Accumulative Roll Bonding—A Review

Abstract

:1. Introduction

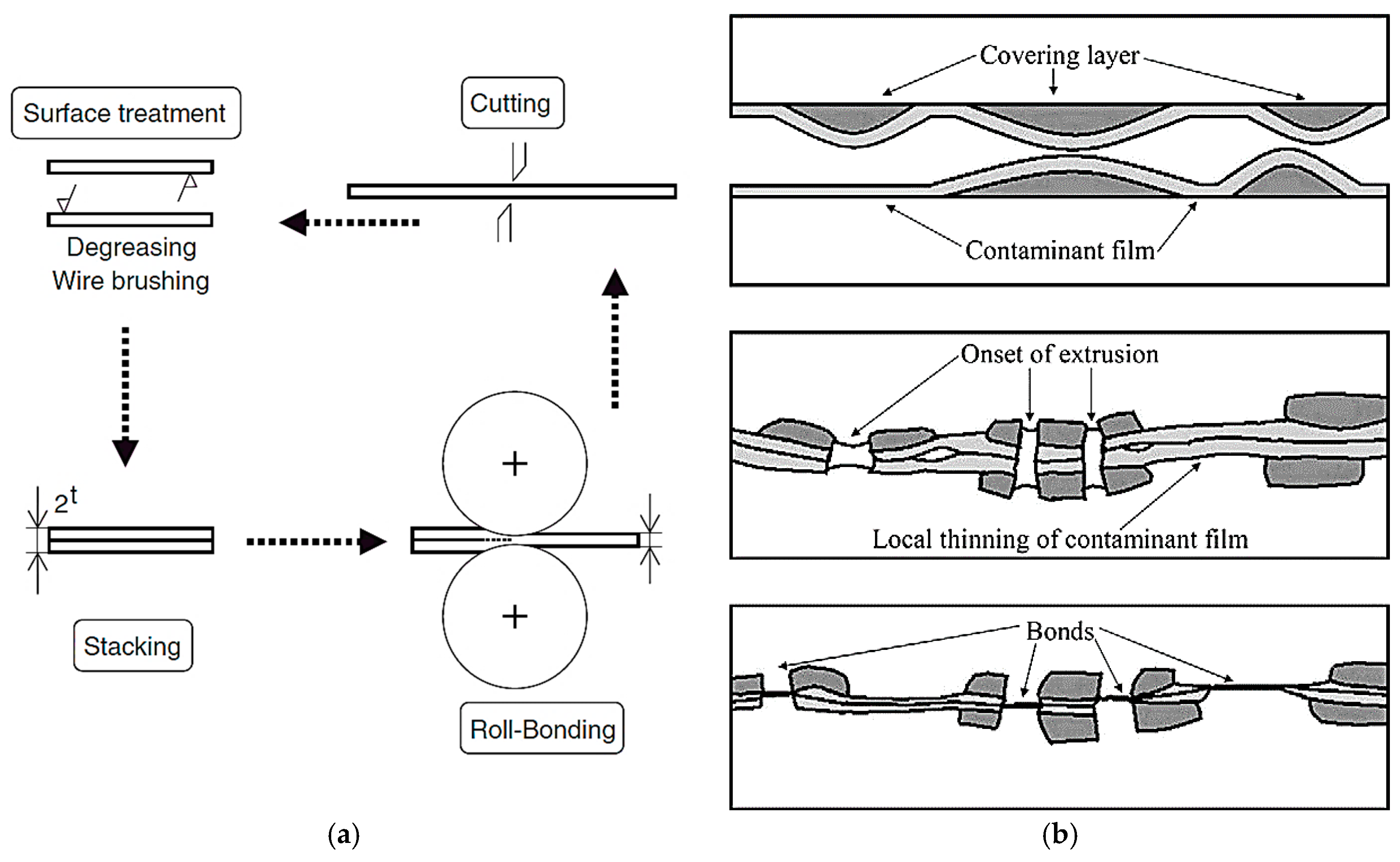

2. Basics and Mechanisms

- Film theory;

- Energy barrier;

- Recrystallization

- Diffusion bonding.

