Classifying Degraded Three-Dimensionally Printed Polylactic Acid Specimens Using Artificial Neural Networks based on Fourier Transform Infrared Spectroscopy

Abstract

1. Introduction

2. Methodology

2.1. 3D Printed Specimen

2.2. High-Temperature Storage Test for PLA Thermal Degradation

2.3. Fourier-Transform Infrared Spectroscopy

2.4. Training Strategy for Artificial Neural Networks

- The number of hidden layers is fixed to two;

- The size of the hidden layers should be between the sizes of the input and the output layers;

- The number of hidden neurons should be half that, in case of the previous hidden layer.

3. Results and Discussion

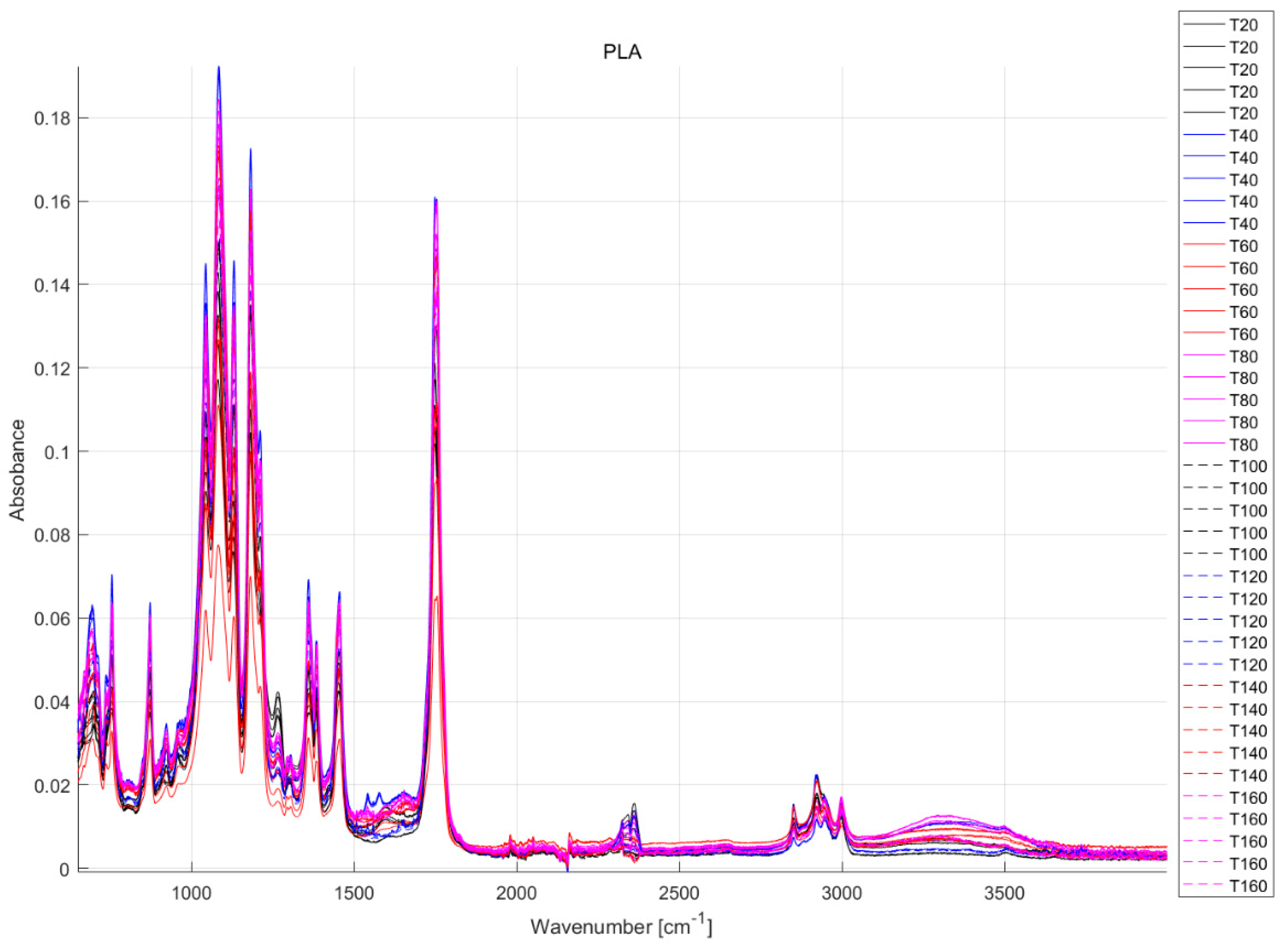

3.1. Input Datasets for ANNs

3.2. Validation of ANN Models

4. Conclusions

Funding

Conflicts of Interest

References

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput. Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Low, Z.X.; Chua, Y.T.; Ray, B.M.; Mattia, D.; Metcalfe, I.S.; Patterson, D.A. Perspective on 3D printing of separation membranes and comparison to related unconventional fabrication techniques. J. Membr. Sci. 2017, 523, 596–613. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Wojtyła, S.; Klama, P.; Baran, T. Is 3D printing safe? Analysis of the thermal treatment of thermoplastics: ABS, PLA, PET, and nylon. J. Occup. Environ. Hyg. 2017, 14, D80–D85. [Google Scholar] [CrossRef] [PubMed]

