Model Tests of Soil Reinforcement Inside the Bucket Foundation with Vacuum Electroosmosis Method

Abstract

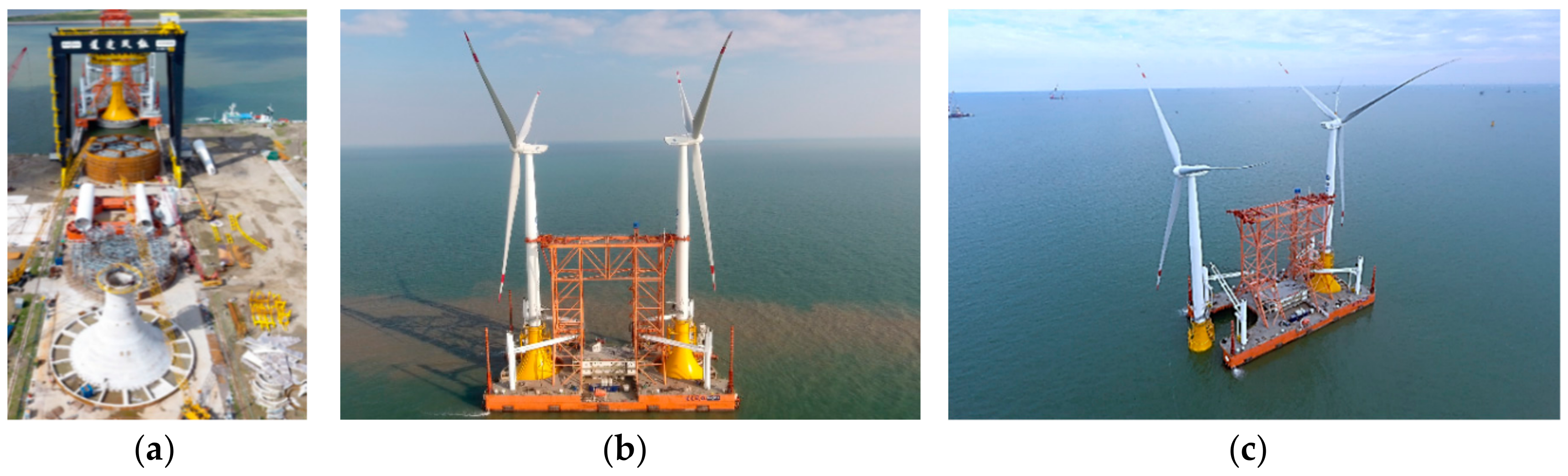

:1. Introduction

2. Model Tests

2.1. Soil Preparation and Parameters

2.2. Test Setup

2.3. Test Procedure

3. Results and Discussion

3.1. Effects of Foundation Settlement and Displacement during Soil Improvement

3.2. Effect of Pore Water Pressure during Soil Reinforcement

3.3. Effects of Shear Strength and Soil Moisture Content before and after Soil Reinforcement

4. Bucket Foundation Bearing Capacity before and after Soil Reinforcement

4.1. Influence of Soil Reinforcement on Bucket Foundation Vertical Bearing Capacity

4.2. Influence of Soil Reinforcement on Bucket Foundation Horizontal Bearing Capacity

4.3. Influence of Soil Reinforcement on Rotation Centers

5. Conclusions

- (1)

- The vacuum electroosmosis reinforcement significantly improves soil strength inside the bucket foundation when using the bucket wall as the anode, and undrained shear strength increases with increasing the voltage. The undrained shear strength of the soil applied the voltage of 20 V is 3–4.5 times that applied the voltage of 3.75 V in this study. Furthermore, a higher driving voltage can improve the uniformity of soil reinforcement in the vertical direction. The vertical bearing stiffness of the reinforced foundation during soil compression is 3.25 times the bearing stiffness of an unreinforced foundation.

- (2)

- Using the bucket wall as the cathode causes a percolation passage along the bucket wall to form, which decreases the reinforcement effect. The strengthening effect of the conversion electrode method was weaker than using the bucket wall as the anode. In addition, increased internal vertical drainage channel during the reinforcement can effectively improve vacuum pressure transmission inside the soil, thereby improving the reinforcement.

