Experimental Study on Photocatalytic Effect of Nano TiO2 Epoxy Emulsified Asphalt Mixture

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Mixture Design

2.1. TiO2 Powder

2.2. Binder

2.3. Mixture Design

3. Experimental Design

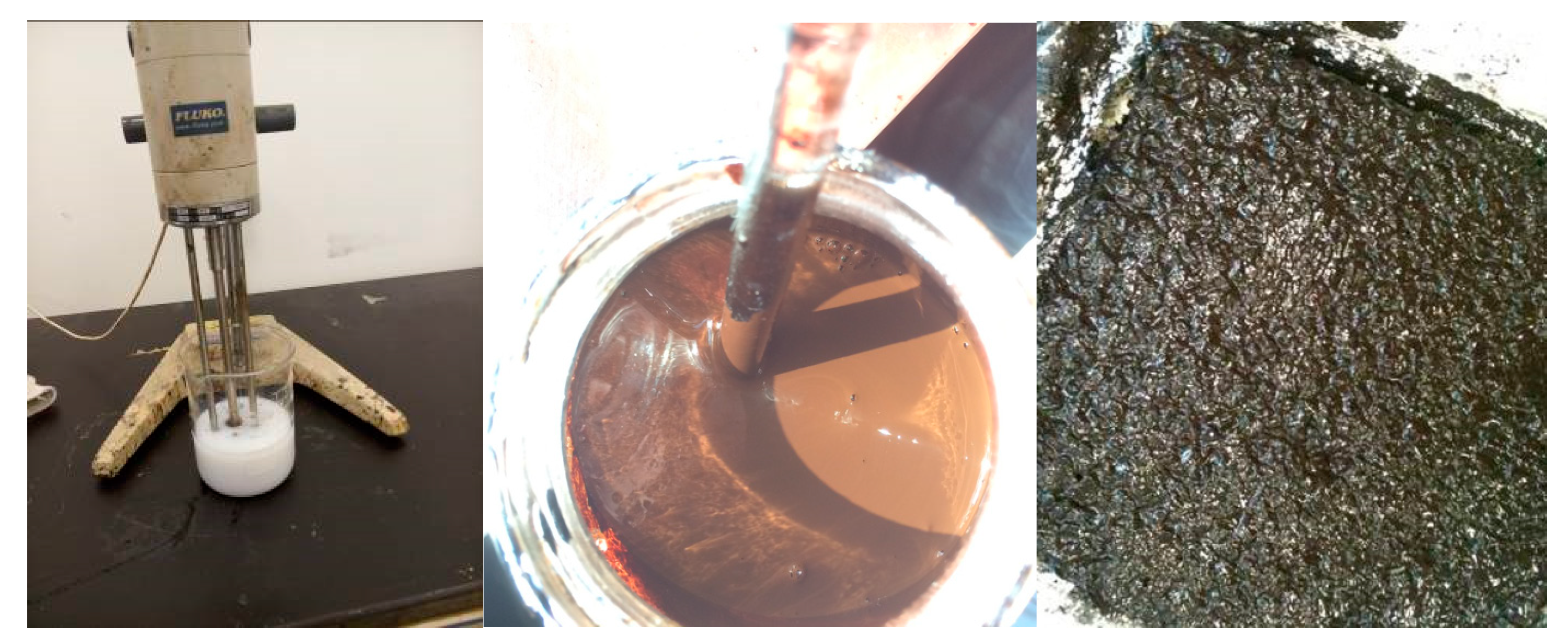

