4.1. Simulation Verification

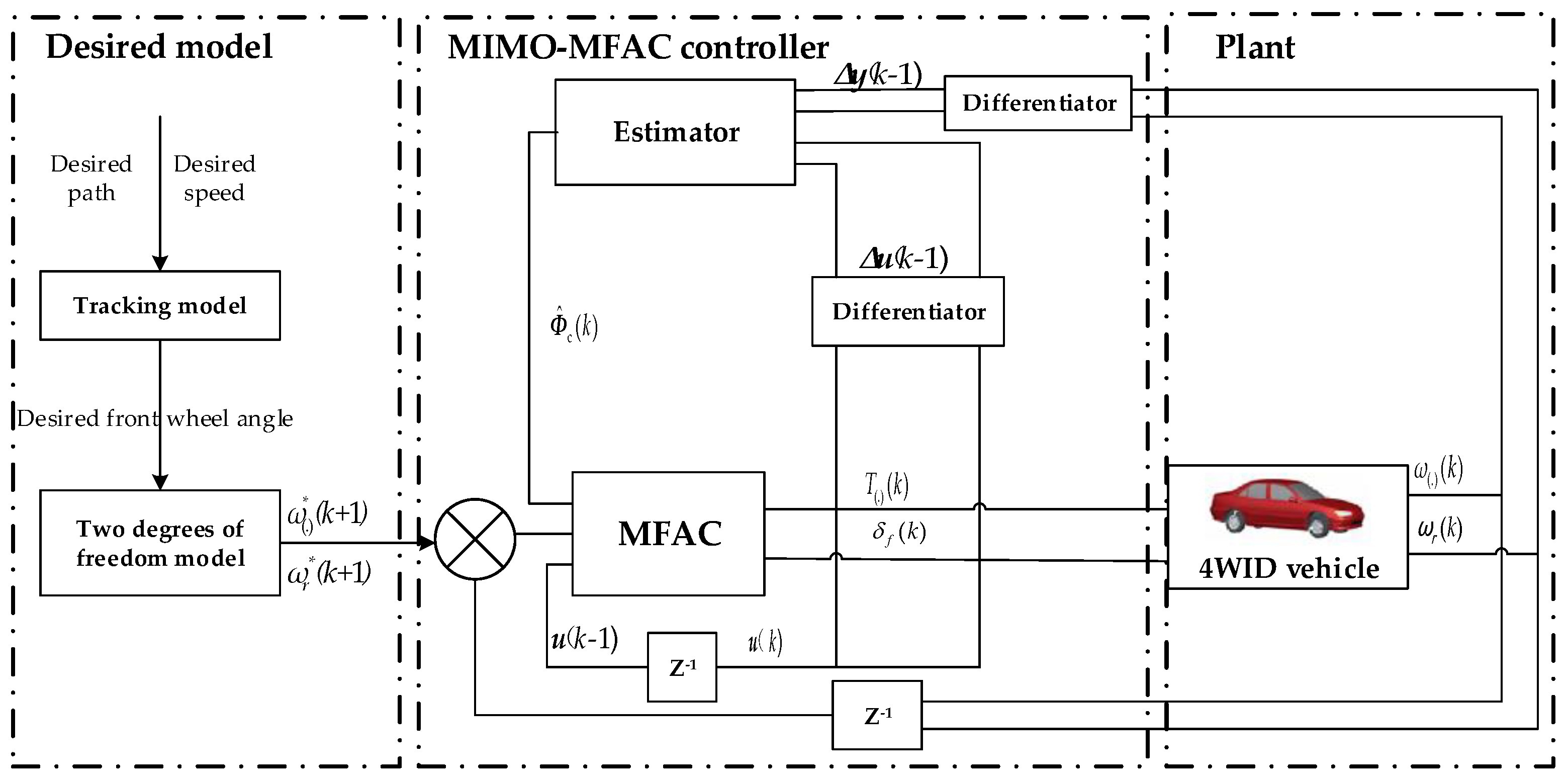

The failure modes of the 4WID electric vehicle system can be categorized as single wheel failure, opposite side double wheel failure, same side double wheel failure and multiple wheel failure. It is well known that if same side motor failure and multiple motor failures occur as the ultimate failure conditions for 4WID electric vehicles, we must take necessary precautions to brake the vehicles. This paper proposes the MIMO-MFAC active fault-tolerance method for the single wheel failure and opposite side-wheel failure conditions. All of the failure conditions of the drive system of 4WID electric vehicles are simulated and verified and the simulation time step is 0.01 s. When the drive system fails, the proposed method only utilizes the I/O data of the vehicle and uses a new dynamic linearization technique with a pseudo-partial derivative to correct the vehicle posture and to ensure that the vehicle maintains the desired values, thereby resulting in improved safety levels of the vehicles. Thus, the desired control objectives can be achieved by the coordinated adaptive fault-tolerant control of the drive and steering systems under all of the conditions illustrated below.

Table 2,

Table 3 and

Table 4 display the maximum speed deviation, yaw rate and lateral position deviation, respectively, with or without control, under different working conditions. The results indicate that the proposed active fault-tolerant control method can ensure and improve vehicle safety, as well as enhance the longitudinal and lateral tracking ability under different failure conditions through cooperative fault-tolerant control of the drive and steering systems.

The simulation verification analysis of the active fault-tolerant control method under the typical condition, as displayed in

Table 5, will be described in detail below.

Condition F1: The vehicle is traveling at a constant speed and the expected speed is 72 km/h. At the 8th second, left front motor failure occurs.

The vehicle is traveling at a constant speed of 72 km/h in a straight-line condition and the left front motor fails at the 8th second. It is obvious from

Figure 3e that the vehicle completely deviates from its trajectory without control, which easily induces traffic accidents. Moreover, under the control of the MIMO-MFA active fault-tolerant control algorithm proposed in this paper, when the left front wheel fails, the steering wheel illustrated in

