Effect of Harsh Conditions on the Tensile Behaviour of Lap-Spliced Carbon Fiber Textile-Reinforced Mortar (TRM) with Different Surface Treatment Methods

Abstract

1. Introduction

2. Materials and Methods

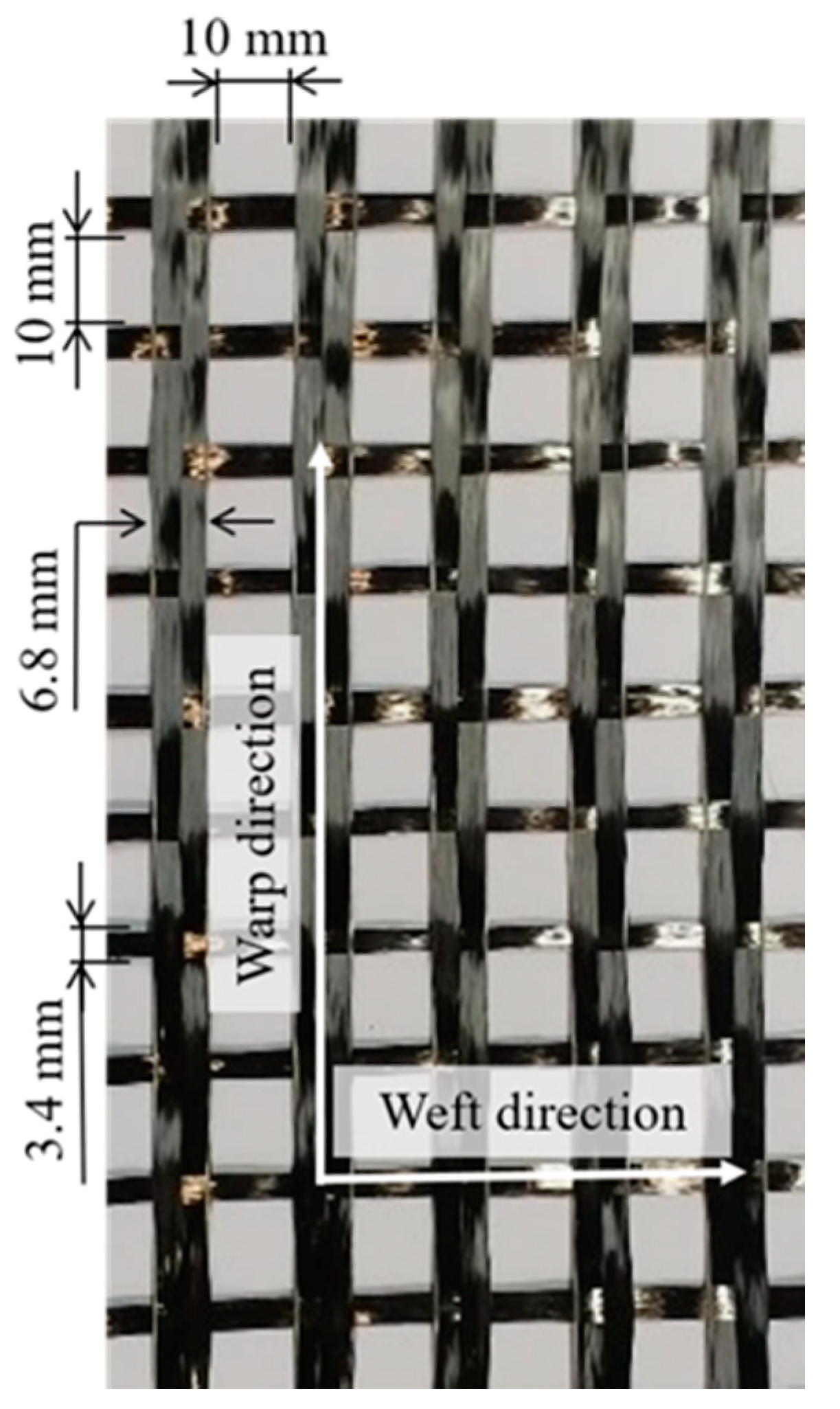