3.1. Preparation of Carriers and Mixtures

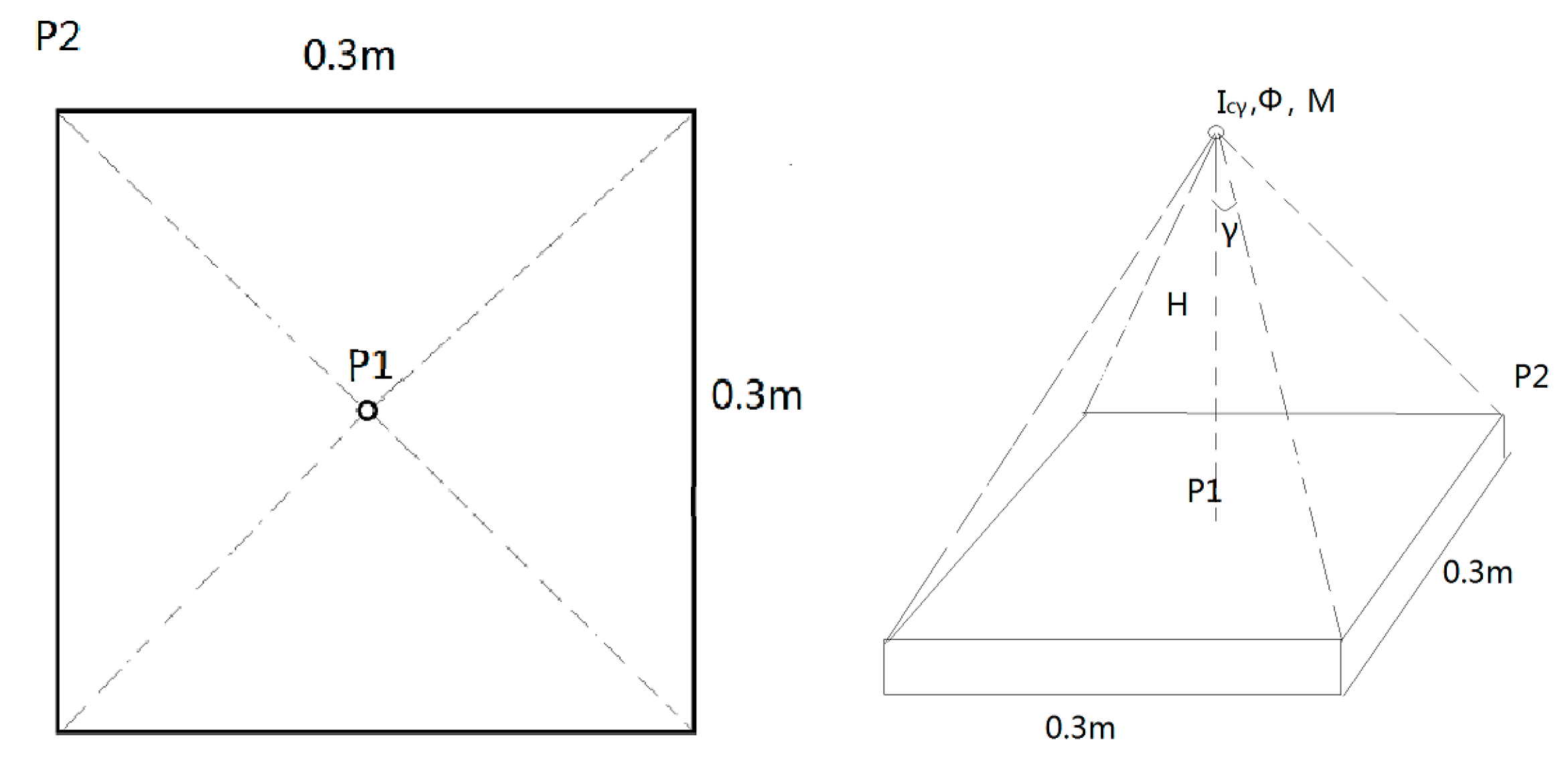

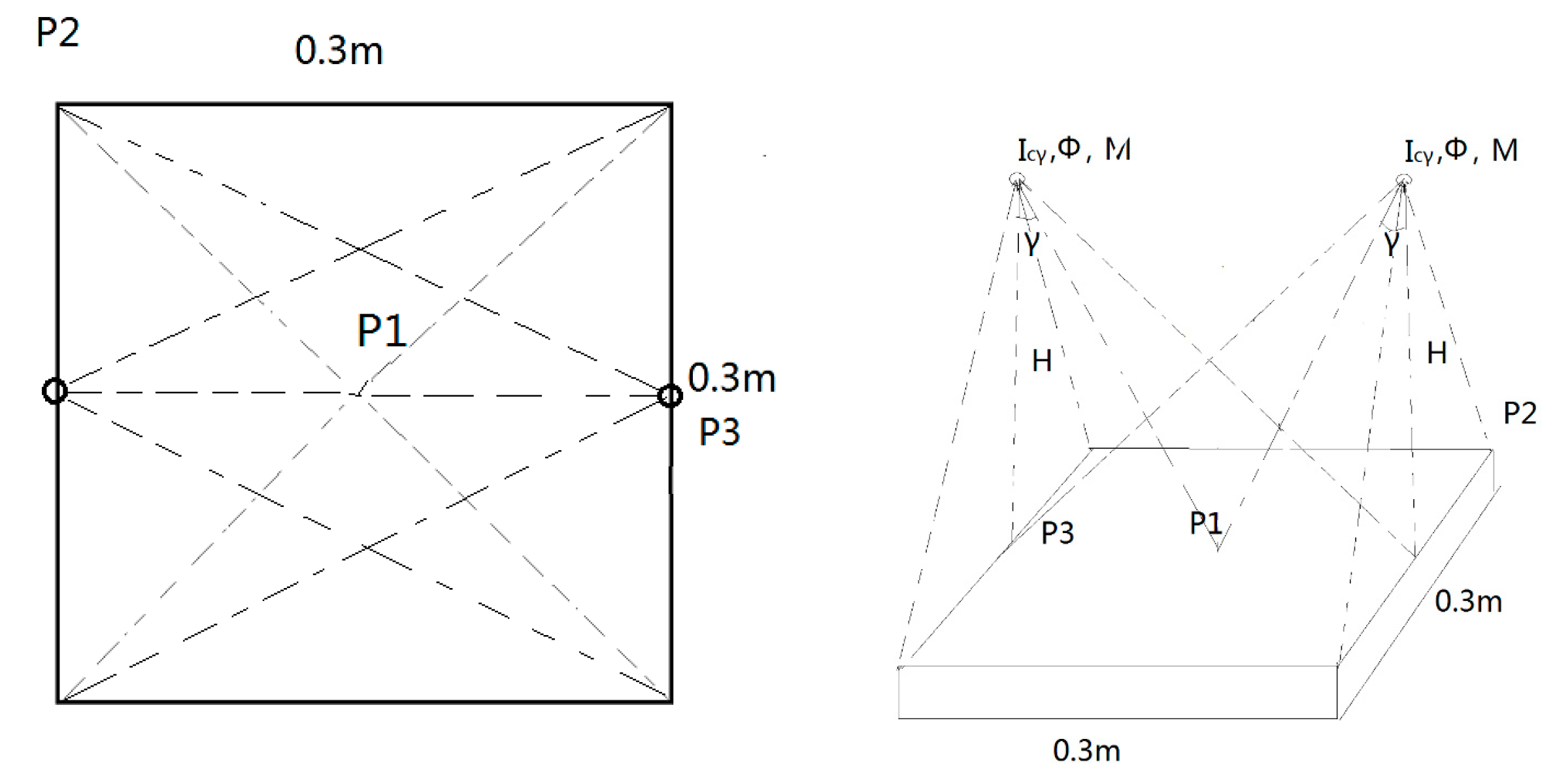

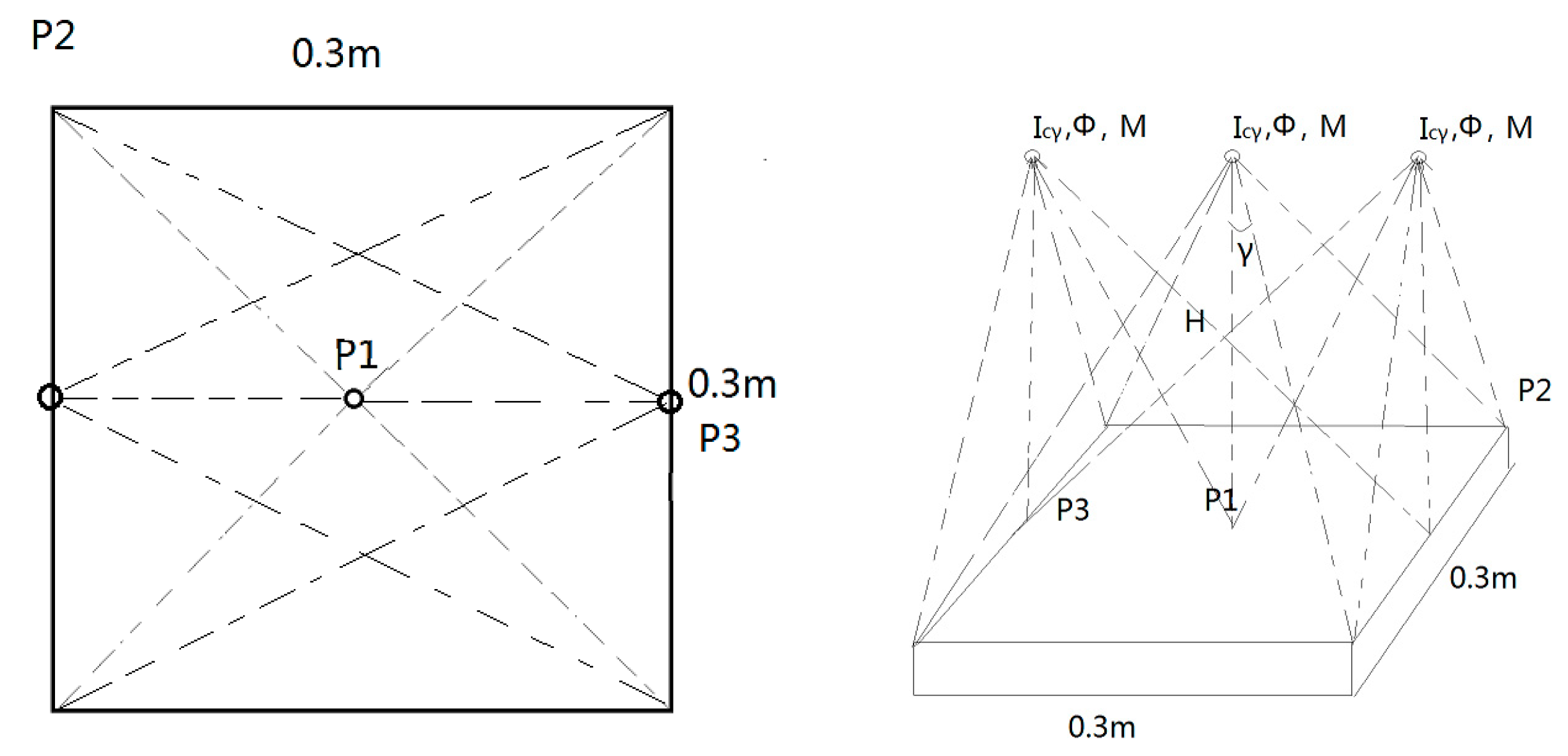

3.2. Optical Parameters of Laboratory Simulated Light Source

- Epi –illumination of point P generated by the particular lamp (lx);

- γ–light incident angle of point P from the particular lamp (°);

- Icγ–light intensity value of point P (cd);

- M–maintenance correction coefficient of the particular lamp, usually 0.6–0.7;

- Φ–rated luminous flux of the particular lamp (lm);

- H–the height of lamp light center to the road surface (m).

