Small Dam Drainage with Nonwoven Geotextile after 40 Years of Exploitation

Abstract

:1. Introduction

2. Materials and Methods

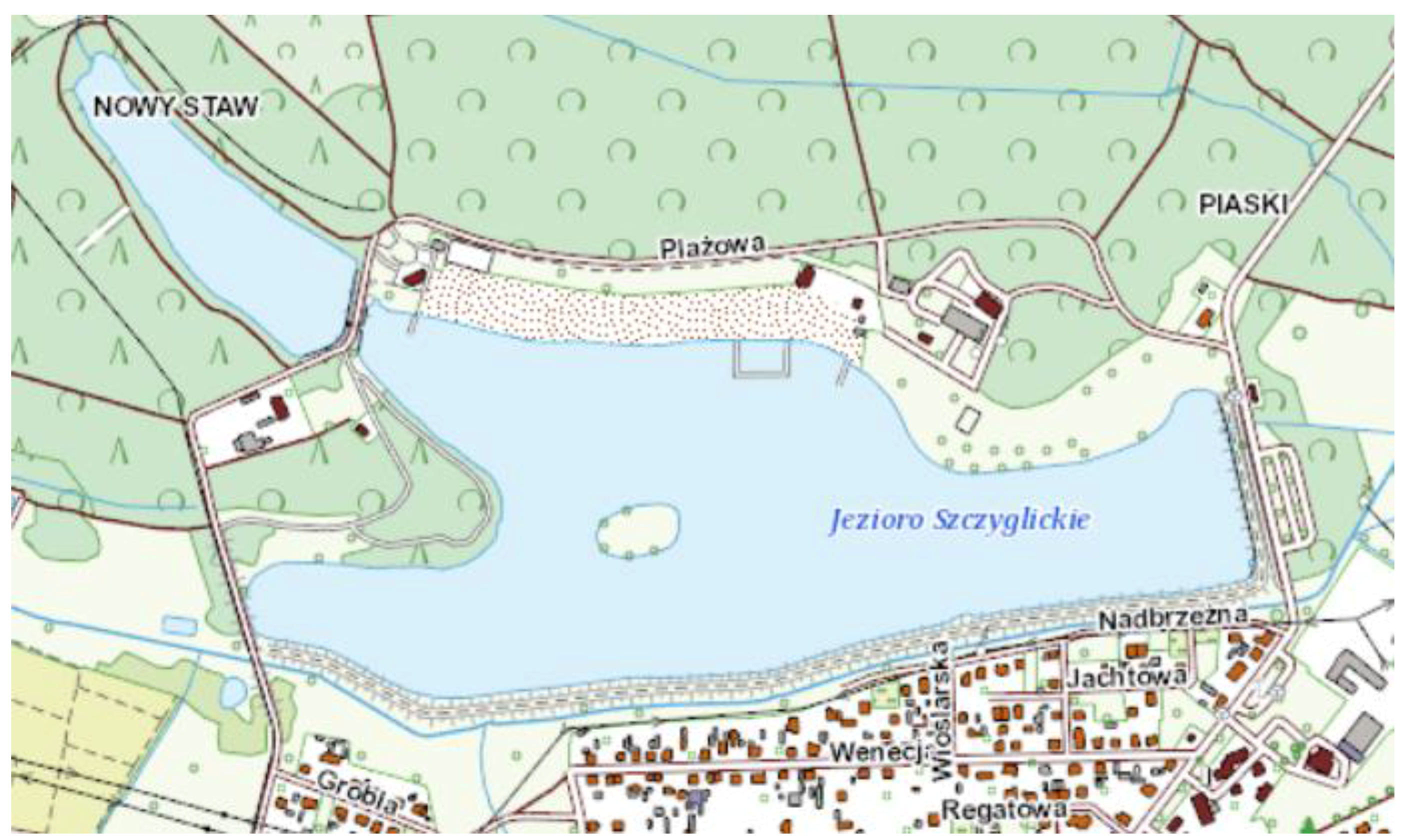

2.1. The Piaski-Szczygliczka Reservoir

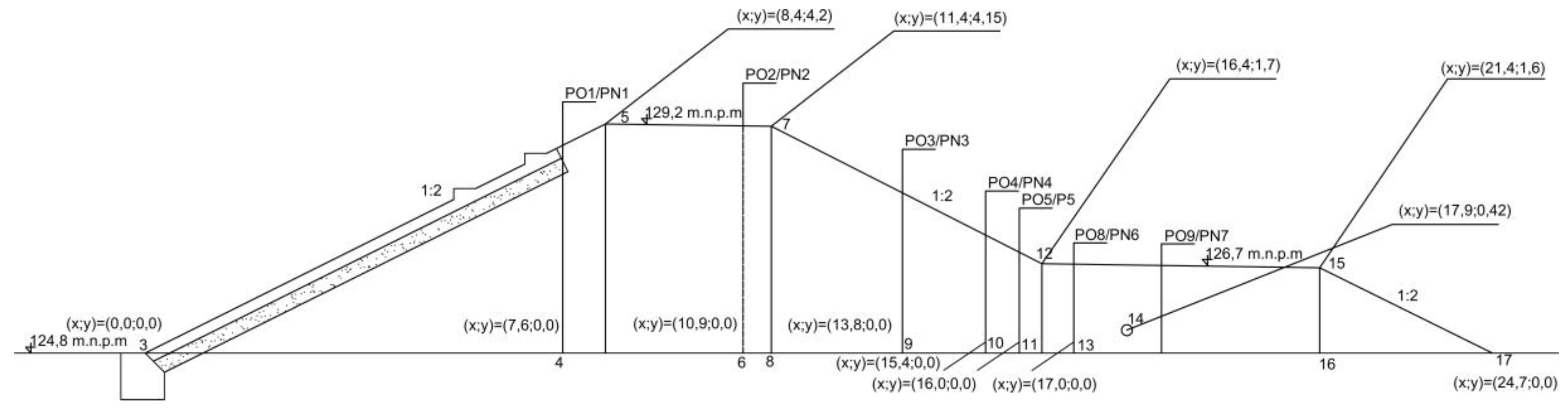

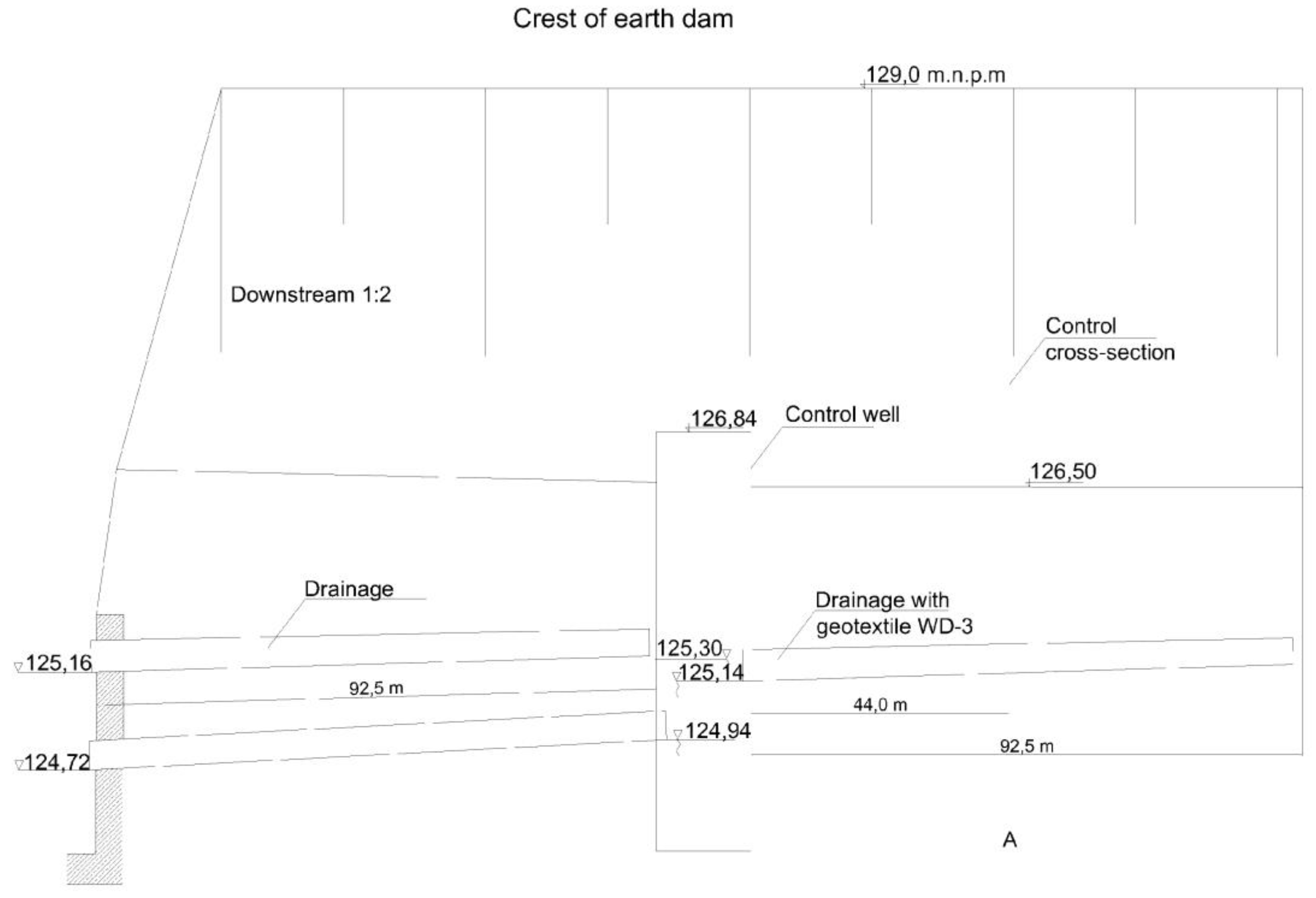

