A Review of Early Injection Strategy in Premixed Combustion Engines

Abstract

:1. Introduction

1.1. Conception of HCCI and PCCI Combustion

1.2. Early Injection Strategy

1.3. Alternative Fuel

2. Injection Pressure

3. Injection Timing

3.1. Single Early Injection

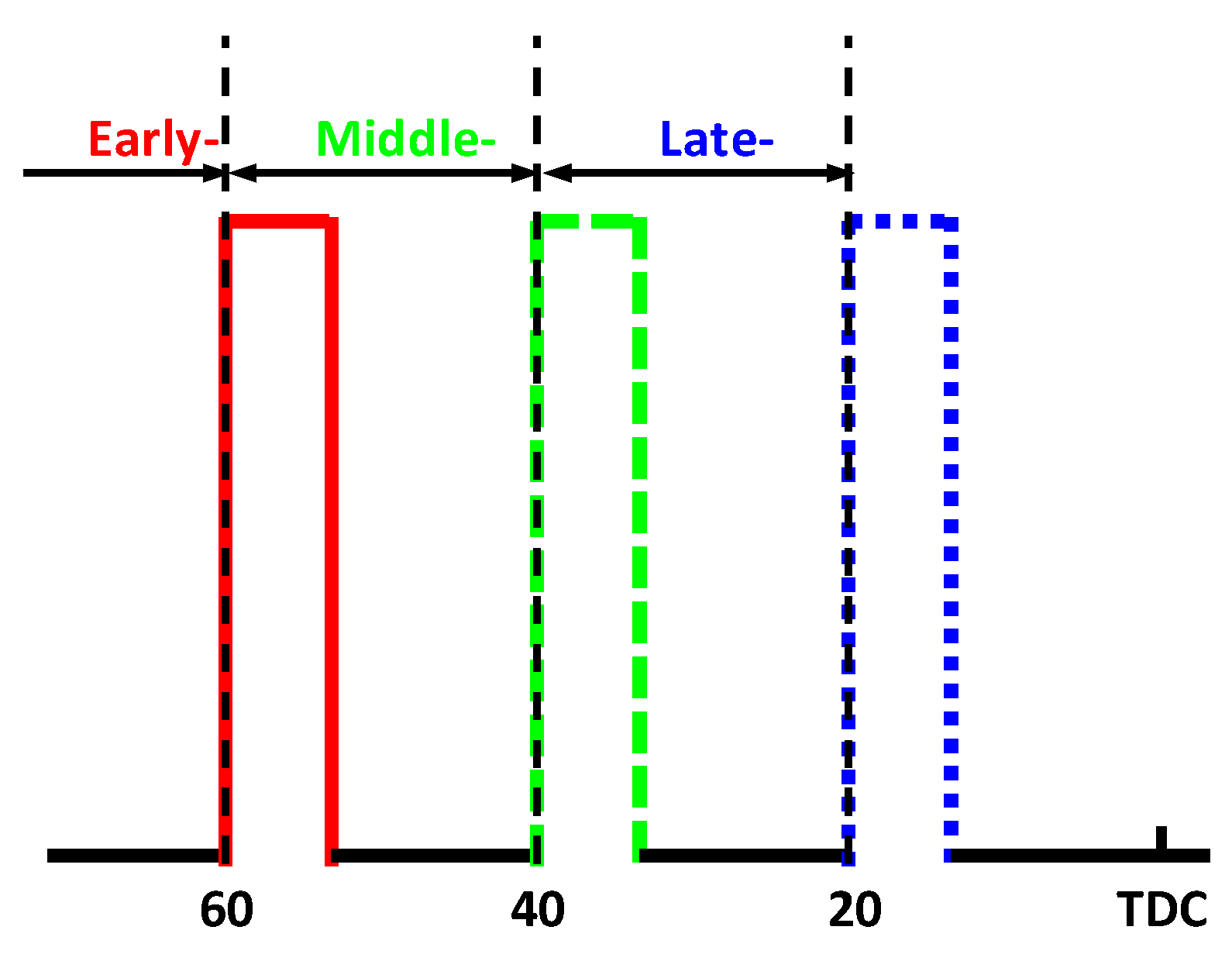

3.2. Two-Stage Early Injection

3.2.1. First Injection Timing

3.2.2. Second Injection Timing

3.2.3. First Injection Quantity

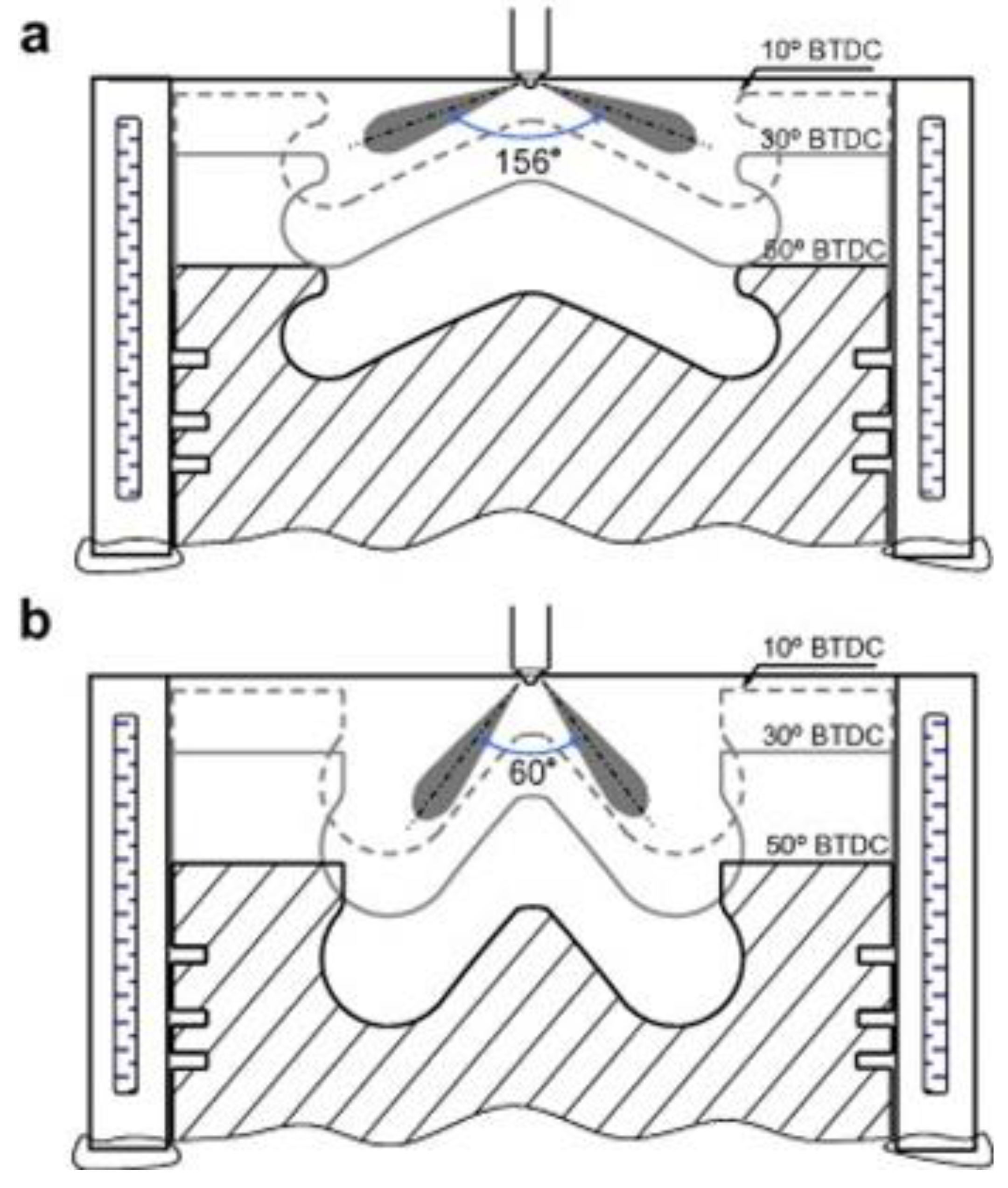

4. Injection Angle

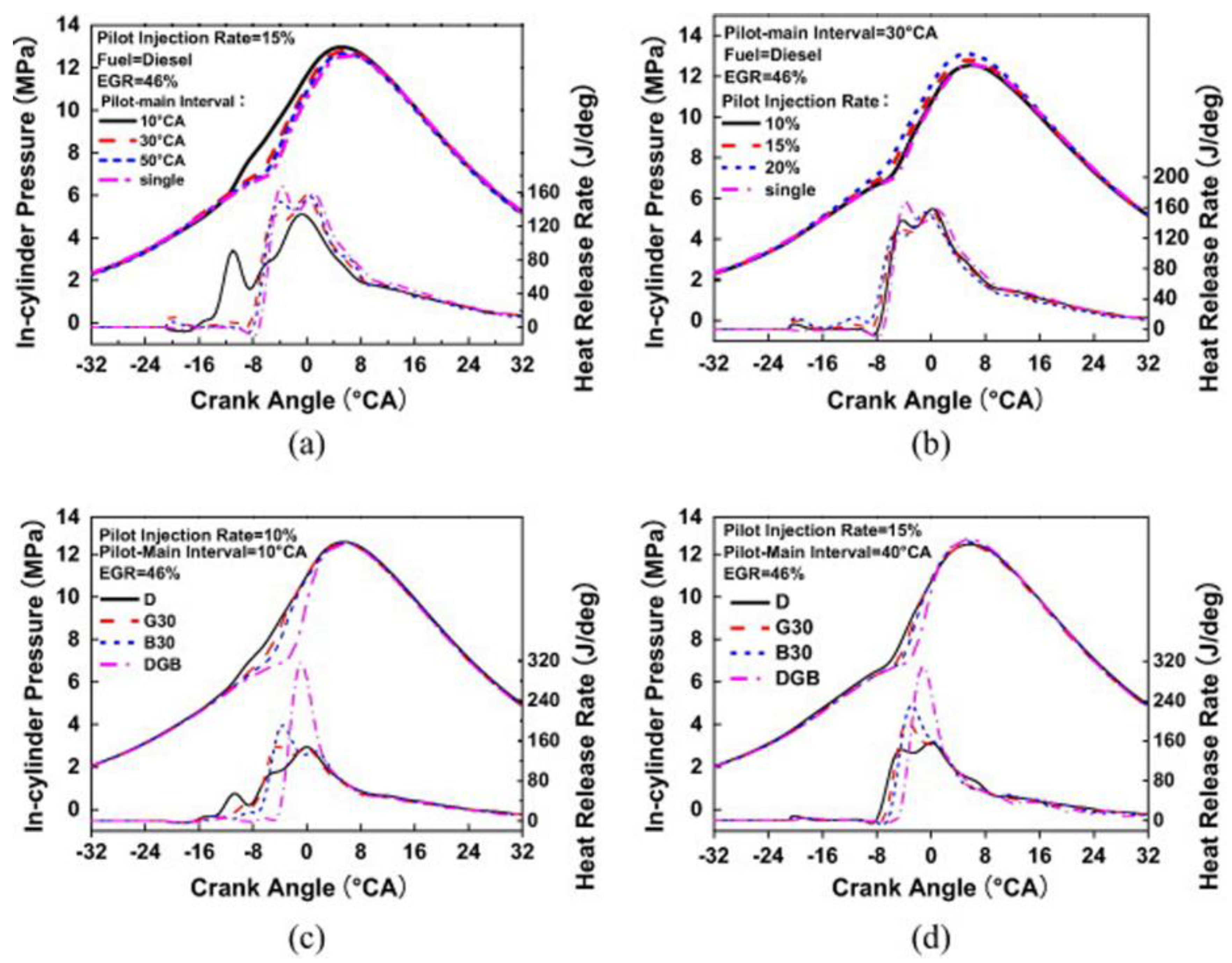

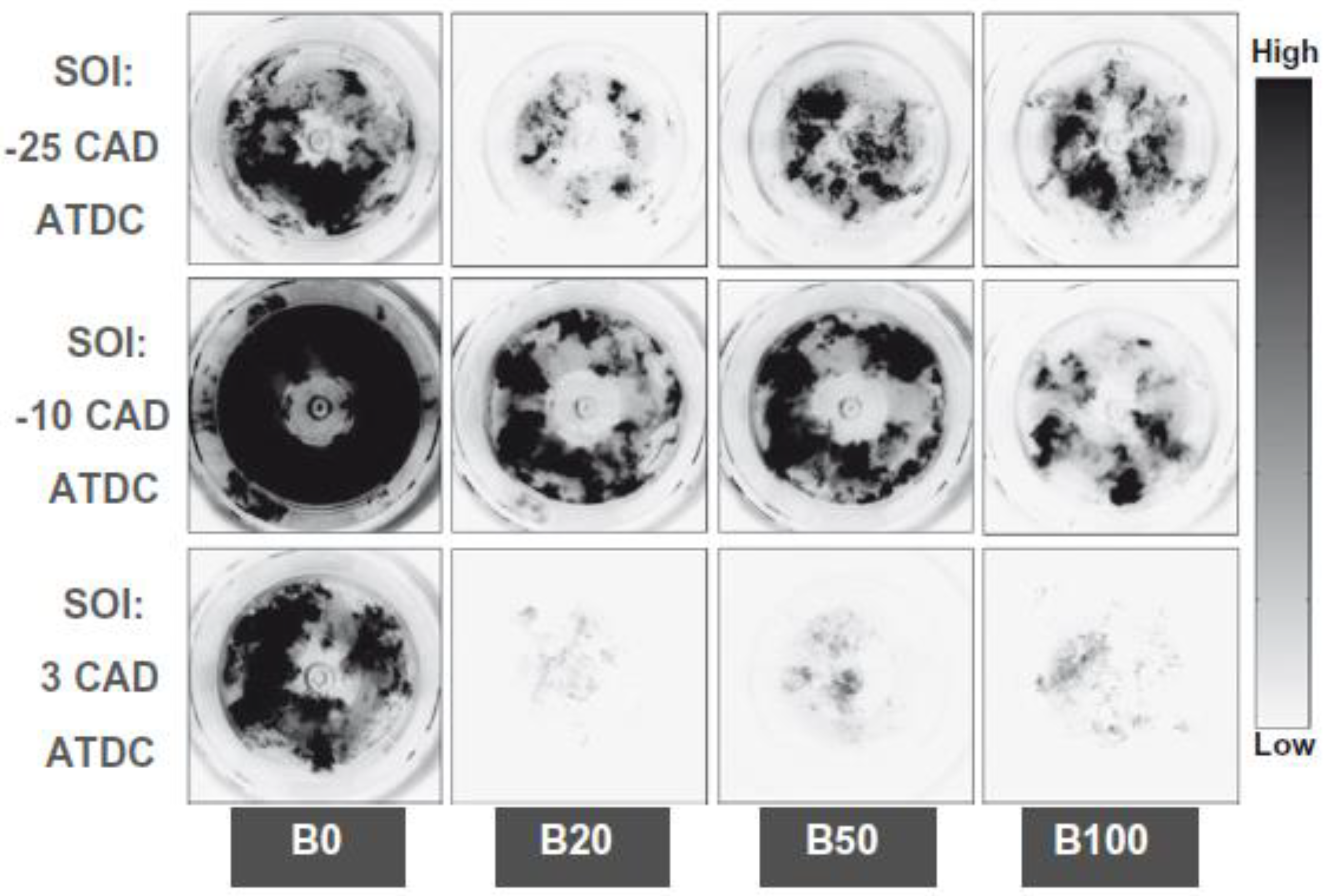

5. Blending Ratio

6. Summary and Conclusions

- Increasing the injection pressure improved the engine thermal efficiency and decreased soot emissions. This is because a higher injection pressure will result in a better fuel spray, which will make the fuel burn more completely. HC and CO emissions were determined by the paradoxical effect of high injection pressure. They are uncertain. NOx emissions increased slightly with increasing injection pressure due to the higher combustion temperature. Wetting-wall phenomenon caused by higher injection pressure can lead to the opposite results.

- Advancing the injection timing of HCCI engines was beneficial in terms of better NOx emissions, but with increased HC and CO emissions. Soot emission depended on the opposite effects of longer premixing time and more serious wall-wetting. In theory, longer premixing time can reduce soot emissions, but wall-wetting can cause incomplete or low-temperature combustion that can increase soot emissions. The engine performance deteriorated with advanced injection timing due to the increased negative work and incomplete combustion.

- Advancing the first injection timing of PCCI engines was beneficial in terms of better NOx and soot emissions, but HC and CO emissions increased and engine performance deteriorated. In addition, retarding the second injection timing also reduced NOx emissions. However, soot, HC, and CO emissions increased and engine performance deteriorated due to the shifting of diffusive combustion to later than TDC. From the previously cited literature, wetting-wall phenomenon must be considered when using two-stage early injection strategy, which has an important impact on engine performance and emissions.

- Increasing the first injection quantity of PCCI engines increased HC and CO emissions. NOx emissions also increased due to the faster heat release rate and higher combustion temperature caused by a large portion of premixed combustion. Soot emission was determined by the opposite effects of wall-wetting, higher combustion temperature, and lower proportion of diffusive combustion. As far as experimental values go, the first injection quantity should be limited to 40% of the total injection fuel, which will obtain better engine performance and emission characteristics.