2.1. Material Properties

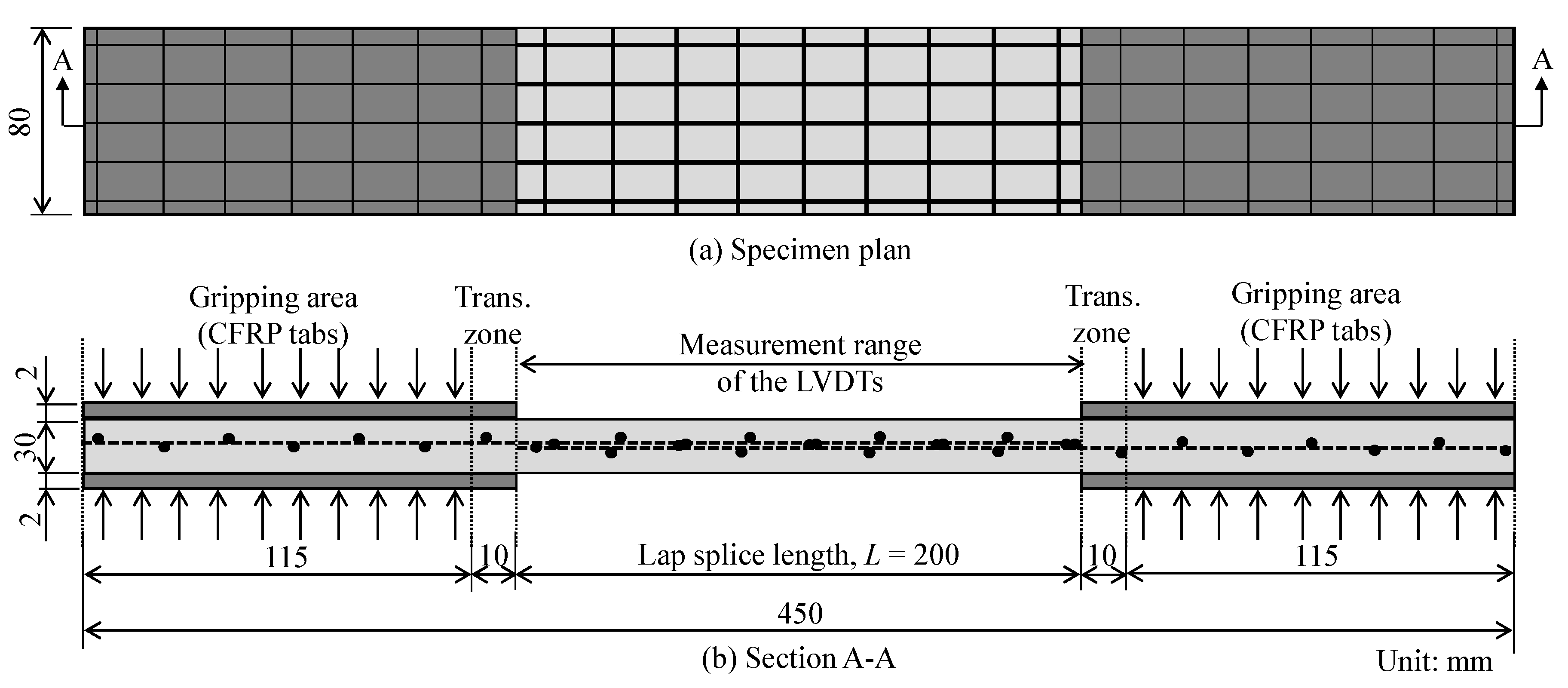

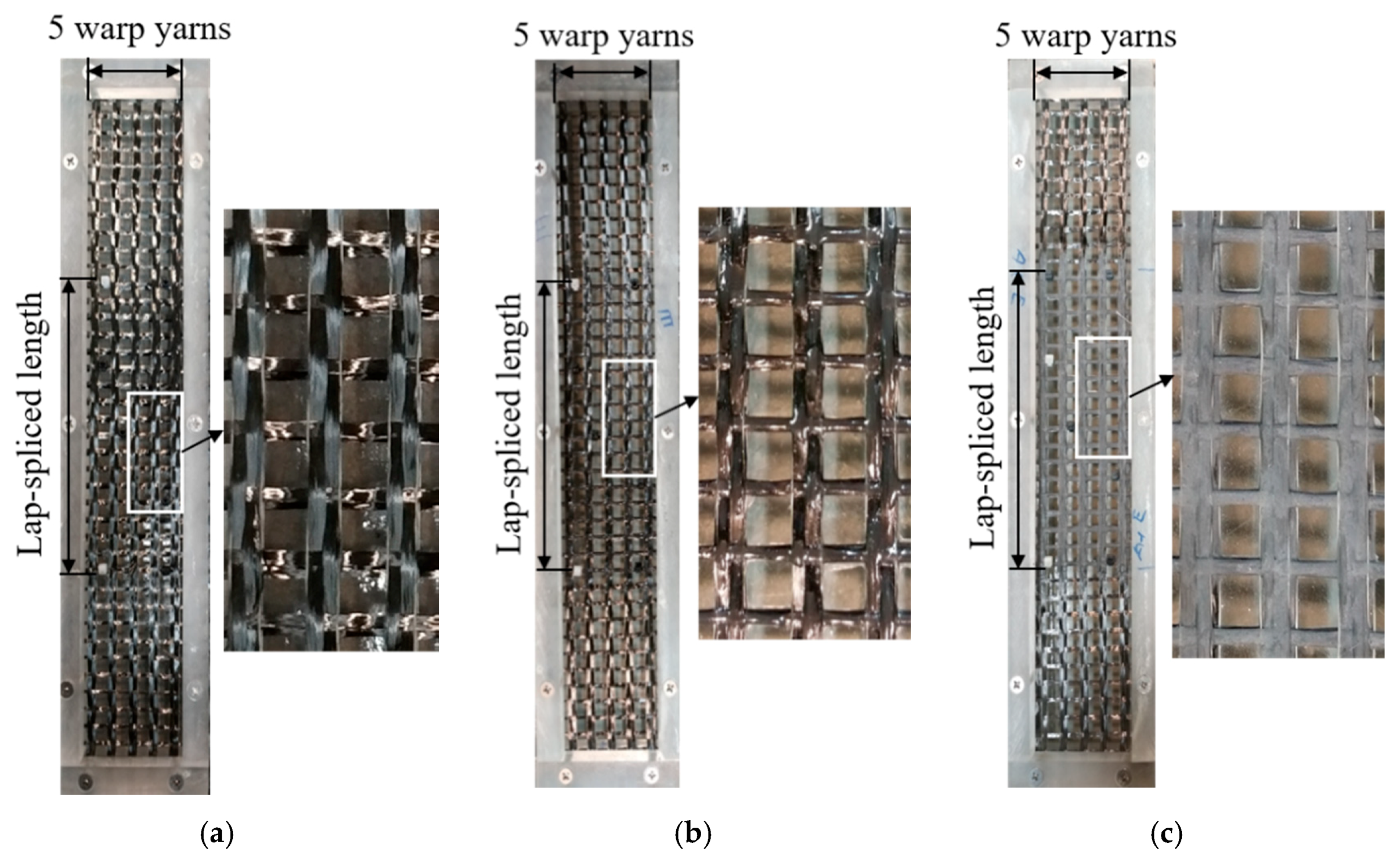

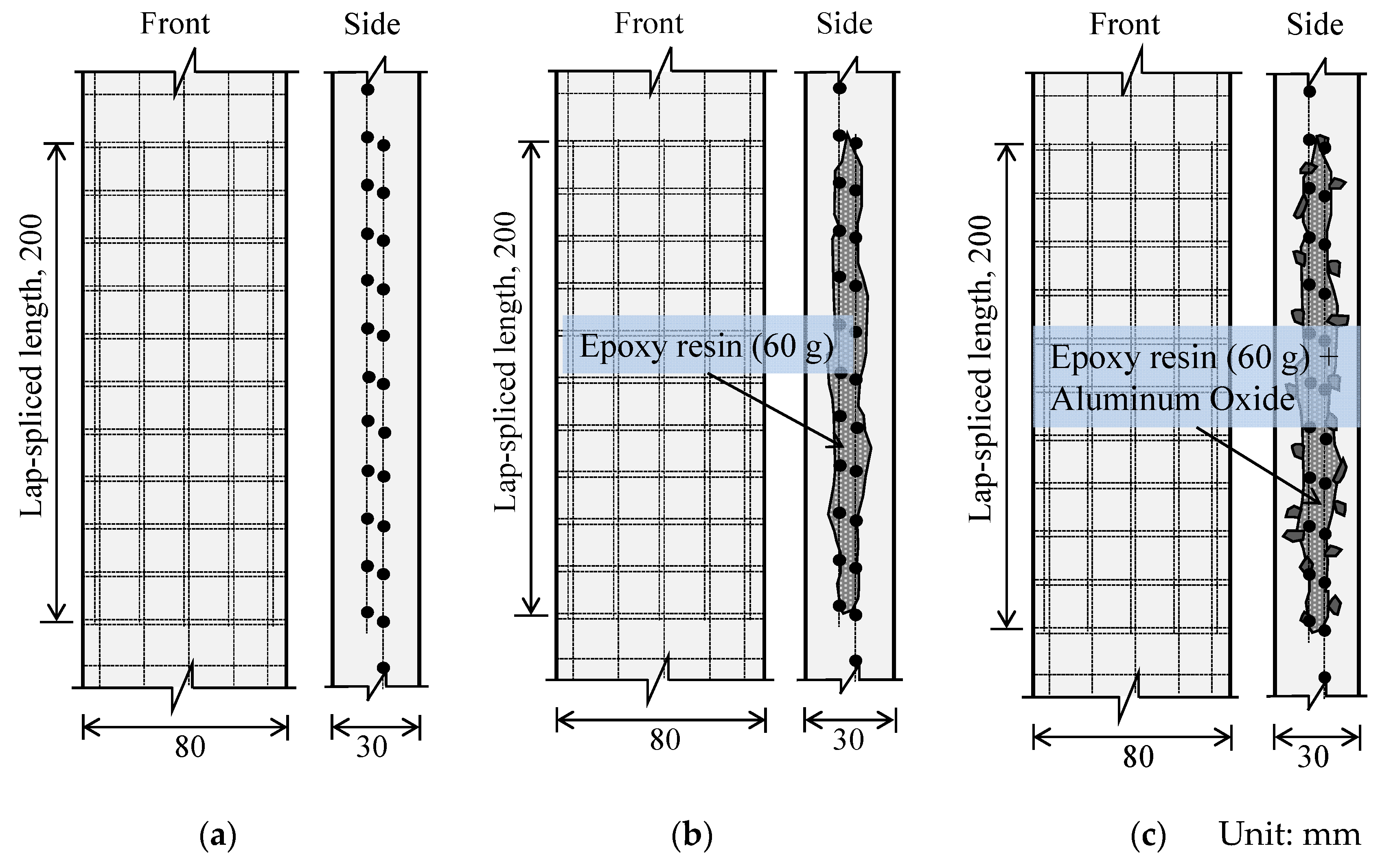

2.2. Coupon Details

2.3. Test Parameters

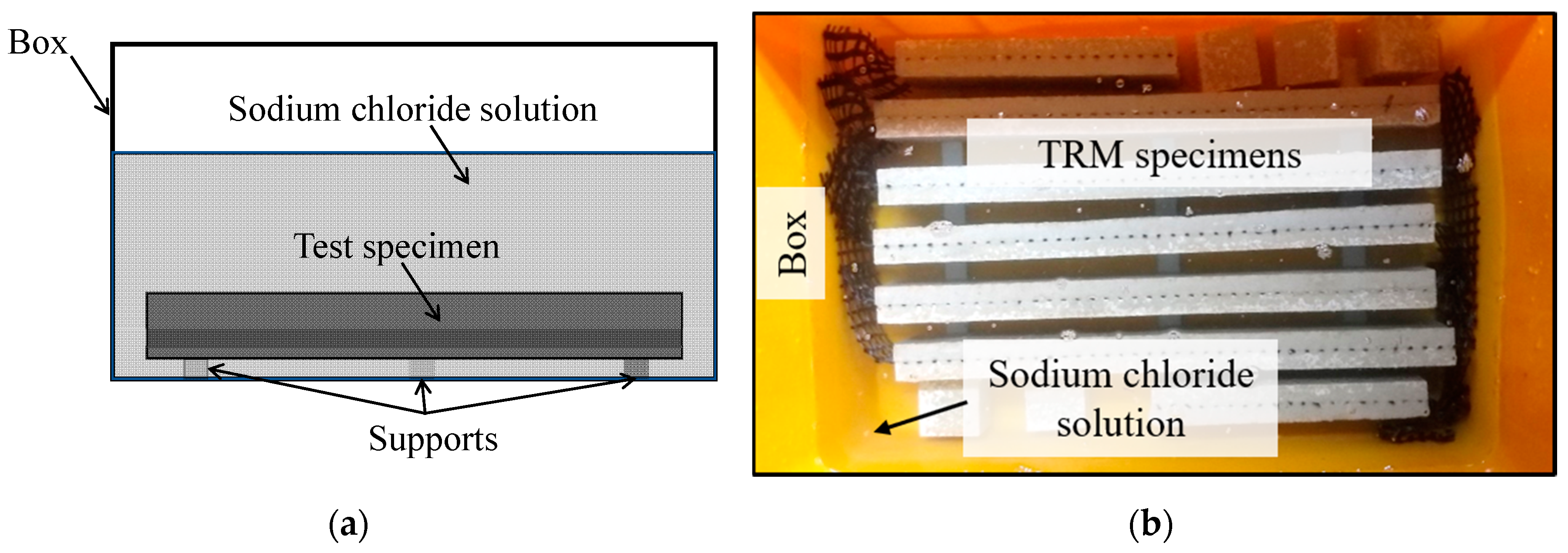

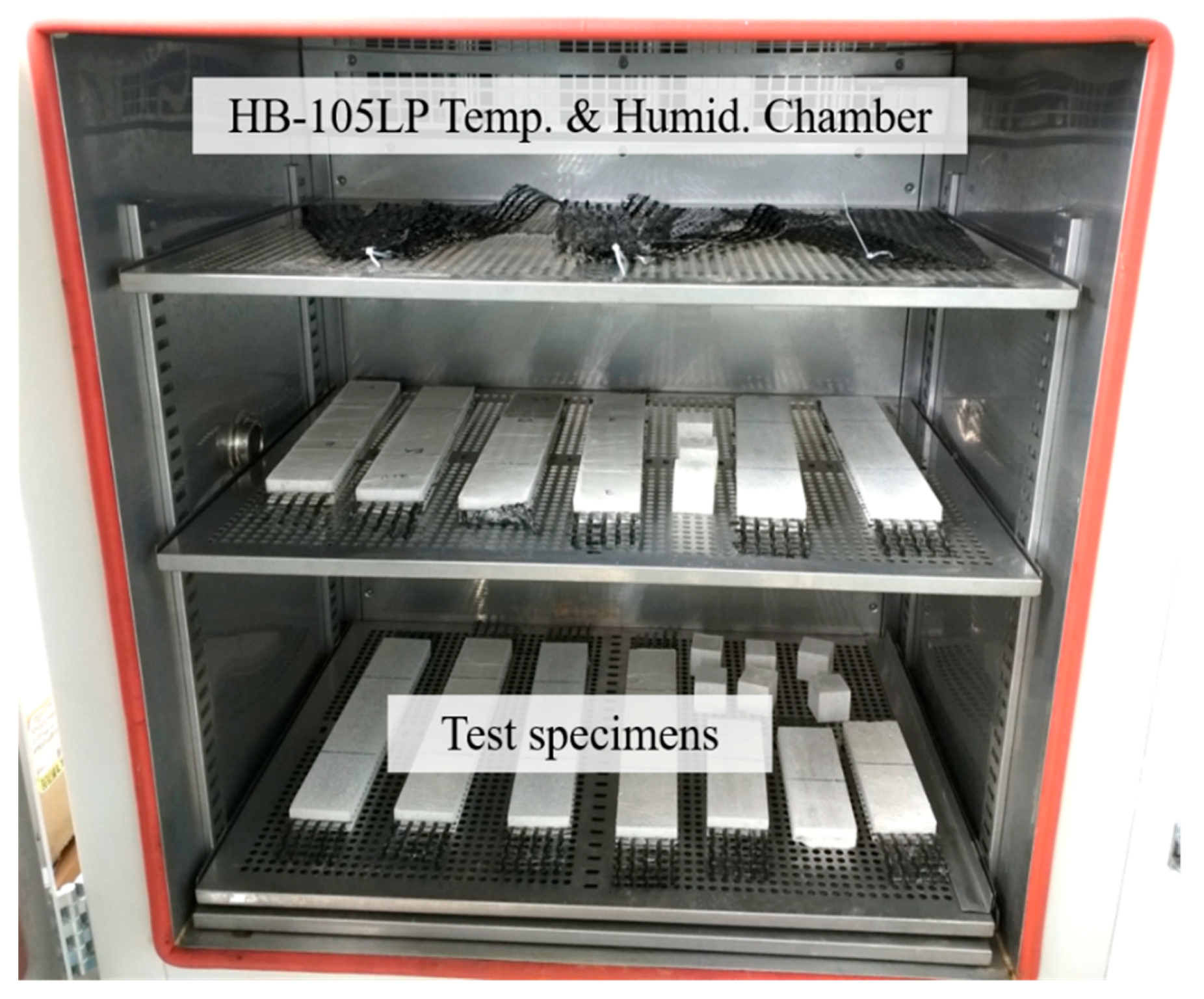

