A G-Code Generator for Volumetric Models

Abstract

1. Introduction

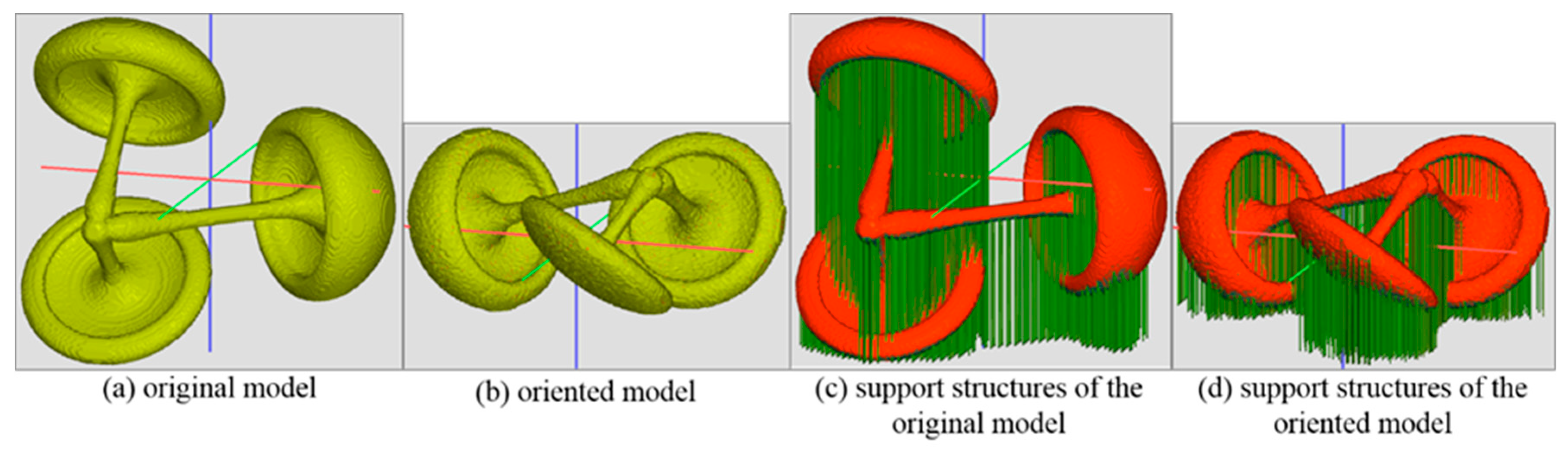

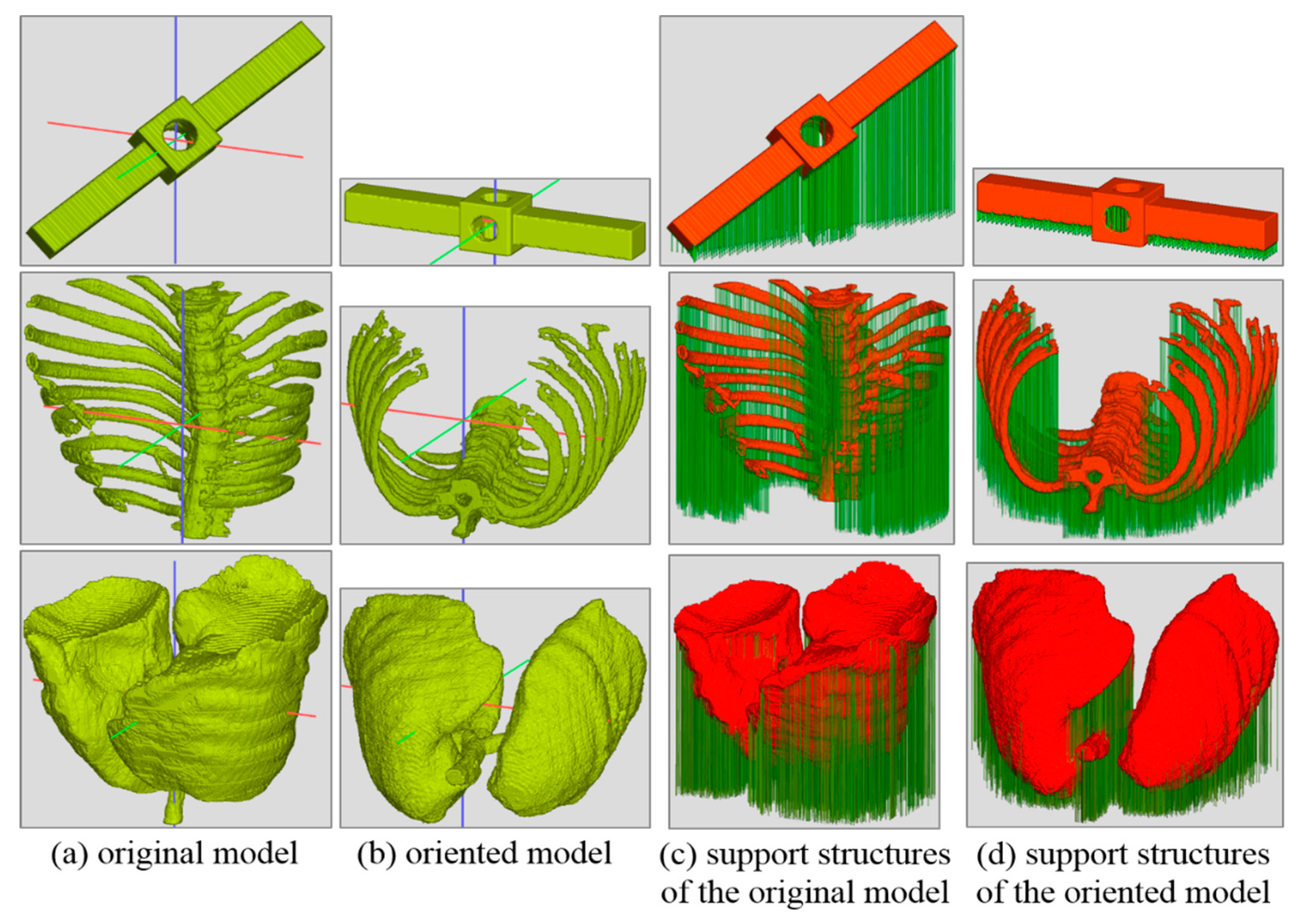

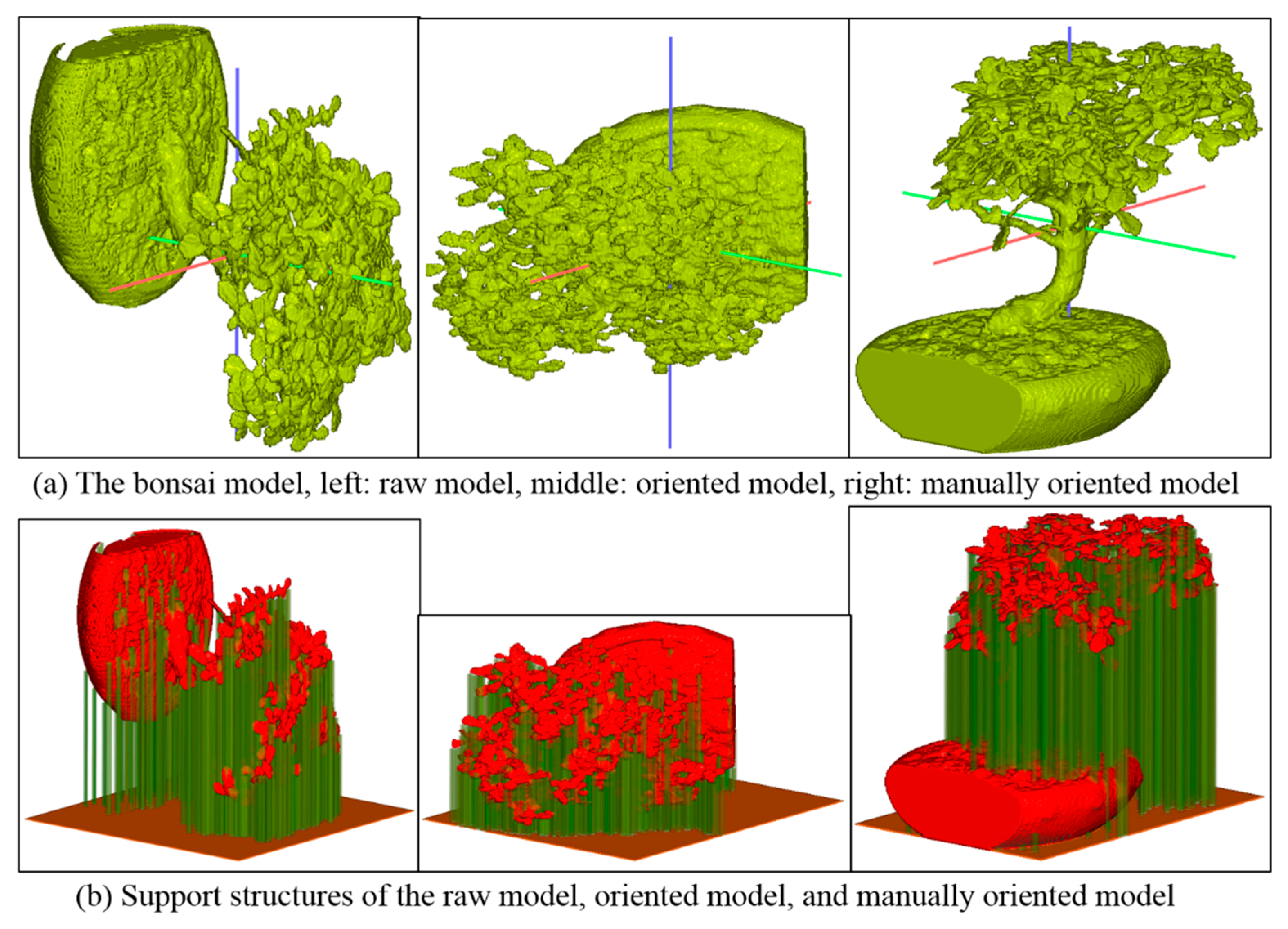

