Design and Motion Planning of a Biped Climbing Robot with Redundant Manipulator

Abstract

:Featured Application

Abstract

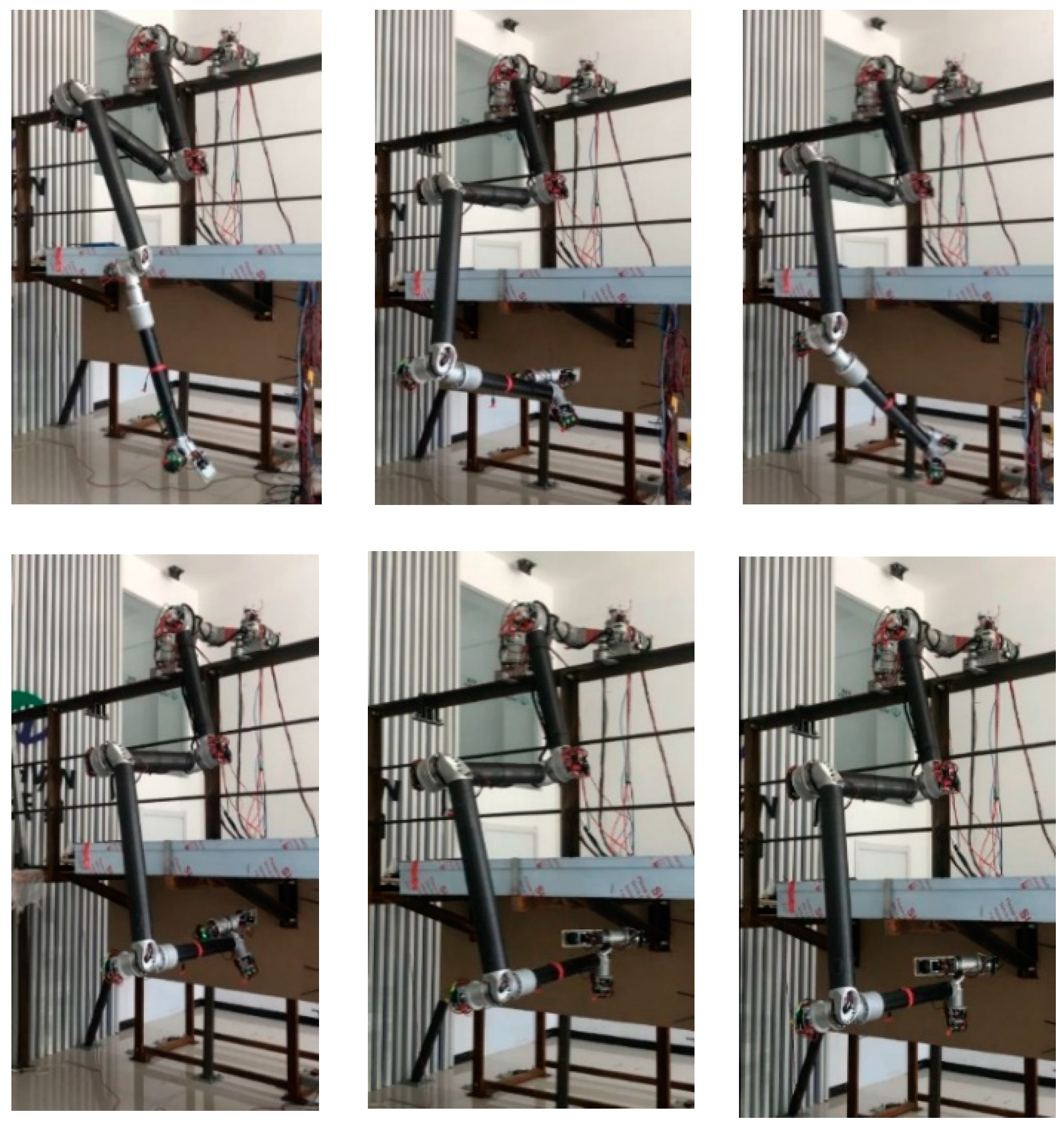

1. Introduction

2. Design of the Robotic Systems

2.1. Design Indicators

- The mass of the robot should be less than 100 kg.

- The robot can move on the guardrail and crossover a gap with a length of 10 cm.

- The robot can attach to the guardrail when it performs maintenance tasks.

- The workspace of the robot can cover a cuboid with the dimensions of 1540 × 1100 × 1500 mm, and the robot is able to avoid obstacles as it performs tasks.

