PTG-HEFA Hybrid Refinery as Example of a SynBioPTx Concept—Results of a Feasibility Analysis

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

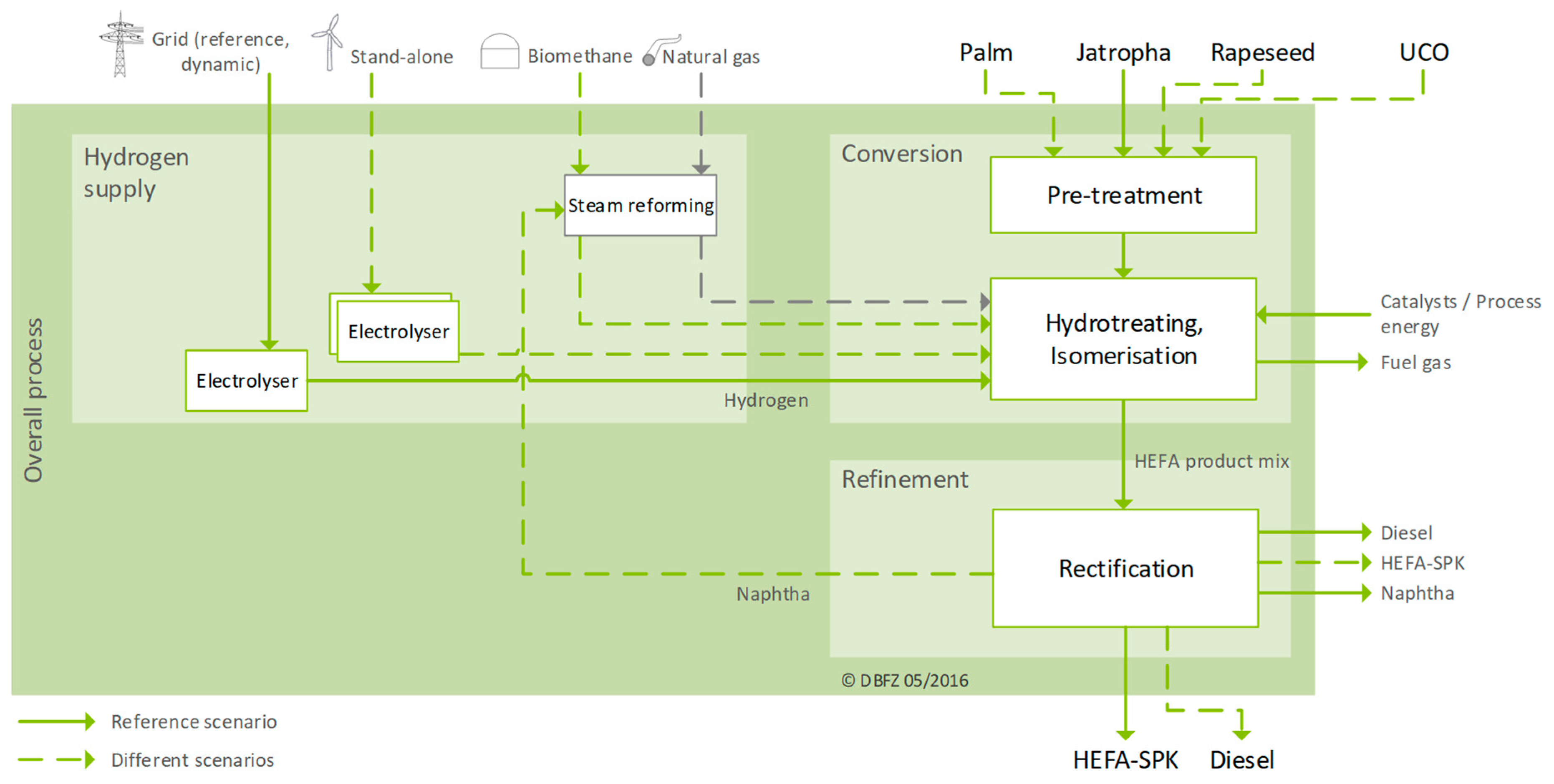

2.1. Scenarios for PTG-HEFA Plant Setup

- (a)

- Electricity supply: constantly from the electricity grid with the specific electricity mix based on different primary energy sources, in a dynamic mode with based best cost-effectivity (in case of cheap spot market prices) whilst using electricity from the grid or as stand-alone power system based on fluctuating renewable energies (here, onshore wind park and solar photovoltaic park);

- (b)

- Hydrogen supply: based on alkaline electrolysers with different storage systems depending on the electricity supply and—more conventionally—based on steam reforming from either natural gas, biomethane, or internal use of by-products of the HEFA plant such as naphtha and fuel gases (as is done today in most of the HVO/HEFA plants).