- We explore the mass distribution of the input model to calculate the printing direction. Hence, the stability of the input model is maximized, and the volume of the support structures is greatly reduced.

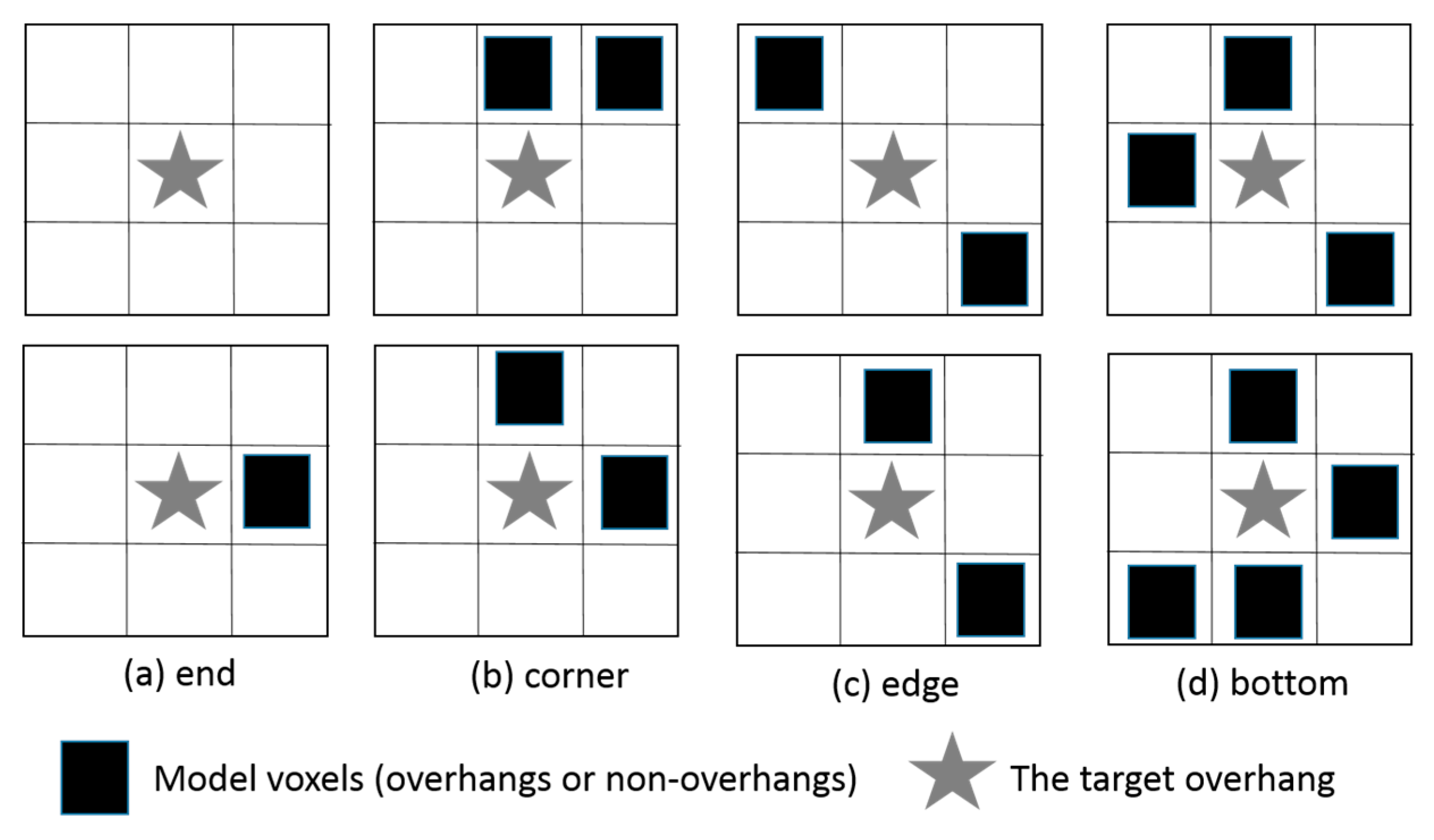

- We design patterns to classify overhangs to avoid generating too much support structures while necessary pillars are always created.