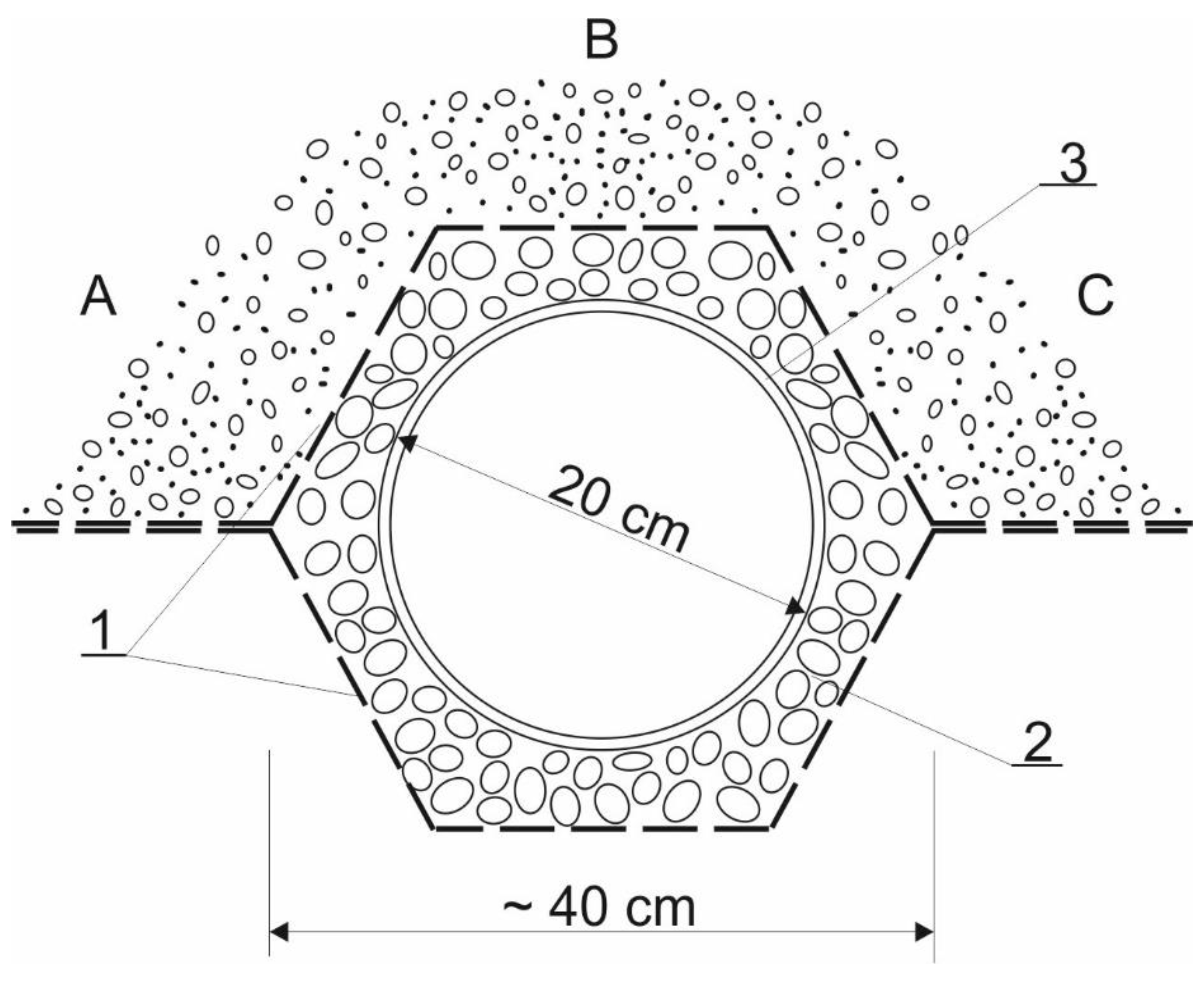

2.2. The Dam Drainage

2.3. Method

- The sampling site was taken approximately 10 m above the well connecting the upper and lower sections of the drainage (place indicated as control cross-section in Figure 4);