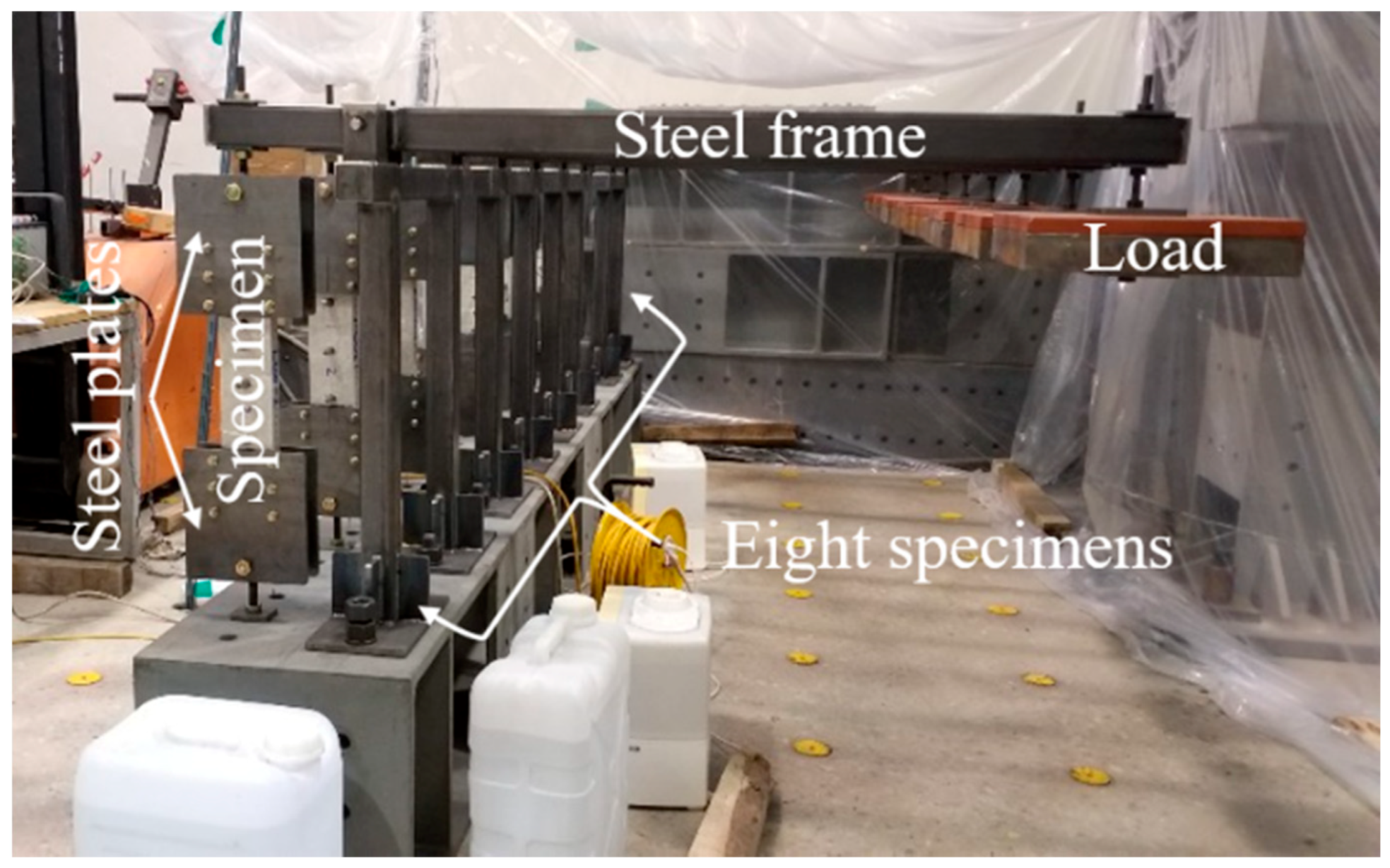

2.4. Test Environments

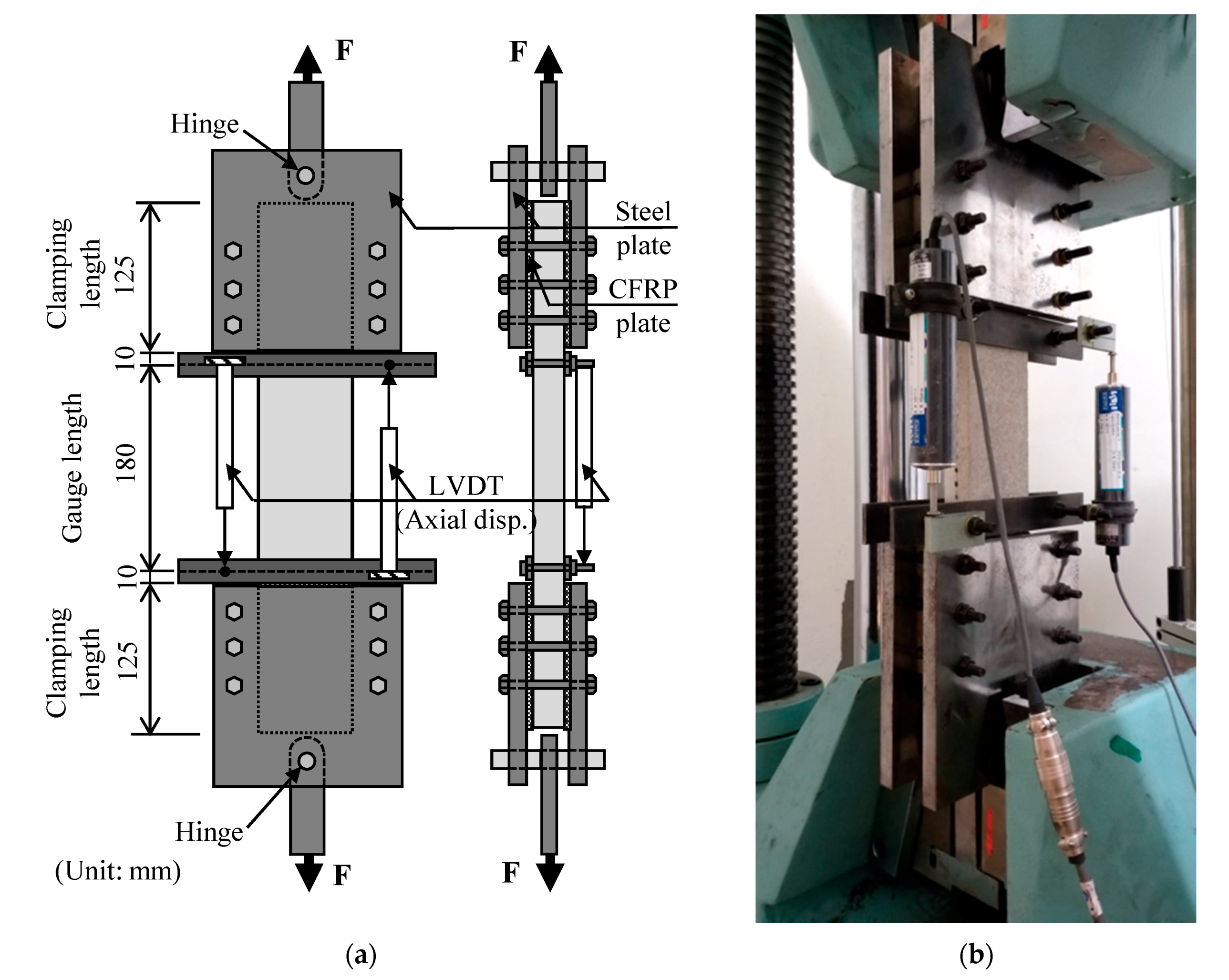

2.5. Test Setup and Instrumentation

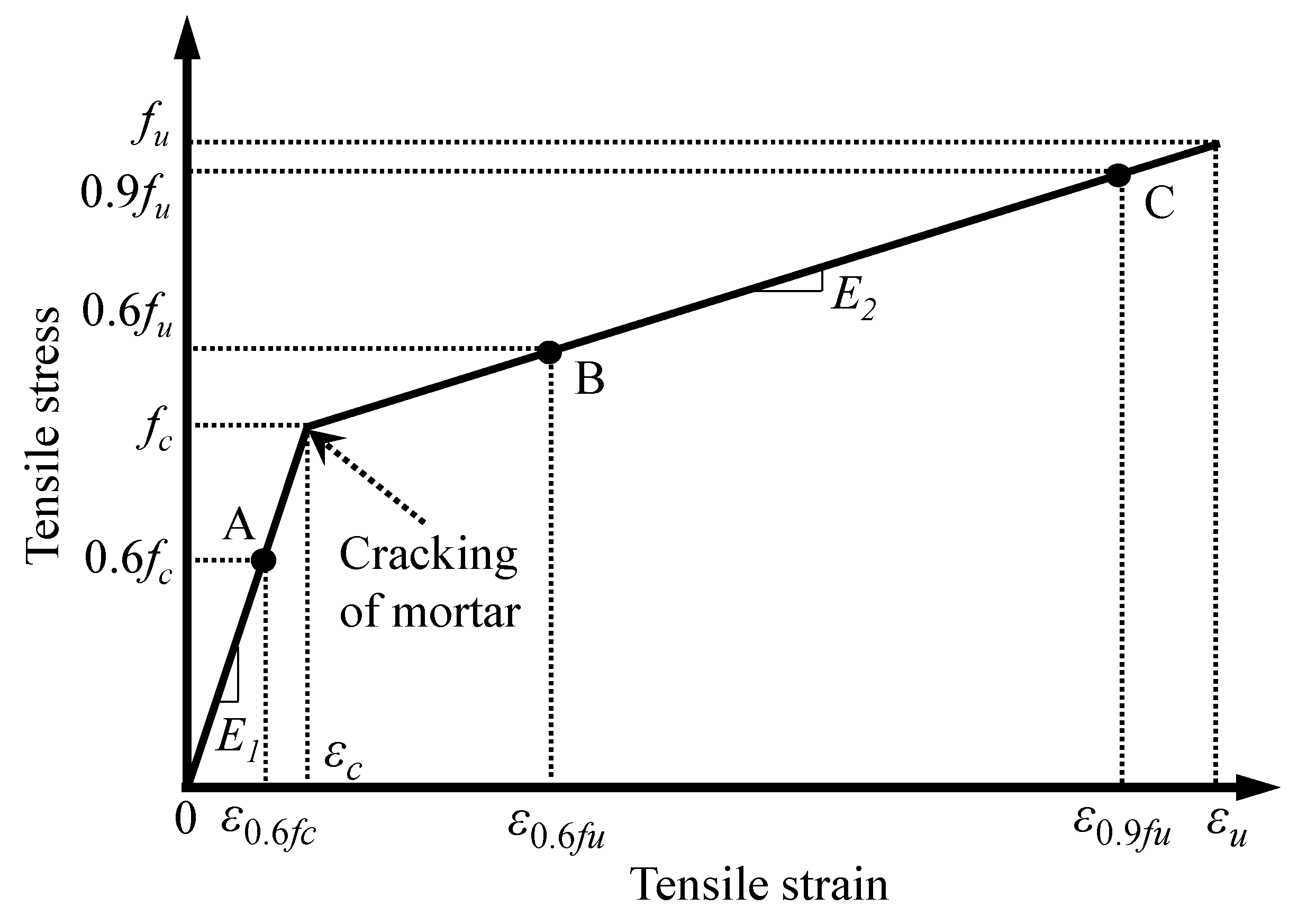

3. Test Results and Discussions

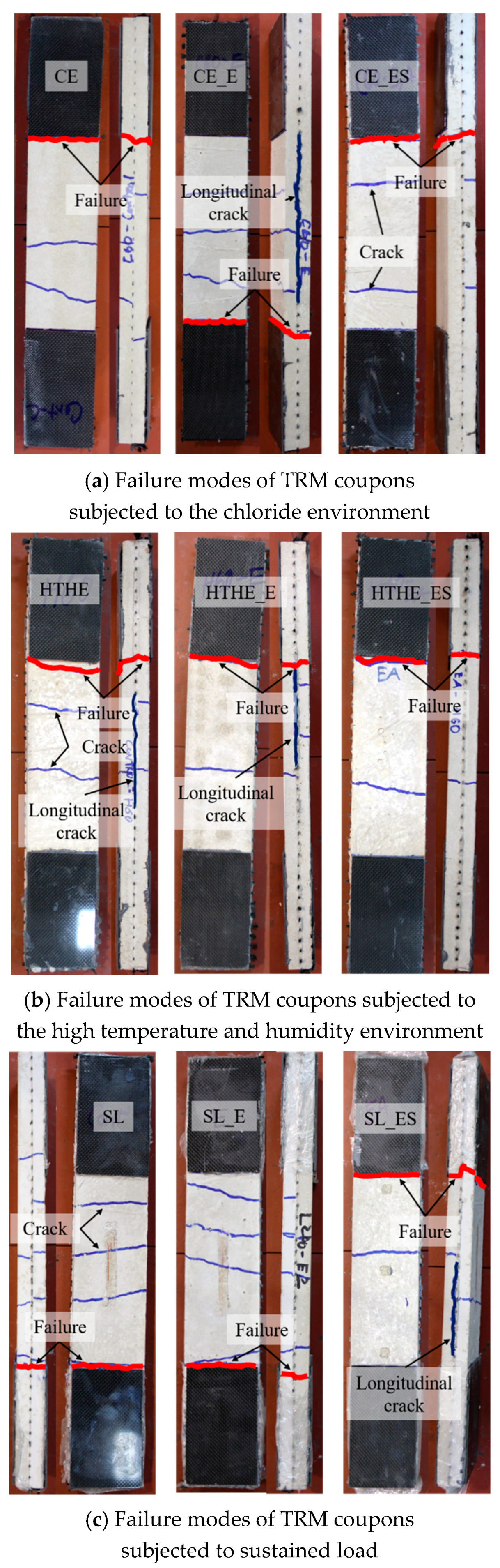

