zhang, Z.; Zhu, J. Dynamic Measurement Error Modeling and Analysis in a Photoelectric Scanning Measurement Network. Appl. Sci. 2019, 9, 62. https://doi.org/10.3390/app9010062

Shi S, Yang L, Lin J, Long C, Deng R, Zhang Z, Zhu J. Dynamic Measurement Error Modeling and Analysis in a Photoelectric Scanning Measurement Network. Applied Sciences. 2019; 9(1):62. https://doi.org/10.3390/app9010062

Chicago/Turabian StyleShi, Shendong, Linghui Yang, Jiarui Lin, Changyu Long, Rui Deng, Zhenyu Zhang, and Jigui Zhu. 2019. "Dynamic Measurement Error Modeling and Analysis in a Photoelectric Scanning Measurement Network" Applied Sciences 9, no. 1: 62. https://doi.org/10.3390/app9010062

APA StyleShi, S., Yang, L., Lin, J., Long, C., Deng, R., Zhang, Z., & Zhu, J. (2019). Dynamic Measurement Error Modeling and Analysis in a Photoelectric Scanning Measurement Network. Applied Sciences, 9(1), 62. https://doi.org/10.3390/app9010062