- Decreasing the injection angle limited or reduced the wall-wetting phenomenon, resulted in decreased HC and CO. However, soot emission was directly affected by the location of spray targeting. Generally, decreasing the injection angle was not good for the control of soot emission, but NOx emissions could be suppressed by the rich fuel–air mixture and low combustion temperature. As the same time, the narrow injection angle is also beneficial to reduce the BSFC, due to avoiding incomplete combustion caused by wetting-wall phenomena.

- The impingement target is an important factor influencing engine emissions, and the impingement target was commonly determined by the injection timing, injection angle, and piston structure. When the spray impinged at the bowl lip bottom edge, the secondary atomization process was enhanced, resulting in a drop of HC and CO emissions.

- For HCCI and PCCI engines fueled with alternative fuels, the blending ratio of the alternative fuel directly affected the performance and emission characteristics. Oxygenated fuel was beneficial for the reduction of NOx and soot emissions, but was not good for decreasing HC and CO emissions. For gasoline–diesel blended fuel, the increased gasoline ratio resulted in reduced NOx and soot but increased HC and CO emissions.

- For HCCI and PCCI engines, an appropriate early injection strategy can effectively improve engine performance and improve engine emissions characteristics. However, due to the actual working process of the engine, its performance and emissions are affected by many factors. Therefore, it is also necessary to study the effects of multiple factors (Injection pressure; Injection Timing; Injection Angle and fuel) on engine performance and emissions.

7. Future Research Directions

- Methods to limit or avoid the wall-wetting problem caused by early injection strategy, including improved injection system or multiple-pulse injection strategy.

- Accurate spray-wall impingement mechanism, especially the fuel, including alternative fuel, because the physical and chemical characteristics changed with the addition of alternative fuel.

- The effect of the impingement target on mixture formation and emission distribution in the cylinder; in addition, optimization of the impingement target should consider the factors of injection timing, injection angle, and piston structures simultaneously.

- The effects of the early injection parameters on combustion noise radiation, which is expected to gain interest with the development of HCCI and PCCI engines.

- The interrelationship between early injection strategy and modern catalytic devices, such as Diesel Particulate Filter (DPF), Selective Catalytic Reduction (SCR), and Lean NOx Trap (LNT), especially with respect to particle number concentration and distribution, but also possibly due to durability issues.