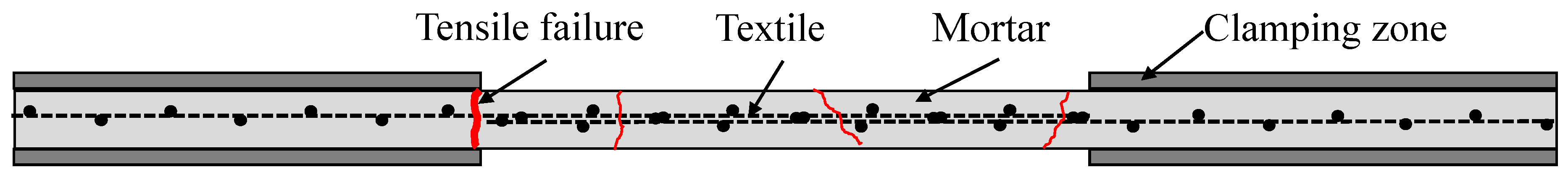

3.1. Crack Pattern and Failure Mode

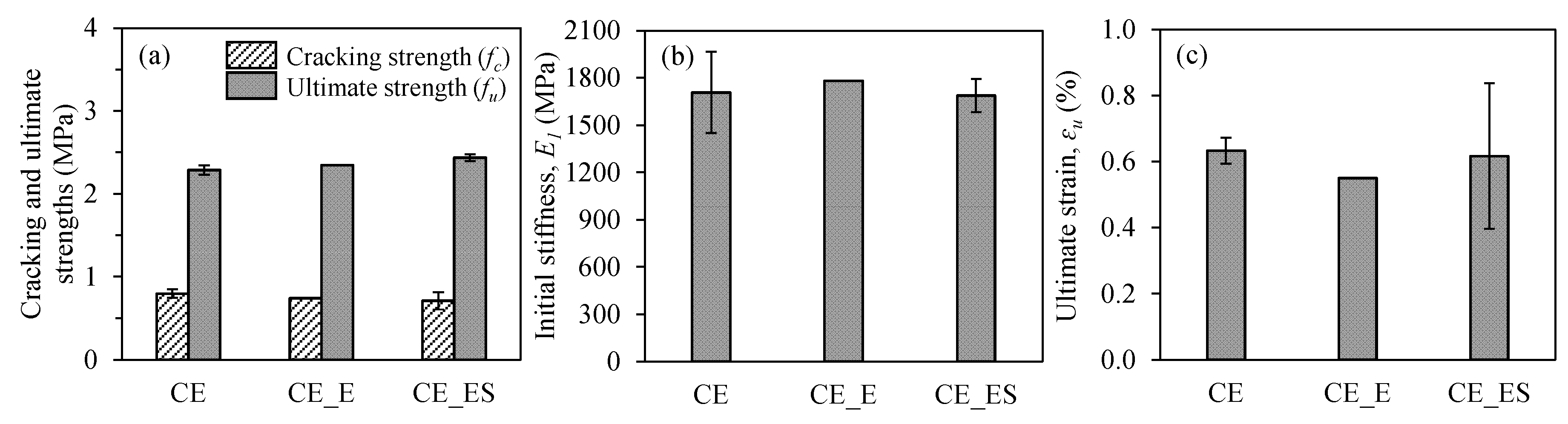

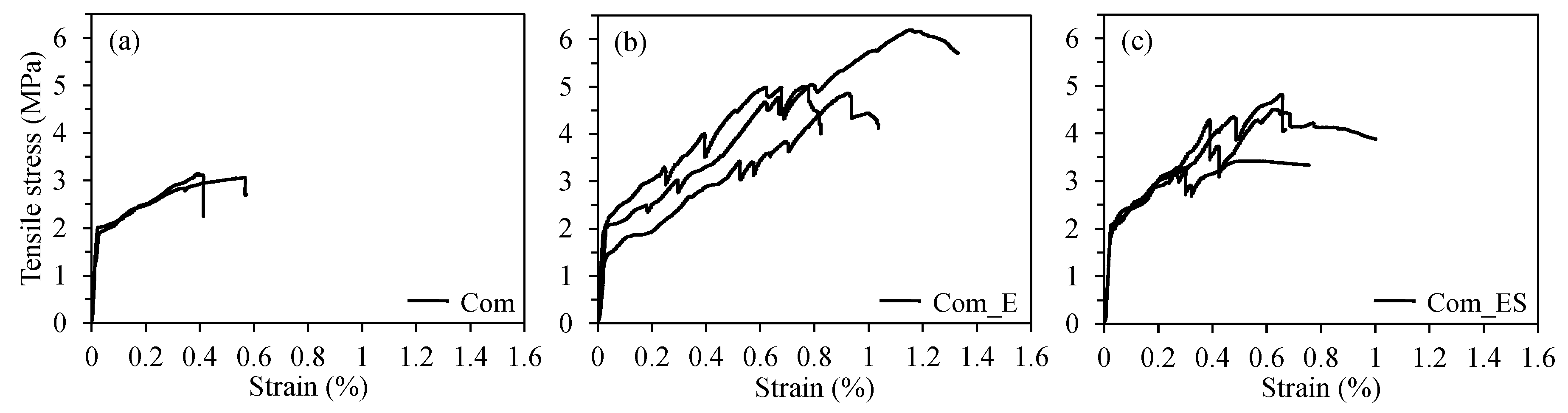

3.2. Effect of Chloride Environment

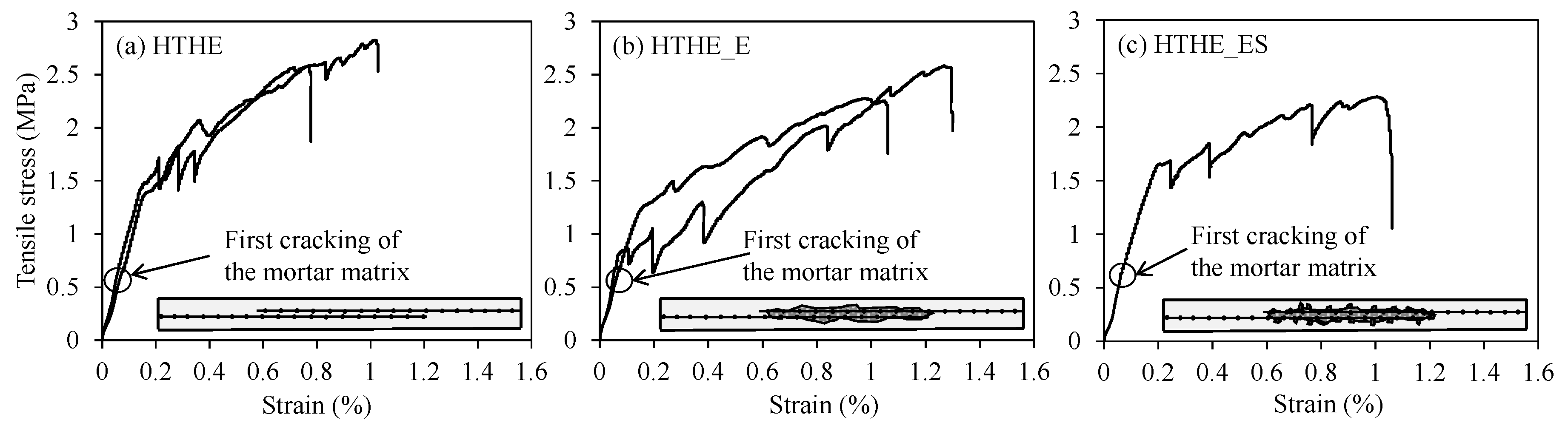

