Automatic Steering Control Algorithm Based on Compound Fuzzy PID for Rice Transplanter

Abstract

:1. Introduction

2. Materials and Methods

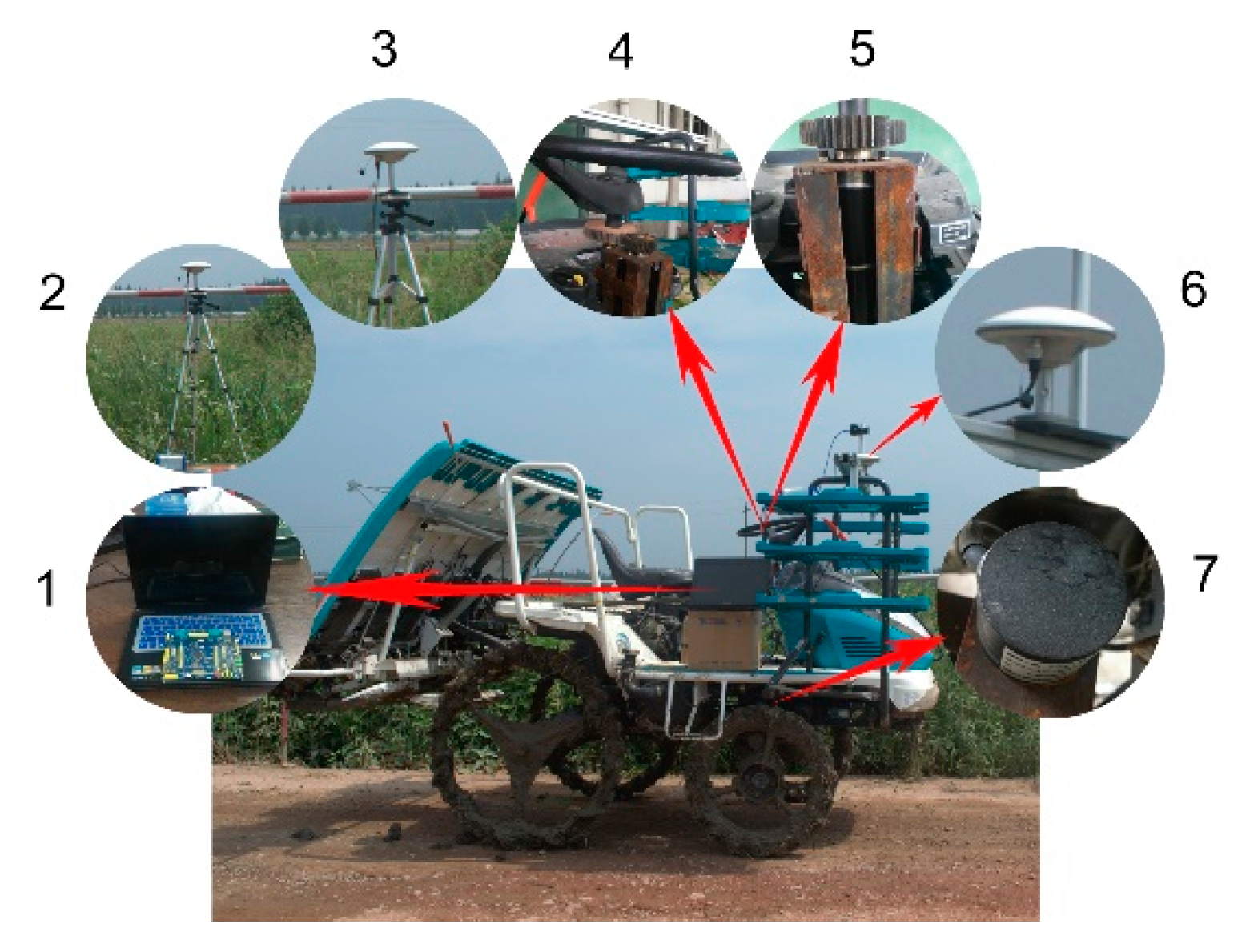

2.1. Automatic Steering Experimental Platform

2.2. Analysis of Kinematics of Rice Transplanter

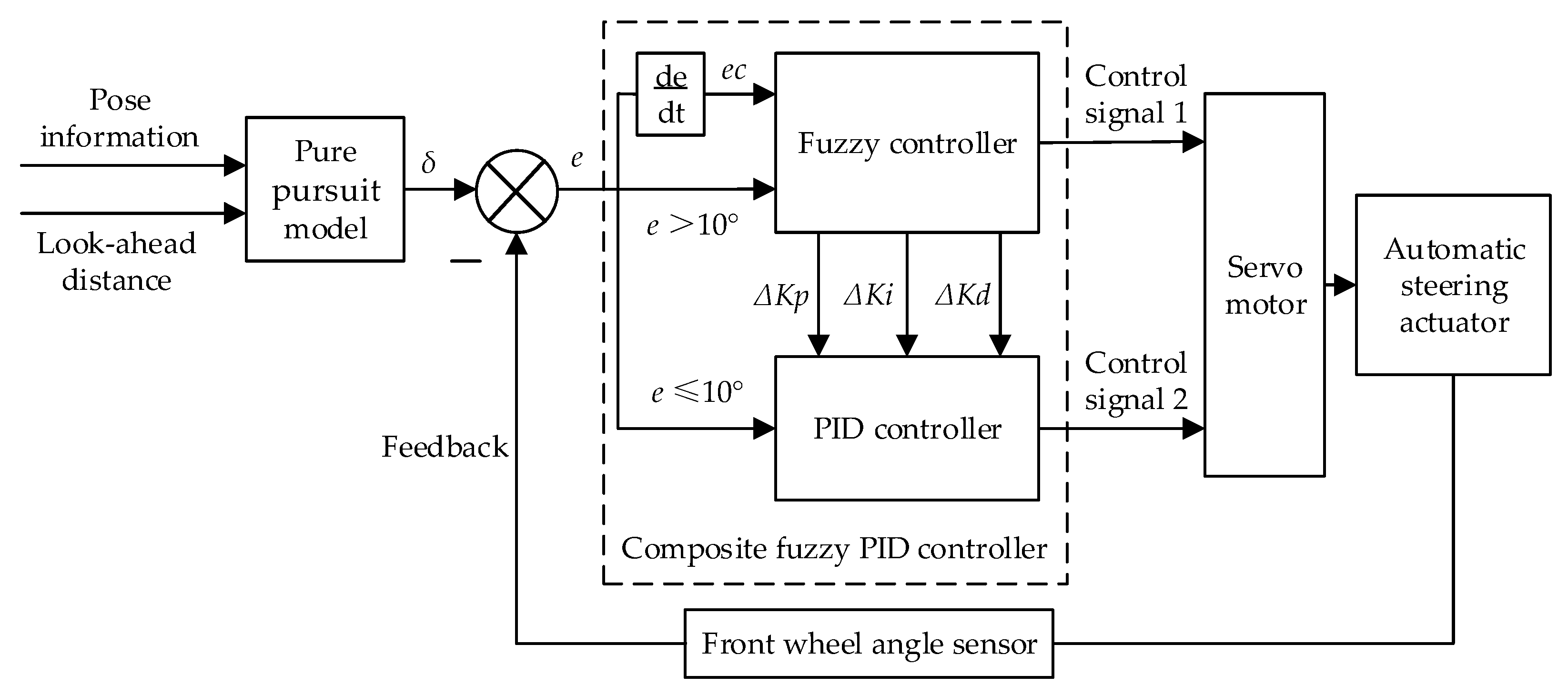

3. Design of the Automatic Steering Control Algorithm

3.1. The Compound Fuzzy PID Control Algorithm

3.2. Control Variable Fuzzification and Membership Function

- Front wheel angle deviation e. The basic domain is: [−30°, 30°], the quantification domain is: {−6, −4, −2, 0, 2, 4, 6} = {NB, NM, NS, ZO, PS, PM, PB}, and the quantization factor is: 6/30 = 0.2;

- Steering angle deviation change rate ec. The basic domain is: [−6, 6], the quantification domain is: {−6, −4, −2, 0, 2, 4, 6} = {NB, NM, NS, ZO, PS, PM, PB}, and the quantization factor is: 6/6 = 1;

- Proportional parameter ΔKp. The basic domain is: [−10, 10], the quantification domain is: {−3, −2, −1, 0, 1, 2, 3} = {NB, NM, NS, ZO, PS, PM, PB}, and the quantization factor is: 3/10 = 0.3;