- (c)

- Feedstocks: as alternatives to jatropha oil; rapeseed oil with regard to the domestic option of, palm oil with regard to cost and specific hydrogen demand, and used cooking oils (UCO) with regard to lower GHG emissions (according the current regulations in the EU) .

- (d)

- Main product: referring to the different operational modes of a HEFA plant with regard to products, compared to the HEFA-SPK case, the alternative operation mode is focused on producing diesel.

2.2. Technical Assessment

2.2.1. PTG part

2.2.2. HEFA part

2.3. Environmental Assessment

2.4. Economic Assessment

- (a)

- Capital-linked costs: single and total investments for the different plant designs for the PTG-HEFA hybrid refinery;

- (b)

- Consumption-linked costs: feedstocks, electricity, and auxiliaries (e.g., water, catalysts, natural gas and biomethane for steam reforming);

- (c)

- Operation-linked costs: (plant staff, maintenance);

- (d)

- Other costs: administration, insurance.

2.5. Excursion on Favorable Regions

3. Results and Discussion

3.1. Technical Assessment

3.2. Environmental Assessment

3.3. Economic Assessment

3.4. Excursion on Favorable Regions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| a | annum/year |

| aireg | Aviation Initiative for Renewable Energy in Germany e.V. |

| app. | approximately |

| ASTM | American Society for Testing and Materials |

| CAP | Climate action plan 2050 for Germany |

| csp | concentrated solar power |

| EU | European Union |

| GHG | greenhouse gas emissions |

| GWP | global warming potential |

| HEFA | hydrotreated esters and fatty acids |

| IATA | International Air Transport Association |

| kt | kilo tons (1000 t) |

| LCA | Life Cycle Assessment |

| PJ | Petajoule |

| PTG | power-to-gas (here: based on electrolysis to hydrogen) |

| PTL | power-to-liquid |

| pv | photovoltaics |

| RED | Renewable Energy Directive |

| SAF | sustainable aviation fuels |

| SPK | synthetic paraffinic kerosine |

| SynBioPTx | synergies (syn) of biomass-based (bio) and electricity-based (PTx) fuels and product processes |

| UCO | used cooking oil |

| VDI | Verein Deutscher Ingenieure (Association of German Engineers’) |

References

- EASA. European Aviation Environmental Report 2019; EASA, EEA, Eurocontrol: Brussels, Belgium, 2019. [Google Scholar] [CrossRef]

- Le Feuvre, P. Commentary: Are Aviation Biofuels Ready for Take Off? Available online: https://www.iea.org/newsroom/news/2019/march/are-aviation-biofuels-ready-for-take-off.html (accessed on 22 March 2019).

- Dietrich, S.; Oehmichen, K.; Zech, K.; Müller-Langer, F.; Majer, S.; Kalcher, J.; Naumann, K.; Wirkner, R.; Pujan, R.; Braune, M.; et al. Studie im Rahmen der Mobilitäts-und Kraftstoffstrategie der Bundesregierung (MKS) im Auftrag für das Bundesministerium für Verkehr und digitale Infrastruktur (BMVI). In Machbarkeitsanalyse für eine PTG-HEFA Hybridraffinerie in Deutschland; Deutsches Biomasseforschungszentrum gemeinnützige GmbH (DBFZ): Leipzig, Germany, 2017. [Google Scholar]

- Naumann, K.; Schröder, J.; Oehmichen, K.; Etzold, H.; Müller-Langer, F.; Remmele, E.; Thuneke, K.; Raksha, T.; Schmidt, P. Monitoring Biokraftstoffsektor, 4th ed.; Deutsches Biomasseforschungszentrum Gemeinnützige GmbH (DBFZ): Leipzig, Germany, 2019; ISBN 978-3-946629-36-8. [Google Scholar]

- Müller-Langer, F.; Dietrich, R.U.; Krol, R.V.D.; Arnold, K.; Harnisch, F.; Erneuerbare Kraftstoffe für Mobilität und Industrie. FVEE Themen 2016—Netze und Speicher für die Energiewende—Erneuerbare Kraftstoffe. 2016. Available online: http://www.fvee.de/fileadmin/publikationen/Themenhefte/th2016/th2016_07_05.pdf (accessed on 13 September 2019).