- Copinet, A.; Legin-Copinet, E.; Erre, D. Compostability of Co-extruded starch/poly(lactic acid) polymeric material degradation in an activated inert solid medium. Materials (Basel) 2009, 2, 749–764. [Google Scholar] [CrossRef]

- Lanzotti, A.; Martorelli, M.; Maietta, S.; Gerbino, S.; Penta, F.; Gloria, A. A comparison between mechanical properties of specimens 3D printed with virgin and recycled PLA. Procedia CIRP 2019, 79, 143–146. [Google Scholar] [CrossRef]

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused filament fabrication of fiber-reinforced polymers: A review. Addit. Manuf. 2018, 21, 1–16. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Kumar, A.; Tumu, V.R.; Chowdhury, S.R.; SVS, R.R. A green physical approach to compatibilize a bio-based poly (lactic acid)/lignin blend for better mechanical, thermal and degradation properties. Int. J. Biol. Macromol. 2019, 121, 588–600. [Google Scholar] [CrossRef] [PubMed]

- Wittbrodt, B.; Pearce, J.M. The effects of PLA color on material properties of 3-D printed components. Addit. Manuf. 2015, 8, 110–116. [Google Scholar] [CrossRef]

- Xu, H.; Tang, Y.; Liu, Z.; Cai, Y.; Wang, Y. The Study of Typical Failure Modes and Failure Mechanism of Polymer Materials. IOP Conf. Ser. Mater. Sci. Eng. 2017, 231, 1–6. [Google Scholar] [CrossRef]

- Faghihzadeh, F.; Anaya, N.M.; Schifman, L.A.; Oyanedel-Craver, V. Oyanedel-Craver.Fourier transform infrared spectroscopy to assess molecular-level changes in microorganisms exposed to nanoparticles. Nanotechnol. Environ. Eng. 2016, 1, 1–16. [Google Scholar] [CrossRef]

- Liu, X.; Khor, S.; Petinakis, E.; Yu, L.; Simon, G.; Dean, K.; Bateman, S. Effects of hydrophilic fillers on the thermal degradation of poly(lactic acid). Thermochim. Acta 2010, 509, 147–151. [Google Scholar] [CrossRef]

- González, E.A.S.; Teno, J.; González-Benito, J.; Olmos, D. Accurate Evaluation of Dynamics and Specific Interactions in PLA/TiO2 Nanocomposites. Sci. J. Mol. Phys. 2017, 1, 1–13. [Google Scholar]

- Leroy, A.; Ribeiro, S.; Grossiord, C.; Alves, A.; Vestberg, R.H.; Salles, V.; Brunon, C.; Gritsch, K.; Grosgogeat, B.; Bayon, Y. FTIR microscopy contribution for comprehension of degradation mechanisms in PLA-based implantable medical devices. J. Mater. Sci. Mater. Med. 2017, 28, 87. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.U. Degradation Classification of 3D Printing Thermoplastics Using Fourier Transform Infrared Spectroscopy and Artificial Neural Networks. Appl. Sci. 2018, 8, 1224. [Google Scholar] [CrossRef]

- Nair, V.; Hinton, G.E. Rectified Linear Units Improve Restricted Boltzmann Machines. In Proceedings of the ICML’10 27th International Conference on International Machine Learning, Haifa, Israe, 21–24 June 2010; pp. 807–814. [Google Scholar]

- Ramachandran, P.; Zoph, B.; Le, Q.V. Searching for Activation Functions. In Proceedings of the ICLR 2018 Conference Blind Submission, Vancouver, BC, Canada, 6 February 2018; pp. 1–13. [Google Scholar]

- Heaton, J. Introduction to Neural Networks for Java, 2nd ed.; Heaton Research: St. Louis, MO, USA, 2008. [Google Scholar]

- Kumar, A.; Rao, T.V.; Chowdhury, S.R.; Reddy, S.R. Compatibility confirmation and refinement of thermal and mechanical properties of poly (lactic acid)/poly (ethylene-co-glycidyl methacrylate) blend reinforced by hexagonal boron nitride. React. Funct. Polym. 2017, 117, 1–9. [Google Scholar] [CrossRef]