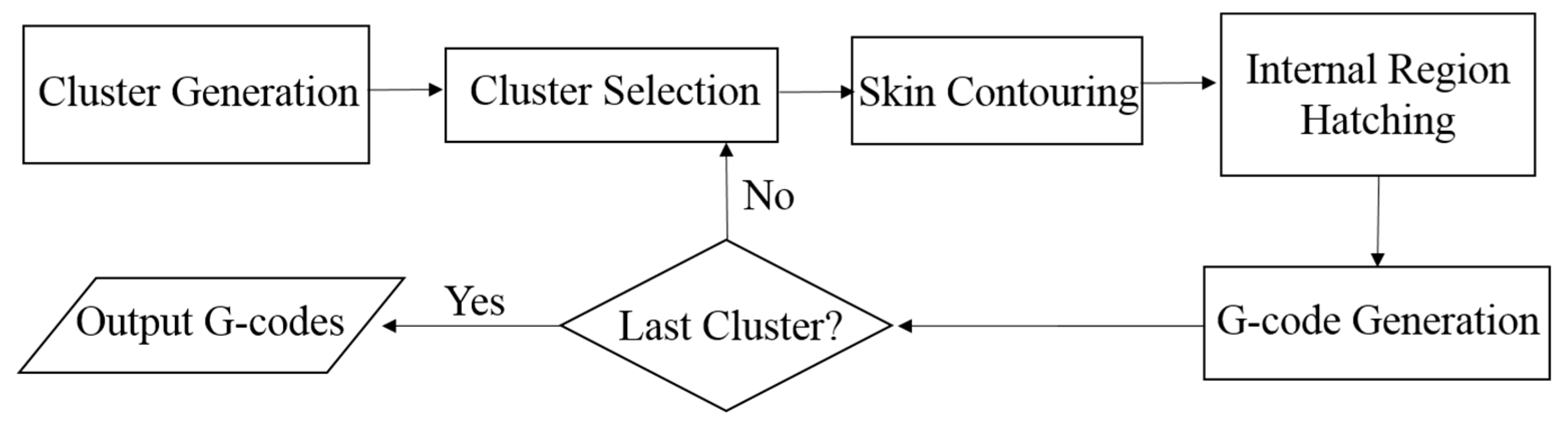

- Thirdly, we treat the input model as a 3D image such that the skin region can be produced by using image processing techniques. Contouring the skin region can be accomplished by using erosion and graph traversal algorithms.

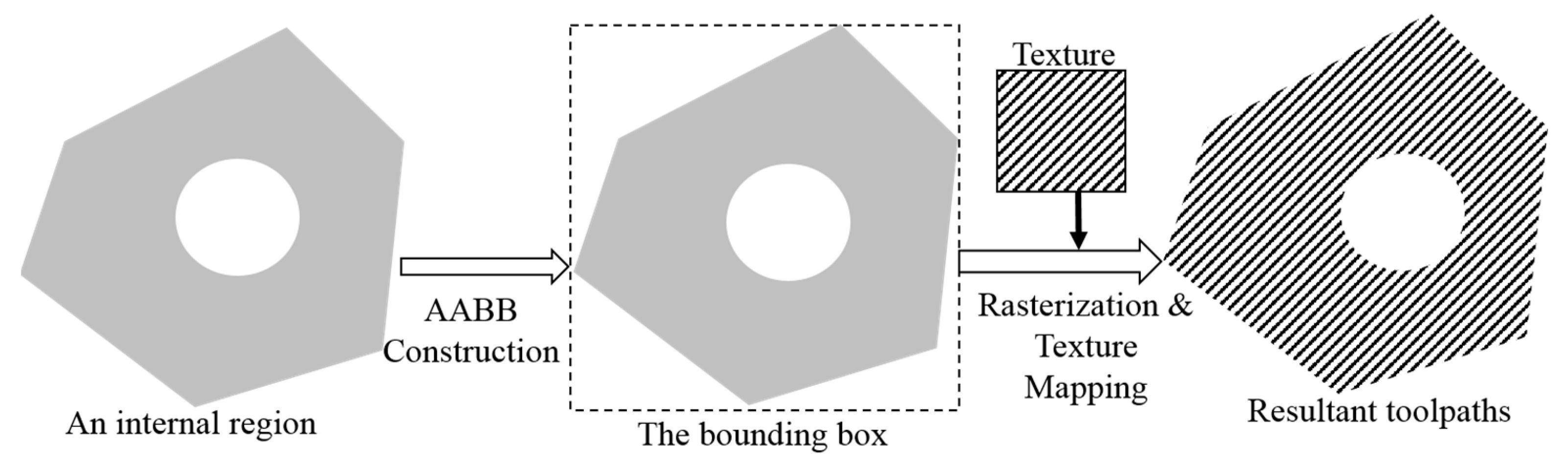

- Our slicer adopts a texture mapping method in filling the internal region. Users can use geometrical transformation operators to adjust the infilling pattern, and thus the hatching process becomes more flexible.