- Müller-Langer, F.; Etzold, H.; Naumann, K. BTx and PTx as competitors or companions: A systemic assessment. In Proceedings of the 8th ETIP Stakeholder Plenary Meeting, Brussels, Belgium, 11–12 April 2018; Available online: http://www.etipbioenergy.eu/images/SPM8_Presentations/ETIP_Mueller-Langer_2018-04_new.pdf (accessed on 13 September 2019).

- Schmidt, P.; Weindorf, W.; Roth, A.; Batteiger, V.; Riegel, F. Power-to-Liquids—Potentials and Perspectives for the Future Supply of Renewable Aviation Fuel; German Environment Agency: Dessau-Roßlau, Germany, 2016; Available online: https://www.umweltbundesamt.de/sites/default/files/medien/377/publikationen/161005_uba_hintergrund_ptl_barrierrefrei.pdf (accessed on 13 September 2019).

- Schmidt, P.; Weindorf, W.; Zittel, W. Renewables in Transport 2050—Empowering a Sustainable Mobility Future with Zero Emission Fuels from Renewable Electricity—Europe and Germany. In Report 1086–2016; Forschungsvereinigung Verbrennungskraftmaschinen e.V.: Frankfurt am Main, Germany, 2015; Available online: http://www.lbst.de/news/2016_docs/FVV_H1086_Renewables-in-Transport-2050-Kraftstoffstudie_II.pdf (accessed on 13 September 2019).

- Schmied, M.; Wüthrich, P.; Zah, R.; Althaus, H.J.; Friedl, C. Postfossile Energieversorgungsoptionen für einen treibhausgasneutralen Verkehr im Jahr 2050: Eine verkehrsträgerübergreifende Bewertung. In TEXTE 30/2015—Umweltforschungsplan des Bundesministeriums für Umwelt, Naturschutz, Bau und Reaktorsicherheit; German Environment Agency: Dessau-Roßlau, Germany, 2015; Available online: https://www.umweltbundesamt.de/sites/default/files/medien/378/publikationen/texte_30_2015_postfossile_energieversorgungsoptionen.pdf (accessed on 13 September 2019).

- Albrecht, F.G.; Dietrich, R.-U. Alternative fuels from Biomass and Power (PBtL) A case study on process options, technical potentials, fuel costs and ecological performance. In Proceedings of the European Biomass Conference, Stockholm, Sweden, 12–15 July 2017; Available online: https://elib.dlr.de/115071/ (accessed on 13 September 2019).

- Müller-Langer, F.; Vogel, A.; Brauner, S. Renwew—Renewable fuels for advanced powertrains—Deliverable 5.3.8. Overall Costs; Institute for Energy and Environment: Leipzig, Germany, 2008; Available online: http://www.renew-fuel.com/download.php?dl=del_sp5_wp3_5-3-8_08-02-27_iee-draft.pdf&kat=18 (accessed on 13 September 2019).

- Zech, K.M.; Dietrich, S.; Reichmuth, M.; Weindorf, W.; Müller-Langer, F. Techno-economic assessment of a renewable bio-jet-fuel production using power-to-gas. Appl. Energy 2018, 231, 997–1006. [Google Scholar] [CrossRef]

- Jauslin Stebler, A.G. Erdgas-Röhrenspeicher Urdorf. Available online: https://www.jauslinstebler.ch/VGA/VEM/projekte/erdgas-roehrenspeicher-urdorf.html (accessed on 23 July 2018).

- Doradei, S.; Crotogino, F.; Acht, A.; Horvarth, P.-L. Speicherung von Wasserstoff in Salzkavernen. In Integration von Wind-Wasserstoff-Systemen in das Energiesystem; Nationales Innovationsprogramm Wasserstoff-und Brennstoffzellentechnologie (NIP): Berlin, Germany, 2013. [Google Scholar]

- Gröngröft, A.; Meisel, K.; Hauschild, S.; Grasemann, E.; Peetz, D.; Mayer, K.; Teil, I.I. Wissenschaftliche Untersuchung von Wegen der Biokerosinproduktion aus verschiedenen Biomassetypen. In Abschlussbericht zu dem Vorhaben Projekt BurnFAIR; Zschocke, A., Ed.; Deutsche Lufthansa: Frankfurt am Main, Germany, 2014. [Google Scholar]