Figure 3b responds immediately. Furthermore, it decreases the normal wheel motor torques at the right front and rear and increases the normal wheel motor torques of the left rear, as illustrated in

Figure 3a. Therefore, it ensures vehicle safety after the drive system fails and maintains the expected speed, as indicated in

Figure 3c, so it does not deviate from the expected trajectory illustrated in

Figure 3e.

We can also observe from

Figure 3a,b that, during the entire fault-tolerant process, the adjustment ratio of the steering wheel angle is decreased with the drive system adjustment, thereby achieving the coordinated fault-tolerant result of the two systems. This provides an easy method for avoiding the overloading problem caused by using only the single actuator for fault tolerance after failure of the drive system and improving the vehicle safety.

Table 6 below displays the vehicle speed and yaw rate and the later position deviation in the controlled and uncontrolled conditions after failure occurs.

Therefore, it can be concluded that the algorithm achieves the proposed active fault-tolerant result; moreover, this method can control the vehicle deviation within 10 cm and speed error within 3%.

Condition F2: The vehicle is traveling at a constant speed and the expected speed is 72 km/h. At the 8th second, left front and right front motor failure occur at the same time.

Without control, it is obvious from

Figure 4c that the vehicle speed is reduced immediately when the motor fails but under the algorithm proposed in the paper, we can observe from

Figure 4a that the controller increases the normal left rear and right rear motor torque to compensate for the lost motor torque of the left front and right front wheels. Therefore, it maintains the desired vehicle speed of 72 km/h, as the left front and right front wheels fail at the same time and the 4WID electric vehicle failure mode is the opposite side double-wheel failure. As illustrated in

Figure 4b,d, no additional steering wheel angle and yaw rate are generated in the lateral direction. From the above analysis, the effectiveness of the designed controller designed is verified. The controller ensures that the vehicle can maintain the desired speed after failure of the drive system and will not allow deviation from the established path.

Table 7 displays the vehicle speed, yaw rate and later position deviation with control or without control after failure occurs.

Condition F3: The vehicle is turning at a constant speed and the expected speed is 72 km/h. At the time of the 0th second, left front wheel failure occurs.