- As the input model is assembled by voxels, staircases prevail in the model surface. They may deteriorate the quality of the finished part. Our slicer employs an encoding algorithm to smooth the saw-tooth effect and to connect short toolpaths. Therefore, staircases are decreased in the printed part.

- When combined with a voxelization program, the proposed slicer is capable of processing polygonal models too. It can serve as an ordinary slicer for polygonal models in LM processes.

2. Related Work

3. Materials and Methods

3.1. System Overview and Preprocessing

3.2. Orientation

3.3. Support Structure Generation

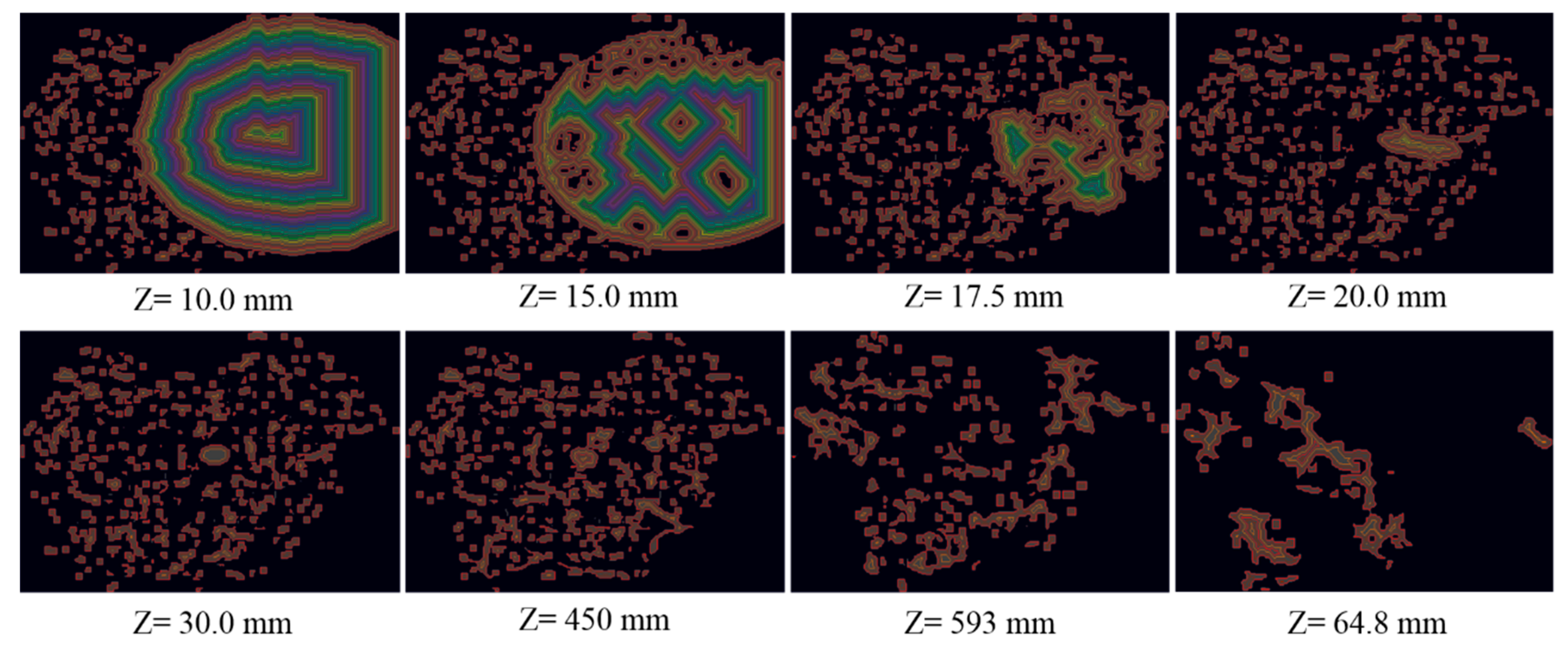

3.4. Skin Separation and Slice Generation

3.5. Skin Region Contouring

3.6. Internal Region Hatching

3.7. Toolpath and G-Code Generation

- Assume the toolpath is c(x,y);

- Create a straight line l(x,y) connecting the first and last pixels of c(x,y);

- Compute the maximum distance from each pixel of c(x,y) to l(x,y);

- If the maximum distance is greater than the threshold, break c(x,y) into c1(x,y) and c2(x,y) at the pixel where the maximum distance occurs (i.e., the splitting point). Then steps 2–4 are repeated upon c1(x,y) and c2(x,y) recursively;

- Otherwise, generate a G-code by using the coordinates of the first and last pixels of l(x,y).

