Statistical Analysis and Data Envelopment Analysis to Improve the Efficiency of Manufacturing Process of Electrical Conductors

Abstract

:1. Introduction

1.1. Manufacturing 23-AWG Wire Process and Die-Nozzle

1.2. Data Envelopment Analysis

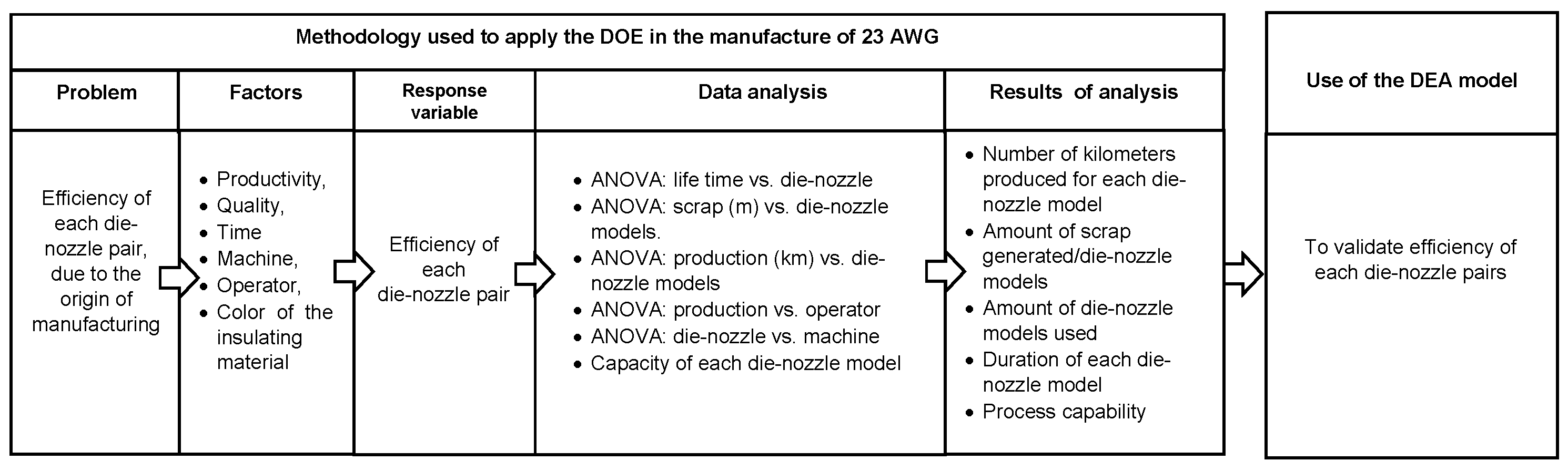

2. Methodology

- Line A where the colors black, red, brown and blue are processed.

- Line B with the colors orange, green, yellow and violet.

- Line C that processes the colors white, gray, beige and pink.

- 1DNL: die-nozzle of german manufacturing, diameter: 0.60 mm, material: DIN 420.

- 2DNV: die-nozzle of USA manufacturing, diameter: 0.58 mm, material: ASTM (AISI) 316Ti.

- 3DND: die-nozzle of mexican manufacturing, diameter: 0.59 mm, material: ASTM (AISI) 420.

- 4DNK: die-nozzle of australian manufacturing, diameter: 0.58 mm, material: BSI 316S.

- 5DNS: die-nozzle of japanese manufacturing, diameter: 0.60 mm, material: JIS (SUS 304).

DEA Model

Formulation of DEA Model for Die-Nozzle Pairs

- Productivity: meters produced with a specific die-nozzle pair/total meters by period (%).

- Machine: numbers of machine-hours used with a specific die-nozzle pair/total of machine hours/period (%).

- Time: time in hours using a specific die-nozzle pair/total of hours by period (%).

- Cpk: capability process index.