- Early injection strategy combined with reactivity controlled compression ignition (RCCI), research and analysis of the impact of early injection strategy on RCCI engine, including injection timing, injection pressure, injection angle and so on.

- Combining different types of lubricating oils, one can study the influence of early injection strategies on engine performance and emission characteristics.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| HCCI | homogeneous charge compression ignition |

| PCCI | premixed charge compression ignition |

| RCCI | reactivity controlled compression ignition |

| NOx | nitrogen oxides |

| EGR | exhaust gas recycling |

| TDC | top dead center |

| BTDC | before top dead center |

| CO | carbon monoxide |

| HC | hydrocarbon |

| DME | dimethyl ether |

| IMEP | indicated mean effective pressure |

| DI | direct injection |

| HSDI | high-speed direct-injection |

| FIP | fuel injection pressure |

| PM | particulate matter |

| HRR | heat release rate |

| BTE | brake thermal efficiency |

| BSFC | brake-specific fuel consumption |

| ASOI | after start of injection |

| CAD | crank angle degree |

| CI | compression ignition |

| LTR | low-temperature reaction |

| HTR | high-temperature reaction |

| L/HTC | low-/high-temperature combustion |

| ATDC | after top dead center |

| HCHO | formaldehyde |

| DGB | diesel/gasoline, diesel/n-butanol |

| BSHC | brake specific HC emissions |

| BSCO | brake specific CO emissions |

| BSNOx | brake specific NOx emissions |

| CFD | computational fluid dynamics |

| MIT | main injection timing |

| ISFC | indicated specific fuel consumption |

| CRDI | common rail direct-injection |

| DBE | diesel biodiesel ethanol |

| SOI | start of injection |

| DPF | diesel particulate filter |

| SCR | selective catalytic reduction |

| LNT | lean NOx trap |

| DDCL | diesel from direct coal liquefaction |

| HD | heavy duty |

| ROHR | rate of heat release |

| Pmax | maximum pressure |

References

- Mohan, B.; Yang, W.; Kiang Chou, S. Fuel injection strategies for performance improvement and emissions reduction in compression ignition engines—A review. Renew. Sustain. Energy Rev. 2013, 28, 664–676. [Google Scholar] [CrossRef]

- Berggren, C.; Magnusson, T. Reducing automotive emissions—The potentials of combustion engine technologies and the power of policy. Energy Policy 2012, 41, 636–643. [Google Scholar] [CrossRef]

- Valentino, G.; Corcione, F.E.; Iannuzzi, S.E.; Serra, S. Experimental study on performance and emissions of a high speed diesel engine fuelled with n-butanol diesel blends under premixed low temperature combustion. Fuel 2012, 92, 295–307. [Google Scholar] [CrossRef]