- (3)

- The horizontal and vertical bearing capacity of bucket foundation can be significantly increased through vacuum electroosmosis reinforcement. General shear failure of the bucket foundation occurs under vertical load. The vertical bearing stiffness of the reinforced foundation during soil compression is 3.25 times the bearing stiffness of an unreinforced foundation, and the vertical bearing capacity of the foundation increased by 2.1 times after soil reinforcement.

- (4)

- The bucket foundation undergoes forward destructive failure when subjected to horizontal load. In the elastic stage, the horizontal resistance of the reinforced foundation is 8.3 times that of the unreinforced foundation, and the horizontal bearing capacity increased by 2.9 times. Soil reinforcement improves the stiffness of the soil and the passive earth pressure; thus, the height of the rotation center is significantly reduced after soil reinforcement.

Author Contributions

Funding

Conflicts of Interest

References

- Byrne, B.W.; Houlsby, G.T. Foundations for offshore wind turbines. Phil. Trans. Roy. Soc. Lond. Math. Phys. Eng. 2003, 361, 2909–2930. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Zhou, L.; Lian, J.J.; Ding, H.Y. Behavior of monopile foundations for offshore wind farms in sand. J. Waterw. Port Coast. Ocean Eng. 2016, 142, 1–11. [Google Scholar] [CrossRef]

- Bienen, B.; Gaudin, C.; Cassidy, M.J.; Rausch, L.; Purwana, O.A.; Krisdani, H. Numerical modelling of a hybrid skirted foundation under combined loading. Comput. Geotech. 2012, 45, 127–139. [Google Scholar] [CrossRef]

- Fiumana, N.; Bienen, B.; Govoni, L.; Gourvenec, S.; Cassidy, M.J.; Gottardi, G. Combined loading capacity of skirted circular foundations in loose sand. Ocean Eng. 2019, 183, 57–72. [Google Scholar] [CrossRef]

- Kim, D.J.; Choo, Y.W.; Kim, J.H.; Kim, S.; Kim, D.S. Investigation of monotonic and cyclic behavior of tripod suction bucket foundations for offshore wind towers using centrifuge modeling. J. Geotech. Geoenviron. 2014, 140, 1–10. [Google Scholar] [CrossRef]

- Li, D.; Zhang, Y.; Feng, L.; Gao, Y. Capacity of modified suction caissons in marine sand under static horizontal loading. Ocean Eng. 2015, 102, 1–16. [Google Scholar] [CrossRef]

- Wang, X.; Yang, X.; Zeng, X. Centrifuge modeling of lateral bearing behavior of offshore wind turbine with suction bucket foundation in sand. Ocean Eng. 2017, 139, 140–151. [Google Scholar] [CrossRef]

- Zhang, P.; Guo, Y.; Liu, Y.; Ding, H. Experimental study on installation of hybrid bucket foundations for offshore wind turbines in silty clay. Ocean Eng. 2016, 114, 87–100. [Google Scholar] [CrossRef]

- First Suction Bucket Jacket Foundation Installed at EOWDC. Available online: https://www.geplus.co.uk /news/first-suction-bucket-jacket-foundation-installed-at-eowdc/10029529.article (accessed on 27 May 2019).

- Ding, H.; Liu, Y.; Zhang, P.; Le, C. Model tests on the bearing capacity of wide-shallow composite bucket foundations for offshore wind turbines in clay. Ocean Eng. 2015, 103, 114–122. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, Z.; Liu, Y.; Ding, H. Experimental study on installation of composite bucket foundations for offshore wind turbines in silty sand. J. Offshore Mech. Arct. Eng. 2016, 138, 1–11. [Google Scholar] [CrossRef]

- Zhang, P.; Han, Y.; Ding, H.; Zhang, S. Field experiments on wet tows of an integrated transportation and installation vessel with two bucket foundations for offshore wind turbines. Ocean Eng. 2015, 108, 769–777. [Google Scholar] [CrossRef]

- Senders, M. Suction Caissons in Sand as Tripod Foundations for Offshore Wind Turbines. Ph.D. Thesis, The University of Western Australia, Perth, Australia, 2008. [Google Scholar]

- Cotter, O. The Installation of Suction Caisson Foundations for Offshore Renewable Energy Structures. Ph.D. Thesis, University of Oxford, Oxford, UK, 2009. [Google Scholar]

- Zhang, P.; Ding, H.; Le, C. Installation and removal records of field trials for two mooring dolphin platforms with three suction caissons. J. Waterw. Port Coast. Ocean Eng. 2013, 139, 502–517. [Google Scholar] [CrossRef]