3. Results 23-AWG Production Process

3.1. Results of Volume vs. Scrap

3.2. Results of Data Analysis

3.3. Results of Analysis Machine, Production and Operator

3.4. Key Performance Indicator (KPI) Analysis

3.5. Determination of Process Capacity Indexes

3.6. Result of Analysis and Calculation of Sigma Level

3.7. Computational Results of the DEA Model

4. Discussion and Conclusions

4.1. Discussion

4.2. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ambühl, S.; Kramer, M.; Sørensen, J. Reliability-based structural optimization of wave energy converters. Energies 2014, 7, 8178–8200. [Google Scholar] [CrossRef]

- Mejia-Parra, D.; Sánchez, J.R.; Ruiz-Salguero, O.; Alonso, M.; Izaguirre, A.; Gil, E.; Palomar, J.; Posada, J. In-Line Dimensional Inspection of Warm-Die Forged Revolution Workpieces Using 3D Mesh Reconstruction. Appl. Sci. 2019, 9, 1069. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Hsu, Q.C. Surface roughness analysis in the hard milling of JIS SKD61 alloy steel. Appl. Sci. 2016, 6, 172. [Google Scholar] [CrossRef]

- Costa, A.; Cappadonna, F.; Fichera, S. A hybrid metaheuristic approach for minimizing the total flow time in a flow shop sequence dependent group scheduling problem. Algorithms 2014, 7, 376–396. [Google Scholar] [CrossRef]

- Ambühl, S.; Kramer, M.; Dalsgaard Sørensen, J. Structural reliability of plain bearings for wave energy converter applications. Energies 2016, 9, 118. [Google Scholar] [CrossRef]

- Arbogast, G.W. A case study: Statistical analysis in a production quality improvement project. J. Qual. Manag. 1997, 2, 267–277. [Google Scholar] [CrossRef]

- Coro, A.; Macareno, L.M.; Aguirrebeitia, J.; López de Lacalle, L.N. A Methodology to Evaluate the Reliability Impact of the Replacement of Welded Components by Additive Manufacturing Spare Parts. Metals 2019, 9, 932. [Google Scholar] [CrossRef]

- Umeda, S.; Nakano, M.; Mizuyama, H.; Hibino, N.; Kiritsis, D.; Von Cieminski, G. Advances in Production Management Systems: Innovative Production Management towards Sustainable Growth: IFIP WG 5.7 International Conference, APMS 2015; Springer: Berlin/Heidelberg, Germany, 2015; Volume 459, pp. 7–9. [Google Scholar]

- Boning, D.S.; Mozumder, P. DOE/Opt: A system for design of experiments, response surface modeling, and optimization using process and device simulation. IEEE Trans. Semicond. Manuf. 1994, 7, 233–244. [Google Scholar] [CrossRef]

- Weissman, S.A.; Anderson, N.G. Design of experiments (DoE) and process optimization. A review of recent publications. Org. Process Res. Dev. 2014, 19, 1605–1633. [Google Scholar] [CrossRef]

- Khan, M.A.; Husain, I.; Islam, M.R.; Klass, J.T. Design of experiments to address manufacturing tolerances and process variations influencing cogging torque and back EMF in the mass production of the permanent-magnet synchronous motors. IEEE Trans. Ind. Appl. 2013, 50, 346–355. [Google Scholar] [CrossRef]

- Rowlands, H.; Antony, J. Application of design of experiments to a spot welding process. Assem. Autom. 2003, 23, 273–279. [Google Scholar] [CrossRef]

- Andersen, P.; Petersen, N.C. A procedure for ranking efficient units in data envelopment analysis. Manag. Sci. 1993, 39, 1261–1264. [Google Scholar] [CrossRef]

- Khezrimotlagh, D.; Chen, Y. Decision Making and Performance Evaluation Using Data Envelopment Analysis; Springer: Berlin/Heidelberg, Germany, 2018; Volume 269, pp. 217–234. [Google Scholar]

- Koksal, G.; Batmaz, İ.; Testik, M.C. A review of data mining applications for quality improvement in manufacturing industry. Expert Syst. Appl. 2011, 38, 13448–13467. [Google Scholar] [CrossRef]

- Pendharkar, P.C. A data envelopment analysis-based approach for data preprocessing. IEEE Trans. Knowl. Data Eng. 2005, 17, 1379–1388. [Google Scholar] [CrossRef]

- Naghiha, S.; Maddahi, R.; Ebrahimnejad, A. An integrated AHP-DEA methodology for evaluation and ranking of production methods in industrial environments. Int. J. Ind. Syst. Eng. 2019, 31, 343–359. [Google Scholar] [CrossRef]

