A Novel X-Ray Radiation Sensor Based on Networked SnO2 Nanowires

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of Networked SnO2 NWs

2.2. Characterization

2.3. X-Ray Sensing studies

3. Results and Discussion

3.1. Growth of Networked SnO2 NWs

3.2. Morphological and Structural Analyses

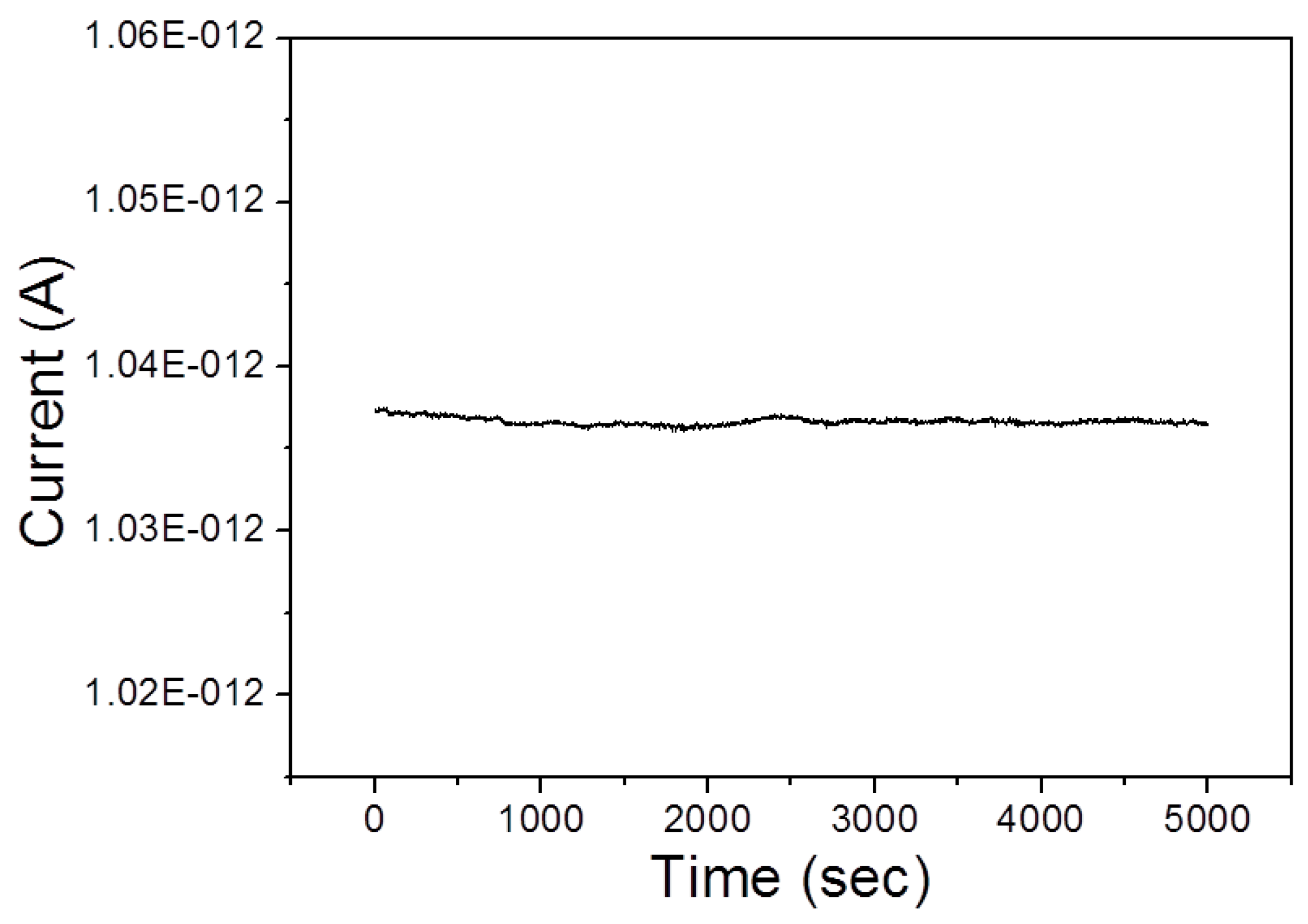

3.3. Leakage Current and X-Ray Sensing Studies

3.4. Sensing Mechanism

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Schlesinger, T.E.; James, R.B. Semiconductors for Room Temperature Nuclear Applications, 1st ed.; Academic Pres: New York, NY, USA, 1995. [Google Scholar]

- Arshak, K.; Korostynska, O.; Fahim, F. Various Structures Based on Nickel Oxide Thick Films as Gamma Radiation Sensors. Sensors 2003, 3, 176–186. [Google Scholar] [CrossRef]

- Wei, Z.; Wei, X.; Wang, S.; He, D. Preparation and Visible-Light Photocatalytic Activity of α-Fe2O3/γ-Fe2O3 Magnetic Heterophase Photocatalyst. Mater. Lett. 2014, 118, 107–110. [Google Scholar] [CrossRef]

- Kwon, Y.J.; Mirzaei, A.; Kang, S.Y.; Choi, M.S.; Bang, J.H.; Kim, S.S.; Kim, H.W. Synthesis, Characterization and Gas Sensing Properties of ZnO-Decorated MWCNTs. Appl. Surf. Sci. 2017, 413, 242–252. [Google Scholar] [CrossRef]

- Gancarz, M.; Nawrocka, A.; Rusinek, R. Identification of Volatile Organic Compounds and Their Concentrations Using a Novel Method Analysis of MOS Sensors Signal. J. Food Sci. 2019, 84, 2077–2085. [Google Scholar] [CrossRef]