- The samples were taken from a 2.0 m × 1.5 m excavation from a depth of 1.65 m;

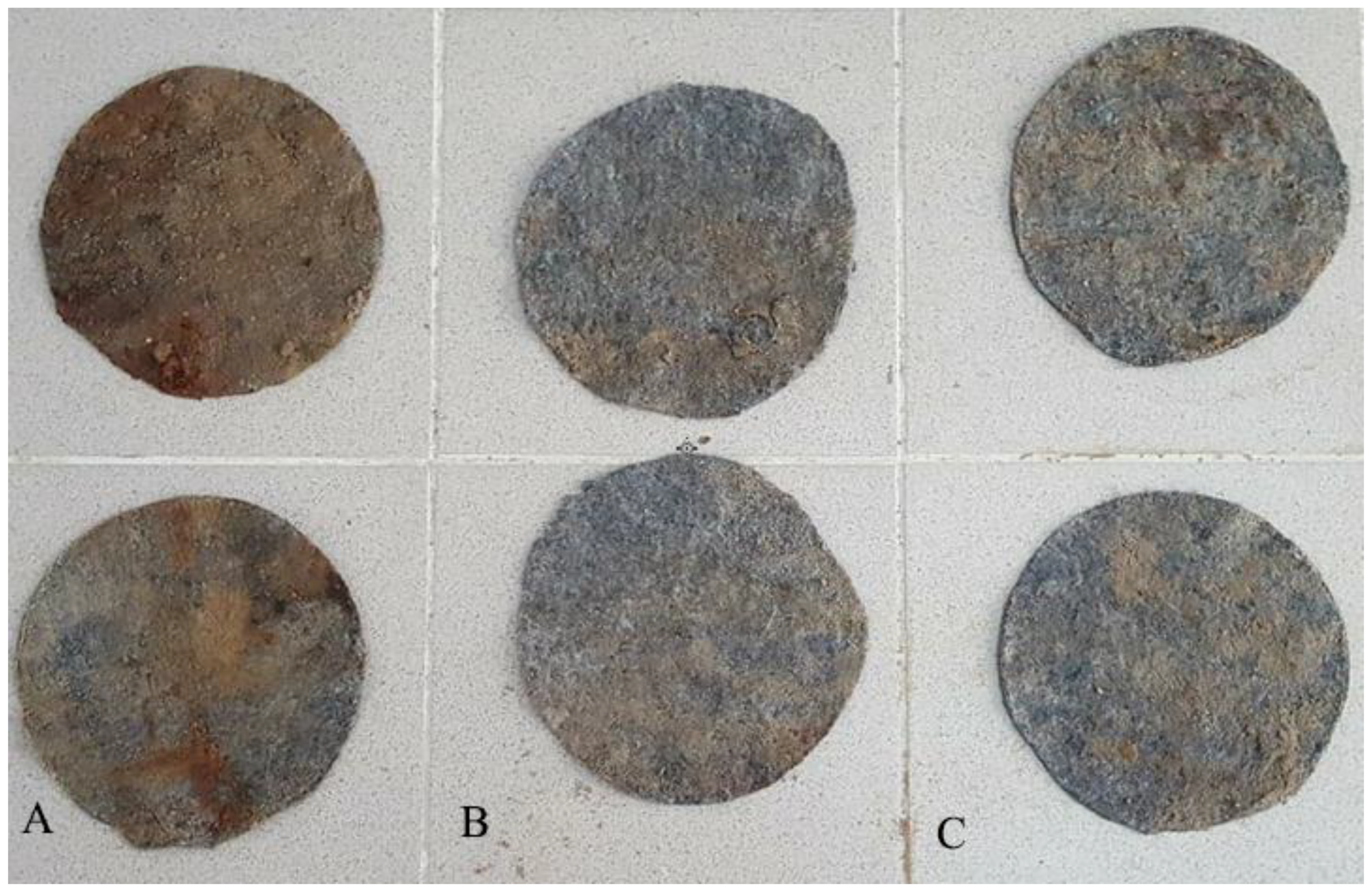

- A fragment of nonwoven geotextile with dimensions of 1.0 m × 1.5 m was cut out, which was divided into six samples;

- The non-woven fabric was placed in a plastic bag, which allowed the moisture of the sample to be maintained until the water permeability test was carried out;

- The material taken was replaced by a nonwoven geotextile with similar characteristics;

- A 10 cm layer of soil directly covering the nonwoven geotextile was removed with particular care, simultaneously collecting three soil samples for grain size analysis.

2.4. Numerical Calculations

- The nonwoven geotextile permeability was adopted in accordance with the measurement from the sample taken,

- The permeability of nonwoven geotextile lying below the drainage pipe was taken similarly to geotextile A. This assumption was made because the research should be conducted in future and taking a sample below the drain would cause a disturbance in the drainage pipe. The geotextile sample can only be taken without distribution above a drainage pipe.

3. Results and Discussion.

4. Conclusions

- The drainage with nonwoven geotextile after 40 years of operations still works properly. During this time, the permeability coefficient was reduced more than four-fold, but it is still many times higher (more than 18 times) than the permeability coefficient of earth dam soil.

