1. Introduction

Microchannel fabrication for biomedical or chemical analysis is an emerging technique as a fast, low-consumption, miniaturized tool in the biochemistry, analytical chemistry, microsensor, and microtechnology fields [

1,

2,

3,

4]. As a typical biologically friendly material, fused quartz glass is widely used in microfluidics owing to various advantages such as low cost, high optical transparency, and structural stability [

5,

6,

7]. Thus, the quartz glass microchannel manufacturing technique attracted increasing attention, especially ultraviolet (UV) laser ablation using excimer lasers (157, 193, and 248 nm) or higher-order harmonics of neodymium-doped yttrium aluminum garnet (Nd: YAG) lasers (266 and 355 nm), which are commercially available and provide large single-photon energy, great flexibility, and high manufacturing precision [

8,

9]. However, fused quartz glass microchannel fabrication by UV laser is still challenging due to the brittle nature of glass and the wide band gap (9 eV) of fused quartz. Good quality of the treatment surface and sufficient etching depth are difficult to approach using traditional direct laser etching [

10,

11,

12,

13]. To solve these problems, great effort was exerted in both the theoretical and experimental study of UV laser ablation.

Laser-induced plasma ablation (LIPA), as a novel indirect laser etching technique, was proposed for higher etching efficiency and quality. In such processing, after the laser irradiation, the plasma vapor generated from a metal target on the bottom can effectively ablate the quartz sample’s rear surface, even though the UV laser beam is highly transparent to the substrate. By means of LIPA, the quality of the etched bottom surface can be significantly improved. Zhang et al. presented the LIPA method for fused quartz grating manufacture using a 248 nm KrF laser. The relationship between the grating depth and the number of laser pulses was studied, showing good quality by implementing a 1.06 μm grating period and a 300-nm grating depth [

14]. Duan et al. applied the LIPA technique with a UV pulse laser (355 nm) to fabricate quartz glass channels, showing a neat microchannel etched edge without brittle cracking or edge chipping [

15]. Cheng et al. proposed backside wet etching using an indium–gallium cryogenic eutectic mixture as the absorption liquid, showing that the etched edge was neat, and the roughness of the bottom surface was approximately 30 nm [

16]. In addition to merging the quartz in the liquid, the method of electroplating an absorbing film on the rear quartz surface was also used in LIPA. Hopp et al. presented an LIPA scheme using a 248 nm KrF excimer laser on a fused quartz plate with a 100 nm thick layer of silver. The etched depth of a single pulse reached 600 nm, and the roughness was as low as 2.2 nm [

17]. Ihlemann et al. presented the same scheme with a UV absorbing oxide film instead of a silver coating, and single-pulse ablation depths ranging from a few to 500 nm were obtained, with a surface roughness lower than 5 nm [

18]. Chemical corrosion [

19] or successive electroplating [

20] were also employed in LIPA treatment for the fabrication of good-quality microchannels.

Nevertheless, the wet etching system is complicated, and the liquid environment is often toxic. On the other hand, the absorbing layers in the existing literature are only several hundred nanometers thick, the ablation is limited to single-pulse operation, which is insufficient for microchannel fabrication, and tedious coating and removal are necessary during the preparatory and post-processing procedures, respectively. Furthermore, many theoretical models, such as charge and kinetic exchange between the plasma and the sample surface, were proposed to describe the ablation procedure; however, these hypotheses were not validated, and the mechanism of LIPA remains unclear.

To obtain better insight into the processing, we applied LIPA experiments onto fused quartz glass with economic 304-type stainless streel, and an exhaustive morphological study of ablation performance under different influences and laser pulse numbers was conducted with a view to understanding the mechanism. The present paper is organized as follows: firstly, the manufacturing system and the properties of the materials are presented in detail. Secondly, the morphological characteristics of the LIPA channels in different cases are compared, and the ablation mechanism is investigated by discussing and analyzing the experimental results. Finally, through optimization of the parameters, high-quality microchannels were obtained for biomedical applications.

