Low-Cost Electrode Modification to Upgrade the Bioelectrocatalytic Oxidation of Tannery Wastewater Using Acclimated Activated Sludge

Abstract

:1. Introduction

2. Material and Methods

2.1. Activated Sludge Acclimation to Industrial Tannery Wastewater

2.2. Preparation of Clay-Modified Electrodes

2.3. Characterization of Unmodified and Modified Electrodes

2.4. Electroanalytical Techniques

2.5. Biofilm Visualization

2.6. Wastewater Analysis Techniques

3. Results and Discussion

3.1. Effect of Activated Sludge Acclimation on Electroactive Biofilm Formation

3.2. Effect of Carbon Felt Modification

3.2.1. Physicochemical Characterization of the Unmodified and Modified Carbon Felt Surfaces

3.2.2. Electrochemical Performances of Tannery Wastewater Oxidizing Bioanodes

Chronoamperometry Analysis

Cyclic Voltammetry

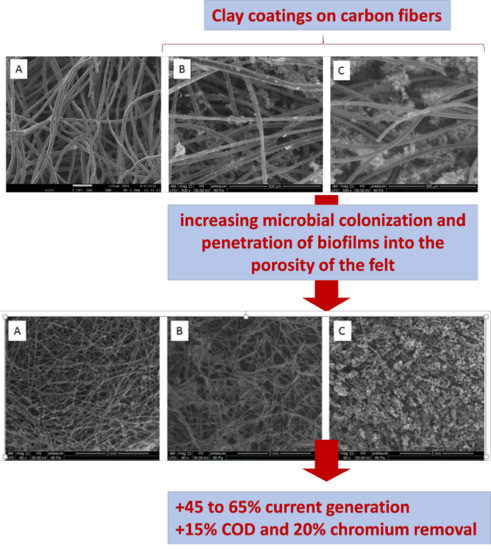

3.3. Biofilm Colonization

3.4. COD, Chromium Removal, and Coulombic Efficiency

3.4.1. COD Removal and Coulombic Efficiency

3.4.2. Chromium Removal

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Ezziat, L.; Elabed, A.; Ibnsouda, S.; El Abed, S. Challenges of Microbial Fuel Cell Architecture on Heavy Metal Recovery and Removal From Wastewater. Front. Energy Res. 2019, 7, 1–13. [Google Scholar] [CrossRef]

- Liu, H.; Ramnarayanan, R.; Logan, B.E. Production of Electricity during Wastewater Treatment Using a Single Chamber Microbial Fuel Cell. Environ. Sci. Technol. 2004, 38, 2281–2285. [Google Scholar] [CrossRef]

- Heidrich, E.S.; Dolfing, J.; Scott, K.; Edwards, S.R.; Jones, C.; Curtis, T.P. Production of hydrogen from domestic wastewater in a pilot-scale microbial electrolysis cell. Appl. Microbiol. Biotechnol. 2013, 97, 6979–6989. [Google Scholar] [CrossRef] [PubMed]

- Li, W.-W.; Yu, H.-Q.; He, Z. Towards sustainable wastewater treatment by using microbial fuel cells-centered technologies. Energy Environ. Sci. 2013, 7, 911–924. [Google Scholar] [CrossRef] [Green Version]

- Pant, D.; Van Bogaert, G.; Diels, L.; Vanbroekhoven, K. A review of the substrates used in microbial fuel cells (MFCs) for sustainable energy production. Bioresour. Technol. 2010, 101, 1533–1543. [Google Scholar] [CrossRef]

- Paul, D.; Noori, M.T.; Rajesh, P.P.; Ghangrekar, M.M.; Mitra, A. Modification of carbon felt anode with graphene oxide-zeolite composite for enhancing the performance of microbial fuel cell. Sustain. Energy Technol. Assessments 2018, 26, 77–82. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, Y.; Li, T.; Dong, Z.; Wang, Y. Modification of carbon felt anodes using double-oxidant HNO3/H2O2 for application in microbial fuel cells. RSC Adv. 2018, 8, 2059–2064. [Google Scholar] [CrossRef]

- Zhao, Y.G.; Ying, M.; Fu, Y.B.; Chen, W. Improving Electrochemical Performance of Carbon Felt Anode by Modifying With Akaganeite in Marine Benthic Microbial Fuel Cells. Fuel Cells 2019, 19, 190–199. [Google Scholar] [CrossRef]

- Mohamed, H.O.; Sayed, E.T.; Cho, H.; Park, M.; Obaid, M.; Kim, H.Y.; Barakat, N.A.M. Effective strategies for anode surface modification for power harvesting and industrial wastewater treatment using microbial fuel cells. J. Environ. Manag. 2018, 206, 228–235. [Google Scholar] [CrossRef]

- Blanchet, E.; Desmond, E.; Erable, B.; Bridier, A.; Bouchez, T.; Bergel, A. Comparison of synthetic medium and wastewater used as dilution medium to design scalable microbial anodes: Application to food waste treatment. Bioresour. Technol. 2015, 185, 106–115. [Google Scholar] [CrossRef] [Green Version]

- Belaabed, R.; Elabed, S.; Addaou, A.; Laajab, A.; Rodr??guez, M.A.; Lahsini, A. Synthesis of LTA zeolite for bacterial adhesion. Bol. la Soc. Esp. Ceram. Vidr. 2016, 55, 152–158. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.Y.; Tong, F.; Song, T.S.; Gao, X.Y.; Xie, J.J.; Zhou, C.C.; Zhang, L.X.; Wei, P. Effect of zeolite-coated anode on the performance of microbial fuel cells. J. Chem. Technol. Biotechnol. 2013, 90, 87–92. [Google Scholar] [CrossRef]