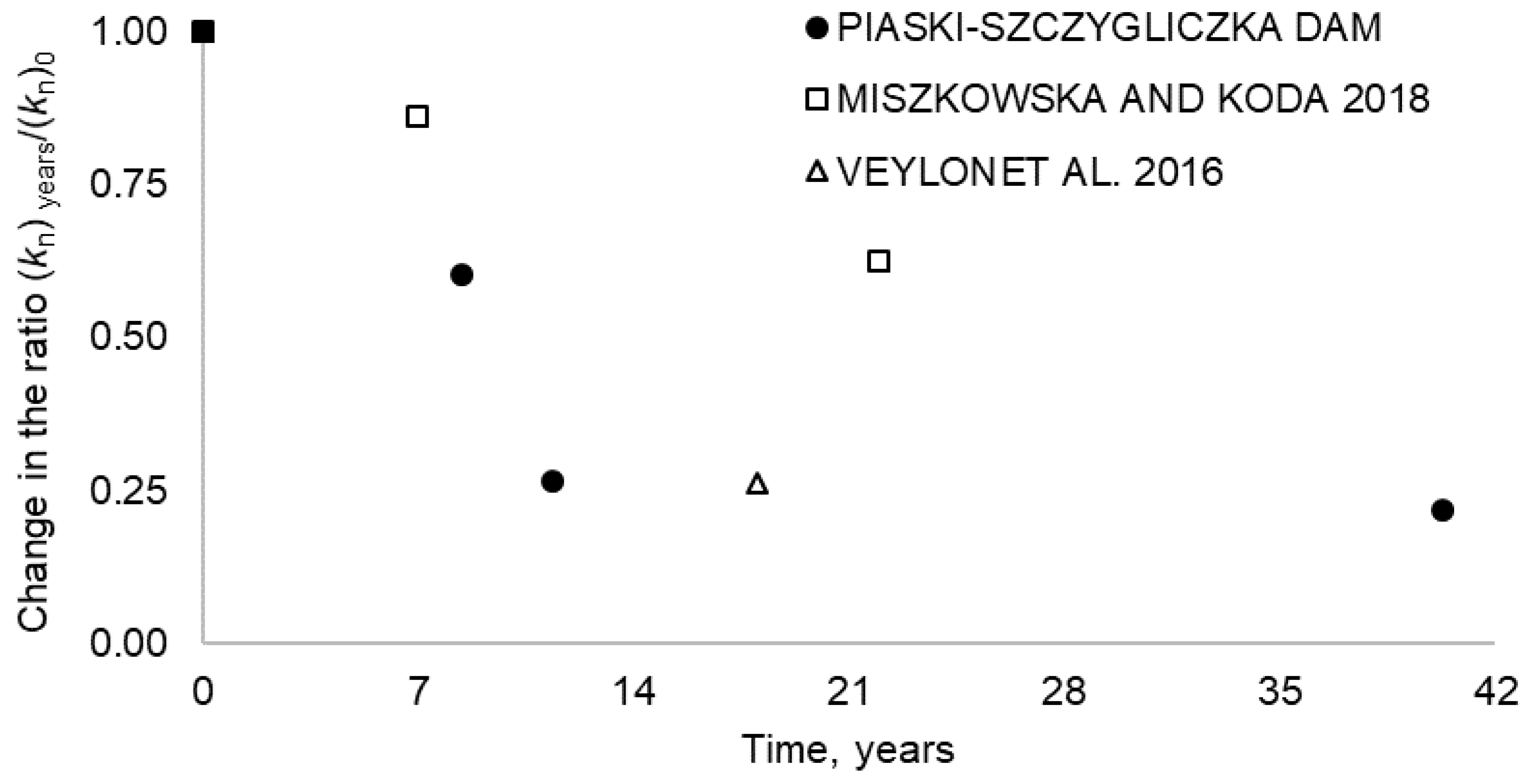

- Both our own research and that of other authors indicate that a significant change in permeability (reduction of it, about from three to four times) of nonwoven geotextile comes after the first 10 years of drainage work. Additionally, with the determination coefficient equal to about R2 = 0.75, it can be concluded that the permeability of nonwoven geotextile is reduced by about 6% per year of operation.