2. Experimental Set-Up

The homemade excimer laser manufacturing system is illustrated in

Figure 1. The laser source used in the present work was a commercial KrF excimer LPXpro305 (Coherent Co., Ltd., Santa Clara, CA, USA) that works at 248 nm. The laser pulse width and frequency were 30 ns and 1 Hz, respectively. The excimer laser beam was well aligned using an He–Ne laser indicator light (4D-B, Tuoda Co., Ltd., Beijing, China). A homemade mask with a 2 mm × 2 mm stainless-steel square pinhole was inserted into the beam axis to control the laser focal spot shape and size, through which the excimer laser beam was directed. After placement of the mask, the laser beam was deflected by 90° using a UV reflecting mirror, and subsequently tightly focused on the glass sample by a 10× UV objective. To control the microchannel dimensions and ablation pattern, the glass sample position was adjusted using a three-dimensional (3D) stage. The stage resolution was better than 2 μm in the 50 mm translation range, and the flight velocity could be varied from 0.01 to 6 mm/s along each axis. The laser output parameter settings and the stage translation were controlled by computer. After the ablation experiment, the etched depth and surface roughness were measured by a surface profiler (P7, KLA Tencor. Co., Ltd., Milpitas, CA, USA).

A 1 mm thick UV transparent quartz glass was used in this experiment, and the content of SiO

2 was no less than 99.96%. We measured the transmittance spectrum of the fused quartz glass in the UV range prior to ablation using a spectrophotometer. As can be seen in

Figure 2, such glass has a good transmittance window in the UV range, and the transmittance is greater than 92% at 248 nm. The 8% transmission loss is due to reflection at the quartz layer surface, such that the 248 nm laser beam is hardly absorbed by the substrates [

21]. A 304-type stainless-steel plate (20 mm × 20 mm × 10 mm) was chosen as the target for plasma vaporization generation. The metal target was kept in contact with the rear surface of the fused quartz glass so that the glass could be etched directly by the high-temperature plasma. For preparation, both the glass sample and the stainless-steel target were ultrasonically cleaned in ethanol for 10 min to remove the oxide on the surface before the experiment.

3. Results

Different LIPA processing configurations were performed to understand the mechanism of LIPA. Firstly, to analyze the direct laser–quartz interaction effect, we applied 50 pulses of laser shooting at 2 J/cm