- Nanthananon, P.; Seadan, M.; Pivsa-Art, S.; Suttiruengwong, S. Enhanced crystallization of poly (lactic acid) through reactive aliphatic bisamide. IOP Conf. Ser. Mater. Sci. Eng. 2015, 87, 012067. [Google Scholar] [CrossRef]

| Name of Dataset | Description | # of Training Sets | # of Testing Sets |

|---|---|---|---|

| D01 | PLA (24 h, 20 °C) | 140 | 10 |

| D02 | PLA (24 h, 40 °C) | 140 | 10 |

| D03 | PLA (24 h, 60 °C) | 140 | 10 |

| D04 | PLA (24 h, 80 °C) | 140 | 10 |

| D05 | PLA (24 h, 100 °C) | 140 | 10 |

| D06 | PLA (24 h, 120 °C) | 140 | 10 |

| D07 | PLA (24 h, 140 °C) | 140 | 10 |

| D08 | PLA (24 h, 160 °C) | 140 | 10 |

| Name of Division | Range of Wavenumber (cm−1) | Accuracy of the ANN Model (%) | Characteristic Peaks (cm−1) |

|---|---|---|---|

| P1/4 | 650–1487 | 75% | 757 cm−1 870 cm−1 956 cm−1 |

| P2/4 | 1487–2324 | 100% | 1184 cm−1 1757 cm−1 |

| P3/4 | 2324–3160 | 60% | 2946–2998 cm−1 |

| P4/4 | 3160–4000 | 75% | 3501 cm−1 3656 cm−1 |

| P1/8 | 650–1068 | 75% | 757 cm−1 870 cm−1 956 cm−1 |

| P2/8 | 1068–1487 | 50% | 1184 cm−1 |

| P3/8 | 1487–1905 | 100% | 1757 cm−1 |

| P4/8 | 1905–2324 | 55% | |

| P5/8 | 2324–2724 | 30% | |

| P6/8 | 2724–3160 | 45% | 2946–2998 cm−1 |

| P7/8 | 3160–3579 | 100% | 3501 cm−1 |

| P8/8 | 3579–4000 | 65% | 3656 cm−1 |

| P1/16 | 650–859 | 100% | 757 cm−1 |

| P2/16 | 859–1068 | 100% | 870 cm−1 956 cm−1 |

| P3/16 | 1068–1277 | 100% | 1184 cm−1 |

| P4/16 | 1277–1487 | 100% | |

| P5/16 | 1487–1696 | 70% | |

| P6/16 | 1696–1905 | 95% | 1757 cm−1 |

| P7/16 | 1905–2115 | 50% | |

| P8/16 | 2115–2324 | 25% | |

| P9/16 | 2324–2533 | 35% | |

| P10/16 | 2533–2724 | 45% | |

| P11/16 | 2724–2951 | 45% | |

| P12/16 | 2951–3160 | 75% | 2946–2998 cm−1 |

| P13/16 | 3160–3370 | 50% | |

| P14/16 | 3370–3579 | 50% | 3501 cm−1 |

| P15/16 | 3579–3788 | 65% | 3656 cm−1 |

| P16/16 | 3788–4000 | 65% |

| Characteristic Peaks | Description |

|---|---|

| 757 cm−1 | -C-C- crystalline phase |

| 870 cm−1 | -C-C- amorphous phase |

| 956 cm−1 | C-CH3 group |

| 1184 cm−1 | C-O-C group |

| 1757 cm−1 | Carbonyl Group (C=O) |

| 2946–2998 cm−1 | CH3 group |

| 3501 cm−1 | The carboxylic acid terminal group |

| 3656 cm−1 | Hydroxyl group (O-H) |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.-U. Classifying Degraded Three-Dimensionally Printed Polylactic Acid Specimens Using Artificial Neural Networks based on Fourier Transform Infrared Spectroscopy. Appl. Sci. 2019, 9, 2772. https://doi.org/10.3390/app9132772

Zhang S-U. Classifying Degraded Three-Dimensionally Printed Polylactic Acid Specimens Using Artificial Neural Networks based on Fourier Transform Infrared Spectroscopy. Applied Sciences. 2019; 9(13):2772. https://doi.org/10.3390/app9132772

Chicago/Turabian StyleZhang, Sung-Uk. 2019. "Classifying Degraded Three-Dimensionally Printed Polylactic Acid Specimens Using Artificial Neural Networks based on Fourier Transform Infrared Spectroscopy" Applied Sciences 9, no. 13: 2772. https://doi.org/10.3390/app9132772

APA StyleZhang, S.-U. (2019). Classifying Degraded Three-Dimensionally Printed Polylactic Acid Specimens Using Artificial Neural Networks based on Fourier Transform Infrared Spectroscopy. Applied Sciences, 9(13), 2772. https://doi.org/10.3390/app9132772