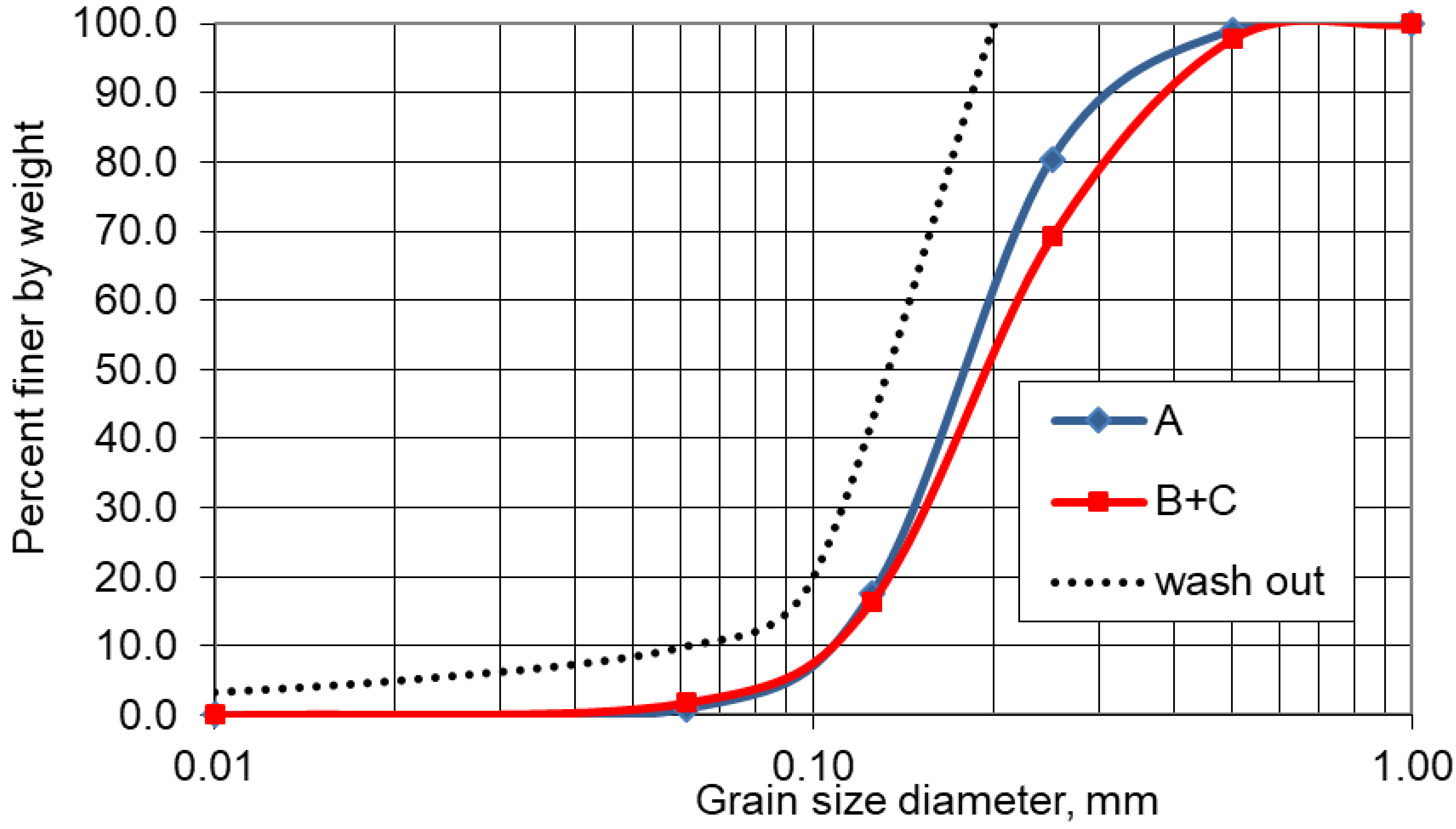

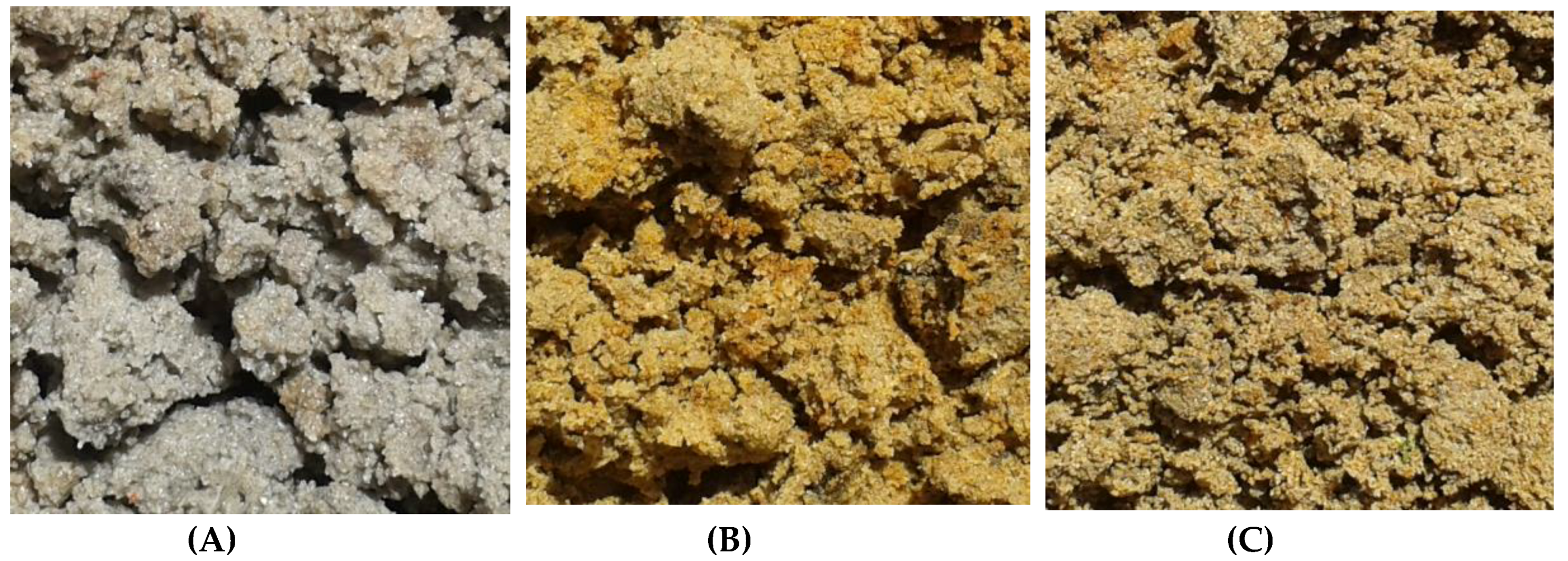

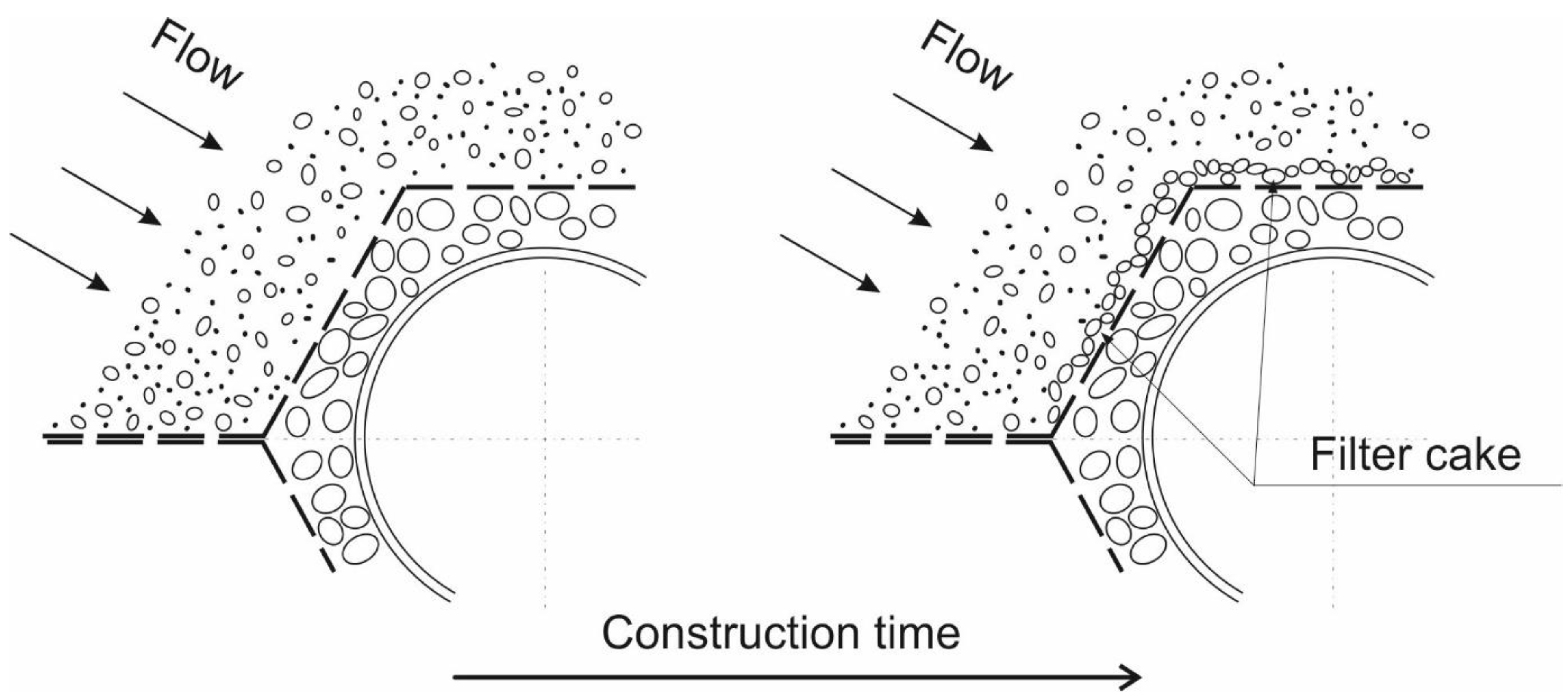

- The main reason for reduction of geotextile permeability is mechanical clogging caused by fine sand which builds structures called bridges (a kind of filter cake).