- Liu, Y.; Sotelo-Boyás, R.; Murata, K.; Minowa, T.; Sakanishi, K. Hydrotreatment of vegetable oils to produce bio-hydrogenated diesel and liquefied petroleum gas fuel over catalysts containing sulfided Ni–Mo and solid acids. Energy Fuels 2011, 25, 4675–4685. [Google Scholar] [CrossRef]

- Dubois, V.; Breton, S.; Linder, M.; Fanni, J.; Parmentier, M. Fatty acid profiles of 80 vegetable oils with regard to their nutritional potential. Eur. J. Lipid Sci. Technol. 2007, 109, 710–732. [Google Scholar] [CrossRef]

- Abidin, S.Z.; Patel, D.; Saha, B. Quantitative analysis of fatty acids composition in the used cooking oil (UCO) by gas chromatography−mass spectrometry (GC-MS). Can. J. Chem. Eng. 2013, 91, 1896–1903. [Google Scholar] [CrossRef]

- Majer, S.; Hauschild, S.; Müller-Langer, F. Kurzstudie im Auftrag des Verbandes der Deutschen Biokraftstoffindustrie e.V., der Union zur Förderung von Öl-und Proteinpflanzen e.V. und des OVID Verband der ölsaatenverarbeitenden Industrie in Deutschland e.V. In Energie-und Treibhausgasbilanz von HVO-Kraftstoff. Eine vergleichende Analyse; Deutsches Biomasseforschungszentrum gemeinnützige GmbH (DBFZ): Leipzig, Germany, 2014. [Google Scholar]

- Endisch, M.; Balfanz, U.; Olschar, M.; Kuchling, T. Vegetable Oil Hydrotreating for Production of High Quality Diesel Components. In Proceedings of the DGMK Future Feedstocks for Fuels and Chemicals Conference, Berlin, Germany, 29 September–1 October 2008. [Google Scholar]

- Nikander, S. Greenhouse Gas and Energy Intensity of Product Chain: Case Transport Bio-fuel. Master’s Thesis, Helsinki University of Technology, Helsinki, Finland, 9 May 2008. [Google Scholar]

- Smejkal, Q.; Smejkalová, L.; Kubička, D. Thermodynamic balance in reaction system of total vegetable oil hydrogenation. Chem. Eng. J. 2008. [Google Scholar] [CrossRef]

- Jęczmionek, Ł.; Porzycka-Semczuk, K. Hydrodeoxygenation, decarboxylation and decarbonylation reactions while co-processing vegetable oils over NiMo hydrotreatment catalyst. Part II. Thermal effects—Experimental results. Fuel 2014, 128, 296–301. [Google Scholar] [CrossRef]

- Hiller, H.; Reimert, R.; Stönner, H.-M. Gas Production. 1. Introduction. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH: Weinheim, Germany, 2014. [Google Scholar] [CrossRef]

- Kinder, J.D.; Rahmes, T. Evaluation of Bio-Derived Synthetic Paraffinic Kerosene (Bio-SPK). 2009. Available online: http://www.safug.org/assets/docs/biofuel-testing-summary.pdf (accessed on 15 August 2019).

- Myllyoja, J.; Aalto, P.; Savolainen, P.; Purola, V.-M.; Alopaeus, V.; Grönqvist, J. Process for the Manufacture of Diesel Range Hydrocarbons. U.S. Patent US8022258 B2, 20 September 2011. [Google Scholar]

- German Institute for Standardisation. Environmental Management—Life Cycle Assessment—Principles and Framework; DIN ISO 14040: Geneva, Switzerland, 2006. [Google Scholar]

- German Institute for Standardisation. Environmental Management—Life Cycle Assessment—Requirements and Guidelines; DIN ISO 14044: Geneva, Switzerland, 2006. [Google Scholar]

- European Commission. Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the promotion of the use of energy from renewable sources and amending and subsequently repealing Directives 2001/77/EC and 2003/30/EC. Off. J. Eur. Union 2009. Available online: http://www.nezeh.eu/assets/media/fckuploads/file/Legislation/RED_23April2009.pdf (accessed on 27 September 2019).