3. Parameters

3.1. Materials Parameters

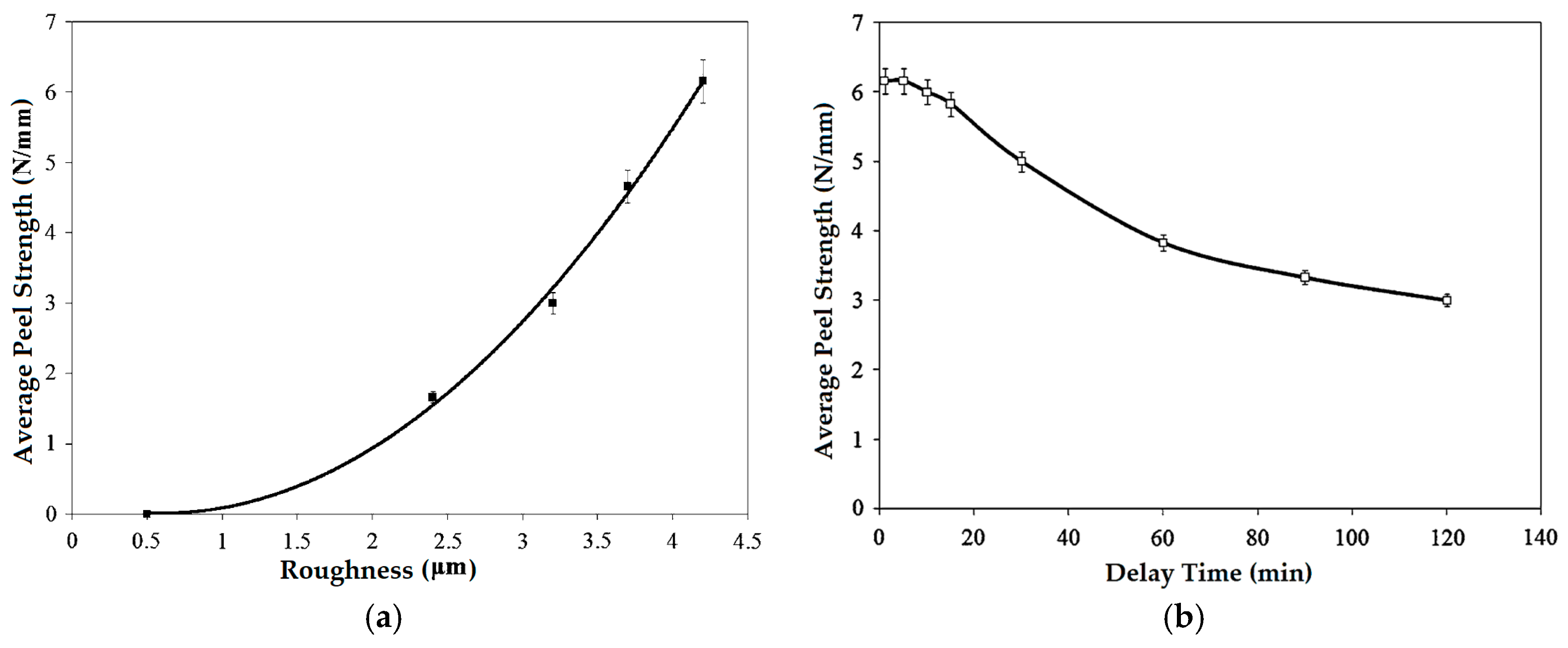

3.2. Surface Parameters

3.3. Rolling Parameters

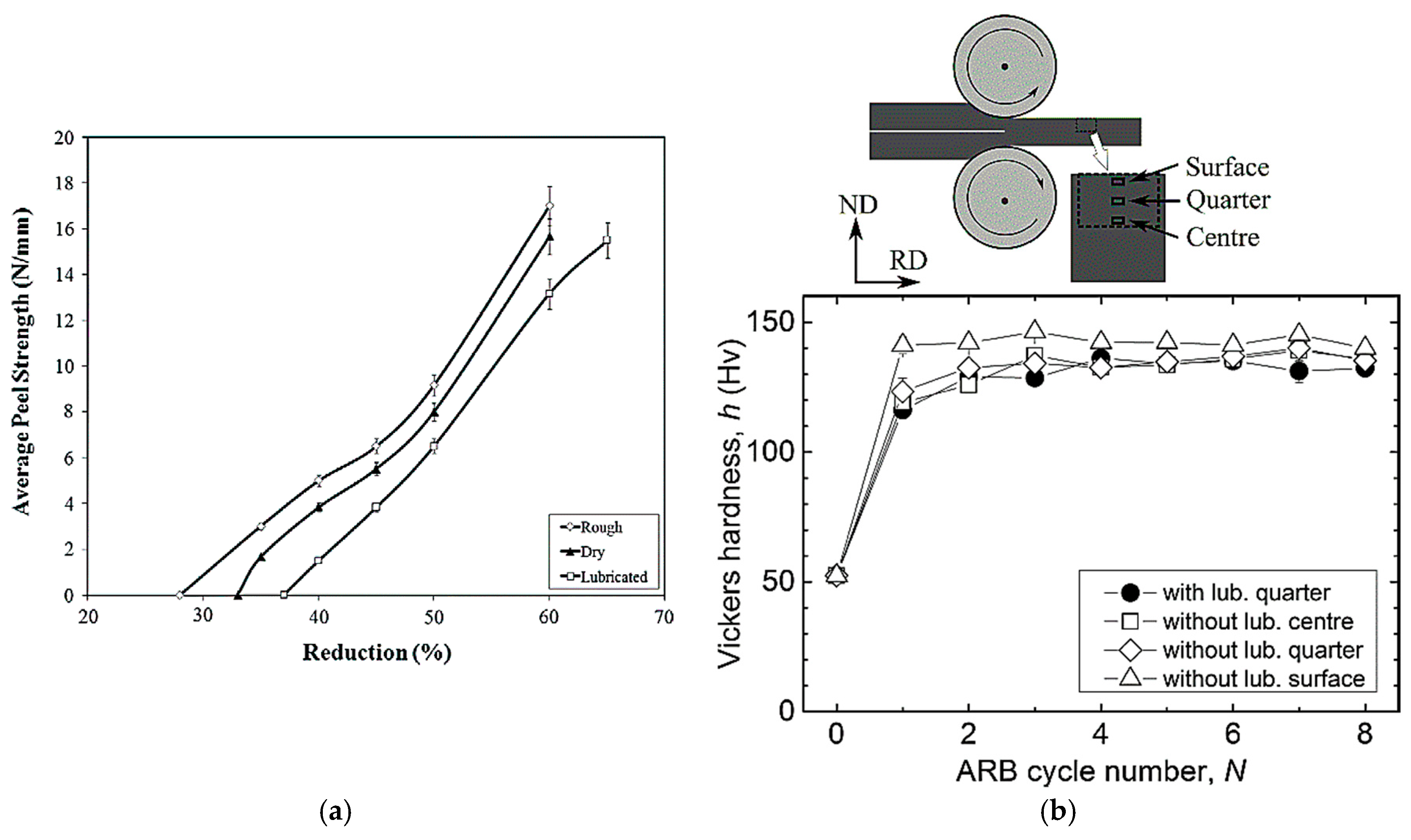

3.3.1. Rolling Reduction

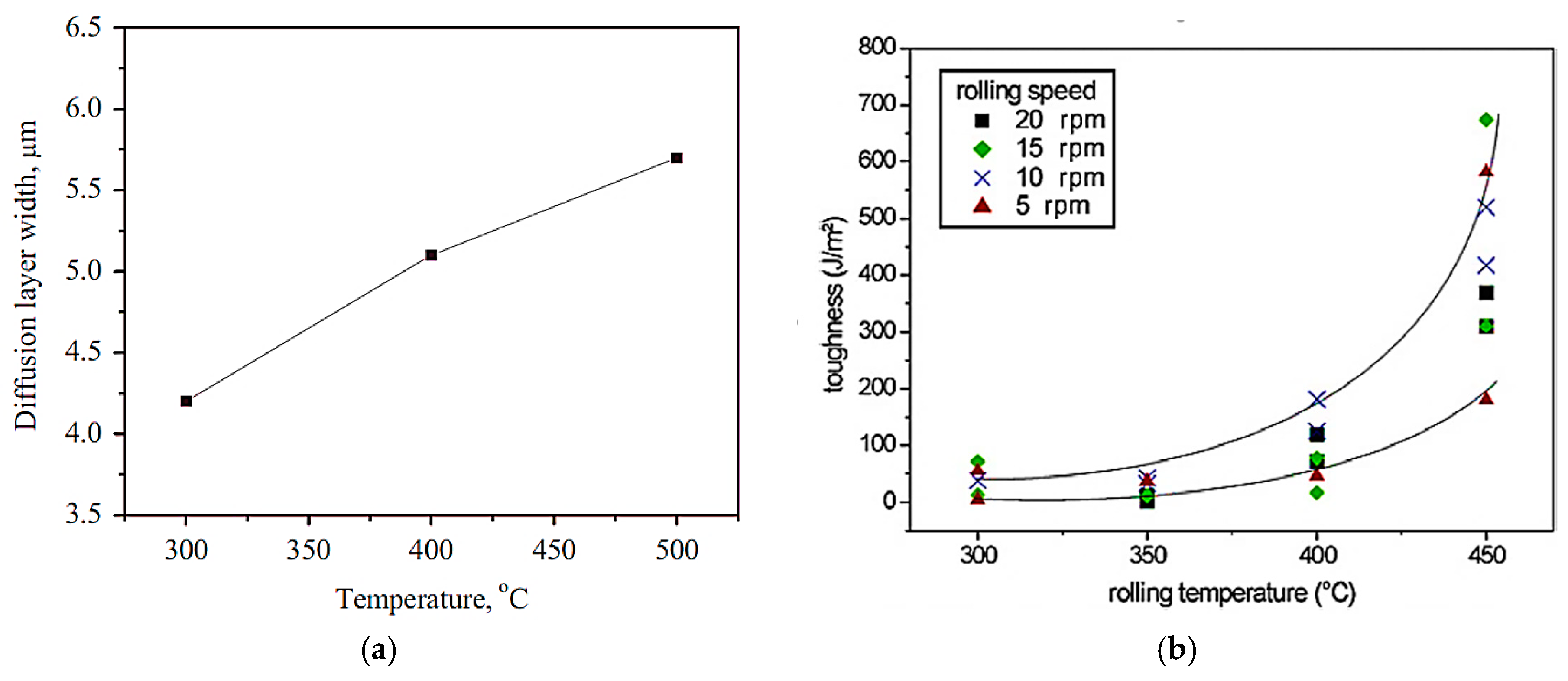

3.3.2. Rolling Temperature

3.3.3. Rolling Speed

3.3.4. Rolling Friction

3.3.5. Number of Layers

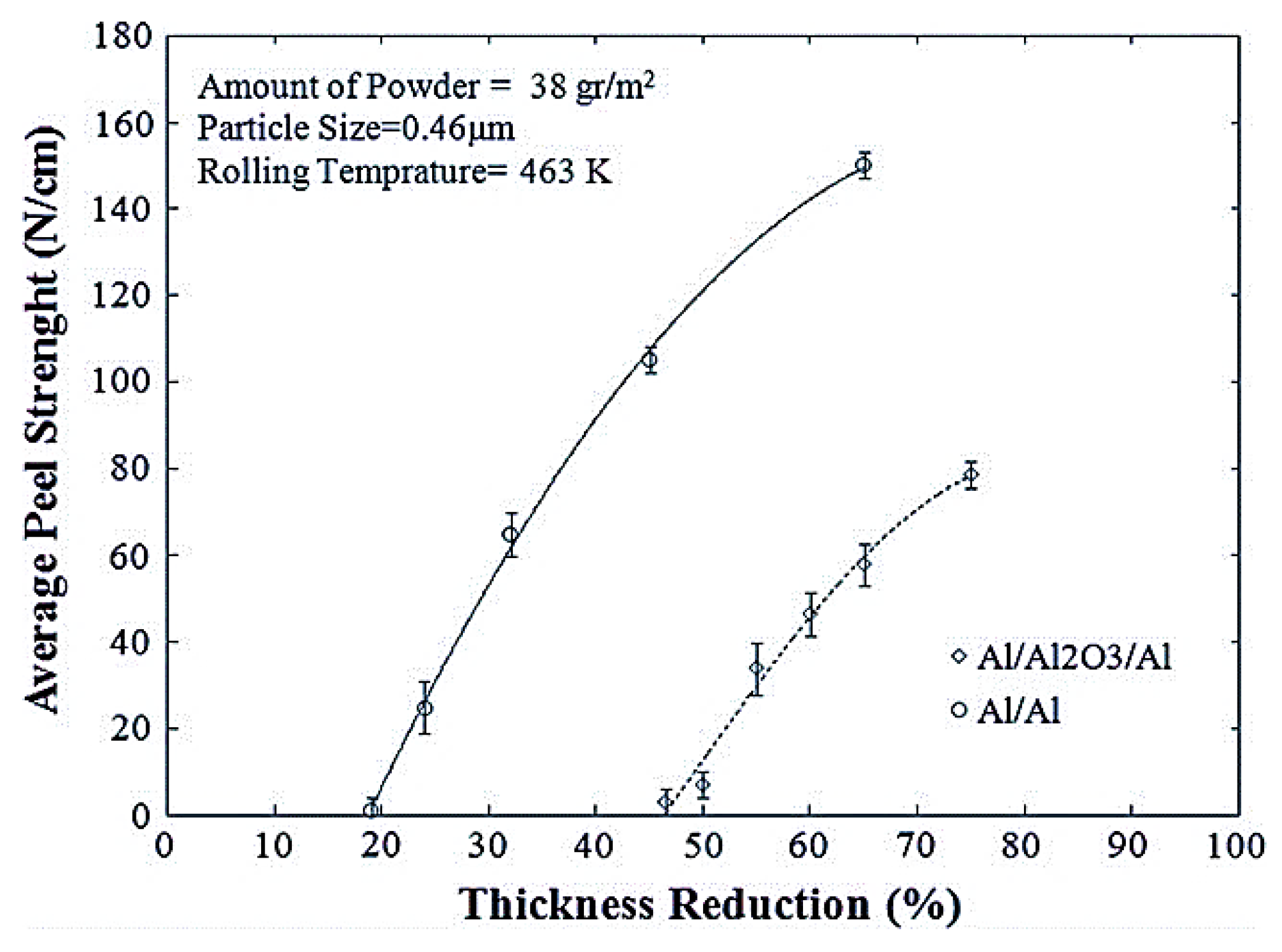

3.3.6. Reinforcement Particles

3.3.7. Post-Heat Treatment

4. Properties

4.1. Strength and Ductility

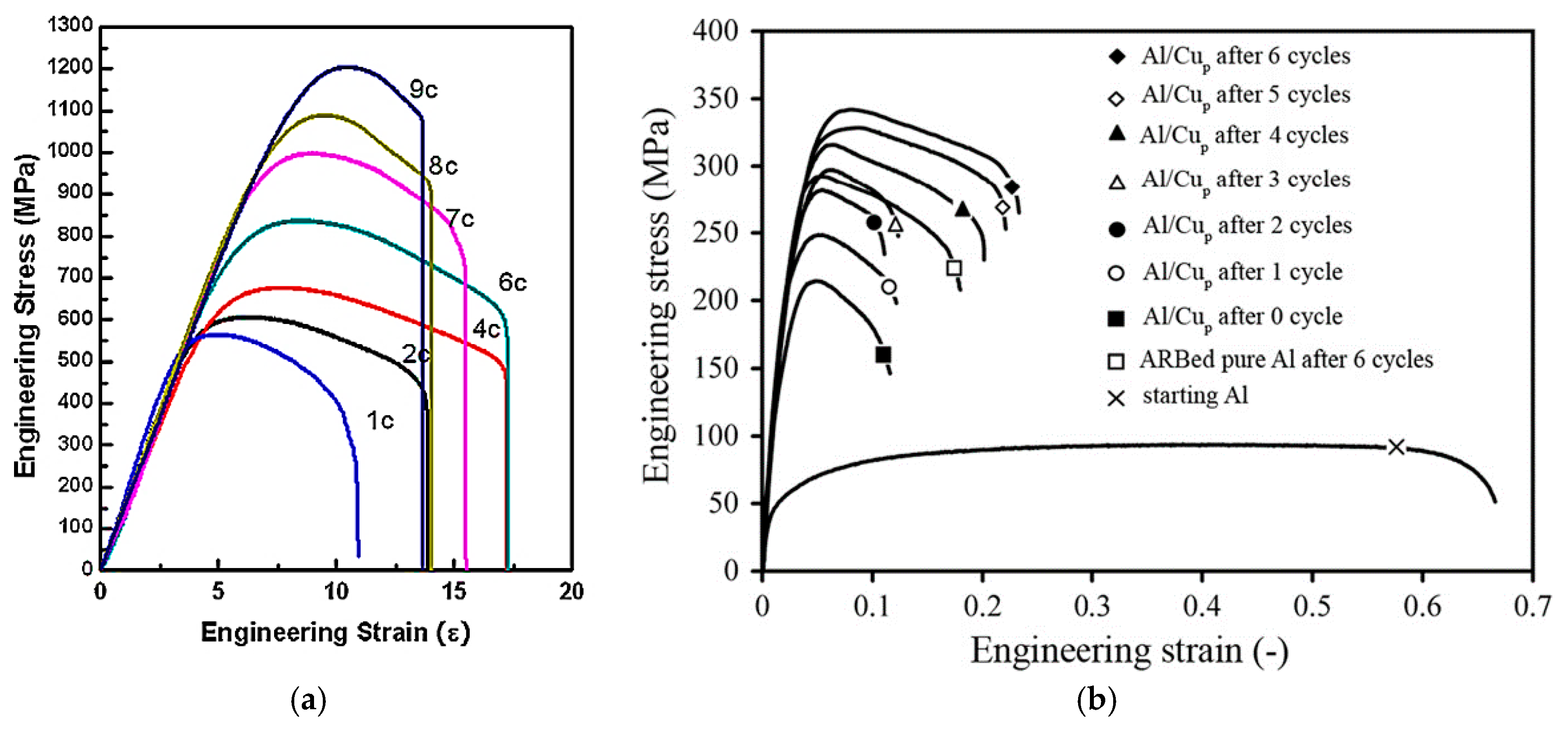

4.1.1. Sheets with Similar Materials

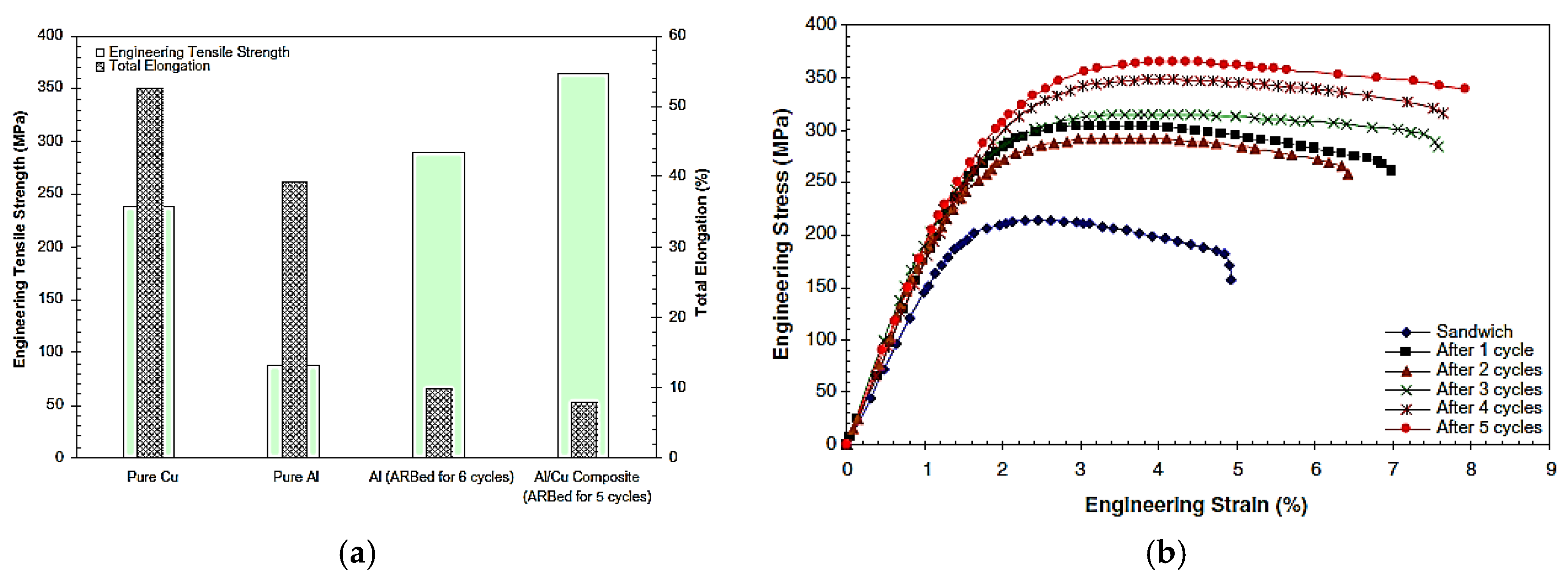

4.1.2. Sheets with Dissimilar Materials

4.1.3. Sheets with Reinforcements

- Improved bonding quality at the matrix/particle interfaces. Regardless of volume fraction, size, shape and the spatial distribution, the mechanical property greatly depends upon how well externally applied load is transferred to reinforcing materials, i.e., stronger interfacial adhesion enhances load transfer capacity leading to improved mechanical performance [105]. Better interfacial adhesion may be obtained through increasing ARB cycles [53]. Also, porosity may have detrimental effects on bonding quality between the reinforcing agents and the host matrix where the interfacial adhesion may be lowered by porosity causing interfacial debonding. When pores are located at the particle-matrix interface, particles are debonded from the matrix even under low stress [106]. Last but not least, porosity tends to reduce effective cross-section area and hence adversely affect mechanical strength [107].