4. Test Results

4.1. Orientation and Support Structure Generation

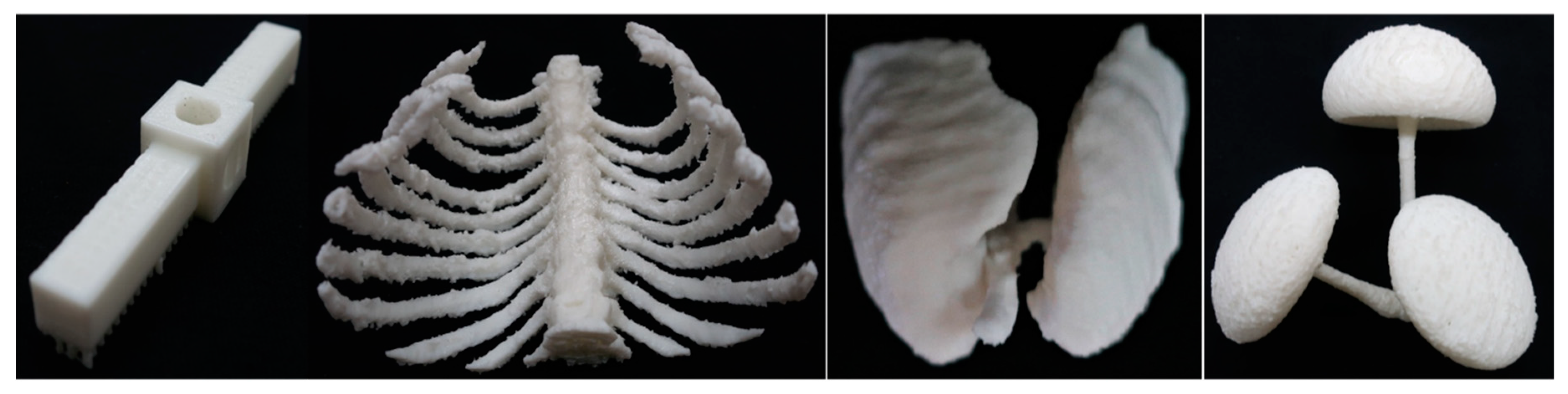

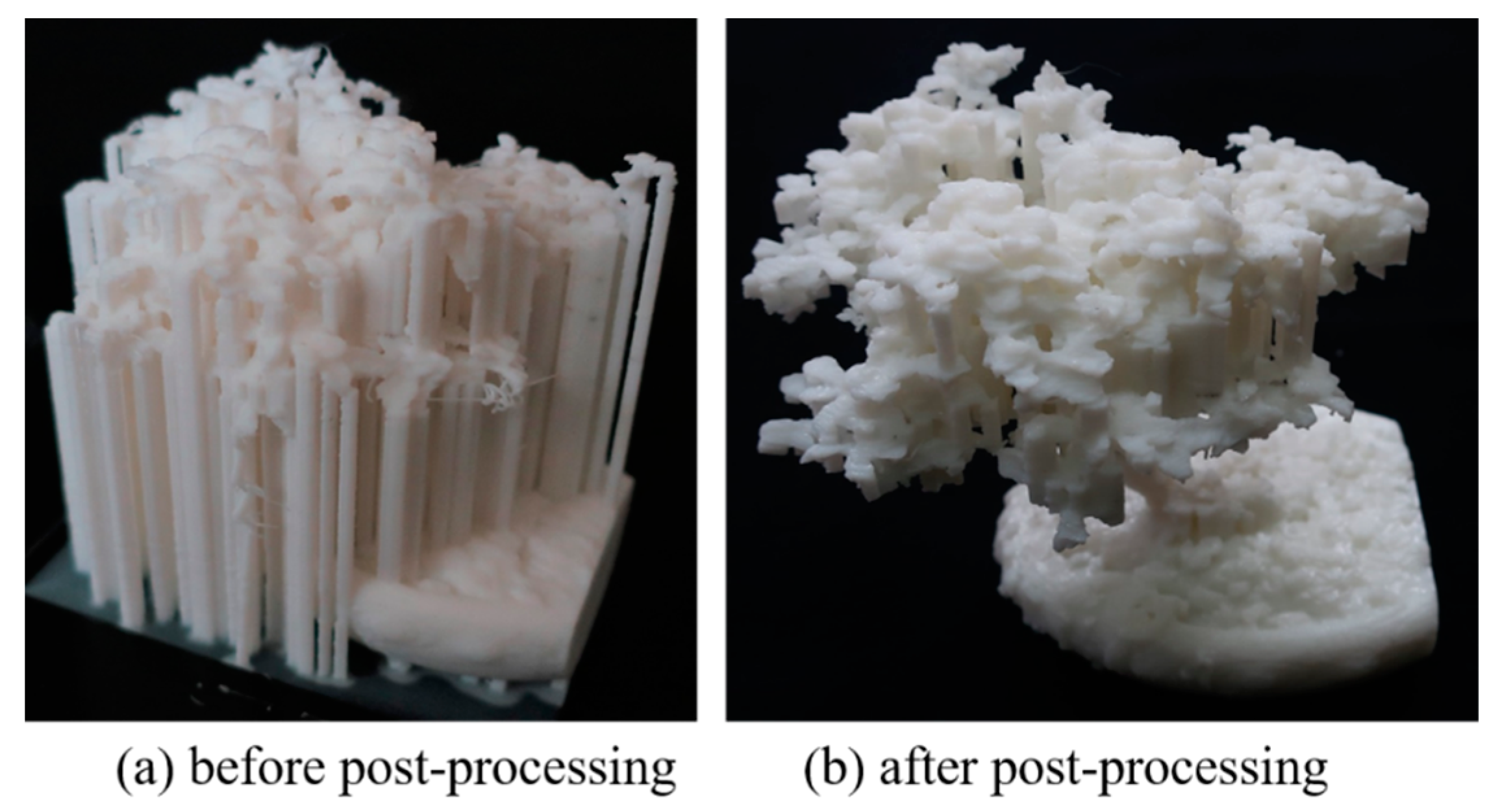

4.2. The Printed Objects

4.3. Visualization and User-Interferene

5. Discussion and Implementation Issues

- All the individual parts must fit the printable scope of the printer.

- The interfaces between the parts must be smooth enough for gluing the parts together.

- The interfaces must contain joints for connecting the parts.

- The sizes of the parts should be approximately equal.

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Pandey, P.M.; Reddy, N.V.; Dhande, S.G. Slicing procedures in layered manufacturing: A review. Rapid Prototyp. J. 2003, 9, 274–288. [Google Scholar] [CrossRef]

- Kamble, P.S.; Khoje, S.A.; Lele, J.A. Recent Developments in 3D Printing Technologies. In Proceedings of the IEEE International Conference on Intelligent Computing and Control Systems, Madurai, India, 14–15 June 2018; pp. 468–473. [Google Scholar]

- Mancas, M.; Gosselin, B.; Macq, B. Segmentation using a region-growing thresholding. Image Process. Algorithms Syst. IV 2005, 5672, 388–398. [Google Scholar]

- Chandru, V.; Manohar, S.; Prakash, C.E. Voxel-based modeling for layered manufacturing. IEEE Comput. Graph. Appl. 1995, 15, 42–47. [Google Scholar] [CrossRef]

- Wang, H.; Luo, F.; Jiang, J. 3D reconstruction of CT images based on isosurface construction. In Proceedings of the IEEE International Conference on Intelligent Computation Technology and Automation, Hunan, China, 20–22 October 2008. [Google Scholar]