- Ecoinvent Center. Ecoinvent Version 3 Life Cycle Inventory Database; Swiss Center for Life Cycle Inventories: St. Gallen, Switzerland, 2016; database. [Google Scholar]

- IINAS GmbH. GEMIS—Global Emissions Model for integrated Systems V4.94. Version: International Institute for Sustainability Analysis and Strategy GmbH. Database. Available online: http://www.gemis.de (accessed on 26 September 2019).

- Solomon, S.; Quin, D.; Manning, M.; Chen, Z.; Marquis, M.; Averyt, K.B. Climate Change 2007: The Physical Science Basis. Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press, IPCC: Cambridge, UK; New York, NY, USA, 2007. [Google Scholar]

- The Association of German Engineers (VDI). Guideline 6025—Economy Calculation Systems for Capital Goods and Plants; Beuth-Verlag GmbH: Berlin, Germany, 2012. [Google Scholar]

- National Renewable Energy Laboratories (NREL). Task 1: Cost estimates of small modular systems. In Equipment Design and Cost Estimation for Small Modular Biomass Systems, Synthesis Gas Cleanup, and Oxygen Separation Equipment; NREL/SR-510-39943; National Renewable Energy Laboratories (NREL): Golden, CO, USA, 2006. [Google Scholar]

- Davis, R.; Kinchin, C.; Markham, J.; Tan, E.; Laurens, L.; Sexton, D.; Knorr, D.; Schoen, P.; Lukas, J. Process Design and Economics for the Conversion of Algal Biomass to Biofuels: Algal Biomass Fractionation to Lipid and Carbohydrate-Derived Fuel Products; NREL/TP-5100-62368; National Renewable Energy Laboratories (NREL): Golden, CO, USA, 2014. Available online: https://www.nrel.gov/docs/fy14osti/62368.pdf (accessed on 3 September 2019).

- Eurostat. Harmonized index for consumer prices; industrial goods; Table: [prc_hicp_aind]; 2016. Available online: http://appsso.eurostat.ec.europa.eu/nui/show.do?dataset=prc_hicp_aind&lang=de (accessed on 25 September 2019).

- Eurostat. Euro/Ecu exchange rates; Table: [ert_bil_eur_a]; 2018. Available online: http://appsso.eurostat.ec.europa.eu/nui/show.do?dataset=ert_bil_eur_a&lang=en (accessed on 25 September 2019).

- Deutsches Zentrum für Luft-und Raumfahrt (DLR); Ludwig-Bölkow-Systemtechnik (LBST); Fraunhofer ISE; KBB Underground Technologies. Studie über die Planung einer Demonstrationsanlage zur Wasserstoff-Kraftstoffgewinnung durch Elektrolyse mit Zwischenspeicherung in Salzkavernen unter Druck. Stuttgart, Germany, 2015. Available online: http://www.lbst.de/ressources/docs2015/BMBF_0325501_PlanDelyKaD-Studie.pdf (accessed on 23 July 2018).

- Nationales Innovationsprogramm Wasserstoff-und Brennstoffzellentechnologie (NIP). Integration von Wind-Wasserstoff-Systemen in das Energiesystem, Berlin, 2013. Available online: https://www.now-gmbh.de/content/1-aktuelles/1-presse/20140402-abschlussbericht-zur-integration-von-wind-wasserstoff-systemen-in-das-energiesystem-ist-veroeffentlicht/abschlussbericht_integration_von_wind-wasserstoff-systemen_in_das_energiesystem.pdf (accessed on 18 July 2018).

- Braune, M.; Grasemann, E.; Gröngröft, A.; Klemm, M.; Oehmichen, K.; Zech, K. Die Biokraftstoffproduktion in Deutschland—Stand der Technik und Optimierungsansätze, 1st ed.; DBFZ report no. 22; Deutsches Biomasseforschungszentrum gemeinnützige GmbH (DBFZ): Leipzig, Germany, 2016; ISBN 978-3-9817707-8-0. [Google Scholar]

- Turton, R.; Shaeiwitz, J.A.; Bhattacharyya, D.; Whiting, W.B. Analysis, Synthesis and Design of Chemical Processes, 5th ed.; Pearson Education; Prentice Hall International Series in the Physical and Chemical Engineering Sciences: Boston, MA, USA, 2018. [Google Scholar]

- Aviation Initiative for Renewable Energy in Germany e. V. (aireg). Database on Jatropha. 2015; unpublished. [Google Scholar]