- Musculus, M.P.B.; Miles, P.C.; Pickett, L.M. Conceptual models for partially premixed low-temperature diesel combustion. Prog. Energy Combust. Sci. 2013, 39, 246–283. [Google Scholar] [CrossRef]

- Zhang, J.; McCreanor, J.E.; Cullinan, P.; Chung, K.F.; Ohman-Strickland, P.; Han, I.; Nieuwenhuijsen, M.J. Health effects of real-world exposure to diesel exhaust in persons with asthma. Health Eff. Inst. 2009, 138, 111–123. [Google Scholar]

- Pope, C.A.; Thun, M.J.; Namboodiri, M.M.; Dockery, D.W.; Evans, J.S.; Speizer, F.E.; Heath, C.W. Particulate air pollution as a predictor of mortality in a prospective study of US adults. Am. J. Respir. Crit. Care Med. 1995, 151, 669–674. [Google Scholar] [CrossRef]

- Katsouyanni, K.; Schwartz, J.; Spix, C.; Touloumi, G.; Zmirou, D.; Zanobetti, A. Short term effects of air pollution on health: A European approach using epidemiologic time series data: The APHEA protocol. J. Epidemiol. Commun. Health 1996, 50, S12–S18. [Google Scholar] [CrossRef]

- Li, N.; Kim, S.; Wang, M.; Froines, J.; Sioutas, C.; Nel, A. Use of a stratified oxidative stress model to study the biological effects of ambient concentrated and diesel exhaust particulate matter. Inhal. Toxicol. 2002, 14, 459–486. [Google Scholar] [CrossRef]

- Li, N.; Hao, M.; Phalen, R.F.; Hinds, W.C.; Nel, A.E. Particulate air pollutants and asthma. A paradigm for the role of oxidative stress in PM-induced adverse health effects. Clin. Immunol. 2003, 109, 250. [Google Scholar] [CrossRef]

- Attfield, M.D.; Schleiff, P.L.; Lubin, J.H.; Blair, A.; Stewart, P.A.; Vermeulen, R.; Silverman, D.T. The diesel exhaust in miners study: A cohort mortality study with emphasis on lung cancer. J. Natl. Cancer Inst. 2012, 104, 869–883. [Google Scholar] [CrossRef]

- Mansoury, M.; Jafarmadar, S.; Talei, M.; Lashkarpour, S.M. Optimization of HCCI (Homogeneous Charge Compression Ignition) engine combustion chamber walls temperature to achieve optimum IMEP using LHS and Nelder Mead algorithm. Energy 2017, 119, 938–949. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw Hill: New York, NY, USA, 1988. [Google Scholar]

- Onishi, S.; Jo, S.H.; Shoda, K.; Jo, P.D.; Kato, S. Active Thermo-Atmosphere Combustion (ATAC)—A New Combustion Process for Internal Combustion Engines; SAE International: Warrendale, PA, USA, 1979. [Google Scholar]

- Noguchi, M.; Tanaka, Y.; Tanaka, T.; Takeuchi, Y. A Study on Gasoline Engine Combustion by Observation of Intermediate Reactive Products During Combustion; SAE International: Warrendale, PA, USA, 1979. [Google Scholar]

- Stanglmaier, R.H.; Roberts, C.E. Homogeneous Charge Compression Ignition (HCCI): Benefits, Compromise, and Future Engine Applications; SAE International: Warrendale, PA, USA, 1999. [Google Scholar]

- Yao, M.F.; Zheng, Z.L.; Liu, H.F. Progress and recent trends in homogeneous charge compression ignition (HCCI) engines. Prog. Energy Combust. Sci. 2009, 35, 398–437. [Google Scholar] [CrossRef]

- Lu, X.C.; Han, D.; Huang, Z. Fuel design and management for the control of advanced compression-ignition combustion modes. Prog. Energy Combust. Sci. 2011, 37, 741–783. [Google Scholar] [CrossRef]

- Swor, T.A.; Kokjohn, S.; Andrie, M.; Reitz, R.D. Improving Diesel Engine Performance Using Low and High Pressure Split Injections for Single Heat Release and Two-Stage Combustion; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Harada, A.; Shimazaki, N.; Sasaki, S.; Miyamoto, T.; Akagawa, H.; Tsujimura, K. The Effects of Mixture Formation on Premixed Lean Diesel Combustion; SAE International: Warrendale, PA, USA, 1998. [Google Scholar]

- Simescu, S.; Fiveland, S.B.; Dodge, L.G. An Experimental Investigation of PCCI-DI Combustion and Emissions in a Heavy-Duty Diesel Engine; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Kanda, T.; Hakozaki, T.; Uchimoto, T.; Hatano, J.; Kitayama, N.; Sono, H. PCCI Operation with Early Injection of Conventional Diesel Fuel; SAE International: Warrendale, PA, USA, 2005. [Google Scholar]

- Simescu, S.; Ryan, T.W.; Neely, G.D.; Matheaus, A.C.; Surampudi, B. Partial Pre-Mixed Combustion with Cooled and Uncooled EGR in a Heavy-Duty Diesel Engine; SAE International: Warrendale, PA, USA, 2002. [Google Scholar]

- Weiskirch, C.; Mueller, E. Advanced in Diesel Engine Combustion: Split Combustion; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Eastwood, P.G.; Morris, T.; Tufail, K.; Winstanley, T.; Hardalupas, Y.; Taylor, A.M.K.P. The Effects of Fuel-Injection Schedules on Emissions of NOx and Smoke in a Diesel Engine during Partial-Premix Combustion; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Boot, M.; Rijk, E.; Luijten, C.; Somers, B.; Albrecht, B. Spray Impingement in the Early Direct Injection Premixed Charge Compression Ignition Regime; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Han, M.; Assanis, D.N.; Bohac, S.V. Sources of hydrocarbon emissions from low-temperature premixed compression ignition combustion from a common rail direct injection diesel engine. Combust. Sci. Technol. 2009, 181, 496–517. [Google Scholar] [CrossRef]

- Ryan, T.W.; Matheaus, A.C. Fuel Requirements for HCCI Engine Operation; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Aceves, S.M.; Flowers, D.; Martinez-Frias, J.; Espinosa-Loza, F.; Pitz, W.J.; Dibble, R. Fuel and Additive Characterization for HCCI Combustion; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Kawano, D.; Naito, H.; Suzuki, H.; Ishii, H.; Hori, S.; Goto, Y.; Odaka, M. Effects of Fuel Properties on Combustion and Exhaust Emissions of Homogeneous Charge Compression Ignition (HCCI) Engine; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- Agarwal, A.K. Biofuels (alcohols and biodiesel) applications as fuels in internal combustion engines. Prog. Energy Combust. Sci. 2007, 32, 233–271. [Google Scholar] [CrossRef]

- Demirbas, A. Biodiesel production from vegetable oils via catalytic and non-catalytic supercritical methanol transesterification methods. Prog. Energy Combust. Sci. 2005, 31, 466–487. [Google Scholar] [CrossRef]

- Graboski, M.S.; McCormick, R.L. Combustion of fat and vegetable oil derived fuels in diesel engines. Prog. Energy Combust. Sci. 1998, 24, 125–164. [Google Scholar] [CrossRef]

- Komninos, N.P.; Rakopoulos, C.D. Modeling HCCI combustion of biofuels: A review. Renew. Sustain. Energy Rev. 2012, 16, 588–610. [Google Scholar] [CrossRef]