3.3. Influence Factors

4. Results and Discussion

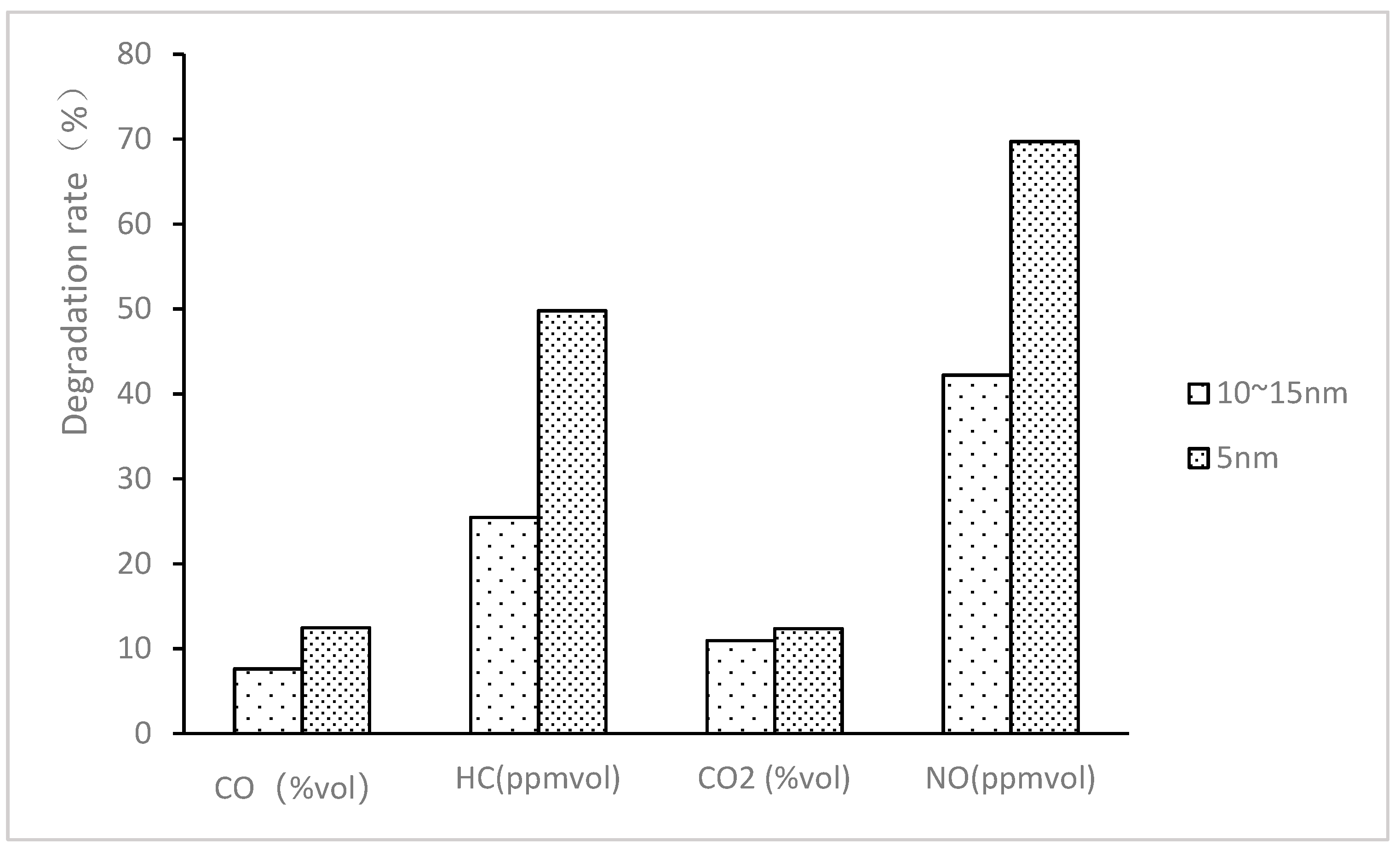

4.1. Comparative Study on Two Particle Sizes

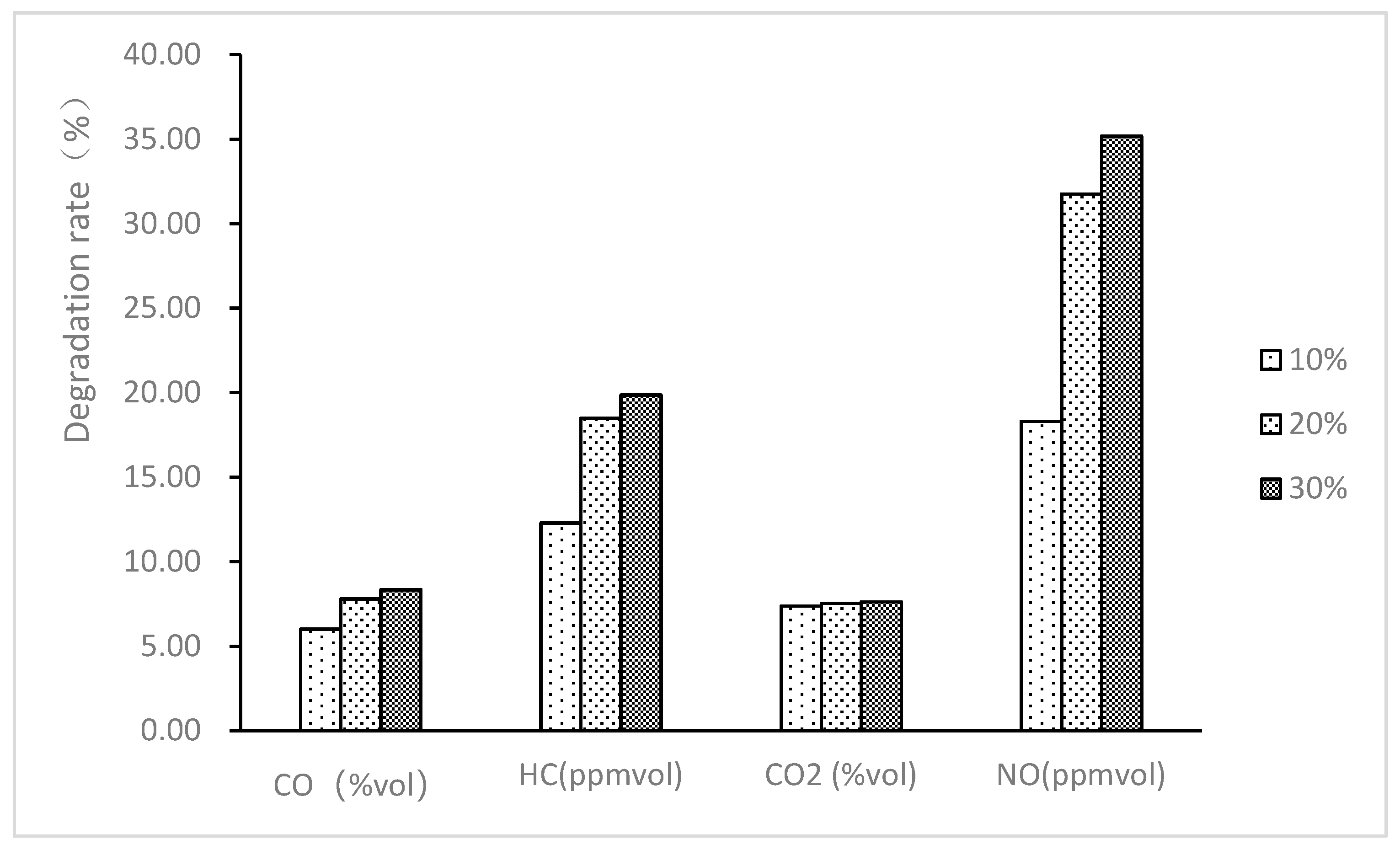

4.2. Different Nano-TiO2 Dosage

4.3. Degradation Effect Changes with the Length of Degradation Time