- Li, H.; He, H.; Shan, J.; Cai, J. Innovation efficiency of semiconductor industry in China: A new framework based on generalized three-stage DEA analysis. Socio-Econ. Plan. Sci. 2019, 66, 136–148. [Google Scholar] [CrossRef]

- Shin, J.; Kim, C.; Yang, H. Does Reduction of Material and Energy Consumption Affect to Innovation Efficiency? The Case of Manufacturing Industry in South Korea. Energies 2019, 12, 1178. [Google Scholar] [CrossRef]

- Emrouznejad, A.; Yang, G.L.; Amin, G.R. A novel inverse DEA model with application to allocate the CO2 emissions quota to different regions in Chinese manufacturing industries. J. Oper. Res. Soc. 2019, 70, 1079–1090. [Google Scholar] [CrossRef]

- Kamarudin, N.F.; Rani, R.M.; Halim, F.A. Improving the Food Manufacturing System by Using Simulation and DEA. In Proceedings of the Third International Conference on Computing, Mathematics and Statistics (iCMS2017); Springer: Singapore, 2019; pp. 555–561. [Google Scholar] [CrossRef]

- Liu, G.; Zhou, Z.; Qian, X.; Wu, X.; Pang, W. Multidisciplinary design optimization of a swash-plate axial piston pump. Appl. Sci. 2016, 6, 399. [Google Scholar] [CrossRef]

- Ammons, D.N.; Roenigk, D.J. Benchmarking and interorganizational learning in local government. J. Public Adm. Res. Theory 2014, 25, 309–335. [Google Scholar] [CrossRef]

- Thue, W.A. Electrical Power Cable Engineering; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- MINITAB. Computer Program Manual; Software; MINITAB: State College, PA, USA, 2014. [Google Scholar]

- Yang, Y.; Cao, J. Solving quadratic programming problems by delayed projection neural network. IEEE Trans. Neural Netw. 2006, 17, 1630–1634. [Google Scholar] [CrossRef] [PubMed]

- Tai, Y.T.; Pearn, W.L.; Kao, C.-M. Measuring the Manufacturing Yield for Processes with Multiple Manufacturing Lines. IEEE Trans. Semicond. Manuf. 2012, 25, 284–290. [Google Scholar] [CrossRef]

- Xiao, R.; Liu, B.; Shen, J.; Guo, N.; Yan, W.; Chen, Z. Comparisons of energy management methods for a parallel plug-in hybrid electric vehicle between the convex optimization and dynamic programming. Appl. Sci. 2018, 8, 218. [Google Scholar] [CrossRef]

- Zhu, J. Super-efficiency and DEA sensitivity analysis. Eur. J. Oper. Res. 2001, 129, 443–455. [Google Scholar] [CrossRef]

- Zhu, J. Quantitative models for performance evaluation and benchmarking: Data envelopment analysis with spreadsheets. Int. Ser. Oper. Res. Manag. Sci. 2014, 213, 175–205. [Google Scholar] [CrossRef]

- Andreadou, N.; Lucas, A.; Tarantola, S.; Poursanidis, I. Design of Experiments in the Methodology for Interoperability Testing: Evaluating AMI Message Exchange. Appl. Sci. 2019, 9, 1221. [Google Scholar] [CrossRef]

- Han, C.; Sin, I.; Kwon, H.; Park, S. The Role of the Process and Design Variables in Improving the Performance of Heat Exchanger Tube Expansion. Appl. Sci. 2018, 8, 756. [Google Scholar] [CrossRef]

- Lou, P.; Yuan, L.; Hu, J.; Yan, J.; Fu, J. A Comprehensive Assessment Approach to Evaluate the Trustworthiness of Manufacturing Services in Cloud Manufacturing Environment. IEEE Access 2018, 6, 30819–30828. [Google Scholar] [CrossRef]

- Yaste, R.E.; Budrow, R.B. Void-Free Electrical Conductor for Power Cables and Process for Making Same. US Patent 4,319,074, 1982. [Google Scholar]