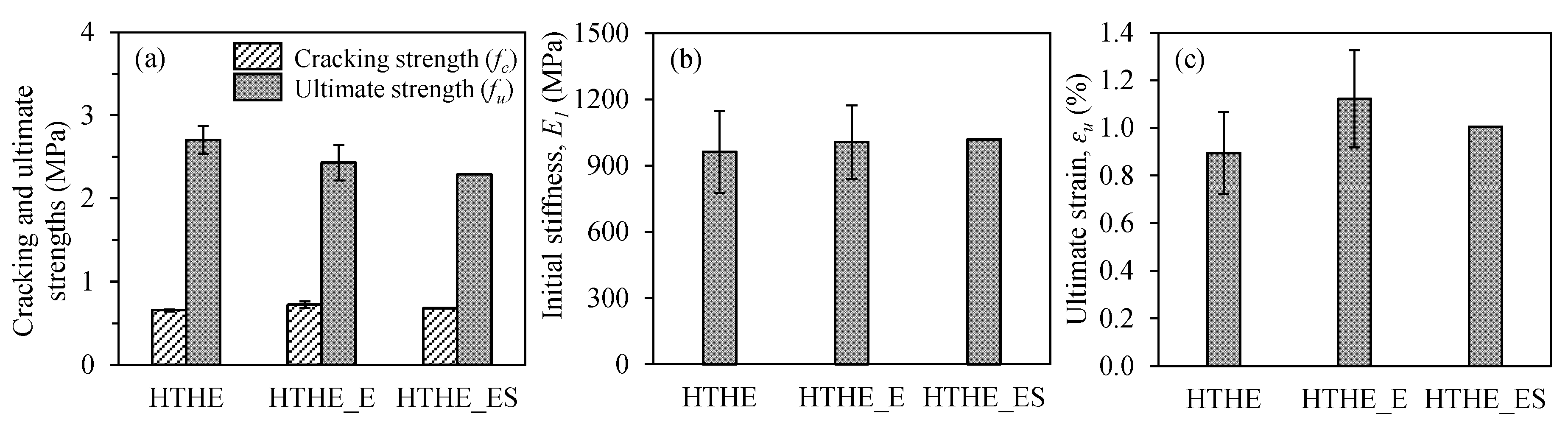

3.3. Effect of the High Temperature and Humidity Environment

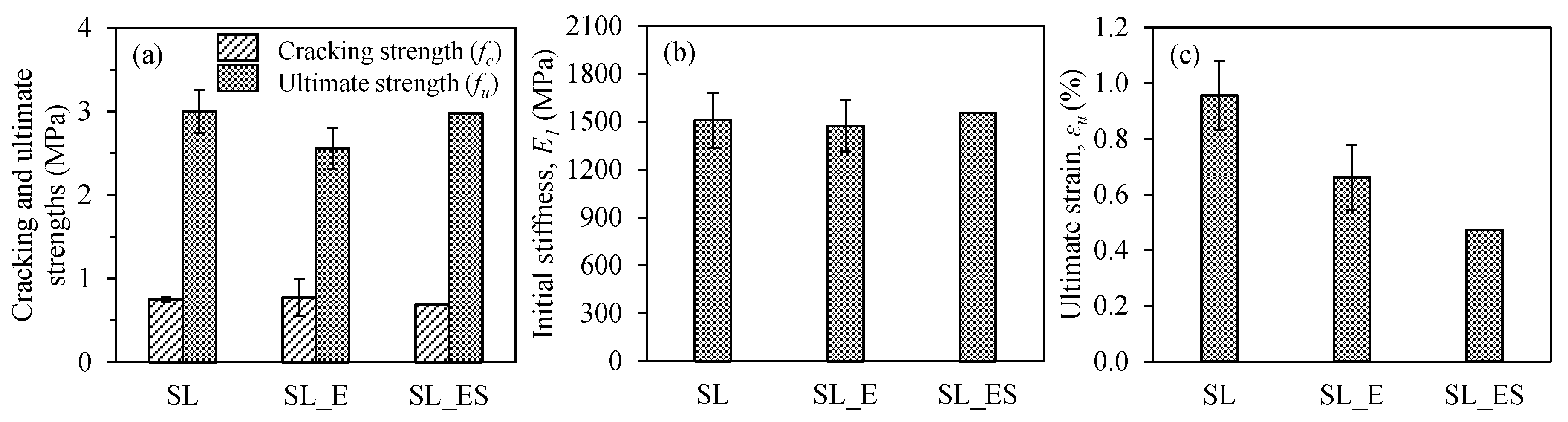

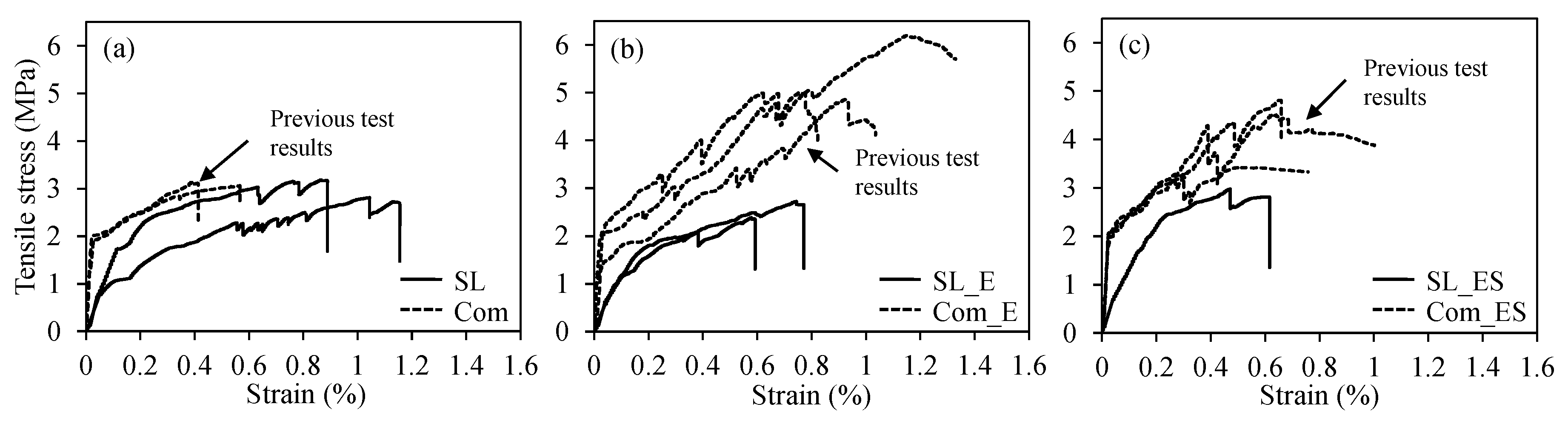

3.4. Effect of the Sustained Load

4. Conclusions

- All the TRM coupons failed near the transition region and showed the same failure mode;

- The tensile strength of TRM coupons under harsh conditions significantly decreased;

- Harsh conditions significantly decreased the improvement in tensile behavior by means of surface treatment.