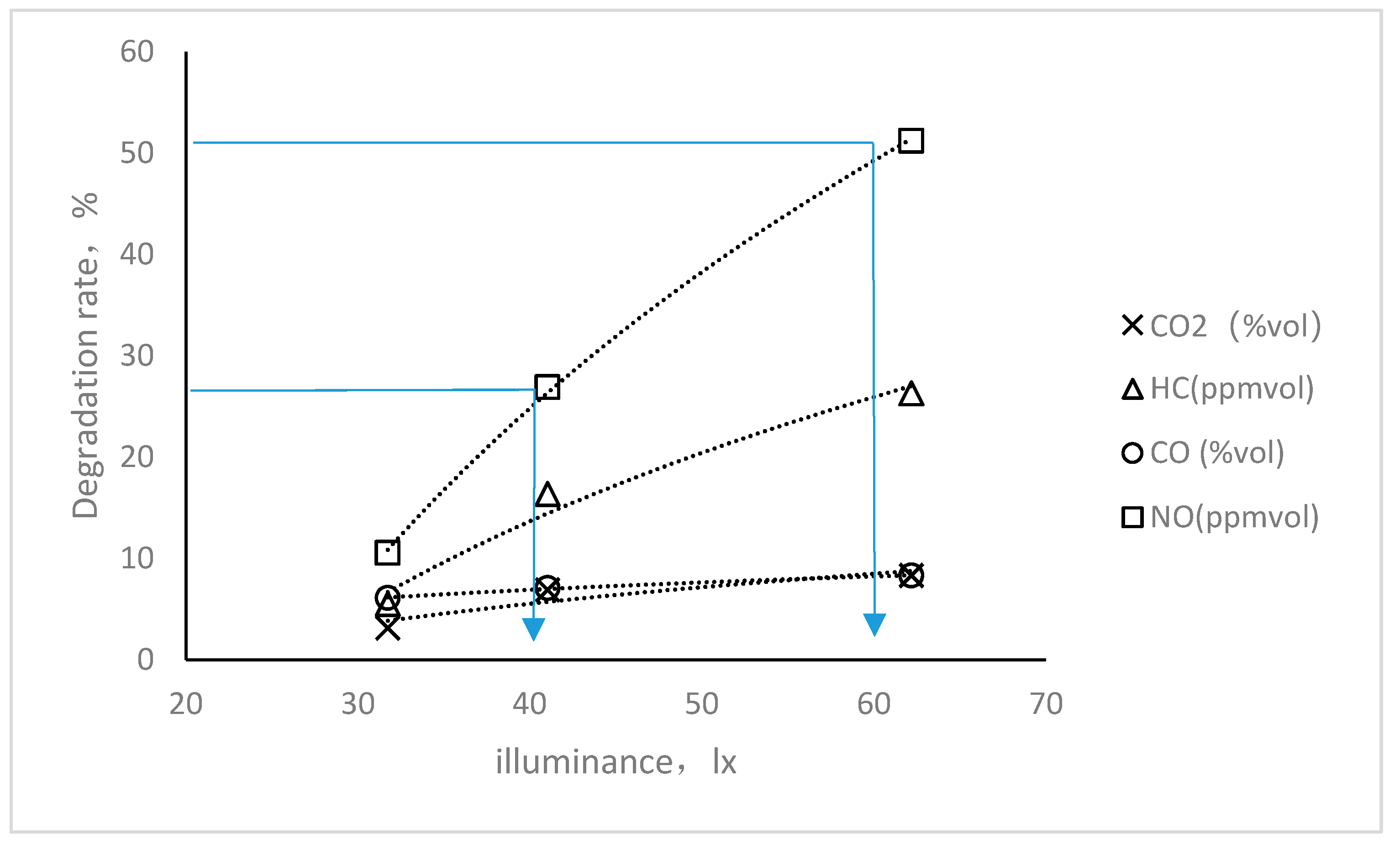

4.4. Different Light Intensity

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Keyte, I.J.; Albinet, A.; Harrison, R.M. On-road traffic emissions of polycyclic aromatic hydrocarbons and their oxy-and nitro-derivative compounds measured in road tunnel environments. Sci. Total Environ. 2016, 566, 1131–1142. [Google Scholar] [CrossRef] [PubMed]

- Moretti, L.; Cantisani, G.; Di Mascio, P. Management of road tunnels: Construction, maintenance and lighting costs. Tunn. Undergr. Space Technol. 2016, 51, 84–89. [Google Scholar] [CrossRef]