- Realyvásquez-Vargas, A.; Arredondo-Soto, K.; Carrillo-Gutiérrez, T.; Ravelo, G. Applying the Plan-Do-Check-Act (PDCA) Cycle to Reduce the Defects in the Manufacturing Industry. A Case Study. Appl. Sci. 2018, 8, 2181. [Google Scholar] [CrossRef]

- Dyck, T.; Bund, A. Influence of the Bead Geometry and the Tin Layer on the Contact Resistance of Copper Conductors. IEEE Trans. Compon. Packag. Manuf. Technol. 2018, 8, 1863–1868. [Google Scholar] [CrossRef]

- Kilickap, E.; Yardimeden, A.; Çelik, Y.H. Mathematical Modelling and Optimization of Cutting Force, Tool Wear and Surface Roughness by Using Artificial Neural Network and Response Surface Methodology in Milling of Ti-6242S. Appl. Sci. 2017, 7, 1064. [Google Scholar] [CrossRef]

- Sorensen, D.G.H.; Brunoe, T.D.; Nielsen, K. A classification scheme for the processes of the production system. Procedia CIRP 2018, 72, 609–614. [Google Scholar] [CrossRef]

- Yang, C.M.; Lin, K.P.; Chen, K.S. Confidence Interval Based Fuzzy Evaluation Model for an Integrated-Circuit Packaging Molding Process. Appl. Sci. 2019, 9, 2623. [Google Scholar] [CrossRef]

- Godina, R.; Pimentel, C.; Silva, F.; Matias, J.C. Improvement of the Statistical Process Control Certainty in an Automotive Manufacturing Unit. Procedia Manuf. 2018, 17, 729–736. [Google Scholar] [CrossRef]

- Amasaka, K. Applying New JIT, a management technology strategy model at Toyota-Strategic QCD studies with affiliated and non-affiliated suppliers. Int. J. Prod. Econ. 2002, 80, 135–144. [Google Scholar] [CrossRef]

- Rau, H.; Wu, C.H.; Shiang, W.J.; Huang, P.T. A decision support system of statistical process control for printed circuit boards manufacturing. In Proceedings of the 2010 International Conference on Machine Learning and Cybernetics, Qingdao, China, 11–14 July 2010; Volume 5, pp. 2454–2458. [Google Scholar] [CrossRef]

- Coro, A.; Abasolo, M.; Aguirrebeitia, J.; de Lacalle, L.L. Inspection scheduling based on reliability updating of gas turbine welded structures. Adv. Mech. Eng. 2019, 11. [Google Scholar] [CrossRef] [Green Version]

| AWG | Diameter (mm) | Section mm | Number of Turns/cm | kg/km | Resistance (/km) | Capacity (A) |