- Teng, H.; McCandless, J.C.; Schneyer, J.B. Compression Ignition Delay (Physical + Chemical) of Dimethyl Ether—an Alternative Fuel for Compression—Ignition Engines; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Yao, M.F.; Zheng, Z.Q.; Xu, S.D.; Fu, M.L. Experimental Study on the Combustion Process of Dimethyl Ether (DME); SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Sahin, Z.; Durgun, O. Prediction of the effects of ethanol–diesel fuel blends on diesel engine performance characteristics, combustion, exhaust emissions, and cost. Energy Fuel 2009, 23, 1707–1717. [Google Scholar] [CrossRef]

- Mohammadi, A.; Kee, S.S.; Ishiyama, T.; Kakuta, T.; Matsumoto, T. Implementation of Ethanol Diesel Blend Fuels in PCCI Combustion; SAE International: Warrendale, PA, USA, 2005. [Google Scholar]

- Park, S.H.; Cha, J.; Lee, C.S. Effects of bioethanol-blended diesel fuel on combustion and emission reduction characteristics in a direct-injection diesel engine with exhaust gas recirculation (EGR). Energy Fuels 2010, 24, 3872–3883. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, J.P.; Han, Z.Y.; Du, B.; Liu, Y.; Lee, C. Study on performance and emissions of a passenger-car diesel engine fuelled with butanol–diesel blends. Energy 2013, 55, 638–646. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Giakoumis, E.G.; Dimaratos, A.M.; Kyritsis, D.C. Effects of butanol–diesel fuel blends on the performance and emissions of a high-speed DI diesel engine. Energy Convers. Manag. 2010, 51, 1989–1997. [Google Scholar] [CrossRef]

- Bessonette, P.W.; Schleyer, C.H.; Duffy, K.P.; Hardy, W.L.; Liechty, M.P. Effects of Fuel Property Changes on Heavy-Duty HCCI Combustion; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Inagaki, K.; Fuyuto, T.; Nishikawa, K.; Nakatita, K.; Sakata, I. Dual-Fuel PCI Combustion Controlled by in-Cylinder Stratification of Ignitability; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Yao, M.F.; Zhang, B.; Zheng, Z.Q.; Chen, Z. Experimental study on homogeneous charge compression ignition combustion with primary reference fuel. Combust. Sci. Technol. 2007, 179, 2539–2559. [Google Scholar] [CrossRef]

- Liu, H.F.; Yao, M.F.; Zhang, B.; Zheng, Z.Q. Influence of fuel and operating conditions on combustion characteristics of a homogeneous charge compression ignition engine. Energy Fuels 2009, 23, 1422–1430. [Google Scholar] [CrossRef]

- Yang, B.B.; Li, S.J.; Zheng, Z.Q.; Yao, M.F.; Cheng, W. A Comparative Study on Different Dual-Fuel Combustion Modes Fuelled with Gasoline and Diesel; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Leermakers, C.A.J.; Van den Berge, B.; Luijten, C.; Somers, L.M.T.; de Goey, L.P.H.; Albrecht, B.A. Gasoline–Diesel Dual Fuel: Effect of Injection Timing and Fuel Balance; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Siewert, R.M. Spray Angle and Rail Pressure Study for Low NOx Diesel Combustion; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Shimazaki, N.; Tsurushima, T.; Nishimura, T. Dual Mode Combustion Concept with Premixed Diesel Combustion by Direct Injection near Top Dead Center; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Kiplimo, R.; Tomita, E.; Kawahara, N.; Yokobe, S. Effects of spray impingement, injection parameters, and EGR on the combustion and emission characteristics of a PCCI diesel engine. Appl. Therm. Eng. 2012, 37, 165–175. [Google Scholar] [CrossRef]

- Jeong, K.; Lee, D.; Park, S.; Lee, C.S. Effect of Two-Stage Fuel Injection Parameters on NOx Reduction Characteristics in a DI Diesel Engine. Energies 2011, 4, 2049–2060. [Google Scholar] [CrossRef] [Green Version]

- Park, S.H.; Cha, J.; Kim, H.J.; Lee, C.S. Effect of early injection strategy on spray atomization and emission reduction characteristics in bioethanol blended diesel fueled engine. Energy 2012, 39, 375–387. [Google Scholar] [CrossRef]

- Fang, T.G.; Coverdill, R.E.; Lee, C.F.F.; White, R.A. Effects of injection angles on combustion processes using multiple injection strategies in an HSDI diesel engine. Fuel 2008, 87, 3232–3239. [Google Scholar] [CrossRef]

- Ayush, J.; Akhilendra, P.S.; Avinash, K.A. Effect of fuel injection parameters on combustion stability and emissions of a mineral diesel fueled partially premixed charge compression ignition (PCCI) engine. Appl. Energy 2017, 190, 658–669. [Google Scholar]

- Abraham, J. Computational Study of Charge Stratification in Early-injection SCCI Engines Under Light-load Conditions. Int. J. Automot. Technol. 2011, 12, 721–732. [Google Scholar] [CrossRef]

- Liu, H.F.; Ma, S.Y.; Zhang, Z.; Zheng, Z.Q.; Yao, M.F. Study of the control strategies on soot reduction under early-injection conditions on a diesel engine. Fuel 2015, 139, 472–481. [Google Scholar] [CrossRef]

- Chen, L.; Yang, F.Y.; Yang, Y.P.; Yang, X.Q.; Ouyang, M.G. Application of Narrow Cone Angle Injectors to Achieve Advanced Compression Ignition on a Mass-Production Diesel Engine—Control Strategy and Engine Performance Evaluation; SAE International: Warrendale, PA, USA, 2009. [Google Scholar]

- Arun, K.S.; Ashok, K.; Murugan, S. Experimental investigation of the effect of compression ratio, injection timing & pressure in a DI (direct injection) diesel engine running on carbon black-water-diesel emulsion. Energy 2015, 93, 511–520. [Google Scholar]

- Nanthagopal, K.; Ashok, B.; Raj, R.T.K. Influence of fuel injection pressures on Calophyllum inophyllum methylester fuelled direct injection diesel engine. Energy Convers. Manag. 2016, 116, 165–173. [Google Scholar] [CrossRef]

- Deep, A.; Sandhu, S.S.; Chander, S. Experimental investigations on the influence of fuel injection timing and pressure on single cylinder C.I. engine fueled with 20% blend of castor biodiesel in diesel. Fuel 2017, 210, 15–22. [Google Scholar] [CrossRef]

- Jagannath, H.; Vivek, B.; Jisa, R. Effect of Compression Ratio, Injection Pressure and Injection Timing on Performance and Smoke Emissions of CI engine Fuelled with Waste Fried Oil Methyl Esters Diesel Blend. Mater. Today Proc. 2018, 5, 1563–1570. [Google Scholar]

- Benajes, J.; Garcia-Oliver, J.M.; Novella, R.; Kolodziej, C. Increased particle emissions from early fuel injection timing Diesel low temperature combustion. Fuel 2012, 94, 184–190. [Google Scholar] [CrossRef]

- Kim, M.Y.; Lee, C.S. Effect of a narrow fuel spray angle and a dual injection configuration on the improvement of exhaust emissions in a HCCI diesel engine. Fuel 2007, 86, 2871–2880. [Google Scholar] [CrossRef]

- Kim, H.M.; Kitn, Y.J.; Lee, K.H. A Study of the Characteristics of Mixture Formation and Combustion in a PCCI Engine Using an Early Multiple Injection Strategy. Energy Fuels 2008, 22, 1542–1548. [Google Scholar] [CrossRef]