- Zhang, P.; Ding, H.; Le, C. Model tests on tilt adjustment techniques for a mooring dolphin platform with three suction caisson foundations in clay. Ocean Eng. 2013, 73, 96–105. [Google Scholar] [CrossRef]

- Ding, H.; Li, Z.; Lian, J.; Zhang, P.; Huang, X. Soil reinforcement experiment inside large-scale bucket foundation in muddy soil. Trans. Tianjin Univ. 2012, 18, 168–172. [Google Scholar] [CrossRef]

- Ding, H.; Liu, Y.; Zhang, P. Negative pressure consolidation of silt inside bucket foundation. Trans. Tianjin Univ. 2015, 21, 333–340. [Google Scholar] [CrossRef]

- Zhang, P.; Ding, H.; Zhai, S.; Xiong, K. Test on muddy soil reinforcement by negative pressure and electroosmosis inside cover-bearing-type bucket foundation for offshore wind turbines. Trans. Tianjin Univ. 2013, 19, 10–16. [Google Scholar] [CrossRef]

- Le, C.; Ding, H.; Zhang, Y. Experimental study of muddy soil inside bucket foundation using vacuum electro-osmotic reinforcement. J. Dalian Univ. Technol. 2013, 53, 97–101. [Google Scholar]

- Holtan, G.W. Vacuum stabilization of subsoil beneath runway extension at Philadelphia International Airport. In Proceedings of the 6th International Conference of Soil Mechanics & Foundation Engineering (ICSMFE), 8–15 September 1965; Volume 2, pp. 61–65. [Google Scholar]

- Chu, J.; Yan, S.W.; Yang, H. Soil improvement by the vacuum preloading method for an oil storage station. Geotechnique 2000, 50, 625–632. [Google Scholar] [CrossRef]

- Chu, J.; Guo, W.; Lam, K.P.; Yan, S. Use of clay slurry and waste for land reclamation. In Proceedings of the 18th Southeast Asian Geotechnical & Inaugural (AGSSEA) Conference, Singapore, 29–31 May 2013; pp. 755–760. [Google Scholar]

- Bergado, D.T.; Balasubramaniam, A.S.; Fannin, R.J.; Holtz, R.D. Prefabricated vertical drains (pvds) in soft Bangkok clay: A case study of the new Bangkok International Airport project. Can. Geotech. 2002, 39, 304–315. [Google Scholar] [CrossRef]

- Doyle, K.; Qiu, T. Piecewise-Linear modeling of combined vacuum and surcharge preloading at the second Bangkok International Airport. Geo Chic. 2016, 2016, 836–844. [Google Scholar]

- Gouw, T.L. Soil improvement by vacuum preloading for a power plant project in Vietnam. In Proceedings of the 18th Southeast Asian Geotechnical & Inaugural (AGSSEA) Conference, Singapore, 29–31 May 2013. [Google Scholar]

- Indraratna, B.; Rujikiatkamjorn, C.; Zhong, R. Recent developments of vacuum-assisted consolidation of soft estuarine clays. Geotech. Struct. Eng. Congr. 2016, 2016, 950–959. [Google Scholar]

- Rujikiatkamjorn, C.; Indraratna, B. Current state of the art in vacuum preloading for stabilizing soft soil. Geotech. Eng. J. 2013, 44, 77–87. [Google Scholar]

- Long, P.V.; Nguyen, L.V.; Bergado, D.T.; Balasubramaniam, A.S. Performance of PVD improved soft ground using vacuum consolidation methods with and without airtight membrane. Geotex. Geomembr. 2015, 43, 473–483. [Google Scholar] [CrossRef]

- Cassagrande, I.L. Electroosmosis in soils. Geotechnique 1949, 1, 159–177. [Google Scholar] [CrossRef]

- Cassagrande, I.L. Stabilization of soils by means of electroosmosis—State-of-the-art. J. Boston Soc. Civ. Eng. 1983, 69, 255–302. [Google Scholar]

- Esrig, M.I. Pore pressures, consolidation, and electrokinetics. J. Soil Mech. Found. Div. 1968, 94, 899–920. [Google Scholar]