- Rusinek, R.; Siger, A.; Gawrysiak-Witulska, M.; Rokosik, E.; Malaga-Toboła, U.; Gancarz, M. Application of an Electronic Nose for Determination of Pre-Pressing Treatment of Rapeseed Based on the Analysis of Volatile Compounds Contained in Pressed Oil. Int. J. Food Sci. Technol. 2019. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, W.; Han, Y.; Yang, Z.; Huang, Y. Single-Nanowire Fuse for Ionization Gas Detection. Sensors 2019, 19, 4358. [Google Scholar] [CrossRef]

- Lavanya, N.; Sekar, C.; Anithaa, A.; Sudhan, N.; Asokan, K.; Bonavita, A.; Leonardi, S.; Neri, G. Investigations on the Effect of Gamma-Ray Irradiation on the Gas Sensing Properties of SnO2 Nanoparticles. Nanotechnology 2016, 27, 385502. [Google Scholar] [CrossRef]

- Arshak, K.; Korostynska, O. Effect of Gamma Radiation onto the Properties of TeO2 Thin Films. Microelectron. Int. 2002, 19, 30–34. [Google Scholar] [CrossRef]

- Arshak, K.; Korostynska, O.; Clifford, S. Screen Printed Thick Films of NiO and LaFeO3 as Gamma Radiation Sensors. Sens. Actuators A 2004, 110, 354–360. [Google Scholar] [CrossRef]

- Arshak, K.; Korostynska, O. Preliminary Studies of Properties of Oxide Thin/Thick Films for Gamma Radiation Dosimetry. Mater. Sci. Eng. B 2004, 107, 224–232. [Google Scholar] [CrossRef]

- Arshak, K.; Korostynska, O.; Henry, J. Thick Film pn-Junctions Based on Mixed Oxides of Indium and Silicon as Gamma Radiation Sensors. Microelectron. Int. 2004, 21, 19–27. [Google Scholar] [CrossRef]

- Arshak, K.; Korostynska, O. Thin Films of (TeO2)1−x(In2O3)x as Gamma Radiation Sensors. Sens. Rev. 2003, 23, 48–54. [Google Scholar] [CrossRef]