- Kim, H.; Ryu, J.; Lee, K. A Study on the Characteristics of Spray and Combustion in a HCCI Engine according to Various Injection Angles and Timings. J. Mech. Sci. Technol. 2007, 21, 133–140. [Google Scholar] [CrossRef]

- Miyamoto, T.; Tsurushima, T.; Shimazaki, N.; Harada, A.; Sasaki, S.; Hayashi, K. Modeling Ignition and Combustion in Direct Injection Compression Ignition Engines Employing Very Early Injection Timing. JSME Int. J. 2002, 45, 872–880. [Google Scholar] [CrossRef] [Green Version]

- Kook, S.; Park, S.; Bae, C. Influence of Early Fuel Injection Timings on Premixing and Combustion in a Diesel Engine. Energy Fuels 2008, 22, 331–337. [Google Scholar] [CrossRef]

- Fang, T.G.; Coverdill, R.E.; Lee, C.F.; White, R.A. Smokeless Combustion within a Small-Bore HSDI Diesel Engine Using a Narrow Angle Injector; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Yoon, S.H.; Cha, J.P.; Lee, C.S. An investigation of the effects of spray angle and injection strategy on dimethyl ether (DME) combustion and exhaust emission characteristics in a common-rail diesel engine. Fuel Process. Technol. 2010, 91, 1364–1372. [Google Scholar] [CrossRef]

- Kim, K.; Kim, D.; Jung, Y.; Bae, C. Spray and combustion characteristics of gasoline and diesel in a direct injection compression ignition engine. Fuel 2013, 109, 616–626. [Google Scholar] [CrossRef]

- Wamankar, A.K.; Murugan, S. Effect of injection timing on a DI diesel engine fuelled with a synthetic fuel blend. J. Energy Inst. 2015, 88, 406–413. [Google Scholar] [CrossRef]

- Sindhu, R.; Rao, G.A.P.; Murthy, K.M. Effective reduction of NOx emissions from diesel engine using split injections. Alex. Eng. J. 2017, 57, 1379–1392. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Rakopoulos, D.C.; Mavropoulos, G.C.; Kosmadakis, G.M. Investigating the EGR rate and temperature impact on diesel engine combustion and emissions under various injection timings and loads by comprehensive two-zone modeling. Energy 2018, 157, 990–1014. [Google Scholar] [CrossRef]

- Parka, S.H.; Kimb, H.J.; Shinc, D.H.; Leeb, J.T. Effects of various split injection strategies on combustion and emissions characteristics in a single-cylinder diesel engine. Appl. Therm. Eng. 2018, 140, 422–431. [Google Scholar] [CrossRef]

- Damodharan, D.; Sathiyagnanam, A.P.; Rana, D.; Kumar, B.R.; Saravanan, S. Combined influence of injection timing and EGR on combustion, performance and emissions of DI diesel engine fueled with neat waste plastic Oil. Energy Convers. Manag. 2018, 161, 294–305. [Google Scholar] [CrossRef]

- Mobasheri, R.; Peng, Z.J. A Computational Investigation into the Effects of Included Spray Angle on Heavy-Duty Diesel Engine Operating Parameters; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Abdullah, N.R.; Mamat, R.; Wyszynski, M.L.; Tsolakis, A.; Xu, H.M. Effects of pilot injection timing and EGR on a modern V6 common rail direct injection diesel engine. ICMER 2013, 50, 012008. [Google Scholar] [CrossRef] [Green Version]

- Torregrosa, A.J.; Broatch, A.; Garcia, A.; Monico, L.F. Sensitivity of combustion noise and NOx and soot emissions to pilot injection in PCCI Diesel engines. Appl. Energy 2013, 104, 149–157. [Google Scholar] [CrossRef] [Green Version]

- Yin, B.; Wang, J.; Yang, K.; Jia, H. Optimization of EGR and Split Injection Strategy for Light Vehicle Diesel Low Temperature Combustion. Int. J. Automot. Technol. 2014, 15, 1043–1051. [Google Scholar] [CrossRef]

- Kim, Y.J.; Kim, K.B.; Lee, K.H. Effect of a 2-stage injection strategy on the combustion and flame characteristics in a PCCI engine. Int. J. Automot. Technol. 2011, 12, 639–644. [Google Scholar] [CrossRef]

- Yamane, K.; Shimamoto, Y. Combustion and Emission Characteristics of Direct-Injection Compression Ignition Engines by Means of Two-Stage Split and Early Fuel Injection. Trans. ASME 2002, 124, 660–667. [Google Scholar] [CrossRef]

- Kook, S.; Bae, C. Combustion Control Using Two-Stage Diesel Fuel Injection in a Single-Cylinder PCCI Engine; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- Yao, M.F.; Wang, H.; Zheng, Z.Q.; Yue, Y. Experimental study of n-butanol additive and multi-injection on HD diesel engine performance and emissions. Fuel 2010, 89, 2191–2201. [Google Scholar] [CrossRef]

- Zhuang, J.; Qiao, X.Q.; Bai, J.L.; Hu, Z. Effect of injection-strategy on combustion, performance and emission characteristics in a DI-diesel engine fueled with diesel from direct coal liquefaction. Fuel 2014, 121, 141–148. [Google Scholar] [CrossRef]

- Zheng, Z.Q.; Yue, L.; Liu, H.F.; Zhu, Y.X.; Zhong, X.F.; Yao, M.F. Effect of two-stage injection on combustion and emissions under high EGR rate on a diesel engine by fueling blends of diesel/gasoline, diesel/n-butanol, diesel/gasoline/n-butanol and pure diesel. Energy Convers. Manag. 2015, 90, 1–11. [Google Scholar] [CrossRef]

- Yang, B.; Wang, L.; Ning, L.; Zeng, K. Effects of pilot injection timing on the combustion noise and particle emissions of a diesel/natural gas dual-fuel engine at low load. Appl. Therm. Eng. 2016, 102, 822–828. [Google Scholar] [CrossRef]

- Yoon, H.; Jeon, J.; Bae, C. The Effects of Two-Stage Fuel Injection on Dimethyl-ether (DME) Homogeneous Charge Compression Ignition Engine Combustion; SAE International: Warrendale, PA, USA, 2009. [Google Scholar]

- Ali, T.; Deniz, A.M.; Gokhan, C.; Mustafa, C. Numerical and experimental investigations of the effects of the second injection timing and alcohol-gasoline fuel blends on combustion and emissions of an HCCI-DI engine. Fuel 2018, 219, 50–61. [Google Scholar]

- Coskun, G.; Soyhan, H.S.; Demir, U.; Turkcan, A.; Ozsezen, A.N.; Canakci, M. Influences of second injection variations on combustion and emissions of an HCCI-DI engine: Experiments and CFD modelling. Fuel 2014, 136, 287–294. [Google Scholar] [CrossRef]

- Das, P.; Subbarao, P.M.V.; Subrahmanyam, J.P. Effect of main injection timing for controlling the combustion phasing of a homogeneous charge compression ignition engine using a new dual injection strategy. Energy Convers. Manag. 2015, 95, 248–258. [Google Scholar] [CrossRef]

- Lee, J.; Hong, K.; Choi, S.; Yu, S.; Choi, H.; Min, K. Comparison of the effects of multiple injection strategy on the emissions between moderate and heavy EGR rate conditions: Part 1-pilot injections. J. Mech. Sci. Technol. 2013, 27, 1135–1141. [Google Scholar] [CrossRef]