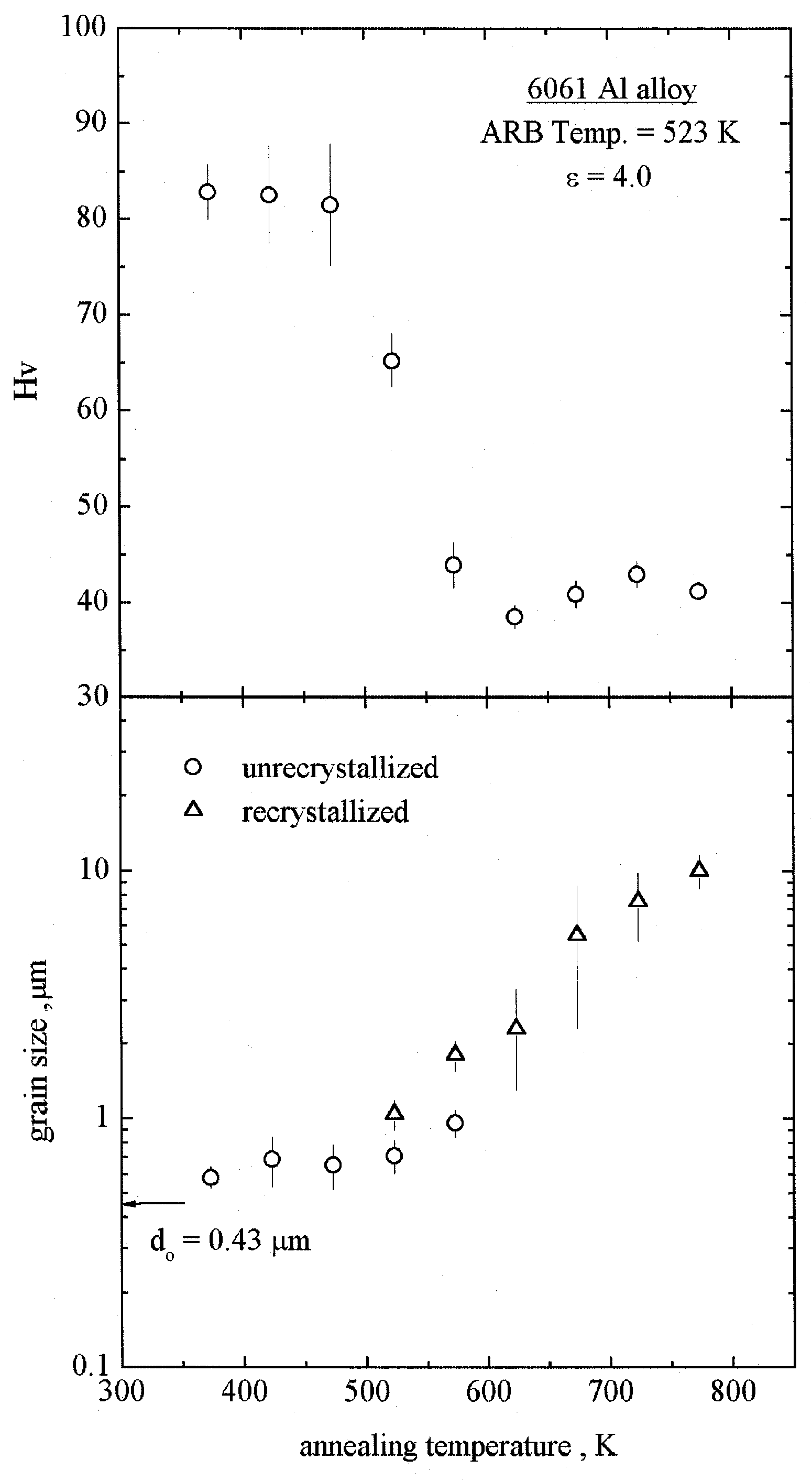

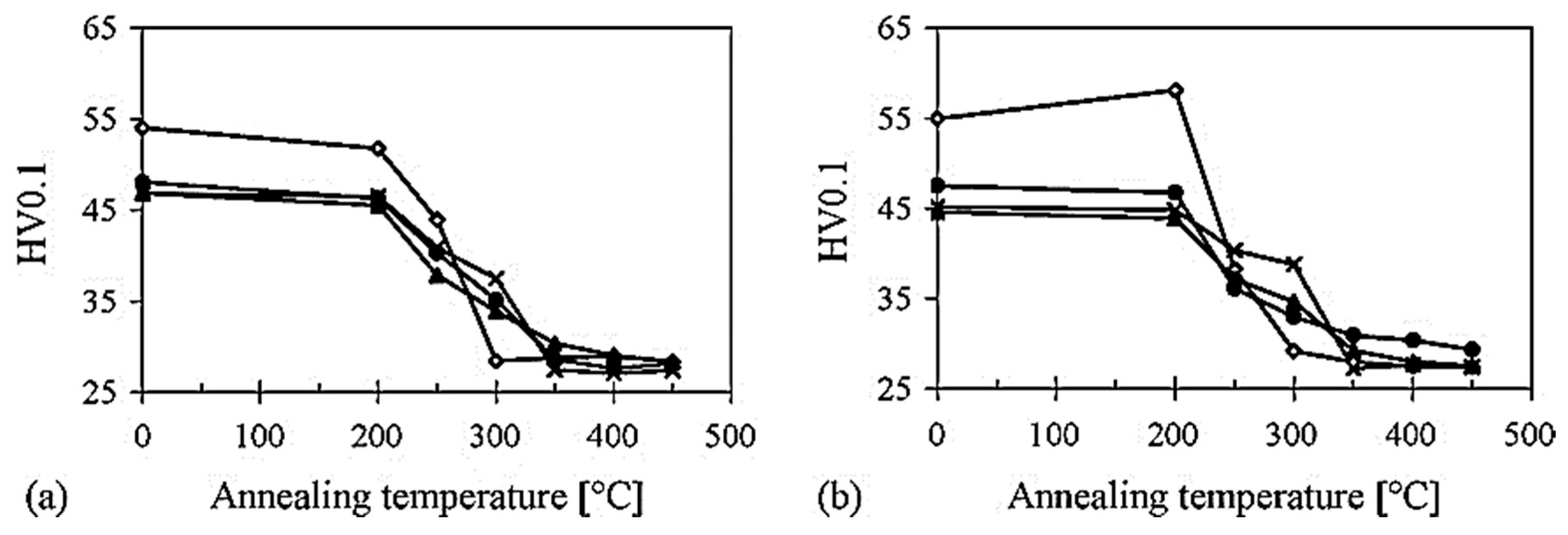

4.2. Thermal Stability

4.3. Superplasticity

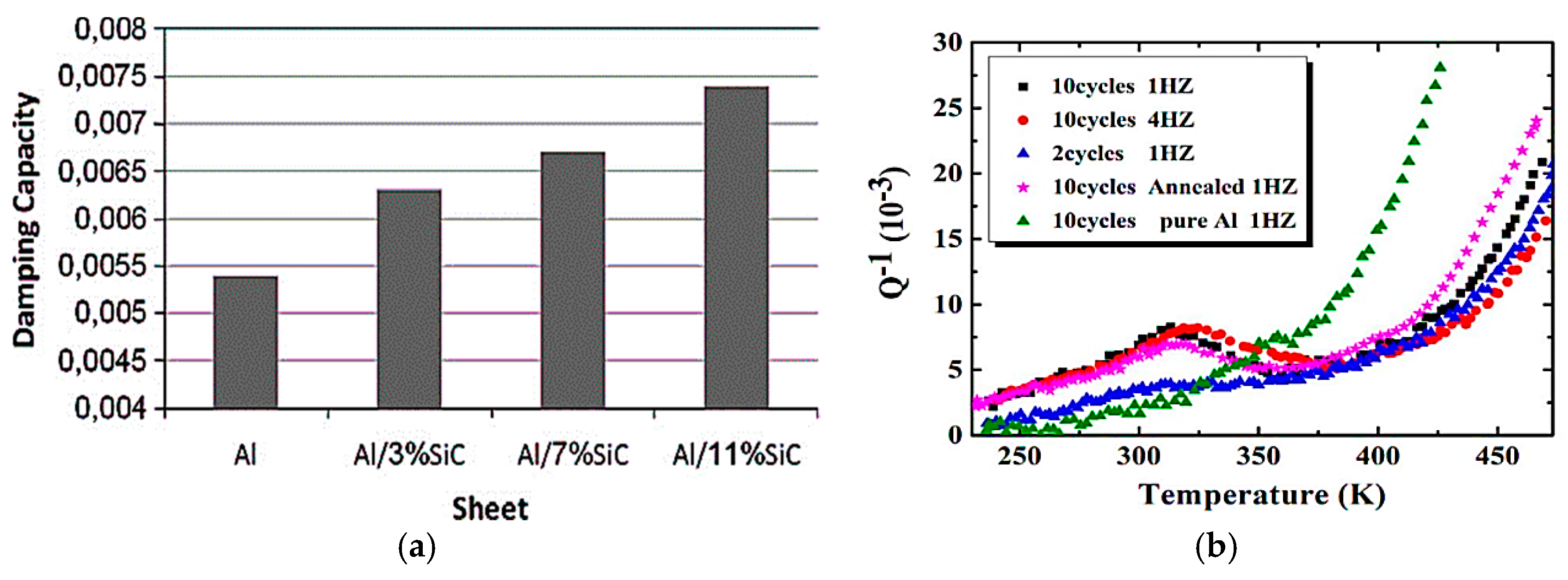

4.4. Damping

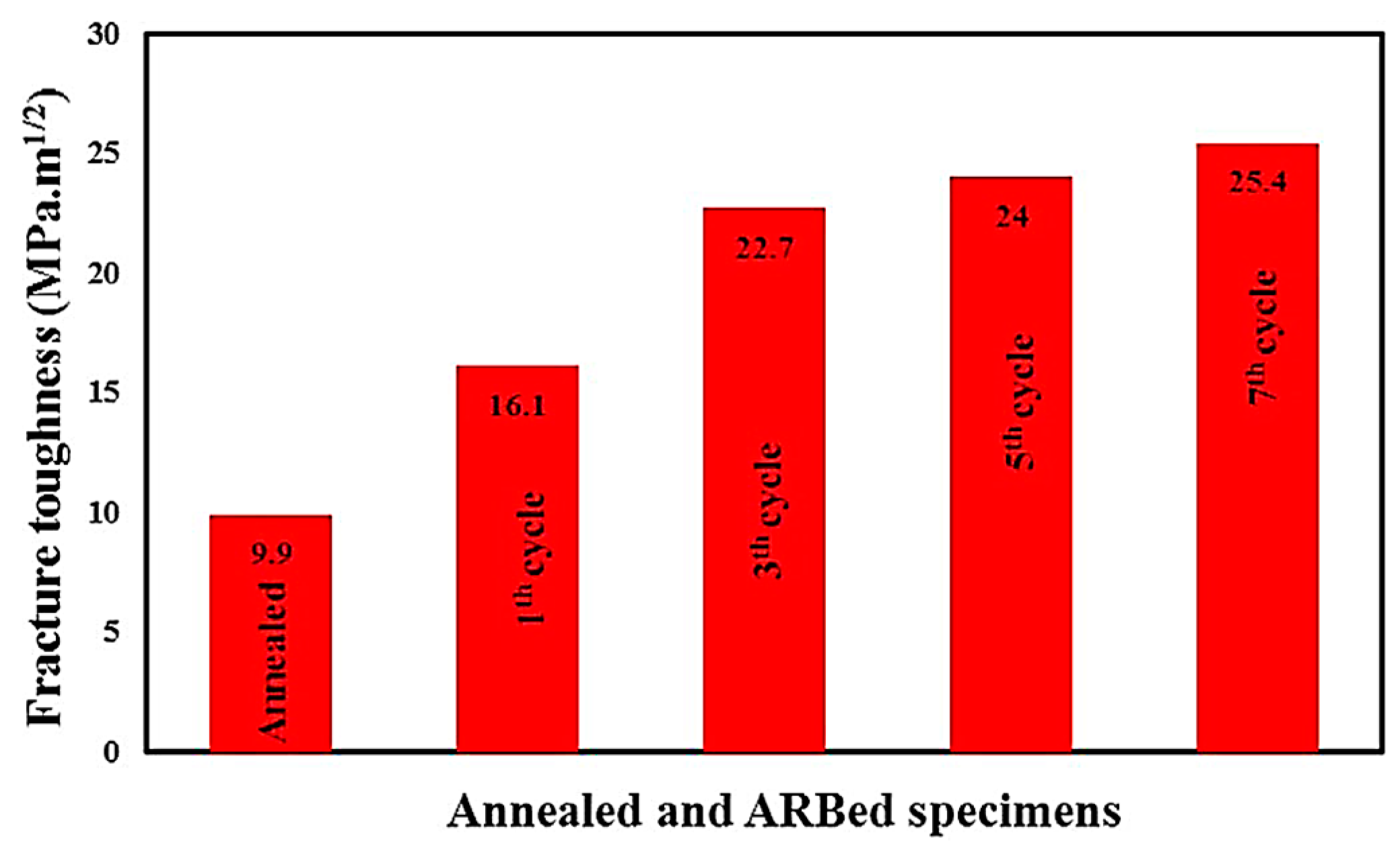

4.5. Fracture Toughness

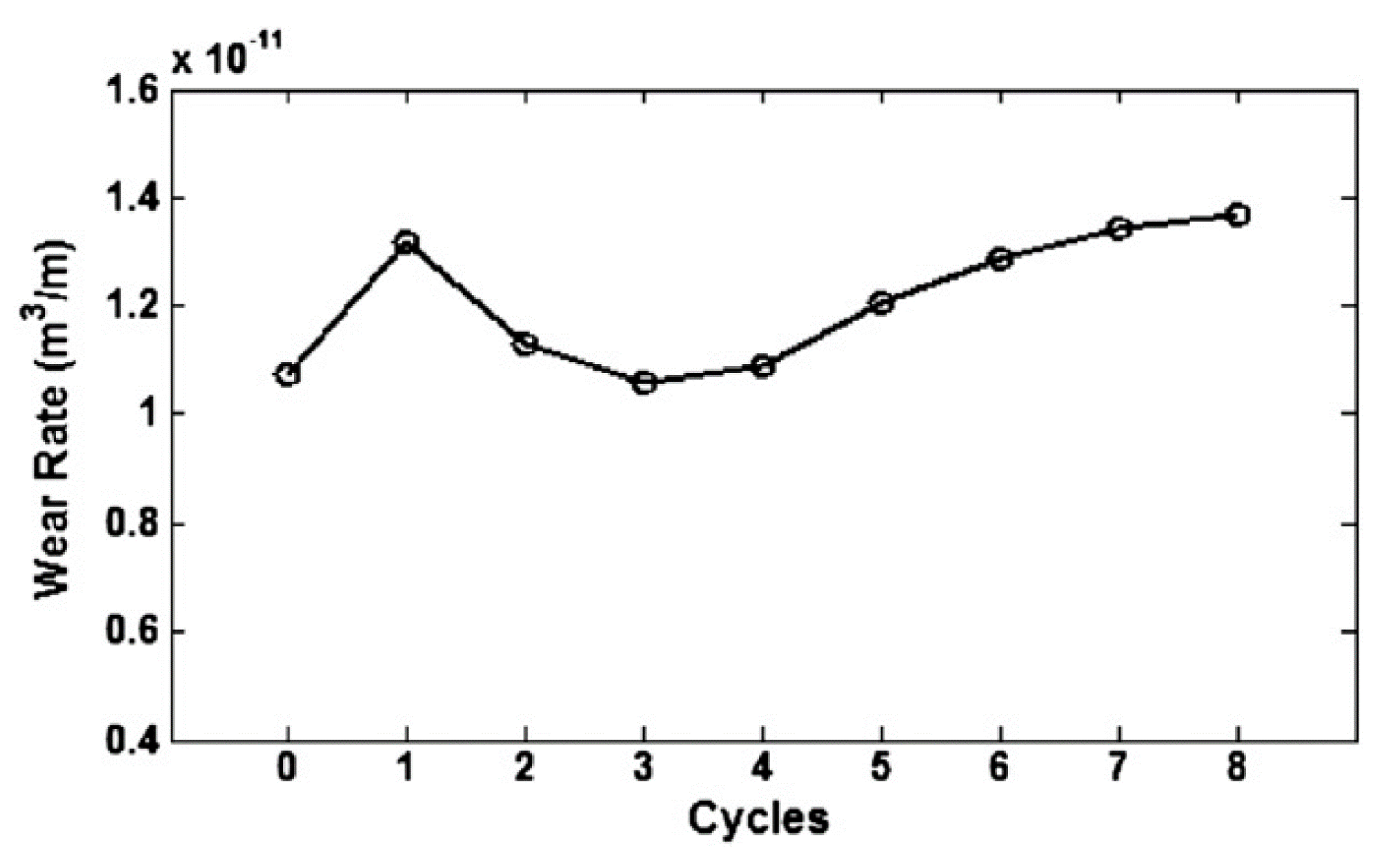

4.6. Wear

4.7. Corrosion

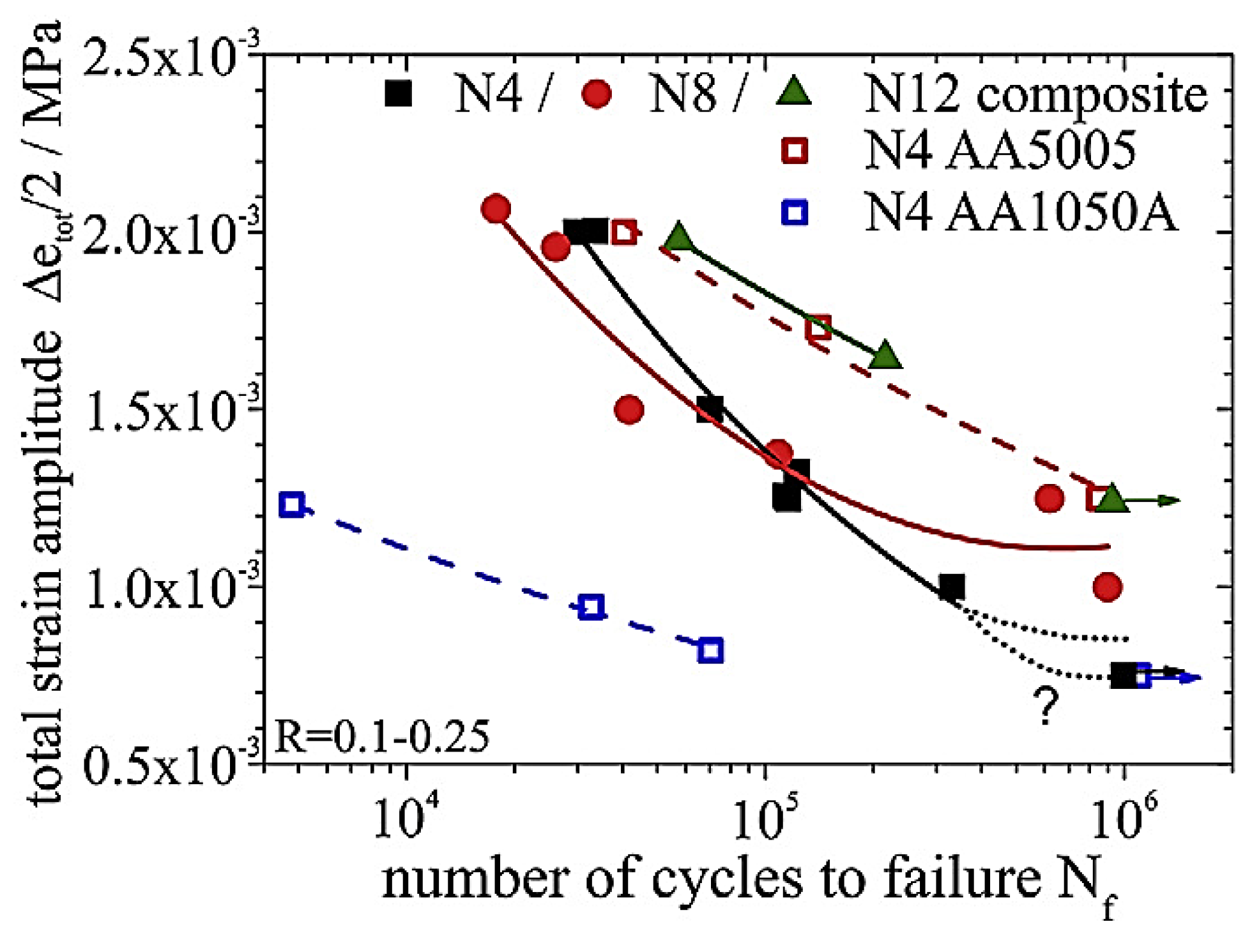

4.8. Fatigue

5. Computational Studies

6. Concluding Remarks

Funding

Conflicts of Interest

References

- SegaL, V. Materials processing by simple shear. Mater. Sci. Eng. 1995, 197, 157–164. [Google Scholar] [CrossRef]

- Abdulov, R.; Valiev, R.; Krasilnikov, N. Formation of submicrometre-Grained structure in magnesium alloy due to high plastic strains. J. Mater. Sci. Lett. 1990, 9, 1445–1447. [Google Scholar] [CrossRef]

- Ghalehbandi, S.; Fallahi-Arezodar, A.; Hosseini-Toudeshky, H. Fatigue crack growth resistance of 7075 Al alloy after equal channel angular pressing. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 1517–1525. [Google Scholar] [CrossRef]

- Horita, Z.; Fujinami, T.; Nemoto, M.; Langdon, T. Improvement of mechanical properties for Al alloys using equal-Channel angular pressing. J. Mater. Process. Technol. 2001, 117, 288–292. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-Channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Ghalehbandi, S.M.; Arezoodar, A.F.; Hosseini-Toudeshky, H. Influence of aging on mechanical properties of equal channel angular pressed aluminum alloy 7075. J. Proc. Inst. Mech. Eng. Part B 2017, 231, 1803–1811. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-Pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Wei, Q.; Zhang, H.; Schuster, B.; Ramesh, K.; Valiev, R.; Kecskes, L.; Dowding, R.; Magness, L.; Cho, K. Microstructure and mechanical properties of super-Strong nanocrystalline tungsten processed by high-pressure torsion. Acta Mater. 2006, 54, 4079–4089. [Google Scholar] [CrossRef]

- Edalati, K.; Fujioka, T.; Horita, Z. Microstructure and mechanical properties of pure Cu processed by high-pressure torsion. Mater. Sci. Eng. 2008, 497, 168–173. [Google Scholar] [CrossRef]

- Tsuji, N.; Saito, Y.; Utsunomiya, H.; Tanigawa, S. Ultra-Fine grained bulk steel produced by accumulative roll-Bonding (ARB) process. Scr. Mater. 1999, 40, 795–800. [Google Scholar] [CrossRef]

- Sheng, L.; Yang, F.; Xi, T.; Lai, C.; Ye, H. Influence of heat treatment on interface of Cu/Al bimetal composite fabricated by cold rolling. Compos. Part B 2011, 42, 1468–1473. [Google Scholar] [CrossRef]

- Kitazono, K.; Sato, E.; Kuribayashi, K. Novel manufacturing process of closed-Cell aluminum foam by accumulative roll-Bonding. Scr. Mater. 2004, 50, 495–498. [Google Scholar] [CrossRef]

- Fattahi, M.; Aghaei, V.N.; Dabiri, A.; Amirkhanlou, S.; Akhavan, S.; Fattahi, Y. Novel manufacturing process of nanoparticle/Al composite filler metals of tungsten inert gas welding by accumulative roll bonding. Mater. Sci. Eng. 2015, 648, 47–50. [Google Scholar] [CrossRef]

- Sabetghadam-Isfahani, A.; Zalaghi, H.; Hashempour, S.; Fattahi, M.; Amirkhanlou, S.; Fattahi, Y. Fabrication and properties of ZrO2/AZ31 nanocomposite fillers of gas tungsten arc welding by accumulative roll bonding. Arch. Civ. Mech. Eng. 2016, 16, 397–402. [Google Scholar] [CrossRef]

- Dhib, Z.; Guermazi, N.; Gaspérini, M.; Haddar, N. Cladding of low-Carbon steel to austenitic stainless steel by hot-Roll bonding: Microstructure and mechanical properties before and after welding. Mater. Sci. Eng. 2016, 656, 130–141. [Google Scholar] [CrossRef]