Author Contributions

Funding

Conflicts of Interest

References

- Triantafillou, T.; Papanicolaou, C.C.G. Innovative applications of textile-based composites in strengthening and seismic retrofitting as well as in the prefabrication of new structures. Adv. Mater. Res. 2013, 639, 26–41. [Google Scholar] [CrossRef]

- Triantafillou, T.C. Composites: A new possibility for the shear strengthening of concrete, masonry and wood. Compos. Sci. Technol. 1998, 58, 1285–1295. [Google Scholar] [CrossRef]

- Angelillo, M.; Babilio, E.; Cardamone, L.; Fortunato, A.; Lippiello, M. Some remarks on the retrofitting of masonry structures with composite materials. Compos. Part B Eng. 2014, 61, 11–16. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Kashani, A.T. Experimental study on effect of EBR and EBROG methods on debonding of FRP sheets used for shear strengthening of RC beams. Compos. Part B Eng. 2013, 45, 1704–1713. [Google Scholar] [CrossRef]

- GangaRao, H. Infrastructure Applications of Fiber-Reinforced Polymer Composites. In Applied Plastics Engineering Handbook; William Andrew Publishing: Norwich, NY, USA, 2017; pp. 675–695. [Google Scholar]

- Saleem, M.U.; Qureshi, H.J.; Amin, M.N.; Khan, K.; Khurshid, H. Cracking Behavior of RC Beams Strengthened with Different Amounts and Layouts of CFRP. Appl. Sci. 2019, 9, 1017. [Google Scholar] [CrossRef]

- D’Antino, T.; Papanicolaou, C. Comparison between different tensile test set-ups for the mechanical characterization of inorganic-matrix composites. Constr. Build. Mater. 2018, 171, 140–151. [Google Scholar] [CrossRef]

- Bournas, D.A.; Lontou, P.V.; Papanicolaou, C.G.; Triantafillou, T.C. Textile-reinforced mortar (TRM) versus FRP confinement in reinforced concrete columns. ACI Struct. J. 2007, 104, 740–748. [Google Scholar]

- De Santis, S.; De Felice, G. Tensile behaviour of mortar-based composites for externally bonded reinforcement systems. Compos. Part B Eng. 2015, 68, 401–413. [Google Scholar] [CrossRef]

- Scheerer, S.; Zobel, R.; Müller, E.; Senckpiel-Peters, T.; Schmidt, A.; Curbach, M. Flexural Strengthening of RC Structures with TRC—Experimental Observations, Design Approach and Application. Appl. Sci. Basel 2019, 9, 1322. [Google Scholar] [CrossRef]

- Bielak, J.; Adam, V.; Hegger, J.; Classen, M. Shear Capacity of Textile-Reinforced Concrete Slabs without Shear Reinforcement. Appl. Sci. 2019, 9, 1382. [Google Scholar] [CrossRef]

- Park, J.; Hong, S.; Park, S.-K. Experimental Study on Flexural Behavior of TRM-Strengthened RC Beam: Various Types of Textile-Reinforced Mortar with Non-Impregnated Textile. Appl. Sci. 2019, 9, 1981. [Google Scholar] [CrossRef]

- D’Ambrisi, A.; Focacci, F. Flexural Strengthening of RC Beams with Cement-Based Composites. J. Compos. Constr. 2011, 15, 707–720. [Google Scholar] [CrossRef]

- Schladitz, F.; Frenzel, M.; Ehlig, D.; Curbach, M. Bending load capacity of reinforced concrete slabs strengthened with textile reinforced concrete. Eng. Struct. 2012, 40, 317–326. [Google Scholar] [CrossRef]

- Koutas, L.N.; Bournas, D.A. Flexural strengthening of two-way RC slabs with textile-reinforced mortar: Experimental investigation and design equations. J. Compos. Constr. 2016, 21, 04016065. [Google Scholar] [CrossRef]

- Tetta, Z.C.; Koutas, L.N.; Bournas, D.A. Textile-reinforced mortar (TRM) versus fiber-reinforced polymers (FRP) in shear strengthening of concrete beams. Compos. Part B Eng. 2015, 77, 338–348. [Google Scholar] [CrossRef]

- Askouni, P.D.; Papanicolaou, C.C.G.; Kaffetzakis, M.I. The Effect of Elevated Temperatures on the TRM-to-Masonry Bond: Comparison of Normal Weight and Lightweight Matrices. Appl. Sci. Basel 2019, 9, 2156. [Google Scholar] [CrossRef]

- De Munck, M.; Tysmans, T.; Wastiels, J.; Kapsalis, P.; Vervloet, J.; El Kadi, M.; Remy, O. Fatigue Behaviour of Textile Reinforced Cementitious Composites and Their Application in Sandwich Elements. Appl. Sci. 2019, 9, 1293. [Google Scholar] [CrossRef]

- Rampini, M.C.; Zani, G.; Colombo, M.; Di Prisco, M. Mechanical Behaviour of TRC Composites: Experimental and Analytical Approaches. Appl. Sci. 2019, 9, 1492. [Google Scholar] [CrossRef]

- Kapsalis, P.; El Kadi, M.; Vervloet, J.; De Munck, M.; Wastiels, J.; Triantafillou, T.; Tysmans, T. Thermomechanical Behavior of Textile Reinforced Cementitious Composites Subjected to Fire. Appl. Sci. 2019, 9, 747. [Google Scholar] [CrossRef]

- Vervloet, J.; Tysmans, T.; El Kadi, M.; De Munck, M.; Kapsalis, P.; Van Itterbeeck, P.; Wastiels, J.; Van Hemelrijck, D. Validation of a Numerical Bending Model for Sandwich Beams with Textile-Reinforced Cement Faces by Means of Digital Image Correlation. Appl. Sci. 2019, 9, 1253. [Google Scholar] [CrossRef]

- Carozzi, F.G.; Bellini, A.; D’Antino, T.; De Felice, G.; Focacci, F.; Hojdys, Ł.; Laghi, L.; Lanoye, E.; Micelli, F.; Panizza, M.; et al. Experimental investigation of tensile and bond properties of Carbon-FRCM composites for strengthening masonry elements. Compos. Part B Eng. 2017, 128, 100–119. [Google Scholar] [CrossRef]

- Carozzi, F.G.; Poggi, C. Mechanical properties and debonding strength of Fabric Reinforced Cementitious Matrix (FRCM) systems for masonry strengthening. Compos. Part B Eng. 2015, 70, 215–230. [Google Scholar] [CrossRef]

- Wagner, J.; Curbach, M. Bond Fatigue of TRC with Epoxy Impregnated Carbon Textiles. Appl. Sci. 2019, 9, 1980. [Google Scholar] [CrossRef]

- Xu, S.; Krüger, M.; Reinhardt, H.-W.; Ožbolt, J. Bond Characteristics of Carbon, Alkali Resistant Glass, and Aramid Textiles in Mortar. J. Mater. Civ. Eng. 2004, 16, 356–364. [Google Scholar] [CrossRef]

- Yin, S.; Xu, S.; Li, H. Improved mechanical properties of textile reinforced concrete thin plate. J. Wuhan Univ. Technol. Sci. Ed. 2013, 28, 92–98. [Google Scholar] [CrossRef]

- Donnini, J.; Corinaldesi, V.; Nanni, A. Mechanical properties of FRCM using carbon fabrics with different coating treatments. Compos. Part B Eng. 2016, 88, 220–228. [Google Scholar] [CrossRef]

- Xu, S.; Li, H. Bond properties and experimental methods of textile reinforced concrete. J. Wuhan Univ. Technol. Sci. Ed. 2007, 22, 529–532. [Google Scholar] [CrossRef]

- Peled, A.; Zaguri, E.; Marom, G. Bonding characteristics of multifilament polymer yarns and cement matrices. Compos. Part A Appl. Sci. Manuf. 2008, 39, 930–939. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Filho, R.D.T.; Silva, F.D.A.; Mobasher, B.; Müller, S.; Mechtcherine, V. Interface characteristics of jute fiber systems in a cementitious matrix. Cem. Concr. Res. 2019, 116, 252–265. [Google Scholar] [CrossRef]