- Neely, G.D.; Sasaki, S.; Leet, J.A. Experimental Investigation of PCCI-DI Combustion on Emissions in a Light-Duty Diesel Engine; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- De Ojeda, W.; Zoldak, P.; Espinosa, R.; Kumar, R. Development of a Fuel Injection Strategy for Partially Premixed Compression Ignition Combustion; SAE International: Warrendale, PA, USA, 2009. [Google Scholar]

- Park, Y.; Bae, C. Influence of EGR and Pilot Injection on PCCI Combustion in a Single-Cylinder Diesel Engine; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Fang, Q.; Fang, J.H.; Zhuang, J.; Huang, Z. Influences of pilot injection and exhaust gas recirculation (EGR) on combustion and emissions in a HCCI-DI combustion engine. Appl. Therm. Eng. 2012, 48, 97–104. [Google Scholar] [CrossRef]

- Yu, H.Z.N.; Liang, X.Y.; Wang, Y.S.; Zhang, H.S. Numerical Investigation on Combustion and Emission of a Diesel Engine using Two-stage Injection Strategy. In Proceedings of the 8th International Conference on Applied Energy (ICAE 2016), Beijing, China, 8–11 October 2016; pp. 1344–1349. [Google Scholar]

- Park, S.H.; Yoon, S.H.; Lee, C.S. HC and CO emissions reduction by early injection strategy in a bioethanol blended diesel-fueled engine with a narrow angle injection system. Appl. Energy 2013, 107, 81–88. [Google Scholar] [CrossRef]

- Vanegas, A.; Won, H.; Peters, N. Influence of the Nozzle Spray Angle on Pollutant Formation and Combustion Efficiency for a PCCI Diesel Engine; SAE International: Warrendale, PA, USA, 2009. [Google Scholar]

- Kim, H.; Reitz, R.D.; Kong, S.C. Modeling Combustion and Emissions of HSDI Diesel Engines Using Injectors with Different Included Spray Angles; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Fang, T.G.; Lin, Y.C.; Foong, T.M.; Lee, C.F. Biodiesel combustion in an optical HSDI diesel engine under low load premixed combustion conditions. Fuel 2009, 88, 2154–2162. [Google Scholar] [CrossRef]

- Ma, S.Y.; Zheng, Z.Q.; Liu, H.F.; Zhang, Q.C.; Yao, M.F. Experimental investigation of the effects of diesel injection strategy on gasoline/diesel dual-fuel combustion. Appl. Energy 2013, 109, 202–212. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Dhar, A.; Gupta, J.G.; Kim, W.I.; Choi Lee, C.S.; Park, S. Effect of fuel injection pressure and injection timing of Karanja biodiesel blends on fuel spray, engine performance, emissions and combustion characteristic. Energy Convers. Manag. 2015, 91, 302–314. [Google Scholar] [CrossRef]

- Guedes, A.D.M.; Braga, S.L.; Pradelle, F. Performance and combustion characteristics of a compression ignition engine running on diesel-biodiesel-ethanol (DBE) blends—Part 2: Optimization of injection timing. Fuel 2018, 225, 174–183. [Google Scholar] [CrossRef]

| Conventional Combustion | HCCI Combustion | PCCI Combustion | |

|---|---|---|---|

| Injection strategy | injection close to Top Dead Center (TDC) | Early injection | Early injection + TDC injection |

| Combustion mode | Diffusion | Premixed | Premixed + diffusion |

| Ignition | Auto-ignition (controlled by injection timing) | Auto-ignition (controlled by chemical kinetics) | Auto-ignition (controlled by injection timing) |

| Combustion temperature | Partially high | Relatively low | Relatively low |

| NOx | High NOx emissions due to high combustion temperature | Low NOx emissions due to low combustion temperature | Low NOx emissions due to low temperature and exhaust gas recycling (EGR) dilution |

| Soot | High soot emissions due to diffusion combustion mode | Low soot emissions due to lean homogeneous charge | Low soot emissions due to lean homogeneous charge |

| Author | Injection Pressure (bar) | Fuel | BSFC | NOx | HC | CO | Soot |

|---|---|---|---|---|---|---|---|

| Jeong et al. [50] | 500–900 | Diesel | na | → | na | na | ↓ |

| Fang et al. [52] | 600/1000 | Diesel | na | ↑ | na | na | ↓ |

| Shimazaki et al. [48] | 300–1200 | Diesel | ↓↑ | ↓ | ↑ | ↑ | → |

| Kiplimo et al. [49] | 800/1400 | Diesel | ↓ | ↑ | ↓ | → | ↓ |

| Liu et al. [55] | 600–1400 | Diesel | na | na | na | na | → |

| Chen et al. [56] | 1000–1400 | Diesel | ↓ | ↑ | na | na | ↓ |

| Siewert [47] | 800–1600 | Diesel | ↓ | na | ↓ | ↓ | ↓ |

| Park et al. [51] | 400/1200 | Bioethanol blends | ↓ | ↑ | ↑ | ↑ | ↓ |

| Arun et al. [57] | 200–240 | Carbon black–water–diesel | na | ↓↑ | ↓↑ | ↓↑ | ↓↑ |

| Nanthagopal et al. [58] | 200–240 | Biodiesel | ↓ | ↑ | ↓ | ↓ | ↓ |

| Author | Injection Timing (° BTDC) | Fuel | BSFC | NOx | HC | CO | Soot |

|---|---|---|---|---|---|---|---|

| Benajes et al. [61] | 33–24 | Diesel | na | na | ↑ | ↑ | ↑ |

| Kiplimo et al. [49] | 40–20 | Diesel | ↑ | ↓ | ↑ | ↑ | ↑ |

| Kim and Lee [62] | 70–20 | Diesel | ↑ | ↓ | na | na | na |

| Fang et al. [67] | 80–40 | Diesel | na | ↓ | na | na | ↑ |

| Kim et al. [63] | 180–20 | Diesel | ↑ | na | na | na | ↓ |

| Kim et al. [64] | 180–20 | Diesel | ↑ | ↓ | na | na | ↓ |

| Miyamoto et al. [65] | 180–20 | Diesel | na | ↓ | ↑ | na | ↓ |

| Kook et al. [66] | 200–50 | Diesel | ↑ | ↓ | ↑ | ↑ | ↓ |

| Park et al. [51] | 40–20 | Bioethanol blends | ↑ | ↓ | ↑ | ↑ | ↑ |

| Yoon et al. [68] | 40–20 | DME | ↑ | ↓ | ↑ | ↑ | → |

| Kim et al. [69] | 40–20 | Gasoline | ↑ | ↓ | ↑ | ↑ | na |

| Wamankar and Murugan [70] | 26–20 | Diesel | ↑ | ↓ | ↑ | ↑ | ↑ |

| Author | First Injection Timing (° BTDC) | Second Injection Timing (° BTDC) | Fuel | BSFC | NOx | HC | CO | Soot |

|---|---|---|---|---|---|---|---|---|

| Abdullah et al. [76] | 30–9 | −1.4 | Diesel | na | ↓↑ | na | na | ↓ |

| Mobasheri and Peng [75] | 30–15 | 9 | Diesel | ↑ | ↑ | na | na | na |

| Torregrosa et al. [77] | 34–26 | 18 | Diesel | ↑ | ↓ | na | na | ↓ |

| Yin et al. [78] | 35–10 | TDC | Diesel | ↑ | ↓↑ | na | na | ↓ |

| Jeong et al. [50] | 70–20 | −5 | Diesel | ↑ | ↓ | ↑ | ↑ | → |

| Kim et al. [79] | 70–45 | −5 | Diesel | ↓ | ↓ | na | na | ↓ |

| Yamane and Shimamoto [80] | 110–70 | na | Diesel | ↑ | ↓ | na | na | ↓ |

| Kook and Bae [81] | 250–50 | 20 | Diesel | ↓ | → | → | ↑ | ↓ |

| Yoon et al. [68] | 35–15 | 5 | DME | ↑ | ↓ | ↑ | ↑ | ↓ |

| Yao et al. [82] | 42–21 | 5 | n-butanol | na | na | na | ↑ | ↓ |

| Zhuang et al. [83] | 45.5–8.5 | −1 | Diesel from Direct Coal Liquefaction(DDCL) | ↑ | ↑↓ | na | na | ↓ |