- Bay, N. Cold welding. Part 1: Characteristics, bonding mechanisms, bond strength. Met. Constr. 1986, 18, 369–372. [Google Scholar]

- Li, L.; Nagai, K.; Yin, F. Progress in cold roll bonding of metals. Sci. Technol. Adv. Mater. 2008, 9, 023001. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.G.; Acoff, V.L. Using cold roll bonding and annealing to process Ti/Al multi-Layered composites from elemental foils. Mater. Sci. Eng. 2004, 379, 164–172. [Google Scholar] [CrossRef]

- Kwan, C.; Wang, Z.; Kang, S.B. Mechanical behavior and microstructural evolution upon annealing of the accumulative roll-bonding (ARB) processed Al alloy 1100. Mater. Sci. Eng. 2008, 480, 148–159. [Google Scholar] [CrossRef]

- Mozaffari, A.; Hosseini, M.; Manesh, H.D. Al/Ni metal intermetallic composite produced by accumulative roll bonding and reaction annealing. J. Alloys Compd. 2011, 509, 9938–9945. [Google Scholar] [CrossRef]

- Takata, N.; Yamada, K.; Ikeda, K.I.; Yoshida, F.; Nakashima, H.; Tsuji, N. Change in microstructure and texture during annealing of pure copper heavily deformed by accumulative roll bonding. Mater. Trans. 2007, 48, 2043–2048. [Google Scholar] [CrossRef]

- Roostaei, A.A.; Zarei-Hanzaki, A.; Abedi, H.; Rokni, M. An investigation into the mechanical behavior and microstructural evolution of the accumulative roll bonded AZ31 Mg alloy upon annealing. Mater. Des. 2011, 32, 2963–2968. [Google Scholar] [CrossRef]

- Talebian, M.; Alizadeh, M. Manufacturing Al/steel multilayered composite by accumulative roll bonding and the effects of subsequent annealing on the microstructural and mechanical characteristics. Mater. Sci. Eng. 2014, 590, 186–193. [Google Scholar] [CrossRef]

- Kwan, C.; Wang, Z. Microstructure evolution upon annealing of accumulative roll bonding (ARB) 1100 Al sheet materials: Evolution of interface microstructures. J. Mater. Sci. Lett. 2008, 43, 5045–5051. [Google Scholar] [CrossRef]

- Yoda, R.; Shibata, K.; Morimitsu, T.; Terada, D.; Tsuji, N. Formability of ultrafine-Grained interstitial-Free steel fabricated by accumulative roll-Bonding and subsequent annealing. Scr. Mater. 2011, 65, 175–178. [Google Scholar] [CrossRef]

- Parks, J.M. Recrystallization welding. Weld. J. 1953, 209–222. [Google Scholar] [CrossRef]

- Semenov, A. The phenomenon of seizure and its investigation. Wear 1961, 4, 1–9. [Google Scholar] [CrossRef]

- Vaidyanath, L.; Nicholas, M.; Milner, D. Pressure welding by rolling. Bri. Weld. J. 1959, 6, 13–28. [Google Scholar]

- Mohamed, H.; Washburn, J. Mechanism of solid state pressure welding. Weld. J. 1975, 8, 302–310. [Google Scholar]

- Pan, D.; Gao, K.; Yu, J. Cold roll bonding of bimetallic sheets and strips. Mater. Sci. Technol. 1989, 5, 934–939. [Google Scholar] [CrossRef]

- Cantalejos, N. Morphology of the Interface of Roll-Bonded Aluminum. J. Inst. Met. 1972, 100, 20–23. [Google Scholar]

- Jamaati, R.; Toroghinejad, M.R. Effect of friction, annealing conditions and hardness on the bond strength of Al/Al strips produced by cold roll bonding process. Mater. Des. 2010, 31, 4508–4513. [Google Scholar] [CrossRef]

- Wu, H.-Y.; Lee, S.; Wang, J.Y. Solid-State bonding of iron-Based alloys, steel–Brass, and aluminum alloys. J. Mater. Process. Technol. 1998, 75, 173–179. [Google Scholar] [CrossRef]

- Clemensen, C.; Juelstorp, O.; Bay, N. Cold welding. Part 3: Influence surface preparation on bond strength. Met. Constr. 1986, 18, 625–629. [Google Scholar]