- Nobili, A.; Signorini, C. On the effect of curing time and environmental exposure on impregnated Carbon Fabric Reinforced Cementitious Matrix (CFRCM) composite with design considerations. Compos. Part B Eng. 2017, 112, 300–313. [Google Scholar] [CrossRef]

- Micelli, F.; Aiello, M.A. Residual tensile strength of dry and impregnated reinforcement fibres after exposure to alkaline environments. Compos. Part B Eng. 2019, 159, 490–501. [Google Scholar] [CrossRef]

- American Concrete Institute. Guide to Design and Construction of Externally Bonded Fabric-Reinforced Cementitious Matrix (FRCM) Systems for Repair and Strengthening Concrete and Masonry Structures; ACI 549.4R-13; American Concrete Institute: Farmington Hills, MI, USA, 2013. [Google Scholar]

- Yang, H.J.; Jin, S.H.; Ann, K.Y. Chloride Transport of High Alumina Cement Mortar Exposed to a Saline Solution. Adv. Mater. Sci. Eng. 2016, 2016, 1–8. [Google Scholar] [CrossRef]

- Korean Standard Association. Testing Method for Compressive Strength of Hydraulic Cement Mortars; KS L 5105; Korean Standards Association: Seoul, Korea, 2017. [Google Scholar]

- Donnini, J.; Chiappini, G.; Lancioni, G.; Corinaldesi, V. Tensile behaviour of glass FRCM systems with fabrics’ overlap: Experimental results and numerical modeling. Compos. Struct. 2019, 212, 398–411. [Google Scholar] [CrossRef]

- Brauer, G.; Laughlin, R.M.; Huget, E. Aluminum Oxide as a Reinforcing Agent for Zinc Oxide-Eugenol-o-Ethoxybenzoic Acid Cements. J. Dent. Res. 1968, 47, 622–628. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Sherwood, P.M.A. Coatings of Aluminum Oxide and Magnesium Oxide on Carbon Fiber Surfaces. Chem. Mater. 1994, 6, 650–657. [Google Scholar] [CrossRef]

- Truong, G.T.; Park, S.H.; Choi, K.K. Tensile Behaviors of Lap-Spliced Carbon Fiber-Textile Reinforced Mortar Composites Exposed to High Temperature. Materials 2019, 12, 1512. [Google Scholar] [CrossRef] [PubMed]

- American Society for Testing and Materials. Standard Practice for the Preparation of Substitute Ocean Water; ASTM D1141-98; ASTM International: West Conshohocken, PA, USA, 1998. [Google Scholar]

- Kim, H.S.; Truong, G.T.; Park, S.H.; Choi, K.K. Tensile Properties of Carbon Fiber-Textile Reinforced Mortar (TRM) Characterized by Different Anchorage Methods. Int. J. Concr. Struct. Mater. 2018, 12, 73. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM D3039; ASTM International: West Conshohocken, PA, USA, 2000. [Google Scholar]

- Leone, M.; Aiello, M.A.; Balsamo, A.; Carozzi, F.G.; Ceroni, F.; Corradi, M.; Gams, M.; Garbin, E.; Gattesco, N.; Krajewski, P.; et al. Glass fabric reinforced cementitious matrix: Tensile properties and bond performance on masonry substrate. Compos. Part B Eng. 2017, 127, 196–214. [Google Scholar] [CrossRef]

- Donnini, J. Durability of glass FRCM systems: Effects of different environments on mechanical properties. Compos. Part B Eng. 2019, 107047. [Google Scholar] [CrossRef]

| Test Coupons | Surface Treatment | Experimental Conditions | Number of Test Coupons |

|---|---|---|---|

| CE | Non-coating | Chloride environment (for 60 days) | 2 |

| CE_E | Epoxy | 1 | |

| CE_ES | Epoxy + sand blasting | 2 | |

| HTHE | Non-coating | High temperature and humidity environment (for 60 days) | 2 |

| HTHE_E | Epoxy | 2 | |

| HTHE_ES | Epoxy + sand blasting | 1 | |

| SL | Non-coating | Sustained load (for 60 days) | 2 |

| SL_E | Epoxy | 2 | |

| SL_ES | Epoxy + sand blasting | 1 |

| Test Coupons | Cracking Tensile Stress | Cracking Tensile Strength | First Stiffness | Ultimate Tensile Strength | Ultimate Tensile Strain | Second Stiffness | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| fc (MPa) | Aver. fc (MPa) | εc (%) | Aver. εc (%) | E1 (MPa) | Aver. E1 (MPa) | fu (MPa) | Aver. fu (MPa) | εu (%) | Aver. εu (%) | E2 (MPa) | Aver. E2 (MPa) | |

| CE1 | 0.76 | 0.80 | 0.050 | 0.047 | 1525.00 | 1707.31 | 2.25 | 2.29 | 0.661 | 0.634 | 189.84 | 199.30 |

| CE2 | 0.83 | 0.044 | 1889.61 | 2.33 | 0.606 | 208.75 | ||||||

| CE_E | 0.74 | - | 0.042 | - | 1780.00 | - | 2.35 | - | 0.550 | - | 190.91 | - |

| CE_ES1 | 0.64 | 0.71 | 0.040 | 0.042 | 1613.67 | 1688.09 | 2.47 | 2.44 | 0.772 | 0.617 | 247.22 | 383.11 |

| CE_ES2 | 0.78 | 0.044 | 1762.50 | 2.41 | 0.461 | 519.00 | ||||||

| HTHE1 | 0.66 | 0.66 | 0.061 | 0.069 | 1093.13 | 961.74 | 2.83 | 2.70 | 1.017 | 0.894 | 132.39 | 170.30 |

| HTHE2 | 0.65 | 0.078 | 830.36 | 2.58 | 0.772 | 208.21 | ||||||

| HTHE_E1 | 0.69 | 0.72 | 0.078 | 0.073 | 889.29 | 1007.15 | 2.28 | 2.43 | 0.978 | 2.245 | 128.13 | 142.44 |

| HTHE_E2 | 0.75 | 0.067 | 1125.00 | 2.58 | 1.267 | 156.74 | ||||||

| HTHE_ES | 0.68 | - | 0.067 | - | 1018.75 | - | 2.29 | - | 1.01 | - | 106.68 | - |

| SL1 | 0.77 | 0.75 | 0.056 | 0.050 | 1387.50 | 1509.38 | 2.82 | 3.00 | 1.044 | 0.956 | 148.53 | 169.05 |

| SL2 | 0.73 | 0.044 | 1631.25 | 3.18 | 0.867 | 189.56 | ||||||

| SL_E1 | 0.93 | 0.78 | 0.068 | 0.054 | 1359.76 | 1472.74 | 2.39 | 2.56 | 0.579 | 0.662 | 201.69 | 200.68 |

| SL_E2 | 0.62 | 0.039 | 1585.71 | 2.73 | 0.744 | 199.66 | ||||||

| SL_ES | 0.69 | - | 0.044 | - | 1556.25 | - | 2.98 | - | 0.472 | - | 458.57 | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tran, H.V.; Truong, G.T.; Choi, K.-K. Effect of Harsh Conditions on the Tensile Behaviour of Lap-Spliced Carbon Fiber Textile-Reinforced Mortar (TRM) with Different Surface Treatment Methods. Appl. Sci. 2019, 9, 3087. https://doi.org/10.3390/app9153087

Tran HV, Truong GT, Choi K-K. Effect of Harsh Conditions on the Tensile Behaviour of Lap-Spliced Carbon Fiber Textile-Reinforced Mortar (TRM) with Different Surface Treatment Methods. Applied Sciences. 2019; 9(15):3087. https://doi.org/10.3390/app9153087

Chicago/Turabian StyleTran, Hai Van, Gia Toai Truong, and Kyoung-Kyu Choi. 2019. "Effect of Harsh Conditions on the Tensile Behaviour of Lap-Spliced Carbon Fiber Textile-Reinforced Mortar (TRM) with Different Surface Treatment Methods" Applied Sciences 9, no. 15: 3087. https://doi.org/10.3390/app9153087

APA StyleTran, H. V., Truong, G. T., & Choi, K.-K. (2019). Effect of Harsh Conditions on the Tensile Behaviour of Lap-Spliced Carbon Fiber Textile-Reinforced Mortar (TRM) with Different Surface Treatment Methods. Applied Sciences, 9(15), 3087. https://doi.org/10.3390/app9153087