- Arshak, K.; Korostynska, O. Gamma Radiation Dosimetry Using Tellurium Dioxide Thin Film Structures. In Proceedings of the IEEE Sensors 2002, Orlando, FL, USA, 12–14 June 2002; Volume 1, pp. 547–551. [Google Scholar]

- Lu, X.; Zhou, L.; Chen, L.; Ouyang, X.; Liu, B.; Xu, J.; Tang, H. Schottky X-ray Detectors Based on a Bulk β-Ga2O3 Substrate. Appl. Phys. Lett. 2018, 112, 103502. [Google Scholar] [CrossRef]

- Zhou, L.; Huang, Z.; Zhao, X.; He, Y.; Chen, L.; Xu, M.; Zhao, K.; Zhang, S.; Ouyang, X. A High-Resistivity ZnO Film-Based Photoconductive X-ray Detector. IEEE Photonics Technol. Lett. 2019, 31, 365–368. [Google Scholar] [CrossRef]

- Katsumata, T.; Takeuchi, H.; Komuro, S.; Aizawa, H. X-ray Detector Based on Mn Doped MgAl2O4 and Si Photodiode. Rev. Sci. Instrum. 2018, 89, 095104. [Google Scholar] [CrossRef]

- Kim, J.-H.; Lee, J.-H.; Mirzaei, A.; Kim, H.W.; Kim, S.S. Optimization and Gas Sensing Mechanism of n-SnO2-p-Co3O4 Composite Nanofibers. Sens. Actuators B 2017, 248, 500–511. [Google Scholar] [CrossRef]

- Kwon, Y.J.; Kang, S.Y.; Mirzaei, A.; Choi, M.S.; Bang, J.H.; Kim, S.S.; Kim, H.W. Enhancement of Gas Sensing Properties by the Functionalization of ZnO-Branched SnO2 Nanowires with Cr2O3 Nanoparticles. Sens. Actuators B 2017, 249, 656–666. [Google Scholar] [CrossRef]

- Liang, G.; Sun, X.; Lai, J.; Wei, C.; Huang, Y.; Hu, H. Adding Lithium Fluoride to Improve the Electrochemical Properties SnO2@C/MWCNTs Composite Anode for Lithium-Ion Batteries. J. Electroanal. Chem. 2019, 853, 113401. [Google Scholar] [CrossRef]

- He, J.; Wu, J.; Hu, S.; Shen, H.; Hu, X. A Low-Cost Flexible Broadband Photodetector Based on SnO2/CH3NH3PbI3 Hybrid Structure. Opt. Mater. 2019, 88, 689–694. [Google Scholar] [CrossRef]

- Cho, C.J.; Pyeon, J.J.; Hwang, C.S.; Kim, J.S.; Kim, S.K. Atomic Layer Deposition of Ta-Doped SnO2 Films with Enhanced Dopant Distribution for Thermally Stable Capacitor Electrode Applications. Appl. Surf. Sci. 2019, 497, 143804. [Google Scholar] [CrossRef]

- Kim, J.-H.; Mirzaei, A.; Bang, J.H.; Kim, H.W.; Kim, S.S. Selective H2S Sensing without External Heat by a Synergy Effect in Self-Heated CuO-Functionalized SnO2-ZnO Core-Shell Nanowires. Sens. Actuators B 2019, 300, 126981. [Google Scholar] [CrossRef]

- Zhong, X.; Shen, Y.; Zhao, S.; Li, T.; Lu, R.; Yin, Y.; Han, C.; Wei, D.; Zhang, Y.; Wei, K. Effect of Pore Structure of the Metakaolin-Based Porous Substrate on the Growth of SnO2 Nanowires and Their H2S Sensing Properties. Vacuum 2019, 167, 118–128. [Google Scholar] [CrossRef]