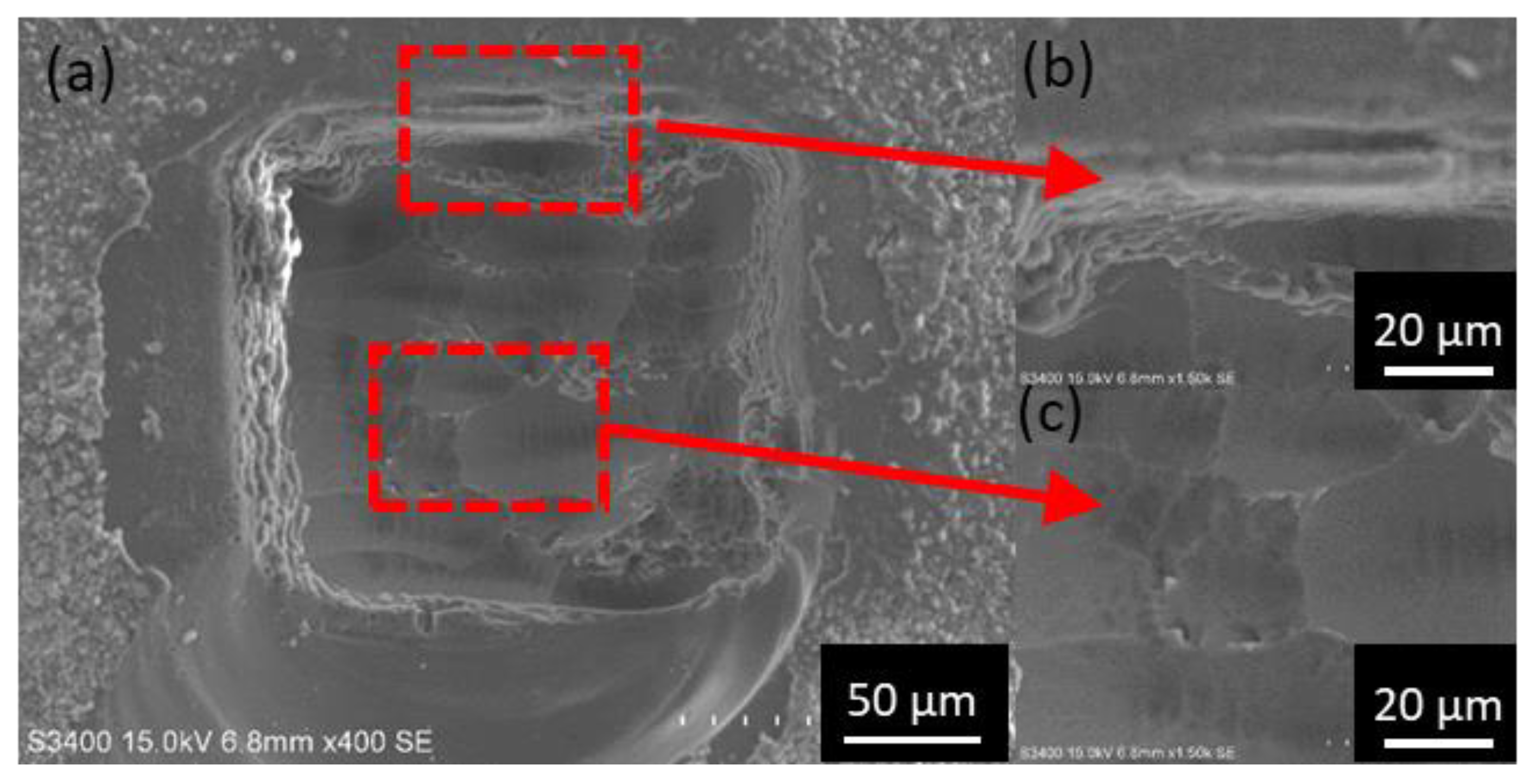

2 laser fluence on the bare quartz glass sample without the metal target on the bottom. There was no ablation trace on the quartz surface, proving the extremely low absorption rate of the bare quartz substrate. Subsequently, keeping the quartz sample in the same vertical position, the 304-type stainless-steel target was placed under the quartz layer, and we reapplied 50 pulses at the same laser fluence. The quartz sample after the processing is shown in

Figure 3, where a well-defined ablation pattern can be observed very easily, measuring 180 μm × 180 μm. Furthermore, after LIPA, some micro-cracks under the recast layer were found in the rear surface and the edge of the quartz plate [

19].

Then, we varied the laser fluence from 0 to 4 J/cm

2 and performed a single-pulse ablation series with the metal target to study the dependence of depth on the laser fluence. The resulting depths measured by the surface profiler are shown in

Figure 4. When the fluence was lower than 0.7 J/cm

2, no ablation occurred, since the laser irradiation fluence was lower than the damage threshold value. Afterward, the ablation depth increased linearly with increasing laser fluence.

Next, we repeated the ablation from 1–250 laser pulses at a fixed 4 J/cm

2 laser irradiation energy density. Photographs of the rear surface of the glass and the top surface of the metal target are shown in

Figure 5. With 10 laser pulses, the glass was modestly etched (

Figure 5a); however, the ablation effect became increasingly obvious as the pulse number increased (

Figure 5b). After 220 pulses, the glass broke, and edge chipping was observed (

Figure 5c). On the other hand, with increasing laser pulses, the penetration depth of the stainless-steel target increased, and there was more black metal residuum on both the glass and the metal surfaces.

The ablation depth is shown as a function of the pulse number in

Figure 6. The depth value increased with the number of pulses in each position. It can be observed that, when the number of pulses was less than 70, the laser ablation effect was very modest, and the depth was less than 3 μm. However, when the pulse number was greater than 70, the ablation depth significantly increased. Furthermore, when the number of pulses exceeded 130, the ablation depth increased more slowly with the number of pulses, and the ablation efficiency began to saturate.

We planned to reapply the direct etching without the metal target with the etched quartz sample after LIPA processing instead of the bare one in

Figure 3a, to check if the properties of the sample were changed during the etching. We firstly moved the stage to make a 600 × 1000 μm groove; then, in each node position, 150 laser pulses of LIPA with the metal target at 4 J/cm

2 were performed, and the depth was measured to be around 24 μm, similar to that in

Figure 6. Consequently, we removed the metal target and reapplied a secondary 20-pulse direct ablation onto the grooving area at the same quartz substrate height.

Figure 7 shows the morphology of the sample prior to (a) and following the secondary direct ablation (b). Even without the metal target, the laser could still etch the quartz (in the red circle), which should result from an effect other than plasma etching.

We performed a series of direct ablations without the target under different pulse numbers in the grove area, and the ablation depth values under 20, 50, 70, and 100 pulses are illustrated in

Figure 8 (red). These depth values were found to be comparable with those from the previous ablation series with the metal target (blue) under pulse numbers from 150 to 250 in

Figure 6. This result indicates again that, with large a pulse number (here, more than 150), the plasma ablation effect can be neglected, while another phenomenon contributes to the quartz etching.