- Jamaati, R.; Toroghinejad, M.R. Manufacturing of high-Strength aluminum/alumina composite by accumulative roll bonding. Mater. Sci. Eng. 2010, 527, 4146–4151. [Google Scholar] [CrossRef]

- Mehr, V.Y.; Toroghinejad, M.R.; Rezaeian, A. The effects of oxide film and annealing treatment on the bond strength of Al–Cu strips in cold roll bonding process. Mater. Des. 2014, 53, 174–181. [Google Scholar] [CrossRef]

- Milner, D. Vaidyanath, L. Significance of surface preparation in cold pressure welding. Met. Constr. Br. Weld. J. 1960, 7, 1–6. [Google Scholar]

- Jamaati, R.; Toroghinejad, M.R. The role of surface preparation parameters on cold roll bonding of aluminum strips. J. Mater. Eng. Perform. 2011, 20, 191–197. [Google Scholar] [CrossRef]

- Sancaktar, E.; Gomatam, R. A study on the effects of surface roughness on the strength of single lap joints. J. Adhes. Sci. Technol. 2001, 15, 97–117. [Google Scholar] [CrossRef]

- Kim, S.H.; Kim, H.W.; Euh, K.; Kang, J.H.; Cho, J.H. Effect of wire brushing on warm roll bonding of 6XXX/5XXX/6XXX aluminum alloy clad sheets. Mater. Des. 2012, 35, 290–295. [Google Scholar] [CrossRef]

- Nicholas, M.; Milner, D. Pressure welding by rolling at elevated temperatures. Br. Weld. J 1961, 8, 375–383. [Google Scholar]

- Quadir, M.; Wolz, A.; Hoffman, M.; Ferry, M. Influence of processing parameters on the bond toughness of roll-Bonded aluminium strip. Scr. Mater. 2008, 58, 959–962. [Google Scholar] [CrossRef]

- Naseri, M.; Reihanian, M.; Borhani, E. Bonding behavior during cold roll-Cladding of tri-Layered Al/brass/Al composite. J. Manuf. Process. 2016, 24, 125–137. [Google Scholar] [CrossRef]

- Hosseini, M.; Manesh, H.D. Bond strength optimization of Ti/Cu/Ti clad composites produced by roll-Bonding. Mater. Des. 2015, 81, 122–132. [Google Scholar] [CrossRef]

- Ma, M.; Huo, P.; Liu, W.; Wang, G.; Wang, D. Microstructure and mechanical properties of Al/Ti/Al laminated composites prepared by roll bonding. Mater. Sci. Eng. 2015, 636, 301–310. [Google Scholar] [CrossRef]

- Zhan, M.Y.; Li, Y.Y.; Chen, W.P. Improving mechanical properties of Mg-Al-Zn alloy sheets through accumulative roll-Bonding. Trans. Nonferrous Metals Soc. China 2008, 18, 309–314. [Google Scholar] [CrossRef]

- Abbasi, M.; Sajjadi, S.A. Mechanical properties and interface evaluation of Al/AZ31 multilayer composites produced by ARB at different rolling temperatures. J. Mater. Eng. Perform. 2018, 27, 3508–3520. [Google Scholar] [CrossRef]

- Xing, Z.; Kang, S.; Kim, H. Microstructural evolution and mechanical properties of the AA8011 alloy during the accumulative roll-Bonding process. Metall. Mater. Trans. A 2002, 33, 1521–1530. [Google Scholar] [CrossRef]

- Quadir, M.; Al-Buhamad, O.; Bassman, L.; Ferry, M. Development of a recovered/recrystallized multilayered microstructure in Al alloys by accumulative roll bonding. Acta Mater. 2007, 55, 5438–5448. [Google Scholar] [CrossRef]

- Miyajima, Y.; Uchiyama, M.; Adachi, H.; Fujii, T.; Onaka, S.; Kato, M. Effect of Roll-Bonding and Subsequent Annealing on Microstructure Evolution of Accumulative Roll Bonded Pure Copper. Mater. Trans. 2016, 57, 1411–1417. [Google Scholar] [CrossRef] [Green Version]

- Jang, Y.; Kim, S.; Han, S.; Lim, C.; Goto, M. Tensile behavior of commercially pure copper sheet fabricated by 2-And 3-Layered accumulative roll bonding (ARB) process. Metals Mater. Int. 2008, 14, 171. [Google Scholar] [CrossRef]

- Lee, S.H.; Utsunomiya, H.; Sakai, T. Microstructures and mechanical properties of ultra low carbon interstitial free steel severely deformed by a multi-Stack accumulative roll bonding process. Mater. Trans. 2004, 45, 2177–2181. [Google Scholar] [CrossRef]

- Alizadeh, M.; Paydar, M. Fabrication of Al/SiCP composite strips by repeated roll-Bonding (RRB) process. J. Alloys Compd. 2009, 477, 811–816. [Google Scholar] [CrossRef]

- Rezayat, M.; Akbarzadeh, A. Bonding behavior of Al–Al2O3 laminations during roll bonding process. Mater. Des. 2012, 36, 874–879. [Google Scholar] [CrossRef]

- Jamaati, R.; Toroghinejad, M.R. High-Strength and highly-Uniform composite produced by anodizing and accumulative roll bonding processes. Mater. Des. 2010, 31, 4816–4822. [Google Scholar] [CrossRef]

- Liu, C.; Wang, Q.; Jia, Y.; Zhang, B.; Jing, R.; Ma, M.; Jing, Q.; Liu, R. Evaluation of mechanical properties of 1060-Al reinforced with WC particles via warm accumulative roll bonding process. Mater. Des. 2013, 43, 367–372. [Google Scholar] [CrossRef]

- Karimi, M.; Toroghinejad, M.R. An alternative method for manufacturing high-Strength CP Ti–SiC composites by accumulative roll bonding process. Mater. Des. 2014, 59, 494–501. [Google Scholar] [CrossRef]

- Liu, C.; Wang, Q.; Jia, Y.; Zhang, B.; Jing, R.; Ma, M.; Jing, Q.; Liu, R. Effect of W particles on the properties of accumulatively roll-Bonded Al/W composites. Mater. Sci. Eng. 2012, 547, 120–124. [Google Scholar] [CrossRef]

- Ahmadi, A.; Toroghinejad, M.R.; Najafizadeh, A. Evaluation of microstructure and mechanical properties of Al/Al2O3/SiC hybrid composite fabricated by accumulative roll bonding process. Mater. Des. 2014, 53, 13–19. [Google Scholar] [CrossRef]

- Jamaati, R.; Toroghinejad, M.R.; Edris, H.; Salmani, M.R. Comparison of microparticles and nanoparticles effects on the microstructure and mechanical properties of steel-Based composite and nanocomposite fabricated via accumulative roll bonding process. Mater. Des. 2014, 56, 359–367. [Google Scholar] [CrossRef]

- Kent, D.; Xiao, W.; Wang, G.; Yu, Z.; Dargusch, M. Thermal stability of an ultrafine grain β-Ti alloy. Mater. Sci. Eng. 2012, 556, 582–587. [Google Scholar] [CrossRef]

- Gazder, A.A.; Hazra, S.S.; Pereloma, E.V. Annealing behaviour and mechanical properties of severely deformed interstitial free steel. Mater. Sci. Eng. 2011, 530, 492–503. [Google Scholar] [CrossRef]

- Dhal, A.; Panigrahi, S.; Shunmugam, M. Precipitation phenomena, thermal stability and grain growth kinetics in an ultra-Fine grained Al 2014 alloy after annealing treatment. J. Alloys Compd. 2015, 649, 229–238. [Google Scholar] [CrossRef]

- Morovvati, M.; Dariani, B.M. The effect of annealing on the formability of aluminum 1200 after accumulative roll bonding. J. Manuf. Process. 2017, 30, 241–254. [Google Scholar] [CrossRef]

- Rezaei, M.R.; Toroghinejad, M.R.; Ashrafizadeh, F. Effects of ARB and ageing processes on mechanical properties and microstructure of 6061 aluminum alloy. J. Mater. Process. Technol. 2011, 211, 1184–1190. [Google Scholar] [CrossRef]

- Xing, Z.; Kang, S.; Kim, H. Softening behavior of 8011 alloy produced by accumulative roll bonding process. Scr. Mater. 2001, 45, 597–604. [Google Scholar] [CrossRef]

- Lee, S.; Saito, Y.; Sakai, T.; Utsunomiya, H. Microstructures and mechanical properties of 6061 aluminum alloy processed by accumulative roll-Bonding. Mater. Sci. Eng. 2002, 325, 228–235. [Google Scholar] [CrossRef]

- Rezaei, M.R.; Toroghinejad, M.R.; Ashrafizadeh, F. Production of nano-Grained structure in 6061 aluminum alloy strip by accumulative roll bonding. Mater. Sci. Eng. 2011, 529, 442–446. [Google Scholar] [CrossRef]

- Pirgazi, H.; Akbarzadeh, A.; Petrov, R.; Kestens, L. Microstructure evolution and mechanical properties of AA1100 aluminum sheet processed by accumulative roll bonding. Mater. Sci. Eng. 2008, 497, 132–138. [Google Scholar] [CrossRef]

- Toroghinejad, M.R.; Ashrafizadeh, F.; Jamaati, R. On the use of accumulative roll bonding process to develop nanostructured aluminum alloy 5083. Mater. Sci. Eng. 2013, 561, 145–151. [Google Scholar] [CrossRef]

- Su, L.; Lu, C.; Li, H.; Deng, G.; Tieu, K. Investigation of ultrafine grained AA1050 fabricated by accumulative roll bonding. Mater. Sci. Eng. 2014, 614, 148–155. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.; Zheng, H.; Wu, R.; Yang, J.; Ma, X.; Zhang, M. Preparation of Fine-Grained and High-Strength Mg–8Li–3Al–1Zn Alloy by Accumulative Roll Bonding. Adv. Eng. Mater. 2016, 18, 304–311. [Google Scholar] [CrossRef]

- Lim, C.Y.; Han, S.Z.; Lee, S.H. Formation of nano-Sized grains in Cu and Cu− Fe− P alloys by accumulative roll bonding process. Metals Mater. Int. 2006, 12, 225–230. [Google Scholar] [CrossRef]

- Shaarbaf, M.; Toroghinejad, M.R. Nano-Grained copper strip produced by accumulative roll bonding process. Mater. Sci. Eng. 2008, 473, 28–33. [Google Scholar] [CrossRef]

- Song, H.; Kim, Y.; Nam, W. Mechanical properties of ultrafine grained 5052 Al alloy produced by accumulative roll-Bonding and cryogenic rolling. Metals Mater. Int. 2006, 12, 7–12. [Google Scholar] [CrossRef]

- Ruppert, M.; Höppel, H.W.; Göken, M. Influence of cross-Rolling on the mechanical properties of an accumulative roll bonded aluminum alloy AA6014. Mater. Sci. Eng. 2014, 597, 122–127. [Google Scholar] [CrossRef]