- The load at the end of the robot is greater than 5 kg.

- The climbing speed of the robot is not less than 0.1 m/s, the speed of the end effector is not less than 0.3 m/s.

2.2. Mechanical Configuration

2.3. Control System

2.4. Work Process

3. Motion Planning

3.1. Motion Planning of the Climbing Mechanism

3.2. Motion Planning of the Redundant Manipulator

4. Experiments

5. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lattanzi, D.; Miller, G. Review of robotic infrastructure inspection systems. J. Infrastruct. Syst. 2017, 23, 04017004. [Google Scholar] [CrossRef]

- Chu, B.; Jung, K.; Han, C.S.; Hong, D. A survey of climbing robots: Locomotion and adhesion. Int. J. Precis. Eng. Manuf. 2010, 11, 633–647. [Google Scholar] [CrossRef]

- Takeda, M.; Shimoyama, I. Slip and Magnetic Attraction Effects in a Microrobot with Magnetic-Wheels and Skid-Steering. Micromachines 2019, 10, 379. [Google Scholar] [CrossRef] [PubMed]

- Tavakoli, M.; Lourenco, J.; Viegas, C.; Neto, P.; de Almeida, A.T. The hybrid OmniClimber robot: Wheel based climbing, arm based plane transition, and switchable magnet adhesion. Mechatronics 2016, 36, 136–146. [Google Scholar] [CrossRef]

- Lee, G.; Kim, H.; Seo, K.; Kim, J.; Sitti, M.; Seo, T. Series of Multilinked Caterpillar Track-Type Climbing Robots. J. Field Robot. 2016, 33, 737–750. [Google Scholar] [CrossRef]

- Robertson, M.A.; Paik, J. New soft robots really suck: Vacuum-powered systems empower diverse capabilities. Sci. Robot. 2017, 2. [Google Scholar] [CrossRef]

- Tun, T.T.; Elara, M.R.; Kalimuthu, M.; Vengadesh, A. Glass facade cleaning robot with passive suction cups and self-locking trapezoidal lead screw drive. Autom. Constr. 2018, 96, 180–188. [Google Scholar] [CrossRef]

- Qian, Z.Y.; Zhao, Y.Z.; Fu, Z.; Cao, Q.X. Design and realization of a non-actuated glass-curtain wall-cleaning robot prototype with dual suction cups. Int. J. Adv. Manuf. Technol. 2006, 30, 147–155. [Google Scholar] [CrossRef]

- Graule, M.; Chirarattananon, P.; Fuller, S.; Jafferis, N.; Ma, K.; Spenko, M.; Kornbluh, R.; Wood, R. Perching and takeoff of a robotic insect on overhangs using switchable electrostatic adhesion. Science 2016, 352, 978–982. [Google Scholar] [CrossRef] [Green Version]

- Yehya, M.I.; Hussain, S.; Wasim, A.; Jahanzaib, M.; Abdalla, H. A cost effective and light weight unipolar electroadhesion pad technology for adhesion mechanism of wall climbing robot. Int. J. Robot. Mechatron. 2014, 2, 1–10. [Google Scholar] [CrossRef]

- Sintov, A.; Avramovich, T.; Shapiro, A. Design and motion planning of an autonomous climbing robot with claws. Robot. Auton. Syst. 2011, 59, 1008–1019. [Google Scholar] [CrossRef]

- Jiang, Q.; Xu, F. Grasping Claws of Bionic Climbing Robot for Rough Wall Surface: Modeling and Analysis. Appl. Sci. 2017, 8, 14. [Google Scholar] [CrossRef]

- Sun, Z.; Li, H.; Jiang, Z.; Song, Z.; Mo, Y.; Ceccarelli, M. Prototype Design and Performance Tests of Beijing Astronaut Robot. Appl. Sci. 2018, 8, 1342. [Google Scholar] [CrossRef]

- Koh, K.H.; Sreekumar, M.; Ponnambalam, S. Hybrid electrostatic and elastomer adhesion mechanism for wall climbing robot. Mechatronics 2016, 35, 122–135. [Google Scholar] [CrossRef]

- Canfield, S.L.; Hill, T.W.; Zuccaro, S.G. Prediction and Experimental Validation of Power Consumption of Skid-Steer Mobile Robots in Manufacturing Environments. J. Intell. Robot. Syst. 2019, 94, 825–839. [Google Scholar] [CrossRef]