- Integration parameter ΔKi. The basic domain is: [−8, 8], the quantification domain is: {−3, −2, −1, 0, 1, 2, 3} = {NB, NM, NS, ZO, PS, PM, PB}, and the quantization factor is: 3/8 = 0.375;

- Differential parameter ΔKd. The basic domain is: [−6, 6], the quantification domain is: {−3, −2, −1, 0, 1, 2, 3} = {NB, NM, NS, ZO, PS, PM, PB}, and the quantization factor is: 3/6 = 0.5;

3.3. Compound Fuzzy PID Control Rules

- When |e| is a small value, to maintain good steady-state performance of the system, ΔKp and ΔKi should be set as larger values, and the value of ΔKd depends on |ec|. When |ec| is small, ΔKd takes a larger value, whereas ΔKd should take a smaller value to avoid oscillation of the system.

- When |e| is a medium value, to reduce the overshoot of the system, the values of ΔKp and ΔKi should be smaller, and the value of ΔKd should be appropriate to speed up the response of the system.

- When |e| is a large value, to quickly reduce the system error and increase the reflection speed, the ΔKp value should be larger; ΔKi is often set to 0 to avoid the differential oversaturation caused by the instantaneous increase of the |e| value.

4. Simulation Analysis

5. Field Experimental Results and Discussion

5.1. Field Experimental Scheme

5.2. Analysis of Experimental Results

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, M.N.; Lu, X.L.; Tao, J.P.; Yin, W.Q.; Feng, X.B. Design and experiment of automatic guidance control system in agricultural vehicle. Trans. Chin. Soc. Agric. Mach. 2016, 47, 42–47. [Google Scholar]

- Ma, J.F.; Wang, D.C.; Tang, Y.W.; Zhao, J.B. Automatic control system of agricultural machinery based on Beidou navigation. In Proceedings of the IEEE 3rd Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 3–5 October 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 318–323. [Google Scholar]

- Reid, J.F.; Zhang, Q.; Noguchi, N.; Dickson, M. Agricultural automatic guidance research in North America. Comput. Electron. Agric. 2000, 25, 155–167. [Google Scholar] [CrossRef]

- Torii, T. Research in autonomous agriculture vehicles in Japan. Comput. Electron. Agric. 2000, 25, 133–153. [Google Scholar] [CrossRef]

- Wang, X.C.; Lu, W.; Chen, M.; Wang, T.; Zhang, Y.; Boukangou, M.P. Automatic following system for greenhouse harvesting transportation based on adaptive pure pursuit model. Trans. Chin. Soc. Agric. Mach. 2016, 47, 8–13. [Google Scholar]

- Tang, X.T.; Tao, J.F.; Li, Z.T.; Li, Y.; Liu, C. Fuzzy control optimization method for stability of path tracking system of automatic transplanter. Trans. Chin. Soc. Agric. Mach. 2018, 49, 29–34. [Google Scholar]

- Elbanhawi, M.; Simic, M.; Jazar, R. Receding horizon lateral vehicle control for pure pursuit path tracking. J. Vib. Control 2018, 24, 619–642. [Google Scholar] [CrossRef]

- Quan, M.M.; Zhai, Y.; Jiang, Y.; Sun, Y.J.; Xu, D.L.; Gong, J.W. An Improved pure pursuit algorithm for four-wheel-steering autonomous driving vehicle. Appl. Mech. Mater. 2014, 3006, 958–962. [Google Scholar] [CrossRef]

- David, S.A.; de Sousa, R.V.; Valentim, C.A., Jr.; Tabile, R.A.; Machado, J.A.T. Fractional PID controller in an active image stabilization system for mitigating vibration effects in agricultural tractors. Comput. Electron. Agric. 2016, 131, 1–9. [Google Scholar] [CrossRef]

- Wen, S.; Zhang, Q.Y.; Deng, J.Z.; Lan, Y.B.; Yin, X.C.; Shan, J. Design and experiment of a variable spray system for unmanned aerial vehicles based on PID and PWM control. Appl. Sci. 2018, 8, 2482. [Google Scholar] [CrossRef]

- Sujaritha, M.; Annadurai, S.; Satheeshkumar, J.; Sharan, S.K.; Mahesh, L. Weed detecting robot in sugarcane fields using fuzzy real time classifier. Comput. Electron. Agric. 2017, 134, 160–171. [Google Scholar] [CrossRef]