- Alvandi, H.; Farmanesh, K. Microstructural and mechanical properties of nano/ultra-Fine structured 7075 aluminum alloy by accumulative roll-Bonding process. Proced. Mater. Sci. 2015, 11, 17–23. [Google Scholar] [CrossRef]

- Alvand, M.; Naseri, M.; Borhani, E.; Abdollah-Pour, H. Nano/ultrafine grained AA2024 alloy processed by accumulative roll bonding: A study of microstructure, deformation texture and mechanical properties. J. Alloys Compd. 2017, 712, 517–525. [Google Scholar] [CrossRef]

- Terada, D.; Inoue, S.; Tsuji, N. Microstructure and mechanical properties of commercial purity titanium severely deformed by ARB process. J. Mater. Sci. 2007, 42, 1673–1681. [Google Scholar] [CrossRef]

- Fattah-alhosseini, A.; Ansari, A.R.; Mazaheri, Y.; Karimi, M.; Haghshenas, M. An Investigation of mechanical properties in accumulative roll bonded nano-Grained pure titanium. Mater. Sci. Eng. 2017, 688, 218–224. [Google Scholar] [CrossRef]

- Fattah-alhosseini, A.; Keshavarz, M.K.; Mazaheri, Y.; Ansari, A.R.; Karimi, M. Strengthening mechanisms of nano-Grained commercial pure titanium processed by accumulative roll bonding. Mater. Sci. Eng. 2017, 693, 164–169. [Google Scholar] [CrossRef]

- Naseri, M.; Reihanian, M.; Borhani, E. A new strategy to simultaneous increase in the strength and ductility of AA2024 alloy via accumulative roll bonding (ARB). Mater. Sci. Eng. 2016, 656, 12–20. [Google Scholar] [CrossRef]

- Zhang, R.; Acoff, V.L. Processing sheet materials by accumulative roll bonding and reaction annealing from Ti/Al/Nb elemental foils. Mater. Sci. Eng. 2007, 463, 67–73. [Google Scholar] [CrossRef]

- Eizadjou, M.; Talachi, A.K.; Manesh, H.D.; Shahabi, H.S.; Janghorban, K. Investigation of structure and mechanical properties of multi-Layered Al/Cu composite produced by accumulative roll bonding (ARB) process. Compos. Sci. Technol. 2008, 68, 2003–2009. [Google Scholar] [CrossRef]

- Eizadjou, M.; Manesh, H.D.; Janghorban, K. Microstructure and mechanical properties of ultra-Fine grains (UFGs) aluminum strips produced by ARB process. J. Alloys Compd. 2009, 474, 406–415. [Google Scholar] [CrossRef]

- Ng, H.P.; Przybilla, T.; Schmidt, C.; Lapovok, R.; Orlov, D.; Höppel, H.W.; Göken, M. Asymmetric accumulative roll bonding of aluminium–Titanium composite sheets. Mater. Sci. Eng. 2013, 576, 306–315. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, B.; Yu, P.; Jing, R.; Ma, M.; Liu, R. Microstructures and mechanical properties of Al/Zn composites prepared by accumulative roll bonding and heat treatment. Mater. Sci. Eng. 2013, 580, 36–40. [Google Scholar] [CrossRef]

- Mozaffari, A.; Manesh, H.D.; Janghorban, K. Evaluation of mechanical properties and structure of multilayered Al/Ni composites produced by accumulative roll bonding (ARB) process. J. Alloys Compd. 2010, 489, 103–109. [Google Scholar] [CrossRef]

- Tayyebi, M.; Eghbali, B. Study on the microstructure and mechanical properties of multilayer Cu/Ni composite processed by accumulative roll bonding. Mater. Sci. Eng. 2013, 559, 759–764. [Google Scholar] [CrossRef]

- Su, L.; Lu, C.; Tieu, A.K.; Deng, G.; Sun, X. Ultrafine grained AA1050/AA6061 composite produced by accumulative roll bonding. Mater. Sci. Eng. 2013, 559, 345–351. [Google Scholar] [CrossRef]

- Sun, Y.; Tsuji, N.; Fujii, H.; Li, F. Cu/Zr nanoscaled multi-stacks fabricated by accumulative roll bonding. J. Alloys Compd. 2010, 504, 443–447. [Google Scholar] [CrossRef]

- Dehsorkhi, R.N.; Qods, F.; Tajally, M. Investigation on microstructure and mechanical properties of Al–Zn composite during accumulative roll bonding (ARB) process. Mater. Sci. Eng. 2011, 530, 63–72. [Google Scholar] [CrossRef]

- Alizadeh, M.; Samiei, M. Fabrication of nanostructured Al/Cu/Mn metallic multilayer composites by accumulative roll bonding process and investigation of their mechanical properties. Mater. Des. 2014, 56, 680–684. [Google Scholar] [CrossRef]

- Ghalandari, L.; Mahdavian, M.; Reihanian, M. Microstructure evolution and mechanical properties of Cu/Zn multilayer processed by accumulative roll bonding (ARB). Mater. Sci. Eng. 2014, 593, 145–152. [Google Scholar] [CrossRef]

- Chang, H.; Zheng, M.; Xu, C.; Fan, G.; Brokmeier, H.; Wu, K. Microstructure and mechanical properties of the Mg/Al multilayer fabricated by accumulative roll bonding (ARB) at ambient temperature. Mater. Sci. Eng. 2012, 543, 249–256. [Google Scholar] [CrossRef]

- Yang, D.; Cizek, P.; Hodgson, P.; Wen, C.E. Ultrafine equiaxed-Grain Ti/Al composite produced by accumulative roll bonding. Scr. Mater. 2010, 62, 321–324. [Google Scholar] [CrossRef]

- Alizadeh, M.; Talebian, M. Fabrication of Al/Cup composite by accumulative roll bonding process and investigation of mechanical properties. Mater. Sci. Eng. 2012, 558, 331–337. [Google Scholar] [CrossRef]

- Lu, C.; Tieu, K.; Wexler, D. Significant enhancement of bond strength in the accumulative roll bonding process using nano-Sized SiO2 particles. J. Mater. Process. Technol. 2009, 209, 4830–4834. [Google Scholar] [CrossRef]

- Amirkhanlou, S.; Rezaei, M.R.; Niroumand, B.; Toroghinejad, M.R. Refinement of microstructure and improvement of mechanical properties of Al/Al2O3 cast composite by accumulative roll bonding process. Mater. Sci. Eng. 2011, 528, 2548–2553. [Google Scholar] [CrossRef]

- Ardakani, M.R.K.; Khorsand, S.; Amirkhanlou, S.; Nayyeri, M.J. Application of compocasting and cross accumulative roll bonding processes for manufacturing high-Strength, highly uniform and ultra-Fine structured Al/SiCp nanocomposite. Mater. Sci. Eng. 2014, 592, 121–127. [Google Scholar] [CrossRef]

- Boesl, B.; Lahiri, D.; Behdad, S.; Agarwal, A. Direct observation of carbon nanotube induced strengthening in aluminum composite via in situ tensile tests. Carbon 2014, 69, 79–85. [Google Scholar] [CrossRef]

- Melaibari, A.; Fathy, A.; Mansouri, M.; Eltaher, M. Experimental and numerical investigation on strengthening mechanisms of nanostructured Al-SiC composites. J. Alloys Compd. 2019, 774, 1123–1132. [Google Scholar] [CrossRef]

- Wagih, A.; Fathy, A.; Ibrahim, D.; Elkady, O.; Hassan, M. Experimental investigation on strengthening mechanisms in Al-SiC nanocomposites and 3D FE simulation of Vickers indentation. J. Alloys Compd. 2018, 752, 137–147. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, D. Contribution of Orowan strengthening effect in particulate-Reinforced metal matrix nanocomposites. Mater. Sci. Eng. 2008, 483, 148–152. [Google Scholar] [CrossRef]

- Monazzah, A.H.; Pouraliakbar, H.; Jandaghi, M.R.; Bagheri, R.; Reihani, S.M.S. Influence of interfacial adhesion on the damage tolerance of Al6061/SiCp laminated composites. Ceram. Int. 2017, 43, 2632–2643. [Google Scholar] [CrossRef]

- Luo, J.G.; Acoff, V.L. Processing gamma-Based TiAl sheet materials by cyclic cold roll bonding and annealing of elemental titanium and aluminum foils. Mater. Sci. Eng. 2006, 433, 334–342. [Google Scholar] [CrossRef]

- Knudsen, F. Dependence of mechanical strength of brittle polycrystalline specimens on porosity and grain size. J. Am. Ceram. Soc. 1959, 42, 376–387. [Google Scholar] [CrossRef]

- Hosseini, M.; Yazdani, A.; Manesh, H.D. Al 5083/SiCp composites produced by continual annealing and roll-bonding. Mater. Sci. Eng. 2013, 585, 415–421. [Google Scholar] [CrossRef]

- Reihanian, M.; Hadadian, F.K.; Paydar, M. Fabrication of Al–2 vol% Al2O3/SiC hybrid composite via accumulative roll bonding (ARB): An investigation of the microstructure and mechanical properties. Mater. Sci. Eng. 2014, 607, 188–196. [Google Scholar] [CrossRef]

- Toroghinejad, M.R.; Jamaati, R.; Nooryan, A.; Edris, H. Hybrid composites produced by anodizing and accumulative roll bonding (ARB) processes. Ceram. Int. 2014, 40, 10027–10035. [Google Scholar] [CrossRef]

- Ana, S.A.; Reihanian, M.; Lotfi, B. Accumulative roll bonding (ARB) of the composite coated strips to fabricate multi-Component Al-Based metal matrix composites. Mater. Sci. Eng. 2015, 647, 303–312. [Google Scholar] [CrossRef]

- Shamanian, M.; Mohammadnezhad, M.; Asgari, H.; Szpunar, J. Fabrication and characterization of Al–Al2O3–ZrC composite produced by accumulative roll bonding (ARB) process. J. Alloys Compd. 2015, 618, 19–26. [Google Scholar] [CrossRef]

- Liu, X.; Wei, D.; Zhuang, L.; Cai, C.; Zhao, Y. Fabrication of high-Strength graphene nanosheets/Cu composites by accumulative roll bonding. Mater. Sci. Eng. 2015, 642, 1–6. [Google Scholar] [CrossRef]

- Reihanian, M.; Shahmansouri, M.J.; Khorasanian, M. High strength Al with uniformly distributed Al2O3 fragments fabricated by accumulative roll bonding and plasma electrolytic oxidation. Mater. Sci. Eng. 2015, 640, 195–199. [Google Scholar] [CrossRef]

- Rezayat, M.; Akbarzadeh, A.; Owhadi, A. Production of high strength Al–Al2O3 composite by accumulative roll bonding. Compos. Part A 2012, 43, 261–267. [Google Scholar] [CrossRef]

- Park, K.T.; Kwon, H.J.; Kim, W.J.; Kim, Y.S. Microstructural characteristics and thermal stability of ultrafine grained 6061 Al alloy fabricated by accumulative roll bonding process. Mater. Sci. Eng. 2001, 316, 145–152. [Google Scholar] [CrossRef]