4. Discussion

Considering that the energy gap of quartz is 9 eV, electron excitation from the valence band to the conduction band by a 248 nm KrF laser (5 eV) under an extremely low absorption rate is impossible, such that no ablation trace can be found after direct ablation without the metal target, as shown in

Figure 3a. However, with the metal sacrificial plate below, LIPA can effectively etch the quartz sample (

Figure 3b). The plasma formation directly depends on laser power, such that the etching depth increases linearly with the irradiation influence, as shown in

Figure 4.

From the morphology result displayed in

Figure 7 and

Figure 8, there appears to be another ablation mechanism when the metal target is absent. After reviewing the literature [

22,

23], we propose a two-step ablation hypothesis during LIPA to describe the processing dynamics. A schematic of the process in our experiment is depicted in

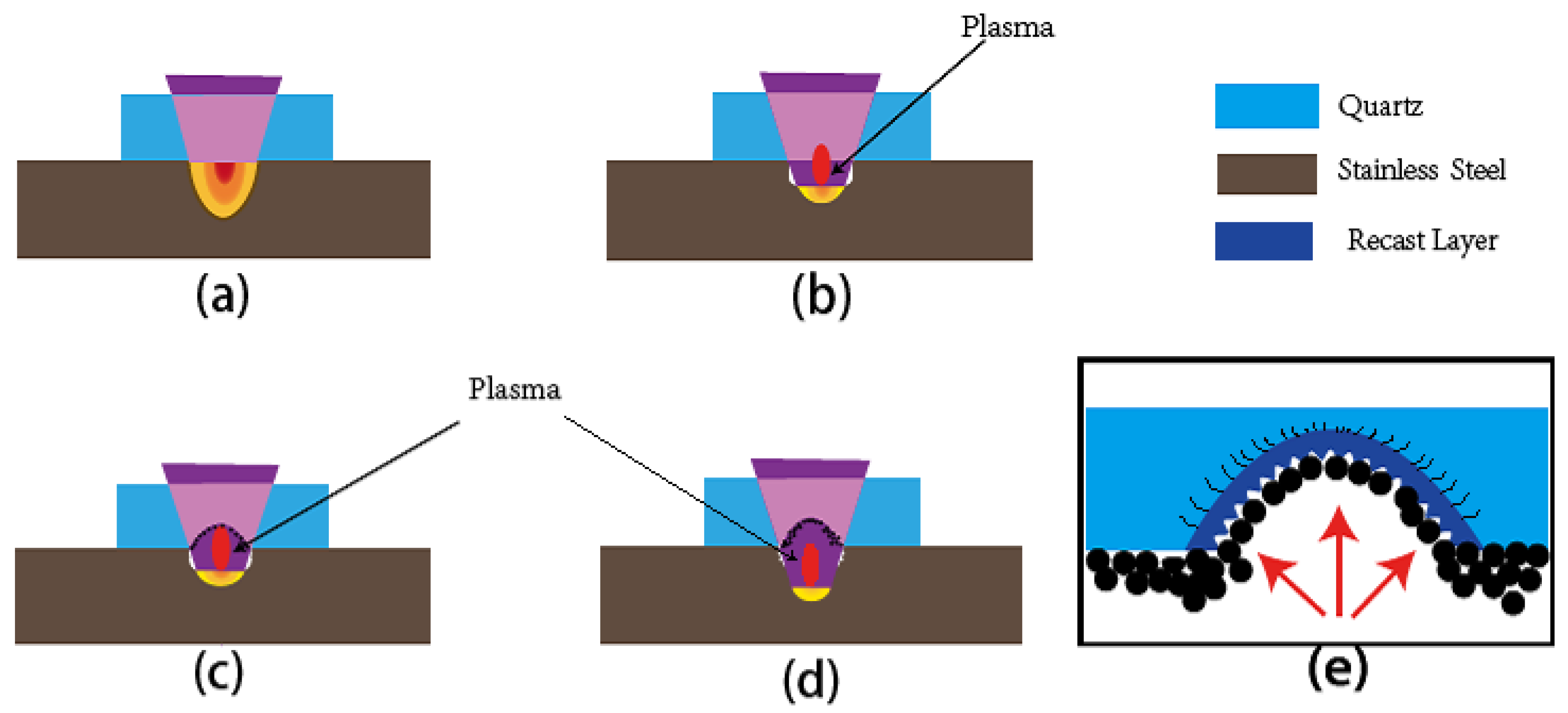

Figure 9.