- Burnotte, F.; Lefebvre, G.; Grondin, G. A case record of electroosmotic consolidation of soft clay with improved soil–electrode contact. Can. Geotech. J. 2004, 41, 1038–1053. [Google Scholar] [CrossRef]

- Chien, S.C.; Ou, C.Y.; Wang, M.K. Injection of saline solutions to improve the electro-osmotic pressure and consolidation of foundation soil. Appl. Clay Sci. 2009, 44, 218–224. [Google Scholar] [CrossRef]

- Cardoso, R.; Santos, J.N. Experimental study on the use of electroosmosis for accelerating the consolidation of clays under increasing vertical stress. In Proceedings of the 5th BIOT Conference on Poromechanics, Vienna, Austria, 10–12 July 2013; pp. 1515–1523. [Google Scholar]

- Wu, H.; Hu, L.; Qi, W.; Wen, Q. Analytical solution for electro-osmotic consolidation considering nonlinear variation of soil parameters. Int. J. Geomech. 2016, 17, 060160321–060160329. [Google Scholar]

| Soil Type | Moisture Content w (%) | Plastic Limit wp (%) | Liquidity Index IL (%) | Plasticity Index IP | Shear Strength Su (kPa) | Permeability Coefficient k (cm·s−1) | Unit Weight γ (kN·m−3) | Coefficient of Compressibility a (MPa−1) |

|---|---|---|---|---|---|---|---|---|

| Clay | 50 | 22 | 37 | 15 | 1~2 | 6.7 × 10−6 | 17.2 | 0.91 |

| Test Nos. | Vacuum Loading (kPa) | Voltage (V) | Reinforcement Time (h) | Bucket Wall Electrode | Copper Rod Electrode |

|---|---|---|---|---|---|

| T1 | 60 | 0 | 70 | —— | No |

| T2 | 60 | 0 | 70 | —— | Yes |

| T3 | 60 | 3.75 | 70 | Anode | Yes |

| T4 | 60 | 3.75 | 27 | Cathode | Yes |

| T5 | 60 | 3.75 | 70 | A ↔ C * | Yes |

| T6 | 60 | 20 | 70 | Anode | Yes |

| TV1 | —— | —— | —— | —— | —— |

| TH1 | —— | —— | —— | —— | —— |

| TV2 | 60 | 20 | 70 | Anode | Yes |

| TH2 | 60 | 20 | 70 | Anode | Yes |

| Test Nos | 2.5 h | 10 h | 50 h | |||

|---|---|---|---|---|---|---|

| Settlement (mm) | Water Discharge (kg) | Settlement (mm) | Water Discharge (kg) | Settlement (mm) | Water Discharge (kg) | |

| T1 | 2.942 | 0.388 | 6.941 | 0.782 | 15.659 | 1.786 |

| T2 | 5.471 | 0.454 | 10.506 | 0.922 | 17.522 | 2.054 |

| T3 | 8.614 | 0.796 | 14.133 | 1.339 | 26.189 * | 3.143 * |

| T4 | 13.599 | 0.924 | 18.105 | 1.410 | - | - |

| T5 | 9.150 | 0.471 | 13.247 | 0.947 | 21.813 | 2.158 |

| T6 | 11.864 | 0.706 | 20.740 | 1.411 | 31.412 | 5.646 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, H.; Ding, H.; Zhang, P.; Le, C. Model Tests of Soil Reinforcement Inside the Bucket Foundation with Vacuum Electroosmosis Method. Appl. Sci. 2019, 9, 3778. https://doi.org/10.3390/app9183778

Zhai H, Ding H, Zhang P, Le C. Model Tests of Soil Reinforcement Inside the Bucket Foundation with Vacuum Electroosmosis Method. Applied Sciences. 2019; 9(18):3778. https://doi.org/10.3390/app9183778

Chicago/Turabian StyleZhai, Hanbo, Hongyan Ding, Puyang Zhang, and Conghuan Le. 2019. "Model Tests of Soil Reinforcement Inside the Bucket Foundation with Vacuum Electroosmosis Method" Applied Sciences 9, no. 18: 3778. https://doi.org/10.3390/app9183778

APA StyleZhai, H., Ding, H., Zhang, P., & Le, C. (2019). Model Tests of Soil Reinforcement Inside the Bucket Foundation with Vacuum Electroosmosis Method. Applied Sciences, 9(18), 3778. https://doi.org/10.3390/app9183778