- Chuan, L.; Xiaofeng, H.; Zijuan, L.; Lingyan, H. A Tunnel Test for PM2.5 Emission Factors of Moto Vehicles in Shenzhen. Environ. Sci. Technol. 2012, 35, 150–153. [Google Scholar]

- Cai, X. Application of Warm Mixed Asphalt Technology in Pavement of Urban Long Tunnel. Urban Roads Bridges Flood Control 2015, 8, 253–255. [Google Scholar]

- Hurley, G.; Prowell, B. Evaluation of Aspha-Min® Zeolite for Use in Warm Mix Asphalt; NCAT Report 05-04; National Center for Asphalt Technology: Auburn, AL, USA, 2005; Available online: http://dsp2002.eng.auburn.edu/research/centers/ncat/files/reports/2005/rep05-04.pdf (accessed on 15 May 2019).

- Tan, Y.; Li, L.; Wei, P.; Sun, Z. Application Performance Evaluation on Material of Automobile Exhaust Degradation in Asphalt Pavement. China J. Highw. Transp. 2010, 23, 21–27. [Google Scholar]

- Wang, D.; Leng, Z.; Hüben, M.; Oeser, M.; Steinauer, B. Photocatalytic pavements with epoxy-bonded TiO2-containing spreading material. Constr. Build. Mater. 2016, 107, 44–51. [Google Scholar] [CrossRef]

- Toro, C.; Jobson, B.; Haselbach, L.; Shen, S.; Chung, S.; Chung, S. Photoactive roadways: Determination of CO, NO and VOC uptake coefficients and photolabile side product yields on TiO2 treated asphalt and concrete. Atmos. Environ. 2016, 139, 37–45. [Google Scholar] [CrossRef]

- Zhang, W. Experimental Studies on Automobile Exhaust Photocatalytic Degradationly Asphalt Pavement Material. Ph.D. Thesis, Chang’an University, Xi’an, China, 2014. [Google Scholar]

- Strini, A.; Cassese, S.; Schiavi, L. Measurement of benzene, toluene, ethylbenzene and o-xylene gas phase photodegradation by titanium dioxide dispersed in cementitious materials using a mixed flow reactor. Appl. Catal. B 2005, 61, 90–97. [Google Scholar] [CrossRef]

- Langridge, J.M.; Gustafsson, R.J.; Griffiths, P.T.; Cox, R.A.; Lambert, R.M.; Jones, R.L. Solar driven nitrous acid formation on building material surfaces containing titanium dioxide: A concern for air quality in urban areas? Atmos. Environ. 2009, 43, 5128–5131. [Google Scholar] [CrossRef]

- Shen, S.; Burton, M.; Jobson, B.; Haselbach, L. Pervious concrete with titanium dioxide as a photocatalyst compound for a greener urban road environment. Constr. Build. Mater. 2012, 35, 874–883. [Google Scholar] [CrossRef]

- Liu, W.; Wang, S.; Zhang, J.; Fan, J. Photocatalytic degradation of vehicle exhausts on asphalt pavement by TiO2/rubber composite structure. Constr. Build. Mater. 2015, 81, 224–232. [Google Scholar] [CrossRef]

- Luo, S.; Qian, Z.; Wang, H. Condition survey and analysis of epoxy asphalt concrete pavement on Second Nanjing Yangtze River Bridge: A ten-year review. J. Southeast Univ. 2011, 27, 417–422. [Google Scholar]

- ASTM D1763-00(2013). Standard Specification for Epoxy Resins. Available online: https://www.astm.org/Standards/D1763.htm (accessed on 12 June 2019).

- Huang, M.; Wen, X.; Wang, L. Influence of foaming effect, operation time and health preserving properties of foam epoxy asphalt mixtures. Constr. Build. Mater. 2017, 151, 931–938. [Google Scholar] [CrossRef]

- JTJ F40-2004. Technical Specifications for Construction of Highway Asphalt Pavements; Communications Press: Beijing, China, 2004. [Google Scholar]

- JTG E20-2011. Standard Test Method of Bitumen and Bituminous Mixtures for Highway Engineering; Communications Press: Beijing, China, 2011. [Google Scholar]

- Hassan, M.M.; Dylla, H.; Asadi, S.; Mohammad, L.N.; Cooper, S. Laboratory Evaluation of Environmental Performance of Photocatalytic Titanium Dioxide Warm-Mix Asphalt Pavements. J. Mater. Civ. Eng. 2012, 24, 599–605. [Google Scholar] [CrossRef]

- JTG/T D70/2-01-2014. Guidelines for Design of Lighting of Highway Tunnels; Communications Press: Beijing, China, 2014. [Google Scholar]