- Bonadies, S.; Smith, N.; Niewoehner, N.; Lee, A.S.; Lefcourt, A.M.; Gadsden, S.A. Development of proportional–integral–derivative and fuzzy control strategies for navigation in agricultural environments. J. Dyn. Syst. Meas. Control 2018, 140, 061007. [Google Scholar] [CrossRef]

- Soares, F.T.; Cappelli, N.L.; Garcia, A.P.; Umezu, C.K. Fuzzy control applied to an electrical power generation system mounted on tractors for driving of agricultural implements. Eng. Agric. 2016, 36, 846–857. [Google Scholar] [CrossRef] [Green Version]

- Camci, E.; Kripalani, D.R.; Ma, L.; Kayacan, E.; Khanesar, M.A. An aerial robot for rice farm quality inspection with type-2 fuzzy neural networks tuned by particle swarm optimization-sliding mode control hybrid algorithm. Swarm Evol. Comput. 2018, 41, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Csillik, O.; Cherbini, J.; Johnson, R.; Lyons, A.; Kelly, M. Identification of citrus trees from unmanned aerial vehicle imagery using convolutional neural networks. Drones 2018, 2, 39. [Google Scholar] [CrossRef]

- Eski, İ.; Kuş, Z.A. Control of unmanned agricultural vehicles using neural network-based control system. Neural Comput. Appl. 2019, 31, 583–595. [Google Scholar] [CrossRef]

- Duau, J.; Zhang, L.; Zhang, Z.; Zhao, J.; Jiang, Y. Research on Automatic Steering System of Agricultural Machinery Based on Fuzzy Neural Network. In Proceedings of the 2018 2nd IEEE Advanced Information Management, Communicates, Electronic and Automation Control Conference (IMCEC), Xi’an, China, 25–27 May 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1602–1605. [Google Scholar]

- García-Pérez, L.; García-Alegre, M.C.; Ribeiro, A.; Guinea, D. An agent of behavior architecture for unmanned control of a farming vehicle. Comput. Electron. Agric. 2008, 60, 39–48. [Google Scholar] [CrossRef]

- Remarka, M.; Griepentrog, H.W.; Nielsen, J.; Søgaard, H.T. The development and assessment of the accuracy of an autonomous GPS-based system for intra-row mechanical weed control in row crops. Biosyst. Eng. 2008, 101, 396–410. [Google Scholar]

- Nagasaka, Y.; Umeda, N.; Kanetai, Y.; Taniwaki, K.; Sasaki, Y. Autonomous guidance for rice transplanting using global positioning and gyroscopes. Comput. Electron. Agric. 2004, 43, 223–234. [Google Scholar] [CrossRef]

- Luo, X.W.; Zhang, Z.G.; Zhao, Z.X. The Method of Headland Turning in the Navigation Control for Wheeled Agricultural Machinery Compilation of the 2007 Annual Conference of the Chinese Society of Agricultural Engineering; South China Agricultural University: Guangzhou, China, 2007. [Google Scholar]

- Xu, L.L. Development of Tractor Automatic Navigation System Controller. Master’s Thesis, China Agricultural University, Beijing, China, 2011. [Google Scholar]

- Wang, F.X. Automatic steering control system for wheeled agricultural machinery. Agric. Eng. 2018, 8, 36–38. [Google Scholar]

- Qi, Z.J.; Yang, Z.G.; Huang, Y. Lane change track control for intelligent 4WS vehicle based on fuzzy adaptive PID. Chin. J. Autom. Eng. 2012, 2, 379–384. [Google Scholar]

- Xie, M.S.; Li, Y.N.; Zheng, L.; Pei, J.H. Synthesized feedback control of the ESP system based on fuzzy technology. J. Chongqing Univ. (Nat. Sci. Ed.) 2007, 30, 1–5. [Google Scholar]

- Li, G.; Wang, Y.; Guo, L.F.; Tong, J.; He, Y. Improved pure pursuit algorithm for rice transplanter path tracking. Trans. Chin. Soc. Agric. Mach. 2018, 49, 21–26. [Google Scholar]