- Adler, P.; Billig, E.; Brosowski, A.; Daniel-Gromke, J.; Falke, I.; Fischer, E.; Grope, J.; Holzhammer, U.; Postel, J.; Schnutenhaus, J.; et al. (Eds.) Leitfaden Biogasaufbereitung und-einspeisung; Fachagentur Nachwachsende Rohstoffe e.V.: Gülzow, Germany, 2014; ISBN 3-00-018346-9. [Google Scholar]

- Oil Price Information Service (OPIS). Europe Jet, Diesel and Gasoil Report; Oil Price Information Service (OPIS): Rockville, MD, USA, 2016. [Google Scholar]

- Kumar, S.; Singh, J.; Nanoti, S.M.; Garg, M.O. A comprehensive life cycle assessment (LCA) of Jatropha biodiesel production in India. Bioresour. Technol. 2012, 110, 723–729. [Google Scholar] [CrossRef] [PubMed]

- Eshton, B.; Katima, J.H.Y.; Kituyi, E. Greenhouse gas emissions and energy balances of jatropha biodiesel as an alternative fuel in Tanzania. Biomass Bioenergy. 2013, 58, 95–103. [Google Scholar] [CrossRef]

- Dehue, B.; Hettinga, W. GHG Performance Jatropha Biodiesel. Commissioned by D1 oils, Ref no. PBIONL073010. Ecofys Reference 2. 2008. Available online: https://pdfs.semanticscholar.org/2f0b/c772fedd5e7988593084bd4113c1a5c78472.pdf (accessed on 26 September 2019).

| Scenario | Feedstock | Electricity Supply | Necessary Hydrogen Supply (Electricity Demand in MW) 1 | Main Product |

|---|---|---|---|---|

| 1 (reference) | jatropha oil | Constant from grid (with electricity mix): 8000 h a−1 | 121 MW alkaline electrolyser incl. tube buffer storage | HEFA-SPK |

| 2 (dynamic) | Dynamic from grid (spot market prices): 4000 h a−1 | 244 MW alkaline electrolyser incl. salt cavern storage | ||

| 3 (stand-alone) | Stand-alone system (wind 360 MW and solar 250 MW): 2600 h a−1 | 373 MW alkaline electrolyser with operated in varying part loads incl. salt cavern storage | ||

| 4 (natural gas) | Constant from grid (with electricity mix): 8000 h a−1 | via steam reforming from natural gas | ||

| 5 (biomethane) | via steam reforming from biomethane | |||

| 6 (naphtha) | via steam reforming from naphtha and fuel gas | |||

| 7 (rapeseed) | rapeseed oil | 121 MW alkaline electrolyser incl. tube buffer storage | ||

| 8 (palm) | palm oil | |||

| 9 (UCO) | used cooking oil | |||

| 10 (diesel) | jatropha oil | diesel |

| Methodology Step | Assumptions for PTG–HEFA Hybrid Refinery |

|---|---|

| Goal and scope definition | |

| Considered impact categories | Global warming potential (GWP) |

| Functional unit | 1 MJ fuel ex hybrid refinery |

| System boundary for LCA | Well-to-tank-chain including feedstock production (w/o direct or indirect land use changes), biomass collection of UCO and fuel production. No consideration of infrastructure (i.e., built up of plants, components, and vehicles) |

| Consideration of by-products | According to European Renewable Energy Directive (2008/29/EC) allocation of by-products (here, the subdivision of emissions and demands along the production chain between HEFA-SPK and naphtha, fuel gas, and diesel) and according to their energy content (lower heating value) |

| Inventory calculation | |

| Input/output analysis | Consideration of all relevant input and output streams (i.e., energy and feedstock inputs, auxiliaries and utilities, products and by-products, and waste) within the system boundary Concepts based on process simulation, own data, and EcoInvent Version 3.3 [30] External electrical power based on country specific mixes for 2015, emissions according to Gemis [31] |

| Impact assessment | |

| Approach | Evaluation of data resulting from input/output analysis regarding potential environmental impacts by means of so called characterising factor aggregation with regard to one reference substance |

| GHG emissions | According Forth IPCC Assessment Report (AR4) CH4 with 25 CO2-eq, N2O with 298 CO2-eq (w/o consideration of process-related biogenous CO2 emissions) [32] |