- Clesceri, L.S.; Greenbaerg, A.E.; Eaton, A.D. Standard Methods for Examination of Water and Wastewater, 20th ed.; APHA American Public Health Association: Washington, DC, USA, 1998; Volume 552, pp. 5–16. [Google Scholar]

- Di Lorenzo, M.; Scott, K.; Curtis, T.P.; Head, I.M. Effect of increasing anode surface area on the performance of a single chamber microbial fuel cell. Chem. Eng. J. 2010, 156, 40–48. [Google Scholar] [CrossRef]

- Thu Pham, H.T.; Jo, C.; Lee, J.; Kwon, Y. MoO2 nanocrystals interconnected on mesocellular carbon foam as a powerful catalyst for vanadium redox flow battery. RSC Adv. 2016, 6, 17574–17582. [Google Scholar] [CrossRef]

- Guo, K.; Freguia, S.; Dennis, P.G.; Chen, X.; Donose, B.C.; Keller, J.; Gooding, J.J.; Rabaey, K. Effects of surface charge and hydrophobicity on anodic biofilm formation, community composition, and current generation in bioelectrochemical systems. Environ. Sci. Technol. 2013, 47, 7563–7570. [Google Scholar] [CrossRef] [PubMed]

- Santoro, C.; Guilizzoni, M.; Correa Baena, J.P.; Pasaogullari, U.; Casalegno, A.; Li, B.; Babanova, S.; Artyushkova, K.; Atanassov, P. The effects of carbon electrode surface properties on bacteria attachment and start up time of microbial fuel cells. Carbon N. Y. 2014, 67, 128–139. [Google Scholar] [CrossRef]

- Blanchet, E.; Erable, B.; De Solan, M.L.; Bergel, A. Two-dimensional carbon cloth and three-dimensional carbon felt perform similarly to form bioanode fed with food waste. Electrochem. Commun. 2016, 66, 38–41. [Google Scholar] [CrossRef] [Green Version]

- Basaldella, E.I.; Vázquez, P.G.; Iucolano, F.; Caputo, D. Chromium removal from water using LTA zeolites: Effect of pH. J. Colloid Interface Sci. 2007, 313, 574–578. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, B.; Xi, Y.; Megharaj, M.; Krishnamurti, G.S.R.; Rajarathnam, D.; Naidu, R. Remediation of hexavalent chromium through adsorption by bentonite based Arquad® 2HT-75 organoclays. J. Hazard. Mater. 2010, 183, 87–97. [Google Scholar] [CrossRef] [PubMed]

- Vasiliadou, I.A.; Papoulis, D.; Chrysikopoulos, C.V.; Panagiotaras, D.; Karakosta, E.; Fardis, M.; Papavassiliou, G. Attachment of Pseudomonas putida onto differently structured kaolinite minerals: A combined ATR-FTIR and 1H NMR study. Colloids Surf. B Biointerfaces 2011, 84, 354–359. [Google Scholar] [CrossRef] [PubMed]

- Erdoan, B.C.; Ülkü, S. Cr(VI) sorption by using clinoptilolite and bacteria loaded clinoptilolite rich mineral. Microporous Mesoporous Mater. 2012, 152, 253–261. [Google Scholar] [CrossRef] [Green Version]

- Vullo, D.L.; Ceretti, H.M.; Daniel, M.A.; Ramírez, S.A.M.; Zalts, A. Cadmium, zinc and copper biosorption mediated by Pseudomonas veronii 2E. Bioresour. Technol. 2008, 99, 5574–5581. [Google Scholar] [CrossRef] [PubMed]

| COD Removal (%) | Cr Removal (%) | CE (%) | |

|---|---|---|---|

| Carbon felt | 78.7 ± 1.3 | 72.4 ± 3.1 | 14.4 ± 1.9 |

| LTA zolite-modified anode | 93.8 ± 1.7 | 94.6 ± 3.6 | 21.2 ± 2.1 |

| Bentonite-modified anode | 96.3 ± 2.1 | 97.5 ± 2.2 | 29.4 ± 1.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elabed, A.; El khalfaouy, R.; Ibnsouda, S.; Basseguy, R.; Elabed, S.; Erable, B. Low-Cost Electrode Modification to Upgrade the Bioelectrocatalytic Oxidation of Tannery Wastewater Using Acclimated Activated Sludge. Appl. Sci. 2019, 9, 2259. https://doi.org/10.3390/app9112259

Elabed A, El khalfaouy R, Ibnsouda S, Basseguy R, Elabed S, Erable B. Low-Cost Electrode Modification to Upgrade the Bioelectrocatalytic Oxidation of Tannery Wastewater Using Acclimated Activated Sludge. Applied Sciences. 2019; 9(11):2259. https://doi.org/10.3390/app9112259

Chicago/Turabian StyleElabed, Alae, Redouan El khalfaouy, Saad Ibnsouda, Régine Basseguy, Soumya Elabed, and Benjamin Erable. 2019. "Low-Cost Electrode Modification to Upgrade the Bioelectrocatalytic Oxidation of Tannery Wastewater Using Acclimated Activated Sludge" Applied Sciences 9, no. 11: 2259. https://doi.org/10.3390/app9112259

APA StyleElabed, A., El khalfaouy, R., Ibnsouda, S., Basseguy, R., Elabed, S., & Erable, B. (2019). Low-Cost Electrode Modification to Upgrade the Bioelectrocatalytic Oxidation of Tannery Wastewater Using Acclimated Activated Sludge. Applied Sciences, 9(11), 2259. https://doi.org/10.3390/app9112259