|---|---|---|---|---|---|---|

| 23 | 0.58 | 0.26 | 16.0 | 2.29 | 56.4 | 0.73 |

| A. Average life duration in hours per month for each die-nozzle model | ||||||

| Model | January | February | March | April | May | June |

| 1DNL | 58 | 60 | 57 | 63 | 66 | 80 |

| 2DNV | 53 | 48 | 61 | 45 | 56 | 50 |

| 3DND | 62 | 64 | 56 | 73 | 76 | 69 |

| 4DNK | 39 | 46 | 44 | 51 | 37 | 43 |

| 5DNS | 49 | 36 | 54 | 40 | 47 | 38 |

| B. Average production per unit in meters per month | ||||||

| for each model of die and nozzle | ||||||

| Model | January | February | March | April | May | June |

| 1DNL | 719,368 | 699,942 | 769,032 | 783,215 | 694,142 | 793,167 |

| 2DNV | 879,598 | 759,975 | 869,432 | 779,216 | 865,774 | 894,302 |

| 3DND | 689,050 | 659,920 | 679,106 | 746,627 | 653,511 | 696,131 |

| 4DNK | 798,534 | 789,231 | 898,535 | 899,477 | 775,281 | 892,387 |

| 5DNS | 899,506 | 799,926 | 877,924 | 895,685 | 864,309 | 894,033 |

| C. Amount of average scrap per unit in meters, generated each month | ||||||

| for each model of die and nozzle, used in the extrusion process | ||||||

| Model | January | February | March | April | May | June |

| 1DNL | 7366 | 7620 | 7239 | 8001 | 8382 | 101,607 |

| 2DNV | 9129 | 8268 | 10,507 | 7751 | 9646 | 8613 |

| 3DND | 6402 | 6608 | 5782 | 7537 | 7847 | 7124 |

| 4DNK | 7493 | 8838 | 8454 | 9798 | 7109 | 8661 |

| 5DNS | 10,161 | 7466 | 11,198 | 8295 | 9747 | 7880 |

| Production Line A | ||||||

| January | February | March | April | May | June | |

| Production quantity in km | 44,889 | 40,454 | 46,736 | 45,650 | 43,647 | 47,956 |

| Number of die-nozzles/month | 151 | 145 | 152 | 143 | 159 | 138 |

| Production Line B | ||||||

| January | February | March | April | May | June | |

| Production quantity in km | 44,597 | 39,794 | 45,476 | 47,487 | 43,794 | 46,433 |

| Number of die-nozzles/month | 124 | 139 | 134 | 121 | 135 | 145 |

| Production Line C | ||||||

| January | February | March | April | May | June | |

| Production quantity in km | 42,753 | 38,738 | 45,488 | 43,876 | 41,376 | 44,289 |