- Zhu, G.Y. Study on Automatic Steering Control System of High-Speed Rice Transplanter. Master’s Thesis, Anhui Agricultural University, Hefei, China, 2018. [Google Scholar]

| Name | Component | Type | Number | Parameter |

|---|---|---|---|---|

| Beidou high-precision differential positioning system | Positioning receiver | C201 | 2 | ±2 cm, ±0.5° (precision) |

| Measuring antenna | 3 | |||

| Radio communication module | 2 | |||

| Navigation controller | Host computer PC | 1 | ||

| Lower computer STM32 microcontroller | 1 | |||

| Automatic steering system | Servo motor | RE50 | 1 | 30 Nm (Torque) i = 1/91 (transmission ratio) |

| Reducer | GP52C | 1 | ||

| Driver | EPOS2 70/10 | 1 | ||

| Gear pair | 1 | i = 1/2 (transmission ratio) | ||

| Front wheel angle measuring sensor | Absolute encoder | Rongwei Technology | 1 | 0°~360° (working range) |

| ΔKp | ec | |||||||

|---|---|---|---|---|---|---|---|---|

| NB | NM | NS | ZO | PS | PM | PB | ||

| e | NB | PB | PB | PM | PM | PS | ZO | ZO |

| NM | PB | PB | PM | PS | PS | ZO | NS | |

| NS | PM | PM | PM | PS | ZO | NS | NS | |

| ZO | PM | PM | PS | ZO | NS | NM | NM | |

| PS | PS | PS | ZO | NS | NS | NM | NM | |

| PM | PS | ZO | NS | NM | NM | NM | NB | |

| PB | ZO | ZO | NM | NM | NM | NB | NB | |

| ΔKi | ec | |||||||

|---|---|---|---|---|---|---|---|---|

| NB | NM | NS | ZO | PS | PM | PB | ||

| e | NB | NB | NB | NM | NM | NS | ZO | ZO |

| NM | NB | NB | NM | NS | NS | ZO | ZO | |

| NS | NB | NM | NS | NS | ZO | PS | PS | |

| ZO | NM | NM | NS | ZO | PS | PM | PM | |

| PS | NM | NS | ZO | PS | PS | PM | PB | |

| PM | ZO | ZO | PS | PS | PM | PB | PB | |

| PB | ZO | ZO | PS | PM | PM | PB | PB | |

| ΔKd | ec | |||||||

|---|---|---|---|---|---|---|---|---|

| NB | NM | NS | ZO | PS | PM | PB | ||

| e | NB | PS | NS | NB | NB | NB | NM | PS |

| NM | PS | NS | NB | NM | NM | NS | ZO | |

| NS | ZO | NS | NM | NM | NS | NS | ZO | |

| ZO | ZO | NS | NS | NS | NS | NS | ZO | |

| PS | ZO | ZO | ZO | ZO | ZO | ZO | ZO | |

| PM | PB | NS | PS | PS | PS | PS | PB | |

| PB | PB | PM | PM | PM | PS | PS | PB | |

| e | Controller | Response Process | Overshoot | Response Time | Stable Time |

|---|---|---|---|---|---|

| 8° | Compound fuzzy PID | Strict monotony | 0.2° | 0.34 s | 0.52 s |

| Traditional PID | Attenuation oscillation | 0.4° | 0.48 s | 1.05 s | |

| 25° | Compound fuzzy PID | Slight shock | 1.6° | 0.45 s | 0.94 s |

| Traditional PID | Attenuation oscillation | 3.5° | 0.68 s | 1.85 s |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, J.; Zhu, D.; Liao, J.; Zhu, G.; Wang, Y.; Zhang, S. Automatic Steering Control Algorithm Based on Compound Fuzzy PID for Rice Transplanter. Appl. Sci. 2019, 9, 2666. https://doi.org/10.3390/app9132666

Yin J, Zhu D, Liao J, Zhu G, Wang Y, Zhang S. Automatic Steering Control Algorithm Based on Compound Fuzzy PID for Rice Transplanter. Applied Sciences. 2019; 9(13):2666. https://doi.org/10.3390/app9132666

Chicago/Turabian StyleYin, Junnan, Dequan Zhu, Juan Liao, Guangyue Zhu, Yao Wang, and Shun Zhang. 2019. "Automatic Steering Control Algorithm Based on Compound Fuzzy PID for Rice Transplanter" Applied Sciences 9, no. 13: 2666. https://doi.org/10.3390/app9132666

APA StyleYin, J., Zhu, D., Liao, J., Zhu, G., Wang, Y., & Zhang, S. (2019). Automatic Steering Control Algorithm Based on Compound Fuzzy PID for Rice Transplanter. Applied Sciences, 9(13), 2666. https://doi.org/10.3390/app9132666