The excimer irradiation pulse train heats the stainless-steel target, and the martial temperature continuously rises, as shown in

Figure 9a. When the fluence is high enough, the upper layer of the metal target is completely melted and vaporized, and a plasma plume including a metal ion and radical is formed, as shown in

Figure 9b [

19]. The metal vaporization threshold

Eth can be expressed as follows [

24]:

where

Tv and

Tm are the vaporizing and melting temperature values of the material, and

T0 is room temperature;

d is the laser spot diameter, and

τ is the pulse duration;

λl,

Al,

Cl, and

ρl are the mean values of thermal conductivity, absorptivity, heat capacity, and density in the liquid state. Likewise,

λs,

As,

Cs, and

ρs are the mean values corresponding to the solid state.

The kinetic energy of the ions and free radicals in the plasma vaporization is very high, in the range of a few to several hundred eV. Afterward, the kinetic energy is transferred to the rear surface of the quartz sample, the plasma plume heats the quartz substrate, and the temperature rapidly rises to the 2000 K melting point, at which the quartz sample is melted and vaporized.

We assume the etching depth during each pulse as the same, and the etching duration as shorter than the pulse duration, such that the etching depth

h after a single laser pulse of energy

E can be expressed simply as follows:

where

α is the etching coefficient. The etching depth is expected to be a linear function of the influence

I in a given laser spot area

S, which as validated by the result in

Figure 4. While considering that the influence distribution is not the uniform, the influence in the central part is higher than at the edge, such that a slightly arched etched top instead of flat top on the quartz rear surface should be formed after the ablation (see

Figure 9e). On the other hand, because of the thermal expansion and contraction strain after the rapid melting and cooling of quartz, some micro-cracks appear under the recast layer in

Figure 3c,d [

19].

Afterward, the metal vapor cools down and freezes, and the black microscale molten metal residuum remains on the rear surface of the quartz. Following several pulses, we propose a hypothesis that the accumulated metal residuum layer and the ablation-induced glass defects cause an increase in the laser absorption rate of the quartz glass, as shown in

Figure 9c [

25]. Moreover, inverse bremsstrahlung absorption gives rise to a change in the optical properties of the quartz, increasing the absorption rate as well [

21]. Then, the laser ablation effect on the glass sample includes both plasma thermal ablation and direct laser–quartz interaction. This can fully explain

Figure 6, showing that, when the pulse number was more than 70, the etching rate increased dramatically. In

Figure 9d, during ablation processing, the height of the ablation gap between the quartz and the metal surface increased and eventually exceeded the distance of the plasma ejection range. Therefore, less and less plasma vapor can approach the top surface and ablate the quartz, and the ablation efficiency tends to saturate. In this case, the contribution of plasma-induced ablation can be omitted. Only the direct laser ablation effect continues, with absorption enhancement of the metal residuum. This is why the ablation depth increased slowly with more than 150 laser pulses in

Figure 6, and the ablation still occurred even without the metal target in

Figure 8. However, the residuum does not distribute uniformly on the surface (see

Figure 9e), but mainly on the ablation gap edge, and glass edge chipping occurs due to the nonuniform heat conduction (similar to

Figure 5f).

To validate our hypothesis of absorption enhancement resulting from the metal residuum, the absorption rates of the resulting quartz sample after the LIPA at 4 J/cm

2 fluence were measured using a UV spectrometer (UH-4150, HITACHI Co., Ltd., Marunouchi, Tokyo, Japan). As shown in

Figure 10, the absorption ecoefficiencies at 248 nm were measured to be 2.5% and 3.2% after exposure to 10 and 50 laser pulses, respectively. Nevertheless, the absorption rate of the bare quartz plate before exposure was measured to be less than 0.01%. The absorption rate increased by at least two orders of magnitude.

After analyzing the LIPA processing mechanism, we attempted to implement a microscale channel for biomedical application using the optimized parameters. As shown in

Figure 11, the LIPA scanning process of a straight-line pattern on fused quartz glass was launched. Considering the practical microchannel dimension requirements and the manufacturing efficiency, the processing parameters were set as follows: laser energy density, 4 J/cm

2; translation velocity of the stage, 50 μm/s; laser pulse frequency, 10 Hz. After processing, the metal residuum and molten quartz dust were removed by HF corrosion in the supersonic cleaner. We can observe from

Figure 11 the good surface quality of the glass microchannel bottom without edge cracking in the entire structure. The depth was 28 μm, and the roughness on the bottom surface was approximately 150 nm. The channel can be qualified for biomedical microfluidic applications including cell culture or DNA analysis [

5,

6,

7]. It should be noted that, during ablation, the neighboring ablation positions overlapped partly; thus, the depth after the scan was slightly more than that in the single localized hole measured before.