- Ueng, S.K.; Huang, H.C.; Chou, C.S. Rapid prototyping of medical image data based on distance field concept. In Proceedings of the IEEE International Conference on Applied System Invention, Chiba, Japan, 13–17 April 2018. [Google Scholar]

- Brown, A.C.; de Beer, D. Development of a stereolithography (STL) slicing and G-code generation algorithm for an entry level 3-D printer. In Proceedings of the IEEE AFRICON, Pointe-Aux-Piments, Mauritius, 9–12 September 2013. [Google Scholar]

- Tata, K.; Fadel, G.; Bagchi, A.; Aziz, N. Efcient slicing for layered manufacturing. Rapid Prototyp. J. 1998, 4, 151–167. [Google Scholar] [CrossRef]

- Hiller, J.; Lipson, H. Design and analysis of digital materials for physical 3D voxel printing. Rapid Prototyp. J. 2009, 15, 137–149. [Google Scholar] [CrossRef]

- Tedia, S.; Williams, C.B. Manufacturability analysis tool for additive manufacturing using voxel-based geometric modeling. In Proceedings of the 27th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2016. [Google Scholar]

- Ueng, S.-K.; Chen, L.-G.; Jen, S.-Y. Voxel-based virtual manufacturing simulation for three-dimensional printing. Adv. Mech. Eng. 2018, 10. [Google Scholar] [CrossRef]

- Rengier, F.; Mehndiratta, A.; Von Tengg-Kobligk, H.; Zechmann, C.M.; Unterhinninghofen, R.; Kauczor, H.-U.; Giesel, F.L.; Tengg-Kobligk, H. 3D printing based on imaging data: Review of medical applications. Int. J. Comput. Assist. Radiol. Surg. 2010, 5, 335–341. [Google Scholar] [CrossRef] [PubMed]

- Kitsakis, K.; Alabey, P.; Kechagias, J.; Vaxevanidis, N. A Study of the dimensional accuracy obtained by low cost 3D printing for possible application in medicine. IOP Conf. Ser. Mater. Sci. Eng. 2016, 161, 012025. [Google Scholar] [CrossRef]