- Symptoms of chemical clogging noted on the air side of drainage did not worsen the permeability.

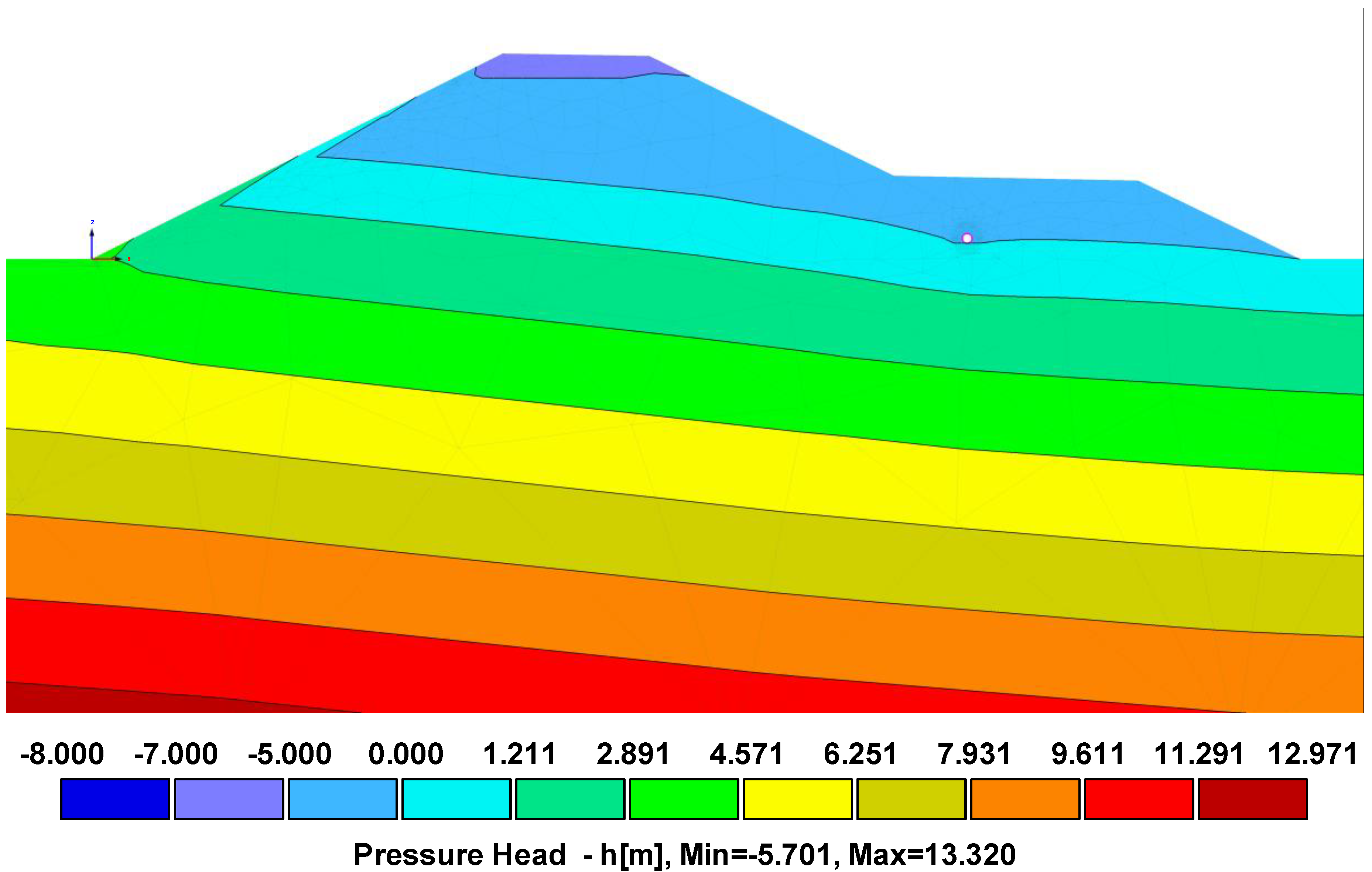

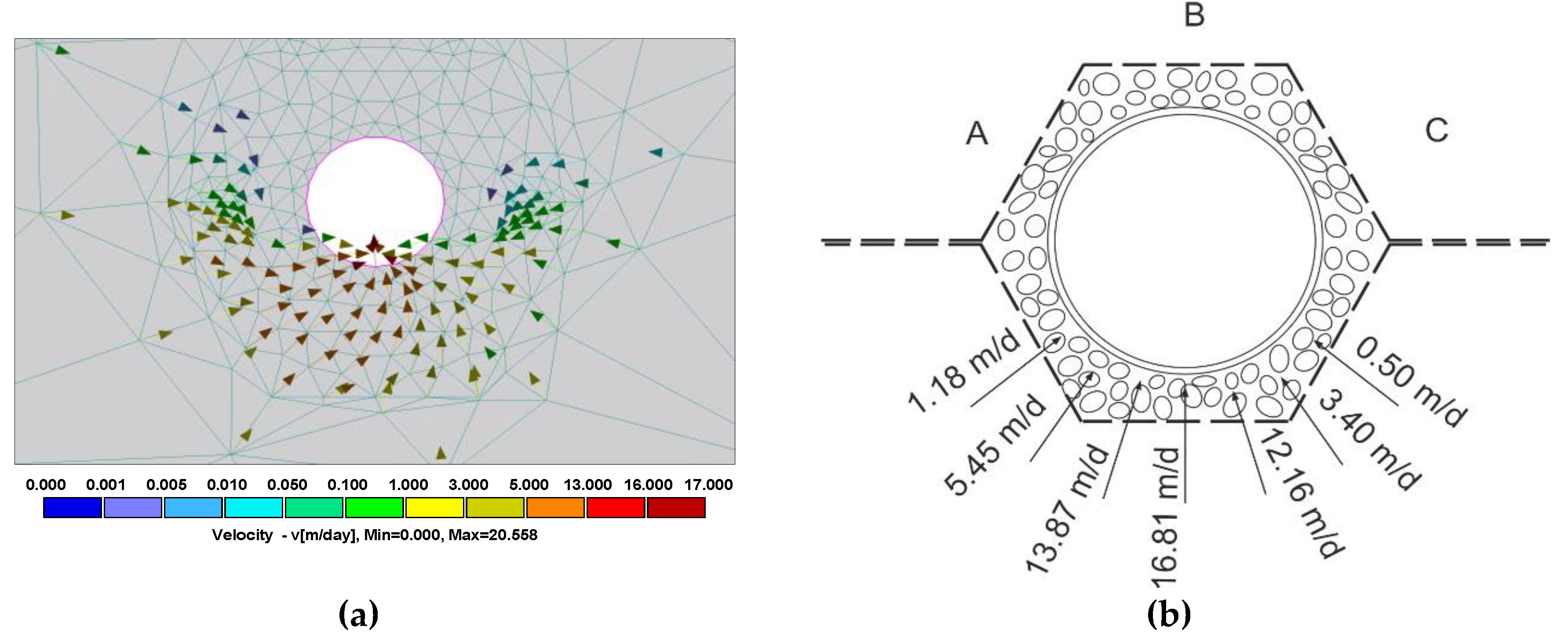

- Simulations performed using HYDRUS (2D/3D) software showed that at the maximum water level in the reservoir equal to 3.32 m, water supply to the drainage is higher from upstream than from downstream. Particularly, water supply from above to the drainage is absent.

- HYDRUS (2D/3D) simulations allow one to predict changes of hydraulic characteristics of geotextiles and protected soil under the drainage pipe in case in situ research is unavailable without structural damage.

Author Contributions

Funding

Conflicts of Interest

References

- Holtz, J. Geosynthetics for Soil Reinforcement; The Ninth Spencer J. Buchanan Lecture, November 2001; Geo-Institute of ASCE: Seattle, WA, USA, 2001. [Google Scholar] [CrossRef]

- Leflaive, E. Geotextiles: Their rationale and future. Geotext. Geomembr. 1985, 2, 23–30. [Google Scholar] [CrossRef]

- Młynarek, J. Hydraulic conductivity and pore sizes of nonwoven filter fabrics. Geotext. Geomembr. 1985, 2, 65–77. [Google Scholar] [CrossRef]

- Gniewek, A.; Gawryluk, A. Metody badań właściwości filtracyjnych geosyntetyków. Pr. Inst. Tech. Bud. Kwart. 2011, 1, 15–27. Available online: http://yadda.icm.edu.pl/yadda/element/bwmeta1.element.baztech-article-BTB2-0069-0055/c/Gniwek.pdf (accessed on 30 July 2019). (In Polish).

- Bolt, A.F.; Duszyńska, A. Kryteria doboru geosyntetyków jako warstw separacyjnych i filtracyjnych. Inżynieria Morska Geotech. 1998, 1, 1–11. Available online: http://www.pg.gda.pl/~adusz/pliki/IMG_Kryteria_98.pdf (accessed on 30 July 2019). (In Polish).

- Giroud, J.P. Development of criteria for geotextile and granular filters. IGS News. 2004, 20, pp. 12–14. Available online: https://www.igs-uk.org/wp-content/uploads/2014/06/DeveolpmenCriteriaForGeotextilesGranularFilters.pdf (accessed on 30 July 2019).