- Gao, N.; Li, H.Y.; Zhang, W.; Zhang, Y.; Zeng, Y.; Zhixiang, H.; Liu, J.; Jiang, J.; Miao, L.; Yi, F.; et al. QCM-Based Humidity Sensor and Sensing Properties Employing Colloidal SnO2 Nanowires. Sens. Actuators B 2019, 293, 129–135. [Google Scholar] [CrossRef]

- Ngoc, T.M.; Van Duy, N.; Hoa, N.D.; Hung, C.M.; Nguyen, H.; Van Hieu, N. Effective Design and Fabrication of Low-Power-Consumption Self-Heated SnO2 Nanowire Sensors for Reducing Gases. Sens. Actuators B 2019, 295, 144–152. [Google Scholar] [CrossRef]

- Chen, Y.; Qiu, W.; Wang, X.; Liu, W.; Wang, J.; Dai, G.; Yuan, Y.; Gao, Y.; Sun, J. Solar-Blind SnO2 Nanowire Photo-Synapses for Associative Learning and Coincidence Detection. Nano Energy 2019, 62, 393–400. [Google Scholar] [CrossRef]

- Singh, M.K.; Pandey, R.K.; Prakash, R. High-Performance Photo Detector Based on Hydrothermally Grown SnO2 Nanowire/Reduced Graphene Oxide (rGO) Hybrid Material. Org. Electron. 2017, 50, 359–366. [Google Scholar] [CrossRef]

- Suh, D.-I.; Byeon, C.C.; Lee, C.-L. Synthesis and Optical Characterization of Vertically Grown ZnO Nanowires in High Crystallinity Through Vapor–Liquid–Solid Growth Mechanism. Appl. Surf. Sci. 2010, 257, 1454–1456. [Google Scholar] [CrossRef]

- Park, S.; Hong, T.; Jung, J.; Lee, C. Room Temperature Hydrogen Sensing of Multiple Networked ZnO/WO3 Core–Shell Nanowire Sensors under UV Illumination. Curr. Appl. Phys. 2014, 14, 1171–1175. [Google Scholar] [CrossRef]

- Chinh, N.D.; Van Toan, N.; Van Quang, V.; Van Duy, N.; Hoa, N.D.; Van Hieu, N. Comparative NO2 Gas-Sensing Performance of the Self-Heated Individual, Multiple and Networked SnO2 Nanowire Sensors Fabricated by a Simple Process. Sens. Actuators B 2014, 201, 7–12. [Google Scholar] [CrossRef]

- Kar, A.; Stroscio, M.A.; Meyyappan, M.; Gosztola, D.J.; Wiederrecht, G.P.; Dutta, M. Tailoring the Surface Properties and Carrier Dynamics in SnO2 Nanowires. Nanotechnology 2011, 22, 285709. [Google Scholar] [CrossRef]

- Abideen, Z.U.; Kim, J.-H.; Kim, S.S. Optimization of Metal Nanoparticle Amount on SnO2 Nanowires to Achieve Superior Gas Sensing Properties. Sens. Actuators B 2017, 238, 374–380. [Google Scholar] [CrossRef]

- Choi, S.-W.; Katoch, A.; Sun, G.-J.; Wu, P.; Kim, S.S. NO2-Sensing Performance of SnO2 Microrods by Functionalization of Ag Nanoparticles. J. Mater. Chem. C 2013, 1, 2834–2841. [Google Scholar] [CrossRef]

- Park, J.Y.; Choi, S.-W.; Kim, S.S. Junction-Tuned SnO2 Nanowires and Their Sensing Properties. J. Phys. Chem. C 2011, 115, 12774–12781. [Google Scholar] [CrossRef]

- Calestani, D.; Zha, M.; Salviati, G.; Lazzarini, L.; Zanotti, L.; Comini, E.; Sberveglieri, G. Nucleation and Growth of SnO2 Nanowires. J. Cryst. Growth 2005, 275, e2083–e2087. [Google Scholar] [CrossRef]