- Wang, D.; Leng, Z.; Yu, H.; Hüben, M.; Kollmann, J.; Oeser, M. Durability of epoxy-bonded TiO2-modified aggregate as a photocatalytic coating layer for asphalt pavement under vehicle tire polishing. Wear 2017, 382, 1–7. [Google Scholar] [CrossRef]

- Wang, C.; Yan, K.; Han, X.; Shi, Z.; Li, B.; Feng, X.; Ping, N.; Wu, S. Physico-chemical Characteristic Analysis of PM2.5 in the Highway Tunnel in the Plateau City of Kunming. Environ. Sci. 2017, 38, 4968–4975. [Google Scholar]

| Criterion | Unit | Detecting Result | Specification | Specification | |

|---|---|---|---|---|---|

| Residue by sieve test (1.18 mm) | % | 0.01 | ≤0.1 | T 0652 | |

| Particle charge | Positive (+) | Positive (+) | T 0653 | ||

| Engler viscosity, E25 | - | 3–30 | T 0622 | ||

| Residue by distillation | % | 62.1 | ≥60 | T 0651 | |

| Test on residue from distillation | penetration (100 g, 25 °C, 5 s) | 0.1 mm | 67.6 | 40–100 | T 0604 |

| Softening point (R/B) | °C | 59.2 | ≥57 | T 0606 | |

| Ductility (5 °C) | cm | >100 | ≥20 | T 0605 | |

| Solubility (trichloroethylene) | % | 99.5 | ≥97.5 | T 0607 | |

| Storage stability | 1 d | % | 0.2 | ≤1 | T 0655 |

| 5 d | % | 2.3 | ≤5 | ||

| Chemical Composition | Viscosity (mPa·s) | Epoxy Equivalent(g/eq) | Density (23 °C) (g/cm3) |

|---|---|---|---|

| 2,2-bis(4-(2,3-epoxpropyloxy(phenyl)propane | 11,000–14,000 | 211–290 | ≤1.10 |

| Size (mm) | Mineral Powder | 0~3 | 3~5 | 5~10 | 10~13 | 13~19 |

|---|---|---|---|---|---|---|

| gravity | 2.788 | 2.835 | 2.866 | 2.875 | 2.903 | 2.909 |

| Test Index | Basalt Aggregate | Standard Requirement (JTJ F40-2004) [12] | |

|---|---|---|---|

| Crushed stone value (%) | 23.2 | 28 | |

| Weared stone value (Los Angeles) (%) | 21.3 | 30 | |

| Content of flat particle (%) (size between 4.75 and 13.2 mm) | 10.3 | 20 | |

| Sand equivalent value (size 2.36 mm) (%) | 91.0 | 60 | |

| Angularity (%) | size between 2.36 and 4.75 mm | 30 | 30 |

| Size 2.36 mm | 49.2 | ||

| Size (mm) | Grade | 16.0 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Passing rate (%) | AC-13 | 100 | 93 | 77 | 54 | 35 | 22 | 17 | 10 | 8 | 6 |

| Scheme | A | B | C | |

|---|---|---|---|---|

| Typical Point | ||||

| P1 | 36.22 | 48.31 | 84.53 | |

| P2 | 27.23 | 34.23 | 61.46 | |

| P3 | - | 40.56 | 40.56 | |

| Average of Luminosity | 31.73 | 41.03 | 62.18 | |

| Influence Factor | Grade | |||||

|---|---|---|---|---|---|---|

| Particle size of nanoscale titanium dioxide | 5 nm | 10–15 nm | ||||

| Dosage of nano TiO2 | 10% | 20% | 30% | |||

| Duration | 2 h | 3 h | 4 h | 6 h | 10 h | 24 h |

| Luminosity | 31.73 lx | 41.03 lx | 62.18 lx | |||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, M.; Wen, X. Experimental Study on Photocatalytic Effect of Nano TiO2 Epoxy Emulsified Asphalt Mixture. Appl. Sci. 2019, 9, 2464. https://doi.org/10.3390/app9122464

Huang M, Wen X. Experimental Study on Photocatalytic Effect of Nano TiO2 Epoxy Emulsified Asphalt Mixture. Applied Sciences. 2019; 9(12):2464. https://doi.org/10.3390/app9122464

Chicago/Turabian StyleHuang, Ming, and Xuejun Wen. 2019. "Experimental Study on Photocatalytic Effect of Nano TiO2 Epoxy Emulsified Asphalt Mixture" Applied Sciences 9, no. 12: 2464. https://doi.org/10.3390/app9122464

APA StyleHuang, M., & Wen, X. (2019). Experimental Study on Photocatalytic Effect of Nano TiO2 Epoxy Emulsified Asphalt Mixture. Applied Sciences, 9(12), 2464. https://doi.org/10.3390/app9122464