- Giroud, J.P. The Vienna Terzaghi lecture. In Geosynthetics Engineering: Successes, Failures and Lessons Learned, Proceedings of 5 Osterreichische Geotechniktagung, Osterreichischer Ingenieur und Architekten Verein, Vienna, Austria, 21–22 February 2005; International Geosynthetics Society: Jupiter, FL, USA, 2006; pp. 11–54. Available online: http://www.jcigs.org/8ICG/SL/GiroudTerzaghiLectureHandoutForYokohamaA4.pdf (accessed on 30 July 2019).

- Koerner, R.M.; Koerner, G.R. Lessons learned from geotextile filter failures under challenging field conditions. Geotext. Geomembr. 2015, 272–281. [Google Scholar] [CrossRef]

- Młynarek, J.; Lewandowski, J.B.; Rollin, A.L.; Boldue, G. Soil-geotextile system interaction. Geotext. Geomembr. 1991, 10, 161–176. [Google Scholar] [CrossRef]

- Miszkowska, A.; Koda, E.; Krzywosz, Z.; Król, P.; Boruc, N. Zmiany właściwości filtracyjnych włókniny po 22 latach eksploatacji w drenażu zapory ziemnej. Acta Sci. Pol. Archit. 2016, 15, 119–126. Available online: http://www.architectura.actapol.net/pub/15_3_119.pdf (accessed on 30 July 2019).

- Miszkowska, A.; Koda, E. Change of water permeability of nonwoven geotextile exploited in earthfill dam. In Proceedings of the 25th Anniversary of MendelNet Conference Proceedings, Brno, Czech Republic, 7–8 November 2018; pp. 440–445. Available online: https://mendelnet.cz/pdfs/mnt/2018/01/92.pdf (accessed on 30 July 2019).

- Veylon, G.; Stoltz, G.; Mériaux, P.; Faure, Y.H.; Touze-Foltz, N. Performance of geotextile filters after 18 years’ service in drainage trenches. Geotext. Geomembr. 2016, 44, 515–533. [Google Scholar] [CrossRef]

- Lewandowski, J.B.; Młynarek, J.; Zawadzki, P. Badania skuteczności działania geotekstyliów w konstrukcjach budownictwa wodno-melioracyjnego. Zeszyty Naukowe AR Krakowie 1990, 249, 387–403. Available online: https://www.researchgate.net/publication/330729419_Badania_skutecznosci_dzialania_geotekstyliow_w_konstrukcjach_budownictwa_wodno-melioracyjnego_Investigation_on_geotextile_filter_performance_in_hydraulic_engineering_structures (accessed on 30 July 2019). (In Polish).