| Number of die-nozzles/month | 108 | 74 | 111 | 112 | 113 | 88 |

| Inputs | Outputs | ||

|---|---|---|---|

| Machine | Time | Productivity | Cpk |

| Source | DF | SS | MS | F | P |

|---|---|---|---|---|---|

| Model | 4 | 2865.5 | 716.4 | 15.18 | 0.000 |

| Error | 25 | 1179.5 | 47.2 | ||

| Total | 29 | 4045.0 |

| Source | DF | SS | MS | F | P |

|---|---|---|---|---|---|

| Models | 4 | 19,119,336 | 4,779,834 | 4.11 | 0.011 |

| Error | 25 | 29,095,572 | 1,163,823 | ||

| Total | 29 | 48,214,907 |

| A. Tukey Test for Duration | |||

| Model | N | Mean | Grouping |

| 3DBD | 6 | 66.67 | A |

| 1DBL | 6 | 64 | A |

| 2DBV | 6 | 52.17 | B |

| 5DBS | 6 | 44 | B |

| 4DBK | 6 | 43.33 | B |

| B. Tukey Test Production | |||

| Model | N | Production | Grouping |

| 5DNS | 6 | 871,897.2 | A |

| 3DND | 6 | 860,724.2 | A |

| 4DNK | 6 | 842,240.8 | A |

| 2DNV | 6 | 841,382.8 | A |

| 1DNL | 6 | 743,144.3 | B |

| C. Tukey Test for Scrap | |||

| N | Scrap | Grouping | |

| 5DNS | 6 | 9,124,500 | A |

| 2DNV | 6 | 8,985,667 | A |

| 4DNK | 6 | 8,392,167 | AB |

| 1DNL | 6 | 7,869,167 | AB |

| 3DND | 6 | 6,883,333 | B |

| Source | DF | SS | MS | F | P |

|---|---|---|---|---|---|

| Model | 4 | 9.88E10 | 2.47E10 | 28.66 | 0 |

| Error | 25 | 2.15E10 | 8.62E8 | ||

| Total | 29 | 1.20E11 |

| Parameters through ANOVA. | ||||

|---|---|---|---|---|

| Variable | (table value) | |||

| Machine | 7.39 | 3.10 | 0.002 | 0.05 |

| Operator | 129.74 | 3.10 | 0.000 | 0.05 |

| Source | DF | SS | MS | F | P |

|---|---|---|---|---|---|

| Operator | 3 | 22821.2 | 7607.1 | 129.74 | 0 |

| Error | 20 | 1172.6 | 58.6 | ||

| Total | 23 | 23993.8 |

| Model | Performance Indicators | ||||||

|---|---|---|---|---|---|---|---|

| Productivity | Quality | Machine | Operator | Time | Color | Results | |

| 3DND | 0.20 | 0.13 | 0.09 | 0.09 | 0.27 | 0.04 | 81.2% |

| 1DNL | 0.12 | 0.08 | 0.10 | 0.10 | 0.13 | 0.05 | 58.7% |

| 2DNV | 0.22 | 0.13 | 0.08 | 0.08 | 0.26 | 0.04 | 80.6% |

| 5DNS | 0.12 | 0.08 | 0.10 | 0.10 | 0.14 | 0.05 | 59.7% |

| 4DNK | 0.10 | 0.07 | 0.10 | 0.10 | 0.13 | 0.05 | 55.1% |

| Model | Parameters of Process Capability | |||||

|---|---|---|---|---|---|---|

| Standard Deviation | Cp | Cpk | PPM | PPM General | ||

| 1DNL | 0.025 | 0.80 | 0.73 | 18,931 | 18,484 | 0.431 |

| 2DNV | 0.023 | 0.86 | 0.62 | 32,184 | 16,086 | 0.086 |

| 3DND | 0.001 | 1.59 | 1.26 | 17,540 | 4726 | 0.255 |

| 4DNK | 0.037 | 0.55 | 0.52 | 101,853 | 69,866 | 0.736 |

| 5DNS | 0.025 | 0.78 | 0.55 | 50,796 | 103,305 | 0.625 |

| Models | Level Z | PPM | PPM General | Cpk |

|---|---|---|---|---|

| 1DNL | 2.08 | 18,931 | 18,484 | 0.73 |

| 2DNV | 1.85 | 32,184 | 16,086 | 0.62 |

| 3DND | 3.79 | 17,540 | 4726 | 1.26 |

| 4DNK | 1.27 | 101,853 | 69,866 | 0.52 |

| 5DNS | 1.64 | 50,796.14 | 103,304.56 | 0.55 |

| Inputs | Outputs | |||

|---|---|---|---|---|

| Models | Machine | Time (s) | Productivity | Cpk |

| 3DND | 0.09 | 0.27 | 0.20 | 1.26 |

| 1DNL | 0.01 | 0.13 | 0.12 | 0.73 |

| 2DNV | 0.08 | 0.26 | 0.22 | 0.62 |

| 5DNS | 0.1 | 0.14 | 0.12 | 0.55 |

| 4DNK | 0.1 | 0.13 | 0.10 | 0.52 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zamora-Antuñano, M.A.; Cruz-Salinas, J.; Rodríguez-Reséndiz, J.; González-Gutiérrez, C.A.; Méndez-Lozano, N.; Paredes-García, W.J.; Altamirano-Corro, J.A.; Gaytán-Díaz, J.A. Statistical Analysis and Data Envelopment Analysis to Improve the Efficiency of Manufacturing Process of Electrical Conductors. Appl. Sci. 2019, 9, 3965. https://doi.org/10.3390/app9193965

Zamora-Antuñano MA, Cruz-Salinas J, Rodríguez-Reséndiz J, González-Gutiérrez CA, Méndez-Lozano N, Paredes-García WJ, Altamirano-Corro JA, Gaytán-Díaz JA. Statistical Analysis and Data Envelopment Analysis to Improve the Efficiency of Manufacturing Process of Electrical Conductors. Applied Sciences. 2019; 9(19):3965. https://doi.org/10.3390/app9193965

Chicago/Turabian StyleZamora-Antuñano, Marco Antonio, Jorge Cruz-Salinas, Juvenal Rodríguez-Reséndiz, Carlos Alberto González-Gutiérrez, Néstor Méndez-Lozano, Wilfrido Jacobo Paredes-García, José Antonio Altamirano-Corro, and José Alfredo Gaytán-Díaz. 2019. "Statistical Analysis and Data Envelopment Analysis to Improve the Efficiency of Manufacturing Process of Electrical Conductors" Applied Sciences 9, no. 19: 3965. https://doi.org/10.3390/app9193965

APA StyleZamora-Antuñano, M. A., Cruz-Salinas, J., Rodríguez-Reséndiz, J., González-Gutiérrez, C. A., Méndez-Lozano, N., Paredes-García, W. J., Altamirano-Corro, J. A., & Gaytán-Díaz, J. A. (2019). Statistical Analysis and Data Envelopment Analysis to Improve the Efficiency of Manufacturing Process of Electrical Conductors. Applied Sciences, 9(19), 3965. https://doi.org/10.3390/app9193965