- Slamova, M.; Homola, P.; Karlik, M. Thermal stability of twin-Roll cast Al–Fe–Mn–Si sheets accumulative roll bonded at different temperatures. Mater. Sci. Eng. 2007, 462, 106–110. [Google Scholar] [CrossRef]

- Tsuji, N.; Shiotsuki, K.; Saito, Y. Superplasticity of ultra-Fine grained Al–Mg alloy produced by accumulative roll-Bonding. Mater. Trans. 1999, 40, 765–771. [Google Scholar] [CrossRef]

- Koizumi, Y.; Ueyama, M.; Tsuji, N.; Minamino, Y.; Ota, K.I. High damping capacity of ultra-Fine grained aluminum produced by accumulative roll bonding. J. Alloys Compd. 2003, 355, 47–51. [Google Scholar] [CrossRef]

- Emadoddin, E.; Tajally, M.; Masoumi, M. Damping behavior of Al/SiCP multilayer composite manufactured by roll bonding. Mater. Des. 2012, 42, 334–338. [Google Scholar] [CrossRef]

- Zheng, W.; Gao, Y.; Wang, X.; Lu, H.; Zeng, L.; Fang, Q. High strength and damping capacity of LLZNO/Al composites fabricated by accumulative roll bonding. Mater. Sci. Eng. 2017, 689, 306–312. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Hashemi, R.; Mohammadi, B.; Shojaee, T. Experimental evaluation of the plane stress fracture toughness for ultra-Fine grained aluminum specimens prepared by accumulative roll bonding process. Mater. Sci. Eng. 2017, 708, 301–310. [Google Scholar] [CrossRef]

- Cepeda-Jiménez, C.; Hidalgo, P.; Pozuelo, M.; Ruano, O.A.; Carreño, F. Influence of constituent materials on the impact toughness and fracture mechanisms of hot-Roll-Bonded aluminum multilayer laminates. Metall. Mater. Trans. A 2010, 41, 61. [Google Scholar] [CrossRef]

- Pippan, R.; Hohenwarter, A. The importance of fracture toughness in ultrafine and nanocrystalline bulk materials. Mater. Res. Lett. 2016, 4, 127–136. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Talachi, A.K.; Eizadjou, M.; Manesh, H.D.; Janghorban, K. Wear characteristics of severely deformed aluminum sheets by accumulative roll bonding (ARB) process. Mater. Charact. 2011, 62, 12–21. [Google Scholar] [CrossRef]

- Kim, Y.S.; Ha, J.; Shin, D.H. Sliding wear characteristics of ultrafine-Grained non-Strain-Hardening aluminum-Magnesium alloys, Materials science forum. Trans Tech. Publ. 2005, 475, 401–404. [Google Scholar]

- Darmiani, E.; Danaee, I.; Golozar, M.; Toroghinejad, M.; Ashrafi, A.; Ahmadi, A. Reciprocating wear resistance of Al–SiC nano-Composite fabricated by accumulative roll bonding process. Mater. Des. 2013, 50, 497–502. [Google Scholar] [CrossRef]

- Jamaati, R.; Naseri, M.; Toroghinejad, M.R. Wear behavior of nanostructured Al/Al2O3 composite fabricated via accumulative roll bonding (ARB) process. Mater. Des. 2014, 59, 540–549. [Google Scholar] [CrossRef]

- Wei, W.; Wei, K.X.; Du, Q.B. Corrosion and tensile behaviors of ultra-Fine grained Al–Mn alloy produced by accumulative roll bonding. Mater. Sci. Eng. 2007, 454, 536–541. [Google Scholar] [CrossRef]

- Darmiani, E.; Danaee, I.; Golozar, M.; Toroghinejad, M. Corrosion investigation of Al–SiC nano-composite fabricated by accumulative roll bonding (ARB) process. J. Alloys Compd. 2013, 552, 31–39. [Google Scholar] [CrossRef]

- Kadkhodaee, M.; Babaiee, M.; Manesh, H.D.; Pakshir, M.; Hashemi, B. Evaluation of corrosion properties of Al/nanosilica nanocomposite sheets produced by accumulative roll bonding (ARB) process. J. Alloys Compd. 2013, 576, 66–71. [Google Scholar] [CrossRef]

- Fattah-Alhosseini, A.; Naseri, M.; Alemi, M. Corrosion behavior assessment of finely dispersed and highly uniform Al/B4C/SiC hybrid composite fabricated via accumulative roll bonding process. J. Manuf. Process. 2016, 22, 120–126. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Chapetti, M.; Miyata, H.; Tagawa, T.; Miyata, T.; Fujioka, M. Fatigue strength of ultra-Fine grained steels. Mater. Sci. Eng. 2004, 381, 331–336. [Google Scholar] [CrossRef]

- Vinogradov, A.; Hashimoto, S.; Kopylov, V. Enhanced strength and fatigue life of ultra-Fine grain Fe–36Ni Invar alloy. Mater. Sci. Eng. 2003, 355, 277–285. [Google Scholar] [CrossRef]

- Kwan, C.C.; Wang, Z. Cyclic deformation behavior of ultra-Fine grained copper processed by accumulative roll-Bonding. Proced. Eng. 2010, 2, 101–110. [Google Scholar] [CrossRef]

- Kümmel, F.; Hausöl, T.; Höppel, H.W.; Göken, M. Enhanced fatigue lives in AA1050A/AA5005 laminated metal composites produced by accumulative roll bonding. Acta Mater. 2016, 120, 150–158. [Google Scholar] [CrossRef]

- Lin, X.; Koyama, M.; Gao, S.; Tsuji, N.; Tsuzaki, K.; Noguchi, H. Resistance to mechanically small fatigue crack growth in ultrafine grained interstitial-Free steel fabricated by accumulative roll-Bonding. Int. J. Fatigue 2019, 118, 117–125. [Google Scholar] [CrossRef]

- Galantucci, L.; Tricarico, L. Thermo-Mechanical simulation of a rolling process with an FEM approach. J. Mater. Process. Technol. 1999, 92, 494–501. [Google Scholar] [CrossRef]

- Min, W.; He, Y.; Sun, Z.C.; Guo, L.G.; Ou, X.Z. Dynamic explicit FE modeling of hot ring rolling process. Trans. Nonferrous Metals Soc. China 2006, 16, 1274–1280. [Google Scholar]

- Mori, K.; Osakada, K.; Oda, T. Simulation of plane-Strain rolling by the rigid-Plastic finite element method. Int. J. Mech. Sci. 1982, 24, 519–527. [Google Scholar] [CrossRef]

- Jiang, Z.; Tieu, A.; Zhang, X.; Lu, C.; Sun, W. Finite element simulation of cold rolling of thin strip. J. Mater. Process. Technol. 2003, 140, 542–547. [Google Scholar] [CrossRef]

- Beaudoin, A.J.; Mathur, K.; Dawson, P.; Johnson, G. Three-Dimensional deformation process simulation with explicit use of polycrystal plasticity models. Int.l J. Plast. 1993, 9, 833–860. [Google Scholar] [CrossRef]

- Inoue, T.; Tsuji, N. Quantification of strain in accumulative roll-Bonding under unlubricated condition by finite element analysis. Comput. Mater. Sci. 2009, 46, 261–266. [Google Scholar] [CrossRef]

- Tseng, H.C.; Hung, C.; Huang, C.C. An analysis of the formability of aluminum/copper clad metals with different thicknesses by the finite element method and experiment. Int. J. Adv. Manuf. Technol. 2010, 49, 1029–1036. [Google Scholar] [CrossRef]

- Inoue, T.; Yanagida, A.; Yanagimoto, J. Finite element simulation of accumulative roll-Bonding process. Mater. Letters 2013, 106, 37–40. [Google Scholar] [CrossRef]

- Roostaei, A.A.; Zarei-Hanzaki, A.; Parsa, M.; Fatemi-Varzaneh, S. An analysis to plastic deformation behavior of AZ31 alloys during accumulative roll bonding process. J. Mater. Sci. Lett. 2010, 45, 4494–4500. [Google Scholar] [CrossRef]

- Hosseini, M.; Pardis, N.; Manesh, H.D.; Abbasi, M.; Kim, D.I. Structural characteristics of Cu/Ti bimetal composite produced by accumulative roll-Bonding (ARB). Mater. Des. 2017, 113, 128–136. [Google Scholar] [CrossRef]

- Ebrahimi, S.S.; Dehghani, K.; Aghazadeh, J.; Ghasemian, M.; Zangeneh, S. Investigation on microstructure and mechanical properties of Al/Al-Zn-Mg–Cu laminated composite fabricated by accumulative roll bonding (ARB) process. Mater. Sci. Eng. 2018, 718, 311–320. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, T.; Castagne, S.; Gu, C.; Wang, J. Proposal of bond criterion for hot roll bonding and its application. Mater. Des. 2011, 32, 2239–2245. [Google Scholar] [CrossRef]

- Yu, H.; Tieu, A.K.; Lu, C.; Godbole, A. An investigation of interface bonding of bimetallic foils by combined accumulative roll bonding and asymmetric rolling techniques. Metall. Mater. Trans. A 2014, 45, 4038–4045. [Google Scholar] [CrossRef]

- Prakash, A.; Nöhring, W.; Lebensohn, R.; Höppel, H.; Bitzek, E. A multiscale simulation framework of the accumulative roll bonding process accounting for texture evolution. Mater. Sci. Eng. 2015, 631, 104–119. [Google Scholar] [CrossRef]

- Qiao, X.G.; Starink, M.J. Prediction of hardness of Al alloys processed by accumulative roll bonding. Mater. Sci. Eng. 2012, 531, 45–50. [Google Scholar] [CrossRef]

- Milner, J.L.; Bunget, C.; Abu-Farha, F.; Kurfess, T.; Hammond, V.H. Modeling tensile strength of materials processed by accumulative roll bonding. J. Manuf. Process. 2013, 15, 219–226. [Google Scholar] [CrossRef]

- Reihanian, M.; Naseri, M. An analytical approach for necking and fracture of hard layer during accumulative roll bonding (ARB) of metallic multilayer. Mater. Des. 2016, 89, 1213–1222. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghalehbandi, S.M.; Malaki, M.; Gupta, M. Accumulative Roll Bonding—A Review. Appl. Sci. 2019, 9, 3627. https://doi.org/10.3390/app9173627

Ghalehbandi SM, Malaki M, Gupta M. Accumulative Roll Bonding—A Review. Applied Sciences. 2019; 9(17):3627. https://doi.org/10.3390/app9173627

Chicago/Turabian StyleGhalehbandi, Seyed Mahmoud, Massoud Malaki, and Manoj Gupta. 2019. "Accumulative Roll Bonding—A Review" Applied Sciences 9, no. 17: 3627. https://doi.org/10.3390/app9173627

APA StyleGhalehbandi, S. M., Malaki, M., & Gupta, M. (2019). Accumulative Roll Bonding—A Review. Applied Sciences, 9(17), 3627. https://doi.org/10.3390/app9173627