| Result interpretation | |

| cf. Section 3.2 |

| Cost Factor | Value/Assumption | Reference |

|---|---|---|

| Total investment | ||

| HEFA process units/incl. steam reformer | 132/190 million EUR (annual load 8000 h) | [34,35,36,37] |

| electrolyser | 58 million EUR (annual load 8000 h) 116 million EUR (annual load 4000 h) 176 million EUR (annual load 2600 h) | [38], quotations and interviews |

| hydrogen compression and storage | 24 million EUR (annual load 8000 h) 38 million EUR (annual load 4000 h) 70 million EUR (annual load 2600 h) | [13,39] |

| Costs | ||

| weighted average cost of capital | 8% per year | [40] |

| maintenance HEFA part | 2.5% of total investment per year | [34,35] |

| maintenance PTG part | 9% of total investment per year | [38], quotations and interviews |

| administration, insurance, other | 2.5% of total investment per year | [40] |

| personnel staff | 50,000 EUR per year and person with full-time equivalent; app. 50 full-time equivalents required | [40,41,35] |

| feedstock (jatropha, rapeseed, palm, and UCO) | 650/720/547/600 EUR t−1 | [4,42] |

| electricity (reference, dynamic, and stand-alone) | 100/80/80 EUR MWh−1 | [12] |

| auxiliaries steam reformer (natural gas, biomethane) | 480/896 EUR t−1 | [43] (biomethane) |

| ..other auxiliaries (water, potassium hydroxide) | 2/820 EUR t−1 | [40] |

| Revenues | ||

| ..naphtha, fuel gas | 380/400 EUR t−1 | [44] |

| ..diesel, jet fuel | 410/425 EUR t−1 | [44] |

| Scenario | Inputs | Outputs | |||||

|---|---|---|---|---|---|---|---|

| Feedstock a | Electricity b | Water a | HEFA-SPK a | Diesel a | Naphtha a | Fuel Gas a | |

| 1 (reference) | 500 | 988 | 222 | 227 | 40 | 135 | 26.4 |

| 2 (dynamic) | 500 | 996 | 222 | 227 | 40 | 135 | 26.4 |

| 3 (stand-alone) | 500 | 999 | 222 | 227 | 40 | 135 | 26.4 |

| 4 (natural gas) | 500 | 33 | 254 | 227 | 40 | 135 | 36.2 |

| 5 (biomethane) | 500 | 33 | 254 | 227 | 40 | 135 | 36.2 |

| 6 (naphtha) | 500 | 32 | 279 | 227 | 40 | 88 | 13.7 |

| 7 (rapeseed) | 500 | 1088 | 240 | 237 | 45 | 123 | 27.1 |

| 8 (palm) | 500 | 884 | 203 | 249 | 104 | 38 | 25.1 |

| 9 (UCO) | 500 | 1096 | 241 | 235 | 43 | 129 | 24.7 |

| 10 (diesel) | 500 | 826 | 192 | 60 | 328 | 22 | 14.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Müller-Langer, F.; Oehmichen, K.; Dietrich, S.; Zech, K.M.; Reichmuth, M.; Weindorf, W. PTG-HEFA Hybrid Refinery as Example of a SynBioPTx Concept—Results of a Feasibility Analysis. Appl. Sci. 2019, 9, 4047. https://doi.org/10.3390/app9194047

Müller-Langer F, Oehmichen K, Dietrich S, Zech KM, Reichmuth M, Weindorf W. PTG-HEFA Hybrid Refinery as Example of a SynBioPTx Concept—Results of a Feasibility Analysis. Applied Sciences. 2019; 9(19):4047. https://doi.org/10.3390/app9194047

Chicago/Turabian StyleMüller-Langer, Franziska, Katja Oehmichen, Sebastian Dietrich, Konstantin M. Zech, Matthias Reichmuth, and Werner Weindorf. 2019. "PTG-HEFA Hybrid Refinery as Example of a SynBioPTx Concept—Results of a Feasibility Analysis" Applied Sciences 9, no. 19: 4047. https://doi.org/10.3390/app9194047

APA StyleMüller-Langer, F., Oehmichen, K., Dietrich, S., Zech, K. M., Reichmuth, M., & Weindorf, W. (2019). PTG-HEFA Hybrid Refinery as Example of a SynBioPTx Concept—Results of a Feasibility Analysis. Applied Sciences, 9(19), 4047. https://doi.org/10.3390/app9194047