| Zheng et al. [84] | 65–25 | 14 | B30/G30/DGB | na | ↓↑ | ↑ | ↑ | ↓ |

| Author | First Injection Timing (° BTDC) | Second Injection Timing (° BTDC) | Fuel | BSFC | NOx | HC | CO | Soot |

|---|---|---|---|---|---|---|---|---|

| Coskun et al. [89] | 240 | 30–15 | Diesel | na | ↓ | ↑ | na | na |

| Torregrosa et al. [77] | 34 | 26–8 | Diesel | ↓ | ↓ | na | na | ↑ |

| Kook and Bae [81] | 200 | 20-TDC | Diesel | ↑ | na | na | na | na |

| Kanda et al. [21] | 56 | 18–5 | Diesel | ↑ | na | na | na | ↑ |

| Kim et al. [79] | 60 | 5 to −7.5 | Diesel | → | ↓ | na | na | ↑ |

| Kim and Lee [62] | 60 | TDC to −20 | Diesel | ↑ | ↓ | ↑ | ↑ | na |

| Yoon et al. [86] | 80 | 20-TDC | DME | na | ↓ | ↑ | ↑ | na |

| Yao et al. [82] | 42 | 10 to −2.5 | n-butanol | ↑ | na | na | ↑ | ↓ |

| Author | First Injection Quantity | Fuel | BSFC | NOx | HC | CO | Soot |

|---|---|---|---|---|---|---|---|

| De Ojeda et al. [92] | 0–10 mg/cycle | Diesel | na | na | ↑ | na | ↓ |

| Lee et al. [90] | 1–5 mg/cycle | Diesel | ↑ | ↓ | ↑ | na | ↑ |

| Jeong et al. [50] | 2–10 mg/cycle | Diesel | na | ↓↑ | na | na | ↑ |

| Park and Bae [93] | 0–50% | Diesel | na | ↑↓ | ↑ | ↑ | ↓↑ |

| Zheng et al. [84] | 10–20% | Diesel | na | ↑ | ↑ | ↑ | → |

| Kim et al. [79] | 10–50% | Diesel | ↑ | ↑ | na | na | ↑ |

| Neely et al. [91] | 15–35% | Diesel | ↑ | ↑ | na | ↑ | na |

| Torregrosa et al. [77] | 20–60% | Diesel | ↑ | ↓ | na | na | → |

| Chen et al. [56] | 20–60% | Diesel | na | ↑ | na | na | ↑ |

| Zhuang et al. [83] | 2–6 mm3/cycle | DDCL | na | ↑ | na | na | → |

| Author | Injection Angle (°) | Fuel | BSFC | NOx | HC | CO | Soot |

|---|---|---|---|---|---|---|---|

| Kim and Lee [62] | 60/156 | Diesel | ↓ | → | na | na | na |

| Fang et al. [52] | 70/150 | Diesel | na | ↓ | na | na | ↑ |

| Kim et al. [63] | 70–150 | Diesel | ↓ | na | na | na | ↑ |

| Mobasheri and Peng [75] | 90–145 | Diesel | ↓↑ | ↓ | na | na | ↓↑ |

| Vanegas et al. [97] | 100–148 | Diesel | na | ↑ | na | na | ↑ |

| Kook and Bae [81] | 100/150 | Diesel | na | ↑ | ↓ | ↓ | ↓ |

| Siewert [47] | 100–158 | Diesel | na | na | ↓ | ↓ | ↓ |

| Park et al. [96] | 70/156 | Bioethanol blended | ↓ | na | ↓ | ↓ | na |

| Yoon et al. [68] | 60/70/156 | DME | ↓ | → | ↓ | ↓ | → |

| Author | Blending Ratio (%) | Fuel | BSFC | NOx | HC | CO | Soot |

|---|---|---|---|---|---|---|---|

| Fang et al. [99] | 20–100 | Biodiesel | na | ↓↑ | na | na | ↑ |

| Park et al. [38] | 10–30 | Bioethanol | na | ↓ | ↑ | ↑ | → |

| Liu et al. [55] | 30–70 | Gasoline | na | na | na | na | ↓ |

| Ma et al. [100] | 68–84 | Gasoline | na | ↓ | ↑ | ↑ | ↓ |

| Yao et al. [82] | 0–15 | n-Butanol | ↑ | na | na | ↓ | ↓ |

| Early Injection Parameters | Injection Pressure ↑ | Injection Timing | Injection Angle ↓ | |||

|---|---|---|---|---|---|---|

| Single ← | Two-Stage | |||||

| First Injection Timing ← | Second Injection Timing → | First Injection Quality ↑ | ||||

| Advantage | Better air–fuel mixing and fewer fuel-rich regions. Higher heat release rate and temperature. Shorter combustion duration. Higher engine thermal efficiency. Better oxidation of soot, CO, and HC emissions. | Longer premixing time. Better air–fuel mixing and more homogeneous mixture. Lower NOx and soot emissions. | Same as advancing single early injection timing. Second combustion stage promoted soot oxidation. | Lower combustion temperature. Lower NOx emissions. | Better air–fuel mixing and more homogeneous mixture for first combustion stage. Lower NOx and soot emissions. | Decreased wall-wetting fuel. Better air–fuel mixing and more homogeneous mixture. Lower soot, CO, and HC emissions. |

| Disadvantage | Longer spray penetration. More serious wall-wetting results in more soot, CO, and HC emissions. Higher combustion temperature results in higher NOx emissions. | Lower cylinder pressure and temperature during injection period. More serious wall-wetting. Shifting combustion event to earlier side results in more negative work. Deteriorated combustion efficiency and increased incomplete combustion products. Higher soot, CO, and HC emissions. | Same as advancing single early injection timing. | Increased diffusive combustion portion. Higher soot, CO, and HC emissions. | Advancing ignition results in more negative work. Shorter ignition delay and higher combustion temperature of second combustion stage results in higher NOx emission. More serious wall-wetting Higher soot, CO, and HC emissions. | Impingement between spray and piston bowl especially for second injection. Increasing fuel deposition on piston bowl results in higher soot, CO, and HC emissions. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, X.; Zheng, Z.; Zhang, H.; Wang, Y.; Yu, H. A Review of Early Injection Strategy in Premixed Combustion Engines. Appl. Sci. 2019, 9, 3737. https://doi.org/10.3390/app9183737

Liang X, Zheng Z, Zhang H, Wang Y, Yu H. A Review of Early Injection Strategy in Premixed Combustion Engines. Applied Sciences. 2019; 9(18):3737. https://doi.org/10.3390/app9183737

Chicago/Turabian StyleLiang, Xingyu, Zhiwei Zheng, Hongsheng Zhang, Yuesen Wang, and Hanzhengnan Yu. 2019. "A Review of Early Injection Strategy in Premixed Combustion Engines" Applied Sciences 9, no. 18: 3737. https://doi.org/10.3390/app9183737