The vehicle turns at a constant speed of 72 km/h, as indicated in

Figure 5c. At the 0th second, left front motor failure occurs. Without control, as indicated in

Figure 5e, it is clear that the vehicle exhibits an obvious deviation; thus, it is likely to induce traffic accidents. When the left front wheel fails under the control of the proposed algorithm, the steering wheel responds immediately, as illustrated in

Figure 5b. At the same time, as indicated in

Figure 5a, the right front and right rear motor torques are reduced, while the left rear wheel motor torque is increased. Therefore, it is ensured that the vehicle safety can be improved and the desired vehicle speed can be maintained, as illustrated in

Figure 5c and it does not deviate from the desired trajectory, as depicted in

Figure 5d,e.

We can also observe from

Figure 5a,b that, during the entire active fault-tolerant control process, with the addition of the wheel torque adjustment, the steering angle adjustment ratio is continuously reduced, thereby achieving cooperative fault-tolerant control of the drive and steering systems. This method can easily avoid the overload phenomenon caused by the single actuator after actuator failure and improve vehicle safety.

Table 8 displays the vehicle speed, yaw rate and later position deviation with control or without control after failure of the drive system. We can conclude that the algorithm achieves the proposed active fault-tolerant results and the method can maintain the longitudinal speed error within 3% and lateral stability, thus improving the vehicle safety.

4.2. Experimental Verification

In order to verify the real-time algorithm performance, we used the driving simulator platform illustrated in

Figure 6; five screens were positioned around the simulator vehicle, with three screens displaying the front traffic scenes and two displaying the back view. The CarSim software was embedded in the driving simulator to reflect the real vehicle movement features. In order to simulate real driving situations, the vehicle was supported by numerous hydraulic cylinders to achieve pitch, roll and yaw motions. For comparison with the simulation results, the vehicle model in CarSim was selected to be the same as in the simulation and the experimental testing conditions were designed almost the same as those in the simulation, as indicated in

Table 9.

Experimental testing condition E1: The condition for a straight uniform speed is selected and the desired speed is set to 72 km/h, with single left front motor failure at the 0th second, as in the simulation. In this manner, we can conclude that, through the cooperative control of the drive system in

Figure 7a and steering system in

Figure 7b, the vehicles can maintain the expected speed, as indicated in

Figure 7c, as well as the lateral ability, as illustrated in

Figure 7d,e.

Table 10 displays the vehicle speed, yaw rate and later position deviation with control or without control after failure of the drive system. It is demonstrated that the experimental verification results are similar to the simulation results. Moreover, in the driving simulator verification experiment, the system control period is less than 50 ms, so the verification of the control algorithm exhibits satisfactory real-time performance.

Experimental testing condition E2: The condition of straight uniform speed is selected; the desired speed is set to 72 km/h and drive motor failure at the opposite side is selected so that the left front motor and right front motor become completely ineffective at the 0th seconds. In this manner, we can conclude that, through the cooperative control of the drive system in

Figure 8a and steering system in

Figure 8b, the vehicle can maintain the expected speed, as indicated in

Figure 8c, as well as the lateral ability, as illustrated in

Figure 8d.

Table 11 displaces the vehicle speed, yaw rate and later position deviation with control or without control after failure of the drive system. It is demonstrated that the experimental verification results are similar to the simulation results. Furthermore, in the driving simulator verification experiment, the system control period is less than 50 ms, so the verification of the control algorithm exhibits satisfactory real-time performance.

Experimental testing condition E3: The condition of a uniform turning speed is selected, the desired speed is set to 72 km/h and the single left front motor is selected to fail at the 0th second. When motor failure occurs at the 0th second, the remaining motor torque instantly increases and through the cooperative control of the drive system in

Figure 9a and steering system in

Figure 9b, the vehicles can maintain the expected speed, as indicated in

Figure 9c, as well as the lateral ability, as illustrated in

Figure 9d,e.

Table 12 displaces the vehicle speed, yaw rate and later position deviation with control or without control after failure of the drive system. It is demonstrated that the experimental verification results are similar to the simulation results. Moreover, in the driving simulator verification experiment, the system control period is less than 50 ms, so the verification of the control algorithm exhibits satisfactory real-time performance.