- Šimůnek, J.; Šejna, M.; van Genuchten, M.T. The HYDRUS-2D Software Package for Simulating Two-Dimensional Movement of Water, Heat, and Multiple Solutes in Variably Saturated Media; Version 2.0, IGWMC-TPS-53; International Ground Water Modeling Center, Colorado School of Mines: Golden, CO, USA, 1999. [Google Scholar]

- Li, H.; Yi, J.; Zhang, J.; Zhao, Y.; Si, B.; Hill, R.L.; Cui, L.; Liu, X. Modeling of soil water and salt dynamics and its effects on root water uptake in Heihe Arid wetland, Gansu, China. Water 2015, 7, 2382–2401. [Google Scholar] [CrossRef]

- Okamoto, K.; Sakai, K.; Nakamura, S.; Cho, H.; Nakandakari, T.; Ootani, S. Optimal Choice of Soil Hydraulic Parameters for Simulating the Unsaturated Flow: A Case Study on the Island of Miyakojima, Japan. Water 2015, 7, 5676–5688. [Google Scholar] [CrossRef] [Green Version]

- Nieć, J.; Zawadzki, P.; Walczak, Z.; Spychała, M. Calculating earth dam seepage using hydrus software applications. Acta Sci. Pol. Form. Circumiectus 2017, 16, 43–56. Available online: http://www.formatiocircumiectus.actapol.net/pub/16_3_43.pdf (accessed on 30 July 2019). [CrossRef]

- Zawadzki, P. Assessment of test methods used to measure geotextile pore size. In Proceedings of the IV International Conference on Slope Stability and Protection, Wrocław, Poland, 23–25 April 1991; pp. 184–192. Available online: https://www.researchgate.net/publication/330728794_Assessment_of_test_methods_used_to_measure_geotextile_pore_size (accessed on 30 July 2019).

- Hu, H.; Zhang, J.; Li, T. Dam-Break Flows: Comparison between Flow-3D, MIKE 3 FM, and Analytical Solutions with Experimental Data. Appl. Sci. 2018, 8, 2456. [Google Scholar] [CrossRef]

- Hämmerling, M.; Błażejewski, R.; Walczak, N. Modeling of Local Scour in Non-cohesive Soils Below Sills Using SSIIM Computer Code. Annu. Set Environ. Prot. 2013, 15, 538–550. Available online: https://ros.edu.pl/images/roczniki/2013/pp_2013_035.pdf (accessed on 30 July 2019).

- Walczak, Z.; Sroka, Z.; Tschuschke, W.; Stefanek, P.; Wrzosek, K. Reduction of the Warta River flow caused by seepage from river bed, during additional discharge from Jeziorsko Reservoir. Acta Sci. Pol. Form. Circumiectus 2017, 16, 217–232. [Google Scholar] [CrossRef]

- Negm, A.; Capodici, F.; Ciraolo, G.; Maltese, A.; Provenzano, G.; Rallo, G. Assessing the Performance of Thermal Inertia and Hydrus Models to Estimate Surface Soil Water Content. Appl. Sci. 2017, 7, 975. [Google Scholar] [CrossRef]

- Błażejewkski, R.; Nieć, J.; Murat-Błażejewska, S.; Zawadzki, P. Comparison of infiltration models with regard to design of rectangular infiltration trenches. Hydrol. Sci. J. 2018, 62, 1707–1716. [Google Scholar] [CrossRef]

- Šimůnek, J.; van Genuchten, M.T.; Šejna, M. The HYDRUS Software Package for Simulating the Two- and Three-Dimensional Movement of Water, Heat, and Multiple Solutes in Variably-Saturated Porous Media; Technical Manual. Version 2.0; PC-Progress: Prague, Czech Republic, 2012. [Google Scholar]

- Schaap, M.G.; Leij, F.J.; van Genuchten, M.T. ROSETTA: a computer program for estimating soil hydraulic parameters with hierarchical pedotransfer functions. J. Hydrol. 2011, 251, 163–176. [Google Scholar] [CrossRef]

- Finch, S.D.; Radcliffe, D.E.; West, L.T. Modeling trench sidewall and bottom flow in on-site wastewater systems. J. Hydrol. Eng. 2008, 13, 693–701. [Google Scholar] [CrossRef]

- Miszkowska, A.; Lenart, S.; Koda, E. Changes of permeability of nonwoven geotextile due to clogging and cyclic water flow in laboratory conditions. Water 2017, 9, 660. [Google Scholar] [CrossRef]

- Novak, P.; Moffat, A.I.B.; Nalluri, C.; Narayanam, R. Hydraulic Structures. Spon Press; Taylor & Francis Group: London, UK; New York, NY, USA, 2001; ISBN 0-415-25071-4. [Google Scholar]

| Material | Θr | ΘS | a | n | Ks | l |

|---|---|---|---|---|---|---|

| (m3/m3) | (m3/m3) | (1/m) | (-) | (m/day) | (-) | |

| Sand | 0.045 | 0.43 | 14.5 | 2.68 | 7.78 | 0.5 |

| Gravel | 0.05 | 0.4 | 175 | 2.8 | 86.4 | 0.5 |

| Concrete | 0 | 0.069 | 0.000248 | 1.917 | 4.089·10−8 | 0.5 |

| Silty Loam | 0.067 | 0.45 | 2 | 1.41 | 0.108 | 0.5 |

| Clogged A | 0.045 | 0.43 | 14.5 | 2.68 | 129 | 0.5 |

| Clogged B | 0.045 | 0.43 | 14.5 | 2.68 | 345 | 0.5 |

| Clogged C | 0.045 | 0.43 | 14.5 | 2.68 | 259 | 0.5 |

| Samples | kn, cm s−1 | kavr, ± SD cm s−1 |

|---|---|---|

| A | 0.1628 | 0.15 ± 0.01 |

| A | 0.1427 | |

| B | 0.4176 | 0.40 ± 0.02 |

| B | 0.3817 | |

| C | 0.3655 | 0.30 ± 0.06 |

| C | 0.2429 |

| Sample | Area, m2 | Weight, g | Area Density, g m−2 | ||

|---|---|---|---|---|---|

| WD-3 | Before | After | |||

| Before | After | ||||

| A1 | 0.03755 | 36.47 | 16.81 | 971.1 | 447.6 |

| A2 | 0.03761 | 33.95 | 19.75 | 902.7 | 525.1 |

| B1 | 0.03882 | 18.34 | 14.38 | 472.4 | 370.4 |

| B2 | 0.03836 | 20.22 | 14.83 | 527.1 | 386.6 |

| C1 | 0.03796 | 26.60 | 18.03 | 700.8 | 475.0 |

| C2 | 0.03715 | 29.26 | 19.58 | 787.5 | 527.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nieć, J.; Zawadzki, P.; Nowacki, F. Small Dam Drainage with Nonwoven Geotextile after 40 Years of Exploitation. Appl. Sci. 2019, 9, 4161. https://doi.org/10.3390/app9194161

Nieć J, Zawadzki P, Nowacki F. Small Dam Drainage with Nonwoven Geotextile after 40 Years of Exploitation. Applied Sciences. 2019; 9(19):4161. https://doi.org/10.3390/app9194161

Chicago/Turabian StyleNieć, Jakub, Paweł Zawadzki, and Filip Nowacki. 2019. "Small Dam Drainage with Nonwoven Geotextile after 40 Years of Exploitation" Applied Sciences 9, no. 19: 4161. https://doi.org/10.3390/app9194161