- Wu, Y.; Yang, P. Direct Observation of Vapor−Liquid−Solid Nanowire Growth. J. Am. Chem. Soc. 2001, 123, 3165–3166. [Google Scholar] [CrossRef]

- Kim, S.; Bang, J.H.; Choi, M.S.; Oum, W.; Mirzaei, A.; Lee, N.; Kwon, H.C.; Lee, D.; Jeon, H.; Kim, S.S.; et al. Synthesis, Characterization and Gas-Sensing Properties of Pristine and SnS2 Functionalized TeO2 Nanowires. Met. Mater. Int. 2019, 25, 805–813. [Google Scholar] [CrossRef]

- Kim, J.-H.; Kim, S.S. Realization of ppb-Scale Toluene-Sensing Abilities with Pt-Functionalized SnO2-ZnO Core-Shell Nanowires. ACS Appl. Mater. Interfaces 2015, 7, 17199–17208. [Google Scholar] [CrossRef]

- Katoch, A.; Kim, J.-H.; Kwon, Y.J.; Kim, H.W.; Kim, S.S. Bifunctional Sensing Mechanism of SnO2-ZnO Composite Nanofibers for Drastically Enhancing the Sensing Behavior in H2 Gas. ACS Appl. Mater. Interfaces 2015, 7, 11351–11358. [Google Scholar] [CrossRef]

- Schlesinger, T.; Toney, J.; Yoon, H.; Lee, E.; Brunett, B.; Franks, L.; James, R. Cadmium Zinc Telluride and Its Use as a Nuclear Radiation Detector Material. Mater. Sci. Eng. R Rep. 2001, 32, 103–189. [Google Scholar] [CrossRef]

- Ahmadi, M.; Yeow, J.T. Fabrication and Characterization of a Radiation Sensor Based on Bacteriorhodopsin. Biosens. Bioelectron. 2011, 26, 2171–2176. [Google Scholar] [CrossRef]

- Nava, F.; Bertuccio, G.; Cavallini, A.; Vittone, E. Silicon Carbide and Its Use as a Radiation Detector Material. Meas. Sci. Technol. 2008, 19, 102001. [Google Scholar] [CrossRef]

- Owens, A.; Peacock, A. Compound Semiconductor Radiation Detectors. Nucl. Instrum. Methods Phys. Res. Sect. A 2004, 531, 18–37. [Google Scholar] [CrossRef]

- Knoll, G.F. Radiation Detection and Measurement, 3rd ed.; John Wiley & Sons. Inc.: New York, NY, USA, 2000. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-H.; Mirzaei, A.; Kim, H.W.; Kim, H.J.; Quoc Vuong, P.; Kim, S.S. A Novel X-Ray Radiation Sensor Based on Networked SnO2 Nanowires. Appl. Sci. 2019, 9, 4878. https://doi.org/10.3390/app9224878

Kim J-H, Mirzaei A, Kim HW, Kim HJ, Quoc Vuong P, Kim SS. A Novel X-Ray Radiation Sensor Based on Networked SnO2 Nanowires. Applied Sciences. 2019; 9(22):4878. https://doi.org/10.3390/app9224878

Chicago/Turabian StyleKim, Jae-Hun, Ali Mirzaei, Hyoun Woo Kim, Hong Joo Kim, Phan Quoc Vuong, and Sang Sub Kim. 2019. "A Novel X-Ray Radiation Sensor Based on Networked SnO2 Nanowires" Applied Sciences 9, no. 22: 4878. https://doi.org/10.3390/app9224878

APA StyleKim, J.-H., Mirzaei, A., Kim, H. W., Kim, H. J., Quoc Vuong, P., & Kim, S. S. (2019). A Novel X-Ray Radiation Sensor Based on Networked SnO2 Nanowires. Applied Sciences, 9(22), 4878. https://doi.org/10.3390/app9224878