- Giannopoulos, A.A.; Chepelev, L.; Sheikh, A.; Wang, A.; Dang, W.; Akyuz, E.; Hong, C.; Wake, N.; Pietila, T.; Dydynski, P.B.; et al. 3D printed ventricular septal defect patch: A primer for the 2015 Radiological Society of North America (RSNA) hands-on course in 3D printing. 3D Print. Med. 2015, 1, 3. [Google Scholar] [CrossRef] [PubMed]

- Alabey, P.; Pappas, M.; Kechagias, J.; Maropoulos, S. Medical Rapid Prototyping and Manufacturing: Status and Outlook. In Proceedings of the ASME 10th Biennial Conference on Engineering Systems Design and Analysis, Istanbul, Turkey, 12–14 July 2010; pp. 739–745. [Google Scholar]

- Littley, S.; Voiculescu, I. Interpolation of 3D slice volume data for 3D printing. In Proceedings of the Medical Imaging 2017: Image-Guided Procedures, Robotic Interventions, and Modeling. International Society for Optics and Photonics, Orlando, FL, USA, 11–16 February 2017. [Google Scholar]

- Oropallo, W.; Piegl, L.A. Ten challenges in 3D printing. Eng. Comput. 2016, 32, 135–148. [Google Scholar] [CrossRef]

- Pandey, P.; Reddy, N.V.; Dhande, S. Part deposition orientation studies in layered manufacturing. J. Mater. Process. Technol. 2007, 185, 125–131. [Google Scholar] [CrossRef]

- Kechagias, J.; Anagnostopoulos, V.; Zervos, S.; Chryssolouris, G. Estimation of build times in rapid prototyping processes. In Proceedings of the 6th European Conference on Rapid Prototyping & Manufacturing, Nottingham, UK, 1–3 July 1997; pp. 137–148. [Google Scholar]

- Hibbeler, R.C. Engineering Mechanics Dynamics, 14th ed.; Pearson: London, UK, 2017; pp. 591–596. [Google Scholar]

- Golub, G.H.; Van Loan, C.F. Matrix Computations, 2nd ed.; The Johns Hopkins University Press: Baltimore, MD, USA, 1989; pp. 409–474. [Google Scholar]

- Kruth, J.-P.; Leu, M.; Nakagawa, T. Progress in Additive Manufacturing and Rapid Prototyping. CIRP Ann. 1998, 47, 525–540. [Google Scholar] [CrossRef]

- Vanek, J.; Galicia, J.A.G.; Benes, B. Clever Support: Efficient Support Structure Generation for Digital Fabrication. Comput. Graph. Forum 2014, 33, 117–125. [Google Scholar] [CrossRef]

- Ma, W.; He, P. An adaptive slicing and selective hatching strategy for layered manufacturing. J. Mater. Process. Technol. 1999, 89, 191–197. [Google Scholar] [CrossRef]

- Webb, A.; Kagadis, G.C. Introduction to Biomedical Imaging; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Horowitz, E.; Sahni, S.; Anderson-Freed, S. Fundamentals of Data Structures in C, 2nd ed.; Silicon Press: Summit, NJ, USA, 2007. [Google Scholar]

- Angel, E.; Shreiner, D. Interactive Computer Graphics—A Top-Down Approach, 6th ed.; Pearson Education Limited: London, UK, 2012. [Google Scholar]

| Data Sets | Height (in Voxels) | Volume of Support Structure | ||

|---|---|---|---|---|

| Original | Oriented | Original | Oriented | |

| Stick | 150 | 42 | 24,731 | 3632 |

| Bone | 324 | 267 | 499,806 | 405,050 |

| Lung | 316 | 249 | 239,469 | 202,182 |

| Mushroom | 207 | 116 | 67,388 | 50,390 |

| Bonsai | 256 | 169 | 1,311,485 | 1,026,258 |

| Parameters | Parameter Values |

|---|---|

| Layered manufacturing (LM) modality | Fuse deposition modelling (FDM) |

| Filament | Polylactic acid (PLA) |

| Nozzle diameter | 0.4 mm |

| Layer thickness | 0.1 mm |

| Nozzle temperature | 205 °C |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ueng, S.-K.; Huang, H.-K.; Huang, H.-C. A G-Code Generator for Volumetric Models. Appl. Sci. 2019, 9, 3868. https://doi.org/10.3390/app9183868

Ueng S-K, Huang H-K, Huang H-C. A G-Code Generator for Volumetric Models. Applied Sciences. 2019; 9(18):3868. https://doi.org/10.3390/app9183868

Chicago/Turabian StyleUeng, Shyh-Kuang, Hsuan-Kai Huang, and Hsin-Cheng Huang. 2019. "A G-Code Generator for Volumetric Models" Applied Sciences 9, no. 18: 3868. https://doi.org/10.3390/app9183868

APA StyleUeng, S.-K., Huang, H.-K., & Huang, H.-C. (2019). A G-Code Generator for Volumetric Models. Applied Sciences, 9(18), 3868. https://doi.org/10.3390/app9183868