- Huang, H.; Li, D.; Xue, Z.; Chen, X.; Liu, S.; Leng, J.; Wei, Y. Design and performance analysis of a tracked wall-climbing robot for ship inspection in shipbuilding. Ocean Eng. 2017, 131, 224–230. [Google Scholar] [CrossRef]

- Pagano, D.; Liu, D. An approach for real-time motion planning of an inchworm robot in complex steel bridge environments. Robotica 2017, 35, 1280–1309. [Google Scholar] [CrossRef]

- Guan, Y.; Zhu, H.; Wu, W.; Zhou, X.; Jiang, L.; Cai, C.; Zhang, L.; Zhang, H. A modular biped wall-climbing robot with high mobility and manipulating function. IEEE/ASME Trans. Mechatron. 2012, 18, 1787–1798. [Google Scholar] [CrossRef]

- Gu, S.; Zhu, H.; Li, H.; Guan, Y.; Zhang, H. Optimal Collision-Free Grip Planning for Biped Climbing Robots in Complex Truss Environment. Appl. Sci. 2018, 8, 2533. [Google Scholar] [CrossRef]

- Lim, J.; Lee, I.; Shim, I.; Jung, H.; Joe, H.M.; Bae, H.; Sim, O.; Oh, J.; Jung, T.; Shin, S. Robot system of DRC-HUBO+ and control strategy of team KAIST in DARPA robotics challenge finals. J. Field Robot. 2017, 34, 802–829. [Google Scholar] [CrossRef]

- Gao, Z.; Huang, J.; Yang, X.; An, P. Calibration of rotating 2D LIDAR based on simple plane measurement. Sens. Rev. 2019, 39, 190–198. [Google Scholar] [CrossRef]

- Guo, Y.; Sohel, F.; Bennamoun, M.; Lu, M.; Wan, J. Rotational projection statistics for 3D local surface description and object recognition. Int. J. Comput. Vis. 2013, 105, 63–86. [Google Scholar] [CrossRef]

- Rocha, C.; Tonetto, C.; Dias, A. A comparison between the Denavit–Hartenberg and the screw-based methods used in kinematic modeling of robot manipulators. Robot. Comput.-Integr. Manuf. 2011, 27, 723–728. [Google Scholar] [CrossRef]

- Murray, R.M. A Mathematical Introduction to Robotic Manipulation; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Karami, A.; Sadeghian, H.; Keshmiri, M.; Oriolo, G. Hierarchical tracking task control in redundant manipulators with compliance control in the null-space. Mechatronics 2018, 55, 171–179. [Google Scholar] [CrossRef]

- Gilbert, E.G.; Johnson, D.W.; Keerthi, S.S. A fast procedure for computing the distance between complex objects in three-dimensional space. IEEE Trans. Robot. Autom. 1988, 4, 193–203. [Google Scholar] [CrossRef] [Green Version]

| Joint | Link Torsional Angle | Link Length | Link Offset | Joint Angle |

|---|---|---|---|---|

| 1 | 0 | 0 | 0 | θ1 |

| 2 | 90 | 0 | l1 | θ2 |

| 3 | 0 | l2 | 0 | θ3 |

| 4 | 0 | l2 | 0 | θ4 |

| 5 | 90 | 0 | l1 | θ5 |

| Joint | Link Torsional Angle | Link Length | Link Offset | Joint Angle |

|---|---|---|---|---|

| 6 | 0 | 0 | 0 | θ6 |

| 7 | −90 | l3 | 0 | θ7 |

| 8 | 0 | l4 | 0 | θ8 |

| 9 | 0 | l5 | 0 | θ9 |

| 10 | 90 | 0 | l6 | θ10 |

| 11 | −90 | 0 | 0 | θ11 |

| 12 | 90 | 0 | 0 | θ12 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, Q.; Luo, X.; Qiao, Z.; Li, Q. Design and Motion Planning of a Biped Climbing Robot with Redundant Manipulator. Appl. Sci. 2019, 9, 3009. https://doi.org/10.3390/app9153009

Chang Q, Luo X, Qiao Z, Li Q. Design and Motion Planning of a Biped Climbing Robot with Redundant Manipulator. Applied Sciences. 2019; 9(15):3009. https://doi.org/10.3390/app9153009

Chicago/Turabian StyleChang, Qing, Xiao Luo, Zhixia Qiao, and Qian Li. 2019. "Design and Motion Planning of a Biped Climbing Robot with Redundant Manipulator" Applied Sciences 9, no. 15: 3009. https://doi.org/10.3390/app9153009